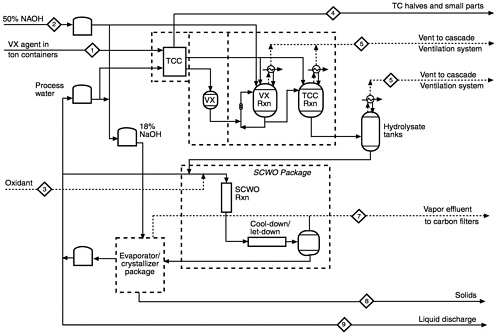

TABLE B-1 NECDF Inputs for Process Mass Balance (stream numbers correspond to streams identified in Figure B-1 )

|

Process Inputs |

||||||

|

Description |

Agent in Ton Containers |

50% NaOH Solution |

Oxidant to SCWO |

Nitrogen to Neutralization Vessels |

Process Air to TCC |

Total Inputs |

|

Stream Number |

1 |

2 |

3 |

N/A |

N/A |

N/A |

|

Total Flow (kg/1,000 kg agent) |

1,000 |

1,195 |

3,500 |

7 |

5,667 |

11,369 |

|

Physical State |

liquid |

liquid |

vapor |

vapor |

vapor |

|

|

temperature (°F) |

70 |

80 |

70 |

70 |

70 |

|

|

pressure (psig) |

14.7 |

14.7 |

3,500 |

17.7 |

100 |

|

|

Vapor Components |

||||||

|

oxygen (kg/1,000 kg agent) |

3,500 |

1,190 |

4,690 |

|||

|

nitrogen (kg/1,000 kg agent) |

7 |

4,477 |

4,484 |

|||

|

Liquid Components |

||||||

|

VX (kg/1,000 kg agent) |

957 |

957 |

||||

|

agent impurities (kg/1,000 kg agent) |

44 |

44 |

||||

|

NaOH (kg/1,000 kg agent) |

598 |

598 |

||||

|

Water (kg/1,000 kg agent) |

598 |

598 |

||||

|

Solid Components |

||||||

|

TC shells (no./1,000 kg agent) |

1.5 |

1.5 |

||||

|

TC valves (no./1,000 kg agent) |

2.9 |

2.9 |

||||

|

TC plugs (no./1,000 kg agent) |

8.8 |

8.8 |

||||

|

Source: Adapted from Stone and Webster, 1997b. |

||||||

TABLE B-2 NECDF Outputs for Process Mass Balance (stream numbers correspond to streams identified in Figure B-1)

|

Process Outputs |

||||||||

|

Description |

Ton Container Parts |

TCC Air Dry Vent |

Neutralization Reactors Vent |

Hydrolysate Tanks Vent |

SCWO Vapor Effluent |

Salt Solids to Disposal |

Discharge to STP |

Total Outputs |

|

Stream Number |

4 |

N/A |

5 |

6 |

7 |

8 |

9 |

|

|

Total Flow (kg/1,000 kg agent) |

5,667 |

6 |

1 |

3,121 |

1,531 |

1,043 |

11,369 |

|

|

Physical State |

solid |

vapor |

vapor |

vapor |

vapor |

solid |

liquid |

|

|

temperature (°F) |

46 |

40 |

80 |

95 |

100 |

|||

|

pressure (psig) |

18 |

21 |

15 |

15 |

15 |

|||

|

Vapor Components |

||||||||

|

oxygen (kg/1,000 kg agent) |

1,190 |

1,803 |

2,993 |

|||||

|

nitrogen (kg/1,000 kg agent) |

4,477 |

6 |

0.3 |

4,483.3 |

||||

|

VOCs (kg/1,000 kg agent) |

0.4 |

1,165 |

1,165.4 |

|||||

|

carbon dioxide (kg/1,000 kg agent) |

82 |

82 |

||||||

|

nitrous oxide (kg/1,000 kg agent) |

0.1 |

0.1 |

||||||

|

inorganic impurities (kg/1,000 kg agent) |

10 |

10 |

||||||

|

Solid/Liquid Components |

||||||||

|

Na2SO4 (kg/1,000 kg agent) |

70 |

451 |

1,043 |

1,574 |

||||

|

Na2HPO4 water (kg/1,000 kg agent) |

530 |

530 |

||||||

|

TOC (kg/1,000 kg agent) |

0.1 |

0.1 |

||||||

|

inorganic impurities (kg/1,000 kg agent) |

10 |

10 |

||||||

|

TC shells (no./1,000 kg agent) |

1.5 |

1.5 |

||||||

|

TC valves (no./1,000 kg agent) |

2.9 |

2.9 |

||||||

|

TC plugs (no./1,000 kg agent) |

8.8 |

8.8 |

||||||

|

Source: Adapted from Stone and Webster, 1997b. |

||||||||

TABLE B-3 Water Formation Resulting from the Neutralization of VX and Oxidation of the Hydrolysate during the NECDF Process

|

Water is formed in the neutralization supercritical water oxidation (SCWO), and pre-evaporation pH adjustment processes. The following illustrates this water formation by showing that elemental hydrogen enters the process in water and other compounds but exits the process mostly as water. |

||

|

The elemental hydrogen inputs to process are for 1,000 kg of agents. |

||

|

Stream |

Constituents |

Hydrogen Content |

|

Agent |

1,000 kg VX |

98 kg |

|

50% NaOH solution |

598 kg NaOH 598 kg H2O |

15 kg 67 kg |

|

Total |

2,195 kg |

180 kg |

|

Notes: For simplification, the agent is assumed to be pure VX, with a molecular weight of 267 and a molecular formula of C11H26O2NPS. The 50% NaOH solution flow shown here includes all caustic to the process, both for neutralization and for post-treatment. |

||

The only product other than water that contains hydrogen is the phosphate salt in stream number 8, Figure B-1, salt solids to disposal, which contains

530 kg Na2HPO4/1,000 kg of agent = 4 kg H/1,000 kg of agent

The balance of hydrogen:

180 - 4 = 176 kg H/1,000 kg of agent

is reacted with oxygen present throughout the process to form water.

The resulting water is found in the following output streams (per 1,000 kg of agent).

|

Stream |

Water Content |

Hydrogen Content |

|

SCWO vapor effluent |

70 kg H2O |

8 kg |

|

Salt solids to disposal |

461 kg H2O |

51 kg |

|

Discharge to STP |

1,043 kg H2O |

116 kg |

|

Total |

1,574 kg H2O |

175 kg |

|

The total amount of water formed in the process is water out minus water in. |

||

|

1,574 - 598 976 kg H2O/1,000 kg of agent |

||

|

Source: Stone and Webster, 1997b |

||