IDENTIFYING THE BARRIERS TO CHANGE

Paul G. Johnson

Smith, Hinchman and Grylls Associates

I would like to speak about factors which limit innovation and change in the way architects design and develop buildings, especially as they relate to materials, systems, and construction techniques.

I have been discussing this subject with my associates at Smith, Hinchman and Grylls and other architects and engineers. I have considered the issue from several points of view, reviewed my past experiences and taken a hard look at the nature of design and construction of buildings over the last 20 or so years. With some surprise, I find that the profession I practice today has changed dramatically and so have the buildings which we design and build. The changes I noted, to list only a few, include:

-

Widespread use of the construction management delivery method

-

Emergence of a common building code format by the three major model code organizations

-

Widespread use of the Construction Specifications Institute three-part specification format

-

A dramatic increase in long-span structures, both in number and length of span

-

Dramatically new and better material technology in several areas

-

The emergence of single-ply roofing systems as a major roof system design

-

The enactment of Occupational Safety and Health Administration and American Disabilities Act legislation

-

The emerging role of plastics in their varied forms in construction

-

The need and demand for energy conservation

-

The emerging concepts of “green” architecture

-

The disproportionate amount of time spent by architects and engineers in consideration of their exposure to risk

-

A lessening in the willingness of owners to commission architects and engineers to provide full services including contract administration

-

The demand for total quality management (TQM) as a way of doing business

-

The high degree of competition for design work and the dwindling fees available to accomplish the work

-

The steadily increasing demand to do more for less, both in service and construction.

In addition:

-

Design-build contracts for construction are more common.

-

Engineering analysis by computers is now commonplace.

-

Computer-aided design systems are now widely available, and they are nearly a necessity for the production of construction drawings.

-

Wind analysis methods have been dramatically refined and now include wind tunnel testing as an accepted alternative method of analysis.

And this is just a beginning. I think it is safe to say that the practice of architecture and engineering is much more complicated today than it was 20 or so years ago, with greatly increased demands being placed on design professionals.

The issues I have identified represent my particular perspective, which is as a provider of professional architectural and engineering services for the design and preparation of documentation required to construct buildings and the administration of the contract for construction on behalf of the building owner. I should add that for the past several years I have been deeply involved in the evaluation of exterior building system failures and the overall evaluation of existing buildings on behalf of owners. Not surprisingly, a number of the failures I have seen were systems which, when constructed, were considered to be innovative. In general, I would agree that innovation and change are healthy and inevitable in the construction industry. However, there is risk involved in change. New materials, techniques, and systems should be encouraged but only with the proper research and development to accompany their use. In too many cases in the past, the building has become the test case. Unless the owner is fully aware of and in agreement with the unknown or unproven nature of the new material, system or technique being considered, it would not be prudent of the designer to proceed in that direction. With this in mind, I would like to discuss four issues which represent barriers to change and, therefore, to innovation and improvement of the completed building. The four issues are:

-

Building Codes and Regulations

-

Risk Exposure

-

Limited Service Contracts

-

Increased Competition/Decreased Compensation

This is not intended as a comprehensive list, but each issue is very important and deserves consideration.

Building Codes and Regulations

The existence of three model building codes—not to mention the numerous state, federal and local regulations—causes a great deal of wasted effort to be expended by the design professional. On any major project it would be fair to say that architects and engineers are faced with an extensive list of agencies, regulations, and publications which govern the design of the buildings in one form or another. This maze of requirements can be very confusing and time consuming.

The seemingly perverse need of City A to use the 1993 Building Officials and Code Administrators (BOCA) Code and City B to use the 1987 BOCA Code (with city amendments) requires the designer to be familiar with multiple codes and therefore detracts from his ability and desire to spend time on innovation or change. His time is tied up in survival, not innovation.

A major overhaul of established codes and regulations to a single national building code and standardization of regulations from state to state and within the federal government would go a long way to free up time for innovative approaches to design and construction.

Risk Exposure

In the construction field, change and innovation inevitably bring risk. Risk to the owner, risk to the contractor, and risk to the design professional. It is difficult enough to design and prepare the required documents for complex projects utilizing time-tested and industry-accepted materials, systems, and methods of design and construction. The perception of many design professionals that simple errors in judgment may lead to legal action resulting from errors, real or imagined, is disruptive, time consuming, and expensive. In fact, the design professional may suffer the results of legal action when there is only the perception of the possibility of an error in judgment.

This climate does not foster, and in fact, barely tolerates change and innovation. Change in design and construction is risky. The use of new systems, methods, and techniques necessarily increases the chance of errors and problems in an already complex process.

From a legal point of view, at least in the perception of many design professionals, change and innovation results in nothing but risk with little or no protection. Under these conditions, is it surprising that they prefer to stick with the tried and true?

Limited Service Contracts

There appears to be a trend for owners to prefer limited service contracts over full service arrangements for professional design services. Often the portion of services which is not commissioned is the administration of the contract for construction, or field representation. This is unfortunate and I believe creates a very unfriendly climate for change and innovation in the selection of new materials, systems, and techniques. Designs which utilize new materials and systems require greater attention by the design professional after award of the contract for construction. The success of these new materials and systems is often dependent upon a clear understanding of how they are to be integrated into the building and how they relate to other building systems. It is very easy for new materials, systems or techniques to be misunderstood and incorrectly utilized during the process of submittal, shop drawing preparation, fabrication and erection, or construction. This is often the critical phase of the entire design and build process.

