Nonlinear Ship Wave Calculations Using the RAPID Method

H.C.Raven (MARIN, The Netherlands)

ABSTRACT

The RAPID (RAised-Panel Iterative Dawson) approach for solving the fully nonlinear wave-resistance problem is described. This method, developed at MARIN, uses an iterative procedure based on a Rankine panel method similar to that of Dawson. No convergence problems are usually met in the speed and fullness range of practical ships, and even for cases showing extensive wave breaking in reality. The validity of the method regarding the occurrence of wave breaking and steep wave slopes is discussed. The modeling of the flow off a transom stern and its implementation in RAPID and in the corresponding linearized problem is studied. The nonlinear solution is found to be realistic and very accurate numerically. A number of validation studies shows that the RAPID results are very good in most respects, and often mean a surprisingly large improvement compared to linearized solutions. The principal remaining problems are resolution of short wave components, certain geometric complications, and the absence of a 3D model for wave breaking.

1. INTRODUCTION

Wave resistance is one of the most important resistance components of a ship, generally contributing 20 to 80 % of the total resistance of a ship sailing in still water. Experience has shown that this resistance component is quite sensitive to modifications in the design, and large reductions of the wave resistance can often be obtained without any important sacrifice in deadweight or cargo capacity. The effect of a bulbous bow is a well-known example. A capability to predict and minimize wave resistance in the design stage of a ship is, therefore, very desirable. Theoretical studies of the wave resistance problem have been carried out already for a century. Since Michell's paper of 1898, many studies of the linearized free-surface potential flow problem have been made, and several alternative solution methods and linearizations have been proposed; some of them very useful for a certain range of applications. Particularly in the early seventies much work has been done on this problem. In 1977, Dawson [1] proposed his well-known method, which in a number of comparative studies turned out to give realistic predictions, and to be more practical than most other proposals.

Much work has been done since on validation and improvement of Dawson 's method. There is a large body of literature on this method, and the mathematical background of the “engineering approach” has been more and more clarified. A code for Dawson's method is available at many institutes all over the world. Still, the actual use in commercial ship design work is quite limited. While at MARIN the code DAWSON [2] is being applied to 70 to 100 hull forms per year in commercial work and important successes have been obtained, most other versions of the method seem to be rarely applied.

As a matter of fact, the routine use at MARIN has made us aware of several shortcomings that make application more difficult. In particular, the resistance predicted by the code is not very reliable; for slender ships the estimate is usually fair, but for full hull forms the wave resistance is underestimated or even negative (a phenomenon explained in [3]). It is, therefore, not safe to optimize a hull form on the basis of the predicted wave resistance alone, as this sometimes even incorrectly indicates the order of merit of design variations. But at the same time the wave pattern and profile, the hull pressure distribution and flow direction have turned out to be realistic enough to be used for improving the design. Hull

form optimization using DAWSON is thus an art that requires insight in the assumptions made in the theory, knowledge of fluid dynamics and wave making, and much experience. Only few have collected enough experience to fruitfully use Dawson's method.

Although, therefore, the shortcomings of Dawson's method do not prohibit its very effective use, a next step has to be made. Not only a greater accuracy of the predictions is desired, but also we should like to include several aspects of the flow that cannot be taken into account in DAWSON. Specifically:

-

the neglect of nonlinear terms and transfer terms in the free surface boundary condition introduces inaccuracies;

-

the hull form above the undisturbed waterline cannot be taken into account in a linearized method; this eliminates the effects of bow flare, flat sterns, surface-piercing bulbous bows and so on;

-

doubts exist on the modeling of the flow off an immersed transom stern.

All these inaccuracies and limitations can in principle be removed by solving the fully nonlinear problem, rather than applying the slow-ship linearization underlying Dawson's method. At several institutes the development of a method for solving the fully nonlinear free surface flow problem is now in progress. Both panel or boundary integral methods, and field equation methods are used. The latter usually deal with viscous flows and almost invariably unsteady problems (or, at least, transient solution methods), and will not be discussed here.

The majority of methods for free surface flows around ships assumes a potential flow. Using Green's identity the problem is conventionally recast in a boundary integral form. There are many boundary integral methods addressing unsteady problems, e.g. [4,5]. Although in most cases the main purpose of the developments is to solve seakeeping or other actually unsteady problems, they may be applied to steady problems as well. One particular method to be mentioned here is that of Cao, Beck and Schultz [6] with its unconventional but very successful use of point sources at a distance above the free surface.

