3

Air Vehicle Technology

TOWARDS NEW AIR VEHICLES

Airliners in the current fleet resemble the configurations introduced more than 40 years ago, with cylindrical fuselages, moderately-swept wings, and externally mounted engines. These configurations have benefited from gradual and continuous improvements based on advances in aerodynamics, structures and materials, and, above all, propulsion technology, and gradual improvements are expected to continue. However, it will be difficult to meet the aggressive NASA goals (in terms of both vehicle attributes and timing) for air transportation cost, efficiency, and environmental compatibility with traditional transport aircraft configurations because they are already highly optimized in design. Therefore, NASA should encourage the exploration of alternative transport configurations, which will require a creative, multidisciplinary approach that closely considers the interactions among airframe, propulsion systems, structural concepts, and control systems.

The development of advanced configurations for air vehicles is an obvious avenue towards meeting NASA's goals, but it is not the only avenue. In this regard, it is useful to classify air R&D into three types. The first is the creation of configurations that look radically different from present configurations. These advanced configurations may have the greatest potential for improvements, but they will also require the most long-term R&D focused on an in-depth understanding of systems integration. The blended-wing body (BWB) is a good illustration. The second category of R&D is focused on vehicle subsystems, such as propulsion systems, that can be applied to advanced air vehicle configurations or to configurations that resemble current configurations although new developments may greatly alter the way they operate. The third category involves major breakthroughs in the processes associated with vehicle development, such as manufacturing and design, which would, for example, enable substantial reductions in cost. These processes could be used for both existing and advanced air vehicle configurations. A major advance in any of these categories, alone or in combination with an advance in another category, may meet one or more of NASA's goals for air transportation.

TECHNOLOGY THRUST AREAS

In this chapter the committee proposes six critical technology thrust areas for new air vehicle configurations that could achieve NASA's eight air transportation-related goals.

-

advanced air vehicle configurations—designs with reduced weight, improved aerodynamic performance, and highly integrated airframe/propulsion systems that are substantially different from current air vehicle configurations. Advanced configurations could have a major impact on reducing the cost of air travel and improving the aviation system throughput and could enable the development of a high-speed civil transport aircraft that would reduce travel time to the Far East and Europe.

-

embedded sensors and controls—intelligent gas turbine engines that can control aeroacoustic, aerodynamic, aerothermodynamic, and aeromechanical instabilities, and aircraft with embedded active control systems for controlling loads, reducing drag, and monitoring health. Embedded sensors and controls could reduce noise, emissions, and costs through more effective diagnosis and maintenance processes.

-

structures and materials—low-cost composite materials, including the manufacturing processes associated with them, new corrosion-resistant, damage-tolerant alloys, and engineered and smart materials. Advanced structures and materials could lead to reduced fabrication and life-cycle costs and reduced travel time (by enabling economically viable commercial supersonic flight) and could expand the general aviation market by creating more options for designing efficient, cost-effective aircraft.

-

advanced propulsion and power—innovative approaches to gas turbine engines with substantially fewer parts and enhanced performance through active control. This technology area could also include propulsion systems with no rotating components (such as pulse detonation wave engines), alternative engine concepts, and alternative fuels. Advanced propulsion and power technologies could contribute to reductions in noise, emissions, air travel cost, and travel time (with high-speed commercial flight).

-

advanced manufacturing—automated manufacturing, including precision manufacturing, automated assembly, and fabrication by light, as well as further applications of lean manufacturing techniques. The major impact of advanced manufacturing would be to reduce the cost of commercial aircraft and possibly the cost of general aviation aircraft.

-

computer-based design, modeling, and simulation—virtual design and testing that could replace, or at least greatly reduce, the time and cost of testing aircraft and propulsion systems and could provide the capability for multidisciplinary design

-

optimization and virtual prototyping. Enhanced modeling and simulation could further NASA's goals related to the cost of air travel, air vehicle design time, general aviation, and high-speed air travel. If models of the air traffic management (ATM) system are included, this technology area could also advance the goals related to safety and throughput.

The impact of these six thrust areas on the eight NASA goals associated with air vehicle technology is illustrated in the matrix shown in Table 3-1. The goals are the horizontal rows, and the technology thrust areas are the column headings.

TABLE 3-1 The Six Air Vehicle Technology Thrust Areas and NASA's Eight Air Transportation-Related Goals

|

|

Advanced Air Vehicle Configurations |

Embedded Sensors and Control Systems |

Structures and Materials |

Advanced Propulsion and Power |

Advanced Manufacturing |

Modeling and Simulation |

|

Emissions |

L |

M |

M |

H |

L |

M |

|

Noise |

M |

H |

M |

M |

L |

M |

|

Safety |

L |

M |

L |

L |

L |

H |

|

Throughput |

M |

M |

L |

L |

L |

H |

|

Travel Cost |

H/M |

M |

H/M |

H |

H/M |

H/M |

|

Design Time |

L |

M |

H/M |

L |

H/M |

H |

|

General Aviation |

M |

L |

H |

M |

H |

H |

|

Travel Time |

H |

L |

H |

H |

H |

H |

|

L = Low impact on achieving the goal. M = Moderate impact. H = High impact. |

||||||

Advanced Air Vehicle Configurations

This first technology area involves exploring new vehicle design concepts that are based on the overarching necessity for the total integration of component technologies in the development of air vehicles. In addition to benefits, most new technologies create penalties, such as increases in weight or cost or decreases in reliability. The payoff of a new

technology must be evaluated in terms of its influence on a complete configuration. The importance of this configuration-driven systems analysis cannot be overemphasized.

