5

Manufacturing Engineering Laboratory

PANEL MEMBERS

Michael J. Wozny, Rensselaer Polytechnic Institute, Chair

Jan D. Achenbach, Northwestern University

Robert Bate, Texas Instruments, Inc. (retired)

Jean M. Bennett, Naval Weapons Division

D. Jeffrey Bostock, Martin Marietta Energy Systems, Inc.

Melvin I. Cohen, AT&T Bell Laboratories

Margaret A. Eastwood, Motorola, Inc.

Albert R. George, Cornell University

E. Ray McClure, Moore Special Tool Co., Inc.

Roger N. Nagel, Lehigh University

Richard P. Paul, University of Pennsylvania

Invited Participant

Sushil Birla, General Motors Corporation

Submitted for the panel by its Chair, Michael J. Wozny,1 this assessment of the fiscal year 1993 activities of the Manufacturing Engineering Laboratory is based on a site visit by the panel on May 19-20, 1993, and on the annual report of the laboratory.

LABORATORY OVERVIEW

Mission and Tactics

The mission of the Manufacturing Engineering Laboratory (MEL) is to bring the resources of NIST to bear on the standards and measurement problems associated with the U.S. mechanical manufacturing industry. In fulfillment of its mission, the MEL conducts active programs of research in the areas of high-precision dimensional measurement; sensing and measurement of force, sounds, vibration, and surface finish characteristics; application of advanced control and sensing techniques to

|

1 |

In December 1993, the panel's chair accepted the position of director of the Manufacturing Engineering Laboratory; however, the chairman was not aware that he was under consideration for director before he submitted his panel's report to the Board and had no opportunity to revise the report subsequent to NIST's notification of interest. |

automated machines, manufacturing systems, and robot manipulators; and application of information technology to manufacturing processes, including product design, process planning, equipment control, logistics support, and data interface standards.

The MEL provides technical support for joint industry committees that are developing voluntary standards for measurements, measurement techniques, hardware, software, and data interfaces. The laboratory also maintains the national standards for length and force, as well as a number of subsidiary standards. It offers primary calibration services for these standards, and under unique circumstances accepts especially complex or sensitive measurement assignments of national significance.

Strategy

The MEL's strategy is to focus on the technical challenges of advanced manufacturing technology and to seek partners both within and outside of government to carry out its programs. MEL has attracted external funding to build its programs and manages hundreds of interactions each year with industry and other external constituencies through Cooperative Research and Development Agreements (CRADAS) and involvement in consortia, standards committees, and seminars, conferences, and workshops.

Resources

As of January 1993, the MEL had a staff (professional, technical, student, clerical, and administrative) of 268 and anticipated a flat operating budget for fiscal year 1993 of approximately $40 million, of which about $11 million had been appropriated by Congress for MEL's Scientific and Technical Research and Services (STRS) funding.

Organization and Structure

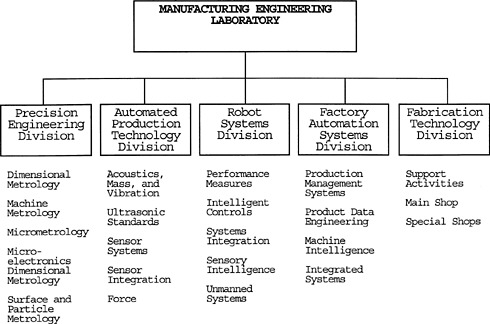

The Manufacturing Engineering Laboratory is subdivided into five divisions--the Precision Engineering Division, Automated Production Technology Division, Robot Systems Division, Factory Automation Systems Division, and Fabrication Technology Division--(Figure 5.1). The laboratory also supports two offices--the Automated Manufacturing Research Facility (AMRF) Program Office, which manages cross-divisional research programs sponsored by other agencies, and the office of Industrial Relations, which is responsible for planning, developing, coordinating, and reviewing programs and activities within the manufacturing community, as well as serving as the liaison to the Department of Commerce (DOC) in advancing product data exchange

efforts and supporting the DOC's interagency National Initiative for Product Data Exchange (NIPDE).

LABORATORY-WIDE ISSUES--FISCAL YEAR 1993

The Manufacturing Engineering Laboratory has initiated serious strategic planning that needs to include more qualitative challenges, such as benchmarking of MEL against world-class technology developers. MEL should continue to search for better ways to carry out its mission, such as through the Manufacturing Technology Centers, and should continue to develop technology road maps, complete with milestones and specific goals.