The most direct way to address the wave resistance problem is the solution of the steady free surface potential flow problem, which has been given much less attention. Most methods in this class are based on an approach similar to the linearized method of Dawson. This means that a distribution of Rankine sources or other simple singularities is used both on the hull and on a part of the free surface around it. For solving the nonlinear problem an iterative procedure is needed. Among the first to study such a method was Ni [7]. His method was Dawson-like, with panels on the free surface that were moved in every iteration. Although convergence was problematic, he succeeded to get converged solutions for a range of cases, subject to several restrictions on the use of particular difference schemes and so on. His method was later extended and improved in Larssons group [8]. Later Kim and Lucas [9] came up with a very similar approach, but found it necessary to apply artificial numerical damping in order to obtain convergence. In [10] they proposed a modified double iteration scheme which was claimed to improve the convergence. Another method was proposed by Delhommeau [11], also using panels on the free surface. Convergence again turned out to be problematic.

At the same time, some other developments were based on the use of singularity distributions not on but above the free surface. This choice was inspired by obvious practical advantages for the problem considered. One of the first efforts was due to Xia [12], who describes some initial attempts to solve the nonlinear problem. However, a too large sensitivity to the distance from the panels to the water surface made him give up. Much more successful were Jensen et al [13,14] with their method using point sources above the wave surface, analytical second derivatives and a special way of satisfying the radiation condition. In several further publications the method has been extended to shallow water, channel flows, unsteady cases in the frequency domain etc. At the same time, convergence of the method still can provide severe problems as soon as e.g. different panel distributions are used.

In [15,16], the present author proposed the so-called RAPID approach (RAised Panel Iterative Dawson). The use of free surface source panels raised above the free surface is largely similar to Jensen's method; but most details are different. The iterative procedure, selected on the basis of previous numerical estimates of the different nonlinear contributions [3], has appeared to be unusually stable and robust: Contrary to almost all previous methods for the same problem, no convergence problems are generally met. It thus seems to be one of the most practical methods, and, together with Jensen's method, it seems to be the only code for the nonlinear problem that is already actually applied in ship design work.

This paper describes recent progress in the further development and validation of the RAPID code. In [16], the essence of the method was explained and the results of several numerical experi-

ments were discussed. This will briefly be summarized in the next section, paying some more attention to the convergence properties and to the importance of nonlinear effects. Section 3 is devoted to a discussion of the flow off an immersed transom stern. The various flow regimes are studied, and the implementation of the transom flow model in both the linearized (DAWSON) and the nonlinear (RAPID) code are described and compared. Section 4 then discusses a number of detailed validation studies.

2. RAPID

2.1 The mathematical model

We consider the flow around a ship hull in a uniform flow from ahead. The origin of our coordinate system is located amidships at the level of the undisturbed free surface. The x-coordinate is positive astern, and y is positive in upward direction. The coordinate system does not move with the dynamic trim and sinkage of the ship. All quantities are nondimensionalized with the ship speed and length.

The potential flow assumption is made, and a velocity potential ![]() is introduced such that:

is introduced such that:

(1)

The field equation to be satisfied is the Laplace equation. The flow is undisturbed far ahead and at large lateral distances, while a wave pattern with a known rate of decay is present downstream.

On the wetted part of the hull the flow must be tangential to the hull, as represented by a Neumann boundary condition for the potential:

φn=0 (2)

On the free surface a kinematic boundary condition is to be satisfied, requiring that the flow is tangential to the wave surface:

φxηx+φyηy−φy=0 on y=η (3)

and a dynamic boundary condition that the pressure in the flow at the free surface must equal the atmospheric pressure (4):

![]() on y=η (4)

on y=η (4)

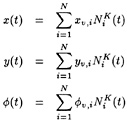

2.2 Iterative solution

Contrary to what is done in linearized methods, these boundary conditions will be applied on the correct surfaces; i.e. the hull condition on the part of the hull that is actually wetted, and the free surface conditions on the actual wave surface. No simplifications are thus made. Solving this fully nonlinear free surface problem requires iteration. The iteration procedure is set up as follows.

While in a linearized method such as DAWSON the flow field and free surface are decomposed into a known base flow and a small perturbation, and linearization in terms of this perturbation is performed, we now make a similar assumption that the solution of a certain iteration differs only by a small amount from the flow field and free surface shape found in the previous iteration. Again we linearize in terms of this perturbation and impose the boundary condition at the previous free surface. Thus we obtain a linear fixed-domain problem to be solved in the current iteration. Having found the solution we update the base flow field and free surface, and start the next iteration.

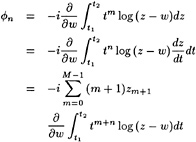

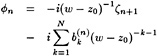

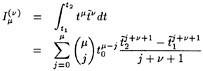

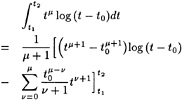

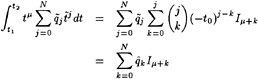

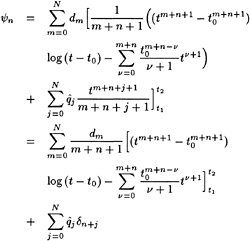

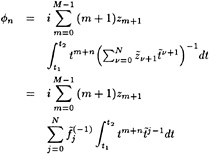

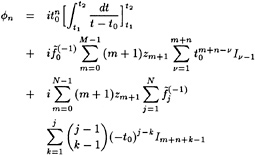

Specifically, defining

η=H+η′ (5)

