II

RECOMMENDED STRATEGY AND OPPORTUNITIES FOR NEAR-TERM AND LONG-TERM RESEARCH

One of the primary objectives of this study was to identify an overall strategy that addresses the Air Force's aging aircraft needs. From the discussion of the aging aircraft problem in Chapter 2, including the assessments of the force management process, it is apparent to the committee that the recommended overall strategy must encompass several engineering and management issues as well as the near-and long-term research opportunities. The committee believes that there are a number of engineering tasks that do not require additional research and that should be accomplished in the near future.

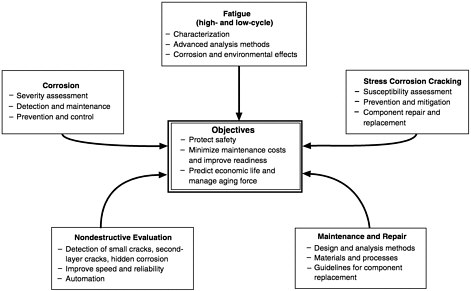

Also, to be effective, the strategy must address the three Air Force objectives that are noted in Chapter 1:

-

identify and correct structural deterioration that could affect safety of flight

-

prevent or minimize structural deterioration that could become an excessive economic burden or adversely affect force readiness

-

predict, for the purpose of future force planning, when the maintenance burden will become so burdensome, or the aircraft availability so poor, that it will no longer be viable to retain the aircraft in the inventory

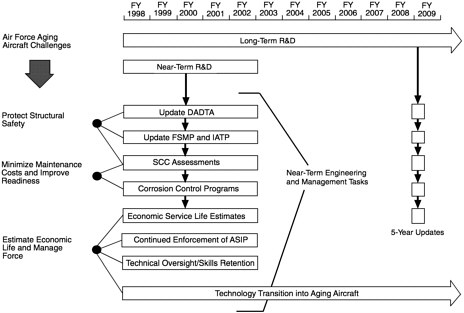

To provide a comprehensive approach that addresses these challenges, the committee recommends that the Air Force adopt a three-pronged strategy that includes (1) near-term engineering and management tasks, (2) a near-term R&D program, and (3) a long-term R&D program. This overall strategy is illustrated in Figure II-1.

Engineering and management tasks are near-term actions (within three to five years) to improve the maintenance and force management of aging aircraft. Each of the three aging aircraft challenges are shown on the left side of the figure connected to the primary engineering and management task that addresses each challenge. It should be noted, however, that this is not exclusively true. For example, the engineering task of obtaining improved corrosion control programs is connected to the challenge to minimize maintenance costs and improve readiness, since corrosion is currently the major contributor to maintenance costs and does not normally affect structural safety. However, corrosion could become a safety issue if not brought under control. Likewise the primary focus of the engineering tasks of updating durability and damage tolerance assessments, force structural maintenance plans, and tracking programs is to protect the structural safety, but they also impact maintenance costs and force readiness. The task of estimating the economic service life of an aircraft weapon system involves both engineering and management; engineering predictions of structural deterioration need to be coupled with a number of cost and operational considerations to arrive at the most probable time that the Air Force should plan on replacing the system. The last three tasks in Figure II-1 deal primarily with the Aircraft Structural Integrity Program and postproduction force management concerns discussed in Chapter 2 and further expanded in Chapter 5.

With the exception of the technology transition task, which is considered to be a continuous effort throughout the life of a weapon system, all of the near-term engineering and management tasks are shown to extend over a five-year period. Also, it is envisioned that some of the tasks should have periodic updates about every five years as indicated in the figure. The background justification and specific recommended actions for each of the eight engineering and management tasks are included in Chapter 5.

Supporting the near-term engineering and management tasks are the near-term R&D efforts that the committee believes should be performed under the direction of the Air Force's laboratories either in-house or by supporting contractors and academic institutions. Also, the Air Force laboratories should utilize the results from complementary near-term R&D efforts that are under the direction of other government agencies (i.e., the National Aeronautics and Space Administration, the Federal Aviation Administration, and the Navy). Figure II-2 illustrates the basic elements of both the near-term and the long-term R&D programs. The near-term program includes those efforts that reasonably can be expected to provide results that will assist in the performance of the near-term engineering tasks during the next five years. The long-term R&D program includes those efforts that the committee believes will take longer than three to five years to achieve a mature technology that could be adopted by industry or the Air Force aircraft maintenance organizations, but nevertheless should be initiated now, or continued if they already have been initiated. These efforts are typically higher

FIGURE II-1 Recommended overall strategy to address Air Force aging aircraft challenges. Strategy includes near-term engineering and management tasks and near-term and long-term R&D programs.

risk than the near-term R&D efforts, but the potentially high payoff justifies their pursuit.

Included in Part II are descriptions of recommended near-term engineering and management tasks; assessments of current and planned research administered by the aging aircraft research program (detailed assessments are contained in the committee's interim report [NRC, 1997]); identification of near-term and long-term research opportunities in the areas of fatigue (low-cycle fatigue, high-cycle fatigue, and environmental effects), corrosion and stress corrosion cracking, and inspection and maintenance technology (nondestructive evaluation and maintenance and repair); and prioritization of recommended research.

Although the investigation of structural aging phenomena is an inherently interdisciplinary endeavor, for convenience the recommended research is presented separately for individual topical areas. Chapters 6 (fatigue), 7 (corrosion and stress corrosion cracking), and 8 (nondestructive evaluation and maintenance) describe R&D opportunities focused on the aluminum structures that dominate the current aging aircraft problems. Chapter 9 provides prioritization of the near-term and long-term research recommendations. Finally, Chapter 10 describes issues related to composite primary structures that are becoming more common on newer aircraft that represent the next generation of aging aircraft.

5

Engineering and Management Tasks

UPDATE OF DURABILITY AND DAMAGE TOLERANCE ASSESSMENTS

As noted in Chapter 4, a number of aircraft failures resulting from fatigue crack growth from preexisting flaws or defects, which were introduced during material processing or manufacturing, caused the Air Force to extensively revise their Aircraft Structural Integrity Program (ASIP) in the early 1970s to include damage tolerance requirements. These requirements were defined in MIL-A-83444 (DOD, 1987) and MIL-STD-1530A (DOD, 1988) and were incorporated into the designs of the new aircraft then under way (e.g., the B-1A, F-16, and A-10). However, to protect the structural safety and assess the durability of the vast majority of Air Force aircraft that were not designed to these requirements, the Air Force and the aircraft contractors performed durability and damage tolerance assessments (DADTAs) on the aircraft models that were already in the operational inventory. By the early 1980s DADTAs had been performed on the F-4C/D/E, A-7D, C-5A, C-141, F-111, B-52D, E-3A, F-5E, T-38, T-37/A-37, KC-135, SR-71, T-39, KC-10, C-130, and F-15. Also, because of changes in use conditions, the durability and damage tolerance of both the A-10 and F-16 had to be revisited after only a short time in operational service.

From the standpoint of safety, the most important outputs from these assessments were the identification of fatigue-critical areas, the determination of safety limits for these areas, and the development of safety inspection requirements. In addition, for some of the larger transport aircraft, estimates were made of the onset of widespread fatigue damage (WFD) and risk analyses were performed (e.g., on the C-5A, KC-135, and C-141). Where appropriate, lower-bound estimates were made of the major component modification or replacement times and modification options were defined.

