4

Procedures, Practices, and Human Factors

The physical systems described in the preceding chapter are only part of the lightering picture. Additional safety considerations are related to operational procedures, industry practices, and human factors. A key operational procedure is communications, which includes fluency in English. Industry practices include international management and safety standards, cooperative systems to enhance learning and performance, and cargo identification and tracking. Relevant human factors include fatigue, training, and simulation. Risk evaluation and its proper application is another consideration.1 This chapter examines opportunities for risk reduction in all of these areas.

Overview

With the assistance of ITOL and other participants at data-gathering meetings, the committee prepared Figure 4–1, a timeline and framework for planning and conducting lightering operations. This chart shows the steps that are usually taken from the initial planning of a voyage to import crude oil to the United States to the actual lightering operations and the departure of the vessel after it has discharged its cargo. The organizations typically involved include refineries, traders, ship operators, lightering service companies, regulators, and other oversight parties. Each step in the process is detailed in Box 4-1.

|

BOX 4-1 The Lightering Process The following is a detailed description of each step shown in the timeline (Figure 4-1).

|

|

the estimated time of arrival (ETA) at the discharge location. A transit from the Arabian Gulf to the United States can take as long as 45 days.

|

|

The committee identified six general changes in the planning and operational process that would increase safety margins. The remainder of this chapter addresses these changes. In addition to reviewing current practices, the committee attempted to identify actions that could be taken to maintain the spill-prevention record in the future. The six areas of opportunity are listed below:

- vessel management and safety standards—identifying ways vessels and crews can maintain high standards of equipment safety and personnel performance through the use of international guidelines and codes, as well as through the training and certification of crews

- cooperative efforts to enhance learning and performance—using cooperative approaches, such as ITOL, harbor safety committees, or similar groups, to promote the sharing and discussion of critical safety issues among industry operators, regulators, government officials, and other service providers so that all parties can learn from each other and address concerns as they arise

- industry guidelines for lightering operations—using the ICS/OCIMF guidelines, which establish best practices for offshore lightering, to set standards for inshore lightering

- communications—improving the methods whereby the crew of each vessel communicates internally and with other vessels and how well they transmit vital operational information, especially during the critical mooring and unmooring steps

- human factors—preventing accidents through attention to human factors that could lead to fatigue and errors, and through the use of best training techniques

- risk evaluation—using formal analytical methods to identify operational risks and the possible causes of accidents

Vessel Management and Safety Standards

Two sets of international shipping industry standards that have recently come into force will enhance, or at least maintain, the safety performance level of crews and operations. These management frameworks, which are mandatory and enforceable for vessels above a certain size threshold, are expected to promote improvements in operational performance and protect the marine environment. The standards will give the USCG further assurance that vessel quality is being maintained on all tankers. The USCG can exercise control measures (including detention of the vessel) if, among other things, a vessel crew's performance is judged to be unsatisfactory or does not meet requirements of the International Safety Management (ISM) code or Standards for Training, Certification, and Watch-keeping (STCW) certifications.

The ISM Code, which was adopted by the IMO in 1994, establishes detailed standards for the safe management and operation of ships and for pollution prevention. The code emphasizes management systems that promote best practices and procedures that rely on internal audits to protect the integrity of the system. To obtain certifications of compliance with ISM Code requirements, companies must undergo rigorous inspections and audits by either flag-state authorities or (when flag-state authorities so designate) by international vessel classification societies, such as the American Bureau of Shipping, Lloyd's Register of Shipping, Det Norske Veritas, or other members of the International Association of Classification Societies (IACS). The ISM requirements for tank vessels of 500 or more gross tons became mandatory in July 1998, the date when port-state authorities began checking to see that covered vessels had certifications on board. Informal industry surveys suggest that the vast majority of the world tanker fleet (unlike some other segments of the fleet) met the deadline.

