3

Identification

Introduction

After a bombing takes place, much information about the improvised explosive device can be obtained through careful processing of the bomb scene. In bombing incidents in which black or smokeless powder is used, bomb components recovered may include unreacted or partially burned powder, chemical products of the reaction, and parts of the device, such as the container used to contain the powder, the container used to transport the device, triggering or delay mechanisms, and adhesive tape. Identifying and tracing the origin of these components, including the brand and product line of the smokeless or black powder used in a bombing, may aid in identifying and eventually convicting the bomber. The Committee on Smokeless and Black Powder was specifically charged with determining whether taggants, added to black or smokeless powder, would substantially assist law enforcement personnel in identifying, apprehending, and convicting bomb makers.1

Identification taggants are coded materials that can be added to a product by the manufacturer to provide information that can be ''read'' by investigators at some later stage in the use of the product. Taggants are currently added by manufacturers to a variety of products, such as gasoline, construction materials, and perfume, to enable detection of product tampering or counterfeiting.2 These

|

1 |

See Appendix B for the statement of task. |

|

2 |

Some commercial applications of taggants for prevention of counterfeiting and for product identification are given by Schlesinger (1998). |

commercial examples may provide useful guidance regarding addition of taggants to smokeless or black powder, although their information content is limited (they need only be identifiable) and they are not designed to withstand explosions.

As a first step in assessing the value of adding taggants to black or smokeless powder, current investigatory methods used by law enforcement personnel are summarized, especially the role of physical evidence in bombing cases. Methods for identifying the powder used in a bomb, such as the use of powder databases, as well as the ability to trace black or smokeless powder from manufacturer to last legal purchaser, have implications that will affect the decision to add taggants. If taggants are to be effective, they must substantially enhance the steps in an investigation and lead to faster apprehension and more certain conviction of the perpetrators.

An additional factor is the nature of the taggant itself. The committee found it helpful to list criteria for an ideal taggant, not only to assess the state of current technology but also to provide guidance for design of new taggant technologies.

Currently, Switzerland is the only country where taggants are added to explosives. This program includes the tagging of black powder, but only that used for blasting purposes. Neither smokeless nor black powder for shooting purposes is tagged. The relevance of the Swiss experience has been carefully assessed in considering the addition of taggants to smokeless and black powder in the United States.

Methods and Approaches

The Role of Physical Evidence in Bombing Cases

The utility of adding taggants to propellant powders rests on the incremental benefits they may offer to law enforcement in the context of all the physical and chemical evidence available in a given case. A primary focus of forensic laboratory examination of postblast evidence is to analyze chemical residues in order to identify the explosive and provide investigators with as much information as possible about its probable origin. Identifying the explosive, however, is but one part of a comprehensive examination process; to better understand the scope of such an investigation, it is instructive to examine typical components of an improvised explosive device and the nature of evidence left after an explosion.

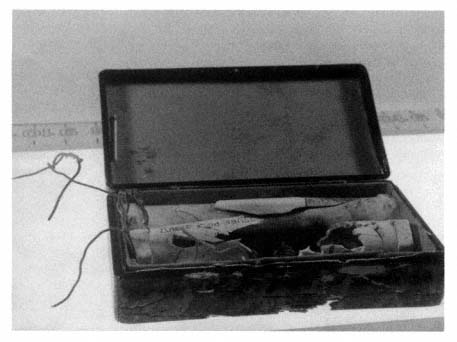

A smokeless or black powder improvised device consists of a number of components, including some or all of the following: powder, a container to confine the powder, delivery and concealment means (bag, parcel, and the like), an ignition mechanism, and a timing or victim-initiated mechanism (see Figure 3.1).

Other sources of physical evidence can include material designed to injure or kill (e.g., nuts and bolts, screws, nails, and metal staples) and packaging material (e.g., wood or cardboard boxes). Such components can result in potentially valuable physical evidence being recovered at the crime scene; examples include

Figure 3.1

Pipe bomb.

SOURCE: Adapted from Scott (1994).

fragments of the container, unburned powder, pieces of the packaging, lengths of safety fuse, wires, springs, initiators, fragments of batteries, fragments of clocks, and the like. Any of the components of an improvised explosive device potentially may be used to associate the device with its builder. One example is the specialty nails recovered at the scene of the Centennial Park bombing. Approximately 6 pounds of 8d nails, called "concrete" or "masonry" nails, were used in the bomb. Both the type of nail and the amount purchased were unusual. As a result, the Federal Bureau of Investigation (FBI) requested that individuals with knowledge of such a purchase contact the FBI.3

Propellant powders are normally designed to function by very rapid burning rather than by detonation. Frequently, unreacted smokeless powder granules are thrown out of an exploding device and can be recovered at the bomb scene. Less often, unreacted black powder can be located similarly, but characteristic residue is nearly always present after black powder bombings (in the absence of water). Information about the powder used in a bomb supplements the data about the

many other kinds of physical evidence typically present at a bomb scene to assist investigators in identifying a suspect and linking the individual to the crime.

Black Powder

Unreacted black powder consists of irregularly shaped granules coated with graphite, giving the granules a distinctive black and glossy appearance when observed through a microscope. As discussed in Chapter 1, the typical composition contains charcoal, sulfur, and potassium nitrate (or occasionally sodium nitrate). Black powder is not a very efficient explosive in that a large percentage of its products are condensed solids rather than gases (AB Bofors Nobelkrut, 1960). This does, however, give forensic scientists an advantage in that black powder, even if entirely consumed, yields significant quantities of characteristic residue (Mohanty, 1998; Bender, 1998). The primary intrinsic characteristics of black powder are its morphology, composition, and the large quantity of residue produced by burning or explosion.

Smokeless Powder

Only single-and double-base smokeless powders (see Chapter 1) are normally encountered in explosive devices.4 As noted previously, smokeless powders contain small amounts of chemical additives, such as stabilizers or flash suppressants; these substances may be identified during the postblast chemical analyses of powders or residues.

Smokeless powders generally have a graphite surface coating and are produced in more regular shapes than black powder. Common shapes include flattened balls, tubes, and disks. An important part of the forensic examination of smokeless powders involves the careful measurement of the granule dimensions (Figure 3.2) either with a microscope equipped with a calibrated micrometer eyepiece or an image profiler. Recently, the National Laboratory Center of the Bureau of Alcohol, Tobacco, and Firearms (ATF) has begun to explore the use of digital image capture and digital image analysis to replace these labor-intensive ways of measuring granule dimensions (Bender, 1998).

Figure 3.2

Physical characteristics of various types of smokeless powder.

SOURCE: Adapted from Bender (1998).