When design professionals are cut off from this portion of the project by a limited service contract, it is not fair or reasonable to expect the professional to create designs utilizing new materials, systems or techniques. Again, the issue of risk arises, for it is likely that the designer would be held accountable for failures—even though they did not have the opportunity to monitor the project to completion. Under these conditions who would be likely to pursue change and innovation?

Increased Competition/Decreased Compensation

If the conditions previously addressed are not enough to kill the natural desire of design professionals to develop and take advantage of innovation and change in the performance of their service, this issue alone would be very discouraging. While I do not have the facts and figures available to support the following statement, I believe it is self-evident to those responsible for the financial survival of design firms that competition for commissions is greatly increasing, and the compensation for performing services is steadily declining. Added to this is the increasing depth of financial commitment to capital investments in computerization, which is an absolute necessity to stay in business today. This combination of conditions places great pressure on design firms to become more efficient in the performance of their services. While this is a desirable condition in some respects, it also detracts from the ability of most firms to allocate resources and concentrate on the development of innovation and change in building materials, systems, and techniques. In point of fact, it is difficult to keep up with the normal changes on the technical side which results from changing codes, regulations, and technology.

In conclusion, the unfortunate but simple fact is that the financial structure of fees and the cost and risk of being in business and staying competitive make it very difficult to promote a culture of innovation and change in the utilization

of new materials, systems, and techniques in construction. Consequently, design professionals cannot, or are not willing to, absorb all of the risk and cost of innovation. In short, the financial pie available for services will rarely accommodate a slice for innovation and change. Until the basic system we operate under is altered dramatically, it is unlikely that design professionals will be able or willing to provide leadership in accomplishing innovation and change in the development and application of new and better building materials, systems, and techniques.

In reviewing these four barriers to change, two common and closely related elements stand out—money and risk. Innovation and change is by its nature more expensive for the design professional, and it carries more risk. Without adequate compensation and protection from risk, innovation will be slow in coming from the design side of the construction industry.

ABOUT THE SPEAKER

Al Neely is the Senior Vice President of Development for the Charles E. Smith Companies responsible for directing the development of the 3-million-sq-ft Worldgate and the 9-million-sq-ft University Center mixed-use projects. Prior to joining the Smith Companies, Mr. Neely was Executive Vice President and Managing General Partner of the New Height Group, a real estate development company. During his nine years with the firm, he was responsible for the development and management of 2.5 million sq ft of mixed-use property. Previously, he was the general manager of a 1,100-acre mixed-use business park, where he managed the development of 3.5 million sq ft of corporate user buildings.

IDENTIFYING THE BARRIERS TO CHANGE

Al Neely

Charles E. Smith Companies

I am a developer for the Charles E. Companies, and my remarks need to be put in that context. The Charles E. Smith Companies is a local or regional developer. We have developed, over the last 35 years, about 20 million sq ft of office space. We still own about 17.5 million sq ft of that portfolio, several million sq ft of which are leased to the federal government.

Our customer, then, is the end user of the office space, the federal government. I'm going to speak from the perspective of the private sector in a very narrow sense. While we are a privately held company, we do tend to function somewhat like an institution, not altogether different than a pension fund, a life insurance company, or even a bank in some cases. We approach a development deal as having three components. The development team is one component. It includes ourselves as the developer, the design professionals, and construction managers or contractors. The tenant, or the user, is the second component and the most important component to us. The third component is the institutional investor, be it a bank for construction lending or permanent financing, or a life insurance company as a joint venture partner.

For those of us in the development business, there are no barriers to change. There are irritations, there are opportunities, but there aren't any barriers. But I'll try and talk about three issues as barriers to innovation in construction practices.

These are cultural rigidity, economics, and adaptability and reuse. When we talk about cultural rigidity, we have to deal with our user, our customer's discomfort with innovation, and there is a certain amount of that. It comes from what I call cultural rigidity. The end user has a response to innovation. Oftentimes it is the federal government that will have that response to innovation. The institution, one of three components in a development deal, is very resistant to innovation. The word “change” creates fear and loathing in the institution. The developer, who is probably the most receptive to it, really can't

do a thing, though, if we can't get the end user to accept it and the institution to accept it. If we don't have the tenant and we don't have the financing, we don't have a deal; it's a non-starter for us. While we like to think of ourselves as innovative, we're constrained by the cultural rigidity of the user and the institutional investor.

Let me talk about economics a little bit, because I really think from the developers' perspective, the heart of the issue is risk reward. The lenders really truly consider innovation to be a dirty word. In fairness to them, it is because the traditional lenders have very thin margins on a typical office building deal or a typical real estate deal. That is, the margins on their cost of funds and what they charge us to borrow those funds are very thin. The lenders are set up to underwrite those deals on that basis. So when you talk to them about welded steel moment connections based on medium scale experimentation or some other innovative technology their response is either “huh?” or “next.”

It is really tough to get innovation with these very thin margins and, really, the lenders' inability to underwrite those risks. They are set up to move a number of deals through the pipeline. They are really not set up to take each individual deal and, when an innovative one appears, to say, “Let's really analyze whether that innovation is a good idea or not.” They either do not deal with it, or they deal with it by laying off the risk. They deal with it by very low loan-to-value ratio, which may kill the project for the developers. From the equity investor's or the lender's side, it is really tough to make innovation happen.