In addition to the exploration of full vehicle configurations, two aspects of advanced vehicle design that cut across a number of proposed configurations warrant special attention: (1) advanced technologies for reducing drag and (2) novel methods of increasing vehicle performance through more effective integration of the propulsion system and airframe to maximize aerodynamic efficiency.

Advanced Configurations

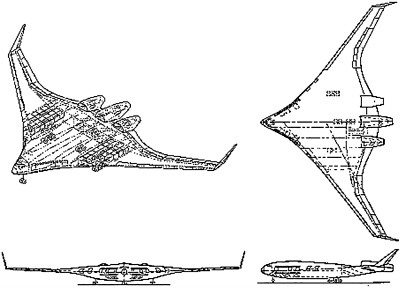

One example of a radically different configuration from current subsonic commercial transport aircraft is the BWB (blended-wing body) being investigated by Boeing and NASA. The BWB is a useful example of the performance level that may be achievable from novel designs. The BWB concept, shown in Figure 3-1, is a large commercial transport design that improves aerodynamic performance by joining hitherto separate aircraft components, such as engines, wings, and fuselage, into a unified frame (Liebeck et al., 1998). Some of the potential advantages of this design over existing designs are shown in Table 3-2. Aircraft purchase prices are directly related to operating empty weight; therefore, a 12 percent reduction in weight will mean a corresponding 12 percent reduction in the initial purchase price, assuming that manufacturing costs remain the same.1 A 27 percent reduction in fuel consumption would also reduce fuel costs, which currently accounts for about 15 percent of total airline costs. Reductions in fuel consumption will also mean lower levels of engine emissions and noise compared to conventional aircraft carrying the same number of passengers over the same distance.

The twin-fuselage/midwing configuration is another example of an unconventional design, but unlike the BWB, it has not been studied in any detail. However, this design deserves renewed consideration because of a number of inherent advantages. For example, the outboard fuselages are detachable to provide logistical flexibility, and the empennages are designed to recoup some of the energy from the wing-tip vortex and convert it into thrust to offset the high induced drag of the short-span center wing. The center wing can be designed with a lightweight structure, because the wing bending moments are reduced through the counteracting inertial loads of the fuselage masses. A lightweight wing structure would lower empty operating weight compared to the weight of a conventional aircraft with equivalent range and cargo capacity.

Although both of these concepts look promising, the adoption of either one as a commercial transport aircraft is unlikely until their viability can be proven under actual flight conditions. Existing air transportation system rules would also have to be modified to accommodate the operating procedures these new configurations would require. Other

advanced concepts, including the box wing and the strut-braced wing, should also be assessed for their potential to meet NASA's goals.

FIGURE 3-1 Isometric view of the BWB airplane. Source: The Boeing Company

Drag Reduction Technologies

Meeting the goal of establishing supersonic air travel at current subsonic travel prices will require improvements in aerodynamic performance through the reduction of drag. Some concepts, such as the generation of a weak plasma flow field to weaken shock strength and laminar flow control, have been shown to have some benefit, but they have not been adopted for use on commercial aircraft because of uncertainties about their costs versus their potential benefits. The integration of these techniques within a supersonic aircraft will have to be investigated before the cost/benefit trade-offs can be determined.

The potential for reducing a supersonic aircraft's shock wave as a means of reducing drag is currently being investigated in a joint NASA/Air Force project. Interest in this concept stems from reports in the Russian literature indicating that the shock structure in a weakly ionized gas at high temperature (plasma) is significantly weaker than in nonionized gases at the same temperature. If this phenomenon can be confirmed, and if interference with communications and sensing equipment is not a problem, shock waves could potentially be reduced during supersonic flight by projecting a weakly ionized plasma flow field into the airflow directly in front of the aircraft. Although operational issues, such as the power

requirements for plasma generation, may make this idea applicable only in the long term, its technical promise for mitigating sonic boom should be explored now.