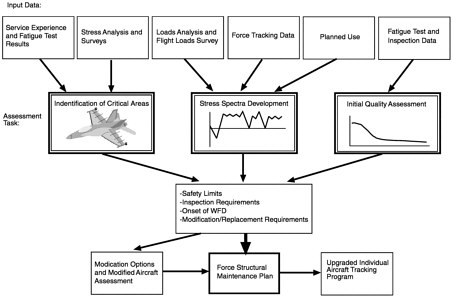

The overall approach or methodology used in conducting the DADTAs is illustrated in Figure 5-1. As can be seen in this figure, the four primary tasks in the assessments are (1) the identification of fracture-critical areas;1 (2) the development of the operational stress spectra for these areas; (3) an assessment of initial flaw distributions and/or the maximum probable initial flaw sizes; and (4) the determination of the safety limits, inspection intervals, and, for fail-safe designs, the estimated onset of WFD. The results were then used to update the individual aircraft tracking programs and the force structural maintenance plans for the aircraft, both of which are key elements of ASIP.

Air Force-Supported Aircraft

To obtain improved visibility of the actions that will be necessary to protect the structural safety of the Air Force's aging aircraft listed in Table 3-1 throughout their projected operational lives and to obtain the best estimates as to when the aircraft will likely be facing the economic impacts of major modifications or replacements, the committee strongly recommends that the DADTAs of these aircraft be updated periodically. In general, an update about every five years is appropriate.

The urgency to perform these updates varies among the different aging aircraft types, depending on several factors: (1) whether the aircraft structure is designed to be fail-safe or is largely of a single load-path design, where missing a critical area could lead to the loss of an aircraft; (2) whether a replacement aircraft has been identified and the older aircraft are being phased out of the inventory; (3) the extent and nature of fatigue cracking problems the aircraft are currently encountering; and (4) whether there has been a recent independent review of the aircraft and corrective actions are already under way. Table 5-1 summarizes these different factors for each of the Air Force's aging aircraft types shown previously in Table 3-1. Also shown in Table 5-1 is the committee's assessment of the priority that should be assigned to performing the DADTA update for each type of aircraft. Those of greatest concern, based on the highest potential for structural safety problems, were given a number 1 priority and those with the least immediate concern were given a number 3 priority. However, it is recommended that the DADTA update be performed on all of the aircraft within the next five years and updated at approximately five-year intervals.

The committee recognizes that the level of effort involved in performing these updates will vary significantly between the different types of aircraft as a function of aircraft complexity, variations in use, the numbers and types of cracking

FIGURE 5-1 Overall approach to durability and damage tolerance assessments.

TABLE 5-1 Prioritization of DADTA Update Needs for Air Force-Supported Aircraft

|

Aircraft |

Fail-Safe Design |

Additional Years in Inventory |

Replacement Aircraft Identified |

Current Fatigue Cracking |

Recent Structural Reviewa |

Review Actions Under Way |

Priority |

|

KC-135 |

yes |

25+ |

no |

limited |

yes |

yes |

3 |

|

C-5A |

yes |

10–25 |

no |

no report |

no |

no |

2 |

|

C-141B |

yes |

0–8 |

yes (C-17) |

yes |

yes |

yes |

3 |

|

A-10 |

no |

25+ |

no |

yes |

no |

no |

1 |

|

B-52H |

no |

25+ |

no |

yes |

no |

no |

3b |

|

B-1B |

no |

25+ |

no |

yes |

yes (horizontal tail) |

yes |

2 |

|

F-15 |

no |

5–25 |

yes (F-22) |

limited |

no |

no |

2 |

|

F-16 |

no |

10–25 |

yes (JSF) |

yes |

yes (fuselage bulkhead) |

yes (bulkhead) |

1 |

|

C-130E/H |

yes |

25+ |

some (C-130J) |

limited |

yes (fuselage) |

unknown |

2 |

|

E-3 (AWACS) |

yes |

17–25 |

no |

limited |

no |

no |

3 |

|

E-8 (JSTARS) |

yes |

15–20 |

no |

yes |

yes (wings) |

unknown |

2 |

|

EC-135 |

yes |

25+ |

no |

limited |

yes |

yes |

3 |

|

U-2c |

no |

25+ |

no |

unknown |

no |

no |

1 |

|

EF-111 |

no |

<5 |

no |

limited |

no |

no |

noned |

|

T-37B |

no |

0–12 |

yes (JPATS) |

limited |

no |

no |

3e |

|

T-38 |

no |

25+ |

no |

yes |

no |

no |

1 |

|

a Within the past three years. b The lower priority is because a DADTA update was performed in 1995. c This aircraft was developed for the government and is maintained by the manufacturer rather than by an air logistics center. d Based on the assumption that all aircraft will be retired in less than five years as planned. e DADTA is currently being performed by Southwest Research Institute. Update suggested within five years. |

|||||||

problems encountered, and how well the different air logistics centers (ALCs) and the airframe contractors have been performing the applicable ASIP tasks on a continuing basis during the aircraft's past operational use. As a minimum, the effort may merely require a summary of available data (e.g., critical areas, safety limits, inspection requirements, estimates of the onset of WFD, estimated future modification and replacement times, and possible future fatigue test needs) and a detailed review by the proposed Aging Aircraft Technical Steering Group discussed later in this chapter. For other aircraft it will require further identification of critical areas, stress spectra development, crack growth calculations and tests, and perhaps some tear-down inspections and/or full-scale fatigue testing.

Contractor Logistics-Supported Commercial-Derivative Aircraft

In a similar manner to the criteria for Air Force-supported aircraft (previous section), priorities are suggested for contractor logistics-supported commercial-derivative aircraft. In addition to the criteria described in the previous section for Air Force-supported aircraft, the experience with the commercial-equivalent aircraft can be taken into account.

The KC-10 and C-27 have previously had DADTAs. It is recommended that they be updated within the next five years. Because there is no immediate safety concern, a priority 3 is suggested.

The E-4, T-43, and C-9 have average ages of 23, 24, and 26 years with plans to keep them in the inventory for many more years. It is recommended that the Air Force form an independent team to review these aircraft. This team should consist of a small number of structures and materials experts chartered to assess the current condition of the aircraft, review the current use spectra, and determine if the current contractor database is sufficient to estimate the onset of WFD and the probable major component modification or replacement times or if DADTAs should be performed. The committee suggests that these reviews be performed within the next five years. Because of the much higher use, it is recommended that the C-9 be addressed first. A priority 2 is suggested for the C-9 and priority 3 for the E-4 and T-43.

The C-18, C-22, and the VC-137 aircraft have quite high utilization times. There is some concern about the possible onset of WFD for the C-18, C-22, and possibly the VC-137. Thus, the committee recommends that an independent structures review be conducted by a team of structures and materials experts in the near future. If the high-use VC-137s are replaced by the C-32, they of course could be dropped from the review. Because of the potential safety implications, a priority 1 is suggested for these reviews.

For the utility and commuter class commercial-derivative aircraft (i.e., the C-12, T-1A, C-21, C-23, C-26, C-20, E-9, UV-18, and T-3), the committee recommends that the Air Force initiate damage tolerance surveys, by a small team of structures and materials experts, similar to those conducted during this past year by the Federal Aviation Administration (FAA) on a number of other types of aircraft in this size class. These surveys should provide a preliminary assessment of the aircraft's damage tolerance, current structural health and estimated longevity, and the potential need for a detailed DADTA. The surveys should be conducted first on the older aircraft or aircraft where structural problems may have already been identified.2

UPDATE OF FORCE STRUCTURAL MAINTENANCE PLANS AND INDIVIDUAL AIRCRAFT TRACKING PROGRAMS

The fourth and fifth tasks of the Air Force's ASIP (shown in Table 2-1) deal with force management. It is here that the results of design, analysis, and full-scale test activities in the previous parts of ASIP (including subsequent DADTAs) come together to define the specific actions that must be taken to protect the safety of the individual aircraft and allow for the timely and cost-effective structural modifications. The two key force management activities in ASIP are the development of the force structural maintenance plan (FSMP) and the individual tracking program (IATP).