However, execution of a planned comprehensive core program for optimum impact on civilian manufacturing does not seem possible unless the laboratory's annual direct appropriations, i.e., funding for STRS, becomes a larger percentage of the laboratory 's total budget. Currently STRS is 27.5 percent of MEL's total budget; the remainder is predominantly other-agency (OA) funding. Many if not most of MEL's achievements stem from OA funding; however, MEL's continued overdependence on OA funding will unavoidably alter the laboratory's support of broad industrial needs. MEL's successful developments under OA funding, as impressive and important as they are and can be, should not overshadow the core program's statutory mandate to develop new and useful industrially related measurement technologies. The transition of MEL to a funding base that better supports MEL's core programs is the panel's highest-priority recommendation.

MEL's RESPONSES TO FISCAL YEAR 1992 RECOMMENDATIONS

In its fiscal year 1992 report, the panel made seven main recommendations (pp. 104-105), to which MEL has responded as indicated below.

-

“The Molecular Measuring Machine of the Precision Engineering Division is a vital demonstration of future metrology technology, and the highest priority must be given to providing critical personnel and funding support.”

The Precision Engineering Division, which has almost one-third of the laboratory's congressionally appropriated money, continues to place almost 28 percent of that resource into nanometer-scale metrology. Progress on the molecular measuring machine has been slower than hoped for and, in fact, has attracted the attention of NIST upper management, but the primary cause of deadline slippage has not been a lack of resources or effort but the technical difficulty of the endeavor.

-

“The . . . [MEL] should work aggressively with the Electronics and Electrical Engineering Laboratory and other NIST

-

laboratories to develop a leadership program on new technologies for electronics fabrication.”

Collaboration was increased in the Product Data Exchange Specification/Standard for the Exchange of Product Model Data (PDES/STEP), and MEL's role in the NIST effort in the High Performance Computing and Communications (HPCC) initiative will involve closer interaction between MEL and the electronics community. Also, EEEL's involvement in NIST's effort for the federal Advanced Manufacturing Technology initiative, in which MEL has the lead, will cause closer MEL/EEEL cooperation. In considering MEL's involvement in electronics fabrication, it must be remembered that NIST is internally organized by market, not technology; therefore, electronics fabrication is the organizational responsibility of the EEEL rather than the MEL.

-

“The Factory Automation Systems Division . . . should formally review and prioritize industrial needs in the division's assigned areas of technology. . . .”

The Factory Automation Systems Division continues to be a laboratory leader in the extent and thoroughness of its planning. With its recent interactions with the ATP-funded Automotive Rapid Response Manufacturing Consortium and its continuing close relationships with the members of PDES, Inc., and USPRO, the input from industry is continuous.

-

Study the possibilities for continuation of the Shop of the '90s Program and continue the upgrading of the Fabrication Technology Division.

Discussions were held with many interested parties, and it was concluded that the Shop of the '90s Program would be discontinued after the program's discoveries were documented and widely circulated, which they were (over 5,000 copies were distributed), and after some further experiments with machine retrofitting were carried out as part of normal instrument shop upgrading. Discussions have been started to discover whether it would make sense to run a benchmarking survey of the best of small shop technology to see if development at a technical level between the Shop of the '90s and the AMRF make sense. Perhaps such an effort would lead to a Shop 2000 program.

-

#8220;The Automated Production Technology Division, which is currently engaged in a wide range of activities, needs to focus on the development of basic standards.”

The Automated Production Technology Division and the Precision Engineering Division have been deeply involved in an internal control review of calibration services. This study made clear the lack of any serious deficiencies in this part of the standards program.

-

“The MEL's Automated Production Technology Division, the Office of Manufacturing Programs, and the Fabrication Technology Division should collaborate more effectively to identify commercial-sector needs and to improve technology transfer to the commercial sector.”

MEL has spent much time and energy in this effort and would welcome concrete suggestions as to how to do it better.

-

“MEL divisions should plan to collaborate fully with the Office of Manufacturing Programs, and with the Manufacturing Technology Centers via the Office of Manufacturing Programs, in meeting their technology transfer objectives.”

-

In the past, MEL divisions have collaborated with the Manufacturing Technology Centers with some success. At the moment, the organizational structure is in too great a flux to be able to plan effectively in this area. Planning exercises will begin soon.

ASSESSMENT OF DIVISION PROGRAMS

Precision Engineering Division

Mission, Tactics, and Organization

The Precision Engineering Division develops and maintains competence in those fields of applied physics and engineering that provide the metrology and standards necessary for the devices and techniques used to generate, measure, and control high-resolution displacement, positioning, and critical dimensions in manufacturing. The division performs research and provides services in electron, light, or mechanical microscopy; optical interferometry, holography, and scattering; machine tool metrology; coordinate measuring machines; and various fabrication and inspection techniques that improve product quality and yield.

The Precision Engineering Division provides industry with systems and standard reference materials (SRMs) for current metrology needs and is developing the instruments and techniques needed to meet the challenges of increased measurement accuracy and much tighter tolerances that will be necessary in the future. The division's main customers are industries that manufacture discrete parts.