TABLE 3-2 Performance Comparison between the Boeing/NASA BWB and a Baseline Conventional Aircraft Configuration with Equivalent Component Technologiesa

Aerodynamic/Propulsive Integration

One way to explain the potential benefits of airframe/propulsion integration is to consider the phenomena of flight using the surrounding air as the frame of reference rather than the air vehicle. The issue of interest is how the airframe affects the airstream. Minimizing the residual disturbances of the airframe and propulsion system on the airstream, which will improve overall aerodynamic performance, requires a higher degree of airframe/propulsion integration. Wake-ingesting propulsion system configurations (which increase the efficiency of the propulsion system) and devices that mitigate wing-tip vortices (possibly by placing engines on wing tips) could be components of integrated aerodynamic/propulsive systems. It may also be useful to investigate the potential for distributed propulsion, either

through electric motors powered by fuel cells or, possibly, arrays of much smaller propulsion devices, such as microengines. If these devices were placed along the trailing edge of the wing, they might reduce profile drag and control lift in addition to providing propulsion.

Finding. Advanced air vehicle configurations that include novel wing designs, drag reduction technologies, and aerodynamic/propulsion integration could lead to substantial progress toward meeting four of NASA's goals: reduced air travel costs; reduced noise and emissions levels; increased aviation system throughput; and high-speed air travel. In general, advanced configurations represent high-risk technologies with potentially high payoffs.

Embedded Sensors and Controls

Embedding sensors and actuators in the subcomponents of air vehicles, such as the airframe structure and the gas turbine engine, will allow many physical properties to be monitored and controlled in a manner that would improve performance and reliability and should advance NASA's air transportation goals. NASA can contribute to this area of technology by supporting the development of new sensors and actuators and the signal processing capability required to use sensors and actuators together.

Aircraft with Controlled ''Adaptive" Structures

Controlled "adaptive" structures include a wide variety of structural concepts that could be useful for both air and space vehicles. Applications include aerodynamic and acoustic load control and reconfiguration and load control in response to structural damage to flight systems. Controlled adaptive structures will not only reduce weight, but should also contribute to aircraft safety and reliability.

Although the development of lower cost, more reliable new sensors and actuators could lead to breakthroughs in the design of air vehicle configurations by allowing designs with marginal vehicle stability and greater flexibility, the most important near-term and midterm application of controlled structures is the monitoring and management of vehicle health. Structural health monitoring and diagnostics add "nerves" to the aircraft system that continuously sense the health or "state" of an aircraft's structure during operation. Parameters include characterization of load spectra for individual components, detection of damage, and monitoring of the severity of damage to determine if repairs are needed, either on the ground or in flight.

Real-time, onboard health monitoring can provide important safety-related information to both operations planners and pilots. The miniaturization and packaging of nondestructive testing equipment, perhaps through the use of microelectro mechanical systems (MEMS), for the onboard detection of cracks or other damage could alert pilots to structural or

engine damage before it becomes critical. This information could also be acquired, stored, and re-acquired, either in flight or on the ground, where it could be retrieved by maintenance organizations, making inspection and repairs less costly and time consuming.

Even though rudimentary health monitoring and management systems are already in use on some military and commercial aircraft, breakthroughs are needed to make these systems more capable. Sensors must be reliable and small enough to be embedded in or attached to a structure, and they must be inexpensive to buy and maintain. Advances are also needed in network, processor, and data storage technology, as well as signal processing capability.

Intelligent Gas Turbine Engines: Moving from Proof of Concept to Deployment

Gas turbine engines are highly optimized and tightly constrained propulsion systems that operate near a number of operational limitations. Improvements in performance often come from small (although hard won) changes in design boundaries. One idea that may allow step improvements is much greater use of closed-loop feedback control either to take better advantage of existing operating margins or to move the operational boundaries. The words "closed-loop feedback" imply a range of possibilities, including concepts such as designing engine operation to maximize life, monitoring engine conditions to enable retirement for cause, and actively controlling aerodynamic and aeromechanical instabilities, such as surge, rotating stall, flutter, main combustor instability, and instabilities associated with after-burner systems. In addition, intelligent gas turbine engines have the potential to reduce noise, either through active noise control or through the direct management of noise sources, perhaps by tailoring rotor wakes. The increased number of robust, versatile sensors may also improve (with suitable system identification techniques) the monitoring of engine health (both preventive and reactive), which could decrease overhaul costs, prevent unwanted in-flight events, and increase safety.

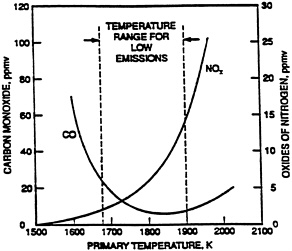

Closed-loop processes could also be used to reduce emissions. Two important pollutants in aircraft emissions are nitrogen oxides, or NOx (mainly NO, and to a lesser extent, NO2) and carbon monoxide (CO). NO, the major contributor to NOx, is mostly generated by a thermal mechanism, which means that the higher the temperature of the combustion process (or the closer to local stoichiometric conditions), the higher the NO emissions. To reduce NOx, engines must operate very lean through a staged-combustion process. CO, however, is not converted to CO2 when the reaction is quite lean or cool, so low NO emissions often mean high CO emissions. Figure 3-2, which shows the formation of NOx and CO as functions of temperature, illustrates this trade-off.