Force Structural Maintenance Plan

During the initial design, the intent was to minimize the amount of structural maintenance that would be needed throughout the life of an aircraft, assuming that the aircraft is used as planned (i.e., it is flown to the design use spectrum). However, full-scale fatigue testing to the design spectrum will uncover critical areas missed during design and analysis, which then necessitates additional damage tolerance analysis, in-service safety inspections, and perhaps in-service modifications. It is the definition of when, where, how, and the estimated costs of these inspections and modifications that constitute the basis for the initial FSMP.

Recognizing that the actual service use of military aircraft often differs from the original design use spectra, ASIP requires that a loads/environment spectra survey be conducted during the first two or three years of operational service to obtain actual use data that can be used to update the original design spectrum. These surveys generally consist of instrumenting 10 to 20 percent of the fleet and using a

multichannel recorder (or more recently, microprocessor systems) to record such data as vertical and lateral road factor; roll, pitch, and yaw rates; roll, pitch, and yaw accelerations; altitude; mach number; rudder and aileron position; and selected strain measurements. These data are then used to generate a new baseline operational spectrum, and new damage tolerance analyses are performed to update the safety inspection and modification requirements with the results added to the FSMP. This updated FSMP then forms the basis for planning and scheduling the structural fatigue maintenance for the overall aircraft weapon system. The damage tolerance analysis should be updated and the results used to update the FSMP any time that there are significant changes in use; when operation is extended beyond the original life goal; or new analysis, test, or service experience indicate a growth in the number of fatigue-critical areas.

Individual Aircraft Tracking Program

In addition to the force-wide baseline operational use spectra being different from the original design spectra for military aircraft, the individual aircraft use within the force may be either more or less severe than that represented by the baseline spectrum. These variations from the baseline spectrum can be quite large, particularly for the high-performance combat type aircraft. Accordingly, the Air Force has included the requirement for individual aircraft tracking as part of the ASIP.

The IATPs for the various types of aircraft within the Air Force inventory vary with regard to data acquisition and processing procedures. For the larger tanker, transport and bomber aircraft (e.g., the KC-135, B-52, and C-141), where the excursions in the flight spectra are relatively small, flight logs and pilot use forms (i.e., Air Force technical order form 16 and tactical maneuver supplemental forms) have been found to be satisfactory to track the aircraft use. For the fighter and attack aircraft the use of counting accelerometers and VGH (velocity; ground range and height) recorders were commonplace in the past, but are limited because they are not able to accommodate critical areas of the structure that are sensitive to asymmetrical loading. The use of multichannel recorders (e.g., the MXU-553), which record many more flight parameters, overcomes this limitation. More recently, the older tape systems are being replaced (as funding will allow) by microprocessor systems, further expanding data capture. Computerized methods have been developed and are used to reduce the measured flight data and to adjust the crack-growth-based damage rates and inspection intervals for each of the critical areas in the airframe for individual aircraft use. As the aircraft ages, the number of critical areas and inspections increase. When this happens, the IATPs must be updated to accommodate these changes.

Although there has been some discussion about upgrading the Air Force's IATP to track potential corrosion damage and/or corrosive environments as well as fatigue damage, the committee believes that the application of sensor devices and data analysis and processing equipment in existing aircraft is currently impractical because of the large number of aircraft involved, the large sizes of affected areas in the aircraft most prone to corrosion damage (i.e., the large transport, tanker, and bomber aircraft), and the cost and intrusiveness of system installation. However, developments in multifunctional chemical and physical sensors (NRC, 1995), microelectromechanical systems, and smart diagnostics do provide some hope that long-term research in on-board health monitoring can be productive.

Following the completion of the updates of the DADTAs, which were recommended above, the committee recommends that

-

the inspection and modification requirements in the FSMPs be updated to reflect any changes in the baseline operational spectra and any additional critical areas that were identified, which in turn will increase the inspection requirements and possibly necessitate new modifications

-

the IATP for each aircraft weapon system be updated to reflect additional critical areas that need to be tracked recording equipment, or analysis procedures that may be deemed necessary to protect the structural safety of the aircraft. In particular the Air Force should push for the force-wide use of the microprocessor-based recorders because of their improved reliability and the expanded data capture.

STRESS CORROSION CRACKING ASSESSMENTS

Although the environmental protection measures and material substitutions to eliminate corrosion-susceptible materials that take place as part of an aircraft's corrosion prevention and control program (CPCP) also apply to the prevention of stress corrosion cracking (SCC), there are some unique aspects about SCC that make this structural deterioration mechanism much more dangerous than other forms of corrosion. Thus, the committee believes that SCC deserves special attention. Stress corrosion cracks are characteristically intergranular and can occur with little or no evidence of corrosion products and as a result are often difficult to detect visually. Although they generally have not caused flight-safety problems, because of their orientation with respect to the applied flight stresses (see Chapter 4), this cannot always be considered to be a certainty. If large in-plane stress corrosion cracks or delaminations go undetected they could cause a loss in shear strength and trigger failure modes other than the tensile mode normally associated with crack propagation. Also, in thick sections (e.g., complex machined fittings) where there may be irregular grain flows and three-dimensionally applied

stresses, it is often difficult to predict if a stress corrosion crack will turn normal to the largest component of stress and result in a tensile fracture.

For fail-safe structural designs, a part or component failure caused by a stress corrosion crack is much less of a concern than in safe crack growth designs because of the second line of defense provided by the surrounding intact structure. In fact, over the years there have been many part failures caused by SCC in both commercial and military aircraft. When this occurs, the parts are generally replaced, ideally with new parts made from more-stress-corrosion-resistant materials. For safe crack growth designs, which are generally associated with high-performance combat aircraft, it is important that the stress corrosion cracks be prevented from occurring or that they be detected before failure, since failure of the parts or components may lead to the loss of the aircraft. As an aircraft ages and protective finishes and coatings break down, concern over part failure caused by SCC becomes more acute. As a result the committee believes that there is a need for the Air Force to periodically assess the susceptibility of their aging aircraft to SCC and take actions to diminish the occurrence of SCC and prevent future part failures. Particular attention should be given to structures that are not designed to be fail-safe.

The committee recommends that the Air Force include an assessment of the vulnerability of each of their aging aircraft to structural failure caused by SCC or SCC combined with fatigue as part of the DADTA updates proposed in this chapter. Specifically, the committee recommends that

-

stress-corrosion-critical areas be identified based on past service experience, the susceptibility of the materials to SCC, grain orientations, and probable levels of both applied and residual stresses

-

the engineers performing the DADTA update make an evaluation of potential failure modes and consequences of failure for each stress-corrosion-critical area

-

protection, inspection, modification, and replacement alternatives be developed as necessary (see recommended short-term research in Chapter 7)

IMPROVED CORROSION CONTROL PROGRAMS

The 1988 accident of the Aloha Airlines 737 aircraft (NTSB, 1988) resulted in much attention being paid to the aging aircraft issue both by the commercial and the military aviation sectors. Although this accident was primarily the result of WFD,3 it focused attention on all of the factors that can contribute to structural deterioration, including corrosion. Both the commercial and the military sectors have since taken actions to reduce corrosion and the very high associated maintenance costs.

