APPENDIX B

REPORT OF THE PANEL1 ON FACILITIES AND RESEARCH AT THE SALT LAKE CITY RESEARCH CENTER

FACTUAL DATA ON THE SALT LAKE CITY RESEARCH CENTER

The Salt Lake City Research Center (SLRC) is one of the oldest labs of the U.S. Bureau of Mines (USBM) having been founded in 1913 as a cooperative venture with the University of Utah. The center ties to the university have remained strong; an interim building was adjacent to the campus and served as the headquarters of the bureau's Metallurgical Division. Although the current site is in the University Research Park and not on the campus proper, the center's most recent director (now retired) is an adjunct professor and bureau staff can take advantage of classes and seminars at the university.

Over the years SLRC research programs have reflected the interests of the region and have often been carried out cooperatively with industry. In addition to a wide variety of metallurgical projects on the major nonferrous metals—copper, lead, and zinc—at various times research was undertaken on oil shale, air quality, mineral beneficiation, auto-scrap recycling, and the hydrometallurgy of uranium and tungsten. Since moving into its current facilities in 1980, recovery of less-common metals has also been a focus, especially from recycling “wastes.”

Today the SLRC has approximately 75,000 ft2 of laboratory and office space that is well laid out and functional. The bureau estimates that the facility could accomodate perhaps as many as 50 additional people. The current complement is approximately 125 people, with just over half having technical degrees. The experience and background skills of the staff seemed generally suited to the center's research program and reflected a careful hiring program by the current director over the past dozen or so years. The budget for FY1994 was $7,200,000 (including some external

|

1 |

The full committee and staff served as the evaluation panel for the Salt Lake City Research Center. |

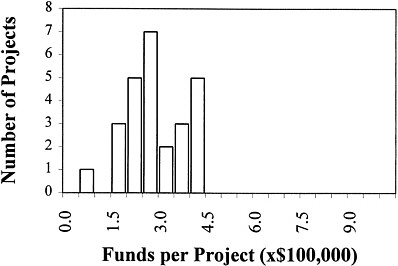

nonbureau funds), of which some three-quarters is related to personnel. In FY1994 the bureau supported 26 research projects at the SLRC, ranging in size from $50,000 to $400,000 (Figure B.1). Approximately 65% of the projects were related to Minerals and Materials Science (MMS) activities and 35% to Environmental Technology (ET); for FY1995 the mix is projected to change slightly, with 60% for MMS and 40% for ET as SLRC moves toward becoming the center of excellence in pollution prevention and control. Most of the center 's resources come from funds appropriated to the bureau, with the remainder from other sources for special projects, such as cooperative research and development agreements (CRADAs) with industry and cooperative projects with the Department of Defense.

In its “Reinventing the USBM” program review document, the bureau proposes to make five “centers of excellence” from the existing research centers and field offices. The panel was told that SLRC will be the center for pollution prevention and control, with the Reno Research Center (RERC) becoming its satellite. If the SLRC and RERC laboratories remain physically separate, there would be savings in administrative costs by consolidating management and administrative activities along with other types of support functions at SLRC. If they move to a single site, there may be other operating savings, but whether more space will be required is an issue the panel did not address.

Figure B.1 Funding for SLRC projects, FY1994.

ENVIRONMENTAL TECHNOLOGY

It was somewhat difficult to determine which projects should be covered in this discussion. This is due in part to some inconsistencies concerning project “ownership” under major research headings. For example, waste minimization seems to be claimed by both the Solids Remediation group and the Minerals and Materials group.

Some overlap is inevitable, and part of the confusion is no doubt due to the necessarily short exposure of the committee to SLRC's structure and programs. The following summary and comments are largely based on the formal briefings and short laboratory tours. Many of the project details were provided in these informal latter presentations.

Table B.1 shows the titles of the individual projects within the ET component of the SLRC. The average annual research project budget in the components involving mine drainage and liquid wastes was about $300,000 for FY1994; over the average term of a project of eight years, the total average budget of a research project is hence a very significant $2.5 million. The information for the other ET components was too inconsistent to permit development of an average project profile. Each project generally has between two and three full-time equivalent (FTE) researchers; individual researchers commonly work on more than one project during any year.