(6)

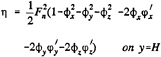

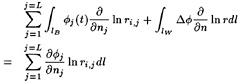

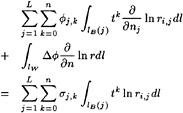

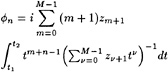

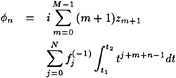

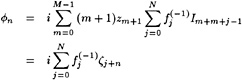

and substituting this into the dynamic and kinematic boundary conditions, we obtain linearized kinematic and dynamic conditions:

(7)

(8)

(8)

These two conditions are combined in exactly the same way as in Dawson 's method by eliminating the wave height perturbation, and we obtain the linearized free surface condition (FSC) to be imposed on the wave surface found in the previous iteration:

(9)

(9)

It is noted in passing that actually a consistent linearization would add certain terms representing the transfer of the boundary condition from the free surface to be calculated, towards the free surface found in the previous iteration. These terms are intentionally disregarded here, as they have been found to be rather irregular for the source distribution employed here and might lead to divergence of the iteration. To the converged solution these terms

make no contribution of course, since η' then vanishes and the FSC is imposed on the actual free surface.

Once the linear problem of the current iteration has been solved, the velocities found are substituted in the original dynamic condition (4), and a new free surface is found. This, together with the new velocity field, is the basis for the linearization of the next iteration.

This iterative process is started from any initial guess. As no assumptions have been made on the relation between the base flow field and the base free surface, this initial guess can be selected on the basis of convenience only. In most cases we start simply from a uniform flow and flat free surface; the first iteration thus becomes the Neumann-Kelvin problem. The iteration is repeated until the residual errors in both the dynamic and the kinematic boundary conditions are below a predefined tolerance in all free surface points (i.e. a maximum norm is used). In most cases, we impose tolerances of 0.1 % of the ship speed for the kinematic condition, and 0.2 % of the stagnation pressure for the dynamic condition. It is important to note that checking these residuals is the only safe procedure; visual inspection of the changes in a hull wave profile, as is often done, does not guarantee that the solution has converged !

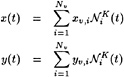

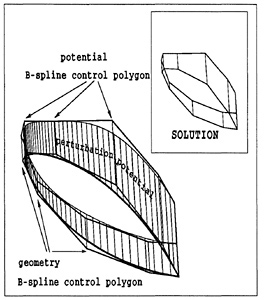

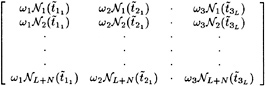

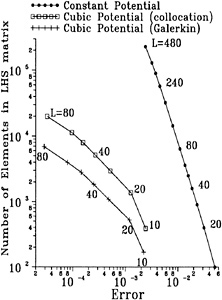

2.3 Implementation

To implement the mathematical model outlined above, singularity distributions are specified for all boundaries where non-trivial boundary conditions are to be imposed, i.e. the wetted part of the hull and the surrounding part of the wave surface. On the hull the familiar distribution of quadrilateral constant-strength source panels is used, with collocation points in the panel centroids. For the free surface however, a less conventional choice has been made: quadrilateral constant-strength source panels are located at a certain distance above the wave surface, while the collocation points are on the wave surface itself. Within certain limits for the distance of the panel to the free surface this is permitted theoretically, and it has several practical advantages:

-

as there is freedom in the distance from a panel to the corresponding collocation point, the panels need not be repositioned in each iteration; only the collocation points are moved towards the new free surface position. This saves some work and avoids potentially destabilizing geometric manipulations;

-

the velocity field in the fluid domain is smoother than with constant-strength source panels on the boundary itself;

-

the numerical dispersion (i.e. the error in the wave length due to the discretization of the continuous velocity field and boundary condition) is far smaller than with the usual implementation;

-

the outer boundaries of the free surface domain are less reflective.

-

the implementation is simplified on several points.

There are, however, some disadvantages as well:

-

the conditioning of the system of equations is slightly worse; by a proper selection of the panel elevation this can, however, be minimized.

-

if the section shape has a large slope above the waterline, the collocation points right under the centers of the free surface panels adjacent to the hull are at a rather large distance from the waterline, with resulting inaccuracy. If the collocation points are kept at a constant distance from the actual waterline, the free-surface boundary condition is better resolved, but the conditioning is worse. This trade-off can present some problems, in particular for flat sterns, fter all, the use of raised panels has turned out to be extremely effective for this class of problems.

