3

Supply Chain Integration

Most OEMs no longer compete solely as autonomous corporations. They also compete as participants in integrated supply chains. This revolution, which is changing the ways products are designed, produced, and delivered, has the potential to alter the manufacturing landscape as dramatically as the industrial revolution or the advent of mass production. This chapter describes the changing nature of supply chains and efforts to optimize their performance.

In the past, OEMs typically drove down the cost of purchased materials through aggressive negotiations, imposing terms and conditions that minimized supplier profitability and often left suppliers in a weakened condition. More recently, OEMs have begun to adopt a strategic partnership approach, which recognizes that increased, sustainable benefits can accrue from long-term relationships between participants in the supply chain (a win-win situation). This approach considers total life-cycle costs over multiple iterations of a product, with the goal of increasing mutual benefits for all participants in the long run.

SUPPLY CHAIN MANAGEMENT

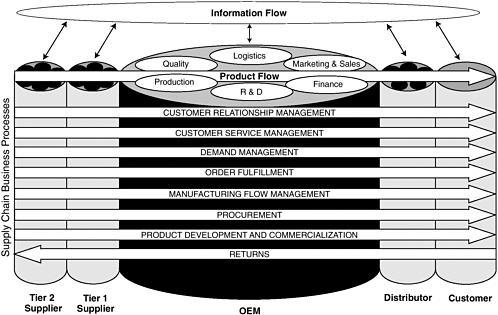

In this era of competition among supply chains, the success of a corporation is increasingly dependent on management's ability to integrate the company's networks of business relationships. Supply chain management (see Figure 3-1) has been defined as the integration of key business processes, from raw-material suppliers through end users, that

provide products, services, and information that add value for customers and other stakeholders (Lambert et al., 1998).

Supply chain management makes use of a growing body of tools, techniques, and skills for coordinating and optimizing key processes, functions, and relationships, both within the OEM and among its suppliers and customers, to enable and capture opportunities for synergy. An OEM's competitive advantage is highly dependent on this integrated management function. Supply chain management attempts to combine the best of both worlds, the scale and coordination of large companies with the low costs, flexibility, and creativity of small companies.

The focus of supply chain management must evolve in response to changing business environments and evolving product life cycles. Different interactions among participants are required during each phase of the product life cycle, from inception through recycling. The supply chains for products in new markets must be flexible to respond to wide fluctuations in demand (both in quantity and product mix). Products in mature, stable markets require supply chains that can reliably deliver products at low cost. Thus, effective supply chain management must be responsive to these changing conditions to ensure that the supply chain evolves accordingly.

For example, marketing excellence used to be the primary source of Procter & Gamble's (P&G's) dominance of the consumer products industry. However, as P&G expanded its product and service offerings in response to market opportunities, the increased complexity of these offerings created difficulties in meeting the needs of retail partners and customers. Traditional marketing strategies involving in-store sales and price promotions created great variations in product demand. To meet heavy short-term marketing-induced peaks in demand, P&G invested in huge manufacturing capacities, inventories, warehouses, and logistics capabilities.

In response to these problems, P&G modified its supply chain focus and remade itself through a series of innovative initiatives. Working both internally and with suppliers and customers, the company created a heralded partnership with Wal-Mart, virtually eliminated price promotions, and streamlined its logistics and continuous replenishment programs. These initiatives reduced variations and uncertainties in demand, thereby reducing the need for surge production capacities and large inventories. Thus, by evolving their primary supply chain focus from marketing to production, inventories, and logistics in response to changing business requirements, P&G was able to reduce costs, meet customer demand, and build strong, coordinated relationships with retail partners and customers.

CONCEPT OF INTEGRATION

An integrated supply chain can be defined as an association of customers and suppliers who, using management techniques, work together to optimize their collective performance in the creation, distribution, and support of an end product. It may be helpful to think of the participants as the divisions of a large, vertically integrated corporation, although the independent companies in the chain are bound together only by trust, shared objectives, and contracts entered into on a voluntary basis. Unlike captive suppliers (divisions of a large corporation that typically serve primarily the parent corporation), independent suppliers are often faced with the conflicting demands of multiple customers. (The technological and investment problems faced by SMEs in attempting to deal with these conflicting demands are discussed in Chapter 9.)