The ISM Code does not apply to barges at all, or to tugboats under 500 gross tons. However, tugs and barges are covered by the Responsible Carrier Program (RCP), which was initiated in 1994 by the American Waterways Operators (AWO), the national trade association representing the U.S. domestic towboat, tugboat, and barge industry. The 300 member companies of AWO operate most of the towing equipment in the United States. Although the RCP is a voluntary program and not enforceable by law, the program establishes operating principles, practices, and guidelines that meet or exceed those currently required by federal law or USCG regulations. The philosophy guiding the program is that, although the federal government clearly has a role to play in ensuring safety and environmental protection by establishing a baseline, industry has the primary responsibility for ensuring safety. Unlike the ISM Code, which establishes a framework but does not address specific operational practices, the RCP specifies best practices and operational guidelines with which all members must comply (see Box 4-2).

The second management framework addresses crew competence and protection of the marine environment. In early 1997, new international standards for the skills and competence of seafarers entered into force. These standards were established by the 1995 amendments to the International Convention on STCW, which has been ratified by 120 countries representing more than 95 percent of the world's merchant fleet (IMO, 1998). These more stringent new standards and a better mechanism for ensuring accountability will help keep crew competence at a high level throughout the maritime industry, which will ultimately benefit lightering operations.

The changes are intended to increase the effectiveness of the 1978 convention, which was designed to establish consistent standards among maritime nations that previously had set their own standards for training, certification, and watchkeeping. By the late 1980s, it had become apparent that the convention's lack of precision had led to widely varying interpretations of the standards and

|

BOX 4-2 Responsible Carrier Program The Responsible Carrier Program (RCP), a program instituted through the American Waterways Operations (AWO), is organized into three parts. The management and administration section requires a company to review eight principal aspects of its operations and develop written policies and procedures for each. The eight aspects are vessel operating procedures, safety policy and procedures, environmental policy and procedures, incident reporting procedures, emergency response procedures, internal audit and review procedures, organizational structure, and personnel policies. The section is designed to give a company the flexibility to tailor the program to meet its specific operational needs. The second section is equipment and inspection. Minimum standards and requirements are set out for the vessel hull, machinery, firefighting and lifesaving equipment, navigation and communications equipment, rigging and towing gear, and environmental controls. These standards either reflect regulatory requirements or establish industry standards which much be reflected in the company's policies and procedures. The third section deals with human factors, including manning, watch-standing and work hours, and training. This section outlines comprehensive criteria to be taken into account by companies in establishing safe manning levels for their vessels. It also establishes work-hour limits for all towing vessel personnel. Specific training is required on an initial and periodic basic depending on the individual's position; the requirements specifically cover captains, mates, engineers, deckhands, and tankermen. These requirements must be specified in the company's policies and procedures. In the initial phase of the RCP, each member company's chief executive officer or senior marine office was asked to notify the AWO president when the company had put the program in place. In 1997, the AWO Board of Directors approved a third-party audit requirement as a mechanism for making the RCP more effective and increasing its acceptance by governing bodies, industry customers, and the public at large. This requirement was approved for implementation in the first quarter of 1998, with the goal of having all members audited by January 1, 2000. |

often ineffective administration and enforcement. As a result, STCW certificates did not provide reliable evidence of competence. The recent revisions define skills and competence in more detail; require direct control over and endorsement of the qualifications of masters, officers, and radio personnel; and make parties to the convention accountable to each other.

The revised convention deals with general provisions, master and deck de-

partment, engine department, radio communications and radio personnel, special training requirements for tankers and other types of vessels, emergency and safety procedures, and watchkeeping and fatigue. By August 1998, parties to the convention were required to inform the IMO of measures taken to ensure compliance, education and training, and certification procedures.

In recent years it has come to the attention of the international maritime community that certain flag states may not be upholding the signatory requirements of international treaties by allowing substandard vessels to operate and by licensing marginally trained officers and crews. In an effort to discourage these practices, many port states have stepped up inspections of vessels of suspect flag states. To ensure that all vessels comply with international standards, the IMO has declared that countries that are not signatories to the conventions must certify that they have in place a similar regime to ensure that their vessels meet the standards set forth by ISM and STCW. These vessels will be subject to the port-state and flag-state controls of countries in which they call, including the United States.