The limits of the distance from the panels to the free surface are, as shown in [16], roughly between 0.5 and 1.5 panel dimension. Here the panel length is more important than the transverse size. It will be obvious that the distance cannot be kept inside these limits if the panels are not adjusted to the free surface shape. E.g. the stagnation height at a ship speed U is U2/2g, and for a usual panel density of 20 panels per transverse wave length this is 1.6 times the panel length. Therefore, as described in [16], the free surface panel distribution must be adapted to the wave surface such as to stay at a more or less constant distance. But there is no need to do this very accurately, as the distance only has to be kept inside the limits mentioned before. Therefore, the calculation is made in separate jobs of 2 to 6 iterations, each time followed by an automatic adaptation of the free surface paneling to the last calculated wave shape, and of the hull paneling to the modified intersection with the free surface panels. If desired, the position of the hull is adapted to the new estimate of the trim and sinkage. Then the process is restarted from the results of the previous iteration. In this way, the efficiency and stability of the process is kept while a good conditioning and accuracy can be guaranteed.

Another detail of the implementation to be mentioned is the use of an upstream difference scheme for the derivatives of velocities in the free surface condition. This is exactly similar to the use in Dawson's method, and helps the satisfaction of the radiation condition at the expense of a small

numerical damping. The detrimental effect of this damping can be minimized by choosing a sufficient panel density. On the other hand, in order to increase the numerical accuracy at a given panel number, the use of a difference scheme might be dispensed with in the future.

The complete iterative procedure can be summarized as follows:

-

Define the initial hull and free surface panel distribution; choose the distance of the panels above the free surface.

-

Choose an initial free surface velocity distribution and wave elevation.

-

Impose the combined FSC, linearized with respect to the last free surface shape and velocity field, in the free surface collocation points; and the hull boundary condition in the hull points;

-

Solve the linear problem. Calculate the new free surface and velocity field;

-

Move the free surface collocation points to the new wave elevation, applying underrelaxation if desired;

-

If needed, adapt the free surface paneling to the new wave surface; adjust the hull paneling; adjust trim and sinkage of the hull.

-

Calculate the residual errors in all points, and decide to stop or to return to step 3.

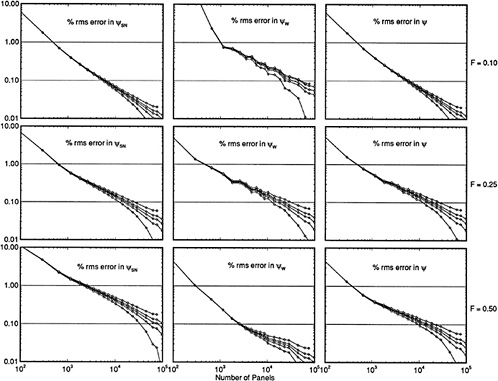

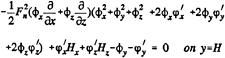

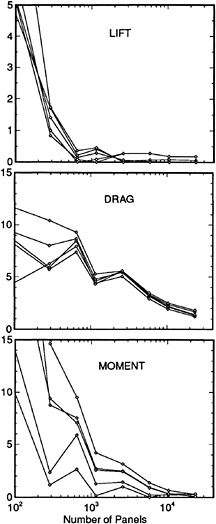

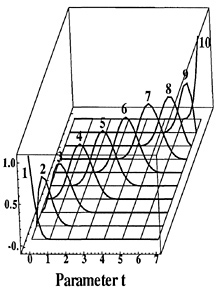

2.4 Convergence and calculation time

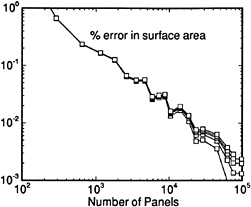

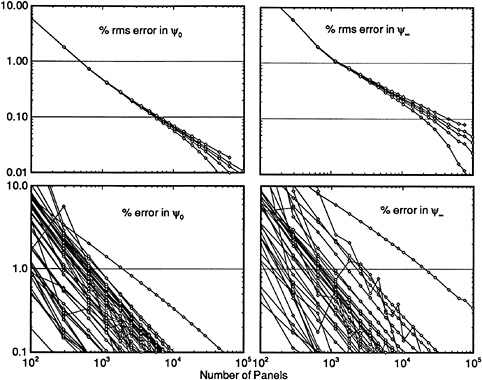

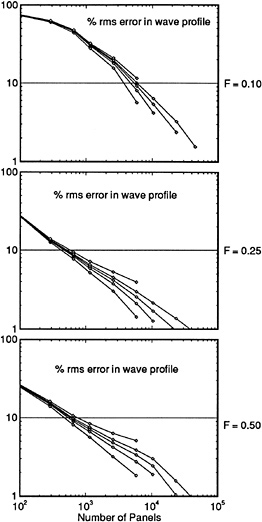

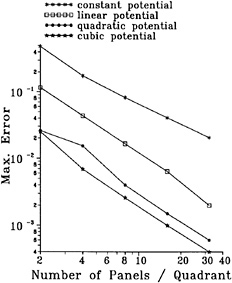

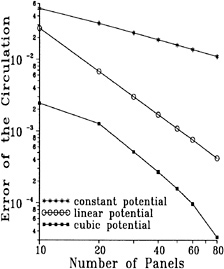

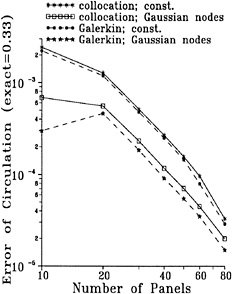

As described in [16], the method displays

-

a good convergence with respect to increasing panel density;

-

only very little effect of the distance of the panels to the free surface;

-

a robust and easy convergence of the iterative procedure, without any tuning, smoothing or filtering.