Use of Black and Smokeless Powder Databases

The FBI Chemistry Unit Laboratory and the National Laboratory Center of the ATF have each devoted considerable effort to accumulating data on the physical dimensions and chemical composition of different types of smokeless powders (see Appendix F) for use in forensic investigations to identify smokeless powder. The creation and maintenance of these two powder databases require the commitment of laboratory resources to accomplish a variety of tasks: liaising with powder manufacturers and distributors to obtain samples of new products, accumulating samples of different lots of powder, analyzing physical dimensions and morphologies of the smokeless powder granules, analyzing the chemical composition of representative samples of the smokeless powders, and entering these data into a computerized powder database (Wallace and Midkiff, 1993; Bender, 1998). Because of the pressure of casework and the limited human and financial resources available for this activity, the powder databases maintained by the FBI and ATF are incomplete.5

Although both the FBI Chemistry Unit Laboratory and the National Laboratory Center of the ATF are able to identify the type of smokeless powder used in a bombing or in an unexploded device in the majority of cases, both laboratories nevertheless do encounter smokeless powder samples that are not in their powder databases. In such cases, valuable time may be lost at the beginning of an investigation because of the need to visit powder manufacturers to solicit their technical staffs' assistance in identifying the powder. In some cases, the origin of the smokeless powder used in a bombing or attempted bombing may remain undetermined. Analysts at both the FBI Chemistry Unit Laboratory and the National Laboratory Center of the ATF expressed the belief that the addition of taggants could aid them by providing the ability to identify the manufacturer and product line of a smokeless powder, especially in those instances in which conventional analytical methods now fail.6

In forensic investigations of black powder, the granule size is the main characteristic examined.7 The FBI and ATF keep samples and/or information about the physical dimensions of various commercially available black powders. These samples and data are available for use in comparisons with evidence from bomb scenes. Both agencies agreed that information about the chemical composition of the different black powders has little evidentiary value.

Tracing the Product Through the Distribution Chain

Taggants may be used to identify the manufacturer and product line of smokeless or black powder used in a bomb without additional record keeping on the part of the manufacturer or retailer. For example, the dyed powder granule that Alliant Techsystems adds to some of its smokeless powder allows the user to identify immediately the specific product line (Red Dot, Blue Dot, Green Dot). However, establishing an additional audit trail would be necessary to enable law enforcement personnel to trace a particular powder used in a bomb from the manufacturer to the last legal purchaser. At each stage in the distribution system, sellers would have to record which tagged powders were sent to which customers, and retail outlets would have to keep their sales records in a form that could be readily accessed by investigators. To examine the issues raised by such a record-keeping system, the committee reviewed the existing system of normal business records kept in the manufacture, distribution, and retail selling of powders.8 Three types of records could be kept in the current system: records within

|

6 |

Site visits to the ATF and the FBI (see Appendix F) and subsequent discussions with laboratory personnel, August 19, 1998. |

|

7 |

Personal communication, Cynthia Wallace, ATF, June 24, 1998. |

|

8 |

For the purposes of this study, analysis of record keeping was limited to black and smokeless powder sold commercially for reloading purposes. Other applications of black and smokeless powders include use in commercial ammunition and specialized military devices, among others. However, the volume of production for commercial ammunition is tremendous, and the array of military |

a manufacturing or distribution facility, records tracking the movement of powder between such facilities, and records at the retail level that identify the purchaser.

Current Record Keeping in the Powder Distribution System

Details of the record-keeping process were provided by a company that both packages its own powder and repackages powders made by other companies;9 the record-keeping procedures were not expected to vary widely throughout the powder industry. In repackaging powders, each 1-pound (or larger) canister of powder is stamped with a date of packing and a lot number. This stamp also goes on the packing boxes that hold the powder containers. Records of the amount packaged, date, and lot number are maintained indefinitely. However, once the powder is shipped from the repackaging facility to either master distributors or retailers, the chain of record keeping ends, and a record of the final destination of the canisters packaged on a given day from a specific lot does not exist.

At the next level of the distribution system, master distributors receive powder from the original manufacturers or repackagers and supply it to smaller distributors and retail outlets (see Figure 1.1 in Chapter 1). Again, records are maintained by the master distributors about the type and quantity of powder on their property, but distribution beyond their facility is not tracked.10

For comparison, the system for tracking high explosives in the United States is more rigorous. In the United States, packaged commercial high explosives are required to be marked with a bar code that indicates the manufacturer and the date and shift on which the explosive was manufactured. These date and shift codes have proven to be useful both in tracing the disposition of purchased explosives and in investigating attempted bombings involving these packaged explosives. Sometimes these packaging markings survive a bomb blast.

|

|

applications for black and smokeless powders is immense. As a result, tracking the disposition of a specific lot of powder through the distribution system to the final use of the ammunition or military device would be very difficult. In addition, the relatively high cost and difficulties involved in obtaining quantities of black or smokeless powder sufficient for use in an improvised explosive device from military devices or ammunition also remove these sources from the main focus of this study. |

|

9 |

Information supplied to the subcommittee during its visit to Hodgdon Powder Company; see Appendix F. |

|

10 |

When large quantities of black or smokeless powder (over 100 pounds) are transported, the powder is shipped as an explosive, and Department of Transportation regulations require more detailed documentation about the shipment. These records might be helpful in tracking the location of black powder, but they are not currently coupled with the record-keeping procedures within individual manufacturing, packaging, or distribution facilities. Smaller quantities of black powder and most smokeless powder are shipped as flammable solids and are subject to less strict federal regulations. |

Current Record Keeping at the Retail Level

One potential advantage of a tagging program would be to enable investigators to obtain information leading to the last legal purchaser of the tagged powder used in a bombing. This would require that retail outlets maintain records of which customers purchased which tagged powders. Even in the absence of a tagging program, however, several forensic investigators contacted by the committee indicated that it would be useful in bombing investigations to be able to obtain from local retailers a list of individuals who had recently bought the same type of powder used in the bombing.11 The committee therefore attempted to characterize the current state of record keeping for the retail sale of powders.

Federal Requirements

Retail purchases of black powder are not regulated for quantities below 50 pounds (Code of Federal Regulations, 1981). Purchases of black powder above 50 pounds are regulated by the ATF in the same way as high explosives: for intrastate or contiguous state use, the purchaser must fill out a form, which is retained by the seller. For interstate transport and use, the purchaser must have a federal license or permit. There are no federal regulations concerning the retail sale of smokeless powders.

State and Local Requirements

Many states have legislation that regulates the purchase or possession of explosive materials, but the great majority have exempted from licensing requirements small amounts of black or smokeless powder, or all black and smokeless powder that is acquired for personal or recreational use (see Appendix H on state laws). Five states have regulatory legislation that places some restrictions on the purchase of small quantities of black or smokeless powders. California has by far the most detailed scheme.12 Three other states, Illinois, Massachusetts, and Michigan, and the District of Columbia require some form of license in order to purchase, possess, or reload powder.13 Mississippi and Virginia require some record keeping on the part of the sellers.14 Although there is no way of knowing the impact of such controls on potential bombers, the committee is aware of anec-

|

11 |

Personal communication from Richard Strobel and Cynthia Wallace, ATF, during a site visit to the ATF National Laboratory Center, March 19, 1998. See Appendix F for more information. |

|

12 |

See Cal. Health & Safety Code § 12102.1 |

|

13 |

See D.C. Code Ann. § 6-2341(a); Ill. Ann. Stat. Ch. 225, § 210/1004; Mass. Gen. L. ch. 140, § 131(E); and Mich. Comp. Laws, ch. 140, § 129(C). |

|

14 |

See Miss. Code Ann. § 45-13-101; Va. Code Ann. § 59.1–138. |

dotal evidence that law enforcement investigators visit retail establishments to determine whether there is any record keeping that might provide leads to bombing suspects.15 Implementation of a uniform record-keeping requirement for all states would require action by Congress.

Taggants for Black and Smokeless Powders

While an initial examination of the current state of the art of forensic investigations of bombings indicates that taggants would assist in such investigations, the effects of adding taggants to black and smokeless powders must be carefully examined. Consideration of the characteristics of an ideal taggant helps to clarify the issues involved.