The Precision Engineering Division is composed of five groups: Dimensional Metrology, Machine Metrology, Micrometrology, Microelectronic Dimensional Metrology, and Surface and Particle Metrology.

Progress and Activities, with Panel Comments

The high-quality work being done by the Precision Engineering Division to support not only the current metrological needs of industry, but also longer-range needs in the form of increased measurement accuracy and tighter tolerances in dimensional measurements, is commendable. Particularly noteworthy are the plans for several new types of instruments that will address future metrology requirements.

The division prepared and distributed Challenges to NIST in Dimensional Metrology: The Impact of Tightening Tolerances in

the U.S. Discrete-Parts Manufacturing Industry (Dennis A. Swyt, NISTIR 4757, U.S. Department of Commerce, Washington, D.C., January 1992), which describes the problems NIST faces in meeting future needs in dimensional metrology. This report, which was given wide circulation and attracted much attention, was followed by a workshop (in August 1992) that addressed issues raised in the report and was attended by representatives from over 50 key industrial firms representing all major discrete-parts manufacturing sectors. As a result, collaboration was started with several industry laboratories that should improve the NIST measurement facilities. An example is the arrangement with the Y-12 Laboratory at Oak Ridge National Laboratory to provide surrogate or master-part certification. The August 1992 workshop also targeted dimensional measurement, inspection, and test systems. Another follow-on workshop with representatives from the gear industry addressed the specific metrology needs of that industry. The workshop generated a list of action items such as improving measurement accuracies, reducing tolerances, and generation of appropriate metrology artifacts needed for certification.

The Surface and Particle Metrology Group initiated the development of an absolute atomic force microscope that will calibrate fine roughness specimens against the wavelength of light in three dimensions to highlight problems of hysteresis and lack of reproducibility in commercial atomic-force microscopes. Such an instrument is critical for nanotechnology metrology as a companion tool to the molecular measuring machine.

The microelectronics industry, an important segment of U.S. industry, needs MEL's metrological standards and measurement services. The industry has severe problems in measuring narrower linewidths, aligning stacks of Photomasks, and aligning masks on wafers. The submicron photomask linewidth standard (SRM 473) issued recently by the Microelectronics Dimensional Metrology Group completes the current series of linewidth standards for certifications using optical microscopes. The group also developed a method using transmission scanning electron microscopy to calibrate linewidths of x-ray masks, used this technique to calibrate several experimental x-ray masks, and completed an interlaboratory study of a prototype, lithographically defined scanning electron microscope magnification standard that showed a clear need for such a standard.

To address future needs in the microelectronics industry, the group has started construction of a new ultraviolet photomask calibration system. The system will be needed for the tighter tolerances in linewidth measurements and mask alignment that come with linewidths below the present 0.5-micrometer limit of the current visible green light system.

The group has made excellent progress since the panel's fiscal year 1992 assessment in spite of severe staffing and funding limitations. Two professionals were lost in a reduction-in-force action caused by insufficient funds, leaving only three

professional staff. The group's resources are too small for providing the vital services needed by the microelectronics industry.

The Dimensional Metrology Group installed a coordinate measuring machine (CCM) for measurements at the 1-µm level, is producing an automated, user-friendly, iodine-stabilized helium-neon laser to be sold as an SRM, is developing a calibrated bar ball SRM, and has a CRADA with Caterpillar, Inc. for joint development of a novel artifact for rapid calibration of CCMs, under which it has performed calibrations valued at $500,000.

Although some improvements have been made in one-dimensional measurement capability at NIST, no programs have been funded to provide two-dimensional measurements or to produce higher-accuracy one-dimensional measurements such as those needed in the semiconductor industry. The Dimensional Metrology Group initiated a project in fiscal year 1992 with the goals of (1) producing measurement algorithms that would allow industry to use grid plates calibrated to high accuracy in one dimension to generate two-dimensional machine calibrations, and (2) developing high-accuracy two-dimensional machining to test algorithms and develop accurate sensors. To date the project has resulted in two master 's degree projects but is currently not funded.

All the groups in the Precision Engineering Division are severely hampered by lack of core funds. For example, during fiscal year 1992, the Dimensional Metrology Group operated on approximately 10 percent NIST funding; i.e., 90 percent of the group's funding was from outside sources. In many cases, externally funded projects are undertaken to support staff. The division could better serve NIST's mission if it could plan for and work on core programs.

Automated Production Technology Division

Mission and Organization

The Automated Production Technology Division develops and maintains competence in the integration of machine tools and robots and develops the interfaces and networks necessary to combine robots and machines in workstations and manufacturing cells; develops and maintains computer-assisted techniques for generation of computer codes necessary for robot-controlled machine tools; develops and maintains competence in the processes and techniques necessary for precision manufacturing; maintains competence in the measurement of mass; develops engineering measurement methodology and sensors; maintains a service in static and dynamic force and force-related quantities; and provides services as needed by the discrete-parts industry, including the development, characterization, and calibration of transducers.