The challenge is to tailor the reaction process to allow an engine to operate lean enough overall (or in stages) to reduce NO but not so lean that the CO emissions increase significantly. This could potentially be achieved with closed-loop engine controls with real-time, detailed, diagnostic sensors, such as optical or MEMS-based sensors. If it were possible to know the local species and temperature distributions at several key locations in

real time, this information could be distilled into a few parameters, such as mixture and temperature pattern factor, that could used as input to a closed-loop controller with "actuators" that control fuel jet injection characteristics, staging characteristics, and dilution jets. This type of active control could also improve fuel-air mixing during the combustion process, which would also lead to a reduction in the emission of "unburned" hydrocarbons.

FIGURE 3-2 NOx and CO formation in gas turbine combustion as a

function of temperature. Source: Lefebrve, 1995.

The development of active control for individual engine components will require robust, real-time sensors and actuators. Current actuation and sensing devices operate in an engine at the macroscopic level. Distributed sensors and actuators that operate at the microscale will have to be much more robust than current optical sensors or silicon-based MEMS.

Research (mostly in universities) on active control of unsteady flow in gas turbines has had encouraging results in long-standing problem areas, including active stall stabilization and the control of combustion instability. From the viewpoint of an engine manufacturer, however, there is an enormous gap between results in a laboratory test facility and a flight-worthy, economically attractive, operational propulsion system. Universities are not well placed to bridge this gap, but NASA can play a key role in making intelligent engines a reality. This will require not only research on controls, structures, and fluids, but also a willingness to examine, and to address, the technological barriers inherent in the flight certification process.

Finding. The development of embedded sensors and controls in air vehicles and components could further a number of NASA's air transportation goals. Better health monitoring, more efficient servicing, and improved performance could lead to reduced operating costs and increased safety. In addition, active combustion control in propulsion

systems appears to be a promising way to meet NASA's goal for reducing emissions. Critical path items are robust, real-time, highly accurate sensors and actuators.

Structures and Materials

The airframe structural weight of long-range transport aircraft comprises about 35 to 40 percent of the takeoff gross weight. Engine weight comprises 15 to 20 percent, and systems/equipment weight (e.g., avionics and air conditioning) comprise another 10 to 15 percent. Aircraft components, such as the engine turbine and compressor, have benefited from advances in materials technology, and major advances in manufacturing and design have produced a more reliable, higher quality airframe. The structural weight fraction of transport aircraft airframes has remained fairly constant over the past 30 years, not because of a lack of progress in structural technology, but because other aircraft components have also benefited from advanced technologies and have maintained their weight fraction values. Engineered materials may offer solutions for continued advancements in airframe structures

Engineered materials are specially designed combinations of materials, either in solution (alloys) or distinct (filamentary carbon/polymeric matrices), that take advantage of superior features of their components. For instance, advanced composites contain lightweight materials, such as carbon fibers, which are brittle but can be processed with a matrix, a resin, or even a metal to minimize the density of flaws that could lead to failures. A matrix can be used as a binder to hold the fibrous material together and act as a load transfer mechanism.

Advanced Composites

Advanced composite structures first appeared more than 30 years ago, but their promise has been largely unrealized in commercial air transport airframes. Although they have high strength-to-weight and high stiffness-to-weight ratios, their failure modes are different from those of conventional metallic materials. Despite decades of study, some failure modes are still poorly understood and unpredictable, which has limited the widespread application of composites in air vehicles.

Because advanced composites are both a material and a microstructural system, they can be designed to control load paths, a capability almost as important as the material's intrinsic low weight. For example, the X-29 research aircraft was the first manned air vehicle to orient, or "tailor," advanced composite directional strength and stiffness to reduce weight and prevent adverse aeroelastic interaction between the wing bending and aircraft flight mechanics modes. Less advanced composite materials, such as fiberglass/epoxy, have been used in small kit-built airplanes because of the ability to fabricate low-cost, smooth, strong airframes. Nevertheless, the high cost of advanced composites is still a major problem limiting their use.

Advanced Metal Alloys

Other engineered materials include advanced alloys, such as those used in high-temperature turbine blades. These materials are solutions of different elements, each of which brings a superior performance attribute to the material system. Engineered materials may have a thin coating deposited or engineered onto the blade surface to resist surface abrasion and wear or to provide thermal properties unavailable from a single material. Deposition schemes can now construct a coating only a few atoms thick and virtually free of defects so that its strength approaches the cohesive strength of an atomic bond. Advanced metal alloys have been developed from extensive, time-consuming, "cut-and-try" research, and making the process less empirical to reduce cost and time will be important.

Other recent improvements in the properties of metals have been achieved by engineering materials, even ordinary substances, such as aluminum or aluminum alloys, at the microstructural level. This is done by purifying and processing to minimize grain size, intermolecular and intergranular distortions, and imperfections. Additional improvements should be possible by alloying any of a wide variety of substances, such as metals and ceramics, and varying the processes to tailor the final material properties. These developments will be the result of continuing work in ultrafine particle metallurgy, plasma jet sprays, and vapor coatings. Newer methods, such as the laser stream method, could lead to "fabrication by light," whereby complex parts and assemblies could be manufactured by depositing material from a wire spool, using a highly accurate, high-powered laser.