Control of Mine Drainage and Liquid Wastes

Biohydrometallurgical Decontamination of Mining and Milling Wastes

This project focuses on developing new biohydrometallurgical techniques to detoxify large volumes of mining and milling wastes containing heavy metals and process chemicals in dilute solution. Most research to date has focused on microbial degradation of cyanide and bacterial removal of selenium and has just begun investigation of microbial enzymes for waste degradation. Enzymatic degradation, particularly of organic wastes, is not novel; SLRC researchers are using fundamental data developed by others to work toward an applied process for degrading flocculants, surfactants, and flotation compounds used in mining and milling activities. The panel questioned whether SLRC has adequate in-house technical expertise for this type of applied research; consideration should be given to using external expertise where appropriate.

SLRC field tested the microbial cyanide degradation process at the gold heap-leach operation in Green Springs (CRADA with USMX, Inc.) and at Round Mountain, Nevada. The test entailed washing the heaps with fresh water and biotreating the cyanide with bacteria. The results of this field trial have been published

TABLE B.1 Environmental Technology Projects, FY1994, Salt Lake City Research Center

|

Control of Mine Drainage and Liquid Wastes ($1,237,000; 10.65 FTEs) Biohydrometallurgical Decontamination of Mining and Milling Wastes Immobilized Extractant Technology for Waste Water Treatment Microbial and Chemical Arsenic Removal from Wastes Predictive Chemical Model for Acid Mine Drainagea Cooperative Remediation Projects ($450,000; 2.7 FTEs)b; Midnite Mine: Bioremediation Midnite Mine: Rock Reactivity Technical Assistance on Federal Lands Army Corps of Engineers: Removal of TNT from Contaminated Soils Army Corps of Engineers: Characterization and Treatment of Contaminated Soils Hazardous Waste ($358,000; 2.1 FTEs) Chicago River Sediments and Remediation Solid Waste Management and Subsidence ($689,000; 5.15 FTEs)c Treatment of Copper Industry Waste Flotation Fundamentals and Volatilization Losses in Sediment Pretreatment d Remediation of Lead-Contaminated Soils at Small Arms Ranges Using Mining and Beneficiation Technology |

|||||

|

aSome cooperative funds from Minnesota Department of Natural Resources. bBudget and FTE figures for U.S. Army Corps of Engineers projects are not included. cBudget and FTE figures for lead-contaminated soils are not included. dFully funded by U.S. Army Corps of Engineers. |

|||||

in the proceedings of several mineral industry conferences. Although the project lacked some technical rigor, the work has led to a greater acceptance by several companies in the mining industry of the potential for using microorganisms for cyanide degradation.

Selenium in trace amounts is a largely unsolved problem in many western mining operations. Developments in this area would be beneficial to the mining industry. The U.S. Bureau of Mines (in cooperation with CANMET) is attempting to translate basic research on bacterial transformations of selenium into practical application for the mining industry. Several papers have been published; however, no field trials have been undertaken or CRADAs negotiated. Review of these publications indicates that researchers are aware of current literature and are advancing this fundamental technology toward a potentially viable application in the mining industry.

Immobilized Extractant Technology for Waste Water Treatment

This project is developing and evaluating immobilized extractants for removing anions, such as arsenate, arsenite, selenate, selenite, nitrate, and phosphate, from mine wastewaters. The USBM-SLRC has developed a biologically-based (sphagnum peat moss) for removal of soluble heavy-metal cations. This agent was licensed to two companies for marketing and has been used. However, nonspecific ion exchange resins are highly competitive with this product in both cost and performance. The current project looks toward improvements and is testing the immobilization of living microorganisms (to transform or accumulate arsenic and selenium species) as a mechanism for treatment of mining and milling effluents.

Several publications have resulted; researchers are aware of current basic developments in this area and are trying to move these toward commercially competitive applications.

Microbial and Chemical Arsenic Removal from Wastes

The purposes of this project are to identify arsenic-contaminated wastes and to develop microbial and chemical controls for contaminants. Several inert adsorbents are being evaluated. Globally, research on sulfate-reducing bacteria spans three decades. In the past 10 years this technology has been employed in anaerobic wetlands for the precipitation of heavy metal cations and anions. This USBM project differs from others at USBM-PRC, the Colorado School of Mines, and the Tennessee Valley Authority as it focuses on removal of arsenic species, previously largely neglected.

Arsenic ions from mining and milling wastewaters are effectively removed by coprecipitating with iron to achieve rigorous discharge standards. Undoubtedly the industry will continue to use iron unless sludge disposal becomes a major issue. The SLRC concepts could be important where sludge disposal is a problem.

