I

PROBLEM DEFINITION AND STATUS OF THE AGING FORCE

In Part I of the report, the committee provides the basis for this study of the U.S. Air Force aging aircraft. Chapter 1 describes the background and objectives for the study. Chapter 2 is a summary of force management processes, future force projections, and an assessment of force management, including the Aircraft Structural Integrity Program. Chapter 3 describes the current structural status of the aging aircraft in the Air Force inventory, including Air Force-supported aircraft and contractor logistics-supported aircraft. Finally, Chapter 4 identifies the technical issues and operational needs associated with Air Force aging aircraft that form the basis for the recommended engineering, management, and research and development tasks presented in Part II.

1

Introduction

BACKGROUND

The U.S. Air Force has many old aircraft that form the backbone of the total operational force structure. The oldest are the more than 500 jet tanker aircraft, the KC-135, that were first introduced into service more than 40 years ago. The B-52H bomber, the C-130 airlifter, the T-38 trainer, and the T-37A primary trainer all became operational 35 to 40 years ago; the C-141 and C-5A airlifters, 25 to 35 years ago; the F-15 air superiority fighter, the A-10 close air support aircraft, and the E-3 (AWACS), 20 to 25 years ago; and the F-16 multirole fighter and the KC-10 jet tanker, 15 to 20 years ago. Of these, only the C-141 is currently being replaced (by the C-17). Other replacements are in various stages of development for the T-37A (by the JPATS), the F-15 (by the F-22), and the F-16 (by the Joint Strike Fighter). For the most part, these replacements are a number of years away, and the program schedules continue to be constrained by and subject to the vagaries of annual funding cycles. For example, at best, it will be at least another 15 to 20 years before there will be a significant number of replacements for the F-16 combat fighter force. The remainder of the aircraft mentioned above have no planned replacements and are expected to remain in service an additional 25 years or more.

To varying degrees, all of these older aircraft either have encountered, or can be expected to encounter, aging problems such as fatigue cracking, stress corrosion cracking, corrosion, and wear. The challenge to the Air Force management and technical community is to meet the following objectives:

Objective A. Identify and correct problems that could threaten aircraft safety.

Objective B. Prevent or minimize problems that could become an excessive economic burden or adversely affect force readiness.

Objective C. For the purpose of future force planning, have the methodology to predict when the maintenance burden will become so high, or the aircraft availability so poor, that it will no longer be viable to retain the aircraft in the inventory.

The Air Force has been aware of these objectives for a number of years and has, through their Aircraft Structural Integrity Program (ASIP) and durability and damage tolerance assessments of their older aircraft, already identified many potential problems, developed individual aircraft tracking programs, developed force structural maintenance plans, and taken many maintenance actions to protect safety and extend aircraft life. The Air Force has also initiated an aging aircraft research and development (R&D) program that is intended to support ASIP and address identified needs in the areas of widespread fatigue damage, corrosion-fatigue interactions, structural repairs, dynamics, health monitoring, non-destructive evaluation and inspection (NDE/I), and various aircraft subsystems (Rudd, 1996).

STUDY OBJECTIVES

The Air Force requested that the National Research Council, through the National Materials Advisory Board, conduct this study with the following specific objectives:

-

identify an overall strategy that addresses the Air Force aging aircraft needs

-

recommend and prioritize specific technology opportunities in (1) fatigue, corrosion-fatigue interactions, and stress corrosion cracking; (2) corrosion prevention and mitigation; (3) nondestructive inspection; (4) maintenance and repair; and (5) failure analysis and life prediction technologies

-

complement, rather than duplicate, the efforts of industry, the Federal Aviation Administration, the National Aeronautics and Space Administration, other military services, and international organizations

To address the overall objectives, the committee performed the following tasks:

-

reviewed and analyzed the structural histories, problems, and force management procedures employed on the older Air Force aircraft to assist in identifying research needs and in developing a recommended overall aging aircraft strategy

-

reviewed and analyzed critical degradation and failure mechanisms associated with aging aircraft that have been experienced to date or can be expected to be experienced in the future

-

reviewed and evaluated corrosion prevention and mitigation procedures and methods that are applicable to aging aircraft, assessed ongoing research, and identified additional opportunities

-

reviewed and evaluated methods for the inspection of structures for the purpose of assessing the adequacy of current methods and identified promising advanced NDE/I methods

-

reviewed and evaluated repair methods and analysis procedures for the purpose of identifying possible deficiencies and promising research that could lead to their correction

-

reviewed the current state of the art in failure analysis, life prediction, and structural risk assessment methodologies; identified deficiencies; assessed ongoing research; and identified additional research opportunities

This study emphasized aging of current airframe structures, especially aluminum primary structures. The important issues related to the aging of aircraft engine structures were not included in the committee's task and would be best addressed separately in the future.

This report summarizes the committee's assessment of the adequacy of the Air Force R&D program, assesses the force management process and its needs, identifies key technology issues and R&D needs, identifies and prioritizes R&D opportunities, and identifies and develops an overall strategy that addresses the Air Force's aging aircraft needs. The committee prepared a interim report (NRC, 1997) that focused on a preliminary assessment of the needs and an assessment of the current Air Force R&D program. This final report expands on this previous publication.

2

Aging Aircraft Problem

Any discussion of the wisdom of maintaining capital equipment is usually based on economic arguments. For example, if the cost of maintaining the equipment on a monthly or annualized basis exceeds the capital, interest, and amortization charges on replacement equipment, the decision to purchase the replacement is straightforward. Often the replacement equipment offers an improved productivity as well.

In the case of Air Force aircraft, safety-of-flight considerations also enter into the decision to repair or replace. Fortunately, inspection and maintenance procedures and the Aircraft Structural Integrity Program (ASIP) have been developed to reduce the likelihood of structural failure during the design service life. However, several external political changes, including the end of the Cold War, have caused the Air Force to change their approach to force management. As a result, the Air Force budget to develop new aircraft systems has been reduced. Because strategic policies have not been altered greatly, Air Force managers have concluded that the only way to meet the mission demands is to extend the service life of some of their aircraft forces.

Ultimately these factors will impact the force planning process. The Air Force aging aircraft problem can be best understood by examining the existing force management process, future force projections, and the current structural condition of the many types of aging aircraft in the Air Force inventory. In this chapter, force management processes and future force projections are summarized, followed by the committee's assessment of the process, including ASIP. A summary of the current structural condition of the many types of aging aircraft in the Air Force inventory is provided in Chapter 3. The committee's assessments of key technical issues related to the aging aircraft problem are discussed in Chapter 4.

MANAGING THE FORCE STRUCTURE

Modernization Planning Process

The Air Force modernization planning process (AFMPP) is the mechanism for supporting the five core competencies—air superiority, space superiority, precision employment, global mobility, and information dominance—provided by executive guidance documents. Aircraft systems are involved primarily in three of the five competencies: air superiority, precision employment, and global mobility.

The AFMPP integrates the elements that provide the foundation for the five competencies into a coherent modernization plan that reaches 25 years into the future. The foundation elements included in the modernization plan are

-

readiness and sustainment

-

research, development, test, and evaluation

-

logistics

-

information technology

-

equipment and facilities

-

manpower

The effectiveness of the aircraft systems (as well as other systems) in providing those competencies is determined largely by how well the foundation elements are integrated and addressed.

The key focus of the AFMPP is ''modernization." Historically, the Air Force has been the world's technological leader in aircraft systems. This has been achieved through a robust science and technology program combined with frequent replacement of aging systems with new or modernized systems. This rapid replacement has slowed significantly in recent years because of budget constraints and affordability considerations. The result has been a shift to increased upgrading and life extension of many systems beyond what was typically done in the past.