Characteristics of an Ideal Taggant

Ideal characteristics are by their nature unattainable, but, by establishing these criteria, proposed taggant concepts may be judged against agreed-upon characteristics. If a significant increase in threat from the illegal use of black and smokeless powder demands quick implementation of a taggant system, reasonable concession may have to be made in the selection of a taggant in order to increase overall public safety. The ideal taggant would have the following characteristics, which are not necessarily of equal importance:

- No real or perceived health or safety risks. The ideal taggant poses no safety risk. It is inert. It does not in any way affect the normal properties of the energetic material in which it is admixed nor does it adversely affect the health or safety of powder workers, powder users, or the general public. The ideal taggant is fully accepted by the public. In addition to posing no real risks, the ideal taggant has no perceived risks. It is unobtrusive and manifests no inconvenience to the end users of the black and smokeless powders nor to the general public.

- Wide forensic applicability and utility for law enforcement. The ideal taggant is applicable to all black and smokeless powder threats. It can provide unambiguous, detailed information to law enforcement agents concerning the manufacture and distribution of powders used in a crime. Law enforcement agents with only modest training and relatively unsophisticated equipment can obtain this information. The ideal taggant is not a source of cross-contamination, and its intrinsic value is not adversely affected by other sources of contamination. The ideal taggant would not only be recoverable from unburned powder, but would also survive a blast in which all the powder had been consumed.

|

15 |

Personal communication to subcommittee during its site visit to the ATF, March 19, 1998, and to the FBI, March 19, 1998; see Appendix F. |

- Chemical and physical compatibility with black and smokeless powders . The ideal taggant is compatible with all black and smokeless powders and has no measurable effect on the powder's material properties nor its performance characteristics. For example, the presence of the taggant has no effect on performance, safety, sensitivity, stability, shelf life, or ballistic properties. In all respects, the behavior of a black or smokeless powder with or without the ideal taggant is indistinguishable.

- No adverse environmental impact or contamination. The ideal taggant does not affect the environment in any way. It has no negative impact on the atmosphere, the soil, the water, or the food chain. The lifetime of the ideal taggant is comparable to the shelf life of the properly stored black or smokeless powder in which it is incorporated. Upon exposure to the elements, the taggant will naturally biodegrade or spontaneously decompose so that there is no environmental accumulation.

- Low cost to various links in the chain of commerce. The ideal taggant is comparatively inexpensive, representing a small fraction of the total cost of the smokeless or black powder in which it is used. This low cost includes the cost of the taggant itself, as well as all manufacturing, distribution, and tracking costs associated with the addition of the taggant. It is safe and simple to incorporate into production of the powders and has minimal, if any, impact on the production process. In addition, the attendant decoding equipment costs are low enough to be affordable to all law enforcement agencies.

- No viable countermeasures. The ideal taggant is exceedingly difficult to remove from the powder in which it is incorporated. The tagged smokeless or black powder looks, smells, feels, and behaves materially exactly like the untagged powder. The presence of the ideal taggant can be discerned only with appropriate equipment, but detection does not facilitate its removal from the powder. The information encoded in the taggant cannot be compromised or destroyed. The ideal taggant is not found in nature nor in common usage in industry. The presence of the ideal taggant at a crime scene is unequivocally indicative of the involvement of black or smokeless powders.

- Unique information that is easy to read. An ideal taggant provides unique information on the manufacturer and chain of custody of each black and smokeless powder in which it is incorporated. Gleaning this information is dependent upon the availability of reading and decoding equipment and applicable powder databases. The ideal taggant can provide useful information to each level (field to laboratory) involved in a forensic investigation.

Taggant Technologies

A large number of companies and other organizations proposed taggant concepts that were considered by this committee (see Appendix D). One of these taggant technologies (the 3M-type taggant) has been used since 1981 in explo-

sives in Switzerland.16 Some of the existing taggant technologies have been used in applications not related to explosives, such as animal feeds, perfume, personal hygiene products, and gasoline. Because many of these industries use taggants as a means to combat counterfeiting, the need to change the taggant code periodically is not as crucial as it would be in the smokeless and black powder industry.

Many of the taggant technologies presented to the committee remain in the conceptual stage, and extensive research, development, and testing would be required before the taggant would be a viable commercial product. If one of these underdeveloped technologies were chosen for use in tagging black and smokeless powder, immediate implementation would not be possible since extensive testing would need to be performed.

Taggant Classification

To understand better the potential features and limitations of proposed taggants, the committee developed a classification scheme for taggant technologies. The two general types of taggants, referred to as Class I and Class II, are discussed below, along with the criteria for ideal taggants identified above, in terms of their application to black powder and smokeless powder. The results are summarized in Table 3.1.

- Class I. Single entity. All coded information is contained within a single structural entity (this could be a macroscopic particle, a microscopic particle, or an individual molecule). The taggant cannot be subdivided, and the information content can be compromised only by destruction of the structural entity (i.e., the particle or molecule). This structural entity could be a particle of the material that is being tagged, or it could be a foreign particle that is mixed with the powder.

- Class II. Multicomponent. The coded information is provided by the presence or absence (and perhaps also by relative amounts or ratios) of several species that can be added individually to the material to be tagged. The information content can be compromised by selective removal or destruction of one or more components—or by adding any of these components (for example, by mixing with material that is tagged with a different coding ratio). Because the information content depends on relative quantities (or the presence or absence) of several components, it is essential to obtain a statistically valid sample at the crime scene.

Any taggant concept can be designed as either Class I or Class II, and methods of analysis would be similar. Class II taggants are more vulnerable to countermeasures. If identification occurs by determining the ratio of the compo-

TABLE 3.1 Classification and Summary of Proposed Taggant Concepts

|

Taggant Type |

Examples |

Comments |

|

Class I—Resistant to countermeasures: mixing could enhance information content rather than destroy taggant code |

||

|

1. Physical |

3M, Microtrace |

Used in Switzerland for explosives, including black powder for blasting |

|

|

Explotracer, HF6 |

Used in Switzerland for high explosives only |

|

|

Microdot |

No data available |

|

2. Spectroscopic |

Organic dyes (e.g., Alliant Red Dot) |

Currently used in smokeless powder |

|

|

Lanthanide (encapsulated) |

Original Westinghouse taggant |

|

3. Chemical |

Biomolecules (proteins, DNA) |

Used in inks, pharmaceuticals |

|

4. Isotopic |

Taggant added in which each ''particle'' has identical isotopic substitution |

No proposed use |

|

Class II—May be susceptible to countermeasures: mixing products could destroy code |

||

|

1. Physical |

Microbeads |

Used in animal feeds |

|

2. Spectroscopic |

Lanthanides |

|

|

3. Chemical |

Mixture of molecules added |

|

|

4. Isotopic |

Isotag LLC method using known, random ratios of deuterated compounds |

Inexpensive, isotopic mixtures |

|

|

Specific labeling |

Used in biochemical trace analysis; expensive |

nents in the taggant, mixing two powder canisters containing a Class II taggant that has two different codes presumably would destroy the taggant information. However, with some of the smaller taggant particle sizes, many taggant particles might adhere to the surface of the larger powder granules, effectively behaving like a Class I taggant. Another consideration is the loss in information that may occur when a Class II taggant is part of an explosive mixture. In an explosion, different components burn at different rates. Loss of information will occur if the different components of the Class II taggant degrade at different rates. Aside from these concerns about countermeasures and information loss, the advantages and disadvantages for Class I and Class II taggants would be similar. (Note that practically any Class II taggant could be converted to Class I by encapsulation.)

Taggants (Class I and II) can be subdivided into four categories, according to the way that the taggant information is encoded.

