3

Lightering Vessels, Systems, and the External Environment

Physical factors, both on board and external, substantially affect lightering safety. Some of these factors are difficult to control. For example, industry experts say a significant variable that is difficult for lightering companies to control is the quality of the STBL. A variety of owners, operators, and vessels are engaged in transporting imported oil and thus are lightering STBLs. Cargo owners commonly contract with independent lightering service companies to provide equipment and supervisory services during lightering operations. These service companies may also operate the service vessels that shuttle cargo to refineries, or they may perform their services using chartered or independently operated vessels. The STBLs are sometimes owned and operated by the cargo owner, but more frequently the cargo owner charters the STBL. The lightering service company, therefore, often has little or no control over the quality of the STBL or the aspects of the operation that have been planned and executed by outside parties. The issue, then, is how to encourage universal adherence to the best industry standards for vessel design, equipment, operation, and maintenance.

Vessel design and the condition of the lightering equipment are critical safety factors. The inherent design of the vessel, including a single or double hull, is one factor. A strong, well designed mooring system, which keeps the STBL and service vessel together, is another. Typically, lines from both vessels are used. A fender system, suitable for each individual lightering operation, is critical to protecting both vessels. A reliable cargo transfer system, including well maintained hoses, is essential. Equipment standards for offshore lightering have been established by the industry (ITOL, 1990; ICS and OCIMF, 1997), but there are no guidelines specifically for inshore lightering. Additional guidelines and

standards have been established by lightering companies, major tanker operators, and other industry entities.1

Lightering safety is also critically affected by external, environmental factors. These factors include weather and sea conditions, the location of oil pipelines buried in the ocean bottom (as factors in safe anchorages), and specific zones for lightering (or where lightering is prohibited) that have been established as regulatory and enforcement measures. In this chapter, physical systems, both on board and external to the vessel, are examined and opportunities identified for reducing the risk of accidents.

Vessels and Special Systems

Navigation systems, vessel maneuverability, and the control of vessels when approaching and departing the lightering area are all factors that affect safe operation. Electronic position-fixing by the differential global positioning system is used to locate operations very accurately. Vessels should also be equipped with accurate and up-to-date navigational charts to locate safe anchorages and to avoid hazards, fixed structures (which may not be well lit), and underwater obstructions (which are not always charted). Modern electronic chart displays can also be valuable navigation aids.2

Effective maneuvering controls are required on board both vessels during mooring and lightering at sea, as well as during unmooring operations. A few service vessels are equipped with bow thrusters, controllable pitch propellers, twin screws, and special rudders to aid in maneuvering. Most also have engine controls on the bridge and sometimes at other locations. Good systems for communications between key locations onboard each vessel and between vessels are critical.

The following sections examine some of the critical shipboard systems that could affect lightering safety and identify the ones that require attention to prevent future problems. The committee identified these systems based on its members' backgrounds and expertise in lightering as well as on a review of the literature and information gathered from industry, regulators, and others during the study.3

The key elements of vessels and special systems are vessel design, mooring systems, fendering systems, and hoses and transfer systems. 4 The key elements

|

1 |

Companies that have in-house guidelines and standards include Chevron Shipping Company, Skaugen PetroTrans, Maritrans, SeaRiver Maritime, Conoco, Statoil, and Shell Oil Company. |

|

2 |

For a more detailed discussion of navigation aids and electronic traffic systems, see NRC 1994a, 1996. |

|

3 |

Information was gathered during meetings of the full committee and by individual members in Houston, Philadelphia, and San Francisco, as well as from discussions with various experts (see Appendix B). |

|

4 |

Navigation control and communications systems are also important, but concerns about their design, function, and effectiveness are not unique to lightering and therefore are not addressed in this report. These systems have been examined in previous studies by the National Research Council (1994a, 1996). |

of the external environment are weather reports and warning systems, pipelines and other structures in the lightering areas, and lightering zones and prohibited areas.

Vessel Design

Lightering vessels may be engaged by a variety of operators and shipping companies. These vessels have a range of design features that make them more or less suitable for lightering activities. Vessels that have been built or converted for lightering, usually service vessels that are dedicated solely to lightering, have standard mooring, fendering, and hose transfer systems built in, and they engage in lightering on a regular basis.