Predictive Chemical Model for Acid Mine Drainage

This project is developing a geochemical model to predict the potential for acid mine drainage from waste rock using information collected during exploration and development. Predictive models, which could accurately assess the potential for acid mine drainage based on minimal characterization of materials during exploration and mining, are urgently needed by the mining industry. Mining companies are already beginning to make disposal of solid wastes an integral part of mine planning.

The objective is for mining companies to use this model in preplanning placement and treatment of waste rock. The USBM has contracted work on the development of the model to the University of Utah. The SLRC is obtaining data to calibrate the model and is cooperating with the Minnesota Department of Natural Resources, the National Institute of Science and Technology/American Society for Testing and

Materials Task Force on Waste Leaching Techniques, and the Environmental Protection Agency (EPA) on this project.

Whether the SLRC and the University of Utah can make a significant contribution in this important area is, in the opinion of the panel, still to be determined.

Cooperative Remediation Projects

Midnite Mine: Bioremediation

The purpose of this project is to test and evaluate biological transformations in treating impounded water (containing soluble uranium) at the Midnite Mine near Spokane. This work relies heavily on earlier and current projects using immobilized extractants. In addition, basic research developed by Dr. Derek Lovely and others at the U.S. Geological Survey (USGS) in Reston, Virginia, is being translated into practical applications. Because this project was just initiated, little information is available to assess progress and direction. Findings could potentially be applied to other uranium mining sites and water contamination at Department of Energy sites.

Midnite Mine: Rock Reactivity

The purpose of the Midnite Mine Remediation project is to assist the Department of the Interior by identifying factors that might contribute to the formation of acidic or metal-laden waters under natural weathering and by proposing remedial options. The SLRC staff indicated some contact with Dr. Charles Alpers and Dr. D. K. Nordstrom of the USGS concerning geochemical modeling on the project. The extent of the coordination was unclear. However, the panel applauds SLRC 's interaction with the USGS to avoid duplication of effort and also because of the apparent lack of necessary geochemical expertise by the SLRC staff.

Technical Assistance on Federal Lands

The purpose of this project is to provide and apply technology to assist the U.S. Forest Service and other government agencies in remediation of acid mine drainage on federal lands. This is a technology transfer project, apparently quite successful that entails providing government agencies with information on existing as well as new USBM-developed technologies for predicting and mitigating acid mine drainage.

U.S. Army Corps of Engineers: Removal of TNT from Contaminated Soils and Characterization and Treatment of Contaminated Soils

The removal of TNT and other explosives from soils is a cooperative project with the U.S. Army Corps of Engineers, Waterways Experiment Station. The role of

the SLRC in this project is to test and recommend physical separation techniques (flotation, size, and gravity) for removing explosives and segregating a variety of contaminants from the different soil types. The Army will test a biological process using white rot fungus for the degradation of TNT and RDX.

Hazardous Wastes

Chicago River Sediments and Remediation

As part of a congressional initiative, the Chicago River Sediments Project has evaluated the potential for metal bioavailability and options for organic contaminant remediation in an urban river environment. The USBM staff demonstrated a good understanding of the chemical processes governing metal mobility and bioavailability, although the addition of an environmental engineer would be useful to the staff. The project has resulted in a number of publications and is a good template for interagency interaction.

Solid Waste Management and Subsidence

Treatment of Copper Industry Wastes

The treatment of copper industry wastes (e.g., smelter flue dust) was another project covered mostly on the panel's laboratory tour with little coverage in the formal presentations. This project is extremely relevant to the current and expected future mission of the center and the bureau and has received considerable funding for it over the years. Kennecott Copper Company has integrated portions of the SLRC process into its new Utah smelter.

Flotation Fundamentals and Volatilization Losses in Sediment Pretreatment

The purpose of this recently initiated study is to answer basic questions related to the mechanisms of adsorption of organics on to solid sediment particles. Ascertaining the fate of these organics would permit the design of surfactants to liberate oleic acids from sediments and facilitate the remediation of organic-contaminated sediments. No information was available on the progress or importance of the work.

Remediation of Lead-Contaminated Soils at Small Arms Ranges Using Mining and Beneficiation Technology

Soil treatment projects involving lead were presented to the panel and also show promise for technology transfer. This Department of Defense project on lead dispersed in rifle ranges is a good example of a project that incorporates many capabilities toward solving environmental problems somewhat outside the normal

mission of the USBM. It demonstrates the potential for technology transfer to environmental problems that are shared by other industries and government sectors.