The extended use of many aircraft results in increased maintenance and repair costs because of structural cracking and corrosion problems. In most cases, older aircraft spend longer times undergoing depot maintenance, with a resulting severe impact on readiness. Furthermore, extended aircraft service places increased importance on forecasting when the system must be replaced, either because of obsolescence or economic reasons (or a combination of both). If a system must be retired before the expected forecast service life, readiness could be impacted severely because a replacement system would not be ready in time to close the gap. Extended production lead times and budget exigencies for new systems make it even more important that the Air Force accurately determine, with a high degree of precision and confidence, the expected structural life of aircraft systems and the economics of sustaining them.

The AFMPP consists of the following six elements:

-

Mission area analysis. Each of the major operating commands within the Air Force performs a mission area analysis that evaluates the military strategy provided by the chairman of the Joint Chiefs of Staff for new or changed missions. This review results in new or changed military tasks that the operating commands within the Air Force must then perform.

-

Mission needs analysis. The operating commands evaluate their ability to accomplish assigned tasks (from the mission area analysis) and identify any issues. In performing this "task-to-need" analysis, the operating commands employ a variety of analytical tools. These analyses identify task deficiencies and possible nonmatériel or matériel solutions. If new or modified hardware is required, the mission need is documented in a mission needs statement.

-

Mission area plan. The results of the mission area and mission needs analyses will be used to document, for the next 25 years, the most cost-effective means of correcting task deficiencies. The corrective actions could include nonmatériel solutions (e.g., changes to tactics and training), changes in force structure, system modification or upgrades, science and technology applications, or new hardware acquisition. Of interest are those solutions involving modifications, upgrades, new technology, and new hardware. Determining which solution is optimum, and planning for it, is greatly influenced by the aging aircraft problem.

-

Technology planning integrated product teams (TPIPTs). TPIPTs provide the vital link to ensure that research efforts are responsive to user needs. In 1996 there were 21 different TPIPTs, each focused in a different mission area and involving all of the operating commands. The teams are administered by the Air Force Matériel Command's product centers. Eight of these TPIPTs are involved directly in aircraft system planning. Each team is responsible for coordinating the technology needs inputs among the technical and logistics communities and introducing them into the operating command's planning process. This is the primary mechanism for entering aging aircraft technology needs into the overall technology planning process. Each TPIPT documents identified needs in a development plan and issues a technology investment recommendation report. These reports serve as input into the technology master process.

-

Technology master process. The technology master process is the vehicle through which technology strategy is planned and executed, based on the identified needs of the aircraft operators and system program directors. This process is designed to be comprehensive by including technology development, transition, application, and transfer. The process ensures that (1) all technologies are identified and prioritized for action, (2) budget-constrained technology projects are formulated in a highly integrated manner with full participation by the stakeholders, and (3) technologies that are candidates for application and insertion are validated and ready to enter the full acquisition cycle.

-

Aging Aircraft Office. The Aging Aircraft Office is a recent addition to the Air Force planning process in support of aging aircraft. This office was established by the Air Force Matériel Command in April 1996 to address recognized problems in planning and executing technology programs in support of aging aircraft. The mission of the Aging Aircraft Office is to work within and outside the Air Force to implement technologies that extend the lives and reduce the cost of operating and maintaining aging aircraft systems. This office is intended to fill an important gap in the overall AFMPP by focusing attention on aging aircraft technologies and ensuring the expeditious implementation of needed technologies.

Service Life Projection during Acquisition

The expected service life for new aircraft is developed through the AFMPP, as was discussed in the preceding section. These goals are summarized in the systems requirements document that also describes the systems design parameters. The aircraft system operator then establishes the mission profiles for the new aircraft system. System design engineers use these mission profiles to develop load spectra, a critical input to the structural design activity. It is also during this time that a damage-tolerance-based ASIP, summarized in Table 2-1, is initiated.

The full-scale durability test task is especially significant with regard to the aging aircraft problem because this testing validates the design service life based on the operator's planned mission profiles. Full-scale durability test results establish the baseline from which the service life is updated throughout the service life cycle as mission profiles and use rates change. Data from the full-scale durability tests also assist in the development of the structural maintenance program required throughout the aircraft life cycle. The initial estimated weapon system phase-out point is also established based on estimates of safety limits and economic life considerations discussed in Chapter 4.

Few aircraft systems have been used as originally projected. This has resulted in the need for service life extension, modifications, or repair actions in advance of the originally projected time frame. The need for life extension, modification, or repair typically has been a result of corrosion or early fatigue damage caused by increased heavy use. Corrosion, unlike fatigue damage, has not been forecast analytically as

TABLE 2-1 Tasks of the Air Force Structural Integrity Program

|

Task I: Design Information |

Task II: Design Analysis and Development Tests |

Task III: Full-Scale Testing |

Task IV: Force Management Data Package |

Task V: Force Management |

|

ASIP master plan |

Materials and joint allowables |

Static |

Final analyses |

Loads and environment spectra survey |

|

Structural design criteria |

Loads analysis |

Durability |

Strength summary |

Individual aircraft tracking data |

|

Damage tolerance and durability control plans |

Design service loads spectra |

Damage tolerance |

Force structural maintenance plan |

Individual aircraft maintenance times |

|

Selection of materials, processes, and joining methods |

Design chemical/thermal environment spectra |

Flight and ground operations |

Loads and environment spectra survey |

Structural maintenance records |

|

Design service life and design use |

Stress analysis |

Sonic |

Individual aircraft tracking program |

|

|

|

Damage tolerance analysis |

Flight vibration |

|

|

|

|

Durability analysis |

Flutter |

|

|

|

|

Sonic analysis |

Interpretation and evaluation of test results |

|

|

|

|

Vibration analysis |

|

|

|

|

|

Flutter analysis |

|

|

|

|

|

Nuclear weapons effects analysis |

|

|

|

|

|

Non-nuclear weapons effects analysis |

|

|

|

|

|

Design development tests |

|

|

|

|

Source: Lincoln (1996). |

||||

part of ASIP. However, historically corrosion has caused an escalation of maintenance costs and, in many cases, severely impacted readiness because of the increased time required in depot repair. Some aircraft have been retired earlier than desired by the force planners because these aircraft became unaffordable because of escalating maintenance costs. Thus, the force management task of ASIP is tied closely to the aircraft aging problem.

Postproduction Force Management

During the deployment phase of the acquisition cycle, the Air Force establishes a maintenance and sustainment program. This program is based in part on data packages generated by ASIP. The maintenance and sustainment program includes such elements as

-

filed maintenance programs

-

depot maintenance programs

-

modification and repair programs

-

technology transition and insertion

-

weapon system assessments

-

ASIP updating

It is the responsibility of the system program director to ensure that ASIP is continued on the weapon system throughout its operational life. This is done through the implementation of the force structural maintenance plan (FSMP), scheduling the required structural inspections and maintenance for the individual aircraft, maintaining structural maintenance records, conducting the loads/environment spectra survey (LESS), and implementing the individual aircraft tracking program (IATP). The system program director must ensure that durability and damage tolerance analyses are performed to provide new inspection and modification requirements if

-

significant changes in use are noted from the LESS or the IATP

-

new and unanticipated fatigue-critical areas show up in service aircraft

-

there are significant structural configuration changes as a result of structural repairs or operational capability enhancement modifications

A durability and damage tolerance analysis may consist of an update of the original analysis conducted either during the design of the aircraft or during a durability and damage tolerance assessment (DADTA) performed subsequent to the initial design.1

In addition to the continuous enforcement of ASIP throughout the operational life of the aircraft and the translation of appropriate inspections to the field level, the system program director is also responsible for enforcing corrosion inspection and maintenance requirements and, as appropriate, translating them to the field level. The field-level ASIP and corrosion tasks can involve the use of standard or specialized nondestructive inspection (NDI) equipment and inspection criteria. The need for field-level repairs may result from these inspections. It is at this field level that insufficient NDI reliability of detection has been a problem. If the NDI techniques are overly complex or tedious and the failure data reporting burdensome, the resulting quality and reliability of both are dramatically reduced. This is also true, to some extent, for depot-level maintenance.