Cooperative Efforts to Improve Learning and Performance

Lightering is a complex operation that demands foresight, experience, and accurate judgment. The vessel captains, mooring masters, officers, and crew all have to make decisions about complex weather conditions, variable crew skills, and different types of equipment so as to minimize the risk of accidents and spills. It is not possible to write specific, detailed regulations or procedures that cover every possible situation. Lightering operations can best be managed through a process that establishes threshold performance standards for equipment and personnel and, as long as these minimum standards are met, allows decision makers to exercise informed judgments in the context of specific events.

A model for this process is provided by ITOL, which has established a mechanism for the consensus-based development of industry standards for lightering in the Gulf of Mexico. Among its accomplishments, ITOL developed the Industry Lightering Operations Supplement to OCIMF Ship to Ship Transfer Guide (ITOL, 1990), which was approved by the local USCG COTP, Galveston, Texas, in 1990. In addition, ITOL has worked with the USCG to develop regulations for lightering zones and to develop pollution-response guidelines for the industry. ITOL also obtained approval from regulatory authorities for the use of oil dispersants in the lightering areas.

Through ITOL, representatives of federal and state agencies and industry can convene and cooperate to identify potential problems and establish procedures. ITOL has raised the awareness of local shipping agents who handle lightering activities and has encouraged all interested parties to express or respond to concerns about lightering operations, thereby fostering communication and creating

an atmosphere of trust. The standards that have emerged from this process have established a high common denominator for safety.

The same organizational model might be used with equal success for lightering areas along the east and west coasts. Even if the number of participants is small, cooperation could be beneficial. This approach could be a vehicle for high-quality regional standards to become industry-wide standards without direct government regulation. Cooperative organizations could promote problem solving, interaction, and cooperation to enhance safety. Existing organizations, such as the AWO/USCG Safety Partnership,2 could be vehicles for implementing this model.

An ongoing safety issue that might be resolved through cooperation is the need for detailed vessel information. All parties responsible for lightering safety need access to information about vessels. This is one of the most difficult issues facing the lightering community, according to ITOL, because much of the information is not readily available.

One source of information about tanker safety and inspections is the OCIMF, which has 34 member organizations that represent most of the world's major oil companies. The SIRE program is a voluntary reporting system that maintains computerized technical information about the condition and operational procedures of tankers. The database includes information from more than 17,000 inspection reports, with 600 new ones submitted each month. The primary objective of SIRE is to promote safety.

The information in the SIRE database is drawn from OCIMF member companies' in-house inspection programs and from comments by tanker operators. The standard format includes information about vessel safety and pollution prevention, certification, crew management, navigation, cargo handling, mooring, and engine room and steering gear. Under the current OCIMF charter, the SIRE information is available only to member oil companies, bulk oil terminal operators, companies that regularly charter tankers, and government agencies responsible for safety or pollution prevention. The information is not available directly to lightering companies.

It is not clear whether it would be legal for lightering companies to obtain SIRE information from traders who charter tankers or whether traders planning to lighter in U.S. waters could legally provide the information to lightering personnel. ITOL and other industry organizations could investigate this matter and propose a workable process. One approach might be to encourage revisions to the OCIMF charter to increase access to the database.

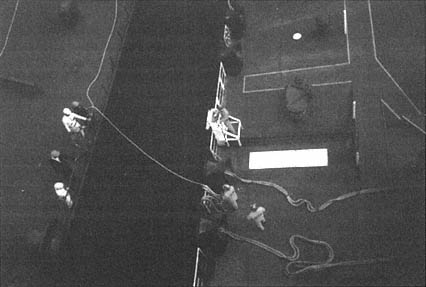

Crews aboard two vessels pass mooring lines.