MINERALS AND MATERIALS SCIENCES

At the time of the committee's visit, the SLRC had 20 projects in progress in this category (see Table B.2), of which three were listed under the heading “Technology Transfer,” supporting other projects in progress or recently completed.

The Minerals and Materials Sciences section of SLRC is well run. An expectation of professionalism is firmly established and clearly understood by the research staff. Facilities are well maintained. Equipment is of high quality and reasonably up to date; the center has a continuing program of equipment procurement, developed in concert with other bureau centers. The support staff is competent and well motivated.

In reviewing the SLRC's projects, the panel noted a characteristic that was also seen in many of the environmental projects—projects in progress were mainly “incremental” in nature (i.e., improvements or extensions of current practice, or potential alternatives). Furthermore, in some cases, technology transfer efforts evoked little or no industrial interest, suggesting that investigators submitting proposals may not have accurately gauged industrial prospects in advance. The panel was concerned about this low level of industry support. Incremental research seeking improvements or alternatives should be the type of work of most interest to industry. The panel recognizes that certain longer-range research must often be initially funded by the bureau alone (where there are historical examples of substantial success), but a number of projects seemed to fall between the incremental and longer-range categories. This suggests that some proposals are being based on technological opportunity rather than either market need or long-range promise and may reflect a lack of appreciation of needs on the part of the staff.

The committee recognizes that full economic analyses cannot be done at the research proposal level nor on the basis of incomplete results. Nevertheless, simple economic impact expectations can and should be routinely set forth in advance. These could be used to establish preliminary targets, to assist in screening by bureau personnel and potential customers in industry, and to evaluate proposals on a basis other than technological attractiveness.

The area of proposal generation and acceptance remains a frustration to investigators and administrators alike. Some panel members remain concerned especially about specific means by which more basic topics in minerals and materials sciences can be introduced, funded, and carried out. This area is discussed in more detail in

the report on the Albany Research Center (Appendix D) and will be the subject of additional inquiry by the full committee.

TABLE B.2 Research Projects in Minerals and Materials Sciences at SLRC, FY1994

|

Clean Processing ($2,020,000; 16 FTEs) Advanced Solvent Extraction Stripping Technology Concentration and Recovery of Heavy Rare-Earth Elements Liquid-Liquid-Solid and Induced-Force Separation Lixiviants for In Situ Leaching of Copper Sulfides National Defense Stockpile—Upgrade Pre-1980 Cobalt Nonconventional Fracture in Comminution Synthetic Rutile from Hard-Rock Ilmenite Systems Approach to In Situ Mining Leach Solutions Control Technology ($1,220,000; 9.65 FTEs) Advancing Autoclave Technology Through Automation Optical Monitors of Metallurgical Processes Rapid Analysis and Control of Process Streams Surface Chemistry of Oxidized Mineral Flotation USBM/Industry Flotation Waste Minimization and Recycling ($1,150,000; 9.35 FTEs) Critical Metals Recovery from Advanced Materials Rare Earths Recovery from Secondary Sources Steel Plant Sludge Dewateringa Waste Minimization in the Copper Industryb Technology Transfer (1.0 FTE)c Scandium Recovery from Tailings and Processing Residues Transfer of Double Membrane Electrolytic Cell Technologyd Yttrium from Domestic Eudialyte Resources |

|

aAbout one-third of funds come from an industry consortium; industry funds are not included. bJoint project with the USBM Albany Research Center. cFunded separately from USBM Headquarters. dIncludes significant cooperator (CRADA) work-in-kind and funding. |

Table B.2 shows the titles of individual projects within the MMS component of the SLRC. The average annual research project budget (excluding the technology transfer component) is about $260,000 for FY1994; over the average term of a project of four years, the total budget of a typical research project is on the order of $1 million for the clean processing and control technology categories, and about

$1.8 million for the waste minimization and recycling categories. The number of full-time equivalent researchers, which is broadly consistent with the overall annual research expenditures, varies between 1.1 and 3.1 for each project.

FACILITIES, SUPPORT, AND STAFF

The SLRC occupies a modern building at an excellent location near the campus of the University of Utah. The facilities are clean and well maintained and provide for a good working environment. The offices and laboratories appear to be appropriate for the size of the staff and for the research activities being conducted. There appears to be adequate laboratory space for research at present, and there are opportunities for growth in the laboratories. A wing can be added to the existing building to provide additional office space if needed.