The system program director is also responsible for implementing the depot maintenance program on the weapon system. This typically consists of programmed depot maintenance (PDM) along with analytical condition inspection (ACI). The ACI tasks are performed annually on a selected small sample of the force. PDM covers the entire force, with a portion of the force scheduled for maintenance each year. In some cases, such as the newer systems, PDM may not exist. In these cases, the aircraft are usually sent to the depot for modifications and updates, along with an ACI. Speedlines and depot field teams are also employed to accelerate modifications. It is during these events that logistics engineers can gain significant insight into potentially life-limiting structural problems. As a result, the system program director can institute significant structural inspections, along with repair and modification programs, that add considerably to the cost of maintaining the weapon system. Therefore, improved technology relating to aging can have the greatest impact in the depot. Improvements in prediction of aging, detection of corrosion and fatigue cracks, and repair technologies can significantly reduce costs, extend service life, and enhance aircraft readiness.

As necessary, special modification and repair programs to accelerate the correction of structural cracking or corrosion are established to augment the PDM. The system program director creates a dedicated speedline at the depot or, in some cases, sends depot personnel to the operational bases as field teams. Speedlines and field teams often rely heavily on specialized NDI techniques tailored for the specific problems and perform specialized repairs when defects are discovered. For NDI and repair techniques, speed, ease of use, and reliability of detection become critical during speedline or field team activity because they directly affect the aircraft inspection and repair flow time and consequently the total time that the aircraft is out of service. Speedlines and field teams require additional aircraft to be taken out of service, impacting availability and readiness. Therefore, improving the technology for both NDI and maintenance and repair can result in significant benefits to aging aircraft systems.

periodically, system program directors assess the health of aircraft over a broad range of indicators and report the status to senior management of the Air Force. One aspect of the assessment is the forecast life of the aircraft and problems affecting longevity. This process provides the system program director the opportunity to gain support to resolve aging aircraft problems and essential information to planners to ensure accurate force structure planning.

FUTURE FORCE PROJECTIONS

There are four major commands within the Air Force that operate aircraft systems to accomplish a wide range of missions. The Air Combat Command (ACC), Air Mobility Command (AMC), Air Force Special Operations Command (AFSOC), and Air Education and Training Command (AETC) all have long-range plans that include the phase-out of existing systems and the phase-in of new systems developed through the mission area planning process described above. Preliminary force structure plans can be summarized best through the use of "sand" charts that cover the next 25 years. These charts illustrate the life extension of existing systems and the introduction of relatively few new aircraft systems as replacements. The sand charts for each of the major operating commands, along with a brief description of each, are shown in the following sections.

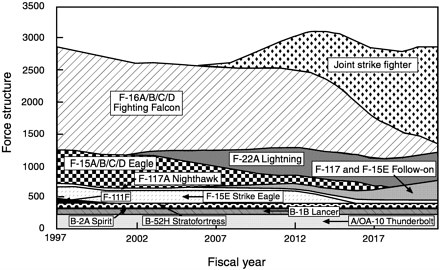

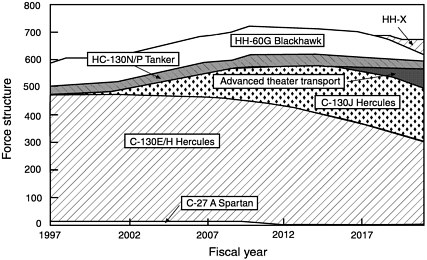

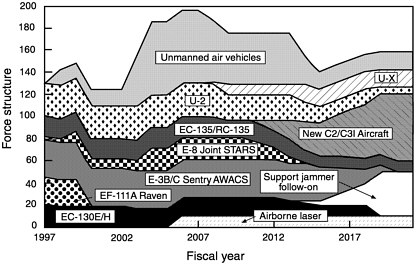

Air Combat Command

Figures 2-1, 2-2, and 2-3 show the ACC force structure for the next 25 years, broken down into fighter, bomber, and attack; airlift and rescue systems; and other specialized systems. The charts indicate that the ACC will have to sustain primary combat systems for at least another 15 years until the F-22 and Joint Strike Fighter begin to enter the inventory in significant quantities.

FIGURE 2-1 Force structure projection for the ACC fighter, bomber, and attack aircraft.

Source: JACG (1996).

FIGURE 2-2 Force structure projection for the ACC airlift and rescue aircraft.

Source: JACG (1996).

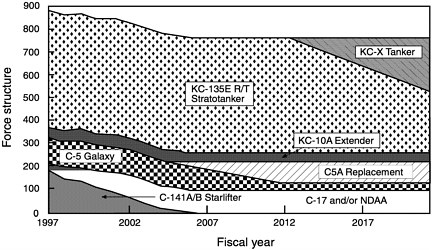

Air Mobility Command

The aircraft program chart for the AMC (Figure 2-4) reflects their core mission aircraft that support the air refueling and airlift missions. The C-141 will be retired in the near future and will be replaced by the C-17. The KC-135 and most of the C-5 forces, however, are being extended for most of the next 25 years.

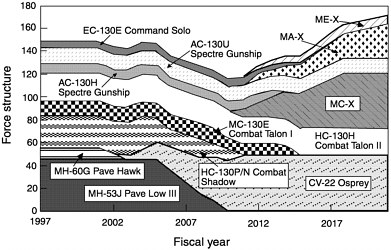

Special Operations Command

As shown in Figure 2-5, the AFSOC employs a wide variety of different aircraft systems in small force sizes to support their mission of force application, mobility, and psychological operations. The AFSOC is currently modernizing their forces, replacing some aging helicopters with the CV-22 tiltrotor over the next ten years. The AFSOC has also recently introduced the

FIGURE 2-3 Force structure projection for other ACC aircraft. Source: JACG (1996).

FIGURE 2-4 Force structure projection for AMC aircraft. Source: JACG (1996).

AC-130U gunship and the MC-130H. The AFSOC force presents some unique challenges in staying abreast of aging problems because of their specialized configurations and mission profiles.

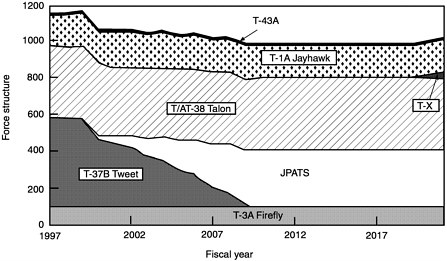

Air Education and Training Command

The AETC operates a relatively new force for its pilot training activities, except for the T-38 and T-43, some of

FIGURE 2-5 Force structure projection for AFSOC aircraft. Source: JACG (1996).

which will be over 50 years old by the year 2020. The aging T-37 is being replaced by the JPATS over the next ten years. The future force structure for AETC is shown in Figure 2-6.

ASSESSMENT OF THE FORCE STRUCTURAL MANAGEMENT PROCESS

Modernization Planning Process

The Air Force modernization planning process contains the essential elements for effective force structure planning and management at all levels. It links the Air Staff, major operating commands, system program directors, and the technology community into a comprehensive planning system. The effectiveness of the AFMPP depends on the timeliness and accuracy of information used to develop the plan. For this reason, it is critical that estimates of the economic service life of the aircraft weapon system be as accurate as possible and be progressively improved as new information becomes available. Continued efforts to employ and refine the AFMPP should ensure that structural economic life considerations are incorporated into the force structure planning.