Most of the firms involved in Gulf Coast lightering (and some on other coasts as well) use service vessels that are not dedicated to lightering. These vessels may split their time between lightering and other activities, such as short-haul deliveries of oil from Mexico or Venezuela to the U.S. Gulf of Mexico. Mooring lines, fenders, and hoses are usually delivered to these vessels just before a lightering operation, used during the offloading of one STBL, and then removed by the service company that was engaged to provide this equipment, expertise, and personnel for the lightering operation. These nondedicated vessels are of varying designs, so the special equipment must be able to accommodate a variety of on-board arrangements.

STBLs exhibit an even greater variety of designs and arrangements of equipment. An STBL can be any vessel from the world tanker fleet with several possible places of construction, any age, any flag of registration, and crew nationality, and so forth. General concerns about the quality of ships, crews, and operators engaged in oil transportation to U.S. ports (see NRC, 1994a) also apply to lightering but are not addressed in this report. The factors that affect lightering include the capabilities of the STBL and operating personnel.

Double-Hull Issues

Certain provisions of OPA 90 raise some safety issues that are unique to lightering. Under OPA 90, which requires that tankers calling on U.S. ports have double hulls, single-hull tankers of 5,000 gross tons or more will be excluded from U.S. waters as of 2010 (except vessels with double sides or double bottoms, which can be used until 2015). However, exemptions in this law will permit single-hull STBLs to lighter offshore in designated lightering zones until 2015. Thus, some single-hull tankers will continue to engage in lightering activities for five years or more beyond the date when they are no longer permitted to enter U.S. ports.

Another factor is a stability problem unique to certain double-hull tanker designs, even though they are built to meet current double-hull standards. A

number of moderate-sized (under 160,000 DWT) double-hull tankers have been built without centerline bulkheads to divide very large cargo tanks. These ''single-tank-across'' tankers can have problems with intact stability5 during loading and unloading of the large tanks (NRC, 1997). Single-tank-across tankers can become unstable and suddenly list to one side unless careful cargo loading and unloading practices are used (NRC, 1997). Several incidents involving the instability of double-hull tankers at U.S. and foreign terminals have been reported (NRC, 1997). It is not known whether these problems have ever arisen during lightering, but these incidents are cause for concern because more than half of the vessels of less than 160,000 DWT in the current fleet of double-hull tankers are single-tank-across vessels (NRC, 1997). The international tanker fleet is gradually converting to double hulls and will be composed almost entirely of double-hull tankers by 2023. It is conceivable that a vessel might suddenly list to one side during a lightering operation, roll against the other vessel, break the mooring lines, and break away. This situation is gradually being corrected as new tankers are built to new International Maritime Organization (IMO) standards that require inherent stability by design. Thus, the percentage of vessels with single-tank-across designs is expected to decrease each year.

The IMO, which is the United Nations agency responsible for maritime safety and protection of the marine environment, has addressed this issue in a draft circular that provides guidelines for ensuring intact stability during cargo transfer operations (IMO, 1997). A recent report by the National Research Council (1997) recommended that the USCG implement operational procedures and crew training for existing tankers that are subject to problems with intact stability and develop design requirements to ensure the intact stability of new double-hull tankers. Although the IMO and USCG efforts to address this problem appear to be adequate for shipping in general, lightering safety in particular will require that vessel operators and crews adhere strictly to the new guidelines and standards. Furthermore, as new tankers are designed, lightering safety is also likely to be improved by ensuring that mooring bitts and chocks, winches, line-handling systems, manifolds and cranes, and emergency quick-release systems all meet safety standards. This equipment is described later in this chapter.

Another aspect of tanker design that affects lightering is the much greater freeboard6 of empty double-hull tankers as compared to single-hull tankers. Because of the large freeboard, the deck of a double-hull STBL averages about 80 feet above the waterline, roughly 60 feet above the deck of a service vessel, during a lightering operation. This results in an awkward, near-vertical arrangement of mooring lines that makes it difficult to hold the vessels together. To minimize this problem, companies have reduced the lightering weather window when

extreme differences in freeboard exist. To optimize the effectiveness of the mooring lines, some operators limit the volumes of the last and next-to-last lifts from the STBL. Another recommended approach to the freeboard problem is to increase the allowed ballast capacity for the STBL to reduce freeboard and the vertical separation of the vessels. This approach would only be appropriate under unusual conditions and would probably require a modification of the current International Convention for the Prevention of Pollution from Ships (MARPOL, 1973), which defines exceptions to ballasting prohibitions.