- Physical. The coding results from physically (or optically) observable properties of the taggant. Class I examples would include Microtrace taggants and miniature "bar code" particles (or some other type of particle with miniaturized "writing"). An example of Class II would be a mixture of different sizes (and/or colors) of glass microspheres.

- Spectroscopic. The coding results from the absorption or emission characteristics of the taggant. Class I examples include particles containing some combination of dyes or lanthanides, including dyes applied directly to individual granules of the powder. Class II examples include addition of a mixture (not encapsulated) of the same dyes or lanthanides to the powder.

- Chemical. The coding corresponds to the chemical structures of the individual taggant molecules, and the code is read by determining the molecular structure. Class I examples include biomolecules such as DNA or proteins, where each molecule contains the full code (which is read by some combination of biological and instrumental techniques). Class II examples include mixtures of compounds in which the code could be read by instrumental analysis.

- Isotopic. This type of coding results from isotopic labeling of one of the components of the powder (usually analyzed by mass spectroscopic techniques). Class I examples would use site-specific isotopic labeling of components of the powder. Class II examples include the Isotag LLC approach of adding a randomly generated (but unique) mixture of deuterium-labeled compound that has a characteristic fingerprint when analyzed by gas chromatography/mass spectrometry.

Evaluation of Taggant Concepts Against Ideal Characteristics

Using all available data, the committee grouped and evaluated proposed taggant concepts according to the stated ideal technical characteristics. As stated above, no taggant technology could be developed that fully meets each of these ideal criteria. But if these criteria were considered as a continuum, then it would be possible to implement a taggant that meets at least some minimum qualification for each of these categories.

The following section describes the issues that arise when considering taggant concepts against each of the ideal characteristics listed above in this chapter. The discussion is not specific to any particular taggant concept, and therefore broad general questions are raised, not all of which would be applicable to all taggant concepts. To illustrate the application of the ideal taggant criteria in a specific scenario, an example of a particular taggant concept and some of the associated research questions are presented in Box 3.1.

|

BOX 3.1 An Example of a Tagging Scenario and Related Research Questions Research on taggants represents the study of a complex system into which some unique material is introduced (the taggant). This material has only one function—to retain information that can survive a bomb blast, typically by being thrown out of the immediate zone of the explosion (along with unconsumed powder) in the course of the release of pressure during bomb-container rupture. The taggant in such a system might carry a variety of information that would allow law enforcement personnel to trace the bomb back to the perpetrator and support the prosecution of the bomber. The following example illustrates some of the research, technological, and forensic questions that need to be addressed to provide sufficient understanding of the use of taggants in black and smokeless powders before a tagging program could be instituted. Taggants could consist of a selected, large number of unique entities that might provide such information as manufacturer, product type, and lot number. These entities could use the following types of labels: various gene sequences; different isotopic ratios of the major powder constituents; or small micron-sized particles of different sizes, composition, and color. Using combinations of these entities, every can of smokeless and black powder potentially could have a unique combination. An appropriate record-keeping system would have to be in place to track the combinations of taggants in each container of the powder. Sample Scenario In one possible scenario, taggants on the order of 5 microns in size could be added to powder consisting of propellant granules roughly 500 microns in diameter at 0.02 percent by mass (assuming equal densities for taggants and the powder granules). The taggants could be added to the canister either concurrently during filling with powder or after filling with powder. In this situation, an individual powder |

No Real or Perceived Health or Safety Risks

The potential for health and safety risks can be considered for two different groups that might be affected: industry workers and end users. In both cases, any potential toxicity or health effects caused by the taggant material must be considered, and, for industry workers, any potential increase in the hazards of the manufacturing process caused by the inclusion of taggants must also be examined.

Biological or chemical materials would be used as taggants only if they do not produce adverse health effects. The "biological" materials that have been suggested for use as taggants could be synthetic materials rather than materials found in nature. Consequently, they would be designed in such a way that no adverse human health effects would be expected. In the case of chemical agents, it would be necessary to establish that any possible toxicity of an added taggant,

|

granule could have between 100 and 1,000 taggants adhered to its surface. The technical questions listed below could be raised about such a system. Statistical Uniformity of the Taggant Information Throughout the Powder Sample

Effect on Legitimate Use of Black and Smokeless Powders

Usefulness in Forensic Investigation After the Bomb Blast

|

or its associated combustion products, would not increase the health risks above any inherent risks posed by the powder itself.

Potential methods of exposure for users include the handling of tagged powders as well as breathing any fumes from the powder or reaction products that are produced in use, such as during the firing of a gun. Thus, the safety of any additives to such powders must be looked at from this perspective. This is not the case with taggants in high explosives where the use of such materials is remote from any operating personnel. Another potential area of concern would be whether the taggants affected the stability of powder in storage. It is possible that any new taggant used with black or smokeless powder could be shown to pose health or safety risks at very high concentrations of the taggants within the powder. However, when assessing the risks that the taggant may add to the use or manufacture of black or smokeless powder, the actual concentrations at which the taggant would be added must be a consideration.

The greatest safety risk during manufacture has been suggested to be the potential for explosion caused by friction associated with a particulate material that might be used as a taggant. The relative hardness and abrasive qualities of a multilayer acrylic particle (a Microtrace-type taggant) are lower than for the ingredients used in black powder manufacturing; on the other hand, they would be greater than the major components of smokeless powder. The Microtrace (originally 3M) taggant has not been used in the manufacture of smokeless powder, but has been used in the manufacture of black blasting powder used in the Swiss mining industry for almost 20 years without incident.

Any of the four taggant categories could be produced in a form that does not require the addition of macroscopic particles akin to the Microtrace taggant. Examples range from biological materials that could be added at extremely low concentrations, to organic dyes, such as those that are now added to smokeless powders containing color-coded propellant granules to identify a particular product.

Although the addition of taggants at low concentrations and in nonparticulate form suggests that tagging may not affect the performance or safe handling of a powder throughout its manufacture and use, any new material proposed for use as a taggant in either black or smokeless powder would have to be carefully evaluated.

Wide Forensic Applicability and Utility for Law Enforcement

To some extent the law enforcement value of a taggant is directly related to its information content (Box 3.2). At one extreme, a taggant with high information content may be correlated with an individual package of powder, and recovery of a taggant at a crime scene could enable investigators to establish (through an audit trail through the sales and distribution network) a direct link with a bomber—or at least to the individual who purchased the powder. At the other extreme, a low-information taggant (such as the red propellant granules added to Alliant's Red Dot powder) might establish only the identity of the manufacturer and type of powder. But even here the value to law enforcement could be substantial. The existence of an audit trail could allow investigators to focus on the subset of sales of that particular type of powder, enabling them to enhance their traditional investigatory procedures in their search for possible suspects. Also, information about the purchase of a particular type of powder by a suspect might help law enforcement officials to establish sufficient probable cause and obtain a search warrant.