Industry Guidelines for Inshore Lightering

Offshore lightering has more formal industry-developed guidelines than inshore lightering. Although USCG regulations and industry standards have been written for offshore operations, particularly those taking place in the Gulf of Mexico, no lightering guidelines have been written specifically for inshore operations. The AWO provides strong leadership for the tugs and barges that constitute much of the inland traffic on U.S. waterways, and there is no indication from the record of accidents and spills that standards for inshore operations are necessary. Nevertheless, given the fact that the operators and conditions in San Francisco Bay, Delaware Bay, and Long Island Sound differ from those in the Gulf of Mexico, establishing standards may be prudent. Standards could also establish a safety baseline if inshore lightering activity increases.

The OCIMF lightering guidelines (ICS and OCIMF, 1997) have established the international standards for offshore operations. Each edition of these guidelines, including a recent update, is developed by a committee of representatives of major operators. It may be advisable to use the same approach, or even the same standards, for inshore operations.

Communications

The issue of maritime communications is being addressed by several organizations, including the American Petroleum Institute, the American Association of Port Authorities, and INTERTANKO. Although there is no need to duplicate their efforts or to address general maritime communications issues here,3 lightering does pose unique challenges that warrant examination.

English is becoming the standard language in the international maritime industry, and English is required by most operators during lightering in the United States. Deck officers on international vessels are usually fluent in English because they are expected to communicate with other vessels by VHF radio in close traffic situations. Other crew members must also be fluent in English during lightering operations; the captains of both vessels and the mooring master must understand one another perfectly. Problems sometimes arise because of language differences or inconsistent terminology.

Every lightering operation is different. A few involve two U.S.-flag vessels with crews that are proficient in English. Most operations involve vessels with senior deck officers who are proficient in English but mixed crews representing many nationalities, some with minimal English skills. Still others may involve foreign-flag vessels with crews of the same nationality who converse in their native language and have limited English skills. Often the captain and the mooring master, lightering master, or assistant mooring master converse and exchange orders and commands in English and then translate them into other languages for the junior officers and crew. This may create problems because the mooring master, who usually speaks only English, cannot monitor the execution of orders.

Extra precautions must be taken when lightering operations involve crews that are not proficient in English. When completing the safety checklists or planning the operation, the mooring master or other individual in charge must identify communications barriers and take extra time to ensure that the plan is understood before initiating the operation. If the plan is not understood, then the operation has to be postponed until an interpreter can be present. If problems are identified early enough, perhaps in the pre-arrival message, an interpreter can be a condition of the lightering. Another approach, which is commonly practiced by major lightering companies, is to put an assistant lightering

master aboard the STBL to provide the necessary English language competency. This assistant can also carefully review lightering procedures with the crew prior to the operation to make sure everyone understands the procedures and commands that will be used.

Human Factors

Human factors can both create problems and provide solutions. Approximately 80 percent of marine casualties have been attributed to human error (USCG, 1995; von Zharen, 1994). Human error has also been identified as a frequent factor in the small number of recent lightering-related spills. Human errors can be related to communication; job design; mental or physical fatigue; knowledge, training, or experience; or human-systems interfaces (von Zharen, 1994). Many maritime codes, standards, regulations, and studies address these issues, and there is no need to duplicate these efforts here. However, certain measures might be taken to help ensure that crews engaged in lightering are alert and well trained. Problems with communication were addressed in the previous section; this section addresses training, certification, and fatigue.

Training and Certification

The training and certification of all shipboard personnel engaged in a lightering operation are critical to safe operations. The lightering process is, however, only a part of any vessel's entire operating regime and must be considered as part of a much larger operating system. Recently, the international maritime industry has adopted comprehensive new standards known as the 1995 Amendments to the International Convention on STCW that represent a milestone for improving ship safety through enhancing personnel skills and training. These standards have come into force over the past year, and in August 1998, all parties were required to submit progress reports. The convention addresses minimum standards of competency, methods of demonstrating competency, and criteria for assessing compliance. It also addresses enforcement measures and specific port-state control measures. Some of the new requirements include mandatory rest periods, proficiency in English, basic safety training, and detailed descriptions of required knowledge, as well as methods for demonstrating competence for each, such as examinations, in-service experience, simulator training, and laboratory training, as appropriate.