Although no accidents have been reported from large freeboard differences between two ships, the committee considers that this is an area where risks of future accidents could be avoided by applying simple preventive measures. One reason no incidents have been reported to date could be that tankers with very high freeboards are just beginning to be commonly used in U.S. waters. The problem could grow in the future. Another reason could be that the skill and good judgment of lightering masters and others have prevented problems so far. However, committee members who have visited lightering operations and those who are experienced with lightering have pointed out that high freeboard is a problem worthy of attention. Preventive measures, such as ballasting, are straightforward and could lead to a safer operation.

The committee considered a number of approaches to solving the high freeboard problem, including enhancements to hose or mooring systems and design changes to double-hull ships, but concluded that these would either not be practical or would take too long in practice to implement. The most practical solution, and the one that had the best chance of being implemented, was to permit greater ballasting.

The committee recognizes that permitting greater ballasting of certain tankers under special circumstances could result in small additional discharges of oil entering the marine environment when the ship is deballasted. The committee did not compare the risk of allowing more dirty ballast on board with the avoided accident risk. But if a modification to MARPOL were adopted, it would be preceded by a full discussion of this issue by the IMO.

Engine Capabilities

When two vessels are brought together while under way, their speed affects the risk of a collision. The slower they are moving, the less likely they are to collide because of the angle of approach or some other factor. The greatest risk of a collision exists when two vessels of similar size traveling in excess of 5 knots are mooring.

Modern motor vessels cannot operate at very slow speeds, which can make both mooring and subsequent operations difficult, especially if a vessel is unable to anchor and the weather is inclement. At present, accommodating the limitations on the design and required operating range of modern diesel engines requires great skill and good judgment on the part of vessel operators. In the future,

it may be possible to design slow-speed propulsion systems that are better suited to lightering operations.

Emergency Equipment

All vessels that engage in lightering operations within the EEZ must have a USCG-approved oil spill response plan, as required by OPA 90 (see Chapter 2, Box 2-1). Response plans are designed for a worst-case discharge and a substantial threat of a discharge of oil. The plans must specify the resources needed to respond to spills of various sizes in different environments and the contracting for a certain percentage of the needed resources. In addition, specific equipment must be carried on board. For example, tank vessels must carry spill-removal equipment, such as sorbents, hand scoops, shovels, buckets, portable pumps with hoses, containers, and protective clothing, in sufficient amounts to contain and remove on-deck oil cargo spills of at least 12 barrels.

Single-hull vessels that engage in lightering must also carry on-board equipment for emergency lightering transfer connections. The required equipment includes reducers, adapters, bolts, washers, nuts, and gaskets for at least two simultaneous transfer connections from the vessel's cargo manifold to cargo hoses of various sizes.

In addition, all tank vessels are required to have made arrangements for firefighting and towing. In some areas, operators are also required to arrange for access to additional emergency equipment. In San Francisco Bay, for example, standby vessels for both spill response and towing are required by state regulation. During deepwater operations at the LOOP, tugs carrying spill-response and firefighting equipment are always on scene during transfer operations. The standby tug can also assist a tanker that loses steering capabilities or has an engine failure. During offshore lightering, the availability and amount of firefighting and towing equipment on the scene, as opposed to on call, is usually up to the individual operator. Although standby equipment is seldom needed, prudent operators always provide it.

Mooring Equipment, Fenders, and Transfer Equipment

The three categories of special equipment necessary for the safe transfer of oil cargo between two vessels on the open ocean are listed below:

- a method of keeping the vessels together (i.e., a strong, well designed mooring system)

- a method of keeping the vessels apart and protecting them from each other (i.e., a fender system suitable for the individual operation)

- a reliable transfer system for moving the oil from one vessel to the other (i.e., hoses, connections, and equipment for connecting and disconnecting them)

The key safety aspects of this equipment are discussed briefly in the following sections.

Mooring Systems

Conventional mooring systems are designed to secure a vessel at a dock, pier, or oil jetty. Over many years, the shipping industry has developed standard approaches and guidelines for the number, composition, and angles of mooring lines for mooring at a dock. These guidelines and standards do not, however, readily apply to lightering when the circumstances are very different, the forces and dynamics are much greater, and each lightering situation is unique. The ICS and OCIMF (1997) provided guidelines for mooring equipment used in ship-to-ship transfer operations. Many companies have also established their own standards.

