APPENDIX D

REPORT OF THE PANEL1 ON FACILITIES AND RESEARCH AT THE ALBANY RESEARCH CENTER

FACTUAL DATA ON THE ALBANY RESEARCH CENTER

The Albany Research Center (ALRC) has a long and distinguished history. Following completion of the Bonneville Dam in 1937, which created great possibilities for a metallurgical industry in the Pacific Northwest, the U.S. Bureau of Mines selected Albany from several sites under consideration for a research center. Processes were developed for the manufacture of titanium and zirconium, which contributed directly to the aerospace, chemical, and nuclear power industries. The recruitment of William Kroll was a great plus for this program and illustrates the importance of a competent leader. The development of successful industries in the Albany area based on this work is a lasting tribute to the intelligent use of public resources to catalyze private sector development.

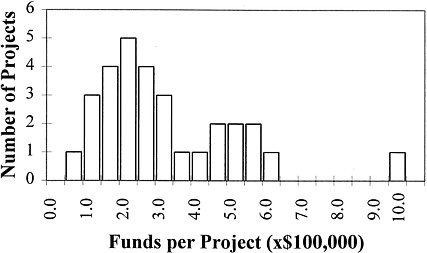

The current number of ALRC staff members is approximately 120. The center's budget over the past three years has been in the $10 million range, supporting 30 projects (Table D.1) ranging from $50,000 to $935,000, with an average size near $300,000 (Figure D.1). The great bulk of this support comes from internal (bureau) funds of the Minerals and Materials Sciences (MMS) Division (approximately 85% during the past three fiscal years). The Environmental Technology (ET) and Health, Safety, and Mining Technology (HSMT) divisions support small amounts, and approximately 10% of the funding comes from external sources, including other government agencies. This latter number is of interest because recent bureau plans have called for the ALRC to obtain up to 50% of its funds from outside sources.

|

1 |

The Panel on Facilities and Research at the Albany Research Center consisted of the following committee members: Harold W. Paxton, Panel Chair, Carnegie-Mellon University; Robert Ray Beebe, Tucson, AZ; Donald C. Haney, University of Kentucky; Frederick C. Johnson, National Institute of Standards and Technology; Dale F. Stein, Michigan Technological University; and Jonathan G. Price, NRC staff. In addition, Sharon K. Young (Magma Copper Company) participated as a guest panelist. |

Figure D.1 Funding for Albany Research Center projects, FY1994.

The research staff of 74 scientists and engineers and 15 technicians is supported by 18 tradesmen and other support specialists and 17 clerical and administrative employees. ALRC has a union for some employees (recently formed), four union appointees serve with four management appointees on the Albany Partnership Council, which is the effective governing body of the center. Twenty-three staff members have Ph.D. degrees, which is among the highest proportion in the bureau. The center director is an adjunct professor at two local universities. Several students from Oregon State University in nearby Corvallis work part time or are completing thesis requirements at the ALRC.

The facilities for pyrometallurgical research are noteworthy if only because such facilities are rare in the United States. One outside research customer who met with the panel was impressed with the way ALRC facilities were used to tackle a job declared impossible by industrial sources. Other services, especially those that need expensive instrumentation, are also a considerable help to small and medium-sized industries in the area.

Research programs at the ALRC are developed in much the same way as at other bureau centers, with what some employees view as frustrating and intrusive “help” from the Washington headquarters and with some involuntary assignment of staff to projects. An interesting exception is a program to produce a useable grade of