Applications of engineered materials include tough, high-temperature materials for efficient, small gas turbines and internal combustion engines used for general aviation aircraft or for the development of large supersonic gas turbines applicable to high-speed civil transports. Engineered materials could also increase attachment efficiency by reducing the number of necessary fasteners. The weight of joints and fittings could also be reduced using "graded" structures that begin as one engineered material and end as another.

Finding. The development of engineered materials, such as low-cost composites and new corrosion-resistant, damage-tolerant alloys, could lead to reductions in life-cycle costs that would enable reductions in the cost of air travel. Engineered materials could also lead to the expansion of the general aviation market through the introduction of new options for designing more efficient and cost-effective aircraft. High-temperature materials for supersonic engines and airframes could also contribute to meeting NASA's goal of reduced travel time.

Advanced Propulsion and Power

The development of advanced power and propulsion systems will have an impact on achieving NASA's air transportation goals for emissions, noise, safety, air travel cost,

general aviation, and high-speed air travel. Advanced engine configurations, and even concepts that could be directly implemented into existing propulsion systems, may require revolutionary advances in specific scientific areas. Therefore, this area of technology merits NASA's long-term focus.

Alternative Fuels

Alternative fuels could improve safety and reduce or eliminate NOX, CO, and carbon dioxide (CO2) emissions. The TWA Flight 800 tragedy has raised concerns about the flammability limits of conventional hydrocarbon fuels, such as Jet A. To address these safety concerns, advanced formulations of existing aviation fuel types specifically tailored to achieve appropriate flammability limits should be explored. Alternative aviation fuels, such as hydrogen fuels, also warrant increased attention because emissions of CO, CO2, and sodium dioxide (SO2), are not produced when hydrogen is burned. CO2 is a primary product of the hydrocarbon combustion process, and its contribution as a "greenhouse gas" to global warming is considered to be significant. Therefore, nonhydrocarbon fuels, such as hydrogen, should be explored as a logical alternative.

Hydrogen fuels also have the potential to reduce NOX emissions because hydrogen has a wide flammability range that allows for the sequential combustion of lean and rich air/hydrogen mixtures. The energetic potential of hydrogen, which is 2.7 times greater than that of most hydrocarbon fuels, is another incentive for the development of hydrogen fuel.

Safety is a major concern in handling hydrogen fuel, but it actually might be safer in the event of an aircraft accident. As NASA studies have shown, the strong buoyancy of hydrogen flames could lead to the quick dissipation of a hydrogen fire, increasing the potential survivability of passengers inside the fuselage (Brewer et al., 1981).

The major challenge to the use of hydrogen as a common aviation fuel is the lack of nationwide and worldwide infrastructures to support safe and efficient fuel generation, transport, and airport handling/aircraft refueling. However, these issues are being studied in Europe and Canada, and NASA should keep abreast of progress in this area. A second challenge to the use of cryogenic hydrogen is its extremely low density—about one-fifth of that of conventional jet fuels. The large amount of required aircraft fuel tankage (which must be pressurized and insulated) would require major changes in the basic design features of aircraft. However, advances discussed in chapter 5, such as gelled hydrogen and the storage of hydrogen in a carbon nanofiber matrix with an ultra-high capacity to absorb/adsorb hydrogen gas, could eventually eliminate tankage problems.

Novel Engine Components

Improvements in the performance of individual engine components can be achieved through current research on magnetic bearings, variable-geometry components, and

passive noise and flow control through novel component designs. The aggressive use of closed-loop flow controls for external as well as internal flows should also be investigated.

Another promising area of research concerns novel methods of controlling flows in aeropropulsion and fluid machinery components. Examples include suction within the inlet and suction and blowing in nozzle/ejector components for improved tonal noise control, as well as controlled suction in "aspirated" compressor blades and end-wall surfaces for increased operating margins, stall/surge control, and thrust-to-weight ratios. Recent conceptual studies on the development of so-called "aspirated" compressors combine aspiration and counter-rotating blade rows (thus causing a higher relative velocity in the rotating blade rows) to yield engines with nearly doubled thrust-to-weight ratios and compressor-stage counts decreased by a factor of two to three (Epstein and Waitz, 1997). Innovative methods for managing viscous flows will be important to the development of aspirated compressors.

Novel Power/Propulsion Devices

The air-breathing engine configurations currently in use (turbojets, turbofans, turboprops, and ramjets) or being tested (scramjets) will take future aircraft designs well into the next century. Novel power generation devices, some of which are still in the embryonic stage of development, also look promising. These devices could be used in advanced air vehicles to generate auxiliary power or in an entirely configuration.