Vessels moored together in an open seaway tend to move independently, and the motion can cause chafing and shock loads and the subsequent failure of mooring lines, particularly lines made of synthetic materials. Moreover, large changes in freeboard and extreme angles between the vessel leads can compromise the efficiency and strength of the lines. Therefore, a ship-to-ship mooring system designed for offshore use must be substantially stronger than a conventional mooring system. For example, the "tails" of mooring lines, which are usually made of nylon, should be rated at 125 percent of the strength of the lines to absorb shock. Short wire pennants can be attached to the tails to withstand abrasion. Vessels can also be fitted with roller chocks to ease the movement of mooring lines. Reliable chocks (or fairleads), preferably enclosed, can help control the lines. Roller chocks must be maintained property or else they become useless. Well placed bitts on deck are also necessary to secure the mooring lines. The recommended mooring arrangement is shown in Figure 3–1.

In addition to being very strong, an offshore mooring system must also be designed to enable rapid breakaways, in case sudden changes in the weather warrant an emergency separation of the vessels. Too many mooring lines can impede breakaways without increasing the reliability or strength of the mooring system. The simplest and safest way to provide for rapid separation is to use quick-release connections.

The crews of both vessels should know, preferably in advance, that the mooring systems are adequate and compatible (i.e., the number of mooring bitts is sufficient and all lines are on permanent winch drums). This information is available from various sources, including the vessel owners and the OCIMF Ship Inspection Report (SIRE) program. The accessibility of SIRE records is discussed in Chapter 4.

The side-by-side mooring arrangement used in a typical lightering operation is only practical in low-to-moderate seas under reasonably good weather conditions. If the weather turns severe and waves reach a certain height, the operations

Figure 3–1

Recommended mooring arrangements for offshore lightering.

must be suspended and the vessels separated. Vigilance and good judgment on the part of all mariners are essential to avoid damaging either vessel.

Fenders

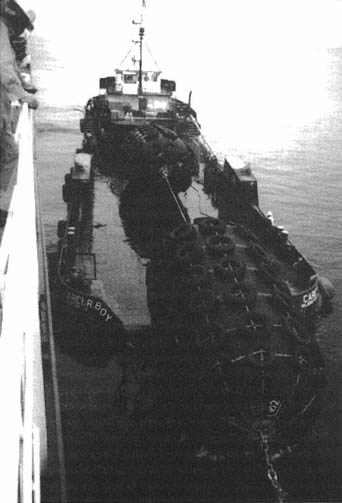

The OCIMF (ICS and OCIMF, 1997) and individual company standards specify the types and testing of fenders. Before a lightering operation begins, the

A workboat delivers fenders to a lightering operation. Photo Credit: Chevron Shipping Co.

mooring master or lightering service company representative tests the pressure of pneumatic fenders, which must be inflated according to the manufacturer's instructions (foam-filled fenders are sometimes used instead). Pneumatic fenders are most reliable when they are fitted with safety release valves to prevent them from bursting when compressed. In the past, some operators used truck tires instead of fenders in inshore waters. It is not known if contacts or accidents were caused by this practice, but by all accounts, this practice is no longer used.

Fenders are deployed between the STBL and the service vessel.

Primary fenders, which absorb the impact from the connection of the two vessels, must have the proper diameter in relation to the vessel's freeboard to prevent the fenders from riding up the sides of the vessel and rolling onto the deck. The OCIMF recommends that fender diameter not exceed half the freeboard at any time. The fenders should also provide maximum protection along the hull, allowing for both approach and departure angles. Experience and skill are required to place fenders properly because vessels meet at different angles. The speed of approach significantly affects fender requirements, and it is prudent

to overestimate the approach speed when selecting fender size. The fender rigging system is also critical.

Secondary (or "baby") fenders provide additional protection in case the angle between the vessels exceeds the protective capability of the primary fenders. Secondary fenders are placed fore and aft of the primary fenders to prevent steel-to-steel contact. The flare and counter of the two vessels, aggravated by motion, results in an almost infinite number of possible contact points. Tankers have extensive parallel mid-bodies, where fenders work best. However, some modern vessels have short parallel mid-bodies, so secondary fenders must be available in appropriate locations. Fenders may have to be moved or adjusted to suit the situation. Some vessels that are routinely engaged in lightering are fitted with permanent mounting points to facilitate the handling of secondary fenders. Some operators of dedicated lightering barges have placed permanent molded-rubber fenders on the sides at these contact points, which eliminates the need to deploy fenders for each lightering operation.