Research equipment is fairly modern and well maintained and seems adequate for current research programs. Continuous acquisitions and upgrading of equipment are accomplished primarily through savings in annual SLRC budgets. Secretarial support is adequate to serve the needs of the SLRC, and support in the area of graphical design, computer drafting, and report preparation appears excellent. Technician support is adequate. A technology transfer team has been assembled, although it currently also functions in part as a public relations group for the SLRC.

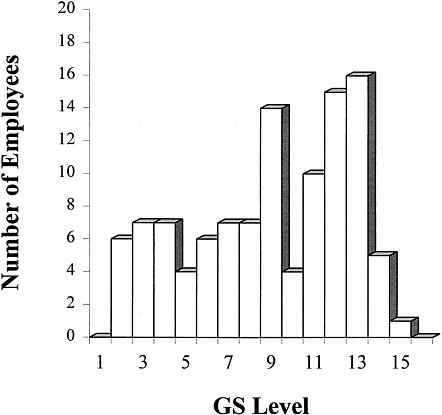

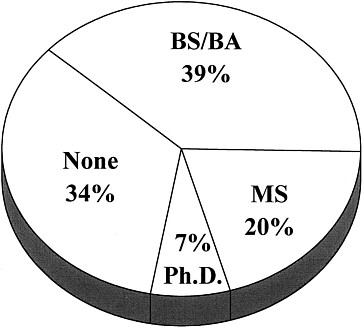

The Salt Lake City Research Center has a healthy mix of employees in terms of General Schedule (GS) grades; the range (Figure B.2) is from GS-2 to GS-15, with approximately 34% of the permanent staff at the full performance level (qualified to be a principal investigator on a research project, at GS-12 or higher). With the exceptions noted earlier, the mix (Table B.3) is also appropriate in terms of disciplines (with number of degrees in metallurgy, chemical engineering, chemistry, geology, biology, and electrical engineering, in that order). The ratios of engineers and scientists to technicians and other support staff are adequate (scientists:technicians plus student aids plus tradesmen:clerical and administrative support is 65:47:13). Only about 17% of the staff have advanced degrees (M.S. and Ph.D.) and most of these are involved in research administration or as principal investigators. Figure B.3 shows the educational degrees of the staff; the large proportion of those with less than a bachelor's degree is dominated by students, technicians, and tradesmen.

The panel was concerned about the relatively poor level of communication between senior management and staff. The panel had the sense that this was not deliberate and could perhaps be improved considerably by appropriate group activities such as seminars by external and internal speakers and brown-bag lunches with informal discussion of work and other broader issues.

Figure B.2 Distribution of general service grades of SLRC employees.

TABLE B.3 Disciplinary Background of SLRC Employees

|

Number |

|

|

Technical Staff |

|

|

Metallurgist |

22 |

|

Chemical Engineer |

18 |

|

Chemist |

13 |

|

Biologist |

5 |

|

Geologist |

5 |

|

Electrical Engineer |

2 |

|

Support Staff (includes technicians and tradesmen) |

25 |

|

Student Aids |

22 |

|

Administrative Staff |

13 |

|

TOTAL |

125 |

Figure B.3 Distribution of highest degrees held by SLRC employees.

USER COMMENTS

Five industry guests2 who are familiar to some degree with the bureau's research were invited to offer their thoughts. The comments below mostly have been aggregated rather than attributed to specific people.

Familiarity with the totality of bureau programs and the degree of cooperation with the bureau was variable. In a specific case, one guest had been intimately involved with the Santa Cruz joint venture (ASARCO and Freeport) for in situ leaching of a copper oxide ore body, which started, after a decade of discussion, in 1988. Delays here have been considerable, largely due to excessive times for permits, which led to a lag of three to four years. The bureau cannot substantially facilitate the permitting process for industry partners. No copper has actually been produced yet

|

2 |

Albert Raihl, metallurgical engineer, ASARCO, Tucson, AZ; Noel Kirschenbaum, manager of mineral project development, metallurgist, Placer Dome, San Francisco, CA; Richard Jolk, metallurgist and environmental engineer, Fluor, Denver, CO (formerly USMX); Preston Chiaro, vice president of technical services, Kennecott Utah Copper, Salt Lake City, UT (formerly EBASCO); and Peter Crimes, director of technology, American Mining Congress, metallurgist, Washington, DC. |

from this project after an outlay of some $22 million. (Approximately one-quarter of this was an in-kind cash contribution, mostly for construction, from the industrial partners; no funds from industry went to the bureau.) ASARCO hopes to produce about $0.5 million of copper in an 18-month test. One interesting comment is the time necessary to establish trust between the cooperators and the bureau; even now this is not complete or synergistic.