Fuel Cells. Fuel cells should be studied as a potential power source for subsonic aircraft propulsion and power systems. Electric motors powered by fuel cells could be used to drive propulsive fans. Presently, the power density of fuel cells is more than an order of magnitude less than the power density of turbofan engines operating at sea level. However, at high altitude, the power density differences are greatly diminished because fuel cells can retain their power generating capacity at altitude. Furthermore, the chemical power conversion efficiency of fuel cells is about twice as high as the thermodynamic power conversion efficiency of standard propulsion systems. Because hydrogen provides 2.7 times more energetic potential than hydrocarbon fuel, hydrogen fuel cells could reduce consumption five-fold over the standard gas turbine engine. However, the storage of an adequate volume of hydrogen remains a critical issue.

Lithium-air fuel cells are a potential source of nonpolluting power, especially for general aviation and light military aircraft. One recent study has shown that a standard 225 horsepower propulsion system for a light airplane could be replaced with an electric motor and lithium-air fuel cell power plant that would have roughly the same power, endurance, and weight (Galbraith, 1996). The power generation process of a lithium-air fuel cell produces no emissions. The by-product of the electrochemical process is lithium hydroxide, which could be retained aboard the aircraft and recycled after flight to retrieve the reusable metallic lithium.

NASA should support aircraft design studies to investigate the integration of fuel cell propulsion technologies. Favorable results could then be the basis of technology development in other areas in which NASA has expertise, such as alternative fuels and new materials.

Microscale Engines and Components. Ultrasmall-scale (micron to millimeter) air-breathing and rocket engines and engine elements, such as heat exchangers, are also at the embryonic stage, with research being pursued at only a few universities and research laboratories. However, the implementation of microscale devices is an exciting prospect, not only as propulsors, but also as miniature thermal cycles for generating energy and environmental control on systems, such as satellites.

Advanced Supersonic/Hypersonic Engine Concepts. The elimination of complicated rotating machinery in aircraft propulsion systems appears to be a worthwhile goal. The detonation-wave engine is one approach that eliminates moving parts. Detonation-wave engine technology demonstrations are being pursued, to a limited extent, by NASA and the Air Force through the Small Business Innovative Research Program. The theoretical advantages are based on the thermal efficiency benefits of the Humphrey cycle over the turbine engine Brayton cycle. Pulse detonation wave (PDW) or oblique detonation wave (ODW) engines may have the potential to increase specific impulse levels. Technological challenges are the stability of detonation in the ODW engine and control in the PDW engine. Although high noise levels are another serious disadvantage, these engine concepts have potential applications for high-speed aircraft.

Finding. NASA's goals related to emissions, noise, cost, general aviation, and high-speed air travel will all be affected by advances in propulsion technology. The major opportunities for breakthrough propulsion technologies include alternative fuels, novel concepts for engine components, active control of propulsion processes, and new power and propulsion devices. The desirability of pursuing any of these technologies to the point of application must be assessed early in their development by assessing their benefits in the context of an overall aircraft system.

Advanced Manufacturing

Low-cost manufacturing is the foundation of low-cost vehicles and propulsion systems and is based on improvements in both processes and economies of scale. Production quantities in aviation typically limit what can be achieved through economies of scale, but as automated manufacturing equipment becomes less specialized and more versatile, it is possible to foresee breakthroughs that allow small production runs to benefit fully from automation, without exacting the enormous cost of specialized automation equipment. Lower aircraft purchase costs resulting from low-cost manufacturing should contribute to NASA's goal of reducing the cost of air travel. In addition, reductions in the cost of new general aviation aircraft could further the achievement of NASA's goal to reinvigorate this sector of the aerospace industry.

Manufacturing is an essential element of aerospace product development and should influence the design of air vehicles, starting with conceptual design. Manufacturing is a key ingredient in the process of computer-based design, modeling, and simulation, which are discussed in the next section. NASA can support the integration of manufacturing into the whole air vehicle production and development process by investigating automated fabrication processes, such as manufacturing by light and high-velocity machining, that could directly link design databases to finished assemblies.

Automated Manufacturing Processes

Labor and associated overhead are the two largest elements in the cost of airframes which in turn is a major factor in the costs of aircraft and air travel. Automated manufacturing entails eliminating the extensive hands-on labor currently required to fabricate parts, assemble airframes, and perform quality inspections. Concepts that enable automated manufacturing and, therefore, a breakthrough in cost, include automated assembly, precision manufacturing, and fabrication by light.

Automated Assembly. Recent progress has been made in the automated assembly of composite structures using filament winding; oriented, chopped-fiber spray systems; and automated tape or tow placement machines. Presently, however, high material costs still limit the application of automated composites. Continued efforts to reduce costs would be worthwhile.

The automation of sheet metal assemblies is another area NASA should pursue. Except for the automatic riveting of flat or moderately curved panels, sheet metal assembly is still a manual operation. Sheet metal structures are assembled with mechanical fasteners (e.g., rivets and screw fasteners) or adhesive bonding. Rivets are typically driven or squeezed, but expensive blind fasteners are used if the inside of the structure is not accessible. An airframe built entirely with blind fasteners is usually too heavy and too costly, so the automation of riveted sheet metal assembly will require a breakthrough in the development of automatic equipment that can drill, seal between panels, align parts, and set rivets on complex structural shapes. One key challenge is gaining access to tight areas in recessed corners, with sufficient jigging to hold contours during assembly operations.