The ICS and OCIMF (1997) guidelines cover the overall design and selection criteria for fenders, and operators refer to these guidelines in their internal company procedures. The guidelines specify numbers, types, sizes, and other criteria for fenders for particular operations and given conditions, such as vessel sizes and speed of approach. However, each operator should design a fendering system that suits the conditions of a particular lightering operation using the equipment performance data provided by the manufacturer. Most operators periodically test and inspect fenders and release valves. No specific testing and inspection standards have been established by regulation or industry guidelines, but prudent operators follow the same general practices they follow for all critical equipment.

Hoses

Many types of hoses are used in lightering. All of them must be certified to U.S. standards for this service. The transfer hoses have a thick outer rubber jacket with an inner liner for reinforcement. Hoses are generally connected to the manifold by means of a fully bolted flange, which provides a strong and reliable connection but is not conducive to rapid disconnection in emergencies. Experienced hose handlers can disconnect them quickly, but quick-release connections (e.g., KAM-locks) can also be installed. The releases must be USCG-approved quick-release mechanisms.

According to USCG MIN-MOD records (see Appendix C), there were nine hose ruptures during lightering operations in U.S. waters between 1984 and 1996; one additional rupture in 1998 is known to the committee. Although the numbers are small, ruptured hoses are more frequent than other causes of spills and, therefore, may present an opportunity for improvement. The committee's examination of federal regulations and industry standards for the construction, testing, and inspection of hoses revealed no obvious deficiencies, although there were some inconsistencies that should be reconciled.

According to the USCG regulations covering oil transfer hoses (33 CFR 154.500), the burst pressure must be at least four times the maximum allowable working pressure (MAWP).7 The operator must clearly mark the hose with the MAWP. Industry guidelines for hose construction (OCIMF, 1978, 1995. Chevron, 1989) refer to a "rated pressure," which must be at least 225 psi but can be higher as specified by the purchaser. The rated pressure is supposed to account for dynamic loads from pressure surges, so it is likely to be somewhat higher than the MAWP.

The USCG testing requirements (33 CFR 156.170) specify a test pressure of one-and-one-half times the MAWP and a complete physical examination. The OCIMF guidelines require a test pressure equal to the rated pressure and some measurements of length that are not required by the USCG. The committee believes that operators should use the MAWP as a baseline for meeting USCG testing requirements, rather than mixing standards by testing hoses at one-and-one-half times the OCIMF rated pressure.

Vessel operators report that personnel involved in the day-to-day handling of hoses inspect them visually. Visual inspections are mandated in the DOI and are listed on OCIMF checklists (see Appendix H). Some companies retire hoses after only a few years in service, whereas others extend hose service life based on a review of performance and test data.

The industry guidelines for the construction and testing of hoses, together with the USCG regulations, provide high standards for the operations, testing, and inspection of hoses. Committee members who routinely conduct lightering operations noted that hose failures during testing are often caused by the separation of the internal liner. However, predicting these failures is difficult because many hoses are collapsible so the inner liners cannot be vacuum-tested for integrity. Prudent operators should adhere to the existing standards while remaining vigilant during cargo transfers to avoid unusual external chafing or axial loading, which can shorten the life of a hose or lead to a rupture. Hoses should be inspected regularly because they are exposed to more wear during lightering operations than when they are used at a terminal.

External Factors

Weather

Weather is a major risk factor in lightering. Weather is both a safety factor, because winds and sea state can affect vessel interactions, and a legal factor, because regulations specify the weather conditions under which lightering may take place in the designated lightering zones in the Gulf of Mexico (33 CFR 156.320). Thus, real-time information about the weather on the scene of the

lightering operation, at locations six to eight hours away, and as much as 24 hours in the future should be available.

As the two vessels come together, vessel operators use information about winds, currents, and sea state to the best advantage. This information also ensures that the vessels will not be ''peeled apart'' during the approach. Once the vessels are safely moored together, the weather is continuously monitored to ensure that conditions do not deteriorate to the point where safety is compromised. Sea state, winds, and currents also affect the unmooring of the two vessels.

If it appears that weather may become marginal, then the operators have several options. They may (1) terminate cargo operations, drain the hoses, and keep the vessels together until the bad weather passes; (2) terminate cargo operations, drain the hoses, and separate the vessels with the intention of coming back together later to finish transferring the cargo; or (3) continue operations. Interrupting an operation and dismantling connections takes time, so the longer the lead time the lower the risk associated with unmooring. When the weather is deteriorating, it is important to have accurate forecasts that give operators sufficient time to unmoor and move the vessels apart before the weather becomes too severe to accomplish this safely.