As to the third barrier to innovation, adaptability or reuse, our typical deal with the federal government may be a 10-year lease. We have to figure out what we are going to do with this building at the end of those 10 years. If we get very innovative in certain physical constraints in the building, be those bay depths, floor-to-floor heights, systems, any of those things, we have to look past the first 5 or 10 years and ask who the next user is going to be. What is the salvage value of that? How can we reuse that building?

Those are the three constraints to innovation that we focus on. Can we overcome the cultural rigidity? Can we balance the risk rewards to get the deal financed? And, what happens at the end of the lease term to this building? What is its reuse? How adaptable is it?

Today, it goes beyond office buildings. Today we must look at whether we turn an office building into an apartment building. Who knows what the office market is going to be in 10 years? I certainly don 't. There are a few buildings I wish I didn't have such deep bay depths on today; I could turn them into apartment buildings based on the current office market.

I would like to dwell on market forces just a little bit more because I think market forces can also impede innovation, at least we see that today in the office building environment. Let me use a very simple example. An office multiplier, when all is said and done, may be around 10. By that I mean that for every $10

per sq ft that a developer spends on a building, he has to collect another dollar of rent on a building. So that if we, today, can build a typical office building for $200 a sq ft, we need to get $20 in rent on a net basis to make the deal work. If the demand outweighs the supply and the market is tight, we can charge $24 for that space and be much more innovative. The additional dollars give us the economic room to take those chances, to innovate, to be able to get the financing. It changes the whole equation, that supply and demand piece of it.

On the other hand, if it costs $200 to build an office building today, and we can only lease it for $17, we're not going to be building many office buildings. That is really the condition that we find ourselves in most markets today. Developers are not interested in a lot of innovation when, today, we construct buildings for $200 per sq ft and can only lease them for $17. However, if innovative technologies could show us how to build them for $170 per sq ft, we would get really interested. In short, we're market driven. It 's really the supply and demand of the market that developers always keep in context.

My last point is the good news. From our perspective, the real estate business is getting tougher and tougher because of the changes in the way we live and work in our society. I don't know what the future of offices is 10 years from today. They may be dinosaurs. We may be working out of our houses. And yet, we have to look at 30- to 50-year horizons and try and figure out what we're going to do. I think the fact that we can count on change, and we can count on societal changes coming faster and faster, opens doors for innovation and flexibility and adaptive reuses. While all of this change on the horizon makes some people uncomfortable, it is an opportunity. We have to be very flexible, though, in our design and in the adaptability of our designs going forward.

ABOUT THE SPEAKER

Thomas J. Pasko, Jr., is the Director of the Office of Advanced Research in the Federal Highway Administration (FHWA). He started his career with the Pennsylvania Department of Transportation and then went to FHWA in 1961, where he conducted research in concrete and steel. He has been in management since 1976 and supervised research in many innovative concepts, such as epoxy-coated rebars, cathodic protection, modifications of and substitutes for asphalt, new deicers, and structural concepts such as pre-stressed pavements and high-strength bridges. He is a registered professional engineer, belongs to about 15 technical organizations, and serves on several advisory boards. He is presently the chairman of an interagency task group on infrastructure materials and a new transportation committee on advanced materials. Mr. Pasko received a B.S. and M.S. in civil engineering from Pennsylvania State University and has completed two years of graduate work in transportation at Cornell University.

IDENTIFYING THE BARRIERS TO CHANGE

Thomas J. Pasko, Jr.

Federal Highway Administration

The Federal Highway Administration (FHWA) funds about 2,000 studies a year. In over 30 years, I've seen many technical successes but not many marketing successes. From my perspective, I just don't see the changes out there that reflect the amount of research completed over the years. Today, I'd like to talk about funding, fragmentation in the industry, education needs, markets, barriers to change, and the future.

Funding

Of the $80 billion a year that the federal government spends for research, most of it is in the defense industry. Funding for transportation is $800 million. There has been an inadequate amount of research funds for infrastructure and construction. The Department of Transportation (DoT) is primarily a regulatory agency. However, we do have almost $800 million a year for research, and it's hardly noticed out there. When people talk research, they talk about the Department of Energy, the National Science Foundation, and the National Aeronautics and Space Administration (NASA). Very little is ever said about transportation. In comparison to Transportation's efforts we can look at the Advanced Materials and Processing Program (AMPP) which was a 1993 program during presidential emphasis on research and development (R&D). The Department of Energy devotes about $700 million of their total research budget of $7 billion a year to basic materials R& D, as contrasted to Transportation's total $800 million R&D budget. Many of the research dollars of AMPP are devoted to basic research into biological materials, fiber optics, superconductivity, etc. DoT is not heavily involved with basic research. For example, on the Maglev experimental electromagnetically propelled high-speed train, the superconductivity research is done for us by the Department of Energy, and on hypersonic aircraft, the research is done by NASA.

A lot of the nation's research is either in defense or it is on the side of basic research and, to be a leader, you need lots of money in these areas. By comparison, the federal government and others have not invested a lot of money in construction R&D. Why has infrastructure not gotten the money?

Fragmentation

Construction is a very fragmented industry, and many industries within construction, like steel and concrete, are not working together. The industry is comprised of many small firms that often have less than 10 employees, and most of the materials produced are of low unit value. For example, when you're putting down concrete pavement where you pay $20 per sq yd for 10 in. of concrete slip-formed into place, it costs less than the carpet in most living rooms.

