2

BACKGROUND

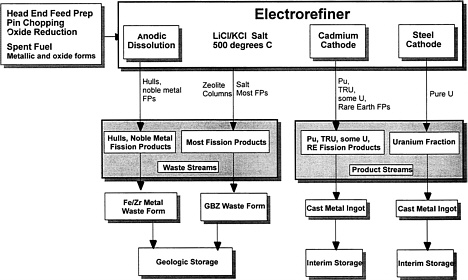

The electrometallurgical processing technique, formerly called pyroprocessing, was investigated by ANL in conjunction with its Integral Fast Reactor (IFR) program and was designed to recycle IFR and spent oxide fuels from light water reactors (LWR) into new IFR fuel. The new fuel would contain substantial quantities of uranium, plutonium, other actinides, and long-lived fission products that then could be “burned” in the fast reactor. With the termination of the IFR program, the electrometallurgical process at ANL was redirected and modified with the goal of being able to treat spent nuclear fuels within the DOE inventory. Initially, the electrometallurgical process under development at ANL (Fig. 1) was designed to separate actinide elements from fission products present in spent fuels and to place the waste products in a form suitable for disposal.

Figure 1. Original ANL electrometallurgical process scheme. In adaptation of the process for treatment of plutonium, the plutonium would be introduced at the point denoted spent fuel, metallic and oxide forms.

The key element of the process is the electrorefining step, in which the metal to be processed is oxidized at the anode and deposited at a cathode in a condition of greater purity by electrotransport through a suitable molten salt electrolyte. It is in this step that the actinide-fission product separation occurs as a consequence of the different oxidation-reduction properties of two different cathodes. Relatively pure uranium is deposited at a steel cathode, and the transuranic element (TRU) fraction is collected at a molten cadmium cathode.

For treating the wide variety of spent fuels known to be in the DOE inventory, the ANL proposal1 included head-end treatments for fuel disassembly and, when required, steps such as oxide reduction. The ANL proposal also included processes for the treatment of electrorefining effluent streams and, when appropriate, for the recycle and reuse of reagents to minimize the generation of secondary waste streams. The end products of the electrometallurgical treatment are two product streams and two waste streams. The product streams would be a nearly pure uranium metal stream and a transuranic metal stream composed of about 30% uranium by weight, the remaining actinides (primarily plutonium), and some rare-earth fission products. The first of the two waste streams would consist of the fission products not reduced to the elemental form (e.g., Sr, Cs, I, and Se) plus trace amounts of the actinides incorporated in a glass-bonded zeolite (GBZ) waste form. The second waste stream would contain the fission products least easily oxidized (the noble metal fission products Nb, Tc, Zr, Mo, the Pt group, and possibly Sn) and the undissolved cladding material remaining at the anode. This second waste stream would be placed in a metal waste form as a mixture of Zr-rich and Fe-rich phases of a Fe-Zr alloy. The original process flow sheet for use of the electrometallurgical technique to treat DOE spent nuclear fuels placed the product metal forms (uranium and the TRU) in interim storage. ANL is initiating a program to evaluate the two forms.

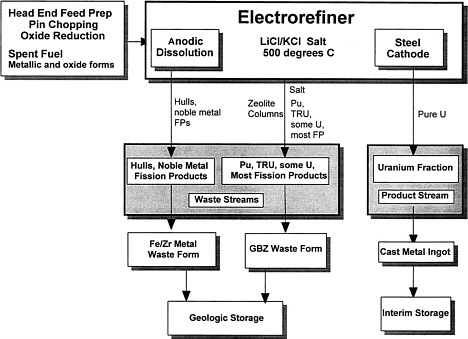

More recently, ANL has modified its flow sheet (Fig. 2) by eliminating the cadmium cathode, which would leave the transuranic elements in the molten salt. This modification would eliminate one of the product streams and the corresponding need for its interim storage. In the new scheme, the transuranic elements would remain with the fission products and be disposed of in the GBZ waste form.

In its earlier reports, the committee observed that “the electrometallurgical technique is not a new technology,”2 and that “the chemical feasibility of the technique is well established except with respect to the proposed zeolite-based steps for waste treatment ” and the possible deleterious effects of high levels of radiation. 3 The committee noted that a major limitation of the electrometallurgical process was its present inability to produce waste forms with behavior that is well understood. Even without considering the uncertainty regarding the waste forms, the committee concluded that a “substantial development and demonstration program is still necessary to show whether the electrometallurgical technique can be a viable option ” for the treatment of DOE spent fuels.4 This observation is consistent with DOE's commitment to process EBR-II spent fuels, for which development and demonstration of the electrometallurgical treatment technology are expected to continue during the several years required for processing (i.e., until 2001, the scheduled completion date for processing EBR-II driver and blanket fuel). In its July 1995 report, the committee further concluded that if the EBR-II processing demonstration were successful, the electrometallurgical technique developed by ANL should be considered as a candidate technology in the context of a larger, “global” waste management plan for the DOE, specifically for the possible treatment of other DOE fuels.