Mariners obtain offshore weather information from several sources. (Harbor and inland information is provided by separate systems, such as NOAA's physical oceanographic real-time system or private forecasting and broadcasting services, such as Navy Fleet Weather.) The National Data Buoy Center8 operates offshore weather stations, funded by NOAA, that provide data to mariners by marine-band radio. Information from weather buoys and other sources is compiled by NOAA for weather updates broadcast by radio. The buoys and NOAA updates are the most heavily used, and probably the most accurate, sources of offshore weather information. Other sources of offshore weather data include the Texas Automated Buoy System, private weather forecasting and broadcasting services, and the U.S. Navy.

Anecdotal reports suggest that the available weather data sometimes do not meet the needs of lightering operators. The reasons include inappropriate locations of weather buoys, a lack of real-time information, and delays in repairs of weather buoys. For example, most weather buoys off the coast of California are located close to shore, and none of them provides useful real-time information. On the East Coast, one weather station (#44001) is located too far southwest to be useful for lightering near Delaware. And, during 1997, NOAA's National Weather Service (NWS) did not allocate funds for the maintenance and repair of some offshore weather stations. As a result, few real-time weather services were available in the Gulf of Mexico for at least six months. After funding from the

|

8 |

Information about individual weather stations and environmental conditions in the area is available on the National Data Buoy Center home page (http://seaboard.ndbc.noaa.gov). |

Minerals Management Service (MMS) for two weather stations (#42019 and #42020) off the Texas coast was depleted in June 1997, the NWS and NOAA were unable to secure funding for the redeployment of the weather buoys until November 1997. At another weather buoy (#42035), the wind direction and speed indicator were inoperable for most of 1997.

There appear to be a number of ways in which weather forecasting could be improved to support lightering operations. When contacted by the committee, the director of the NWS was unaware of the special needs of lightering operators but expressed a willingness to tailor weather forecasts to meet those needs. Better coordination among the agencies involved in shipping safety and weather forecasting could improve services that lightering operators rely on to maintain safety.

Charting Pipelines

More than 20,000 miles of petroleum pipelines can be found in U.S. coastal waters, mostly in the Gulf of Mexico (NRC, 1994b). Between 1967 and 1990, more than 95 percent of the pollution from pipelines was the result of maritime incidents, notably damage from anchors weighing up to 29 tons; four incidents accounted for 85 percent of the total pollution (NRC, 1994b). The best way to protect pipelines from anchor damage is to bury them in the ocean bottom, but shifting sediments in the Gulf of Mexico make it difficult to bury and maintain pipelines at adequate depths. With current technology, moving vessels cannot detect pipelines from far enough away to avoid them.

The vessels involved in lightering need accurate data on the location of pipelines to identify safe anchorages. ITOL has also identified the need for real-time mapping to track pipelines and platforms in the Gulf of Mexico (Caruselle, 1998). The voyage orders for an STBL usually recommend a specific area in which to anchor while the STBL waits for the service vessel. Lightering is done most efficiently and safely while the STBL is at anchor. Vessel masters often incorrectly assume that their voyage orders ensure them a safe, precise anchorage. In fact, to avoid pipelines, the master must have accurate, up-to-date notices, warnings, and charts of the pipelines in designated lightering zones as well as in traditional lightering areas. Warnings are provided in the North Sea, for example, where even temporary operations are publicized and where pipeline locations are disseminated as pipelines are installed.

As oil and gas exploration increases and new pipelines are installed in the Gulf of Mexico, the need for regularly updated data on the locations of pipelines is becoming more urgent. The problem is demonstrated by a pipeline map prepared for ITOL that shows very few safe anchorages in one of the designated lightering zones. In recent years, the MMS has had logistical problems collecting and updating this information. Data on pipeline installations are not collected on a regular basis, and the information takes too long to be recorded on charts or disseminated to users. The committee could not determine the extent of the

backlog in collecting and disseminating pipeline locations from existing data. Although no pipeline ruptures from lightering have been reported, the proliferation of pipelines could increase the risk of spills in the future.

Governmental responsibility for oversight of these pipeline is shared by several agencies (NRC, 1994b). On the outer continental shelf, the Office of Pipeline Safety (OPS) of the U.S. Department of Transportation regulates approximately 13,000 miles of transmission lines (i.e., the larger, longer pipelines that carry oil and gas ashore), whereas the MMS, of the U.S. Department of the Interior, regulates approximately 4,000 miles of production pipelines associated with platform production systems. In state waters, the OPS regulates transmission lines, and the states regulate production pipelines. Under OPA 90, the MMS is responsible for oil spill prevention and response capabilities for all pipelines. The USCG is responsible for declaring pipeline hazards to navigation.