All supply chains are integrated to some extent. One objective of increasing integration is focusing and coordinating the relevant resources of each participant on the needs of the supply chain to optimize the overall performance of the chain. The integration process requires the disciplined application of management skills, processes, and technologies to couple key functions and capabilities of the chain and take advantage of the available business opportunities. Goals typically include higher profits and reduced risks for all participants.

Traditional unmanaged (or minimally managed) supply chains are characterized by (1) adversarial relationships between customers and suppliers, including win-lose negotiations; (2) little regard for sharing benefits and risks; (3) short-term focus, with little concern for mutual long-term success; (4) primary emphasis on cost and delivery, with little concern for added value; (5) limited communications; and (6) little interaction between the OEM and suppliers more than one or two tiers away. Integrated supply chains tend to recognize that all parties should benefit from the relationship on a sustainable, long-term basis and are characterized by partnerships with extensive and open communications. A well integrated system of independent participants can be visualized as a flock of redwing black birds flying over a marsh. Without any apparent signal, every bird in the flock climbs, dives, or turns at virtually the same instant. That is an integrated system! Supply chain members, in a similar manner, must react coherently to changes in the business environment to remain competitive.

Supply chain integration is a continuous process that can be optimized only when OEMs, customers, and suppliers work together to improve their relationships and when all participants are aware of key activities at all levels in the chain. First-tier suppliers can play a key role in

promoting integration by guiding and assisting lower tier suppliers. In an example of multi-tier integration, Wal-Mart thoroughly integrated P&G's Pampers product line into its supply chain. P&G, in turn, worked with 3M to integrate its production of adhesive strips with Pampers manufacturing facilities.

Forces Driving Increased Integration

The following worldwide trends and forces are driving supply chains toward increased integration:

-

Increased cost competitiveness. Having substantially improved the efficiencies of internal operations, OEMs are seeking further cost reductions by improving efficiency and synergy within their supply chains.

-

Shorter product life cycles. The Model-T Ford, for example, was competitive for many years. A personal computer (PC) is state of the art for less than a year, and the trend toward shorter product life cycles continues.

-

Faster product development cycles. Companies must reduce the development cycle times of their products to remain competitive. Early introduction of a new product is often rewarded with a large market share and sufficient unit volumes to drive costs down rapidly.

-

Globalization and customization of product offerings. Customers the world over can increasingly afford and are demanding a greater variety of products that address their specific needs. Mass customization has become the new marketing mantra.

-

Higher overall quality. Increasing customer affluence and tougher competition to supply their needs have led to demands for higher overall quality.

These increased demands on OEMs for improvements in product design, manufacturing, cost, distribution, and support are being imposed, in turn, on their supply chains.

Case Study: Dell Computer and Fujitsu America

Dell Computer Corporation's success in the past few years and its growth relative to the rest of the PC industry made daily headlines throughout the 1990s. Based on the premise that bypassing resellers, building products to order, and reducing inventories would result in a lower cost, more responsive business, Dell has grown into one of the

largest forces in the industry. Nevertheless, it is squeezed into such a narrow business niche that, from some perspectives, its very survival seems tenuous. Dell competes with many capable and, in some cases, lower cost competitors, has virtually no proprietary technology, and must deal with exceedingly robust suppliers, including Intel and Microsoft.

The heart of Dell's success is its integrated supply chain, which has enabled rapid product design, fabrication, and assembly, as well as direct shipment to customers. Inventories have been dramatically reduced through extensive sharing of information, a prudent choice given the risk of technological obsolescence and reductions in the cost of materials that can exceed 50 percent a month. Even with reduced inventories, Dell's strategic use of information has made possible a dramatic reduction in the elapsed time from order to delivery, giving Dell a significant competitive advantage.

Component inventories are monitored weekly throughout the supply chain and, when there are deviations from plan, the sales force steers customers, by means of discounts, if necessary, toward configurations for which there are adequate supplies. Thus, abundant, timely information is used to work the front and back ends of the supply chain simultaneously.

