Executive Summary

The U.S. Army has asked the National Research Council (NRC) to evaluate whether supercritical water oxidation (SCWO) is an effective and appropriate means of eliminating hazardous or toxic organic constituents in VX hydrolysate for ultimate disposition. The NRC was not asked to conduct an in-depth analysis of the entire integrated VX bulk agent destruction and disposal process for the Newport Chemical Agent Disposal Facility. As the facility design is being finalized (March 1999-April 2000), the NRC will probably be asked to assess all aspects of the facility design, including monitoring, containment, process control, and redundancy, as well as the quantitative risk assessment (QRA). This report outlines the elements of the proposed neutralization/SCWO technology, evaluates the results of ongoing SCWO tests, and makes recommendations concerning aspects of the technology that require further development. The scope of this evaluation did not include evaluations of other potential technologies or management options for the treatment of VX hydrolysate.

BACKGROUND

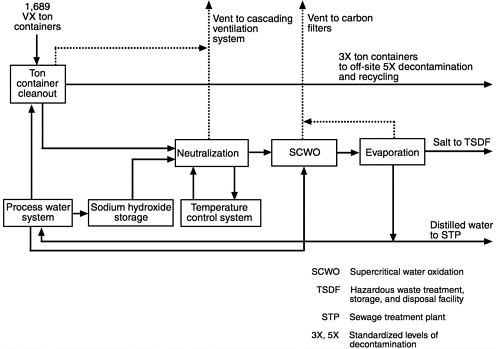

The United States undertook the destruction of its stockpile of chemical weapons long before the passage of the Chemical Weapons Convention (CWC), which came into force April 29, 1997. The U.S. Army, as the executive agent for the U.S. Department of Defense, presently uses a combination of incinerators to destroy chemical agents in bulk containers and assembled munitions (e.g., rockets and artillery projectiles) at two sites. The Army also plans to use incinerators at several other stockpile storage sites. However, public concerns associated with incineration have prompted the Army to consider alternative destruction technologies at two sites (Aberdeen, Maryland, and Newport, Indiana) where chemical agents are stored in bulk and are more accessible than those contained in weapons. The technology chosen for these two sites was chemical neutralization, which detoxifies chemical agents. This decision was reached with input from the NRC Panel on Alternative Chemical Disposal Technologies (AltTech Panel). For the stockpile site at Aberdeen, Maryland, chemical neutralization followed by microbial degradation was selected by the Army for the destruction of mustard, which is the only agent in the stockpile stored there. The overall process for treatment of the nerve agent VX at Newport, Indiana, (shown in Figure ES-1) consists of four primary operations in series:

-

draining VX from ton containers and ton container cleanout operations (ton container cleanout)

-

neutralization of the agent and ton-container cleanout fluids (neutralization)

-

SCWO

-

evaporation followed by condensation of water for recycling and filtration to recover crystallized salts for disposal (evaporation)

The overall process is planned to be operated 24 hours a day, seven days a week, with up to six ton containers of VX being processed each day (1,689 ton containers holding a total of 1,269 tons of VX are stored at the Newport site).

VX (C11H26NO2PS) is one of the most toxic chemical agents. It has a low vapor pressure and evaporates slowly under normal atmospheric conditions. As little as 10 mg of the agent absorbed through the skin or lungs will kill or incapacitate a 70 kg individual by a massive disruption of central nervous system function. Thus, the cleaning of containers and the processing of streams that contain VX can only be done in carefully designed and ventilated enclosures.

In the first processing step, ton container cleanout, the ton containers will be drained, cut in half, and cleaned with steam and hot water sprays. The wash water will contain small amounts of VX and will be treated during the agent neutralization process.

In the second processing step, neutralization, VX will be hydrolyzed in a hot (90°C) solution of about

FIGURE ES-1 Overview of the disposal process for VX ton containers.

13 wt. percent NaOH (sodium hydroxide) in water in a six-hour batch process. Parallel systems of batch processing will be provided to facilitate continuous operation and allow for periodic maintenance. The main function of the neutralization process is to break the phosphorus-sulfur bond in the VX molecule, which greatly reduces the toxicity of the neutralization/ hydrolysis products. The main reaction products are the sodium salt of ethyl methylphosphonic acid (EMPA) and a thiol (a hydrocarbon derivative that also contains nitrogen and sulfur atoms). A side reaction produces methylphosphonic acid (MPA), a relatively innocuous substance. Laboratory and pilot-scale neutralization tests indicate that the neutralization process has an overall destruction efficiency for VX of more than 99.9999 percent. Prior to release from the neutralization process step to subsequent treatment steps, both VX and EA-2192 1 must be nondetectable in the hydrolysate, with detection limits established at 20 ppb for VX and 5 ppm for EA-2192.