TABLE D.1 Research Projects, FY1994, Albany Research Center

|

Materials Research ($4,569,000) Infusion Gas Alloying (Nitrogen Alloying of Steels)a Modeling of Wire and Synthetic Rope Behavior During Static and Dynamic Loading Micromechanics of Compressive Fracture in Heterogeneous Material Wear Corrosion Mechanisms in Minerals Processing Smart Materials–Monitoring and/or Alarm Systems for Structural Members in Mines Smart Materials–Strain Monitor Systems Contract Structure and Properties of Advanced Intermetallics Synthesis and Joining of Advanced Materialsa Mechanisms of Passivity of Pseudostainless Steels (Low-Chromium) Corrosion Performance on Reinforced Concrete Structures in Coastal Environmentsa Effects of Nonequilibrium/Engineered Microstructures on Deformation Low-Cost Titanium–Lightweight Titanium Ceramic Composites Minerals Research ($3,635,000) Low-Cost Titanium–Production of Powder by Vapor-Phase Reductiona Low-Cost Titanium–Titanium Alloys from Secondary Sourcesa Low-Cost Titanium–Continuous Production of Titanium Powdera Metal Extraction from Dilute Solutions with Emulsion Membranea Solvent Extraction Fundamentals Clean Technology–Waste Minimization in the Copper Industry Parameters Affecting Selective Leaching of Copper Thermodynamic Data Compilation In Situ Leaching of Phosphate Predictive Control of Nonlinear (Chaotic) Processes Identification, Characterization, and Recycling of Advanced Materials and Alloys (Aluminum-Lithium)a Removal of Copper and Tin from Ferrous Scrap Recovery of Vanadium from Titanium Chlorinator Wastesa Characterization of Fine Particle Values by Image Analysis Characterization and Waste Separation Studies on DOE Sitesa,b Environmental Technologies ($540,000) Water Treatment Systems–Liquid Emulsion Membranesa Midnight Mine–Liquid Emulsion Membrane Detoxification of Hazardous Wastes by Vitrificationa Health, Safety, and Mining Technology–Mining Safety Systems ($145,000) Laboratory Analysis of Wire Rope |

|

a Projects on which the panel was given briefings during its site visit. b Fully funded by the U.S. Department of Energy (DOE). |

titanium at a significantly lower price. This program developed from a discussion in the Oregon Metals Initiative—a consortium of industry, academic, and government partners in the state—as a highly desirable lever to increase the use of titanium in consumer products.

The panel queried several bureau employees about their thoughts on the “Reinventing the USBM” documents. In general, there was resignation and some irritation to the length of time with no actions. The proposal to cut layers of supervision produced some cynicism with the theme that it was unlikely that the “right” people would be cut.

Relations with other centers in sharing expensive equipment were clearly in evidence; the ALRC is the principal resource for surface science.

RESEARCH PROGRAMS

Process Metallurgy

The ALRC Process Metallurgy Division conducts research in pyrometallurgy and hydrometallurgy. The emphasis is on improved efficiency of extraction and processing of primary materials and on recovery of materials from secondary sources. The principal areas of research that were highlighted for the panel include processes for the production of low-cost titanium, metal extraction using liquid emulsion membranes, recovery of vanadium from titanium chlorinator waste, and removal of copper and other impurities from ferrous scrap.

A major program ($1,750,000 in FY1994 funding for four separate projects) of the division is focused on the production of low-cost titanium metal, both from primary raw materials and alloy scrap. The panel viewed this work as being especially promising because of its relevance to the longer-range development of titanium as an economic, high-performance metal for general industrial use. The overall project includes continuous production of titanium powder via vapor-phase reduction, low-cost further processing of the powder produced, and recovery of metal currently wasted in alloy scrap. An important feature of the low-cost titanium project is its recognition that useful grades of titanium can be produced without reaching the ultimate purity required for aerospace applications.

The division's work on liquid emulsion membranes is also receiving significant emphasis, but the panel does not think that this technology will replace or even radically alter the solvent extraction technology in commercial practice today. Nevertheless, this project has promise for remediation where low-grade metal bearing

solutions must be cleaned prior to disposal or where the solution can become an economical source of metal.

Other projects in this division involve prediction of nonlinear processes, waste minimization in mining and minerals processing, in situ leaching of phosphate ores, control of acid mine drainage utilizing liquid emulsion membranes, and vitrification processes for volume reduction and passivation of wastes.

Process metallurgy research at the ALRC impressed the panel as being relevant to industrial problems and at the same time sufficiently flexible to allow for investigation of collateral problems or ideas that might arise during the course of the work. The Division is making progress in attracting outside support, and its flexibility appears to encourage further progress in this regard.

Characterization

The Characterization Division has a staff of 26 people with about one-third doing research and two-thirds committed to the analytical support function of the center. The division is changing, moving from minerals processing and mineral resource identification to applying its capabilities to metals and materials separation, waste reduction, and cleanup.

The analytical support activity can be divided into two major areas: physics and wet chemistry, with physics becoming of greater importance. In general, the group appeared to be competent and adequately equipped. The outside user group was very supportive, describing how useful and important these analytical facilities are to the small metal companies located in the region. A new scanning electron transmission microscope (TEM) is expected in the coming year to replace the existing 10-year-old TEM. The ESCA (Electron Spectroscopy for Chemical Analysis) system is older but appears to be adequate for the ALRC's needs. The impression was of a unit that meets the needs of the laboratory and the regional user groups but not one that is lavishly equipped or overstaffed.