Service Life Projection

Currently, there is no clear definition of all the elements that constitute the determination of structural economic life for aircraft systems, or a standard economic model to assist in determining when the costs of operating and maintaining the system reach a level that clearly warrant replacement. Lack of these tools frustrate the ability of Air Force planners to establish a realistic time table to phase out a current system and to begin planning for replacement systems. In addition, no comprehensive system exists for forecasting or assessing the total yearly operating and maintenance costs for an aircraft. An economic-based model to estimate the cost-effective service life would greatly facilitate force structure planning and give credibility to system replacement decisions and budget requirements. Given the long lead times (i.e., more than ten years) for replacement systems, along with their supporting technologies, timely and accurate service life forecasts for current aging systems are critical to maintaining force readiness. The committee believes that the development of an overall economic service life estimation methodology that integrates the time-dependent effects of structural deterioration with economic considerations is essential to force management.

ASIP and Postproduction Force Management

The primary focus of ASIP has been and continues to be to protect structural safety. ASIP was originated with the approval of General Curtis LeMay in 1958 as a result of a series of wing failures on B-47 bombers. However, it was not until the 1970s, with the introduction of damage tolerance requirements into ASIP and use of DADTAs of older aircraft, that the problem of unacceptably high aircraft losses due to structural fatigue failures was finally brought under control. Since this major revision to ASIP

FIGURE 2-6 Force structure projection for AETC aircraft. Source: JACG (1996).

in the early 1970s the program has been a huge success. An indication of this success is that the failure rate for all weapon systems that are maintained using the damage tolerance approach is one aircraft lost due to structural reasons in more than ten million flight hours (Lincoln, 1997). This is two orders of magnitude less than the aircraft loss rate from all other causes.

It has been the implementation of the structural inspections and modifications that have been derived from the damage tolerance approach and applied to the aircraft weapon systems by the Air Force's logistics and operational support organizations that has so successfully protected the structural safety of Air Force aircraft for more than two decades. However, the committee is concerned that the extended use of old aircraft, coupled with the current trends of reducing military budgets and manpower, increased reliance on contracted maintenance, use of commercial design practices rather than military specifications, and possible complacency of Air Force management (because of the greatly reduced number of aircraft lost due to structural failures in recent years) may make this past success rather fragile. It is the committee's opinion that the effectiveness of the damage tolerance approach and its success in preventing structural failures has been dependent on a number of factors:

-

rigid "cradle to grave" enforcement of ASIP by the system program offices at Wright-Patterson AFB and the system program directors at the air logistics centers (ALCs) as required by Air Force Regulation 80-13 and by the aircraft contractors as required by MIL-STD-1530A and the supporting military specifications, which have been required on aircraft weapon system contracts

-

implementation of the IATPs to allow the maintenance program to account for the large variations and changes in usage that are commonplace in military combat aircraft, but virtually absent in normal commercial aircraft operations

-

technical oversight of the DADTAs by an experienced standing Air Force committee up until the mid-1980s, plus periodic reviews of specific weapon systems by Air Force Scientific Advisory Board committees and by Division Advisory Group committees for the Aeronautical Systems Division

-

development of competent ASIP managers and engineering support groups within the ALCs, that had the capability to perform damage tolerance analyses, monitor contractor's analyses, and keep the FSMPs and IATPs up to date

-

sufficient funding of the DADTAs, IATPs, and the other ASIP support activities at the ALCs

-

adequate R&D funding to address design, analysis, inspection, and maintenance and repair needs

Based on discussions with Air Force engineering and logistics personnel, the committee believes that the relatively recent acquisition reforms, budget and manpower reductions throughout the Air Force, and engineering-grade structure limitations at the ALCs have all adversely affected these factors. It will take aggressive actions by Air Force

management and engineers to counter deterioration in capability and loss in the ASIP oversight that apparently has already occurred and to prevent further deterioration in the future. ASIP should continue to be enforced, and sufficient resources should be maintained to continue to track aircraft, keep the damage tolerance assessments up to date, and keep corrosion and stress corrosion cracking from becoming a structural safety issue. Also, sufficient R&D resources should be maintained to support and improve aging aircraft engineering, inspection, and maintenance and repair. Recommended R&D and engineering and management tasks are expanded on in Part II.

3

Current Structural Status of the Aging Force

When discussing the Air Force's aging aircraft, it is helpful to consider the Air Force-supported aircraft separately from the Air Force commercial-derivative aircraft, which typically use contractor logistics support (i.e., contractor logistics-support aircraft). Both are discussed in the following sections.

AIR FORCE-SUPPORTED AIRCRAFT

Table 3-1 summarizes data on aircraft age and planned future replacements for aging aircraft that are maintained by the Air Force.1 During the course of this study the committee received briefings and written material on these aircraft. Some of the more significant structural problems encountered with these aircraft are discussed briefly below. Additional details on all the aircraft listed in Table 3-1 can be found in Appendix A. The B-2 bomber, the F-117 attack aircraft, and the C-17 airlifter are excluded because of their relatively recent introduction into the force. Also, because of time, budget, and technical considerations, the committee elected to exclude the H-1, H-53, and H-60 rotorcraft from this study. Helicopters are somewhat unique in that dynamic excitations in the rotor systems (i.e., causing combined high-and low-cycle fatigue) have been at the root of many past structural problems, and as such the committee suggests that this subject could best be addressed separately.

The Air Mobility Command's (AMC) airlifter and tanker aircraft listed in Table 3-1 were designed based on the fail-safe approach, and, as a result, the primary safety concern with regard to aging is the loss of this fail-safety from the onset of widespread fatigue damage (WFD).2 In fact, both the KC-135 and the C-5A had their original lower wing surfaces replaced in the 1970s and early 1980s because of WFD, and the wings of the C-141 have more recently undergone extensive modification because of WFD (i.e., use of boron composite doublers to repair and prevent further cracking at the weep holes in the lower wing surface risers). In addition, some C-141s are now experiencing WFD in the lower wing surface spanwise slices. Risk analyses performed by the aircraft manufacturer have shown that these splices reach the onset of WFD at about 37,000 flight hours. As shown in Table 3-1, the current plan is to retire all of the C-141s within the next eight years; however, this plan was based on an aircraft retirement time of 45,000 flight hours. For any aircraft that must be flown more than 37,000 hours before retirement, extensive and burdensome inspections are required to protect the structural safety. These inspections involve inspecting more than 6,000 fastener holes per aircraft every 120 days. The committee is not aware of any data to indicate that the KC-135 or the C-5 will experience the onset of WFD in the near future. For example, a blue ribbon panel reviewed the KC-135 during 1996 and concluded that the current data indicate that the aircraft could likely be flown to beyond the year 2040 before encountering WFD. However, the panel recommended some additional actions to improve this estimate and emphasized the need to control the present corrosion and stress corrosion cracking problems.

The Air Combat Command's (ACC) fighter, bomber, and attack aircraft and the Air Education and Training Command's T-37 and T-38 trainer aircraft were either designed to be damage tolerant using the safe crack growth concept or were later analyzed on the basis of crack growth to establish safety limits and inspection requirements. This was accomplished during the durability and damage tolerance assessments (DADTAs) that were performed on these aircraft. Although some of these aircraft have some inherent fail-safety resulting from redundancy in load paths and crack arresting features or because of battle damage requirements, they do not meet the fail-safe standards of the large transport aircraft. As such, with increasing age the primary threat to their structural safety is the growth in fatigue-critical areas and the potential of missing one or more of these areas. As noted in Chapter 4 and Appendix A, there already has been a significant increase in the number of critical areas in the F-16 since its introduction into service in 1979. Also, based on the number of cracking locations currently being reported in the T-38 and A-10 (see Appendix A), it appears that this is also true for these aircraft.