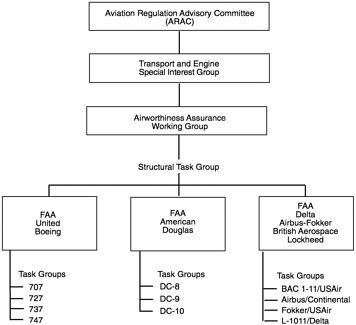

In the commercial sector, the Air Transport Association and the Aerospace Industries Association in cooperation with the FAA, established the Airworthiness Assurance Task Force to evaluate potential deficiencies in current commercial practices and to provide recommendations and guidance to the FAA and the airline industry on maintaining the structural integrity of 11 different aging aircraft models, including the Boeing 707, 727, 737, and 747; the Airbus A-300; the BAC 1-11; the Fokker F-28; the Lockheed L-1011; and the Douglas DC-8, DC-9, and DC-10. In 1992 the Airworthiness Assurance Task Force was incorporated into the FAA's Aviation Regulation Advisory Committee as the Airworthiness Assurance Working Group (AAWG), shown schematically in Figure 5-2. The AAWG proposed a mandatory CPCP to be tailored to each aircraft and operator and implemented by the FAA by airworthiness directives. The need for this program stemmed from fleet surveys, maintenance cost reviews, and comments from operators, all of which pointed to the fact that corrosion resulted in the single largest investment in time and resources in aircraft maintenance programs, and that, in some cases, the aircraft were being maintained in conditions below the manufacturer's expectations. On the other hand, operators that already had comprehensive CPCPs in place experienced much lower amounts of corrosion than those that did not. In fact, if the programs were implemented early in the aircraft's life, the aircraft remained essentially corrosion free. Also, it was noted that operators who utilized liberal applications of corrosion-preventive compounds showed significantly reduced corrosion damage. The essential elements of the AAWG overall CPCP are

-

inspection of all primary structures

-

initial and repeat inspection intervals based on calendar time rather than flight hours or number of flights

-

performance of basic maintenance tasks, including exposure of the corroded area, cleaning, inspection, rework as required, reapplication corrosion-preventive treatments

-

adjustments in the aircraft's overall maintenance program to maintain a corrosion severity of Level I or better (as described below)

The CPCP for each specific type of aircraft was developed by that aircraft's structures task group, which was made up of representatives from the manufacturer, the operators and maintainers, and the FAA.

In the development of CPCPs, the commercial aircraft industry has established severity classification criteria to guide maintenance programs. Corrosion severity is considered to fall into one of the following three classes:

FIGURE 5-2 Organization of commercial aircraft industry aging aircraft working groups.

Source: Hidano and Goranson (1995).

Level I corrosion. (1) Corrosion damage occurring between successive inspections that is local and can be re-worked/blended-out within allowable limits as defined by the manufacturer; or (2) corrosion damage occurring between successive inspections that is widespread and can be reworked/blended-out well below allowable limits as defined by the manufacturer; or (3) corrosion damage that exceeds allowable limits and can be attributed to an event not typical of the operator's use of other airplanes in the same fleet (e.g., mercury spill); or (4) operator experience over several years has demonstrated only light corrosion between successive inspections but latest inspection and cumulative blend-out now exceed allowable limit.

Level II corrosion. (1) Corrosion occurring between successive inspections that requires a single re-work/blend-out which exceeds allowable limits, requiring a repair/reinforcement or complete or partial replacement of a principal structural element, as defined by the original equipment manufacturer's structural repair manual, or other structure listed in the baseline program; or (2) corrosion occurring between successive inspections that is widespread and requires a single blend-out approaching allowable re-work limits.

Level III corrosion. Corrosion found during the first or subsequent inspections, which is determined (normally by the operator) to be an urgent airworthiness concern requiring expeditious action. Note: When level III corrosion is found, consideration should be given to action required on other airplanes in the operator's fleet. Details of the corrosion findings and planned action (s) should be expeditiously reported to the appropriate regulatory authority (Boeing, 1994:1.1-1–1.1-2).

A CPCP is considered effective if corrosion of identified critical structure is limited to Level I or better.

The intent of these CPCPs is to ensure that corrosion is never allowed to progress to the point that it could become a safety issue (hence the emphasis on primary structure). The secondary benefit of the programs is to reduce the operators long-term corrosion maintenance costs.

In the military sector, the Air Force established a Corrosion Program Office at the Warner-Robins Air Logistics Center to

oversee and coordinate the Air Force's corrosion prevention and control activities. However, the development, implementation, and execution of specific weapon system corrosion control efforts is the responsibility of the specific system program director. Guidance is provided by Technical Order 1-1-691, which is a tri-service (Navy/Army/Air Force) coordinated manual entitled ''Aircraft Weapons Systems Cleaning and Corrosion Control," published January 1992. This manual provides detailed information on such items as preventive maintenance procedures, methods, and materials; inspection techniques; corrosion and paint removal methods and the application of surface treatments; and procedures for applying sealing compounds. Appendix E to this manual is for Air Force use only and contains additional information on aircraft cleaning procedures and intervals as a function of aircraft basing, shot peening and roto peening procedures, and chemical corrosion removal procedures. It is intended that this tri-service manual be used in support of Air Force aircraft manuals and, in the event of conflict, the aircraft manual would take precedence. The Air Force Corrosion Control Office along with the Naval Air Systems Command and the Army Aviation Systems Command are responsible for the maintenance of the manual.

The tri-service manual has a great deal of detailed information on corrosion prevention and control, and a significant effort is being made by the Corrosion Control Office to reduce corrosion in the Air Force's aging aircraft. However, the committee believes that the Air Force does not have the type of comprehensive CPCP for each of its aging aircraft weapon systems on the level of those mandated for commercial airplanes. The committee does not believe that corrosion can or will be completely eliminated in the Air Force's aging aircraft, but with comprehensive programs similar to those established for commercial aircraft, corrosion can be reduced significantly.

The committee recommends that the Air Force undertake the following actions to improve corrosion prevention and control in the aging forces:

-

The Air Force's system program directors, in concert with the appropriate major commands and the Corrosion Control Office, should perform an internal audit of each of the Air Force's commercial-derivative aging aircraft (i.e., the E-3, E-8, E-4, VC-25, T-43, C-137, C-18, C-22, KC-10, and C-9) to ensure that the corrosion control programs are in full compliance with the CPCPs mandated for commercial counterparts. In addition to the primary structures covered by the commercial programs, the Air Force should ensure that adequate corrosion control measures are being applied to corrosion-susceptible secondary structures.

-

The Air Force's system program directors, in concert with the appropriate major command and the Corrosion Control Office, should review the detailed corrosion control programs of each of the Air Force's aging aircraft listed in Table 3-1 that is not scheduled to be retired in the near future (i.e., the KC-135, C-5, A-10, B-52H, B-IB, F-15, F-16, C-130E/H, U-2, and T-38) and upgrade them as necessary to a level equivalent to or better than the CPCPs that are mandated for commercial aircraft. Again, corrosion-susceptible secondary structures as well as the primary structures should be included in the programs.

-

The Air Force's ALCs, with the Corrosion Control Office, should evaluate the applicability and cost effectiveness of dehumidification, as described in Chapter 4, to reduce the likelihood of corrosion.