Two research activities were described in some detail: engineered scavenger compounds and the cleanup of sites associated with the Department of Energy (DOE). In both programs the work was competently done, with the scavenging work showing good imagination, although perhaps not applied to a problem with a visible payoff.

The engineered scavenger compounds program is directed at the removal of lithium (Li) from scrap Al-Li alloys that are used primarily in aircraft, with a secondary interest in magnesium removal from alloys (beverage cans) to promote the recycling of aluminum (Al). Briefly, the Li in molten Al-Li alloys is first captured in a metal oxide that has a channel-like structure. Next, the Li-loaded oxide is attached to a power source to remove the Li and is electrodeposited in pure form for recycling

of both the Li and the Al. The economics appear favorable (costs of $600 to $1000 to recycle a ton of lithium compared to a market value of about $1,400 per ton).

It is disappointing that the Al industry and the airframe industry do not support the scavenging program to a significant extent. The problem of Li recycling may not be of great importance to them, as most recent versions of aircraft are not using Al-Li alloys to any great extent.

The primary purpose of the DOE remediation action program is to immobilize radioactive and toxic materials while also reducing the volume of contaminated materials, using mineral processing techniques. This program is supported by DOE, it appears to meet their needs, and it is a good example of bureau capability mated to a customer need.

Materials Sciences

The ALRC's materials sciences program has a staff of 32 people and a budget of $3.9 million. It is an expanding program with several staff additions in recent years. Three programs were presented to the panel in some detail: Infusion Gas Alloying, Synthesis and Joining of Advanced Materials, and Corrosion Performance of Reinforced Concrete.

In each case the people presenting the work demonstrated high competence, enthusiasm, and commitment. The work was well done, with the joining of advanced materials showing exceptional basic insights to the joining process as well as wide-ranging capabilities to join different and difficult materials. The infusion gas alloying program focused on increasing the nitrogen content of steels to produce high strength, with adequate toughness, but it was not clear how big a market exists for the material. The corrosion study is directed at a specific and important problem, that of corrosion of reinforced concrete used in bridges. Although this is an urgent problem for the Oregon Department of Transportation, because bridges along the Pacific Coast are seriously deteriorating, it is also a problem of national consequence.

The joining and gas infusion programs are having difficulty attracting significant outside funding, despite their obvious high quality, and this demonstrates what may be a fundamental problem in choosing research areas. Again, the panel notes that the bureau should develop closer relationships with user communities to identify problems of major need and to promote cooperative research that will attract significant outside support and interest from the customers. This is especially acute for the otherwise impressive gas infusion program, which commands a large budget (nearly $1 million annually). The corrosion project does have a strong customer base, but it was disappointing to find that less than half the cost of the research is being paid for

by the customer. Clearly it is equitable and necessary that the bureau expect additional support when its work is of high quality and meets a customer need.

FACILITIES, SUPPORT, AND STAFF

The ALRC, formerly Albany College, has a number of adequate to very good buildings on a wooded campus-style site that offers attractive working conditions. The space for offices and laboratories seemed quite adequate for the existing staff. No doubt it could be expanded, but there are no plans or obvious needs to do this. There is easy access to Oregon State University in Corvallis and the Oregon Graduate Institute (OGI) in Beaverton; a number of staff members are graduates of these institutions, but area graduates are not so dominant here as at the Salt Lake City Research Center (University of Utah) or the Reno Research Center (University of Nevada, Reno). Oregon State University no longer has a materials program to reinforce the emphasis on materials at the ALRC; OGI does, but it is a little more distant.

One “classical” unit in the ALRC facilities is a pilot-scale melting furnace, which has moved from its metallurgical ancestry to contribute to environmental disposal problems through encapsulation by vitrification. The center is also the focus of equipment for surface studies and, through the commendable informal pooling of resources by the centers for expensive equipment, remains quite current in this area.