The T-38 is of particular concern because of its single-plank lower wing skin, its very small critical crack sizes (i.e., 0.20 to 0.40 in.), and the age of the aircraft in terms of both calendar years and flight hours. Wing failure and

|

1 |

An exception is the U-2, which was developed for the government and maintained by the contractor. |

|

2 |

See Chapter 4 for a discussion of technical issues associated with aging aircraft, including widespread fatigue damage. |

TABLE 3-1 Data on Force Status for Air Force-Supported Aircraft

|

|

|

Current Age Data |

||

|

Aircraft Operator |

Aircraft Type |

Years Since IOCa |

Average Age (years) |

Future Plans |

|

Air Mobility Command |

Airlifter and Tanker Aircraft |

|

|

|

|

|

KC-135 |

41 |

35 |

Retain 25+ years. No replacement identified |

|

|

C-5 |

28 |

18 |

Retire C-5A in 10–15 years. No replacement identified |

|

|

C-141B |

32 |

29 |

Retire over next 8 years. Replace with C-17 |

|

Air Combat Command |

Bomber and Attack Aircraft |

|

|

|

|

|

A-10 |

20 |

15 |

Retain 25+ years. No replacement identified |

|

|

B-52H |

36 |

34 |

Retain 25+ years. No replacement identified |

|

|

B-1B |

11 |

9 |

Retain 25+ years. No replacement identified |

|

|

F-15 |

23 |

12 |

Retire in 5–20 years. Replace with F-22 |

|

|

F-16 |

18 |

8 |

Retire in 10–25 years. Replace with Joint Strike Fighter |

|

|

Other Aircraft |

|

|

|

|

|

C-130E/Hb |

36 |

20 |

Replace 1/3 over 5–25 years with C-130J |

|

|

E-3 (AWACS) |

20 |

16 |

Retire in 17–25 years. No replacement identified |

|

|

E-8 (JSTARS) |

N/A |

15–20 |

Retire in 15–20 years. No replacement identified |

|

|

EC/AC-135 |

40 |

30–35 |

Retain 25+ years. No replacement identified |

|

|

U-2c |

40 |

14 |

Retire in 15–25 years. No replacement identified |

|

|

EC-130E/H |

36 |

20 |

Retire in 15–25 years. No replacement identified |

|

|

EF-111 |

30 |

29 |

Retire within next 4–5 years |

|

Air Education and Training Command |

Trainer Aircraft |

|

|

|

|

|

T-37B |

38 |

33 |

Retire in 2–12 years. Replace with JPATS |

|

|

T-38 |

36 |

29 |

Retain 25+ years. No replacement identified |

|

a IOC: initial operational capability b Operational control of the C-130E/H was recently transferred from the Air Combat Command to the Air Mobility Command. c This aircraft was developed for the government and is maintained by the manufacturer rather than by an air logistics center. |

||||

aircraft losses occurred during the 1970s when these aircraft were put into severe roles. The T-38 was used in the lead-in-fighter (LIF) role3 and the dissimilar air combat training role by the Tactical Air Command. The critical crack size that caused the wings to fail was also about 0.2 in. Since the 1970s it appears that the Air Force's San Antonio Air Logistic Center and their prime contractor, Northrop-Grumman, have done a good job of maintaining structural safety and preventing wing failures through the use of safety inspections,4 structural modifications, design changes, and lower wing surface replacements. Additional full-scale wing fatigue testing has also been performed to identify critical areas in the new and modified structure. Crack growth analyses have performed to establish inspection requirements. Further design changes, wing replacements, and full-scale testing are anticipated by the San Antonio Air Logistics Center. The committee concurs that these changes undoubtedly will be needed if the aircraft are to remain in the inventory for 25 years or more.

Table 3-1 also shows several of the ACC's other aircraft that are used in various missions involving electronic combat, surveillance, intra-theater airlift, and tracking of enemy air and ground forces. Except for the U-2, the structures of these aging aircraft are predominantly of a fail-safe design, in which the threat to safety is the onset of WFD. The E-3 and the E-8 are both derivatives of the Boeing commercial 707 aircraft. However, the E-8 airframes are old commercial airframes that have been modified, whereas the E-3 were new airframes based on the 707 design. In fact, several of the E-8s have airframes that exceed the original design life goal (i.e., 20,000 flights) and, as indicated in Appendix A, a number of the aircraft are either at or are believed to be approaching the onset of WFD and will very likely require lower wing surface replacements in the near future.

The C-130 aircraft included in Table 3-1 (i.e., the C-130E/H and the EC-130E/H) have been in production for more than three decades. The E models were delivered

between 1961 and 1972 and they make up the majority of the active Air Force assets. The H model, which has been supplied since 1973, makes up the balance of the intra-theater airlift and EC-130 electronic combat capability. There have been a number of fatigue cracking and corrosion problems over the years that have led to the retirement of nearly all of the A models and outer wing replacements of the B and E models to the H configuration. There have also been numerous center wing replacements on the B, E, and H models. As pointed out in Appendix A, the major uncertainty about the C-130E/H airframe is the probable service life of the fuselage and the associated future structural maintenance needs. During 1996 an Air Force Structural Review Team looked at this issue and made several recommendations, including the teardown inspection of a high-time aircraft to look for evidence of WFD and the performance of a DADTA to determine future safety inspection requirements.

CONTRACTOR LOGISTICS-SUPPORTED AIRCRAFT

The Air Force's contractor logistics-supported (CLS) commercial-derivative aircraft are listed in Table 3-2. These aircraft range in average age from about 3 years to more than 30 years. In some cases, such as the KC-10 and the C-27, there were DADTAs performed under Air Force guidance. For the E-4 and the C-18, the Air Force had the manufacturer modify their damage-tolerance-derived inspection intervals for anticipated Air Force use. For the most part, the aircraft listed in Table 3-2 have been designed and certified to Federal Air Regulation requirements (e.g., FAR Part 25 for the large transport aircraft and FAR Part 23 for utility and commuter aircraft) and are contractor maintained to commercial standards. One exception is the C-27, which is a later model of a military transport aircraft originally developed in the 1970s by Aeritalia for the Italian Air Force (i.e., the G222TCM).

Because of time and budget limitations, the committee did not attempt to review each of these aircraft with regard to corrosion, fatigue, and stress corrosion cracking histories or their specific Air Force use spectra. However, it has been pointed out to the committee that many of these aircraft have very low utilization rates compared with their commercial counterparts and in many cases are being flown to operational spectra comparable with those flown in commercial operation. Table 3-3 shows a utilization comparison between the large Air Force aircraft shown in Table 3-2 with their commercial counterparts. With the exception of the C-9, the data in this table support the position that, for those commercial

TABLE 3-2 Air Force Commercial-Derivative Aircraft Using Contractor Logistics Supporta

|

Air Force Designation |

Commercial Designation |

Quantity |

Average Age (years) |

Operator(s)b |

|

E-4 |

Boeing 747-200 |

4 |

23 |

ACC |

|

VC-25 |

Boeing 747-200 |

2 |

7 |

AMC |

|

T-43 |

Boeing 737-200 |

13 |

24 |

ACC and ANG |

|

C-137 |

Boeing 707-100/300 |

6 |

21 |

AMC |

|

C-18 |

Boeing 707-323 |

6 |

N/A |

AFMC, ACC, USAFA |

|

C-22 |

Boeing 727-100 |

3 |

32 |

ANG |

|

KC-10 |

McDonnell Douglas DC-10-30F |

59 |

13 |

AMC |

|

C-9 |

McDonnell Douglas DC-9-30 |

23 |

26 |

AMC, USAFE, PACAF |

|

C-12 |

Beechcraft Super King Air 200 |

37 |

17 |

AFMC, PACAF, AETC |

|

T-1A |

Beechjet 400A |

156 |

3 |

AETC |

|

C-21 |

Learjet 35A |

76 |

13 |

All commands |

|

C-23 |

Shorts 330 |

3 |

13 |

AFMC |

|

C-26 |

Fairchild SA227 Metroliner |

40 |

5 |

ANG |

|

C-27 |

Alenia G-222 Model 710Ac |

10 |

5 |

ACC |

|

C-20 |

Gulfstream II, III, IV |

13 |

10 |

AMC and USAFE |

|

UV-18 |

Dehaviland DHC-6 Twin Otter |

2 |

20 |

USAFA |

|

E-9 |

Dehaviland DHC-8 |

2 |

N/A |

ACC |

|

T-3 |

Slingby T67M260 Firefly |

112 |

3 |

AETC and USAFA |

|

a Excludes six types of glider aircraft, two small Cessna aircraft used by the Air Force Academy, and newer aircraft not yet in the inventory (e.g., C-32). b Operators: ACC (Air Combat Command), AMC (Air Mobility Command), AETC (Air Education and Training Command), ANG (Air National Guard), AFMC (Air Force Matériel Command), USAFA (United States Air Force Academy), USAFE (United States Air Forces in Europe), PACAF (Pacific Air Forces). c Not a commercial aircraft, but a military transport originally built for the Italian Air Force. |