Bonded assemblies would also benefit from automation. Using machines to place precision-formed parts automatically into bonding fixtures would reduce costs and eliminate potential variations in quality that result from manual handling of the bond lines and adhesives.

High-Velocity Machining. High-velocity machining of unitized parts has a high probability of reducing assembly costs by eliminating the need for special tooling and large quantity production. In the long run, high-velocity machining may replace standard sheet metal or composite assemblies. This emerging technology enables the fabrication of large monolithic structural parts cut out of metal blocks that are lighter, stronger, and easier to

join to other airframe components. The parts are highly accurate and have smooth surfaces that require little finishing. Walls and ribs can be as thin as 20 to 30 thousandths of an inch thick.

This new manufacturing technology increases metal cutting speeds by a factor of seven or more, with high-power tool spindles running at 25,000 rpm and cutters that advance 600 to 700 inches per minute across the metal block. Metals cut at such high speeds are locally transformed into a plastic state, and the heat produced is carried away by the chips leaving the workpiece cool and undistorted. The development of tool spindles driven by a 100 hp turbine and turning at 100,000 rpm is proceeding. This technology is currently being applied to the cutting of aluminum. Application to titanium and other advanced metallic materials is the next logical step.

Precision Manufacturing. Aluminum continues to be a material of great utility for aerospace applications, but the forming of aluminum parts demands both skill and numerous trials to achieve an acceptably "repeatable" process. The many variabilities of parts require considerable handwork in the assembly jigs to align, reform, and shim them for the best fit. Methods and software for analyzing the forming process are available, but empirical factors and adjustments are still required, which have been barriers to economical automation.

Environmental factors, material variability, and the effects of coiling for storage are all important to the repeatability of forming processes. Improving our understanding of these so precision formed parts can be produced without numerous setup trials would allow the development of adaptable forming equipment based on computer-aided design data and material sample properties to adjust the forming operation. This breakthrough would result in considerable cost savings from reductions in machine time, labor, and the amount of scrap.

Manufacturing by Light. Manufacturing by light is a novel fabrication process that imitates, in a sense, biological growth. Finished parts are obtained in one step from a computer-aided design database. The process, which is currently under development, is also called laser forming and laser engineered net shaping. In this solid, free-form fabrication process, a metal powder, specifically titanium powder, is fused, layer by layer, with a computer-controlled high-power laser to produce high-quality shapes without the use of tools. The mechanical properties are reported to be equivalent or superior to those of wrought titanium. The benefits for large titanium parts include substantial reductions in material cost, machining cost, first-article time, and cycle time. Parts made with other advanced metallic materials, if developed, could also be produced using this fabrication process, which could reduce material costs and machining costs.

Lean Manufacturing

Lean manufacturing is based on five principles: specifying value from the point of view of the customer, identifying the value stream for each product, creating continuous flow in manufacturing and assembly, making products flow only to meet customer demand, and striving for perfection. Lean manufacturing focuses on removing nonvalue-added tasks from the process or processes of interest. Lean manufacturing was pioneered by the Toyota company and is now being adapted to the production of aircraft as a means of cutting costs, reducing cycle times, and improving quality.2 Lean processes can also be extended to the manufacture of propulsion systems and, perhaps, to aspects of the development process, such as testing.

Finding. Lower aircraft purchase costs resulting from low-cost manufacturing are necessary for the achievement of NASA's goals of reducing the cost of air travel and reinvigorating the general aviation industry. Lean manufacturing, and automated manufacturing through techniques such as automated and high-velocity machining of parts, sheet metal assembly, and manufacturing by light, should be investigated.

Computer-Based Design, Modeling, and Simulation

Aircraft technology is highly optimized. Therefore, reductions in operating costs, and improvements in efficiency and environmental compatibility through more efficient engines, lighter weight materials, and enhanced aerodynamic performance have been difficult to achieve while maintaining reasonable development costs and product cycle times. Furthermore, cost issues sometimes become clear only at an advanced stage of design when they are difficult to address or resolve. Multidisciplinary simulation and optimization tools that produce better designs more rapidly and at lower cost would accelerate the introduction of new technologies into air vehicle designs, thus accomplishing NASA's goal to provide the tools necessary for increasing design confidence and reducing the development cycle time, while simultaneously contributing to the achievement of other goals related to air transportation.

Optimizing the Design Process

Much of current design process is sequential and iterative, requiring months (sometimes years) to develop to a final production design. Sometimes expensive delays are caused by time lags in the transfer of data from one discipline to another, which are often physically isolated and have different methods of analysis. Methodologies that can integrate several

disciplines concurrently would make earlier optimization feasible and would be a major improvement.