The division is composed of five groups: Acoustics, Mass, and Vibration; Ultrasonic Standards; Sensor Systems; Sensor Integration; and Force.

Activities and Progress, with Panel Comments

-

The broad range of the Automated Production Technology Division's activities needs more detailed planning.

-

The division's Quality in Automation Program remains one of its most important efforts.

-

The division's open architecture for computation research has shown encouraging results and should be more closely coordinated with similar projects within NIST and elsewhere.

-

The division's development of ultrasonic and other nondestructive techniques for monitoring manufacturing processes has been successful.

-

The division's composition of personnel appears to be about two-thirds researchers, a proportion that seems too large considering the division's dedication to technology development and transfer.

-

As was noted in the fiscal year 1992 report (p. 90), the Automated Production Technology Division has a variety of disparate responsibilities, and only 33 percent of the division's income is from STRS funding. Such a small percentage of core funding diverts the division's talent from research and development to soliciting and managing OA funding and tends to defocus the division's effort.

Robot Systems Division

Mission and Organization

The Robot Systems Division develops and maintains competence in robotics, real-time sensory-interactive control technology, robot programming languages and standards, and advanced robotic systems; conducts research into new techniques of vision and other sensing, sensory data processing, uses and storage of knowledge, databases, communications, world models, robot programming languages and techniques, and interactive graphics for program development and diagnostics; applies artificial intelligence techniques to real-time sensory-interactive control technology for industrial, military, space, and construction applications; performs research on experimental hardware and software and develops measures of system performance for a wide variety of robot applications; performs computer-integrated-manufacturing systems research; and performs technical activities relating to standards for robotic systems.

The division consists of the Performance Measures, Intelligent Controls, Systems Integration, Sensory Intelligence, and Unmanned Systems groups.

Activities and Progress, with Panel Comments

The Robot Systems Division's work on architecture for intelligent flexible manufacturing is in keeping with the division's mission and is needed by U.S. industry. The panel supports the division's general architectural approach; however, difficult issues in establishing interfaces between levels of information need to be resolved and validated through close cooperation with industry, using a series of prototypes for solving in situ production problems.

The Robot Systems Division's outreach to industry and its application of the division's core competence to the enhanced machine controller and the next-generation inspection systems project are commendable.

The division's realization of the active camera platform (TRICLOPS) for foveal vision and rapid feature tracking and its realization of the Stewart platform “crane” were major achievements; however, the relationship of the achievements to the MEL's mission is not clear to the panel.

Factory Automation Systems Division

Mission and Objectives

The Factory Automation Systems Division provides a focus for national research and standards development as needed for flexible computer-integrated manufacturing. The division's objectives are to perform research and development in advanced manufacturing systems and networking; assist industry in implementing voluntary consensus standards relevant to flexible computer-integrated manufacturing; conduct research to identify and overcome technical barriers to the successful and cost-effective operation of advanced manufacturing systems; facilitate industry efforts to develop and test new applications of advanced manufacturing systems; and provide mechanisms for the exchange of information about advanced manufacturing systems and networking.

Strategy and Tactics

The vision of the Factory Automation Systems Division is that future manufacturing will be imbedded in an information infrastructure that supports a “virtual enterprise.” Independent enterprises will be integrated by an information network into an effective system. Within each enterprise, various product-

related functions will transparently share product and process data.

This vision of future manufacturing is supported by the following national activities:

-

The National Critical Technologies Panel identified flexible computer-integrated manufacturing and systems management technology as key technologies required for concurrent engineering.

-

The Agile Manufacturing Forum (consisting of key U.S. industry leaders) developed a vision for 21st-century manufacturing that included specific roles for NIST related to technology and standards development.

-

The federal Advanced Manufacturing Technology initiative identifies “integrated tools for product, process, and enterprise design” as a key thrust. The federal HPCC initiative stresses information infrastructure technology, with an emphasis on systems integration for manufacturing applications.

Twenty-first-century manufacturing will require standards for ensuring interoperability and coordination among components of products. Standards are becoming more essential because of the country's growing reliance on interrelated, sophisticated technologies. Consequently, the rapid pace of technological change drives the need for the rapid development of standards. An office of Technology Assessment (OTA) report, Global Standards: Building Blocks for the Future (OTA, TCT-512, U.S. Government Printing Office, Washington, D.C., March 1992), which addressed how U.S. standards and standards development processes affect U.S. trade, found a direct relationship between the application of standards and competitive advantage.

The panel believes that the United States needs a standards and technology strategy that significantly accelerates the standards approval process. The U.S. standards-setting bodies need the means for analyzing the life cycle development of standards and developing the procedures that accelerate the availability of critical standards.