||||

TABLE 3-3 Comparison between Utilization of Air Force CLS Aircraft and Commercial Equivalents

|

Air Force CLS Aircrafta |

Commercial Aircrafta |

||||||||

|

Aircraft |

Flightsb |

Hours |

Number of Flights |

Flight Hours |

|||||

|

|

|

|

Aircraft |

Average |

High |

Design Goal |

Average |

High |

Design Goal |

|

E-4 |

7,500–11,000 |

8,000–10,000 |

747 |

~10,000 |

~32,000 |

20,000 |

~40,000 |

~95,000 |

60,000 |

|

VC-25 |

N/A |

~2,500 |

747 |

~10,000 |

~32,000 |

20,000 |

~40,000 |

~95,000 |

60,000 |

|

T-43 |

10,000–15,000 |

16,000–18,000 |

737 |

~20,000 |

~75,000 |

75,000 |

~22,500 |

~80,000 |

60,000 |

|

C-22 |

51,000–55,000 |

57,000–59,000 |

727 |

~35,000 |

~72,000 |

60,000 |

~47,000 |

~78,000 |

60,000 |

|

C-18 |

13,000–44,000 |

33,000–62,000 |

707c |

~20,000 |

~37,000 |

20,000 |

~40,000 |

~90,000 |

60,000 |

|

VC-137 |

8,000–24,000 |

7,000–52,000 |

707c |

~20,000 |

~37,000 |

20,000 |

~40,000 |

~90,000 |

60,000 |

|

KC-10 |

1,400–2,500 |

6,300–13,000 |

DC-10 |

N/A |

~36,000 |

42,000 |

N/A |

~90,000 |

60,000 |

|

C-9 |

11,600–51,200 |

11,000–44,600 |

DC-9 |

N/A |

~99,000 |

40,000d |

N/A |

~79,000 |

30,000d |

|

a Approximate data as of 1995 for the commercial aircraft and 1996 for the Air Force CLS aircraft. b Except for the KC-10 and C-9, the data for the Air Force CLS aircraft reflect number of landings, which may be slightly larger than number of flights. c There are 57 707 aircraft remaining in commercial use in the world. There are none registered in the United States. d Contractor revised values to 102,000 flights and 78,000 hours based on retest and tear-down inspection of high-time commercial aircraft. |

|||||||||

derivatives that the Air Force purchased new (i.e., the E-4, VC-25, T-43, and KC-10), the use in terms of both total flight hours and number of flights is low compared with their commercial counterparts and thus would not be expected to experience the onset of widespread fatigue cracking in many more years of operations. The high-time C-9s on the other hand have exceeded the contractor's original design life goals in terms of numbers of flights and total flight hours, but is still considerably less than the 102,000 flights and 78,000 hours that the aircraft manufacturer has now verified by retest and tear-down inspection of a high-time commercial aircraft. Whether or not these revised numbers apply directly to Air Force use is still a question that the committee believes should be investigated.

In addition, some of the large CLS aircraft were not purchased new and had a significant amount of commercial use prior to being modified for Air Force use. As seen from Table 3-3 there are C-22 (727), C-18 (707), and VC-137 (707) aircraft, in which the total number of flights or flight hours are, in some cases, close to or exceed the commercial design life goals. As indicated in Appendix A, the 1996 partial tear-down inspection of the lower wing skin and stringers of a commercial 707-300C aircraft with 57,382 flight hours and 22,533 flights revealed over 1,500 fatigue cracks. Most of these cracks were small, but some were large enough to indicate a high risk of a potential structural failure. This would indicate that the high-time C-18s and VC-137s may be approaching the onset of WFD in their wings and should be investigated further. Although the Air Force has indicated that some of the VC-137s will be replaced in the near future by new C-32 (i.e., 757) aircraft, the committee is not aware of any plans to replace the C-18. The C-22 (727) wings are less susceptible to WFD than the C-18 or VC-135 because of lower stress levels, better stringer materials, and an improved fastener system, but the C-22 fuselage is a potential fatigue cracking concern that also needs to be investigated further.5

With regard to the smaller utility and commuter class aircraft and the C-27 military transport listed in Table 3-3, the committee lacks the information necessary to make any judgments about their structural health and probable longevity. It is noted that several of the aircraft types, which comprise more than 300 aircraft, have very low average ages (i.e., the T-1A, T-3, C-26, and C-27) and thus one would not anticipate fatigue cracking very soon. On the other hand, a fundamental shortcoming in the current FAR Part 23 requirements is that there is no requirement for the aircraft to be designed to be damage tolerant (i.e., either fail-safe or safe crack growth). This shortcoming has been recognized by the Federal Aviation Administration and some commuter aircraft manufacturers, and changes to both the design rule and the supporting advisory circular are currently in process. Nevertheless, these types of aircraft that are currently in service have a large variance in their damage tolerance capabilities. In many cases they have single load-path structures, and the failure of a

single member could result in the loss of the aircraft. To minimize the possibility of such an occurrence, the Federal Aviation Administration has had a team of structural experts conducting damage tolerance surveys of selected aircraft in the commuter fleet over this past year. It is the team's intent to identify aircraft with the highest potential for structural failure, define further damage tolerance analysis requirements, and consider other actions that may be necessary to minimize the potential for failure. It would appear prudent for the Air Force to initiate a similar effort for the CLS utility-and commuter-sized aircraft listed in Table 3-2. These independent surveys or reviews would be to assess the current structural health of each type of aircraft, determine the need for a more detailed DADTA, improve corrosion control, and determine if an economic service life assessment of the aircraft is warranted.

4

Technical Issues and Operational Needs

In this chapter the primary aircraft aging mechanisms are discussed briefly in relation to their impact on aircraft structural health and longevity, and the associated technical issues and operational needs are identified. This is followed by brief discussions of technical issues and needs in the areas of nondestructive evaluation and maintenance and repairs. The focus of this chapter is on the degradation mechanisms for aluminum alloy airframe structures, which are predominant in current aging aircraft. Issues and recommendations concerning future aging aircraft, including composite primary structure are included in Chapter 10. The issues and needs identified in this chapter are the basis for the recommended engineering and management actions and near-term and long-term research and development presented in Part II of this report.

The three primary mechanisms that can affect the structural health and longevity of the Air Force's metallic aircraft structures are

-

corrosion

-

stress corrosion cracking

-

fatigue cracking (including low-cycle and high-cycle fatigue)

CORROSION

Corrosion of airframe structure is the single, most costly maintenance problem for Air Force aging aircraft (SAB, 1994). Corrosion can occur in a variety of nonexclusive forms, including uniform or general corrosion, galvanic corrosion, pitting corrosion, fretting corrosion, crevice (filiform and faying surface) corrosion, intergranular (including exfoliation) corrosion, and stress corrosion cracking (ASM, 1987). Because of the potential structural effects, stress corrosion cracking is considered in greater detail in the following section.