A general observation, given that most companies lost their internal research capabilities and much of their engineering staffs a decade ago, is that when technical or environmental advice is needed, industry quite properly tends to turn to consulting firms rather than to the bureau or any other government agency. Although some small mining companies may desire engineering consulting services from the bureau, this is not the proper role for the bureau's research program. These small companies often do not have the capability to apply newly developed technology, and it is highly likely that the firms that industry hires may well be using bureau data in one form of technology transfer.

This lack of ability by production companies to assess and subsequently interpret technical data was highlighted in a 1990 NRC report on Competitiveness of the U.S. Minerals and Metals Industry, but no serious action has resulted. This could be a major “disconnect” to future effectiveness in the industry.

Contacts between bureau personnel and specific companies could be enriched by expanding a number of currently used approaches to technology transfer, ranging from personal contacts through regional briefings to presentations at technical meetings and publication in bureau reports and technical journals. Such opportunities are often said to be limited by lack of travel funds. (The Technology Transfer Office of the SLRC can perhaps help in this communication issue.) In the opinion of this group of industry representatives, widely broadcast written material from the bureau's headquarters in Washington, DC is not read carefully.

The panel asked for examples of bureau research that led to successful applications of technology. One example is work on the heap leaching of low-grade gold ores, research widely scorned when it was carried out as a basic research program during the days of $35 per troy ounce gold but equally widely praised after gold prices rose well over $100 per ounce. Another important example was the development of the Zadra cell, which is used in gold refining.

Considerable discussion took place on useful and appropriate roles for industry in helping formulate the research program of the bureau. One obvious but not simple role is to help set strategic directions without interfering with individual project selection. Some issues of importance to nearly all mining companies are acid mine drainage (in both operating and abandoned sites), less energy use in comminution, and more knowledge on handling of fine particles.

The lack of knowledge of the existence or program of the Generic Center on Comminution at the University of Utah by some of the visitors was surprising, as was the limited appreciation of the bureau's shift toward environmental matters. The panel does recognize that the generic mineral technology centers are not under the direct control of the bureau, and thus the responsibility for transfer of their technology is not necessarily that of the bureau.

In general, it was concluded that “basic” research of broad application be encouraged, with more emphasis on at least rudimentary economic analysis and, on a case-by-case basis, the provision of enough data to enable applications to practical sizes of equipment. The balance in this is delicate because the bureau cannot appear to be competing with for-profit consulting firms.

The bureaucracy involved in setting up CRADAs and other forms of cooperation between industry and the bureau is lessening but still offers room for improvement. As the bureau seeks further cost-sharing, its business methods must improve. Care should be taken to see that early adopters are not penalized by latecomers getting a free ride.

Relationships between the Mine Safety and Health Administration (MSHA) and the bureau's Health and Safety programs have reached a dynamic equilibrium; the same is not true with the bureau's environmental technology programs and the EPA. Following its pattern of relations with MSHA in the area of health and safety regulations, the bureau can usefully develop an analogous and important role relating to EPA in the area of environmental regulations: by reporting on feasible technologies and developing new ones to meet regulatory goals.

TECHNOLOGY TRANSFER

Within the USBM, technology transfer (TT) is both vertically and horizontally integrated into research operations. The committee was briefed on the structured, vertically integrated method by the SLRC TT officer. Informal dialogue with individual researchers and input from the industry users' representatives provided information with respect to their methods of providing horizontally integrated TT in the USBM, which has been widely practiced to various degrees since formation of the SLRC.

USBM TT today focuses on research programs beyond the traditional metallurgical research results, including process control improvements, materials research, and assistance with data gathering needed for environmental permits. The horizontally integrated TT works only if built on trust between the parties involved because release of information meant to be communicated in confidence can have serious negative

consequences. As industries beyond the traditional mining industry become potential users of USBM research, the issue of trust is perhaps even more critical.

Because recent flat funding of USBM research programs has eroded the percentage of discretionary funding available for each research project, the individual researcher is in a quandry on how to spend time and resources on industry interaction. At a time when national priorities are changing for mineral industry products, less interaction does not enhance trust. Furthermore, the reward system is not seen by the individual researcher as favoring major efforts in TT.