A detailed planning document, “The Technical Program of the Factory Automated Systems Division, 1993” (Howard M. Bloom and Larry W. Masters, draft NISTIR, U.S. Department of Commerce, Washington, D.C., May 1993), with schedules, milestones, and resource needs, identifies the critical role of standards in manufacturing systems and proposes a clear path that accelerates the standards approval process. The planning supports planned growth for the division well.

The Factory Automation Systems Division applies information technology to advanced manufacturing via (1) its advanced manufacturing system research and development project, which focuses on design (product, process, and enterprise), planning, scheduling, process modeling, shop control, simulation, inspection, assembly, and machining, and (2) its manufacturing integration technologies research on integration of manufacturing

applications and systems across and between multiple enterprises. Typical integration and interface technologies include those for networks, communications, databases, and exchange of product and process data. Although concerned primarily with mechanical parts production, the division also has a strong involvement in apparel production.

Organization

The Factory Automation Systems Division has two program offices--the Computer Aided Logistics Support/Product Data Exchange Specification (PDES) Project Management Office, and the Initial Graphics Exchange Specification (IGES)/PDES/STEP Administrative Office--and four groups.

The Production Management Systems Group performs R&D to advance the state of the art for manufacturing systems and to identify open interfaces that will support interoperability. Examples of R&D areas include control architectures, cell controllers, production scheduling, process planning, and off-line programming.

The Product Data Engineering Group's R&D focuses on product data modeling, data access and storage, software tools, and testing procedures leading to a standard product data model.

The Integrated Systems Group advances the knowledge and understanding of information technology (computers, software, and networks). The group transfers its technology through standards and does R&D in distributed systems, configuration management, and enterprise integration.

The Machine Intelligence Group's R&D is in metal powder production, apparel product data exchange, inspection software performance testing, inspection methods, and increasingly, controlling mechanical tolerances.

Resources

The Factory Automation Systems Division's funding for fiscal year 1993 included $5.0 million in OA contracts (Computer Aided Logistics Support, Advanced Research Projects Agency, Navy Mantech Program), $1.6 million in STRS funding, and $1.4 million from the Advanced Technology Program (ATP) and from the NIST Director 's Reserve), for a total of $8.0 million. The division had a staff of 61 (42 technical professionals, 3 technicians/craftsmen, 7 student appointees, and 9 clerks and administrative personnel).

Status and Progress of Division programs, with Panel Comments

The following items are highlights of the Factory Automation Systems Division's program activities since the panel's fiscal year 1992 assessment.

-

Information models and interface specifications were developed for use in Navy procurement specifications for planning and control systems. This project, supported by the Navy Mantech Program, is a specific implementation of the manufacturing systems integration effort, which in turn is a subset of the enterprise integration effort. Currently, the typical approach to systems integration is to customize each application. The goal of the manufacturing systems integration work, which began in fiscal year 1990, is to develop a reference architecture for discrete machined parts that incorporates an integrated production planning and control environment, and to establish a testbed for production management architectures that integrate process planning, production planning, and shop floor control. Accomplishments from this project include a production management model, a manufacturing systems integration architecture, and a control interface specification for controllers.

-

The division reported that protocol requirements were developed for postal network equipment. More specifically, specifications were developed that detail the explicit communications requirements for each of six classes of postal equipment. The specifications extend the generic standard, the Postal Equipment Message Specification proposed in fiscal year 1992. The U.S. Postal Service (USPS) currently has no standard for communication with mail processing equipment (MPE). MPE controllers are not significantly unlike manufacturing equipment controllers and can thus benefit from existing manufacturing standards. The objective of this project is to provide the USPS with a standard messaging protocol for all communication with MPE controllers, using international standards, to ensure interoperability of postal automation systems into the 21st century. It is not clear to the panel how close to manufacturing equipment controllers this work really is.

-

The division reported that a STEP toolkit was installed that accelerates the development of software applications for exchanging product data. The toolkit can represent and manipulate STEP-compatible data structures and exchange file structures (ISO/DIS 10303-11 and 21). This library of software can be used to accelerate the development and improve the quality of STEP-based application software products. The panel is not certain about the extent to which this toolkit has solved the problem, i.e., how universal the application is.

-

The division has implemented an algorithm testing system (ATS) for testing the performance of curve- and surface-fitting software used on coordinate measurement machines (CMMs).

-

Industry needs methods for evaluating the performance of software used in inspection systems. The division's ATS provides a mechanism and the reference algorithms for evaluating CMM software, as well as an environment for conducting experiments to characterize algorithms. The objectives of the ATS project are to enhance the capabilities of the division's ATS and to make the system available to CCM users. The ATS is intended to be the basis for a new NIST dimensional measurement test service that will, for the first time, address how software contributes to measurement uncertainty. The division's professional staff have leadership roles in the appropriate committee activities of the American Society for Mechanical Engineers and the International Organization for Standardization (ISO). The panel was unable to evaluate the software used with the CMMs, i.e., to determine how well the problem had been solved.