However, EMPA and MPA and some other trace compounds in the hydrolysate still contain carbon-phosphorus bonds and are considered “Schedule 2 precursors” in the CWC because they could potentially be reconverted to nerve agent. Therefore, the hydrolysate must be treated further to meet CWC requirements, as well as general requirements for safe and environmentally acceptable disposal.

After reviewing several options for secondary treatment, the Army has selected SCWO as the most promising technology for the third processing step, although further development and testing will have to be done before a full-scale treatment system can be built. The Army's schedule for implementing SCWO technology is ambitious but consistent with CWC treaty deadlines. The SCWO system is a hydrothermal process for the oxidation of the VX hydrolysate that yields a wastewater stream and salts.

In the fourth processing step, evaporation, the waste-water will be evaporated to provide distilled water, which can be recycled back to the process, and residual salts, which will be disposed of in a suitable hazardous waste facility. Excess distilled water from the evaporator will be discharged to a sewage treatment plant.

|

1 |

EA-2192, an intermediate product during the neutralization reaction, further reacts to form EMPA. EA-2192 is a nerve toxin. |

The tank cleaning, neutralization, and evaporation processing steps are all based on well known technologies, although some adaptations will be needed. However, SCWO is a relatively new technology being used for some hazardous waste treatment applications. For the evaluation of SCWO technology for the treatment of VX hydrolysate, the Stockpile Committee reviewed documents on SCWO process fundamentals, previous applications, testing carried out specifically for application to VX hydrolysate, and the planned process design for the Newport facility; met with SCWO academic researchers, process developers from Sandia National Laboratory, and vendors; visited a pilot-scale SCWO testing facility; and discussed the process with the Army and its process design contractors.

SCWO technology involves operations above the critical temperature and pressure of pure water (Tc = 374°C, Pc = 221 bar), where the properties of water are significantly altered. At supercritical conditions, organic compounds that are insoluble at ordinary temperatures usually become more soluble, whereas salts that are soluble at ordinary temperatures become much less soluble. Thus, organic materials in supercritical water can be rapidly oxidized using air or oxygen to produce fully oxidized species, with the salts precipitating out. In the last two decades, SCWO technology has evolved from the bench-scale treatment of certain organic hazardous wastes to limited, modest commercial operation. However, using this technology to treat VX hydrolysate raises several challenges. These include the reaction kinetics, full-scale reactor design, the management of the large volumes of salts generated, and corrosion problems associated with the fluid streams and salt deposits.

The reaction mechanisms for the destruction of organic compounds by SCWO generally involve free radical chain reactions with oxidative radicals (mostly •OH and •OOH). Thermal bond cleavage and polar or ionic reactions, including hydrolysis, also occur under these severe conditions. With residence times of seconds to minutes at temperatures of 400 to 650°C, very high destruction efficiencies (> 99 percent to 99.9999 percent) have been reported for the destruction of a large number of organic compounds. Aqueous organic wastes with sufficient fuel value can be autogenic; i.e., they can sustain the necessary reaction temperatures for extensive oxidation without supplemental fuel.

In a SCWO process, the aqueous input stream is pressurized, heated, and mixed with oxidant (e.g., air or pure oxygen), then pumped through a flow reactor at the supercritical conditions designed to provide the required residence time. Heat produced by the oxidation can be recovered (or must be removed) based on the heat content of the waste stream. If the input stream has inadequate fuel value to heat the reactor, make-up fuel can be added. Downstream of the reactor, the pressure in the system is “let down” either before or after cooling. Solids produced from oxidation reactions can be recovered prior to or following pressure let-down. Cooling prior to pressure let-down often results in the redissolution of salts, which can be removed later via evaporation.

A number of pressure let-down schemes have been devised—predominantly valves or capillary tubes that restrict the release of fluids from the process equipment. The effluent is then passed through gas/liquid separators, and the gas stream and aqueous streams can be treated further, as required for responsible disposal. All gases produced during the SCWO treatment step are filtered prior to release using activated carbon to remove any residual volatile organic contaminants. With adequate salt removal, most of the water effluent can be recycled within the plant. The plant design will be expected to include a final evaporator where the water will be distilled to produce a dry salt. Any excess water requiring disposal should be very clean.

SCWO technology has matured from bench-scale testing to a few pilot-scale demonstrations, as well as one current and several pending full-scale operations. Although it has been tested on a laboratory scale for treatment of a wide variety of wastes ranging from hazardous waste to sewage sludge, pilot-scale testing for the treatment of more complex wastes (e.g., heterogeneous wastes, wastes containing high concentrations of heteroatoms that generate salts, and corrosive wastes) has been limited. Wastes characterized by high salt or salt producing content and corrosivity during treatment have presented major technological challenges.