As part of its present task, the committee was asked to undertake an evaluation of the scientific and technological issues surrounding the potential application of the electrometallurgical treatment technology to the disposition of excess weapons plutonium. Of the estimated 1,100 metric tons (MT) of plutonium in

|

1 |

For a description of the ANL proposal, see Appendix A of the committee's first report, A Preliminary Assessment of the Promise of Continued R&D into an Electrometallurgical Approach to Treating DOE Spent Fuel, National Research Council, Washington, D.C., February 1995. |

|

2 |

See the report cited in footnote 1, p. 2. |

|

3 |

An Assessment of Continued R&D into an Electrometallurgical Approach for Treating DOE Spent Nuclear Fuel, National Research Council, National Academy Press, Washington, D.C., July 1995. |

|

4 |

See the report cited in footnote 3. |

the world, 5 about 25% is believed to be held in military stockpiles. By the year 2005, it is estimated that as a result of nuclear arms reduction agreements and pledges, about 100 MT will be declared excess (50 MT each from the United States and Russia).6 The subject addressed by the committee in its current report is an evaluation of the scientific and technological issues influencing the potential application of electrometallurgical treatment to the disposition of excess weapons plutonium.

Figure 2. Current ANL electrometallurgical process scheme, in which the cadmium cathode has been removed. In adaptation of the process for treatment of plutonium, the plutonium would be introduced at the point denoted spent fuel, metallic and oxide forms.

CISAC FINDINGS

The general issue of the disposition of excess weapons plutonium has been thoroughly addressed by CISAC and its Reactor Panel. Working under the assumption that the duration of intermediate storage of

|

5 |

Management and Disposition of Excess Weapons Plutonium: Reactor-Related Options, Panel on Reactor-Related Options for the Disposition of Excess Weapons Plutonium, Committee on International Security and Arms Control (CISAC), National Academy Press, Washington, D.C., 1995, p. 51. |

|

6 |

See the report cited in footnote 5, p. 49. |

excess WPu should be minimized for security reasons, the disposition options explored by CISAC were “minimized accessibility” (i.e., the creation of physical, chemical, radiological, and isotopic barriers to reduce the material 's accessibility for use in a weapon) and “elimination” (i.e., the removal of the material completely from human access, for example, by allowing the material to fission in a reactor until less than a critical mass remained).7 In order to provide a basis for relative comparisons among options, CISAC in its 1994 report8 introduced the concept of the “spent fuel standard.” In this context, CISAC was not attempting “to imply a specific combination of radiation barrier, isotopic mixture, and degree of dilution of plutonium” but rather to denote a “condition in which the WPu has become roughly as difficult to acquire, process, and use in nuclear weapons as it would be to use plutonium in commercial spent fuel for this purpose. ”9 Since the ratio held in civilian relative to military stockpiles is believed to be about 3:1, the CISAC Reactor Panel concluded that “there would be very little security gain from special efforts to completely eliminate the WPu, or render it much less accessible even than the plutonium in spent fuel, unless society were prepared to take the same approach with the global stock of civilian plutonium. ”10

In addition to general considerations relating to the disposition of excess WPu, the Panel on Reactor-Related Options examined pyroprocessing as an alternative approach for plutonium disposition. At the time the evaluation was made, the panel cited several disadvantages that it believed excluded the electrometallurgical technique as a viable option in the near term:11

-

A substantial reprocessing plant would have to be constructed in order to process enough material to mix with 50 tons of excess WPu to meet the “spent fuel standard” (roughly 1,000 tons for the 50 ton WPu assuming a product of approximately 5 weight percent WPu).

-

Reduction of LWR oxide fuels was the least developed part of the pyroprocessing scheme, and demonstration and validation of this technology would involve additional cost and delays, with no guarantee of providing an economical and effective WPu disposition option.

-

The output of pyroprocessing associated with the IFR was never intended to be a waste, and it remains uncharacterized as a waste form. Further, it is unlikely that the proposed metal waste form would be a suitable form for the chemical environment of Yucca Mountain.

The Reactor Panel concluded that the “pyroprocessing approach is not competitive with either vitrification in borosilicate glass or the use of mixed uranium-plutonium oxide (MOX) in existing reactors, both of which would be likely to involve lower costs, lower technical uncertainties, and shorter delay.”12

In the originally proposed scheme (see Figure 1) that was considered by CISAC and its Reactor Panel, the plutonium, other transuranics, rare-earth fission products, and some uranium were to be reduced to metals at a molten cadmium cathode and finally cast as metal ingots.13 The Reactor Panel report questioned whether it would be possible “to design the process so that a large fraction of the fission products are retained.”14 In addition to pointing out the cost and scheduling issues noted above, the Reactor Panel concluded that it would be “unlikely that a metal matrix such as that produced by the pyroprocessing would be a suitable waste form for the chemical environment of Yucca Mountain: the metal, once exposed to

|

7 |

See the report cited in footnote 5, p. 46. |

|

8 |

Management and Disposition of Excess Weapons Plutonium, National Academy of Sciences Committee on International Security and Arms Control (CISAC), National Academy Press, Washington, D.C., 1994. |

|

9 |

See the report cited in footnote 5, p. 73. |

|

10 |

See footnote 9. |

|

11 |

See the report cited in footnote 5, pp. 219-221. |

|

12 |

See the report cited in footnote 5, p. 221. |

|

13 |

As noted in the report cited in footnote 5, p. 220 (footnote 3), the CISAC analysis utilized the same IFR flow sheets that were considered for another NRC study (Nuclear Wastes: echnologies for Separation and Transmutations, National Research Council, National Academy Press, Washington, D.C., 1995). |

|

14 |

See the report cited in footnote 5, p. 220. |

water, would be expected to undergo both hydration and oxidation reactions, breaking down its structure and releasing the radioactive materials it contained.”15