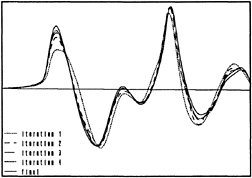

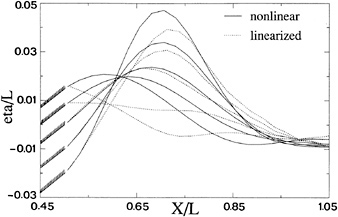

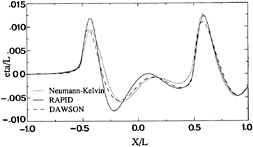

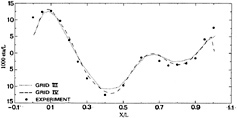

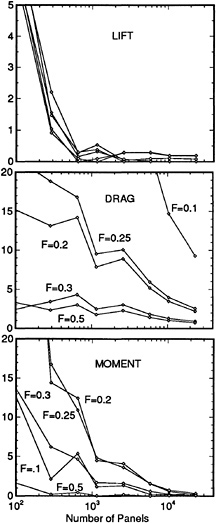

Figure 1. Convergence of hull wave profile

Fig. 1 illustrates the convergence of the hull wave profile for a Series 60 Cb=0.60 hull at Fn=0.316, with a very dense paneling. 12 iterations were required to reduce the residuals to the desired level, but already after 4 iterations the hull wave profile is very close to the final solution.

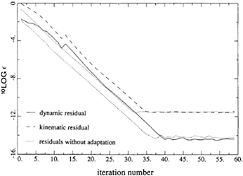

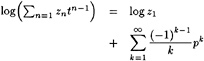

An example of the convergence history is shown in Fig. 2, in which the logarithms of the maximum residual errors in the kinematic and dynamic boundary conditions are plotted against the iteration level.

Figure 2. Convergence history with and without free surface panel adaption

The convergence rate is constant after the initial iterations, and the residuals are reduced until a minimum level determined by the machine accuracy is reached. For the kinematic residual this level is higher than for the dynamic residual as can be understood from its more complicated expression.

The same case was run with the method without any free surface panel adaptation. From Fig. 2 the convergence appears to be slightly faster; the free surface panel adaptations in the original method at iterations 4, 8 and 13 slightly delay the error decrease as a result of e.g. the geometric changes. On the other hand, adaptation from time to time is unavoidable if one wants to use a fine paneling for steep waves and still have convergence. It is noted that methods using panels on the free surface itself are forced to apply such panel adaptations in every iteration. That a raised-panel method makes it unnecessary to do so may be one of the explanations for its robustness.

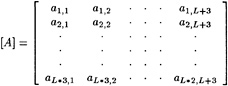

The code currently runs on a CRAY-YMP supercomputer. Calculation times vary widely according to the number of panels. To give some examples:

|

# hull panels |

# FS panels |

CP sec/iteration |

|

340 |

540 |

2.7 |

|

680 |

1056 |

17 |

|

624 |

2312 |

100 |

These calculation times can probably be reduced substantially, but this has not been given priority up to now.

The number of iterations to reach the prescribed level of residual errors usually varies between 5 and 15, dependent on the difficulty of the case. On the basis of a visual inspection of the results, the calculations would probably be terminated after 5 iterations in most cases.

2.5 Nonlinearities and wave breaking

At the 1992 Symposium on Naval Hydrodynamics, discussers of [16] indicated some restrictions of this class of nonlinear solution methods. In the first place, methods that describe the free surface as a single-valued function of the two horizontal coordinates cannot cope with extreme wave slopes, which was stated to be an important drawback in practice. Thus such methods could impossibly converge in cases in which wave breaking occurs in reality, according to these discussers. And even, because of the above, this class of solution methods would be limited to so-called “weak singularities”. Similar statements can be found in [17].

As not all of these statements seem equally true, it may be useful to pay some more attention to the validity of the present method. Let us consider the physical phenomena that occur for steep waves. Most steady breakers are similar to spilling breakers: a region of turbulent flow with air entrainment, riding steadily on top of the wave pattern that otherwise remains relatively smooth. There are several experimental indications that this steady breaking occurs already at a smaller wave steepness than the Stokes limiting wave; but even the latter is described as a single-valued function of the horizontal coordinate. According to Duncan [18], wave breaking induced by a submerged hydrofoil occurs for wave slopes exceeding 16 to 24 degrees. That perhaps the spilling breaker itself has a very large local surface slope is a different issue, as the breaking will require another modeling anyway. But we can conclude that the potential flows giving rise to this kind of wave breaking and underlying the breaking zone can be easily described using a single-valued free surface; and that excessive wave slopes that cannot be described will rarely occur in reality because wave breaking eliminates them.