The vertically integrated TT is, like other USBM programs, micromanaged by the Washington, DC-based headquarters staff, with a complex matrix organization. All of the funds for USBM TT are derived from the research directorate's total operating budget, with vertically integrated TT one of the “overhead” functions that requires support. The balance between TT and public relations is poorly understood and explained to the researchers, and however much the image of the bureau could stand burnishing, to have TT appear to be paid for by research funds is not well received at the research centers.

One observation is that the bureau's researchers need to broaden their networks to ensure that they are keeping current with regard to important broad issues. Two examples may be helpful: (1) more interactions as professionals sharing common goals with state regulatory authorities might have enhanced the Santa Cruz joint venture TT effort, with regards to the permits and (2) directly involving the patent developer of an interesting battery recovery process with the broad audience involved in meetings for the Car of the Future may decrease some of the lack of engagement between the Washington TT staff and the individual researcher in the field.

Even with these caveats, among the bureau centers, the SLRC has an excellent track record in TT for the vertically integrated program. According to the bureau's April 1994 bulletin entitled “U.S. Bureau of Mines Cooperative Research Opportunities,” the SLRC had the largest number of entries (over 25), followed by the PRC (20 entries), out of some 70 total opportunities. It is assumed here that the number of individual entries reflects to some extent the initiative of each center.

It should be noted that the point of contact listed is either the research supervisor or the TT officer, not the individual researcher. According to the staff members who met with the committee at the SLRC, there is a feeling that the bulk of research and the understanding of its significance are at the nonsupervisory research level, or one step above at the group supervisor level. The research supervisor and the TT officer must therefore work diligently to ensure that no impediment to TT is created by the internal transfer of knowledge and applicability. This is a challenge for the USBM research centers, and has not been fully addressed yet in the evolving TT initiative of the bureau.

TABLE B.4 Tools of Technology Transfer used by the Bureau of Mines

|

CUSTOMER AWARENESS Meetings Open industry briefings Demonstrations Videos News releases Special publications Center publications Technology news Technology News Update/Technology Transfer Update TIP Sheets Magazine news items Journal articles Information dissemination Training - BLM/USFS INTELLECTUAL PROPERTY—PATENTS Invention reports Nondisclosure agreements Patent marketing Market surveys Licenses Advertisements CRADA opportunity booklets Commerce Business Daily Opportunity identification Customer identification PARTNERSHIPS CRADAs (cooperative research and development agreements) MOUs (memoranda of understanding)—statements of intent to cooperate between agencies) MOAs (memoranda of agreement—generally used when the bureau has developed a technology and wants to test it at an industrial site) IAGs (interagency agreements, with other government agencies) MIPRs (military contracts with another government agency) |

The bureau uses a wide variety of means of technology transfer (Table B.4). Among these are publications. In the judgment of the panel, by far the most effective are refereed journals. They have been accepted by peers, which lends credibility, and the audience is the broadest possible worldwide. It is perhaps noteworthy that the reputation of the bureau is judged kindly outside North America on the basis of such publications. The panel believes that the bureau should strive to increase the number of publications by its staff in the permanent engineering and scientific literature (Bureau Reports of Investigations and Bureau Information Circulars do not seem to

be as effective as articles in peer-reviewed, nationally or internationally recognized scientific and engineering journals). The bureau provided the panel with a listing of publications by the SLRC Minerals Technology Group from 1986 to 1994; the list contains one bureau Report of Investigations, six other bureau publications, nine articles in peer-reviewed journals, 52 papers in symposium proceedings, and four other outside publications. Given that the current staffing of this group is approximately 36, with roughly one-third of these individuals at the full performance level (GS-12 and above), the panel believes the level of productivity in terms of publications, especially those in the permanent literature, is in need of considerable improvement.

This is a bureau-wide problem, as indicated by the following data. The bureau provided the committee with a listing of 357 publications (perhaps not inclusive) covering calendar year 1993. This represents the overall publication output of 1,283 research employees at the bureau. With approximately 42% of these employees at the full performance level of GS-12 or above, the overall research publication productivity of the group is 0.66 publications per senior-level person per year. This includes all types of publications, from bureau Reports of Investigations, Information Circulars, Technology News, and open-file reports to articles in peer-reviewed journals, symposium proceedings, and other parts of the gray literature. If only Information Circulars (23), Reports of Investigations (40), and articles in peer-reviewed journals (61) are counted, the overall publication productivity is only 0.23 (significant) articles per senior-level person per year (for 1993, less than one every five years if extrapolated over time).