ECONOMIC SERVICE LIFE ESTIMATION

As discussed in Chapter 4, major economic impacts can be expected to occur with the onset of WFD in fail-safe-designed aircraft structures and with the rapid growth in the number of fatigue-critical areas in safe-crack-growth-designed aircraft structures. When either of these occur, the options are to modify the structure, replace major portions or components of the airframe, or retire the aircraft. If the economic impact is sufficient to justify retirement, this would constitute the economic service life of the aircraft. However, there are a number of other factors that also contribute to the economic service life, and this should be viewed from the broader perspective of the total cost to operate an aircraft system. There are several examples in which it has been cost effective to modify or replace major components of an airframe, even when they have experienced WFD. Some of these aircraft have continued in service for many more years (e.g., the KC-135, C-5A, and C-141). On the other hand, it appears quite possible that the economic burden of operating a given type of aircraft could become excessive before the onset of WFD or the rapid rise in fatigue-critical areas. For example, it was pointed out in Chapter 4 that corrosion (including SCC) is currently the most costly maintenance problem for the Air Force's aging aircraft. If not substantially diminished in the future through improved prevention and mitigation measures, corrosion damage, either by itself or in combination with fatigue cracking, could cause the Air Force to undertake major modifications, major component replacements, or perhaps aircraft retirement.

Clearly, as was pointed out in Chapter 2, there is a need for an overall economic service life estimation model that integrates the estimates of structural deterioration caused by fatigue, corrosion, and SCC with all other operating cost elements. The current lack of such a tool inhibits Air Force planners from establishing a realistic time table to phase out a current system and to begin planning for replacement aircraft. Some examples of cost elements that should be tracked and projected for inclusion in such a model are related to

-

field-level personnel, facilities, materials

-

depot-level personnel, facilities, materials

-

acquisition and repair of repairable parts

-

acquisition and repair of consumable parts

-

support equipment

-

field-level sortie generation: fuel, maintenance production

-

depot maintenance program: programmed depot maintenance, analytical condition inspection, and speedline production

-

structural and subsystem modifications: repair and maintenance technology insertion, safety, mission capability

-

field-level maintenance: isochronal inspections

-

engine depot overhaul program

-

sustaining engineering

-

environmental impacts

In addition to these cost elements, there are several operational metrics that can be used by the aircraft system program managers to develop an overall assessment of a system's operational effectiveness, such as

-

mission capability rate

-

sortie generation/abort rate

-

"not mission capable" rates

-

maintenance man hours per flight hour

-

depot flow time and quantity of aircraft in depot status

-

parts cannibalization rate

-

accident rate

The problem of service life estimation is complicated not only by the technical difficulties involved in predicting the onset of WFD and the growth in fatigue-critical areas and the numerous factors affecting structural deterioration caused by corrosion, but also by the interrelationships and the relative importance of the many cost and operational metrics listed above. Ideally, the service life estimation model should utilize the best possible technical estimates of the major structural modification and/or component replacement times, account for the cost and operational metrics listed above, and balance and weigh their relative importance.

The committee recommends that the Air Force make a concerted effort to develop a credible service life estimation model or methodology that would be accepted by the Air Force senior management and the Department of Defense decision makers (e.g., the Defense Acquisition Board) as the authoritative guide for supporting replacement decisions and budget inputs. Such an analysis could be considered to be analogous to the cost and operational effectiveness analysis (COEA) that is undertaken early in a weapon system acquisition cycle to support milestone decisions, but in this case would be done later in the system life cycle to support a modification/update or replacement decision. When the model is completed, it is recommended that it be used to update the service life estimates for the Air Force's aging aircraft listed in Table 5-1.

CONTINUED ENFORCEMENT OF THE AIRCRAFT STRUCTURAL INTEGRITY PROGRAM

The Air Force has been very successful in controlling structural fatigue failures for more than two decades. One of the primary factors contributing to this success has been the rigid enforcement of the ASIP. Internal compliance by Air Force management was directed by Air Force Regulation AFR 80-13, and contractor compliance was achieved by making MIL-STD-1530 and supporting specifications part of the weapon system contract. Placing ASIP on contract ensured that the damage-tolerance-based inspection and maintenance requirements would be developed, and the AFR ensured that the Air Force would follow through with their implementation, including the incorporation of adjustments to the inspection and modification times brought about by changes in aircraft use. ASIP has also provided industry with guidance on all of the design, analysis, and test requirements necessary to achieve the aircraft's design service life goal and has provided Air Force engineers the basis for making sound technical recommendations to system program directors concerning the aircraft structure. It is for these reasons that the committee is very concerned that ASIP, per MIL-STD-1530 and its supporting specifications, will no longer be placed on aircraft acquisition and modification contracts due to former-Secretary of Defense Perry's initiative to reduce the use of government specifications in acquisition programs.

The guidance provided under the initiative directs that the intent of rescinded specifications be incorporated, if appropriate, into contracts through performance requirements, thereby giving contractors wider latitude and greater discretion in how to meet them. The Air Force is presently converting AFR 80-13 to an Air Force Instruction and the ASIP standards and specifications to a "guidance document" for use by government and industry for executing the program. Although these are important first steps, the committee does not believe that they go far enough. The committee believes that the "guidance document" approach will still be vulnerable to inconsistent interpretation and application between the various program offices within the Air Force. This approach will also leave industry uncertain as to the acceptability of their ASIP-related engineering practices to the various government weapon system program offices and result in ASIP provisions in a program that is more vulnerable to programmatic cost reductions. The end result can be incomplete or omitted ASIP tasks that would seriously degrade the effectiveness of the FSMP, which is designed to protect the structural safety of the aircraft.

Short of reinstating AFR 80-13, MIL-STD-1530, and supporting specifications, the committee recommends that the

Air Force take the lead in pursuing the development of a National Aerospace Standard for ASIP. Such a standard would result from the coordinated efforts of the military services and industry as to what constitutes an acceptable and affordable ASIP for new aircraft acquisitions and modifications to existing systems. The standard would be issued by industry and referenced by the government as a measure of acceptable compliance with contractual ASIP performance requirements. This approach would effectively communicate the government's requirements to industry and reduce the likelihood of inconsistent application and execution of ASIP tasks. It is anticipated that the end result would be a continued high level of operational safety and improved force structure management.

TECHNICAL OVERSIGHT AND RETENTION OF TECHNICAL CAPABILITIES

Much of the success of the Air Force ASIP during the past two decades can also be attributed to the competency of the ASIP managers and the engineering support groups within the maintenance organizations and the technical oversight provided by an Air Force Matériel Command, Aeronautical Systems Center (AFMC/ASC) standing committee that has guided the many DADTAs that have been performed. In addition, various Air Force Scientific Advisory Board (SAB) and Division Advisory Group ad hoc committees have contributed to this success.

The aging aircraft engineering disciplines that have been developed and typically reside within the ALC's technology and industrial support engineering (TIE) organizations include specialists in nondestructive inspection, stress analysis, design of structural repairs, fracture mechanics analysis, failure analysis, and corrosion control. However, these groups also draw on the expertise of AFMC/ASC engineering and the Wright Laboratories for assistance on specific problems. Where major modifications or a detailed knowledge of the aircraft design are involved, the ALC normally contracts with the original equipment manufacturer for the required assistance, which has been the case for most of the DADTAs that have been performed over the years.

The committee believes that, in recent years, the Air Force's capability to support ASIP and perform structural assessments has deteriorated somewhat as a result of budget and manpower reductions and grade-level limitations within the ALCs. Unfortunately the reduction in capability comes at a time when the need for capabilities has been increasing because of the aging of the force. ASIP managers are burdened with day-to-day maintenance problems and program cost and schedule pressures that allow them little time to focus on the broader issues such as implementing improved corrosion controls or obtaining improved estimates of when to expect the onset of WFD. Also, there seems to be considerable variability in the engineering capabilities among the different ALCs, perhaps because of insufficient policy direction and oversight from AFMC headquarters (HQ AFMC). Finally, there is no single technical focal point to coordinate ASIP, the supporting DADTAs, and the aging aircraft structures issues. A standing committee that at one time monitored DADTAs has been discontinued.