The next question is then: is it possible to compute waves so steep that breaking occurs? As mentioned above, some discussers expected that divergence would prohibit such calculations. In principle, I see three possibilities:

-

the iteration does not converge;

-

it converges, but a grid-independent solution cannot be obtained;

-

it converges, but to a non-breaking solution that is not physically realizable.

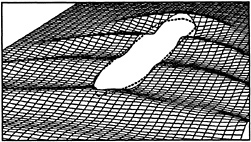

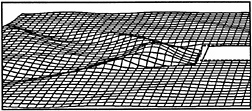

Figure 3 Calculated wave pattern for a tanker at Fn=0.25

Based on results obtained up to now the third option seems most likely, and we can at least reject the first possibility. As an example, Fig. 3 shows the wave pattern found for a tanker with a block coefficient of 0.83, at the unrealistic Froude number of 0.25. A converged solution was fairly easily obtained, although there is no doubt that extensive wave breaking will be present, e.g. in the wave trough behind the bow wave: The calculated local wave slope is almost 30 degrees, and the ratio of peak-to-trough wave height to wave length is 0.16. Both exceed known threshold values for inception of breaking. The panel length was 0.04 transverse wave length here, but grid independence has not been checked thoroughly for this case.

Similarly, in [10] a converged solution was obtained for a Series 60 CB=0.80 model at Fn=0.30, although on a rather coarse free surface grid.

Therefore wave breaking does not necessarily lead to divergence of the iteration process, and nonlinear methods like the one presented here can be a useful tool also in cases with wave breaking. But for completing the flow picture a separate criterion is required to determine whether a potential flow solution in practice will give rise to wave breaking, and some model of the breaking should eventually be incorporated. A proposal for such a model in 2D is [19].

The above example also illustrates that RAPID is stable enough to solve the nonlinear potential flow problem for all realistic speeds. At the same time it refutes the statement that these methods can only deal with “weak nonlinearities”. I am not aware of the existence of a clear definition of the latter, but I would not call the nonlinearities in this example

weak. The calculated peak-to-trough wave height is as large as the draft of the vessel and vertical velocities exceed 45 % of the ship speed.

Of course, other types of wave breaking occur. A sharp ship bow may act as a sort of ploughshare and induce a flow similar to a plunging breaker. This behaviour is definitely outside the reach of RAPID and all similar methods. Other methods, usually time-dependent, with a more general free surface description, have been applied to plunging breakers and do give a picture of the flow up to the moment of impact of the jet on the free surface. But then they stop ! Consequently also those methods have to be supplemented by some kind of local model for the plunging-type wave breaking and its effect on the flow field. In that respect they may have only a small advantage compared to the present approach.

An interesting related point of discussion is the question what happens if the discretization is further and further refined towards the bow. Again the same three pitfalls seem possible: divergence, unresolvable grid-dependence or an unphysical solution. The problem can be studied a little bit further by invoking the similarity between the steady flow at a sharp ship bow and a time-dependent 2D flow in cross planes. For a bow with a finite entrance angle the corresponding 2D case is that of an impulsively started wavemaker. From small-time expansions a logarithmic singularity in the wave elevation has been shown to exist in that case, representing a jet shooting up along the wavemaker. Numerical studies using time-dependent fully nonlinear boundary integral methods, e.g. [20,21] actually reproduced this behaviour. The finer the paneling, the higher the jet, and no grid-independence could be reached. But this is extremely localized, and the result at very small distances away from the wavemaker and everywhere else is totally unaffected by the grid dependence at the intersection. Analogously, and keeping in mind that in 3D steady flows singularities are likely to be weaker than in 2D time-dependent flows, I expect that for sharp bows in fact eventually no convergence will be obtained in RAPID if the discretization is refined towards the waterline; that locally no grid-independent solution or even no physically correct solution may thus be reached; but that the resulting error will be extremely localized and unimportant from the point of view of the global flow field. For almost all practical applications this theoretical drawback is then of no interest. Although there is some speculation in these statements, current experience with the method actually points in this direction. Further study is desired.

All this does not mean that the method proposed here is the final answer; but, subject to certain improvements in resolution and in numerical details, it may be the answer to most of the practical questions that can be dealt with using potential flow assumptions.

3. THE FLOW OFF A TRANSOM STERN

3.1 Physical Phenomena

As most current ship forms have a transom stern, the capability of a method to handle transom flows is of primary importance. In linearized methods the hull form above the undisturbed waterline has no effect, and transom sterns above the design waterline are usually not treated as transom sterns. But in a nonlinear method transom flow modeling is also required for all those cases in which a transom becomes immersed only at speed.