The most expedient approach to improving the quality and quantity of pipeline information available to mariners may be for the MMS, in cooperation with OPS and ITOL, to identify priority areas for immediate charting (ITOL has already requested this assistance [Caruselle, 1998]). The information should be updated at least every two years. Regulators might also consider establishing "pipeline-free" zones in both designated and traditional lightering areas, similar to the LOOP anchorage areas. These designations would assure mariners that specific areas are, and will continue to be, free of underwater obstructions and, therefore, provide safe anchorages.

Designated Lightering Zones and Prohibited Zones

To regulate certain lightering activities in the U.S. Gulf of Mexico, the USCG has established lightering zones for tankers retired under OPA 90, as well as other zones where lightering is prohibited. Both kinds of zones were established in 1996 following a rule-making process to implement the provisions of OPA 90. The designated lightering zones are for single-hull tankers that cannot enter U.S. ports under OPA 90 but can lighter offshore until 2015. The USCG has also established general regulations for lightering that apply to all vessels using the lightering zones. Prohibited zones (e.g., the Flower Garden Bank shown in Figure 2-2) were established to protect sensitive environmental areas.

So far, these zones are the only ones established for offshore lightering in the United States. All other lightering takes place in traditional lightering areas, which are used because the locations are convenient for operators and they do not create unsafe conditions. Notification of the appropriate COTP is required prior to any lightering operation in the EEZ involving cargo destined for a U.S. port, and all firms intending to lighter either offshore or inshore must request USCG approval before starting an operation. The USCG may require the use of a certain location or prohibit the use of an unsafe location.

Lightering operations in the Gulf of Mexico have led some observers to

suggest that designated lightering zones should be established along the East Coast, or possibly off the coast of California. Increasing USCG control over lightering might provide some additional safeguards, but the current regulations require that designated lightering zones in the Gulf of Mexico be at least 60 miles offshore. Thus, as currently structured, the zone concept would not be appropriate for the east and west coasts, where inshore lightering is more common. On these coasts, other avenues of control are available through USCG authority based on COTP orders and not on national regulations. Any COTP can establish a lightering anchorage or regulated navigation area (see Table 2–3). Lightering anchorages have already been established at Big Stone Anchorage in Delaware Bay and Anchorage #9 in San Francisco Bay, for example. No safety problems have arisen in either of these busy locations.

For inshore lightering, the committee believes there is no overriding need for changing the traditional system of lightering in established anchorages. Some regions where lightering activity is new or growing, however, may require attention. The COTP in Long Island Sound, for example, plans to propose that the USCG establish regulated navigation areas under the district commander to enable officials to designate locations and minimum standards for the entire area. However, COTP authority to approve and monitor inshore lightering appears to ensure safety.

For offshore lightering (i.e., in international waters), the USCG's authority to regulate is somewhat uncertain outside of designated lightering zones. Nevertheless, the COTP's authority to require notification (and to regulate all vessels that eventually enter U.S. ports) has had the effect of setting guidelines for safe practices. The committee recognizes that establishing lightering zones offshore would have both positive and negative effects on safety. On the positive side, the USCG could set safety standards with enforceable regulations and could prevent operators with questionable standards from engaging in lightering. On the negative side, operators have noted that some safety problems are created by having to work within a designated zone that limits their flexibility on the high seas. For example, if a vessel drifts out of a zone during lightering, regulations could force it to unmoor before a lift is completed and moor again after reentering the zone. In this situation, the regulations could create hazards instead of preventing them.

The risks of environmental damage from lightering are related, in part, to the proximity of the operation to environmentally sensitive areas. In some regions, this problem can be addressed by prohibiting lightering in or near sensitive areas. The prohibited zones in the Gulf of Mexico are good examples. Some individuals have suggested that prohibited zones be established in other regions to lower risks under certain circumstances. In coastal waters and harbors, the USCG and other local authorities already have ample power to prohibit operations that could threaten sensitive environments. In international waters, however, U.S. jurisdiction and enforcement are limited. At present, lightering activity is substantial and widespread only in the Gulf of Mexico. The limited and familiar operations off

the east and west coasts have been subject to reasonable oversight and review. Increased offshore lightering in the future could warrant a further evaluation of the benefits of designating formal prohibited zones.