-

An intelligent computer-integrated manufacturing monitoring and trouble-shooting tool (Intellimon) is being developed as a software tool that can be used by an operator at a centralized location to track the exchange of data between computer-integrated manufacturing applications, help the operator to maintain a reliable networking environment, and diagnose problems within the networking environment. This, the second year of a 4-year project, is being carried out jointly with General Motors Corporation. The panel was unable to assess the progress.

-

An on-line bibliographic service has been installed, apparently as part of the electronic library services effort, under communications and networking. The goal of the research is to develop mechanisms for the rapid exchange of information.

The panel points out that an on-line service needs to be developed for transferring research information to industry, academia, and government organizations. Such electronic technology transfer would enable researchers to gain timely access to information that might otherwise be out of date if transferred by other media and would also provide remote access to otherwise unavailable computational facilities. The panel agrees with the need to distribute information but believes that this project should be thought through again and benchmarked against established services.

-

Three major state-of-the-art papers were produced in key division programs: tolerance standards, strategic vision for the apparel industry, and database management systems in engineering. The panel commends the division for publishing state-of-the-art papers and would like to see papers published that summarize research performed on Factory Automation Systems Division projects.

-

Finally, the panel lauds the accreditation of the national IGES/PDES Organization, chaired by Factory Automation Systems Division professional staff. The accreditation will aid in accelerating the development and acceptance of STEP.

Panel's Specific Findings

-

The panel is pleased with the Factory Automation Systems Division 's progress since the fiscal year 1992 assessment; however, in some cases the projects appear to be isolated solutions rather than important elements of a unified whole, and in other cases the panel was not able to assess the extent to which progress was made toward a stated goal. Finally, the panel could not evaluate the relative priorities of some of these projects (e.g., the on-line bibliographic service) in the overall mix of projects and recommends that attention be given to developing priorities.

-

Focusing the PDES testbed effort on specific Department of Defense needs is an important narrowing step. In the past, this effort has been all things to all people, and its utility seems to have been targeted well into the future.

-

Having senior division staff members study future needs and postulate a responsive program matched to division capabilities is a commendable practice.

-

The extensive documentation and very complex diagrams used to describe the application of PDES seem to be overly complex and make the process hard to grasp.

-

The validation of algorithms for coordinate measuring machines seems to be a traditional metrology function for NIST that is within the Factory Automation Systems Division's competence but should probably not be a high priority for the division.

-

The division's fiscal year 1993 Strategic Plan for the Factory Automation Systems Division (NISTIR 5148) is a significant step forward but has yet to have been assimilated by the division. This is understandable because of the March 1993 completion date.

-

The panel supports the Factory Automation Systems Division's reorganization to support its strategic plan as an important new commitment; however, no organizational structure will meet the division 's changing needs for long.

-

The networking and testbed efforts described in the Factory Automation Systems Division's strategic plan seem to be an incredibly important component of the future mission that should be emphasized more in the operational plans and program activity.

Fabrication Technology Division

Mission

The mission of the Fabrication Technology Division is to design, fabricate, repair, and modify precision apparatus, instrumentation, components thereof, and specimens as necessary for NIST's experimental research and development. The division focuses on items that are unavailable commercially or that by

their size, complexity, or specialized nature require craft skills and machine tool equipment beyond the capabilities of the NIST technical units. Services include engineering design, scientific instrument fabrication, numerically controlled machining, welding, sheet metal fabrication, microfabrication, grinding, optical fabrication, glassblowing, precision digital measuring, and operation of a tool crib and metal storeroom. The division also provides skilled machinists for technical support to NIST's research and development programs.

Activities and Resources

The Fabrication Technology Division examines existing and new manufacturing technologies for their relevance and/or benefit to the division; implements, as appropriate, those manufacturing technologies that will improve the division's efficiency and productivity; and continues with the 3-year machinery rebuilding program to bring the division 's equipment up to at least near the state of the art. The division works with other MEL divisions to transfer appropriate technology from the Automated Manufacturing Research Facility to the Fabrication Technology Division shop floor.

The fabrication shop has 51 staff members, 46 of whom are technicians/craftsmen.

Panel's Comments

-

If the stated mission of the Fabrication Technology Division is the sole mission, the appropriate measures of performance are cost, quality, and delivery of services relative to alternative sources, e.g., outside shops.