The committee recognizes that improvements in training and certification within the international tanker fleet (represented by STCW) will have a significant impact on the safety of lightering practices because almost all vessels engaged in offshore lightering in the United States are foreign-flag vessels, and better general training will be key to the safety of all operations including lightering. The committee, however, has not conducted an extensive examination

of seafarer training and certification issues, which would be beyond the scope of this study. The committee recognizes the importance of these issues, however, and the major changes that national and international authorities have recently put in place.

Most of the operational evolutions during lightering are not necessarily unique to lightering. For example, cargo transfer steps, such as pumping, loading, and hose handling, may be the same for lightering as for transfer steps at a buoy or a loading dock. The actual mooring of vessels can be as different from vessel to vessel as it is from dock to dock. One intent of STCW was to acknowledge that individual flag states could not certificate or create licenses for every marine job so it was made incumbent upon operators to ensure that vessel crews were qualified for the operations they were expected to perform. The committee considers that this approach is appropriate and will bring the best results.

Officers and crews on ships involved in lightering, both the STBL and service vessels, are qualified for tanker operations through licensing and training processes established by many international and flag-state requirements. Officer licensing standards provide for substantial training and time-in-grade experience. For example, a vessel master is usually a maritime school graduate (or has equivalent experience) with at least 10 years sailing experience and numerous training opportunities, including simulation. Most vessel officers are expert in mooring, unmooring, maneuvering, close navigation, cargo handling, communications, and crew supervision. Each flag authority is required to issue a certificate of endorsement stating that the seaman is qualified to serve on tankers. In addition, under STCW, officers and ratings assigned specific duties and responsibilities related to cargo must have a minimum service experience aboard a tanker and must complete a number of courses directly related to tanker operations. Among the tanker requirements of STCW are training for ship-to-ship-transfers of cargo to establish that the staff on board tankers is fully capable of handling the lightering operations. As an extra precaution, lightering companies assign mooring masters as well.

Lightering companies provide one or two persons expert in lightering and in local requirements to advise the ship staff during the operation. The mooring master is stationed on board the service vessel and, if there is a second lightering company staff member assigned to the operation, an assistant mooring master, he or she is stationed on the STBL to coordinate communications, ensure that everything is ready prior to commencement of the operation, and to assist during the operation. Lightering experts stress the need for skilled crews and experienced mooring masters. Thus, the technical ''fix'' for the human factors problem is to identify individuals who have good basic skills and then train them thoroughly. The government has not set standards or certifications for mooring masters, so each company now trains them to its own standards. Chevron, for example, certifies its lightering personnel according to its own standards, and the industry as a whole sets nearly equal standards.

A candidate for mooring master begins training by observing operations performed by a qualified mooring master, paying close attention to rendezvous positions, rigging methods, approach angles, mooring arrangements, the maintenance of lightering gear, fender retrieval methods, weather forecasting, and operational safety. The candidate also practices vessel separation and mooring under supervision. The training is tailored to each candidate's level of experience and usually lasts for several months. A review committee evaluates the candidate after training is completed. No written certification is issued, although candidates are approved in writing after a thorough evaluation at the fleet manager level. Usually at least four signatures are required before final approval. Chevron's West Coast operation has two levels of approval, one for summer and one for winter operations.

Some vessel operators and lightering companies use simulators for training candidates; others have adopted their own training standards. For example, Skaugen PetroTrans trains its mooring masters at the Ship Maneuvering Simulator Center in Trondheim, Norway. The company also uses a simulator for periodic instruction and testing of experienced personnel. Simulation has proven to be a valuable tool in aviation, and its application in maritime training was recommended in an earlier study (NRC, 1996). Simulation has also proven to be beneficial in training mooring masters. A growing body of literature indicates that simulation can help translate implicit knowledge into explicit knowledge and that it can facilitate the transfer of "experience" to other individuals quickly and precisely. The lightering industry understands these benefits and has applied them as needed.