Although the committee does not believe that these apparent reductions in technical capabilities and oversight are currently jeopardizing structural safety, the prognosis for the future of the aging force is not optimistic unless the following near-term actions are taken.

First, the committee recommends that HQ AFMC form an aging aircraft engineering resources group consisting of engineering management representatives from AFMC headquarters, Aeronautical Systems Center's engineering and technical management organization (ASC/EN), Wright Laboratories, and each of the ALC TIE organizations. This group should be chartered to examine the quantity and quality of the engineering skills in each of the aging aircraft disciplines that are available at the ALCs, ASC/EN, and Air Force Laboratories and to compare these skills with the projected requirements over the next five years. Where imbalances exist between skill requirements and skill availability, the group should examine alternate methods of fixing the imbalances (e.g., redistribution of available resources, hiring contract engineers, more contracted assistance from the original equipment manufacturers, proposed changes in grade structure, or proposed additional military and civilian positions) and prepare a recommended course of action for Air Force senior management.

Second, the committee recommends that an aging aircraft technical steering group (AATSG) be formed that reports to the commander of AFMC and whose chair is a member of the Air Force SAB. This group should meet no less than two times a year, but can meet more often if so desired by the commander of AFMC. The method of operation would be similar to the existing division advisory groups, which implies that the chair report to the SAB steering committee on a semiannual basis. The purpose of the steering group would be to monitor and provide guidance to the various recommended near-term engineering and near-and long-term research activities discussed in this report and to report on progress and, as necessary, potential problems. They would also provide advice and surveillance over near-and long-term research programs to ensure seamless transition of technologies (6.1 through 6.7) into aging aircraft. The members of the AATSG would be selected by the Air Force, in consultation with the SAB, from the government, industry, and academia and represent the various aging aircraft technical disciplines.

Third, the committee recommends that five technical working groups be formed (i.e., one for each of the five basic elements of the proposed near-term and long-term R&D programs as shown in Figure II-2). These working groups

would consist of technical specialists from the Air Force Office of Scientific Research, Wright Laboratories, ASC/EN, and the ALC system management and TIE organizations and would form the technical link from basic research (6.1) through implementation (6.7). These groups would be responsible for understanding and interpreting user needs and ensuring that the R&D efforts in each of the five basic elements are focused on meeting these needs in a timely and economical manner.

Finally, the committee recommends that HQ AFMC appoint a single knowledgeable and experienced technical leader responsible for the oversight of the aging aircraft engineering and the near-term and long-term R&D activities recommended in this report. The selected individual would serve as the primary point of contact with the AATSG and the internal technical working groups and would have the authority to provide the overall day-to-day technical direction to the structural aging aircraft program. The selected individual should report to the appropriate management level within AFMC so as to be given the authority and stature necessary to execute the assigned tasks.

TECHNOLOGY TRANSITION INTO AGING AIRCRAFT

One of the most effective ways for increasing the reliability and speed of nondestructive evaluation and reducing the costs of repairing aircraft with structural cracking and corrosion problems is through the transition of improved technologies into application. In the past, this has been difficult for the system program directors because the links with technology development activities (e.g., labs, industry, other services) were not well established. As a result, system program directors often acquired technologies to solve their specific weapon system problems using internal sustaining-engineering funds. Often, these initiatives required a modest amount of development and in many cases had generic characteristics that would permit application to other systems. Very seldom, however, were these technologies made available to, or embraced by, other system program directors. In addition, existing technologies available in industry or in other services often went undiscovered. Considerable improvement has occurred in recent years as a result as a result of the AFMC technology master process described in Chapter 2, which created a linkage between the technology users (system program directors, ALCs, major commands) and the technology producers (laboratories, industry, other military services). There is clear evidence of substantial improvement in the number of laboratory technology programs that focus on the problem of aging aircraft. Although this progress is evident in programs involving 6.1, 6.2, and 6.3 funding, there has not been a commensurate improvement in the programs that implement technology into aging aircraft (e.g., 6.4, 6.5, 6.6, 6.7). System program directors still rely primarily on producibility, reliability, availability, maintainability, sustaining engineering, and manufacturing technology funding to bring emerging technologies to bear on aging aircraft problems. These funding categories are typically funded well below requirements, some are limited to one year for expenditure, and some have limited application and low funding thresholds per individual project. The solution to this problem is to provide seamless funding of aging aircraft technology transition programs from 6.1 through 6.7.

The committee believes that the concept of a seamless funding—budgeting link from 6.1 through 6.7 for aging aircraft initiatives is very attractive. It is based on the implicit assumption that the project is fully prepared for implementation at the next level. For this to be the case, the principal investigators must fully understand the requirements at the next level, and at the same time they must exercise enough discipline in conducting the study to ensure that the project is able to make the transition at the earliest possible time. This will foster teamwork between the technology developer and the technology users. A considerable effort will be required to make the transitions as straightforward as possible. The initial step, developing a clear definition of the problem and the results required, is of key importance. The important point is for the technology-developer and the technology-user communities to approach aging aircraft technology problems as an integrated team.

The committee recommends that 6.1, 6.2, and 6.3 aging aircraft technology programs that are generic and have potential for wide application not be approved through the technology master process unless it is linked to an appropriate 6.4 through 6.7 program to provide transition to force application. It is critical to the success of the aging aircraft program that a seamless funding—budgeting link be created from development through application. Furthermore, the five technical working groups recommended by the committee should be responsible for ensuring that there is a seamless link in funding for the program from 6.1 through 6.7.

6

Research Recommendations: Fatigue

LOW-CYCLE FATIGUE

As described in Chapter 4, there are two primary technical issues related to low-cycle fatigue:

-

the rapid increase in the number of fatigue-critical areas in safe-crack-growth-designed structures and the potential for missing new areas as they develop

-

the onset of widespread fatigue damage in fail-safe-designed structures

Currently, the primary method for identifying fatigue-critical areas is through a detailed examination of the locations where cracking occurs during full-scale fatigue testing of the aircraft. These findings are supplemented by data from stress analyses, strain surveys, and experience with similar design details, materials, and material forms that have been prone to cracking on other aircraft. Occasionally, fatigue-critical areas that were not previously identified are found during tear-down inspection of actual force aircraft (e.g., during maintenance or inspections of high-time aircraft). However, for safe-crack-growth-designed aircraft, reliance on in-service inspections to identify new critical areas can be extremely dangerous. To be assured that accidents will be avoided, cracks must be found before reaching critical size. For some aircraft structures, these critical sizes can be very small.

Despite the committee's efforts to develop a research initiative that would improve on the current approach for identifying new fatigue-critical areas, no viable near-term or long-term research activities were identified. Likewise, the current Air Force research program has no ongoing or planned research in this area. The committee can only emphasize the extreme importance of using all available full-scale test and service experience data and state-of-the-art stress analysis methods to perform the durability and damage tolerance assessments (DADTAs) recommended in Chapter 5 so that all fatigue-critical areas can be identified. This is particularly important for the high-priority DADTAs (i.e., for the F-16, A-10, T-38, and U-2), all of which concern aircraft that are of non-fail-safe designs. Currently available finite element and solid-modeling stress analysis techniques should be considered for those cases in which the structures have not been analyzed using these modern methods. Fatigue test articles that have not been evaluated in detailed tear-down inspections should be evaluated (if test articles are available). If necessary, additional fatigue testing or detailed tear down of high-time aircraft should be performed. This is the most critical task in the DADTA for non-fail-safe structures.