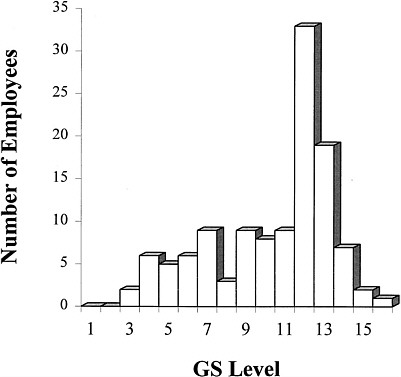

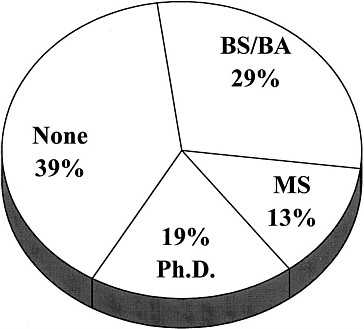

A summary of the expertise of the staff at the center is given in Table D.2 and Figure D.2 and Figure D.3. The mix of scientists and engineers is appropriate for the minerals and materials research conducted at the center. The percentage of researchers with Ph.D. degrees at the ALRC (19%) is significantly higher than at the Salt Lake City Research Center (SLRC; 7%) and the Reno Research Center (RERC; 6%). Approximately 65% of the ALRC principal investigators (those at the full performance level of GS-12 or higher) have either Ph.D. or M.S. degrees. As befits the current and proposed emphasis on materials work, there are a number of relatively new hires, many at the doctorate level, who impressed the panel with the quality of their work.

Support staff seemed adequate and motivated. The question of recognition for providers of significant support services (coauthorship, acknowledgments, etc.) did not seem so acute as at other centers but warrants continued close attention in cutting-edge research where the “extra mile” can be vital.

Communication between the three divisions could be improved; with the exception of a couple of “gatekeepers,” broad knowledge among the staff of the total center's program is weak. A proposal has been made to require the group in materials sciences in the bureau to seek matching funds to warrant continued support. The May 1994 “Reinventing the USBM” states that “cost-shared partnerships with industry

Table D.2 Disciplinary Backgrounds of ALRC Employees

|

Number |

|

|

Technical Staff |

|

|

Chemist |

22 |

|

Chemical engineer |

12 |

|

Metallurgist |

11 |

|

Materials engineer |

10 |

|

Physical scientist |

4 |

|

Mechanical engineer |

3 |

|

Geologist |

3 |

|

Physicist |

2 |

|

Computer engineer |

1 |

|

Physical science technician/aid |

15 |

|

Engineering technician |

6 |

|

Support Staff (includes computer specialists, mechanics, electricians, and others) |

18 |

|

Administrative Staff |

17 |

|

TOTAL |

124 |

would ensure that the Nation's highest priorities are addressed. Materials research that is unable to generate cost sharing should be phased out.” In the panel's view there are some problems with this approach as presently stated:

-

The program of the bureau is a minuscule part of the total national program in materials sciences, very little of which is significantly cost shared by industry. While the program has strengths, it is not so unique that the large materials-related industries will be standing in line to participate, especially with the current bureau structure for overhead.

-

The bureaucratic structure of the centers (fixed employment levels, budget limits, etc.) is not designed to respond to an ebb and flow of business. Compared to the structure of a commercial research house, the response time seems likely to be much longer, at least initially. The center's current employees were generally not hired for their entrepreneurial skills. One means of solving the problems of fluctuating

Figure D.2 Distribution of general schedule grades of ALRC employees.

-

personnel when extramural funding comes into or leaves the research center would be greater use of outside contracts, postdoctoral grants, or part-time employees. These would ease the burden on existing staff and avoid interference with longer-term hard-money projects.

-

Because other activities of the bureau relating to “green” issues and health and safety are not subject to the same requirements for cost sharing, a very difficult management problem has been created; those who are capable but not entrepreneurial will tend to avoid work on materials and exacerbate the difficulty of providing the first-class research necessary to make the program successful.

-

A firm decision on whether to support the materials program on a base similar to others should be made (which, of course, does not rule out garnering outside support from industry or other agencies). If in the view of bureau's upper management, materials research is not supportable in its own right, the program should be phased out directly rather than die a slow death. Other groups may well be interested in taking over some or all of the program, the ultimate acid test of true value.

Figure D.3 Distribution of highest degrees held by ALRC employees.

TECHNOLOGY TRANSFER

The approach to technology transfer at the ALRC is based on the explicitly expressed principle that technology transfer begins with the staff. The center relies on mechanisms distributed among the professional staff, and these activities are supported as necessary (such as preparation of CRADAs) by the administrative staff of the center. Mechanisms to implement technology transfer include attendance at technical and professional meetings, bureau publications, outside publications, patents, CRADAs, and discussions and other working arrangements with industry.