Corrosion of aging aircraft results from a combination of factors, including

-

the use of aluminum alloys and tempers that are more susceptible to corrosion than currently available alternatives

-

inadequacy or deterioration of corrosion protection systems

-

exposure to various corrosive environments (e.g., humid air, saltwater, sump tank water, latrine leakage)

Control of corrosion is predicated on effective prevention, detection, and repair methods. Despite the best intentions of prevention and control practices, the complete elimination of corrosion is virtually impossible. In aging aircraft structures, corrosion protection and control systems deteriorate over time. The major concern with the deterioration of corrosion protection systems for aging aircraft structure is the resulting increase in maintenance costs because corrosion damage that is identified must be repaired. Based on current experience, this practice of identifying and repairing corrosion damage has been adequate for maintaining the integrity of aging structures. However, because corrosion damage is typically found by visual inspection techniques, and a fair amount of corrosion damage occurring on older Air Force aircraft is hidden from direct view, a significant amount of corrosion can remain undetected. Also, there can be a wide variation in extent and severity of corrosion damage among similar aircraft because of differences in environmental exposures and in the amount and type of maintenance that the aircraft may have received.

The different types of corrosion damage exhibit different characteristics and potential consequences with respect to both detectability and structural consequence. For example, exfoliation corrosion (severe intergranular corrosion where the buildup of corrosion products causes flaking and surface blisters) and pitting corrosion can be detected readily, depending on the accessibility of the damaged surface. Although these corrosion forms are evident as surface deterioration, they may not be found if the surface is inaccessible to visual inspection. Intergranular corrosion that propagates along grain boundaries away from exposed surfaces may be indistinguishable from the surface, challenging the reliability of nondestructive inspection (NDI) methods (Mindlin et al., 1996).

Undetected corrosion can progress significantly before being observed, leading to (1) increased maintenance costs and time in the depot for maintenance or (2) an increased risk that corrosion, in the presence of other forms of damage, may cause a more significant decrease in damage tolerance than otherwise estimated. This is discussed later in this chapter. Although corrosion can be very costly to repair, corrosion by

itself has not yet caused any structural failures that have resulted in the loss of an Air Force aircraft. This is because corrosion has been detected and repaired before it could become a flight safety problem.

Corrosion prevention begins—or should begin—during engineering design with proper selection of materials and manufacturing processes. As part of structural maintenance programs, the commercial aircraft industry has developed provisions to upgrade corrosion resistance through the use of substitute materials and heat treatments (e.g., more corrosion-resistant 7050, 7150, or 7055 alloy for 7075, stress corrosion-and exfoliation-resistant T-7X tempers for 7XXX-series aluminum alloys), improved protective finishes and corrosion-preventive compounds (CPCs),1 and incorporation of design features such as drainage and sealing to prevent corrosion. However, similar engineering guidelines that provide advice on materials and processes having better corrosion resistance than the original materials and processes have not been formally developed for Air Force aircraft.

A panel chartered under the ad hoc committee of the Air Force Scientific Advisory Board concluded that a reduction of the relative humidity to 30–40 percent would significantly reduce the corrosion of stored aircraft and that existing dehumidification and storage systems appeared to be adequate (SAB, 1996). The report describes equipment and logistics relevant to dehumidified storage and discusses successful dehumidification programs in the other U.S. services (e.g., Marine Corps A-6E, Navy SH-60B, and Army CH-47D) and internationally (e.g., Swedish and Danish air forces). Since the Scientific Advisory Board study, work has been accomplished to validate the practicality of dehumidified short-term and long-term storage facilities for a range of military hardware using desiccant wheel technology (Cannava, 1997). It is not yet clear that dehumidification will be cost-effective for Air Force aircraft.

The committee believes that, if costly component repair and replacement are to be avoided, much more emphasis should be given to early detection of corrosion and implementation of effective corrosion control and mitigation practices. A practicable and more cost-efficient strategy for dealing with corrosion damage of airframe structures is needed to effectively guide prevention, control, and force management decisions for aging aircraft. The most important operational needs include

-

environmentally compatible protective coatings to replace the hazardous materials being phased out (e.g., chromates)

-

generalized use of CPCs and development of CPCs that can be applied on external surfaces and that will penetrate and protect unsealed joints and around fastener heads on older aircraft structures2

-

guidance for the application of advances in alloys and processes offering improved corrosion protection

-

improved techniques to discover and roughly quantify hidden corrosion without requiring disassembly of the aircraft

-

classification of corrosion severity, similar to current commercial aircraft practice, to provide guidance to maintenance actions

-

improved understanding of the probable rates of corrosion and corrosion trends for specific operational aircraft for use in planning maintenance actions

-

dehumidified storage of aircraft or dehumidification of susceptible areas of particular aircraft

With improved detection methods and the implementation of improved corrosion prevention and control actions, the committee does not believe that physical corrosion damage per se will limit the structural life of Air Force aircraft.

STRESS CORROSION CRACKING

Stress corrosion cracking (SCC) is an environmentally induced, sustained-stress cracking mechanisms. Early metallic aircraft built from thin aluminum sheet experienced few stress corrosion problems. The occurrences that did occur (e.g., pressed-in bushings) were generally diagnosed quickly and solved with little fanfare. However, in the post-World War II era, increasing numbers of stress corrosion problems appeared as a result of the introduction of high-strength 7XXX-series aluminum alloys and the growing use of integrally stiffened structure. The latter entailed installation of shaped components machined from thicker starting stock, which in turn introduced heat treat and assembly residual stresses unanticipated in the original design process. Designers and the aluminum industry gradually learned how to reverse the alarming rise in SCC incidents through an awareness of causes, through the identification of susceptible alloys, and through the introduction of tougher materials with improved corrosion resistance, improved surface preparation processes, and reduced residual stresses.

The results from comprehensive industry surveys on SCC service failures conducted during the late 1960s and early

1970s formed the backbone of current Air Force practices for management of SCC (ASM, 1987; Spiedel, 1975). In general, it was found that the majority of aluminum airframe structures documented as failing by SCC were manufactured from the high-strength 7XXX-and 2XXX-series aluminum alloys that contain Al, Cu, Zn, and Mg. Of these alloys 7075, 7079, and 7178 in the peak strength T6 condition and alloy 2024 in the naturally aged T3 condition contributed to more than 90 percent of the reported aluminum SCC failures. A number of SCC problems have also been observed in high-strength steels. The SCC associated with service failures was observed to be characteristically intergranular, making early visual detection somewhat difficult.

SCC is generally exacerbated by residual tensile stresses remaining from material heat treatment or fit-up, but can also be triggered by operational loads and forces from the buildup of corrosion by-products. Aircraft designers are well aware of the reduced mechanical properties of forgings and thick plate materials in the short-transverse grain direction compared with those in the longitudinal grain directions. As a result, structural components are usually designed so that the primary load paths are parallel to the principal grain direction. In this case, the elongated grain boundaries are parallel to, rather than normal to, the applied operational stresses. Fortunately, when SCC occurs parallel to applied operational stresses, cracks often can be very large (e.g., as much as several inches long) before they become a flight safety problem.

When components containing SCC are discovered, they are either replaced with new components fabricated from more-resistant materials and tempers or they are repaired. Both replacement and repair are often quite difficult and costly (e.g., repairing or replacing sections of large fuselage bulkheads). The need for replacement and repair of components due to SCC could be reduced, or at least delayed, with appropriate maintenance actions. Important operational needs include

-

improved environmental protection systems (e.g., improved CPCs and surface finishes) to reduce the corrosion rate of susceptible components

-

modified manufacturing practices that reduce exposed end-grain and residual stress effects that exacerbate SCC in large structural components

-

improved repair procedures, ranging from structural repairs to the restoration of corrosion-retarding finishes

-

reevaluation of SCC-susceptible structural components to identify potential safety problems; such evaluations could be done during an Aircraft Structural Integrity Program (ASIP) durability and damage tolerance assessment of the aircraft

With continued vigilance, improvement in prevention and control procedures, and replacement of susceptible components with corrosion-resisting alloys with minimized residual stresses, the committee believes that SCC problems in older Air Force aircraft can be managed and that SCC need not be a life-limiting damage mechanism.