The construction industry has not had an effective voice in the political scene. The electronics industry has been effective. The composites industry is starting to do this, but the construction industry has not done it. Some Civil Engineering Research Foundation (CERF) figures from a survey on industry research and development show that most industries, such as electronics, are investing around 4 or 5 percent of their funds in R&D. The construction industry is investing less than one-half of one percent (Table 1). One development that may help is work that is being done by the CERF. The FHWA has helped CERF put together an organization called CONMAT, for construction materials. To date, 10 materials industries are participating,

TABLE 1 Industry R&D Investments

|

Sector |

Annual Investment (percent)a |

|

Electrical/Electronics |

5.5 |

|

Telecommunications |

3.7 |

|

Aerospace |

4.2 |

|

Chemicals |

4.1 |

|

Automotive |

4.0 |

|

Construction |

0.5b |

|

U.S. Average |

3.8 |

|

a Business Week. June 27, 1994. R&D scoreboard. Business Week. (3378): 81-103 b Civil Engineering Research Foundation. December 1993. A nationwide survey of civil engineering-related R&D. SOURCE: Civil Engineering Research Foundation. December 1994. Nationalconstruction goals: a construction industry perspective. |

|

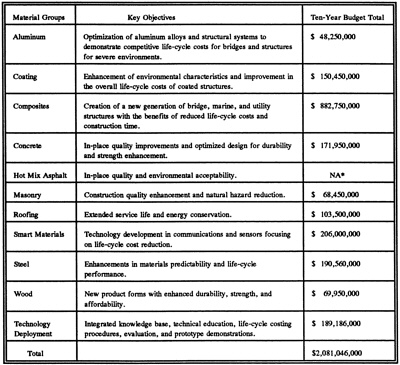

including concrete, steel, and composites. There is now a CONMAT coordinating committee or council that is trying to unite the industry so that the steel representatives will sit down with representatives from the concrete and plastics industries and work together. Together, these people have over the last three years produced several reports. The latest report by CERF was released in December. The underlying goal is to get more research money into theinfrastructure and construction arena. Figure 1 shows the research needs as put together by advisory groups in each of the materials sectors, a $2 billion program. Industry is asking the government to more than double its investment in infrastructure R&D.

FIGURE 1 Proposed R&D on High-Performance Materials

*Specific funding levels have not been established at this time.

SOURCE: Civil Engineering Research Foundation. December 1984. Materialsfor tomorrow's infrastructure. CERF Executive Report 94-5011-E. CivilEngineering Research Foundation.

Development

That is the research side. We also lack funding for development. A market for the new technologies must be created. For example, we know how to put lights, gates, and intrusion alarms at each of our railroad-at-grade intersections. If we did it, we could save possibly 500 lives a year. Why don't we do it? Why don't we help the instrumentation industry by creating a market? Because it is going to cost $18 billion, which is just about what the U.S. government now gives the states for the federal aid highway system. We would have to almost double the money, and the money isn't there.

A few years ago, a barge ran into a bridge structure down in Alabama, causing a train to go into the water. People were killed. The technology is available to keep this from recurring. We could instrument these bridges, and at the same time, we could instrument stream flow, traffic flow, the bridge condition, the micro-weather, or anything we want. We can satellite it, and we can react in record time. Why don't we do it? Why don't we create a market? The defense instrumentation industry is ready to help us. If it costs $25,000 to do this instrumentation on each of 580,000 bridges, it would cost $14 billion, and that' s a big price tag. Where does the money come from?

Education

Now I'd like to talk about education as a barrier to innovation. In a 1990 article in the American Association of State Highway Transportation Officials (AASHTO) magazine, it was found that of the Virginia Department of Transportation's 11,000 employees, 10 percent of them were undergoing remedial reading. This is pretty near the average throughout the population. This is at the state highway department level, high-level government, if you will. In 1990, California, Florida, and Arizona had 14 percent of their high school students drop out before graduating. All of the other states were just a little bit below that. What happens when you look at the worker level of the contractors out there?

The Department of Education has found that 50 percent of the population cannot read above eighth grade level, 13 percent cannot read at all, and 44 percent read less than one book a year. This is a problem that affects us all. How does it affect us? Workers cannot improve their work if they don't understand what they are doing. For example, I advised some of our electronics people, if they want to put in a driveway, ask the contractor questions about how he is going to build the concrete pavement. I said, “Ask him what the concrete strength is.” The fellow came back and said, “He tells me he's going to use whatever the plant gives him.”

I instructed another contractor to ask whether air entrainment was to be used for frost resistance. The contractor said, “We don't need air entrainment. We're going to build it in the summertime.” In my own experience, we wanted sound barriers painted with epoxy paints. The contractors painted it with all of

the part A's and they saved the part B's. They are still waiting for it to dry. The point is, if you want someone to use technology, you have got to sell education. If people understand what they are doing, then they can go out and use an innovative product because they have trust in it and because they are comfortable with it.