The implementation of SCWO technology has evolved into three basic reactor configurations and two approaches to temperature and pressure reduction after reaction at supercritical conditions. The three basic reactor configurations are tubular, vertical cylindrical, and transpiring wall. All three configurations mix the reactants (waste, supplementary fuel [if required], and oxidant) at the entrance or in the uppermost zone of the reactor.

Only the vertical cylindrical configuration has been demonstrated at pilot-scale for the treatment of VX hydrolysate and similar wastes. Tubular reactors utilize relatively small-diameter high pressure tubing with long

lengths (about 3 cm dia. × 36 m) to achieve the required residence times for reaction. The relatively high flow velocities (e.g., 1 m/s) could be helpful for moving precipitated salts along. However, the long reactor lengths are usually oriented horizontally with several passes (i.e., U-bends) or spirals. The narrow inner diameter and the bends in these configurations make them less desirable for systems at pressures of approximately 400 bar and with high salt loadings because of the presence of a solid salt phase and the possibility of salt deposition and plugging. The vertical cylindrical reactor has a larger diameter and much shorter length (9 to 25 cm diameter × 2 to 5 m length) to achieve the residence time required for reaction. Transpiring wall reactors inject significant quantities of water through porous walls to limit salt deposition. Limited experience with transpiring wall reactors suggests that counterdiffusion of reaction constituents can still create corrosion and salt deposition problems. This type of reactor requires additional development testing before it can be scaled up for corrosive, high salt, full-scale applications.

Using SCWO to treat VX hydrolysate raises many challenges. The operating conditions (temperature, pressure, and residence time) for the destruction of the carbon-phosphorus bond in EMPA and MPA, combined with the transition from alkaline to acidic composition during oxidation of the hydrolysate components, creates severe requirements for the materials of construction to prevent corrosion. In addition, the large amount of inorganic salt-producing elements present in the original VX (P, S) and added during the neutralization process (Na as NaOH) require that a high solids content fluid be managed in and downstream of the SCWO reactor. Experience has shown that salts that are insoluble in the SCWO reactor fluid phase have a propensity to adhere to the reactor walls, which can cause reactor plugging, and to erode the components of pressure let-down systems.

These problems have been overcome for the treatment of other wastes. However, the composition of VX hydrolysate is significantly different from other wastes treated by SCWO technology because VX has a high solids-producing content, and the solution is severely alkaline. Pilot-scale testing of SCWO technology specifically for the treatment of VX hydrolysate has been limited to tests of a vertical cylindrical reactor (1) for intervals of a few hours using surrogates for the hydrolysate and (2) three tests with actual VX hydrolysate (two tests for less than two hours and one test for approximately eight hours). Therefore, a specific development program for using SCWO to treat VX hydrolysate will have to be conducted before SCWO can be applied at full scale. The treatment of hydrolysate represents a new type of application for SCWO and consequently is the focus of the findings and recommendations presented here.

FINDINGS

Finding 1. Limited pilot-scale testing has demonstrated the ability of SCWO to achieve high destruction efficiencies for the organic constituents of VX hydrolysate. Effluent from SCWO treatment of VX hydrolysate has been shown to have negligible acute toxicity in intravenous testing in mice, gavage testing in rats, and dermal testing in rabbits. The separation of salts in the effluents from SCWO through an evaporator system should produce relatively pure water suitable for discharge and solid salts suitable for disposal. Treatment requirements for VX hydrolysate are less stringent than they are for VX because the hydrolysate has low toxicity relative to the agent. However, criteria for process destruction efficiency and final disposal standards have not been established.

Finding 2. Using SCWO to treat VX hydrolysate is significantly different and more complex than previous applications. SCWO systems on a pilot scale have been used to treat several other types of wastes, but SCWO is in commercial operation at only one site. There has been only limited pilot-scale or operational-scale experience with wastes that are similar to VX hydrolysate in being highly corrosive and salt-laden. Operation with VX hydrolysate or appropriate surrogates at design conditions, equipment configuration, or approximate scale for full-scale operations has not been demonstrated. A vertical cylindrical reactor is the only reactor configuration that has been successfully demonstrated to date at pilot scale for the treatment of VX hydrolysate and similar waste streams. Additional development and pilot-scale testing of SCWO technology will be necessary to ensure sustained, reliable operation of a full-scale integrated treatment system. Sufficient time appears to be available in the Army's implementation schedule for the Army to carry out development and testing for using SCWO at the Newport site, provided they are carried out expeditiously.