Speed is a critical factor in the computer industry, especially in the area of inventory. In the late 1980s, Dell measured component inventories in weeks. In 1998, they were measured in days. They may soon be further reduced through real-time deliveries so that, as components are used, they are automatically and immediately replaced. The reduction in inventory not only lowers requirements for capital, it also enables rapid changeovers to new product configurations because no old parts must be used up. Faster time to market for new products translates into increased revenues and profits. The change in emphasis from inventory levels to inventory velocity throughout the supply chain has been made possible, in part, by the Internet.

In Dell's new virtual corporation, inventories are reduced by use of timely information; emphasis on physical assets is being replaced by emphasis on intellectual capabilities; and proprietary business knowledge is being increasingly shared in open, collaborative relationships. This extensive integration of the supply chain can be viewed as a shift from vertical corporate integration to a virtually integrated corporation (Magretta, 1998). Vertical integration was essential in the early years of computer manufacturing when the supplier base was not well established and assemblers had little choice but to design and build components and assemble the entire end product in house. Proprietary component technologies were a main source of competitive advantage, although in some cases they had little to do with creating value for the customer. As the industry matured, multitudes of component suppliers became eager to

invest and compete in terms of price and innovation. Leveraging investments by these suppliers has freed Dell to focus on delivering complete solutions to its customers. However, because these components are available to all PC assemblers, it has become harder to compete in terms of end-product differentiation. Thus, a high premium has been placed on speed and process efficiency, blurring the traditional boundaries between supplier, manufacturer, and customer. For instance, peripherals, such as monitors, keyboards, speakers, and mice, need not be gathered in one location prior to shipment to the customer. Manufactured by separate suppliers and labeled with the Dell logo, shippers gather them from all over North America, match them overnight (merge-in-transit), and deliver them as complete hardware sets to customers as if they had come from the same location.

Dell's virtual integration has the following characteristics:

-

use of rapid, seamless communication to build direct relationships between customers, OEM, and suppliers

-

a clear definition of what Dell does best (i.e., core competencies, including branding, marketing, and selling through direct channels), with partnerships for the rest (capital-intensive and labor-intensive component fabrication processes and services). This enables Dell to be highly selective in its capital investments and to focus on activities that create the most value for customers and shareholders

-

selection of partners who are best in their respective fields, inviting them to become intimate parts of the business, and holding them to the same exacting quality and performance standards as in-house segments of the business

-

use of a minimum number of suppliers, to whom Dell is highly loyal as long as they maintain their leadership in technology, quality, cost, and delivery

-

use of the Internet, not just as an add-on to the business, but as an integral part of a strategy to eliminate boundaries between companies and promote effective integration

-

less emphasis on guarding intellectual assets and more emphasis on using assets rapidly before they become technologically obsolete

By using a highly integrated supply chain, Dell has enjoyed many of the advantages of vertical integration while simultaneously benefiting from the investments, innovation, efficiencies, and specialization of highly focused suppliers. Although the Dell model does not fit every situation,

the lessons of Dell's experience can be extracted and adapted to many other supply chain situations, even for SMEs.

By 1998, the success of the Dell model, as might be expected, was causing problems for competitors, including Fujitsu America, which had large inventories and high shipping costs (Washington Post, May 2, 1999). Customers had to wait 10 days for laptops, while competitors were delivering in five. In response, Fujitsu moved its distribution center from Portland, Oregon, to Memphis, Tennessee, and turned distribution over to FedEx Corporation, the parent company of Federal Express. In direct response to orders, FedEx coordinates the shipment of components from worldwide suppliers, oversees the assembly of PCs, and ships them out, all in three or four days. By early 1999, the cycle time on the ground was eight to twelve hours, and the goal was to reduce it to four hours. Fujitsu has essentially eliminated geographic proximity as an issue and has made maximum use of the benefits of globalization, including low cost. Even with the premium price of express shipping, this modification of the Fujitsu supply chain saved the company millions of dollars, slashed inventories by about 90 percent, and increased profits by 25 percent. Most important, these changes have enabled Fujitsu to compete effectively with Dell for Internet sales directly to consumers. However, as is evident from these examples, these innovations in supply chain integration can also impose large burdens on suppliers in terms of responsiveness, inventories, and management of their own supply chains.