Parochialism

Another barrier to innovation is jurisdictional control—the many different codes, different ages of the codes, different state codes, and so forth. In the highway arena, the federal government only owns about 6 percent of the roads. The states have 23 percent of the control, but the rest of the roads are controlled by almost 37,000 different entities. When you deal with water supply issues, you must contend with 59,000 water supply companies. The number of total incorporated communities is about 89,000. A lot of the federal money goes out in federal aid to the different communities. This does not create a uniform situation. The federal government does not dictate, so each entity does things in its own way. In the federal government, there are 14 major departments, one of which is the Department of Transportation with 10 agencies. Other departments have about the same number of major agencies. Additionally, there are 135 independent agencies. It is very complex. You never know who you are talking to, but you've got to sell everybody.

When I went overseas to visit some European projects, I found that countries such as France have one law that covers the country. In contrast, we have 50 different states, and we have to deal with each individually. Each state has its own court system in addition to the federal system, its own tort liability system, and its own professional licensing for civil engineering. If we are going to compete in the future with the European union, we are going to have to find some way of homogenizing, harmonizing, or making more uniform these institutions and regulations.

When you go out to sell a new product, you have got to knock on every door. In our complex system, everybody has to be informed because everybody wants to assert his power or influence. However, there is hope on the horizon, because the public agencies have cut back their staffs. The state departments of transportation used to have 600,000 total employees, and each state had its own new product evaluation board. With the support of AASHTO, FHWA created the Highway Innovation Technology Evaluation Center (HITEC), which is being run by CERF. Hopefully, this will be a one- or first-stop type of operation in which technologies will be evaluated and then moved forward for marketing. AASHTO has gone a step further in creating the National Transportation Product Evaluation Program (NTPEP) to nationally, or regionally, comparatively test the performance of products under AASHTO specifications, such as traffic lights and reflective signs.

Finally, if you are going to sell these innovative technologies, you have to have the owner involved with the R&D or the new technology. One university came to me and said they wanted to do work on high performance concrete. I said, “I won't even talk to you because the university doesn't own any bridges. What are you going to do with the information when you are all done?” This is one of the problems: if you don't own a bridge, you can't really do much to advance the use of the technology. If you have a new product out there, you have to create a win-win-win situation. You get the innovator, he sells his product, he wins. If you can get the displaced industry to buy in, they will win. If they both win, the public is going to win. I say this because one of the biggest obstacles to making changes in cement over the years has been the association of the producers. If they didn't own part of the rights of whatever was being changed, they were an impediment. Widespread fly ash use in concrete was delayed for 50 years until the Environmental Protection Agency said do it.

When you get down to the guy on the street, if you want him to use the innovation, he has to be comfortable with it. If he does not understand it, like a new VCR, he probably will never use it. They tell me that 90 percent of the VCRs in this country just blink all the time. The other point is the user must be confident with it. We have acoustic techniques for measuring pavement thickness or even for distance measuring like on a Polaroid camera. People do not believe it works until they check it with a foot rule. If you give them an acoustic device and tell them to go out and measure the pavement thickness, they will drill a hole and check it. They will be convinced.

Finally, you can have one of the best devices in the world, but it must be affordable. You can have the best suit in the world, and you can go to the corner and try to sell it for $10. If nobody has $10, they are not going to buy it. A more dramatic example is the bridge that fell down in April 1989 where eight people died. We asked, “In the last examination of the bridge, required by federal law, you had scour under here. Why didn't you fix it?” The reply, in essence, was, “We couldn't afford it. This was number 2,000 on a list of 4,000 bridges that need to be fixed out of our total of 40,000, and we didn't know it was going to be the first one to fall.” That's the situation. You're out there trying to sell new technology for the future but people are putting everything into day-to-day operations.

Implementation

We have not been very successful in getting products into practice. We have technical successes such as substitutes for asphalt and different types of admixtures for concrete. However, in most cases, the man with the good product, the good technical success, will go out there and give it away for 5 years to many localities to look at it. They 'll look at it for another 5 years, and after 5 more years—15 years—it might be profitable. For example, one of the

the things we have been trying to sell is high-strength concrete. Figure 2 illustrates some of the benefits of high-strength concrete. Concrete at 10,000 psi as opposed to 6,000 psi will allow the immediate elimination of almost one girder in each direction. There could be a savings of 30 percent in concrete (as the French found), which is probably at least a 10 percent savings in cost overall. I went up to one state materials engineer and asked whether they would build a bridge with 15,000 psi concrete. They responded, “Not until the federal government tests it to show us that it is safe, because we will not accept the liability.”

In Texas they are in the process of building a bridge using high-strength concrete. It looks a little different than some of the others, but by going to a different shape of channel beam they were able to go from 8,000 psi to 13,000 psi. It allowed them to span the roadway because they needed 135 feet, and with the old girders they could only get 120 ft. You can go almost a third longer with this and you save almost a third of your concrete and save money. Now about five states are also using this technology.

Realizing that the states build or rebuild about 5,000 bridges a year, if you want to save 10 percent on each of them and get some money, you have to get out there and sell it. If you want to sell it, you must involve all of the materials industry, all of the designers and the owners, the steel industry, the educators, the constructors and the haulers and riggers.

One of the things that we have tried to do to solve this problem is what I call “saturation involvement” or “saturation education” that involves a possible regional consortia for changing technology. For instance, go into a region like New England with some money and say, “Why don't you work on the problems you want to. ” To get the process started, suggest high-strength concrete. Then you can go in and get government agencies such as DoT and the Department of Energy to use their funds and expertise. You also get the governor 's associations; the highway departments; the owners of this technology; the port, turnpike, and tunnel authorities; the commerce and industry user groups and academic institutions and have them all go ahead and implement as a group. You can get them all involved at the same time to empower them. Then they can make decisions, change the codes, and change the liability barriers, so that they can together overcome these things. They can change the culture and get the project and technology into place.