ISSUES AND CONCLUSIONS

In addition to the two specific issues dealt with below, there were a number of unresolved issues identified by the panel, mostly in the areas of project management, management structure, technology transfer to various users, and communications. Although these were first identified at the SLRC, most were general enough that they are discussed in the main body of the report.

Staff

There are several observations that the committee had concerning staff capabilities. For the type of applied research that predominates at SLRC, the staff is moderately well qualified. The modest number of advanced degrees held by staff members would not be comparable to other research organizations engaged in more

basic research; the numbers are in the low range of many industrial applied research laboratories. The number of Ph.D. scientists is low, and most are in managerial positions where their direct contributions vary considerably. The panel believes that the SLRC needs to increase its percentage of highly qualified technical staff. This can be accomplished through additional hires when possible. These hires should also address technical expertise gaps at the center in the environmental research area (e.g., geochemistry, hydrology, hydrogeology, environmental engineering).

The SLRC staff members believes they are limited by their ability to interact professionally with outside researchers (primarily because of travel restrictions for professional meetings). This lack of outside professional contact is exacerbated by lack of diversity of education, as the vast majority of the center's employees were trained at the same academic institution. There are also limited opportunities for the staff to interact professionally among themselves to exchange of views and results and discuss issues. Many of the researchers have had limited experience with the mining industry. There do not appear to be any barriers for staff to pursue continuing education activities, usually through the local universities.

From the panel's interactions, the staff thinks there is a need for a better plan or framework from bureau management that could provide direction for major research areas. This is thought to be particularly important so that research ideas could be placed into a broader context. The staff also thinks that greater strides could be made to clarify the requirements for scientific advancement on the technical career track (dual-ladder system) and explicit expectations for promotions and career grades.

Some specific actions that the panel believes are desirable include:

-

informal lunch seminars on a monthly basis whereby researchers (both internal and external) can inform colleagues of their research progress and receive constructive comments;

-

increased opportunities for the research staff to participate in professional meetings; and

-

increased staffing in the fields of geochemistry, hydrology, hydrogeology, and environmental engineering and an increased number of Ph.D. researchers.

Project Selection

The bureau has a formal research project selection process that includes solicitation of “miniproposals,” which are evaluated to determine those to be developed into more elaborate full-scale proposals, from which the final selections are made. Miniproposals provide a mechanism to evaluate research ideas without requiring excessive time to develop full-scale project proposals. These miniproposals are

submitted annually to the research directors of the centers. The miniproposals are reviewed and ranked, first by a center's research director, then by the research division. The criteria used are delineated in the bureau's Research Policy and Procedures Manual.

The committee made several observations concerning the research project selection process. The principal concern is in delineation of the actual roles of the principal investigators, the research supervisor, and the SLRC director in developing short- and long-term plans and projects and how these roles are related to Washington staff. The Washington office staff engineers and division chiefs are responsible for the bureau's long-term planning activities and, ultimately, for research project selection and management. There appeared to be some confusion on the part of the researchers preparing miniproposals as to the strategic guidance that these long-range plans provide and the role of the staff engineers of the Washington office. Another concern was to what extent research efforts are politically driven both externally and internally.

This practice appears to be an unsatisfactory loop within the bureau relative to research direction, proposal generation, and selection. More empowerment in this process should be considered at the local level. Technical experts from within and outside the bureau should be involved to an appropriate extent. More feedback to the principal investigator or project initiator should be provided throughout the process, on both successful and unsuccessful proposals.

The research focus at the SLRC is on applied rather than basic research. Although this may be appropriate, a solid theoretical construct for the center's overall mission is essential, with each approved project having a clear place. The greater percentage of short-term, small-scale efforts relative to long-term, large-scale, inter-disciplinary efforts appears to be unwise if more in-depth research is to flourish.

The bureau should consider implementation of a formal external review process whereby in-house research is reviewed by subject area (e.g., environmental technology) and can include the proposal selection and project progress. This could be accomplished, in part, by formal annual external peer reviews of in-house projects. Proposal reviewers should include center directors, selected in-house technical experts from the different centers, and perhaps outside peers (e.g., industry, other government agencies). In addition to a broader review process, this will help with external communications.