Mooring masters are similar to maritime pilots. A pilot must be present on board every vessel entering state waters in the United States. Pilots are considered to be local experts and have the status of advisors but have no legal responsibility in the event of an accident, which is also true for mooring masters. The qualifications for mooring masters are high compared to the qualifications for most pilots. Lightering companies require a master's license for mooring masters and prefer that candidates have sailed as masters.

The committee found no evidence of a need for industry-wide training and certification programs specifically directed toward lightering personnel at this time. This is partly because training and certification is a more general issue applied to all shipboard personnel and partly because of the newly enacted STCW code. However, if lightering becomes more common and new companies enter the industry, then the need for certification should be investigated further.

Fatigue

The role of fatigue in maritime casualties has attracted a good deal of attention worldwide during the 1990s. The USCG accident database indicates that only 1 percent of all accidents are related to fatigue (Battelle Seattle Research Center, 1996), but this low rate may only reflect deficiencies in data collection.

Preliminary results of a Battelle study suggest that fatigue is a contributing factor in 16 percent of critical vessel casualties (Battelle Seattle Research Center, 1996).

The USCG is working on a multiyear project to develop better methods of identifying, investigating, and recording human factors in casualty investigations. Among the tangible results so far is a fatigue investigation work sheet, which is used by investigating officers to keep track of how long crew members worked and slept in the 24 hours preceding a casualty and to identify any other symptoms of fatigue (USCG, 1997).

Anecdotal reports suggest that crew members do not always get the rest stops required under OPA 90 (Section 4114), which states that crew members may not work more than 18 hours in any 24-hour period or more than 36 hours in any 72-hour period. Additional rest hours are prescribed by more recent requirements. Under STCW (Regulation VIII/1), watchkeepers must have a minimum of 10 hours of rest in any 24-hour period, and the hours of rest may be divided into no more than two periods, one of which must be at least 6 hours long. This provision is similar to the rest-hour requirement in 33 CFR 156.210(d) for operations in lightering zones. The mooring master is subject to restrictions on work hours if he or she is directing the movement of the vessel or assisting with navigation and cargo operations. Implementation of the ISM and STCW codes is expected to improve compliance with restrictions on work hours. Given the ongoing attention to this issue by the USCG, as well as officials in Canada and elsewhere, studies related specifically to lightering are probably not warranted.

Risk Evaluation

Only a few formal risk analyses have focused specifically on lightering operations. For example, in a 1993 study of deepwater ports, the USCG concluded that lightering poses a substantially greater risk than using deepwater ports and a slightly greater risk than direct delivery of oil (USCG, 1993). However, that analysis may have inflated the risks of lightering because cargo transfers in the open ocean were considered together with transfers in port, which involve many small spills close to shore, increasing the risk of environmental damage.

Another analysis also noted that most lightering spills are small and concluded that the risks of lightering are manageable. "With adherence to the stringent federal and international requirements for prevention and response as well as the implementation of safety management mandates, the lightering process may be characterized as a relatively and predictably sound environmental risk" (von Zharen, 1994).

The committee discussed the possible application of formal probabilistic risk assessment (or safety assessment) to help determine the risks posed by lightering operations.4 A number of established assessment methods have been used in many other industries (e.g., nuclear power). Some methods, such as actuarial safety assessments, make extensive use of historical accident data and, therefore, may not be appropriate for lightering, which has seldom been implicated in past spills. Another method, known as engineering safety assessment, which requires an extremely detailed analysis of probabilities of failures for all systems and subsystems, has also been used.

Another special type of assessment, the failure modes and effects assessment (FMEA), is nonquantitative and can be used as a first step in a formal process. The nuclear power industry has used this technique for many years, and the USCG has used it for studies of oil spill response plans. The FMEA method has proven to be very useful for evaluating operational risks and identifying the root causes of accidents. The process is designed to identify all possible ways a system can fail and all possible consequences of failures.5 Consequences can be classified or ranked along a spectrum, from insignificant to catastrophic. This approach can be used as a management tool to trace a failure backward from critical events to determine the causative failure modes and take corrective action. This step-by-step formal process also takes into account expert opinion and system design.