If you wanted to do this on a “saturation basis” you would get better materials and better quality control. You take the improved concrete and get a pre-caster who is willing to put in the capital to get his new bed. However, if you only use it on bridges, you are missing the opportunity because only 15 percent of the concrete goes into new bridges. You have to get the high-rise construction industry and the residential market sector to work with you to build one large consumer market (as contrasted to dual inventories).

Reduction in Superstructure Dead Load

The experimental bridge built in Joigny, France, in 1989 characteristics:

-

60 MPa (8,600 psi) design strength

-

Three-span, continuous, externally pre-stressed double-T section, 114 m (375 ft) long, 15.8 m (52 ft) wide

-

Cast in place using concrete made with local materials

Compared with 35-MPa (5,000-psi) concrete, 30 percent less concrete was used, leading to a 24 percent reduction in the dead lead from the superstructure.

Increase in Span Length of Pre-cast Beams

1989 engineering study for North Carolina Department of Transportation by Schemmel and Zia:

-

Investigated the economic benefits of increasing concrete strength from 40 to 80 MPa (6,000 to 12,000 psi)

-

Considered modified AASHTO Type A box beams, 0.91 and 1.22 m (3 and 4 ft) wide

On average, the maximum span length was increased by 17 percent; for some sections the increase was nearly 30 percent.

Reduction in Number of Supporting Girders

1987 FHWA study on application of high-strength concrete for bridges:

-

Studied the potential benefits of increased concrete strengths up to 70 MPa (10,000 psi)

-

Benefits included increased span lengths, wider girder spacings, and reduced section of compression members

For example (see sketch below), for a 45.7-m (150-ft) simply-supported bridge, the number of girders could be reduced from nine to four by increasing the concrete strength from 40 MPa (6,000 psi) to 70 MPa (10,000 psi).

FIGURE 2 Benefits of High-Strength Concrete in Highway Applications

Future

I'm going to shift gears one more time. In looking at the future, one of the trends is that cities are getting bigger. There isn't a city with a population of 27 million in the United States yet, and there may not be one by the year 2000, but sooner or later we are going to get there. For future large cities I always think of going down boulevards in Paris where 8-story buildings just go on and on for miles. These buildings have been in place for more than 100 years, so you find McDonald's in those types of buildings. In the center courtyard, a whole construction firm has all of its high-rise cranes. We haven't had to do this yet. We go out and we put a gas station in; we tear it down. We put up a McDonald's; we tear it down. We come in and put up a bigger restaurant; we tear it down. Sooner or later we're going to have to conserve these buildings, and we're going to have multi-tenant housing, inadequate parking, and all of the congestion that goes with it.

What I would suggest, and this isn't the only approach one could use, is an improvement of the freight movement system. It could be put in place by tunneling under the city, like Japan is starting to do, and separating freight traffic from people. A 6-ft diameter pipe (2 m) can be used to ship 4-ft modules. Self-powered capsules, similar to the old department store capsules that moved pneumatically, can be used to move freight. What are the benefits of this?

In the Washington area, we have had numerous accidents and front page pictures of trucks rolling over on cars. This type of accident happens very frequently. If you reduce the number of trucks on the road and move your freight in some other way, you get just-in-time dependability. Our highway systems are not going to change in their approach to avoiding traffic interruptions until the courts rule against them. In one state, the state had a construction job on the roadway and they shut down the traffic. One of the GM plants shut down because its just-in-time delivery stopped. The plant went ahead and sent a claim to the state saying, “We can document what our losses are. We had to pay our labor. You owe us this amount of money.” Well, it was immediately thrown out because of state sovereignty. When one of those types of claims holds, then we will see a change about the money coming out of somebody else's pocket to cover these problems.

Anyway, an underground system is all-weather, lends itself to automation, is secure, and overcomes environmental concerns. It is going to get tougher and tougher in the next 20 or 30 years to build highways. We need to use advanced technology, and we have to innovate to resolve these issues in an evolutionary manner. More planning and R&D are needed to overcome the problems posed by the increasing populations of our cities before they become crises.

Recapitulation

The barriers to innovation in construction infrastructure are many and diverse. Lack of funding, inadequate education, restrictive codes and laws, and lack of future planning are but a few. Identification of them is fairly easy, overcoming them will be much more difficult because of tradition and the organizational structures that protect the “barrier.” Invention is easy! Changing the culture is difficult.

ABOUT THE SPEAKER

Bory Steinberg is a partner in Steinberg & Associates, a consulting firm in the areas of government relations, water resources issues, infrastructure and project management. The major focus of the firm is to represent non-federal project sponsors in their efforts to implement joint partnership projects with the Corps of Engineers. Dr. Steinberg spent 35 years with the Corps of Engineers, the last 12 of which he served as a senior executive. As Chief of the Corps Program Division, he was actively involved in legislative, policy, budget, and management issues for the entire Civil Works Program of the Corps of Engineers. Dr. Steinberg received his B.S. in civil engineering from Rutgers University in 1956, M.S. in public financial management and budgeting in 1973, and D.P.A. in public administration from George Washington University in 1984.