The committee identified one apparent problem related to geographical constraints on lightering in the Gulf of Mexico. The traditional lightering areas sometimes become congested, and, as pipelines and platforms become more numerous in the Gulf, space is sometimes at a premium. ITOL has reported problems with access to the lightering areas off Southwest Pass, which is near the Ewing prohibited zone (Figure 2–2). The industry has asked if waivers could be requested from the local COTP to allow vessels engaged in lightering to drift through a prohibited zone when this is judged to be safer than turning or separating the vessels. The law currently prohibits certain vessels 9 from coming within 60 miles of shore, and the COTP cannot grant waivers except in an emergency. There is a formal procedure for applying for exemption at a higher level (33 CFR 156.110), but this procedure takes time. An extension of the COTP's authority to grant waivers in certain nonemergency situations may be a reasonable way to handle situations that could deteriorate and increase the risk of spills.

Summary

Existing standards and guidelines have provided a solid foundation for lightering safety. However, the committee identified several aspects of vessel design, operations, and equipment that could be improved. First, lightering operations are safer when vessels have long parallel mid-bodies, an adequate number of well placed mounting points for fenders and enclosed chocks for mooring lines, and engines that enable controlled slow-speed operations. Second, all operators should use mooring lines with synthetic tails to absorb shock, adhere to appropriate standards when inspecting and testing hoses, and remain vigilant during their use. Third, the freeboard on very large STBLs should be limited. A comprehensive approach to this problem would be to work toward an international agreement allowing modifications to the ballasting system.

Regardless of whether and how these issues are addressed, industry standards and guidelines will continue to be voluntary. Based on the site visits by committee subgroups as well as the personal experience of various committee members, the committee recognizes that some vessels (especially STBLs) and equipment used in lightering will fail to meet the best standards and practices. For this reason, lightering operators must remain vigilant in reviewing the condition and characteristics of STBLs prior to lightering.

External conditions that affect the safety of lightering operations could be

improved. Gaps in the information available to mariners about local weather conditions on all coasts and the locations of oil pipelines in the Gulf of Mexico could be filled. The obvious remedy is for federal agencies to improve data collection and dissemination. A cost-effective approach might be for federal officials to meet with lightering companies and cooperative organizations to identify priorities and the best ways to meet them.

At present, the number of designated lightering zones or prohibited zones seems to be adequate, but one aspect of the current regulations could be improved. COTPs should have the authority to grant waivers allowing vessels engaged in lightering to depart from designated lightering zones when it would be safer than maneuvering or separating the vessels.

References

Caruselle, P.A. 1998. Letter from Paul A. Caruselle, chairman of the Industry Taskforce on Offshore Lightering, to Chris Oynes, regional director GOM-OCS, Minerals Management Service, March 3, 1998.

Chevron Shipping Company. 1989. Oil Transfer Hose Testing—Gulf Coast Lightering. Internal guidance document used by Chevron, San Francisco. Unpublished.

ITOL (Industry Taskforce on Offshore Lightering). 1990. Industry Lightering Operations Supplement to OCIMF Ship to Ship Transfer Guidelines for U.S. Gulf Coast—Galveston Zone. Houston: ITOL.

ICS (International Chamber of Shipping) and OCIMF (Oil Companies International Marine Forum). 1997. Ship to Ship Transfer Guide (Petroleum). London: Witherby & Co., Ltd.

IMO (International Maritime Organization). 1997. Guidance on Intact Stability of Existing Tankers during Liquid Transfer Operations. Draft circular written by the IMO Marine Environmental Committee as part of ongoing regulatory development process.

NRC (National Research Council). 1994a. Minding the Helm: Marine Navigation and Piloting. Washington, D.C.: National Academy Press.

NRC. 1994b. Improving the Safety of Marine Pipelines. Washington, D.C.: National Academy Press.

NRC. 1996. Vessel Navigation and Traffic Services for Safe and Efficient Ports and Waterways, Interim Report. Washington, D.C.: National Academy Press.

NRC. 1997. Double-Hull Tanker Legislation: An Assessment of the Oil Pollution Act of 1990. Washington, D.C.: National Academy Press.

OCIMF (Oil Companies International Marine Forum). 1978. Hose Standards—Specification for Rubber, Reinforced, Smooth Bore, Oil Suction and Discharge Hoses for Offshore Moorings (Including Purchaser's Inspection Guide), 3rd ed. London: Witherby & Co., Ltd.

OCIMF. 1995. Guidelines for the Handling, Storage, Inspection, and Testing of Hoses in the Field, 2nd ed. London: Witherby & Co., Ltd.