-

The panel believes that the Fabrication Technology Division can and should play a somewhat broader role than is described in its mission, by providing opportunities for U.S. industry (1) to implement MEL technology and other modern manufacturing technology and provide user feedback to evolve the division's competencies for providing such services and (2) to use new technologies. Technologies so developed would provide tangible benefits to division customers in cost, quality, and timely delivery. Division shop personnel could help to debug new technologies, improve technology transfer, and improve the utility of technologies to customers.

-

The Fabrication Technology Division has made impressive improvements in a number of performance metrics, including reducing the defect rate of fabricated parts from 2.5 percent to 1.2 percent, increasing the number of fully specified jobs from 10 percent to 75 percent, and maintaining “down-time” (the time not worked in support of customer contracts) at about 10 percent, which is considered excellent for small shops.

-

The Fabrication Technology Division's progress to date in refurbishing both equipment and facilities is critical and commendable.

Automated Manufacturing Research Facility Program Office

Mission, Status, and Progress

The Automated Manufacturing Research Facility (AMRF) Program Office is responsible for managing selected cross-divisional research and development programs sponsored by other agencies, including the Navy-sponsored AMRF Program, which has been the MEL flagship program for over a decade.

Until recently the AMRF Program Office was also responsible for the Manufacturing Technology Centers Program. Effective April 1, 1993, the program was transferred to NIST's director's office as part of the larger Manufacturing Extension Partnership Program, which NIST intends to elevate to operating-unit status in the future and to greatly expand in accordance with the Clinton administration's policies.

The AMRF Program Office is currently redefining its roles and responsibilities within MEL. In addition to serving as a catalyst and focal point for formal long-range planning activities within the MEL in the future, the office will also coordinate MEL's response to external planning efforts, such as the recent federal Advanced Manufacturing Technology initiative. To support these functions, the office will undertake and manage planning studies to address long-term research and development opportunities in selected technology areas.

Also, the office will play a larger role in new program development, particularly in areas of overlap between MEL divisions or where coordination is required with other NIST laboratories and outside agencies. Program development areas currently being pursued include electronic commerce, mathematics-based manufacturing, and sensor interfacing.

Panel's Comments

-

The AMRF Program Office has been an important strategic, integrating force for the MEL and has an important future role to play that requires an evolution of the office's form and function.

-

NIST will likely play an increasingly important role in transferring technology, and the AMRF could become one of perhaps several proving grounds for increasingly effective processes for transferring manufacturing technology.

Office of Industrial Relations

Mission, Activities, and Resources

The Office of Industrial Relations, a new administrative unit within the MEL, is responsible for planning, developing, coordinating, and representing manufacturing-related programs and activities that involve significant interactions with the industrial community. The office interacts with colleagues within MEL and NIST, industrial consortia such as PDES, Inc., the National Center for Manufacturing Sciences, parties to CRADAS, and trade associations. The office also serves as liaison to the DOC's under secretary for technology for advancing product data exchange efforts and supporting the NIDPE.

The office of Industrial Relations has seven full-time and one part-time NIST staff members and eight associates sponsored by industry and other government; agencies, along with supporting funds and equipment.

Progress Reported by Office of Industrial Relations

The National Initiative for Product Data Exchange was approved in 1991 by an executive committee of corporate vice presidents and high-level government officials of the National Aeronautics and Space Administration, the Department of Energy, the Department of Defense, and the Department of Commerce. The primary objectives of this industry-led, government-facilitated national plan are to accelerate and coordinate product data exchange activities (research, standards development, and deployment of product data exchange systems) within the United States. The plan has a series of well-defined tasks, milestones, schedules, deliverables, budget requirements, and organization and oversight structure. To execute the plan the Office of Industrial Relations was established in February 1992 and is hosted at NIST. Full-time industry and government personnel are supplied with equipment and funds by industry and federal agencies. Technical oversight is provided by a steering committee composed of more than 20 industrial and government technical managers. A senior-level ad hoc executive board of government officials and industry executives provides policy advice and direction. The NIDPE and the Office of Industrial Relations have a 3-year term that terminates in February 1995.

Panel's Comments

The Office of Industrial Relations and its mission are helpful in carrying out MEL's growing responsibilities. Since the panel's 1992 assessment, significant progress has been made in turning a plan for activity into reality. The involvement of representatives on loan from industry, active industry-dominated

boards, and successful meetings suggest that customers have been found who value the activity and want to be partners.

RECOMMENDATIONS--FISCAL YEAR 1993

-

Invite experts from other U.S. laboratories to an open, broad-based design review of the molecular measuring machine project as soon as possible. Such a design review would increase the expertise available for addressing the project's current and future technical problems and bring the instrument to its desired operating level as soon as possible.

-

Convene more potential user forums in order to prioritize nanotechnology measurements to be addressed by the molecular measuring machine.

-

Support the Dimensional Metrology Group's project to develop and provide two-dimensional machine calibrations.

-

Increase the Precision Engineering Division's core funding should additional STRS funds become available.