Air Force research projects in low-cycle fatigue focus on widespread fatigue damage (WFD), specifically on the development and validation of analysis tools to predict the onset of WFD and on corrosion-fatigue interactions. Program plans for WFD include

-

basic research tasks that include efforts to investigate (1) analysis methods for multiple-site damage, (2) formation of cracks from manufacturing and service-induced defects, and (3) three-dimensional nonlinear fracture predictions; also included is a new initiative that includes fundamental research to characterize and analyze WFD

-

applied research to (1) develop analysis methods to model the effects of WFD, (2) determine initial quality for use in risk analysis, (3) evaluate the effect of WFD on crack growth, (4) upgrade the Damage Tolerance Handbook, (5) develop in-service and experimental WFD data, and (6) develop process sciences methodology for metallic structures

-

exploratory research to perform a structures demonstration for WFD

The committee believes that the Air Force program in WFD, as originally presented, indicated an incomplete understanding, among at least some of the researchers, as to the nature and failure scenarios associated with WFD (NRC, 1997). The concern arose from discussions of plans to evaluate the remaining life of structures with WFD. As discussed in Chapter 4, the onset of WFD is the safety limit, beyond which the aircraft should not fly without modification or replacement of the structure. Consequently, remaining life is not an issue once the structure is in the state of WFD. Recent revisions to the Air Force R&D program address the committee's concern. The committee has identified several particular strengths in the planned research in WFD:

-

the program emphasis on configurations applicable to military aircraft (e.g., thick wing structure and integrally stiffened structures)

-

the stated intention to experimentally verify fail-safe residual strength prediction methodology with large components or panels

-

the effort to determine the initial quality of typical structure for use in structural life and risk analyses, which is an essential element in the prediction of when small widespread fatigue cracks will exist in service aircraft

-

basic research focused on the formation, growth, and distribution of small fatigue cracks from small manufacturing or service-induced defects and corrosion damage

-

the development of advanced probabilistic methods for force risk assessment

-

the work in the area of processing science that could lead to higher-quality materials and tighter process controls that can increase resistance to fatigue crack initiation

-

the effort to update the Air Force's Damage Tolerance Handbook

-

coordination with Federal Aviation Administration (FAA) and National Aeronautics and Space Administration (NASA) research on WFD to ensure that their efforts are complementary

The committee believes that the current engineering approach to WFD should be supplemented with advanced analysis methods and more extensive use of the results of detailed tear-down examinations of full-scale fatigue test articles and retired aircraft.

Near-Term Research and Development

Recommendation 1. Extend and validate recent advances in nonlinear finite element modeling and fracture mechanics to the unique configurations of fail-safe-designed military aircraft for the prediction of residual strength.

Although some emphasis has been placed on the prediction of the fail-safe residual strength of military aircraft structures (i.e., thick wing structure), the committee suggests a critical review of current methods used to determine the fail-safe residual strength levels for the many different detailed structural configurations that exist in military aircraft that could be prone to WFD. Typical configurations of interest include large pressure doors and door hinges, ramps and ramp attachments, canopy attachments, wing-to-fuselage and fin-to-fusalage attachments, multiple adjacent fuselage frames, circumferential fuselage joints and chordwise wing tension joints, chordwise wing splice joints, and engine attachment structures. Where improved methods appear to be necessary, they should then be developed and experimentally verified.

Most engineering fracture mechanics methods assume linear elastic behavior. A number of investigations have established that the use of elastic-plastic fracture mechanics is essential to determining the residual strength of an airframe structure with WFD (Harris et al., 1995; Atluri, 1997). Improved methods are required to treat the effects of plasticity on the fatigue crack growth and fracture behavior typically exhibited by the ductile alloys used in aircraft construction. The committee recommends that the Air Force evaluate ductile fracture criteria for three-dimensional crack configurations and integrate the criteria into analysis methods to predict residual strength. The research should consider the effects of alloy composition, material product forms, structural configurations (e.g., thick, heavily loaded components), and exposure to aircraft environmental conditions.

Recommendation 2. Improve current methods to determine the onset of WFD by (a) comparison of full-scale test articles with tear-down inspection of service aircraft components and metallurgical examinations of full-scale fatigue test articles and (b) critical examination of the procedure for extrapolating the sample of cracks documented during a tear-down examination to generate a distribution function that may be used in a risk assessment.

Although the committee endorses the longer-term R&D efforts to develop analytical methods to predict the initiation and growth of cracks to the sizes at onset of WFD, the primary method to determine the onset of WFD in the near term will be estimates based on empirical data (e.g., full-scale fatigue test results or, if available, tear-down inspection results from operational aircraft), combined with fail-safe residual strength analyses. Because tear-down inspection of actual fleet aircraft entails the destruction of one or more aircraft (or major portions of aircraft) and comes too late to provide data for force planning, the Air Force has been primarily dependent on the results of full-scale fatigue testing to assess WFD. Unfortunately, full-scale fatigue test results are not necessarily representative of the actual operational load spectrum and generally neglect the potential influence that environmental exposure may have on the crack initiation process.

There is no defined effort in the Air Force research program to improve the current method of estimating the onset of WFD in the aging aircraft program. The committee recommends research to assess the validity of (and if necessary, suggest improvements to) the approach to estimation of onset of WFD.

Long-Term Research and Development

Recommendation 3. Conduct experimental research to establish the relationship between the physical basis for crack formation/nucleation and crack distribution functions.

The development of analytical prediction methods for crack initiation, based on rigorous descriptions of initiation processes, would be extremely complex to develop because of several mechanisms and the wide variations in conditions that may be involved at any given structural location. The committee does not believe that rigorous analytical models can be developed that accurately consider all of the various mechanisms and conditions involved in fatigue crack initiation.

Nevertheless, small crack theory uses the equivalent initial flaw (EIF) approach with initial flaw sizes determined from microstructural features characterized by microscopy rather than back calculating from fatigue data (Ritchie and Lankford, 1986; AGARD, 1990). Although predictions of total fatigue life of laboratory test specimens using fracture mechanics analysis methods and initial crack sizes determined from microstructural features have been shown to be accurate, microstructural defects are only one of several possible root causes of fatigue crack initiation. Therefore, the committee believes that the most promising analytical approach to predict the behavior of other initiating mechanisms is to use an EIF size determined from experimental data. A comprehensive EIF-based fracture mechanics approach, including simulative experimental methods for the prediction of initiation and growth of small cracks, is vital to the development of analytical prediction capability for the onset of WFD. The committee suggests the development of an EIF database, correlated with full-scale structural test articles, for cracks that initiate because of fretting, very small defects, scratches, dings, and corrosion damage.

Recommendation 4. Develop and experimentally verify analytical methodology to predict crack distribution functions.

The quantification of the principal parameters—aircraft use spectra, initial quality, stress level, and structural geometry—needed to provide analytical estimates of the time-and use-dependent crack populations and the associated fatigue life and critical crack sizes requires an extension of the existing analytical methods and approaches. The committee suggests that the most promising approach is to combine existing deterministic tools for the prediction of stress levels, residual strength, and crack growth with existing risk analysis tools to account for statistical variability of the situations that might lead to failure of the aircraft. However, to deal effectively with the problems associated with variations of initial quality, local construction, stress level, and use spectra, it is necessary to have an integrated hierarchical approach that uses structural analysis and risk management methods.

The range of cyclic loading conditions that contribute to the development of fatigue cracking may result in crack populations that are unique to each aircraft type and structural location. Therefore, the analytic representation of crack population as a function of service time is extremely difficult because the crack population depends on events and conditions that can only be quantified either in a worst case deterministic sense or bounded in a statistical sense. Because of these inherent uncertainties in developing a unique crack population for each aircraft, probabilistic risk assessment methods are necessary adjuncts to deterministic methods. As described in Chapter 4, current risk assessment analyses use data obtained from aircraft component tear-down examinations to account for the uncertainties in estimates of fatigue crack characteristics and distribution.