Computers and computer information systems already play a central role in improving an aircraft company's design process in terms of quality and competitiveness. Nevertheless, computer-based optimization and reorganization of the entire design and decision-making process during product development is a research area that could become a victim of company traditions and inertia. Past NASA-sponsored research in this area has led to the development of the DeMaid computer program, which uses ''dependency models" to help organizations understand process complexities and reorganize processes to optimize the flow of information and eliminate unnecessary organizational design interactions (Rogers, 1989). Computer-based tools, coupled with better models of the physical elements of vehicles and components, will help to reduce product costs and improve quality.

Creating Nonlinear, Multidisciplinary Aircraft Design Models

Current design tools used in the aircraft industry have several deficiencies, including the use of linear analyses, which are inaccurate for nonlinear (e.g., transonic) flight regimes; and the use of numerous single discipline codes derived from different databases, which makes integration difficult. There is considerable room to improve these tools through the integration of nonlinear computational fluid dynamics (CFD) methods, advanced nonlinear structural analysis methods, and integrated flight and propulsion control models into a single analysis and design system that could be run on advanced parallel computing platforms. The seamless integration of these models, which often have very different levels of fidelity, will require the development of an architecture which currently does not exist. The use of nonlinear methods for CFD, structural analysis, and optimization will also involve several complex, high-risk development efforts. For example, nonlinear optimization will require system-level identification concepts that rely on autoregression or the use of neural networks and fuzzy logic.

Improving Models for Propulsion System Design

The design-to-development process for a jet engine is not only expensive, but also time consuming. It typically takes up to a year longer than the design-to-development cycle for an entire commercial transport aircraft. Therefore, NASA's goal to increase design confidence and cut the development cycle time for aircraft in half is as important to engine manufacturers as it is to airframe builders. Engine manufacturers, in cooperation with NASA, are already investigating computer-based methods for shortening the design-to-development cycle and for reducing costs. The target areas are listed below:

-

improved combustion modeling, which includes not only advanced computational procedures, but also reduced order models (including appropriate descriptions of reacting flows) that allow confident preliminary designs of combustors

-

predictions of fluid/structure interactions for high-cycle fatigue avoidance (e.g., flutter and resonant stress)

-

new methods for identifying aeromechanical and aerodynamic unsteady system responses so that predictions can be rigorously addressed and regimes with high stresses can be identified clearly in the development process

-

virtual engine models, with a goal of overnight simulation of a complete engine, which will require developing ways to capture physical processes at an appropriate level of fidelity and rigorous means for passing information between models with different dimensionalities, fidelities, and descriptions.

Optimizing Human/Computer Integration During the Design Process

In addition to reorganizing the flow of information and improving multidisciplinary models for both aircraft and engines, advances in the design process will depend on stimulating human creativity, both teams and individuals, by providing reliable and repeatable computer assistance for tedious, straightforward tasks. Over-reliance on computers and numerical codes to provide data and information, however, can result in burying design flaws in the design process. These flaws have to be exhumed later and create many problems. Mistakes made during conceptualization and preliminary design become increasingly expensive if they percolate through the entire design process before being discovered. Resolving this problem will depend as much on optimizing the integration of humans and computers, as it will on the development of better microprocessors or new software.

Finding. To reduce the costs and shorten the development cycle for future air vehicles with performance characteristics that meet NASA's air transportation-related goals, substantial improvements will have to be made in computer-based design, modeling, and simulation. These improvements include optimizing the flow of information throughout the design process; enhancing linear and nonlinear simulation capabilities for both aircraft and propulsion systems that fully integrate separate models with varying levels of fidelity; and improving the understanding of the optimal integration of humans and computers throughout the design process.

REFERENCES

Brewer, G.D., G. Wittlin, E.F. Versaw, R. Parmley, R. Cima, E.G. Walther. 1981. Assessment of Crash Fire Hazard of LH2-Fueled Aircraft. NASA CR-165525. Washington, D.C.: National Aeronautics and Space Administration.

Epstein, A., and I. Waitz. 1997. Potential Breakthrough Technologies, Propulsion Research at the Gas Turbine Laboratory, MIT. Presentation to the Committee to Identify Potential Breakthrough Technologies and Assess Long-term R&D Goals in Aeronautics and Space Transportation Technology, Cambridge, Massachusetts, November 18, 1997.

Galbraith, A.D. 1996. Electric Propulsion for Light Aircraft: Lithium-Air Fuel Cell for Primary Power. NIAR 96-3. Witchita, Kansas.: National Institute for Aviation Research, Wichita State University.

Lefebrve, A.H. 1995. The Role of Fuel Preparation in Low-Emission Combustion. Journal of Engineering for Gas Turbines and Power. 117(4): 617–654.

Liebeck, R.H., M.A. Page, and B.K. Rawdon. 1998. Blended-Wing Body Subsonic Commercial Transport. AIAA-98-0438. Reston, Virginia.: American Institute of Aeronautics and Astronautics.

Rogers, R.L. 1989. A Knowledge-Based Tool for Multilevel Decomposition of a Complex Design Problem. NASA TP2903. Washington, D.C.: National Aeronautics and Space Administration.