Even in the complete absence of any information from an audit trail, a taggant could provide useful information in a criminal prosecution. If a taggant recovered from the scene of a bombing or attempted bombing were found to be the same as that in black or smokeless powder found in the possession of a suspect, that information would be another piece of circumstantial evidence linking the suspect to the crime.

|

BOX 3.2 How a Taggant Can Assist Law Enforcement There are various ways in which a taggant could be used by law enforcement personnel in identifying a bombing perpetrator or convicting a known suspect. The examples below are not meant to represent a complete list of uses; they instead provide illustrations of varied taggant applications. Furnish Information That May Justify Issuance of a Search Warrant Scenario 1. Unconsumed smokeless powder recovered at a bombing scene has been identified as to manufacturer and product type. During the past year, the manufacturer and its master distributor sold thousands of pounds of this product to eight retail outlets in the geographical area of the blast. These outlets also carry many other powder products. When an investigator shows a salesclerk at one of these outlets a number of photographs, including photographs of an individual under suspicion because of a possible motive, the salesclerk states that this individual has bought smokeless powder in the past, but the clerk has no idea what kind of powder was bought. On the basis of this information, a law enforcement agent would probably not be able to obtain a warrant authorizing a search of the suspected individual's premises. Scenario 2. The unconsumed smokeless powder recovered at the bombing scene from Scenario 1 also contained a taggant that identifies the manufacturer, product, and date of manufacture. Records indicate that 100 pounds of the tagged product were sold to two retail stores in the geographic area of the blast. When investigators check the retail stores' records, they find that three individuals bought cans of the tagged powder. One of these individuals, who has a possible motive, signed the store's register when buying a 1-pound can of the tagged product 2 weeks before the blast. Under these circumstances, a magistrate might find sufficient "probable cause" to issue a warrant for the search of the purchaser's premises. The search might yield incriminating physical evidence, such as other materials used in making the bomb, which would not otherwise be found. Furnish Information That May Lead to an Indictment Scenario 3. During the legal search of the home of a suspect in a recent bombing, law enforcement agents find the remnants of a box of black powder that contains a taggant. The tagged powder matches the powder and taggant recovered after a previous pipe bomb incident for which no arrests have ever been made. This evidence could lead to an indictment of the suspect for the earlier bombing. Constitute Evidence at Trial That May Lead to a Conviction Scenario 4. No unconsumed powder was found at the scene of a bombing, but taggants were found at the scene. When the taggant code was determined, investigators concluded that the bomb had been filled with black powder manufactured by company X during a particular period. During a legal search of the home of a bombing suspect, law enforcement agents find remnants of black powder containing taggants that match those found at the bombing scene. The evidence of the match could be admissible at trial as it increases the probability that the suspect manufactured the bomb in question. |

Chemical and Physical Compatibility with Black and Smokeless Powders

This characteristic refers to the compatibility of the taggant with the manufacturing process for black and smokeless powders as well as its compatibility with criteria for safety and performance of the final products. The issues and problems are similar to those discussed above for health and safety risks. For the U.S. Office of Technology Assessment (OTA) report (OTA, 1980), some testing was performed on the compatibility of the 3M (Minnesota Mining and Manufacturing Company) taggant with various black and smokeless powders (see Box 3.3 for excerpts from this report). Because follow-up testing has not been carried out since the moratorium on taggant research in the early 1980s,17 there is no comprehensive information about the overall compatibility of this or any other taggant type with all black and smokeless powders.

Consequently, even in the absence of any predictable chemical interactions between a proposed taggant and a black or smokeless powder, one could not be certain that the two would be compatible. Any new material proposed for use as a taggant in either black or smokeless powder would have to be carefully evaluated for chemical and physical compatibility. (For further discussion on the types of tests necessary for investigating chemical and physical compatibility, and for a representative listing of organizations capable of conducting such tests, see Appendix G.)

Compatibility of Taggants in the Black Powder Process. The chemical and physical compatibility of black powder with many of the taggants now commercially available needs to be researched. Some questions to be addressed are the following:

- What reactions, if any, occur between the taggant material and the potassium or sodium nitrate, sulfur, and charcoal in black powder?

- If a reaction occurs, what are the effects of elevated temperatures, pressures, and water concentration?

- Can the taggant serve as a catalyst for the decomposition of the black powder?

- How would any reactions affect stability, sensitivity, and the ballistic performance of the black powder?

|

BOX 3.3 Selections from the 1980 Office of Technology Assessment (OTA) Report Taggants in Explosives As noted earlier, research on integrating taggants into smokeless and black powder is highly limited. The analysis done by OTA covered addition of the (then) 3M taggant into both high and low explosives, and was based on independent research by the Aerospace Corporation (which received information from four subcontractors, Atlas, DuPont, Hercules, and Independent) (OTA, 1980; Aerospace, 1980). The OTA findings relating to smokeless and black powder were as follows:

|

- Can the reaction of a taggant with black powder be suppressed or eliminated without adversely affecting the desirable taggant characteristics and the performance of the black powder?

- Regarding biochemical taggants, are the biological materials capable of surviving in the sulfur-rich environment of conventional black powder?

Compatibility of Taggants in the Smokeless Powder Process. Similar concerns and a lack of information on the chemical and physical compatibility of taggants with smokeless powders exist as they do for black powder. A typical smokeless powder will have 5 to 10 components. These multiple components create a potential for complex and possibly adverse chemistry to exist between a smokeless powder and a taggant material. Information is lacking on the effects of various taggants on the rheology, chemical stability, sensitivity, and ballistic performance of smokeless powders. Also, little is known concerning taggant survivability in the various powder manufacturing processes. Clearly, the chemical and physical compatibility of taggants with smokeless powders also needs to be thoroughly researched.

Effects on Performance. While the smokeless powder industry routinely uses colored dyes (for example, in the manufacture of products such as Alliant Red Dot powders), the dyed granules are themselves propellant powders. The dye has been demonstrated to have no effect on the ballistics or on other physical properties of the powder. It is critical that the effects on performance of any other type of new additive be rigorously investigated. Examples of the types of ballistics testing that would need to be conducted in order to quantify the effects of taggants on the performance of powder used in ammunition are discussed in Appendix G. Also listed in Appendix G are some laboratories that are capable of conducting such tests.

No Adverse Environmental Impact or Contamination

Many of the issues related to environmental impact are the same as those considered above with respect to health and safety in manufacture and end use. There is a shift in focus, however, from those who are directly exposed to those who may be affected in the longer term by residues from manufacturing or discarded powders or from residues that survive the intended use of the powder as a propellant. For both new and existing taggant technologies, the decomposition rates of the taggant in the environment must be determined, and research must be performed on the potential environmental impact.

Low Cost to Various Links in the Chain of Commerce

Introduction of new regulation into any manufacturing process almost always incurs new costs, at least initially. On the issue of introducing taggants into

black and smokeless powders, the question of the cost of this program must be considered in light of the relatively low cost of the final product.18 A tagging system that is excessively expensive may drive some of the powder manufacturers and distributors out of business. In the absence of even a pilot taggant program in the black and smokeless powder industry, costs are difficult to establish definitively. However, the expertise of the committee, combined with the large number of briefings by and visits to representatives from the powder manufacturing and distribution businesses, and the limited experience of tagging in Switzerland, make possible reasonable discussions of the factors affecting costs.

Factors Affecting the Cost of Taggant Materials. The cost for any given taggant is generally expected to correlate directly with its level of information content. The frequency with which the taggant is changed and how much of each version of the taggant is purchased also affect the price. A low-cost taggant whose code never changes incurs minimal cost (an example is the addition of dye to the propellant granules). As stated earlier, however, such a taggant provides only information as to the identity of the company that manufactured the powder and, perhaps, the product line. At the other extreme, an expensive taggant that contains a great deal of information and whose code must be changed daily would be expected to have high costs for the manufacturers of black or smokeless powder. Presumably, the costs of taggants also depend on how much of each particular taggant code was purchased; economies of scale could reduce the taggant purchasing cost. Another factor that would affect the price of the taggant material needed is the concentration of taggant in the powder.