IDENTIFYING THE BARRIERS TO CHANGE

Bory Steinberg

Steinberg and Associates

Three years ago, I retired from the U.S. Army Corps of Engineers, and together with my wife Naomi, established Steinberg & Associates, a government relations consulting firm.

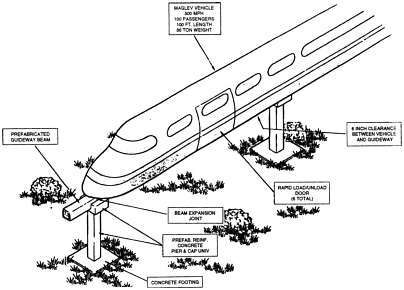

Our first client was the Canaveral Port Authority and through the port we became involved in a Maglev project. Let me first describe Maglev. As you all know, today's trains go on tracks, on steel rails. The vehicles depend on the track for physical support and for steering. Propulsion power is supplied by the locomotive or motor in the cars. The prime source of power is either diesel engines or electric motors, powered from an overhead catenary wire. Similarly, a Maglev guideway provides steering and indirect support. The vehicles are suspended on the cushion of a magnetic field which holds them, one or several cars together, at a fixed distance from the guideway itself. Forward propulsion is provided by a similar electromagnetic source in the guideway, a linear synchronous motor. The interaction of the traveling magnetic fields in the guideway and the fixed magnetic fields on the vehicles move them along the guideway. Very high speeds can be achieved with relatively low power consumption and negligible wear and maintenance since the process is free of contact.

Maglev was pioneered and patented in the United States by Dr. Gordon Danby and Dr. James Powell, who spent 30 years inventing and perfecting the concept. They are now updating their patents based on new technology and applying the greater promise of superconducting magnetic energy to produce very strong and efficient levitation so that Maglev will have the ability to carry freight, as well as passengers.

This enhanced mobility system comes at a strategically useful time through its ability to enhance industrial competitiveness and create employment opportunities for the next century. The successful large-scale Maglev research and development efforts in Japan and Germany have already demonstrated the

basic readiness of Maglev for system commercialization. Their latest improvements and system refinements, however, move beyond this stage to the efficient, cost-effective application to a real-world revenue operation.

The Project

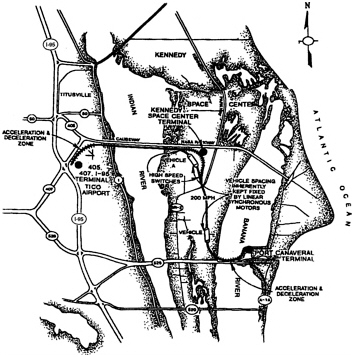

In early 1992, the two scientists, now joined by John Morena, a world expert on composite materials, formed the American Maglev Star (AMS). They got together with some of America's most experienced high technology firms in transportation, industrial design, materials, engineering, and construction and management, proposed to construct a Maglev project that would demonstrate the feasibility and profitability of a 300 mph freight and passenger surface transportation system. Located in Brevard County, Florida, the AMS project was envisaged to connect the Kennedy Space Center visitor center, the Port Canaveral cruise ship terminal, Interstate 95 and Route 407 by a 20-mile dual guideway (Figure 1).

Technology developed by American Maglev Star participants provides for an elevated system constructed on columns (Figure 2). This ensures safety and reliability by separating the system from other surface modes and from pedestrian traffic. Significantly, this also minimizes impacts on fragile ecosystems. The need to lacerate and develop wide corridors through Florida's wetlands is all but eliminated, and sharing existing rights-of-way of other surface modes could use even less land. Maglev technology can provide major transportation advantages to the state of Florida, the nation's fourth largest and one of the fastest growing. Florida is by far the number one tourist destination for both domestic and foreign visitors. Florida provides an inherent market for highly efficient transportation—an advantage enhanced further by the state of Florida's passage of special legislation in 1986 promoting high-speed ground transportation development. Leaders see the advantages of using new technologies to move large numbers of people and to reduce highway congestion for both residents and visitors.

The AMS project is located at some of Florida's most popular attractions. Port Canaveral, with its ambitious schedule for passenger terminal development, is the fastest developing cruise ship port in Florida. Its attraction will further increase as a result of the agreement signed on May 17, 1995, with Disney Cruise Lines to homeport Disney's first two mega cruise ships at Port Canaveral. The AMS system will serve the port by connecting it to the popular NASA tours at the Kennedy Space Center and to remote parking at I-95. This avoids the need for expensive structured parking at the port and once again, protects Florida's fragile environmental systems.

Structuring an Innovative Project

The AMS project would be the first application of a fully American, high-technology transportation system. As such, it would go far beyond the mere

invention of new machinery. It charts the path to a new level of United States industrial pre-eminence and provides the prototype for infrastructure improvements that can rebuild our surface transportation network and increase productivity throughout the economy.

Maglev transportation and its supporting industries could offer an immediate solution to an immense and complicated problem. This problem includes the need to revitalize America's industrial base, increase its competitiveness, and provide jobs. The commercialization of the Maglev industry, with new global, industrial technology, especially American Maglev propulsion and levitation, with related advanced materials and processes, could help assure U.S. global competitiveness and maintain a strong defense development of the nation as a whole. The American Maglev Star project approach, with its 100 percent American technology manufacturing and labor content, contrasts strongly with high-speed rail, steel-wheel-on-steel-rail technologies, whose designs use 100 percent offshore components. Similarly, other Maglev systems currently being developed in the United States, not the AMS, also use high percentages of offshore technologies, thus having less positive impact on American jobs, competitiveness, and economic independence.

