M Components of Explosive Systems

The characteristics of primary and secondary explosives are exploited in the design of the "explosive train." Briefly, the explosive train is an arrangement consisting of (1) a small quantity of highly sensitive initiator (primary explosive), (2) a larger quantity of less sensitive but more powerful high-explosive booster, and (3) the least sensitive main charge, which constitutes the bulk of the explosive charge (propellant or explosive).

DETONATORS

Detonators are used to set off the main charge if it is "cap sensitive" or to initiate a booster if the main charge is a less sensitive blasting agent such as ammonium nitrate/fuel oil (ANFO). "Detonator," not "blasting cap," is the term generally preferred today, although the term "blasting cap" is still used to describe a detonator initiated by a safety fuse.

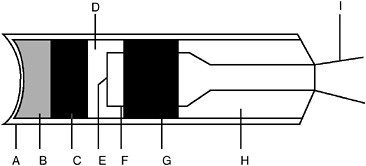

Detonators contain an explosive train that is a miniature version of the larger explosive system. They typically consist of an ignition element (e.g., a "match head" or "primer spot") that is highly sensitive to heat or shock, which then ignites a delay element, if present (Figure M.1). The delay element in turn ignites a primer charge, which undergoes a transition from deflagration to detonation and initiates the main or output charge. Detonators may or may not include the delay feature. The priming charge is usually diazodinitrophenol (DDNP) or lead azide, while the output charge is typically pentaerythritol tetranitrate (PETN). Output strengths can vary over a wide range, depending on the quantity and degree of compaction of the PETN.

FIGURE M.1 Electric detonator. A, metal shell; B, base charge; C, primer charge; D, ignition charge; E, bridge wire; F, ends of leg wires; G, H, plugs and/or filling; I, leg wires. SOURCE: Adapted from materials presented to the committee by Paul Horowitz, JASON Program, March 3, 1997.

There are two general types of detonators: electric and nonelectric. Electric detonators are activated by passing an electrical energy pulse through a bridge wire that is embedded in the ignition charge or primer spot. Electric detonators may be further classified as electric instantaneous, electric delay, electronic, toroid-type, and exploding bridge wire. All are produced with numerous delays, wire lengths, wire colors, and wire configurations.

Nonelectric detonators are initiated by other than electrical means. These include safety fuses, shock tubes, miniature detonating cords, and gas-initiated systems. As with electric detonators, nonelectric detonators are produced with a great variety of tubing or cord lengths, types of plastic closures, and so on. The gas-initiated system is no longer used in the United States, although stocks of these devices may still be found in blasters' magazines.

Until approximately the mid-1970s, the prevailing means of initiating explosives in the United States were by cap and fuse, electric detonators, and detonating cord. Since then, cap and fuse systems have virtually disappeared, but the other methods are still used, with technological improvements. In spite of vast improvements in electric detonator technology and manufacturing quality, nonelectric shock-tube detonators are now the product of choice for the majority of explosive initiation applications. The shock-tube system, invented in Sweden, appeared in the United States in the mid-1970s and quickly spread to all types of blasting. It has virtually taken over civil tunneling and is dominant in most underground mining except coal mining.

The U.S. market is split nearly evenly between electric and nonelectric (mainly shock-tube) detonators, but as described above, the nonelectric shock-tube systems are ascendant. Most detonators in use in the United States are produced domestically or in Canada. The cap and fuse detonators still being used (mainly in small mining operations, avalanche control, and agricultural applications)

are all imported. Some specialized detonators with electronic delays or with toroid electric systems are imported; however, these had a very small market share in the United States as of mid-1997.

Bombers may tend to prefer conventional electric detonators or, if nonelectric, fuse detonators, since all other detonators require something special to initiate them. This special added component may be a piezoelectric starter, a shotgun primer device, a detonating cord, or, in the case of electronic or gas-initiated systems, a unique blasting machine. Conventional electric systems need only a battery and a switch, while a fuse detonator needs only a safety fuse and a source of flame.

Some components of improvised electric detonators are easily made at home using light bulbs or flash cubes, but producing the primary explosive that can be initiated by such components is beyond the capabilities of most bombers. The easiest course is to somehow acquire commercial electric or fuse detonators.

BOOSTERS

Boosters are intermediate components in the explosive train used to ensure the ability of one element to initiate the next element. Specifically, boosters may be used to augment the detonator's output charge in the initiation of less sensitive main charges. They are produced in a great variety of shapes, sizes, and weights. Small extruded, cast, or pressed boosters are slipped over a detonator to initiate ANFO in small underground boreholes. Cast boosters are commonly made with pentolite, a mixture of PETN and trinitrotoluene (TNT), with the ratio dependent on the level of sensitivity desired.

Boosters typically weigh from 0.11 to 5 pounds, but the most commonly used weighs 1 pound. A large booster is not necessary to initiate ANFO, regardless of the size of the ANFO charge; the only advantage to a larger booster is that the mass of ANFO achieves its ultimate detonation velocity sooner, with a resulting increase in explosive yield.

Although most boosters used in the United States are manufactured in the United States or Canada, most of the high explosives used in cast boosters are imported (with the exception of PETN, which is produced domestically and also imported). TNT, composition B, and other such materials used in boosters are imported. There is no commercial U.S. TNT production.

Homemade boosters are easy to produce. The booster might be a stick of dynamite, a cartridge of emulsion, or a small sack of sensitized ANFO. Many mining operations use cap-sensitive or detonating-cord-sensitive cartridges of dynamite, emulsions, or water gels to initiate ANFO or other blasting agents.

MAIN CHARGE

The main charge is the primary source of explosive energy. It can be purchased legally or fraudulently; stolen from commercial sources; obtained illegally from military sources; or improvised by mixing together widely available chemicals, such as AN and fuel oil.1

|

1 |

See Chapter 1 for additional information on sources and use. |