There are many possible and plausible combinations of lot sizes, loading levels, and cost per pound for unique taggants, each yielding a specific added cost for the taggant per pound of powder. In Switzerland, where 3M-type taggants are added to commercial explosives, added costs for the taggant have been reported as $0.08 and $0.16 per pound of explosive, depending upon the mesh size of the taggant. (In Switzerland, the 3M taggant is added to commercial dynamite in concentrations of 0.025 percent.)19

Estimates can be made of the expected order of magnitude of the cost of purchasing taggants to be added to black and smokeless powders. Table 3.2 gives a range of approximate costs for a variety of tagging schemes based on stated assumptions about taggant concentrations, the cost of the taggants per pound, the amount of powder produced annually, and the size of a powder lot. It is important to note that these cost estimates take into account only the cost of the taggant; attendant administrative, production, and processing costs to the smokeless or black powder manufacturer have not been estimated. Under these assumptions, the cost of taggants needed for a pound of powder remains relatively constant at between $0.05 and $0.50 for changing taggant codes for time intervals ranging from annually to daily. The costs go up if the added taggant is specific to each lot or shift.

Factors Affecting the Cost of Incorporating the Taggant. The cost of incorporating a taggant is dependent on how and where it is introduced in the manufacturing process. The two main parts of the production process that would be affected by tagging are the recycling of surplus powder and the cleaning out of the manufacturing equipment. As stated previously, in both black and smokeless powder production, a great deal of rework is involved, when powder from different stages of production is returned to the initial production step for various reasons. Contamination could result from the reworking of powder with old taggants already incorporated. The added costs to avoid such contamination would depend on where in the manufacturing process the taggant was added, the amount of reworking that occurred, and how often the taggant code was changed.

When the taggant code was changed, it would be necessary to clean out the production equipment completely to reduce the chances of contamination. The added costs of this cleaning would depend on the frequency of changing the taggant code, the difficulty involved in cleaning the equipment, the amount of production time lost, and the level of manpower required to clean out the equipment. Such costs could be significant. However, a low-information taggant that was rarely, if ever, changed would not be expected to incur high additional cost.

At least initially, additional cost would also be expected for new equipment to incorporate the taggant into the powder and for modifications to existing equipment and production methods. These start-up costs should decrease as the taggant methodology is perfected.

In Switzerland, 3M-type taggants are incorporated into black powder used for blasting. According to two manufacturers of this powder, one taggant code is used in 15 metric tons of powder (roughly 4 months worth of production), and the tagging process has not resulted in major cost increases.20 This is the only

TABLE 3.2 Estimated Costs of Taggant Material Depending on Concentration and Frequency of Change

|

Frequency with Which Taggant Code Is Changed |

Pounds of Powder Produced During One Tagging Cycle |

Pounds of Taggant Material Required per Change |

Cost ($) of Taggant Material per Change |

Cost ($) of Taggant Material per Pound of Powdera |

|

Annually |

6,000,000 |

1500.0–3000.0 |

300,000–300M |

0.050–0.500 |

|

Semiannually |

3,000,000 |

750.0–1500.0 |

150,000–150M |

0.050–0.500 |

|

Monthly |

500,000 |

125.0–250.0 |

25,000–250,000 |

0.050–0.500 |

|

Weekly |

120,000 |

30.0–60.0 |

6,000–60,000 |

0.050–0.500 |

|

Daily |

24,000 |

6.0–12.0 |

1,200–12,000 |

0.050–0.500 |

|

Per lot |

10,000 |

2.5–5.0 |

1,000–5,000 |

0.100–0.500 |

|

Per shift |

8,000 |

2.0–4.0 |

1,000–5,000 |

0.125–0.625 |

|

NOTE: The following assumptions are made:

a This column represents the cost of purchasing the taggant materials and excludes any costs associated with the powder manufacturing process. |

||||

example of the use of taggants in black or smokeless powder; data on the costs of other taggant technologies or other rates of code changes are not available.

Factors Affecting Costs in the Distribution System. At present, record keeping in the distribution system is mainly an in-house process at the manufacturing or distribution facility; in general, no records are maintained that link records throughout the distribution system. Two methods of additional record keeping potentially may be employed. The first would consist of the powder packagers maintaining records of lot shipments to retailers or other distributors. The level of difficulty in implementing such a system would be expected to depend on the volume of sales and the number of customers. If the record keeping were simply carried out at each stage of distribution, the advantages provided by good records, such as increased information for sales and marketing purposes, might actually outweigh any added costs.21 Alternatively, a centralized record depository may be put in place to track shipment throughout the distribution system. Besides the likelihood that such a repository would be cumbersome and expensive to maintain, confidentiality issues would be a key concern for the packagers and distributors.

Record keeping at the retail level can also provide law enforcement personnel with the opportunity to identify the last legal purchaser of smokeless or black powder. Current record keeping varies widely with both retailer and state (see discussion earlier in this chapter on record keeping at the federal, state, and local level). A nationwide requirement that customers sign for the purchase of black and smokeless powders is one system that could aid law enforcement personnel in their investigation of bombing incidents. As stated previously, even in the absence of a tagging program, several forensic investigators contacted by the committee indicated that it would be useful in bombing investigations to be able to obtain from local retailers a list of individuals who had recently bought the type of powder used in the bombing.22 As with increased record keeping at the distribution level, the question of where the records would be kept, whether with the retailer or in a centralized record-keeping location, must be determined. Another consideration at this level is the privacy of an individual who purchases black or smokeless powder for legal uses. However, there are already some situations today in which purchasers of potentially dangerous items are required to show identification. For example, the purchase of prescription medicine at a pharmacy is one consumer transaction that requires registration information at

|

21 |

These factors are contributing to the increasing use of bar codes to track products in all areas of commerce. |

|

22 |

Personal communications during site visits to the ATF and the FBI, March 19, 1998. See also Appendix F. |

the point of sale. In this case, the regulation is designed to control the distribution of potentially dangerous drugs and ensure that they are used under the supervision of a physician.

Factors Affecting Costs to the End User. Increased cost from any taggant program may eventually be passed on to the consumer. But in the absence of accurate cost estimates for the above categories, no definitive estimate of this price increase can be made. The estimates of the costs of the taggant materials made in Table 3.2 indicate that the added cost could be expected to be at least $0.05 to $0.50 per pound of powder, which corresponds to a price increase of at least 0.3 to 3 percent for a $15 1-pound canister of retail powder.

No Viable Countermeasures

Various types of taggants have differing degrees of vulnerability to countermeasures. For example, water solubility may allow for the removal of a taggant by washing smokeless powder. Visible taggants may be removed manually. Other types of taggants may degrade over time, compared with the long shelf life of black and smokeless powders (from 20 to 50 years). Some taggants, such as biological materials, can be expected to have much greater resistance to countermeasures; however, they would be correspondingly more difficult to isolate and evaluate for forensic purposes. As noted earlier, depending on the amount of taggant associated with an individual powder granule, the Class II taggants may be inherently more vulnerable to countermeasures—either through partial destruction of certain components of the taggant, or through blending of two samples having different mixtures of taggant codes.

Besides actively tampering with the taggant in black or smokeless powder, other options are available for circumventing the effects of taggants completely. Homemade black powder is relatively easy to make, although the quality tends to be substandard, and the manufacturing process is dangerous. Recipes for the manufacture of black powder are readily available on the Internet.23 Another option is to obtain untagged black or smokeless powder through the black market. A final consideration is that if black or smokeless powder used for reloading is tagged, bombers may seek out other sources of explosive materials to be used in improvised bombs. As a result, pyrotechnics and homemade chemical mixtures could become a more common ingredient in these illegal devices.