-

The Automated Production Technology Division should develop a more vigorous strategic plan; project coordinated efforts in research, development, and technology transfer; and develop road maps, milestones, and benchmarking for all division activities rather than for only specific areas, as appears to be the present case.

-

The National Machining Tool Partnership, initiated in February 1993 as a 2-man-year Automated Production Technology Division effort, should be vigorously pursued in cooperation with the Department of Energy and other federal agencies, private industry, and state-supported technical programs.

-

The Automated Production Technology Division's research should be better aligned with the division's overall objectives in manufacturing engineering.

-

To better support U.S. industry, the Robot Systems Division should focus on integrating its programmable positioning, orienting mechanisms, and sensing subsystems into manufacturing systems.

-

The Factory Automation Systems Division should identify and develop metrics for managing and assessing progress in its programs.

-

The Factory Automation Systems Division should develop a strategy with long-, medium-, and short-range time-based objectives. Obvious dependencies and synergies with other divisions in MEL, other NIST laboratories, and external collaborations should be indicated.

-

The Factory Automation Systems Division's strategy should spell out the short-, medium-, and long-range benefits of success in the Product Data Exchange Specification testbed effort.

-

The Factory Automation Systems Division's staff should be encouraged to “buy into” the division's strategic plan.

-

The Factory Automation Systems Division should adopt a flexible organizational structure that allows for rapidly forming

-

task teams that mirror the division's opportunities. The division's staff should be encouraged to cross group boundaries as the need arises.

-

The Factory Automation Systems Division should use its two program offices as customer interfaces and as a means for identifying programmatic opportunities.

-

The Factory Automation Systems Division should make an inventory in order to judge the adequacy of its core competencies for implementing its strategic and organizational objectives. The core competencies should be assessed in the context of national needs.

-

The Factory Automation Systems Division should clearly state core competence needs and opportunities to contribute to the HPCC initiative and to meet its old as well as its new objectives.

-

The Fabrication Technology Division should prepare a vision of its role that is separate from its traditional role as a central shop and from operational issues such as funding and personnel. Once NIST accepts the vision, strategies and tactics for implementation can be developed. Careful consideration should be given to utilizing the capabilities of the Automated Manufacturing Research Facility.

-

The Fabrication Technology Division's performance measures should be more statistically based and should be chosen so that they facilitate benchmark comparisons with other shops and laboratories. The division needs benchmarking for self-improvement and for demonstrating its relative value to customers.

-

The Fabrication Technology Division's shop and design services should be charged at full-cost-recovery rates to facilitate benchmarking and to encourage customers to establish priorities in the expenditure of their funds. Certain specifically identified costs, such as those related to testing and showcasing new technology and processes and evolving competencies, could be borne by a technology transfer or overhead budget and not be charged to customers.

-

The Fabrication Technology Division should become a single point of contact for customers, thus providing requested services in-house or through an outside supplier, in accordance with NIST guidelines, resource constraints, and customer wishes. The division's orientation, then, would move further toward providing services and value to customers rather than focusing on in-house issues.

-

The Fabrication Technology Division should upgrade its equipment to at least state-of-the-art capability, rather than restoring the equipment to its original state. The division should become a showcase of modern fabrication technology.

-

The Automated Manufacturing Research Facility (AMRF) should be a super-testbed, comprising a collection of testbeds for modern manufacturing technology that could showcase the latest manufacturing capabilities, regardless of their origin within or outside of NIST. Considerable study would be required

-

to determinewhether the modernized AMRF should be a physical on-site facility or a virtual, distributed facility. Similarly, determining how to balance emphasis on the equipment level with emphasis on the computer-integrated manufacturing level would have to take into account the increasing importance of computer-integrated manufacturing and MEL capabilities in this area. The AMRF Program office is encouraged to define a new theme and a clear role for the AMRF as a national showcase for new manufacturing capabilities.

-

The Automated Manufacturing Research Facility should undertake additional collaboration with the Fabrication Technology Division to develop novel fabrication processes and ways of transferring technology.

-

To better represent the primary MEL mission and to better support national competitiveness, the Automated Manufacturing Research Facility Program Office should redirect its focus and its personnel from service work to work that is of special interest to commercial industrial customers. To emphasize such a change, the AMRF Program Office should support its new focus and thrust with a new name.

-

Now that significant resources have been assembled for implementing the National Initiative for Product Data Exchange, the Office of Industrial Relations should reevaluate its objectives and goals; in particular, it should develop a simple and clear statement of timed objectives. The statement could also address how additional industry groups can participate and what benefits industry can expect from collaborating with the office. The relationship and benefits to internal NIST activities also could be more clearly defined.

-

Given the 3-year time frame for the National Initiative for Product Data Exchange, it seems important to plan for the termination of the initiative or a transition to a new or revised task when the 3 years are up.