Finding 3. Pilot-scale operation of SCWO in a vertical cylindrical reactor at the temperature and pressure necessary for the effective destruction of hydrolysate constituents has been limited to one eight-hour and two less than two-hour tests. During pilot-scale testing with hydrolysate, the following factors were identified that could create difficulties in sustaining system performance:

-

Large quantities of insoluble salts were produced, which must be effectively managed within, and downstream of, the SCWO reactor.

-

Unexpected fluctuations were observed in temperature, pressure, and salt expulsion from the SCWO reactor.

-

High levels of corrosion and erosion of materials of construction were observed in the reactor liner and pressure let-down valves.

-

The sustained performance and reliability of the pressure let-down system was not demonstrated.

Although at this point in development the Stockpile Committee cannot be certain, it believes that a SCWO system for the treatment of VX hydrolysate with sufficient sustained performance can be achieved with additional development and testing.

Finding 4. Limited bench-scale and pilot-scale tests have demonstrated operating regimes under which SCWO can effectively destroy carbon-phosphorus bonds and oxidize the organic constituents present in VX hydrolysate. The demonstrated conditions for high levels of destruction (> 99 percent) include temperatures between 640°C and 730°C and pressures between 234 and 261 bar. At temperatures and pressures below this regime, effluent from SCWO processing may contain significant concentrations of residual organic species that are difficult to destroy, including constituents with carbon-phosphorus bonds.

A basis for the reliable scale-up and operation of SCWO technology for the treatment of VX hydrolysate has not yet been demonstrated. Fundamental knowledge about the following processes within the SCWO reactor is still not available:

-

the number and characteristics of the physical phases, including large quantities of entrained and adhered solids and potentially liquid, gas, and supercritical fluid phases

-

fluid dynamics and mixing processes complicated by relatively high loadings of insoluble salts

-

heterogeneous and homogeneous reaction mechanisms and kinetics

-

salt nucleation, particle growth, agglomeration and adhesion mechanisms, and kinetics

Because the understanding of fundamental processes is limited and the process operational data and experience are sparse, empirical design and engineering judgment will be required for the selection of a prudent scale for development prior to full-scale demonstration. This is common engineering practice.

Finding 5. Alkaline VX hydrolysate and its destruction products under SCWO reaction conditions create an extremely corrosive and erosive environment that requires the careful selection of materials of construction. Although preliminary data indicate that certain noble metals, such as platinum and gold, may have acceptable properties, the data currently available are insufficient for the selection of materials of construction. The Army has initiated further testing of materials of construction.

Finding 6. Process monitoring and control strategies for the management of salts within the SCWO reactor and the destruction of the organic constituents of the hydrolysate have not been demonstrated.

RECOMMENDATIONS

Recommendation 1. A pilot-scale SCWO process facility with the critical characteristics of the full-scale design should be constructed and operated to further define operating characteristics and demonstrate sustained continuous operation of the process. Objectives for process development and demonstration should include:

-

operation with either hydrolysate or a suitable surrogate to demonstrate reliable operation for periods similar to full-scale design operating cycles

-

the development and validation of process monitoring and control strategies for salt management and the destruction of organic constituents

-

the definition of stable operating regimes, including the temperature, pressure, and the use of the oxidant (liquid oxygen or compressed air) selected for full-scale operation

-

the definition of a basis for process scale-up, operation, and maintenance of a full-scale system

-

the development and demonstration of a reliable pressure let-down system

Because the understanding of the fundamental process mechanisms and operating characteristics is limited, the committee recommends that the pilot-scale system be within an order of magnitude of the total mass and heating throughput of a full-scale design unit. Based on testing and reactor scale-ups to date, a vertical cylindrical reactor configuration is recommended as the system that will probably require the least amount of additional development. Other reactor configurations may perform at required levels but would require significant additional development.

Recommendation 2. Testing of materials of construction should be carried out as necessary to finalize the selection of materials for critical components, including the SCWO reactor and the pressure let-down system. Additional pilot-scale testing indicated in Recommendation 1 should include fabrication with the materials of construction selected from testing smaller samples and evaluation of corrosion and erosion rates for critical components.

Recommendation 3. Flexibility and redundancy of critical components should be incorporated into the design of the full-scale system to allow for uncertainties about the basis for scale-up and operation. Trade-offs should be evaluated to establish an appropriate balance between two 100 percent capacity SCWO reactors or a greater number of smaller reactors. The analysis should consider performance uncertainties associated with process scale-up and complexity, as well as the reliability of operating several reactors in parallel.

Recommendation 4. The Army should make provisions for targeted research and development to resolve problems identified during pilot-scale testing and the full-scale implementation of SCWO technology.

Recommendation 5. Requirements for process destruction efficiencies and final disposal standards for all effluent streams from SCWO treatment should be clearly defined to ensure that the final design meets regulatory standards.