Unique Information That Is Easy to Read

While the usefulness of a taggant is somewhat related to the amount of information it contains, even a low-information taggant can still be valuable. A low-information taggant, such as dyed powder granules in smokeless powder, can provide investigators only with the product manufacturer and product line. However, forensic experts have indicated that the presence of red or blue dots in smokeless powder is sometimes of considerable help in their work, because this information can eliminate hundreds of other possible types of smokeless powder.24

With more sophisticated types of taggants, a great deal of information that possibly would allow tracing to individual 1-pound canisters of powder may be retrieved from a single taggant. However, as useful as this information may prove to be, the analysis is much more complicated than for a simple dyed-powder-granule taggant. For example, the instrumentation required to read the information from a DNA taggant can cost up to $70,000.25 Isotopic taggants also require analysis using expensive instruments. The information content must be weighed against the added complexity and cost of the analysis. One proposed method to lower the costs to forensic laboratories is to subcontract the analysis of postblast powder evidence to independent laboratories for taggant retrieval and decoding.26

Experience with Taggants in Explosives

The experience with taggants in black powder and high explosives in Switzerland provides some information on the utility and difficulties that might be expected in developing or implementing taggants for the U.S. black and smokeless powder markets.

Taggants in High Explosives

Commercial implementation of taggants in explosives is largely limited to one type: a plastic multilayered chip in which the sequence of colored layers provides the coded information. This taggant was originally made by 3M and is now manufactured by Microtrace, Inc., in the United States. This taggant was

tested extensively for use in explosives and, to a more limited extent, for use in propellants during the 1970s and has been used by the Swiss explosives industry since 1981.27 Because there are more test data on the use of Microtrace taggants in explosives than any other type of taggant, the term "taggant" has come to be identified in the popular press with this type of multilayered plastic chip. There is, however, a wide array of taggant concepts in various stages of development (see Table 3.1 and Appendix D). In addition, the use of taggants in nonexplosive commercial applications may provide guidance for the use of taggants in smokeless and black powder.

Use of Taggants in Switzerland

Switzerland requires the use of taggants in all explosives, including black powder used for blasting purposes. However, because smokeless powder and black powder sold for shooting purposes are not tagged, there is little information from the Swiss experience that is directly applicable to the task of the committee. For example, only a single instance of a bombing with tagged black powder was reported between 1989 and 1994 (NRC, 1998, p. 204, Table F.1). Currently, two manufacturers produce the type of black powder used in Switzerland as a blasting agent: Poudrerie d'Aubonne and Kemijiska Industrija Kamnik. Both companies report that they incorporate 3M taggants into the manufactured black powder at the beginning of the mixing operation, at concentrations of 0.025 percent by weight (the process of manufacture is very similar to that described in Chapter 1 and employed at Goex, Inc.). Poudrerie d'Aubonne tags approximately 40 metric tons of black powder per year, changing the taggant code every 15 metric tons. The cost of the taggant material is 550 Swiss francs per kg ($395.68 per kg),28 with no information given on increased costs due to processing or record keeping, though records were said to be kept in the same manner as normal production records. The company reports no deviation from standard industry practice, nor any difficulties added to the process due to taggant inclusion. There are no special considerations taken to separate rework from the process, nor is concern raised over potential taggant contamination during a code change. The Slovenian company tags roughly 25 tons per year. It reports an increase in production costs owing to its policy of burning rejected material rather than recycling it and contaminating the taggant code.29

As implemented in Switzerland, the taggant carries information about the explosive manufacturer, the product type, and general information about the time of manufacture (for reasons of manufacturer convenience, taggant codes are only changed every 6 months). The Swiss police consider their tagging program to be a success, based on the data about their bombing investigations. Between 1989 and 1994, the total number of incidents in Switzerland using black powder was 61, of which only 1 incident involved tagged black powder (there were 7 incidents involving smokeless powder, which does not contain taggants) (NRC, 1998). While the small number of incidents using tagged versus untagged black powder may argue in favor of the effectiveness of taggants, only black powder used for blasting purposes is tagged in Switzerland. Black powder used for sport shooting is not tagged. Presumably, black powder used for sport would be easier to obtain than black powder used for blasting and may account for this discrepancy in numbers. In addition, the overall low number of incidents makes any generalizations about the effectiveness of taggants difficult. Despite the reported success of the taggant program in Switzerland, no other country has chosen to adopt taggants in its explosives industry.

Taggants in Black and Smokeless Powders

As noted earlier, black and smokeless powders designed for shooting applications are not tagged in Switzerland. In the United States, OTA reported that tests on the Microtrace (then 3M) taggant in black and smokeless powder raised compatibility issues with one type of smokeless powder, Herco (OTA, 1980). Some compatibility testing was conducted by Lawrence Livermore Laboratory at elevated temperatures (80 to 120 °C) and taggant concentrations (50 percent).30 Further research was recommended by OTA, but because research funding on taggants was terminated in the United States in 1980,31 the compatibility of these taggants with propellant powders has not been definitively assessed. The results of the early testing on taggant feasibility were discussed in the 1980 OTA report, selections from which are given in Box 3.3.

The information provided by the OTA's 1980 report indicates that, at least

for the 3M taggant, no incompatibilities were found with black powder, and only one negative result with the Herco smokeless powder. OTA did not perform any performance or safety tests, but instead relied on data from research done at the Aerospace Corporation and on information provided by powder manufacturers. Aerospace Corporation's 1980 report does not mention any incompatibilities between the 3M taggant and smokeless powders.32

Though not intended as such, some commercial smokeless powders in the United States do already incorporate a kind of taggant. Alliant Techsystems manufactures smokeless powders that contain propellant granules marked with dyes of various colors. These Red Dot, Green Dot, and Blue Dot products aid the reloader by providing a visual identification of the product in a reloading machine. However, these dyed products also have served another purpose: bomb investigators have indicated to the committee that recovery of the dyed powder granules at a bomb scene facilitates the identification of the powder used and aids the investigation.33

Summary

Depending on the amount of information encoded in the taggant, the frequency with which the manufacturer changes the codes, and the extent of record keeping in the distribution system, tagging of black and smokeless powders could provide investigators with information on the manufacturer, specific product type, and chain of ownership. Taggants could also help to determine if different bombing incidents are connected, and once a suspect has been identified, taggants from a bomb scene could be matched with taggants found in the suspect's possession in order to assist in the prosecution.