FATIGUE CRACKING

Unlike corrosion and SCC, which the committee believes can be controlled and thus would not, in themselves, physically limit structural life, fatigue cracking is a direct result of aircraft use (i.e., load or stress cycles) and will eventually occur in all aircraft. Both low-cycle fatigue (typically due to flight maneuver and gust loading) and high-cycle fatigue (due to vibratory excitation from aerodynamic, mechanical, or acoustic sources) are of concern. Also, the potential accelerating effects of corrosion damage on fatigue cracking must be recognized and accounted for when estimating life limits and determining safety inspection intervals.

Low-Cycle Fatigue

Safety Limit and Economic Life Limit

Fatigue cracking and failures resulting from the growth of cracks from preexisting flaws or defects (introduced during material processing or manufacturing) have occurred quite early in the operational life of an aircraft. In single load-path structures, such as those used in many older fighter aircraft, the structural failures have often led to loss of the aircraft. Because of these failures, the Air Force extensively revised ASIP in the early 1970s to include damage tolerance design and test requirements. These requirements were incorporated in MIL-STD-1530A (DOD, 1988) and MIL-A-83444 (DOD, 1987) and required that the structure be designed with the a priori assumption that it contains the maximum probable-sized initial material or manufacturing flaw or defect located in the most critical areas of the structure. The time required for a crack to grow from this initial flaw size to the critical size (i.e., size at failure) was defined as the safety limit for the structure. The aircraft was not allowed to fly beyond the safety limit without a careful inspection (and repair or modification if necessary). In addition, repeat inspections were required at one-half the time required for the flaw to grow from the size that is barely undetectable by NDI methods to critical size. If the structure was not inspectable or was difficult to inspect, the aircraft operator had only three options once the safety limit was reached: modification, structural replacement, or retirement. For new aircraft, a design goal is to avoid in-service structural safety inspections by selecting stress levels and materials such that the calculated safety limits exceed the expected design life of the aircraft when operated according to the design service use spectrum. The primary problem with this design goal has been that actual service use has very often

been different, and sometimes much more severe, than the original design spectrum.

Deviation from original design spectra have occurred as a result of increased weight and increased frequency of high-load occurrences per flying hour. To a large part, the increased weights have been caused by additional armaments and electronic systems, and the increase in high-load occurrences are the result of changes in tactics. Both have been caused by the change in military threats.

Experience indicates that it is important that, for aircraft having single load-path structures, (1) all fatigue-critical areas and likely root causes for fatigue crack initiation be identified, (2) critical loading conditions be defined, (3) safety limits be established based on actual use conditions, and (4) in-service safety inspections be performed. It is also important that the Air Force maintain the individual aircraft tracking program so that inspection intervals can be adjusted based on actual use and understanding of failure modes.

As aircraft age increases, it is more likely that fatigue cracks will be detected in critical areas and that additional areas of the structure will become critical and will require more inspections, repairs, and modifications. Eventually, the safety inspection, repair, and modification costs, when combined with other maintenance costs (e.g., for corrosion, stress corrosion, and wear), and the reduced availability of aircraft will become so burdensome that it will be more cost effective to replace the aircraft than to continue to maintain it. The Air Force calls this the economic life limit for the aircraft.

As discussed in Chapter 2, the committee believes that the prediction of when a given aircraft will reach its economic life limit is a crucial issue in future force planning. Although various attempts have been made to estimate economic life limits for various aircraft (e.g., the F-4E, KC-135), the Air Force has not yet developed a method for estimating such limits that accounts for all of the relevant cost factors.

From the standpoint of maintaining safety of aircraft that contain single load-path structures, the most important issue is ensuring that all critical areas of the airframe and flight load conditions have been identified. Currently, the Air Force relies on full-scale fatigue test results, past service experience, and various analyses (e.g., stress, fracture mechanics, failure modes, and environmental effects) for the identification of critical areas.

Corrosion Effects on Safety Limits

The Air Force recognizes that crack growth rates may be influenced by environmentally induced corrosion that in turn would affect the safety limits and repeat inspection intervals. In an attempt to account for this effect, data on the rate of crack growth have been developed for materials in environments that are believed to be appropriate (e.g., in high humidity, salt spray). Crack growth is limited to the time to reach the KISCC (i.e., the threshold stress intensity for SCC) in this environment to avoid superposition of fatigue and stress corrosion crack growth rates.3

Although the damage tolerance requirements and the approach for accounting for potential environmental effects have served the Air Force well over the past two decades, the committee continues to be concerned that, as structures age, as corrosion protection systems continue to deteriorate, and as materials corrode, there may be effects that have not been adequately considered. Specific corrosion concerns or issues that could affect safety limits and repeat inspection intervals include

-

the influence of corrosion on applied stresses and stress intensity factors resulting from material thinning and local bulging of thin sheet due to buildup of corrosion products

-

the potential influence of corrosion on material mechanical properties (toughness, strength, elongation) resulting, for example, from the absorption of hydrogen by the metal during the corrosion process

-

the potential influence of corrosion and corrosive environments on crack growth rates below the threshold for SCC

Widespread Fatigue Damage

Although failure that is due to fatigue crack growth from an initial material flaw is of lesser concern in the larger transport and tanker aircraft, which generally have been designed to be fail-safe either through the use of multiple load paths or through the use of crack arrest features,4 there is serious concern about the loss of fail-safety due to the onset of widespread fatigue damage (WFD) initiating from normal quality structural details. This is of particular concern for older aircraft or aircraft that have been flown under a more severe use spectrum than that for which it was designed.

The onset of WFD in a structure is characterized by the simultaneous presence of small cracks in multiple structural details; where the cracks are of sufficient size and density, the structure can no longer sustain the required residual strength load level in the event of a primary load-path failure or a large partial damage incident. Multiple-site damage and multiple-element

damage are subsets of WFD, where there are multiple cracks either in the same structural element or in adjacent structural elements. When the onset of WFD occurs, the airframe (or major component of the airframe) has reached the operational life limit. To preclude unsafe operations once the onset of WFD occurs, flight restrictions or groundings are the only options until the affected structure is modified, replaced, or the aircraft is retired.

To assist in future force structure planning, it is necessary to be able to predict when the onset of WFD will occur (i.e., estimate when a sufficient number and sizes of cracks will degrade the residual strength of the structure to below the fail-safe design level) and to assess if WFD concerns will affect a significant part of the force structure. To predict the onset of WFD, it is necessary to (1) predict accurately the residual strength of the structure after encountering the primary damage (e.g., from a discrete source) with various sizes of small WFD cracks in the adjacent intact structure and (2) predict when these cracks will occur. Although there has been considerable effort over the past few years to develop analytical models that enable prediction of the residual strength of fuselage longitudinal lap splices (as a result of the 1988 Aloha Airlines 737 accident), there has been much less effort directed toward structural configurations typical to military aircraft (e.g., thick chordwise wing joints, plate and stringer wing configurations, shiplap spanwise wing splices, large pressure door hinges, loading ramp hooks, and others). The development of analytical residual strength models for the various structural configurations and materials that are typical of military aircraft is an important technical issue to address in the characterization of WFD.

The Air Force has been almost entirely dependent on using the results from detailed tear-down inspections of full-scale fatigue test aircraft, or actual high-time fleet aircraft, to predict when the small WFD cracks will occur. Tear-down inspections are required because current fatigue analyses are inadequate to predict accurately the initiation and growth of very small flaws, although there has been some promising research in this area. The primary shortcomings of using only full-scale fatigue test results to predict crack initiation are (1) full-scale fatigue test results are not usually representative of the actual operational load spectrum, and (2) the potential influence that environmental exposure may have on the crack initiation process is neglected. Although the tear-down inspection of actual fleet aircraft is the most reliable basis for determining the onset of WFD, it entails the destruction of one or more aircraft (or major portions of aircraft) and comes too late to provide data for force planning.