COSTS OF INTEGRATION

The costs, complexities, and risks of fully integrating and managing a highly integrated supply chain can be as substantial as the costs of integrating and operating a corporation of comparable size. Thus, most supply chain integration efforts to date have been very limited in scope. Some of the major costs are listed below:

-

time devoted to managing, training, and support

-

effort devoted to becoming a better customer

-

investment in supply chain integration software and compatible information systems throughout the chain

-

Opportunity costs (i.e., investments in supply chain integration may necessitate foregoing other business opportunities)

-

risks of production stoppages

Because the extent of interconnectedness and interdependency makes highly integrated chains increasingly vulnerable to disruptions, the risk

of production stoppages should not be overlooked. A highly integrated, interdependent supply chain that consists primarily of sole-source suppliers practicing just-in-time manufacturing with minimal inventories is highly reliant on the timely delivery of quality components and services. Failure by one participant to deliver can rapidly bring other parts of the chain to a halt. This happens, on occasion, even to the best suppliers and logistics providers.

Automakers, for example, who are under constant pressure to reduce costs, have tightened their supply chains to the point that they typically have less than a one-day supply of parts at final assembly facilities. Thus, a breakdown anywhere in the supply chain has the potential of bringing production to a halt (e.g., strikes at two GM parts plants in 1998 resulted in the shutdown of virtually all assembly operations within days, and flooding in 1999 at a single supplier in North Carolina reduced operations at seven DaimlerChrysler and three GM assembly plants to half-shifts due to shortages of a single part).

Potential threats, including storms, power outages, terrorism, computer hackers, disruptions in communications, and equipment breakdowns, can be very difficult to predict and costly to prepare for. In another example, the earthquake that shook Taiwan in September 1999 showed how a power supply disruption in one country can have worldwide reverberations through an entire industry. Damage to two electric power substations was the primary cause of a shutdown of Taiwan's computer-chip industry, which resulted in shortages of components and higher costs in the supply chains of OEMs around the world.

Supply chain participants must individually and collectively assess the probability of production-stopping events and their tolerance for risk, which must be balanced against the savings from increased sole-sourcing, tighter integration with remaining suppliers, and reduced inventories and production capacities. Thus, although good communications and resource sharing can be helpful in preparing for and responding to disruptions, supply chain, participants must be careful to avoid unacceptable levels of risk in their zeal for integration.

Recommendation. Small and medium-sized manufacturing enterprises should develop operating strategies based on an appropriate balance between supply chain performance and risk; assess the probability and effects of potential threats to their supply chains; and maintain sufficient (though sometimes expensive) slack, redundancy, and flexibility to keep the potential threats at manageable levels.

BENEFITS OF INTEGRATION

The most sought-after benefit, or return on investment, in supply chain integration is the cost savings that result from reductions in inventory. Inventories can be reduced by increasing the speed at which materials move through the supply chain and by reducing safety stocks. For example, if the costs of maintaining inventory are approximately 1 percent per month and if an integrated supply chain can reduce inventory levels by 30 percent, the savings, shared among the participants, can be substantial.

Another common benefit of supply chain integration is a reduction in transaction costs. If information sharing can reduce the number of transactions and if electronic systems can reduce the cost of each transaction from the $150 cost of a traditional transaction, each participant can realize substantial savings (LaLonde, 1997).

Reductions in supplier redundancy can reduce product costs by increasing production levels at remaining suppliers and reducing the costs of managing the supply chain. Although this can also increase investment and management burdens on suppliers, the delegation of responsibility and authority to entities closer to the action can result in improved decision making, as long as good communications are maintained throughout the chain.

Other potential benefits of supply chain integration are listed below:

-

reduced friction, fewer barriers, and less waste of resources on procedures that do not add value

-

increased functional and procedural synergy between participants

-

faster response to changing market demands

-

lower cost manufacturing operations

-

lower capital investment in excess manufacturing capacity

-

shorter product realization cycles and lower product development costs

-

increased competitiveness and profitability