Recommendation 5. Validate analytical methods using results of laboratory and full-scale fatigue tests, tear-down inspections of structural components removed from retired aircraft, and experimental tests of built-up structure.

The results of numerous full-scale fatigue tests and tear-down examinations of structural components removed from retired aircraft are already available as a benchmark for validating the advanced analysis methodology. The data obtained from the near-term research Recommendation 2 should be used to the extent possible. Additional carefully defined critical tests with well-characterized boundary conditions and loading histories will also be required to fully verify all aspects of the analysis methodology. The methodology should be verified by comparison with test data obtained from several different aircraft structural components and loading conditions that are susceptible to WFD.

HIGH-CYCLE FATIGUE

The Air Force aging aircraft program related to high-cycle fatigue is included in the research plan for structural dynamics. The dynamics program includes research tasks in predictive methods and suppression techniques. Topics include

-

acoustics and sonic fatigue

-

structural dynamics

-

computational methods

-

health monitoring

-

structural repair and component replacement

The most important elements of the current dynamics research program are upgrade of the design guide for aft body and airframe aeroacoustics and acoustic fatigue, design and test of new structural repairs and components, buffet load alleviation, unsteady aerodynamics and aeroelastic codes, and health monitoring (where it is related to dynamics load definition and temperature and chemical environment definition).

The committee believes that the program would be improved if emphasis were placed on dynamic loading and high-cycle fatigue degradation specifically associated with aging of in-service aircraft. Much of the current Air Force

program, as described to the committee, contains technology development programs that are generally related to the design and analysis of emerging aircraft systems and not to the life extension of existing systems. These programs probably are needed, especially those that are basic research and technology development, but funding should be separated from the aging aircraft budget.

The committee recommends that near-term and long-term research focus on dynamic loading cases that are related specifically to aging aircraft. Suggested near-term research opportunities include efforts to improve methods to determine dynamic response. Recommended long-term research extends the near-term program to include characterization of threshold crack growth behavior, analytical prediction of dynamic response, expert systems for the design and analysis of repairs, and dynamic load monitoring and alleviation.

Near-Term Research and Development

Recommendation 6. Improve and verify methods to predict dynamic strains and deflection responses of unrepaired and repaired structures and improve laboratory and flight test methods for measuring structural response.

The response of structure under critical load conditions must be determined before a repair of a dynamically loaded structure can be performed successfully. This is crucial because the repair must be sufficiently durable to provide structural integrity under these loading conditions, and because the dynamic response of the structure is often affected by the repair. This change in response is key to developing a long-lasting repair that does not induce further damage in surrounding structures.

It is often difficult to determine the dynamic response for structures subjected simultaneously to high-and low-cycle fatigue loads. In many cases, both loading conditions must be included to accurately simulate the failure and to develop a long-lasting repair. Improved ground testing or flight testing methods to determine the structural response under dynamic load conditions will be important in verifying the driving forces and structural responses responsible for early cracking or cracking in aging structures.

Long-Term Research and Development

Recommendation 7. Characterize threshold crack growth behavior for materials and structures used in Air Force aircraft. Examples of specific tasks include

-

determination of the relationship between conventional fatigue endurance limits and crack growth threshold stress intensity factors

-

evaluation of the sensitivity of crack growth thresholds to aggressive environments, such as humidity, saltwater, fuel, or hydraulic fluids

-

modification of current test methods or development of new low-cost methods to develop crack growth threshold stress intensity factors

-

estimation of fatigue life under high-cycle and mixed high-cycle-low-cycle regimes for intact and repaired structural components

Dynamic fatigue failures are very sensitive to the threshold crack growth rates of the materials involved, which are related to the time to initiate cracks from inherent defects within the material or to the surface finish or roughness of the finished part (Bucci et al., 1996). Maintaining sufficient fatigue life in the presence of dynamic loading requires either maintaining very low vibratory stress levels or increasing controls on material defects and design details (stress concentrations) that can lead to early fatigue failures. Knowing the relationship between conventional crack initiation behavior and threshold crack growth for the materials of interest in the Air Force aging aircraft could be valuable in the development of low-cost methods to determine the effects of high-frequency loads on fatigue.

Threshold crack growth behavior, and therefore dynamic fatigue life, is very sensitive to the effects of aircraft environments, including humidity, saltwater, fuel, or hydraulic fluids. These environmental conditions can reduce loads at the threshold crack growth regimes by as much as a factor of two and dynamic fatigue life by as much as an order of magnitude. The committee believes that the environmental sensitivity of dynamic fatigue behavior must be determined, validated by test, and documented specifically for materials used by the Air Force.

Generally, threshold crack growth test methods involve shaker table testing of sheet materials. These methods generate large numbers of cycles in very little time, but the crack growth data are not usually measured (Beier, 1997a). Modification of current tests to correlate with threshold data or development of cost-effective methods that characterize the relationship between threshold crack growth rates and time to crack initiation for uncracked samples are needed. The potential for linking naturally occurring flaw growth to a corresponding threshold crack growth rate would be a significant outcome of this development.

Life prediction for dynamically loaded structures is difficult to achieve with accuracy, given the sensitivity of the life to the threshold load levels. Also, the combined loading at both low-and high-cycle frequencies complicate this prediction problem notably. Some recent strides have been made in life prediction under combined high-and low-cycle fatigue loading (Saff and Ferman, 1986). But the problem remains one of determining the root source of the problem and modeling this root cause properly. The committee recommends an

effort to validate life predictions under both dynamic and combined high-and low-cycle fatigue to provide Air Force maintenance organizations with the capability to rapidly and accurately predict the lifetimes of both structures and repairs subjected to dynamic loading conditions.

The problem of life prediction of the repaired structure is similar to that of the unrepaired structure, except that the effect of the repair on load paths, mode shapes, and loading frequencies must be predicted accurately before the life prediction can be accurate. Given the uncertainty in the original life predictions noted above, the committee recommends that a program be performed to determine the potentially significant effect of repairs on component fatigue life.

Recommendation 8. Develop and validate through laboratory or flight tests analytical methods to predict dynamic response of aging structures and repairs. Include consideration of affected structure away from the repair/modification and the accelerating effects of environmental exposure.

Methods to analytically predict structural dynamic response, validated through the laboratory or flight tests, are required to assess aging structures and repairs. In some cases, structural repairs to address high-cycle fatigue serve to exacerbate the dynamic loading problems because local repairs of dynamically loaded structures can move the failure to a new location defined by the repair itself. Analytical methods must be capable of determining the response of the structure beyond the repairs.

Recommendation 9. Develop and implement an expert system, based on analytical methods and previous experience, to aid the design and analysis of repairs or modifications (both damped and undamped) of components susceptible to high-cycle fatigue damage. Examples of specific tasks include

-

development by the original equipment manufacturer of a database of dynamic loading conditions for particular locations on the structure and the acceptable frequencies and duration of the response in those locations

-

determination of damping levels for the repaired structure required to achieve the desired frequency range for the structure and the damped repair configuration (stand-off damping or adhesive layer or stiffening)

Given the potential and the capabilities afforded by today's materials, the ability to apply damped repairs should be pursued. These repair systems have been studied for two to three years and are nearing the point at which flight demonstration is becoming feasible (Beier, 1997b; Rogers et al., 1997). Nevertheless, there are repair considerations for dynamically loaded structures, for both damped and undamped repairs, to ensure successful repairs. These special considerations include

-

critical modes and responses (and natural frequencies) of the original structure

-

critical modes and responses of the repaired structure

-

response level required to obtain the desired life of the structure

-

driving force behind the cracking that was the root cause of the original problem