For ships having a transom stern, three flow regimes may be distinguished:

-

the “regular” type of flow, which is similar to the flow past a cruiser stern. This type of flow will occur if the transom is at a sufficient distance above the undisturbed free surface. Dependent on the hull form the last part of the actual waterline in potential flow may be either a streamline or an envelope of streamlines that leave the hull tangentially and continue on the free surface. At the smooth detachment of the free surface from the hull surface, both the hull boundary condition and the two free surface boundary conditions must be satisfied. Unless the detachment is in a stagnation point, this means that the flow leaves the hull tangentially.

-

the “transom flow”, occurring for immersed transoms at a sufficiently high speed. At the transom edge the hull streamlines leave the hull and continue on the free surface. The negative hydrodynamic pressure needed to make the pressure at the transom edge atmospheric is achieved by an upward curvature of the flow immediately aft of the transom edge, resulting in a more or less marked “rooster tail”.

-

The flow around a deeply immersed transom at low speed. At the sharp convex corner of the transom edge, viscous flow separation occurs and a dead-water region aft of the transom is formed.

The transitions between the various flow regimes are practically relevant, as a dead-water region is to be avoided, and a transom that is at a too high position as well. Let us further consider what phenomena determine these transitions. Suppose a regular flow type occurs, with the transom above the

water surface, and we increase the draft of the vessel. The detachment position is likely to move aft and at some moment reaches the transom edge. The streamline shape then further adjust so as to maintain a zero pressure at the edge. While in regular flow the curvature is bounded at detachment, this need not be true in the transom flow.

For a further increasing transom depth or for decreasing speed the hydrodynamic pressure coefficient required to balance the hydrostatic pressure at the transom edge increases in absolute value, and the upward curvature of the streamlines must increase. A very steep forward face of the wave aft of the transom results, eventually giving rise to a spilling breaker following the transom at a short distance. At still lower speed or greater draught this closes upon the transom and forms a dead-water zone.

From these preliminary considerations, we can list the requirements of the “ultimate” nonlinear potential flow model:

-

it should contain a model for at least the regular and the transom flow;

-

it should indicate the transition from a regular to a transom flow and reversely;

-

it should preferably indicate the transition from transom flow to dead-water flow.

If not all transitions can be incorporated in the code, one may try both flow regimes and check for anomalies. We can immediately note that point III will perhaps still be impossible to realize. If it is true that wave breaking determines this transition, a proper breaking criterion will be indispensable. Furthermore one should be aware of possibly large viscous effects on this transition. Moreover, point II requires the ability to compute the regular flow for extremely flat afterbodies; this is a very high demand for any iterative nonlinear method, as a small change of the wave elevation then results in a very large (and destabilizing) shift of the waterline.

Below, we shall consider the modeling of the transom flow in linearized and nonlinear models, and discuss the question of the transitions.

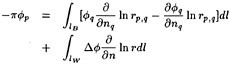

3.2 Mathematical Modeling

There seems to be some confusion about the type of modeling appropriate for transom flows. The boundary conditions to be imposed are fairly evident: on the hull the flow again must be tangential, and on the entire free surface it must be tangential and have a zero pressure. That there are two boundary conditions on the free surface corresponds with the additional degree of freedom there, the elevation of the free surface. At the transom edge however, the confluence of boundary conditions poses some problems. The two kinematic conditions can be reconciled if the flow leaves the hull tangentially. But as the edge location is fixed, the degree of freedom due to the wave elevation seems to be lost. How to impose the dynamic boundary condition?

This apparent overspecification of the problem reminds of the flow around a lifting body, in which circulation provides the additional degree of freedom. The analogy with a Kutta condition, which also imposes an extra condition on the flow at a sharp corner, has sometimes been invoked. Consequently, trailing vortex wakes or dipole sheets are introduced, e.g. in [22]. But the success of such an implementation could not be shown convincingly; in [22] the use of source panels on the transom instead of a trailing vortex wake led to almost identical results.

Another proposal for modeling transom flows is [23], which deals with slender hulls at very high speeds. Also here the necessity of introducing trailing longitudinal vorticity on the free surface is advocated. However, this vorticity appears not to result from the presence of a transom but from the use of a reverse image of the flow above the still water surface, as is appropriate in the infinite-Froude-number limit. The same trailing vorticity would in this model be required for hulls without transom. The slender-body formulation adopted causes this boundary vorticity to extend to downstream infinity with constant strength.

To study the meaning of trailing vorticity for transom flows, let us first consider the flow around a two-dimensional body with a transom stern. The flow domain is bounded by the hull and the free surface which originates from the transom edge. Therefore the domain is singly connected, and there cannot be any unknown circulation around the body.