FMEA analysis may be useful for analyzing lightering operations. Although it may not be necessary for operators with a long history of success, it might be useful for newer operations under special circumstances and for new lightering companies that want to learn from other's mistakes and successes. Companies and cooperative industry organizations, as well as USCG, may wish to become familiar with these techniques and to evaluate the possibility of using them in appropriate circumstances.

Summary

The committee identified four possible safety improvements in current procedures, practices, and communications related to lightering. The first two improvements are related to industry cooperation. The benefits of information sharing and cooperative problem solving have been demonstrated by ITOL, which has contributed through published guidelines and meetings to the excellent safety record of the very busy lightering industry in the Gulf of Mexico in recent years. ITOL is also a model of a good working relationship between industry and the USCG. Similar cooperative forums on the east and west coasts, perhaps based on

existing groups, could be established. Another improvement would be making reliable information about the condition of prospective STBLs available to lightering operators. This information is compiled in the SIRE system but is not currently accessible by lightering operators. Direct access to SIRE data could be provided only if OCIMF were willing to revise its charter regulations.

Another gap in the safety net is the absence of formal industry guidelines for inshore lightering. Although the committee did not identify any safety problems that reveal a need for guidelines, establishing a consistent safety threshold would be prudent. Many inshore operators use the OCIMF guidelines, which were written for offshore lightering, but some unique aspects of the vessels and practices used inshore may warrant the development of separate or modified guidelines.

Finally, the critical importance of good communications among the officers and crews aboard both vessels involved in a lightering operation underscores the necessity of all key personnel being fluent in English. Service vessel personnel should also be fluent in English.

References

Ang, A. H-S., and W.H. Tang. 1984. Probability Concepts in Engineering Planning and Design. Vol. 2. Decision, Risk, and Reliability. New York: John Wiley & Sons.

AWO/USCG Quality Action Team. 1997. Tank Barge Transfer Spills: Managing Toward Zero Spills. Report presented to the AWO/Coast Guard National Quality Steering Committee. October 1997.

Battelle Seattle Research Center. 1996. Procedures for Investigating and Reporting Human Factors and Fatigue Contributions to Marine Casualties. Report No. CG-D-09-97. Available from the National Technical Information Service, 5285 Port Royal Road, Springfield, Virginia 22161.

ITOL (Industry Taskforce on Offshore Lightering). 1990. Industry Lightering Operations Supplement to OCIMF Ship to Ship Transfer Guidelines for U.S. Gulf Coast—Galveston Zone. Houston: ITOL.

ICS (International Chamber of Shipping) and OCIMF (Oil Companies International Marine Forum). 1997. Ship to Ship Transfer Guide (Petroleum). London: Witherby & Co., Ltd.

IMO (International Maritime Organization). 1998. IMO News 1(1): 6 pages.

NRC (National Research Council). 1996. Simulated Voyages: Using Simulation Technology to Train and License Mariners. Washington, D.C.: National Academy Press.

USCG (U.S. Coast Guard). 1993. Deepwater Port Study. Washington, D.C.: USCG Office of Marine Safety, Security, and Environmental Protection.

USCG. 1995. Prevention Through People Quality Action Team Report. Washington, D.C.: U.S. Department of Transportation.

USCG. 1997. Fatigue Investigation Worksheet. G-MOA Policy ltr 5–97, October 21, from the USCG Commandant.

von Zharen, W.M. 1994. Risk Evaluation of Ship-to-Ship Oil Transfer: An Assessment of Lightering as a Predictably Sound Environmental Risk: Inherent Relevant Concerns and Operational Safeguards. Galveston, Texas: Maritime and Environmental Management Research, Inc. and Texas A&M University Texas Institute of Oceanography.