1

Background and Task

The Office of Environmental Management (EM) within the U.S. Department of Energy (DOE) is responsible for managing and preparing for disposal all noncommercial spent nuclear fuel generated by U.S. nuclear materials and research reactor programs as well as some foreign research reactor programs. EM has responsibility for more than 150 different fuel types in storage at DOE and research reactor facilities around the world. This fuel exists in a number of different chemical forms (e.g., metal oxide, aluminum alloy, carbide) with different types of metal cladding (e.g., zircalloy, aluminum, stainless steel) and with uranium-235 (235U) enrichment levels ranging from a few percent to more than 90 percent (DOE, 1995). At the end of 1995, DOE EM had under management approximately 2,650 MTHM1 of spent nuclear fuel, primarily at the Hanford, Idaho National Engineering and Environmental Laboratory (INEEL), and Savannah River sites (DOE, 1996a; Figure 1.1).2

Beginning in 1995, DOE completed a number of programmatic environmental impact statements (PEISs) and issued a series of records of decision (RODs) affecting the management of spent fuel throughout the DOE complex. The Savannah River Site, which is located near Aiken, South Carolina (Figure 1.1), was designated to manage the department's

inventory of aluminum spent nuclear fuel3 from foreign4 and domestic 5 research reactors, the subject of this report6. During the next four decades, Savannah River will be responsible for receiving and storing this fuel at the site, processing it as necessary to put it into ''road-ready" form7 for eventual shipment to a repository, and providing for interim storage of the road-ready product until a repository is ready to accept it.

Approximately 20 MTHM of the aluminum spent fuel from research reactors was in storage at Savannah River as of October 1, 1997 (WSRC, 1998): 19 MTHM of depleted uranium8 targets and blankets and 1 MTHM of highly enriched uranium (HEU).9 This fuel is being stored in

Figure 1.1

Location of DOE sites with large inventories of spent nuclear fuel. SOURCE: Modified from DOE (1996b), Figure 1-2.

two water-filled pools, or wet basins, at the site: the L-Reactor Basin,10 (L-Basin for short) and the Receiving Basin for Offsite Fuels, (RBOF; see Figure 1.2).

By 2035, the site expects to receive an additional 10 MTHM from government and university reactors around the United States and 12

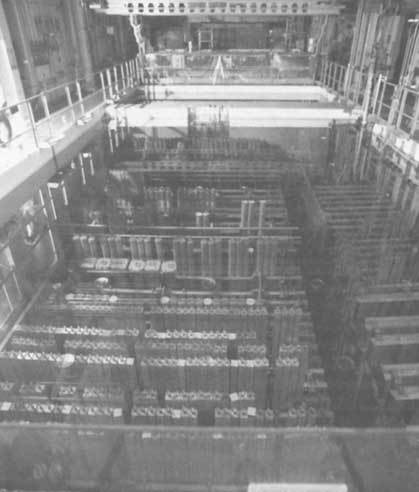

Figure 1.2

Interior view of the RBOF facility. After receipt at the facility, the fuel is placed into racks in the water-filled pool or "wet basin" shown in the photo. The water surface can be seen on the right side of the pool. The water is conditioned to minimize aqueous corrosion of the fuel.

SOURCE: Savannah River Laboratory.

MTHM from research reactors in more than 25 countries (Figures 1.3, 1.4).11 The domestic fuel is expected to include 9.4 MTHM of HEU and 0.6 MTHM of LEU,12 whereas the foreign fuel is expected to include 2.6 MTHM of HEU and 9.4 MTHM of LEU. Some of the fuel that is planned to be received has not yet been fabricated or shipped to the reactors where it will be used. The inventory of materials to be received is very diverse, ranging from intact reactor fuel elements to damaged or corroded fuel elements to uranium-bearing materials such as reactor blankets and powdered irradiation targets (Figure 1.5).

DOE is now in the process of developing a draft PEIS for management of aluminum spent fuel. This PEIS will determine the need for additional treatment and storage facilities at the site to accommodate the receipt of fuel from domestic and foreign sources. It also will assess alternative treatment technologies and select one or more treatment options for preparing the fuel for disposal in a repository. Formal decisions on treatment options and facilities are expected to be announced in a ROD that will be issued by DOE in the first quarter of FY99. Implementation13 of the ROD is expect to begin around 2000.

Task Statement And Study Process

As part of its efforts to prepare the aluminum spent fuel PEIS, the Savannah River Office of DOE asked the National Research Council (NRC) to review the options that it has identified to treat aluminum spent fuel (see Appendix A). These options are discussed in Chapter 2 of this report.

Figure 1.3.

(A) Locations of domestic research reactors that have or will generate aluminum spent fuel for shipment to and treatment at Savannah River. SOURCE: Data from Savannah River Laboratory.