From January 1992 to August 1994, ALRC staff published 86 articles in outside journals and periodicals and issued 11 bureau publications, for a total of 97 articles in a period of about two and one-half years. There are 89 staff members in the research cadre of the center, so the average rate of publication is less than one-half article per year per professional staff member—still on the low side for a technology-

rich program. The effectiveness of research staff publications as a technology transfer mechanism would be enhanced by a higher rate of publication. Eight patents were issued to ALRC staff in 1993 and through August 1994.

Professional conference attendance by the Albany research staff totaled approximately 120 per year in FY1992 and FY1993, but the projected total attendance for FY1994 is only 75, a significant decrease that hampers one of the most effective mechanisms for professional staff to interact with industry. This decrease was the consequence of an explicit decision to emphasize training of the nonresearch staff for a period of time. Approximately 7% of the Albany center's budget is for an item that includes professional travel, training, and support contracts. Currently, informal staff comments indicate that they are satisfied with their ability to attend professional meetings.

In FY1994 there were slightly more that 30 CRADAs and other agreements between the ALRC and industry and other government agencies. These agreements totaled about $1.6 million in funds for the ALRC, although not all funds came into the center in FY1994. In addition, there were several in-kind contributions from industry. The large majority of the funding comes from a few arrangements with other federal agencies, and approximately $600,000 in funding comes from 16 agreements with industry, for an average of less than $40,000 per industrial agreement. Comments from some industrial representatives indicate that in general they are pleased with the timeliness and responsiveness of the CRADAs generated by the ALRC. However, in other informal private discussions questions were raised as to whether the commitments were serious or only casual. Emphasis should be placed on serious committed interactions with ALRC cooperators.

An alternative mechanism that may be helpful for the Albany center would be to consider CRADAs or other imaginative joint mechanisms with more industry groups in addition to arrangements with individual companies. (The panel noted that the titanium program arose from an arrangement of this type.) Group arrangements would enable a broader cross-section of industry participation and would increase the amount of funding per agreement without requiring a larger contribution for each industry partner. This approach could be facilitated through a series of workshops with strong participation from industry and be focused on specific research needs in a given technology area. These workshops would have as a goal identification of a joint agenda for action with clearly defined roles for the bureau and the industry (and other agency) participants. This type of approach has proved successful in other areas of the federal research program that are working to achieve increasingly productive interactions with industry.

As at other centers, industry workshops as an aid for program planning would also be helpful in assuring that the center's research program is considered relevant

and well-focused by its industrial clientele. Comments to the panel from industry indicate concern about the relevance of some of the programs at the ALRC. It would also be useful for economic feasibility studies to be conducted much earlier in the life cycle of a research project. This would provide a basic reality check and an additional mechanism for assuring widely perceived relevance of a research program. It is noted that currently all economic studies are performed in the Washington headquarters office of the bureau. This concentration in Washington may be a barrier to the effectiveness of early economic analyses, and it may well be desirable to have some basic economic assessment capability available at the center itself.

USER COMMENTS

The panel met for approximately two hours with six industry, university, and government cooperators2concerning their relations with the bureau. The comments below have been aggregated rather than attributed to specific people.

The quality of bureau research has been good to excellent, and cooperation with the bureau researchers generally has been fine. Communication between the bureau and industry customers with regard to research needs and willingness to cooperate is good in some areas, such as the domestic copper industry, but there is a need for better communication with some industries and with other government agencies. For example, some bureau researchers are unaware of published and patented technologies that are directly relevant to the work they are doing or propose to do.

Furthermore, some potential users of bureau research are unaware of bureau work. One successful project was initiated after the cooperator read about bureau research in a trade journal. The cooperator would not have thought to approach the bureau to help solve its problems. Although using trade journals is a valid means of technology transfer, it is clear that the bureau's work is not widely appreciated or known.

The establishment and operation of CRADAs with the bureau in general have been accomplished smoothly and to the full satisfaction of the cooperators. There is concern that overhead may be too high, especially in areas of procurement. The bureau has wide flexibility in developing CRADAs. A 50:50 match of funds with industry is more likely if industry 's match can be in-kind services and expenditures

|

2 |

The following people participated in discussions with the panel: Matthew S. Burkins, U.S. Army, Aberdeen Proving Ground, MD; John Haygarth, Teledyne Wah Chang, Corvallis, OR; Gary Hicks, College of Engineering, Oregon State University, Corvallis, OR; Jay Mackie, CH2M Hill, Corvallis, OR; Jim Ogilvy, U.S. Army, Tank and Automotive Command, Warren, MI; and Steve Reichman, Oregon Metallurgical Corporation, Albany, OR. |

rather than cash to the bureau. Programs like Advanced Technologies Program of the National Institute of Standards and Technology, in which industry receives cash from the government, are likely to be preferred by some cooperators.