Discussion

The current capabilities of investigators and possible benefits of taggants for the investigation of bombings using black or smokeless powders are summarized in Tables 3.3 and 3.4. The current ability to use chemical and physical methods

|

32 |

During the committee's open meetings (see Appendix E), several participants commented on the possible implications of an explosion at a Goex manufacturing site in East Camden, Arkansas, that occurred in July 1979. As noted in the ATF's Progress Report: Study of Marking, Rendering Inert, and Licensing of Explosive Materials (Department of the Treasury, 1997), ''While Goex asserted that taggants in boosters which were being reworked caused the explosion, it has never been established that taggants were involved in, or the cause of, the explosion.'' The committee further notes that the Goex plant in question was manufacturing high explosives rather than smokeless or black powder. |

|

33 |

Personal communication during subcommittee site visit, Ron Kelley, Federal Bureau of Investigation, March 19, 1998. |

TABLE 3.3 Level of Current Capability in Chemical and Physical Analysis in a Forensic Investigation and the Incremental Value of Taggants

|

|

Capability with Current Forensic Methods (without Taggants) |

|||

|

Task |

For Black Powder |

For Black Powder Replicas |

For Smokeless Powder |

Incremental Value of Taggants |

|

Identification of powder materiala |

||||

|

Burnedb |

High—characteristic inorganic residue usually precentc |

Low to moderate—decomposition powders have characteristics similar to those of pyrotechnic compositions |

Not identifiable—combustion products are gases |

May be high if taggant survives and no residue is recovered |

|

Unreacted |

Readily identifiable |

Readily identifiable |

Readily identifiable |

Low—information usually available without taggants |

|

Identification of manufacturer of powder material |

||||

|

Burned |

Low—inorganic residues only |

Low—inorganic residues only |

Not identifiable—combustion products are gases |

May be high if taggant survives |

|

Unreacted |

Moderate—unburned black powder from the one U.S. manufacturer and some foreign manufacturers can be differentiated |

Moderate to high—relatively few manufacturers, and powders tend to contain characteristic additives |

High—powder size, morphology, and composition point to manufacturer |

Moderate for black powder and replicas; lower for smokeless powder as information is already available |

|

|

Capability with Current Forensic Methods (without Taggants) |

|

|||

|

Task |

For Black Powder |

For Black Powder Replicas |

For Smokeless Powder |

Incremental Value of Taggants |

|

|

Identification of product line/type (granulation or designation) |

|||||

|

Burned |

Low—inorganic residues only |

Low—inorganic residues only |

Not identifiable—combustion products are gases |

May be high if taggant survives |

|

|

Unreacted |

Moderate—mesh size provides some information |

Moderate—mesh size and chemical composition can provide useful information |

Moderate—can distinguish between ball, flake, and extruded; more difficult to differentiate within these categories |

Moderate to high—could identify product types if not already known |

|

|

a Ability of chemical analysis to distinguish between smokeless powder, black powder, and black powder substitutes. b Burned powder refers to the products resulting from deflagration of a powder in an explosion and excludes traces of unburned powder. This is an unlikely scenario, especially for smokeless powder, since unreacted powder is recovered or no solid combustion products remain. Further assumptions are made that no residue would have been dissolved by water or destroyed by fire. c Although inorganic ions found in burned black powder are common in the environment, their high concentration at a bomb scene would be characteristic of burned blacked powder. SOURCE: Adapted from information received on site visits by the committee (see Appendix F), presentations of law enforcement and forensic personnel, and Bender (1998). |

|||||

TABLE 3.4 Capability of Law Enforcement to Trace a Known Powder Used in an Improvised Explosive Device

|

Task |

Current Capability |

Capability with Adding Record Keeping Only |

Capability with Adding Taggants Only |

Capability with Adding Taggants and Record Keeping |

|

Identify a lot or batch |

Low |

Low |

Low |

High |

|

Identify distribution chain |

Low |

Low |

Low |

High |

|

Identify last legal purchaser |

Low (moderate in significant cases where a large effort is made to investigate retail outlets) |

Moderate—depends on the volume of sales of the powder |

Low |

High |

|

Trace the powder in a bomb to possible suspects |

Low (moderate in significant cases where a large effort is made to investigate retail outlets) |

Moderate—effective if bomber is the last legal purchaser, no aid otherwise |

Low |

Moderate |

|

Obtain supporting evidencea |

Low to moderate—value depends on frequency of specific powder use |

Moderate—could aid in identifying the time of powder purchase with respect to time of bombing |

Moderate to high—value depends on frequency of taggant code change |

High—record keeping may not be necessary if taggant code is sufficiently specific |

|

a Represents the utility of record keeping and/or taggants in strengthening evidence linking powder in a known suspect's possession with that used in a bomb. |

||||

to identify black or smokeless powder is compared with the incremental value of adding taggants in Table 3.3. In Table 3.4, the incremental value of taggants is indicated in light of the increased ability to trace a particular powder from the manufacturer to the last legal purchaser.

Implications of Taggant Use for the Analysis of Black and Smokeless Powders

The incorporation of taggants in black and smokeless powders could affect the standard analytical procedures currently used by forensic scientists. An established minimum amount of taggant would have to be found to allow scientists to be sure that the presence of the taggant was not a result of some kind of contamination (at the manufacturing, environmental, or evidence-collection stages). This minimum amount would depend on the taggant type, the amount of taggant per pound of powder, and the frequency with which the taggant was changed. For example, in the case of the multilayer acrylic particle (Microtrace) taggant, the Aerospace report (1980) established that 20 particles should be found at the bomb scene to ensure statistical accuracy of their presence. In Switzerland, law enforcement personnel must find 10 like-coded taggants in order to declare the use of a tagged explosive material in the exploded device (Schärer, 1996). In U.S. courts, it is highly probable that conventional analysis would be required to supplement taggant-based evidence and to negate arguments about contamination.

If visible taggants were used, a microscopic analysis might suffice to identify the taggant's presence and decode its information without resorting to detailed chemical analysis. If a taggant were used that was too small to be seen, the microscopic examination of debris and dirt would have to proceed as it would in the absence of taggant analysis to ensure the recovery of significant items of evidence. The search for and analysis of small (molecular-level) taggants could then probably proceed using one of the methods currently employed in the identification and analysis of untagged black and smokeless powders.

Table 3.3 indicates what are believed to be the levels of success of current forensic techniques in addressing the different aspects of an investigation of powder used in an improvised explosive device, as well as the committee's judgment about the incremental potential of taggants to increase this capability. Unfortunately, neither the ATF nor the FBI maintain statistics on the solve rate of criminal bombings, and so it is difficult to evaluate quantitatively the potential of taggants to increase the solve rate. Swiss authorities have claimed that in cases where taggants are recovered at the scene of a bombing, the solve rate is higher than in cases where no taggants are recovered.34

Matching the Bomb Filler to Materials in a Suspect's Possession

As noted earlier, many items of physical evidence, including unconsumed powders, containers, batteries, timing devices, tape, and so forth, typically survive a bomb blast. These may be used by investigators to connect a series of incidents or help identify the perpetrator if they can be matched to similar items proven to have been acquired by a suspect or matched to items found in the suspect's possession. This latter match is possible only if a suspect has already been identified and a search warrant obtained.

Taggants recovered at the bombing scene would provide an additional piece of evidence that could help connect serial bombings or provide a match with similar taggants in powders in the suspect's possession. The more specific the taggant, the greater its utility for these purposes. As noted in Table 3.3, using taggants to match bomb filler material to materials in a suspect's possession, unlike tracing a particular powder through the manufacturing and distribution process, is, independent of additional record keeping.

The data in Tables 3.3 and 3.4 indicate that current methods and techniques of forensic analysis of unburned smokeless powder or black powder residues recovered at the scene can be very helpful in determining the filler type, manufacturer, and even the product type, especially for smokeless powders. However, such recovered powders are by themselves of little value in identifying the last legal owner of the powder or in connecting the bomb to a particular suspect. Correspondingly, the incremental value of taggants is moderate for identifying the manufacturer and product type. The incremental value is relatively high for establishing the chain of possession of the powder if a record-keeping system is instituted with the taggant system, and the increase in the ability to link a particular bomb to a particular suspect is also high with either a record-keeping system or by using a sufficiently specific taggant code,