The statement of task for this study involves a review of the following aspects of DOE's program for developing a preferred strategy to treat for disposal this aluminum spent fuel:

- examination of the set of technologies chosen by DOE and identification of other alternatives that DOE might consider;

- examination of the waste-package performance criteria developed by DOE to meet anticipated waste acceptance criteria for disposal of aluminum spent fuel and identification of other factors that DOE might consider; and

Figure 1.3.

(B) Locations of foreign research reactors that have or will generate aluminum spent fuel for shipment to and treatment at Savannah River. SOURCE: Data from Savannah River Laboratory.

-

- to the extent possible given the schedule for this project, an assessment of the cost and timing aspects associated with implementation of each spent nuclear fuel treatment technology.

This study is focused primarily on the treatment step of the process for disposing of aluminum spent fuel, that is, the options for treating this fuel to make it acceptable for disposal in a repository. This report does not review the other components of the disposal program-for example, the shipment of aluminum spent fuel to Savannah River for treatment, the shipment of treated fuel to a repository, or emplacement of

Figure 1.4

Projected receipts and transfers of aluminum spent fuel at Savannah River. NOTE: FRR = foreign research reactor fuel; DRR = domestic research reactor fuel; HFIR = High-Flux Isotope Reactor fuel (HFIR is located at the Oak Ridge site; see Figure 1.1); from INEEL = aluminum spent fuel now in storage at the Idaho National Engineering and Environmental Laboratory that will be shipped to Savannah River for treatment; to INEEL = non-aluminum spent fuel at Savannah River that will be shipped to INEEL for treatment; to repository = treated aluminum spent fuel that will be shipped to a repository for disposal; SRS = Savannah River Site. SOURCE: WSRC (1998), Figure 2.

that treated fuel in the repository14—but it does provide some analysis of the impacts of these other components on the selection and implementation of treatment options.

At the request of DOE, this study was undertaken using a principal investigator (P.I.) rather than a study committee. The P.I., a member of the National Academy of Engineering who has a great deal of expertise in spent fuel processing, was appointed by the Chair of the NRC to perform this study. He was responsible for gathering information used in the study, weighing the evidence, and developing the final report.

The study director was responsible for assisting the P.I. with these tasks and ensuring that the study process and product met the NRC's high standards of objectivity and completeness. As part of the NRC's quality assurance process, the report received a thorough review prior to publication by a group of experts selected by the NRC's Report Review Committee for their knowledge of the issues under consideration. The review was conducted anonymously, that is, the identities of the reviewers were not divulged to the P.I. until after the report was approved for publication. The report reviewers are identified in the Foreword.

Information for this study was gathered in two meetings that were open to the public: the first held in Aiken, South Carolina, on November 4-5, 1997, and the second held in Augusta, Georgia on December 2-3, 1997. The agendas for these meetings are given in Appendix B. During the first meeting, the P.I. and study director received scoping briefings from DOE and contractor staff on the aluminum spent fuel program at Savannah River and the work completed to date on the alternative treatment technologies.

The second meeting comprised a more detailed set of briefings on the alternative treatment technologies and was attended by the P.I.,

study director, and 11 expert consultants (hereafter referred to as "consultants") selected by the P.I. for their knowledge of and experience with the following issues: metallurgy and corrosion, remote processing, criticality, proliferation, cost, and regulations. Each consultant was charged with reviewing the issues within his or her own area of expertise but was not asked to evaluate the overall program. The consultants were asked to provide written answers to sets of questions developed by the P.I. and the study director prior to the meeting. These question sets also were provided to DOE staff prior to the meeting so that they could plan informative presentations. The questions and the written answers of the consultants are provided in Appendixes C and D, respectively. Additionally, the P.I. solicited and received written answers to these questions from two other consultants on proliferation policy who did not attend the second meeting. These also are included in Appendix D.

The findings, conclusions, and recommendations in the body of this report are the responsibility of the P.I., who used his professional judgment in weighing the evidence presented by DOE and the consultants (Appendix D), as well as the responsibility of the NRC, which, as noted previously, subjected the report to review by an independent group of reviewers. The P.I. considered carefully the advice he received from the consultants in developing this report, and in many cases the findings, conclusions, and recommendations in the report body are consistent with those articulated by the consultants in their individual reports (Appendix D). In some cases, however, the P.I. reached different conclusions than the consultants on particular issues—because, for example, there was no agreement among the consultants on a particular issue or because overall system considerations lead the P.I. to a different conclusion. The consultants' reports have been reproduced in full in Appendix D so that readers can assess for themselves the advice offered therein, and also so that the process used in this review will be transparent and differences among consultants and the P.I. will be readily apparent.

Organization of this Report

The remainder of the report is organized into four chapters, one chapter for each of the three charges in the statement of task and a concluding chapter with additional observations judged to be of value to DOE's program. An effort was made to keep the chapters as short as possible but also to provide enough information so that they should be understandable to nonexperts. Each chapter begins with background material and data needed to understand the issue and concludes with discussions of each charge of the task statement.