There has been a clear loss to industry from the elimination of the bureau's efforts in the determination of thermodynamic data needed for the mineral industry, a decision that has met with some heavy criticism. These data are necessary not only for industrial processing applications but increasingly for environmental applications.

The better engineering students graduating from local universities tend not to go to work for the government, including the bureau, in part because of pay but also because of less exciting challenges than in industry.

CONCLUSIONS

-

The project selection system in its present form distorts the ability to carry out research effectively, even though the Albany Research Center is more selective than some bureau centers in what is sent by way of proposals. If a program or a funding methodology is assigned from the Washington office, the availability and commitment of skilled and knowledgeable people may be stretched beyond reason.

-

Communication between the bureau and other government agencies (EPA, USGS, etc.) is spotty; in many cases this can cause redundant or misdirected activities. A similar situation exists with the industries that are very natural complements to ALRC, with its history of developing many of the local industries. A concerted effort to improve this poor coupling from the top levels of the bureau to the bench worker would produce a quick payoff.

-

A formal mechanism to include more external reviewers in the center 's program definition would help to maintain relevance and standards. It would also serve to improve communication on bureau projects and may attract more tangible interest (e.g., CRADAs The interchange with potential users and/or customers at the front end of a project would help to minimize the technically excellent but questionably relevant programs.

-

The ALRC director appears to try to get enough people to meetings where they can interface with a broader group or to training courses, but the established policies of bureau headquarters stifle some of the possibilities. A major dilemma arises because promotion is heavily dependent on one's external reputation from papers and presentations as a specialist, but the flexibility in program execution required of the ALRC director creates the need for team players. This is a fundamental management problem on which the panel heard no constructive ideas.

-

Personnel policies cause the quality of new hires to be marginal in too many cases. The regional characteristics noted at SLRC and RERC are less obvious, but still present, at ALRC; some of this is desirable and unavoidable for work-force stability, but a balance of people with other backgrounds is essential. Few make it (or are likely to make up) through the recently installed peer review system, and thus the system itself loses credibility, especially regarding the concept of a dual-ladder system. If a better group of role models were available, the expectation levels would be clearer. As a minimum, there should be a cadre of people who could earn tenure at a good university. This is true of many government labs, but the panel saw few at the bureau who would qualify. The bureau may be well advised to look for people at the DOE and other government labs that are candidates for downsizing, even though many candidates will not be familiar with bureau issues.

-

The ALRC staff has produced 86 publications in the past two and one-half years; closer inspection revealed that, commendably, almost half were in peer-reviewed journals—heavily materials oriented. Even so, the productivity is marginal on average.

In general, the panel makes the following three observations:

-

The U.S. Bureau of Mines should increase its efforts at technology transfer and communication with industry, government, and university cooperators. The panel encourages the bureau to pursue making its publications and information about ongoing research available electronically over the Internet. bureau researchers should meet regularly with potential cooperators in industry, government, and academia.

-

The bureau should develop closer relationships with the user communities to identify problems of major need and to promote cooperative research that will attract significant outside support and interest from customers. The bureau should expect additional support (up to 100% of the total project costs) when its work is of high quality and meets a specific customer need. Emphasis should be on serious committed interactions with cooperators.

-

The bureau should consider CRADAs or other joint mechanisms with industry groups in addition to arrangements with individual companies. Group arrangements would enable a broader cross-section of industry participation and increase the amount of funding per agreement without requiring a larger contribution for each industry partner. This approach could be facilitated through a series of workshops with strong participation from industry and be focused on specific research needs in a given technology area. These workshops would have a goal of identifying a joint agenda for action with clearly defined roles for the bureau and the industry (and other

-

agency) participants. This type of approach has proved successful in other areas of the federal research program that are working to achieve increasingly productive interactions with industry.

The use of industrial workshops as an aid for program planning would also be helpful in assuring that the research program of the center is considered to be relevant and well focused by its industry clientele. Comments to the panel from industry indicate concern about the relevance of some of the programs at the ALRC. It would also be useful for economic feasibility studies to be conducted much earlier in the life cycle of a research project. This would provide a basic reality check and an additional mechanism for assuring widely perceived relevance of a research program. It is noted that currently all economic studies are performed at the Washington headquarters office of the bureau. This concentration in Washington may be a barrier to the effectiveness of early economic analyses, and it may well be desirable to have some economic assessment capability available at the centers.