It is very important to note that the American Maglev Star is also capable of carrying freight. This multi-use orientation increases the financial viability of the system and serves a complementary market in fast freight movement which has grown geometrically in the past years. By serving needs already in existence, the Maglev system increases mobility and transportation value in ways congenial to the actual conduct of modern American life. The system is designed to serve the way we live, rather than demanding that we adjust to the technology. For example, AMS can bring to the United States major benefits, including enhanced mobility, reduced energy consumption, reduced pollution, increased travel safety, preservation of the environment, maintenance of an industrial capability for defense needs, and opportunities for economic growth and development.

Barriers to an Innovative Project

First of all, intellectual property ownership is a major barrier. When the federal government finances projects involving innovative technology, the government wants the rights to the patents. The United States must take the patent system seriously. It must keep other nations from developing and profiting from the technologies without paying for patent rights.

Financing is a major barrier. We had hoped that significant portions of the AMS project could be privately funded. Breakthroughs in design and construction and the operating characteristics of this Maglev system would allow for a speedy amortization of capital costs and a profitable return on investment. At the same time, federal support and funding for the fixed facility was needed for the project, as provided in the Intermodal Surface Transportation Efficiency

Act. Other federal sources could stimulate the embryonic Maglev industry and support the adoption of advance materials and processes through technology transfer.

Federal agencies need to take risks and provide financing. It's a catch 22 situation in that the private sector is unlikely to build a Maglev system without substantial federal participation. Yet, the technology is currently available. AMS is working with the state government in Florida, as well as hoping that the state will be the primary government agency that will make the Brevard County proposal proceed. We are hoping that Florida will own the infrastructure but not the technology. The federal government needs to have a solid, long-term plan, recognizing the difference between enhancing an existing technology and developing practical applications with a new and innovative technology. Federal agencies have to be willing to recognize the best design and work toward implementing the project. It is important to understand that the research and development has been done. This project is ready to go. It doesn't need another 10 years of research.

The state needs to recognize the new jobs and other benefits that would result from a Maglev project. In addition, at the local level, metropolitan planning organizations often oppose any movement for technological development, so it's very important to get their support. It is also important to have the support of local environmental groups and residents in the area.

The administration and Congress must recognize the crucial need for building a sound infrastructure that will take the nation into the twenty-first century, and that it will require substantial investment that may yield the return only in the next century.

The fundamental difference between Japan and Germany, versus the United States, is that they invest and plan for the long term and the United States does not. The United States government used to do that, but not anymore. The Corps of Engineers used to build dams for flood control, hydropower, water supply, and inland waterways, all of which were long-term projects. The payoff would be over at least 50 to 100 years but the projects could last for centuries. Today, we make slight improvements in existing infrastructure projects but fail to develop new technologies. This applies to both the private sector and the public sector. In Japan and Germany, on the other hand, they do plan for the future. The Japanese, for example, are using the Danby and Powell early technology and have already invested several billion dollars in Maglev projects, including opening up the center of the country through mountain tunnels to connect Tokyo and Osaka.

Dr. Danby and Dr. Powell believe there is no need for further research and development. The key issue is engineering integration and, of course, minimizing the cost of the guideway, which includes the levitation and propulsion system. It is really an engineering and design effort. This accounts for 90 percent of the construction, with the vehicles only accounting for 10

percent of the cost. Civil and structural engineering design would reduce the cost of the guideway. If we had a major system throughout the nation, the cost would be reduced to about $10 million a mile, rather than a higher cost of one or two projects.

Based on the current design, including the weight of the vehicles, the Maglev system can handle both freight and passengers. Levitation and propulsion is now stronger, and economy in the cost of a guideway will be a crucial factor. Certainly, with a national Maglev network, this would be more likely to be achievable. Other economic advantages will be achieved by using, to the maximum extent possible, existing rights-of-way or government land.

ABOUT THE SPEAKER

Ken P. Chong is Director of Structural Systems and Construction Processes, Engineering Directorate, National Science Foundation (NSF). He chaired the NSF task committee which developed the Civil Infrastructure Systems Initiative. He has given keynote lectures in Europe, Asia, Australia, and America. His research on hybrid girders has been incorporated into American Institute of Steel Concrete manuals. He is a registered professional engineer and a recipient of the American Society of Engineering Education (ASEE) Dow Outstanding Young Faculty Award in 1977 and the Halliburton outstanding research and graduate teaching award in 1987. He was Eminent Engineer of Tau Beta Pi in 1976 and has been a fellow of the American Society of Civil Engineers since 1985. He received the Professional Eminence Award from the Colorado Engineering Council in 1988; the NSF Special Achievement Award in 1989; NSF Superior Performance Award in 1990, 1991, 1993, and 1994; and the NSF Strategic Planning Award in 1992-1993. Dr. Chong graduated with distinction from Queen Elizabeth School, Hong Kong, in 1960. He received a B.S. in civil engineering from Taiwan National Cheng Kung University in 1964; an M.S. in structural engineering from the University of Massachusetts in 1966; and an M.S.E., M.A., and Ph.D. in structures and solid mechanics from Princeton University in 1969. He is the author of 150 refereed journal papers, and five major books, the editor of two journals, and a member of several boards.