In the period since CISAC and its Reactor Panel evaluated the pyroprocessing approach, ANL has modified its process to capture the plutonium and other transuranic elements in a zeolite matrix along with most of the fission products (see Figure 2). In both of these alternative schemes, the waste form would include both the plutonium and radioactive fission products, thereby providing the rationale for plutonium disposition in accord with the “spent fuel standard.” ANL has proposed using the electrometallurgical technique for disposition not only of weapons “pits” (the plutonium components of nuclear weapons, named by analogy with the pit of a fruit such as a peach), but also of the non-pit materials that include plutonium in any other shape or chemical form.

EFFORTS OF THE FISSILE MATERIALS DISPOSITION PROGRAM

The DOE, through its Fissile Materials Disposition Program (FMDP), is making an extensive and ongoing effort to examine options for the disposition of excess weapons-usable nuclear materials (principally plutonium and highly enriched uranium). The present inventory of excess plutonium within the DOE complex is estimated to be about 73 MT, of which about 50 MT is in the form of stabilized plutonium metal. Approximately 2 MT is thought to be in the form of chloride or nitrate solutions, and the remaining inventory consists of lean (|lessthan|50% plutonium) residues and mixed oxides (6 MT) and rich (>50% plutonium) metals, metal alloys, and oxides (15 MT).

The options for disposition currently being considered by the FMDP fall into one of the following three groupings:

-

Plutonium burning in once-through reactors as MOX fuel followed by disposal of the spent fuel in a repository,

-

Immobilization or fixation in an acceptable matrix to create an environmentally benign waste form for direct disposal in a repository, and

-

Disposal in deep boreholes (with or without prior fixation).

During the last year, the FMDP Immobilization Task Team has evaluated and eliminated during the first phase of its study a number of disposition options associated with the second grouping.16 The electrometallurgical approach continues to be under consideration by the FMDP Immobilization Task Team.17,18 Also being considered are the following: the Glass Material Oxidation and Dissolution System (GMODS), and both internal and external (e.g., “can-in-canister”) radiation barrier concepts for vitrified borosilicate glass and ceramics technologies. These same candidate technologies plus the new, adjunct melter for the Savannah River Site (SRS) Defense Waste Processing Facility (DWPF) form the basis for the seven immobilization options cited in the FMDP long-range research and development plan for immobilization technologies.19

|

15 |

See the report cited in footnote 5, p. 221. |

|

16 |

DOE Fissile Material Disposition Program, Screening of Alternate Immobilization Candidates for Disposition of Surplus Fissile Materials, Lawrence Livermore National Laboratory, L-20790-1, 1996. |

|

17 |

DOE Fissile Material Disposition Program, Alternative Team Technical Data Document: Electrometallurgical Treatment Alternative, Lawrence Livermore National Laboratory, L-20220-1, Predecisional Draft, 1995. |

|

18 |

Also see comments of William Magwood as summarized in Appendix A, pp. 34-35, of this report. |

|

19 |

DOE Fissile Material Disposition Program, Long-Range Research and Development Plan: Immobilization Technologies, Lawrence Livermore National Laboratory, L-18833-5, Revision 2, Predecisional Draft, dated May 26, 1995. |

In addition to the efforts noted above, the FMDP is preparing its Programmatic Environmental Impact Statement (PEIS) for Fissile Materials Disposition. The PEIS is the primary document that describes in detail the potential environmental impacts of technologies being considered for achieving the objectives of the FMDP. The PEIS is also one of the required steps in the process of arriving at a Record of Decision for the FMDP. Regarding the electrometallurgical technique, ANL has submitted a PEIS data call input draft report20 to the FMDP describing the immobilization of surplus fissile materials as part of the effort to evaluate the electrometallurgical technique for the treatment of spent fuels. In preparing the document, ANL assumed that the WPu disposition operations would be integrated with the treatment of spent fuels and that the same “hot” cells and some of the same equipment would be used. ANL indicates in the PEIS data call input draft report that the primary purpose of its treatment process is to convert spent fuel (primarily metallic or oxide fuel with stainless steel or zirconium cladding) into disposable waste forms.

|

20 |

DOE Fissile Material Disposition Program, Immobilization of Surplus Fissile Material with Electrometallurgical Treatment of Spent Fuels, PEIS Data Call Input Report, L-20768-1, Revision 1, Second Working Draft, June 13, 1995. |