In a three-dimensional case the situation is similar. Is there any reason why the three-dimensionality would suddenly introduce spanwise vorticity? If it would, trailing longitudinal vorticity would in fact also be present. However, this vorticity would start at the transom edge, i.e. on the free surface, so it would remain on the free surface; on the boundary of the fluid domain therefore. There is no cut in the domain, no additional degree of freedom, and the boundary vorticity has no physical effect on the flow field in the domain at all; it just affects the form of the Fredholm equation to be solved.

Therefore, in my opinion the use of a trailing vortex wake for transom flows, although perhaps

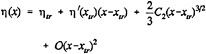

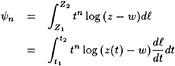

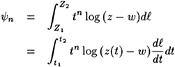

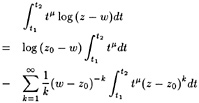

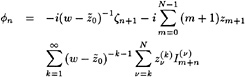

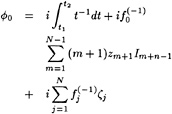

numerically helpful in some models, cannot be given any physical meaning. Rather than pointing out the analogy with the Kutta condition we might consider free streamline theory, as applied to e.g. the cavity or wake flow behind a flat plate at large incidence. Although the neglect of gravity may well affect some of the conclusions, free-streamline theory tells that the flow leaves the transom edge tangentially, but with infinite curvature. Even more illuminating is [24], in which for a flat-ship linearization in a 2D free-surface potential flow around a semi-infinite body the behaviour at the transom edge is derived. Again, the conclusion is that the slope of the streamline is continuous (tangential flow), but that the curvature tends to infinity at the edge. Specifically, the free surface shape aft of the transom is described as follows:

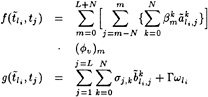

(10)

where ηtr is the height of the transom edge and the coefficient C2, which can be expressed in the hull geometry, is the degree of freedom required to satisfy the dynamic condition. Although the details of this result may be a consequence of the necessary simplifications and linearization, this study suggests that all transom conditions can be satisfied without any physical vorticity; that the additional degree of freedom is the streamline shape at the transom edge; and that a more or less singular behaviour at the edge may result.

3.3 Implementation

We shall now discuss the implementation of transom conditions. Because of the mentioned lack of general agreement on the proper modeling it seems useful to study the implementation in a linearized method as well. This has been used already for several years in the DAWSON code and provided good guidelines for the nonlinear implementation which we shall consider subsequently.

It is interesting to note that implementing transom conditions in a linearized method is basically inconsistent. Linearization assumes that the variation of the hull shape near the undisturbed waterline is small; i.e. a small curvature, and in slow-ship theory also a small slope of the sections and buttocks. Only then the exact position of the hull—free surface intersection has a negligible effect on the flow and linearization is permitted. However, at a transom edge the hull curvature is infinite, and we want to have a particular hull—free surface intersection. Nevertheless a quite reasonable representation of transom flows appears to be possible in linearized methods as well.

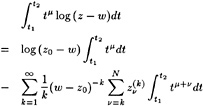

In the hull paneling the transom is left open. The free surface panel distribution is adapted to the transom by the addition of a few extra strips of panels aft of the transom. One might think of imposing transom conditions in points right at the transom edge; but with the usual constant-strength source panels on the hull the velocity field is singular here in the discretized formulation. Therefore transom conditions are to be imposed in the first collocation points aft of the transom.

In the linearized problem we can only impose one single FSC, a combination of the kinematic and dynamic FSC. The usual FSC is derived by expressing the term ηx in the kinematic condition in the wave elevations η in the point considered and a few upstream points using a difference scheme; and expressing these η's in the velocities through the dynamic condition. In this process any abritrary pressure added to the dynamic condition drops out; in other words, the combined form actually means that in the free surface collocation points the velocity must be parallel to the isobar surface passing through that point, but the pressure corresponding to that isobar surface is eliminated. The wave elevation is only retrieved afterwards from the dynamic FSC. Thus the ordinary form of the FSC makes it impossible to impose any condition on the wave elevation at or near the transom itself, and the free surface will most likely start somewhere at the transom face.

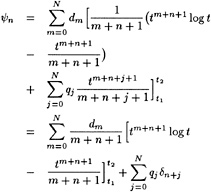

The solution of this difficulty is well known: the FSC must be modified so as to avoid elimination of the pressure level. This is easily achieved by imposing in the first collocation points the condition that the velocity must be directed parallel to a line from the transom edge to the wave elevation at the point, e.g.

(11)

The same transom condition can be derived by substituting into the usual FSC the velocity required for zero pressure at the transom edge.

Instead of the two-point formula for ηx, higher-order expressions may be used. These require that an assumption is made on the local behaviour at the edge. Two alternatives have been tried:

-

the behaviour according to Schmidt [24], (10)

-

a simple Taylor expansion in the transom edge point

The former has been derived from a flat-ship linearization and is, therefore, not necessarily appropriate here; but it allows an infinite curvature at the edge. The second formulation is generally applicable to regular behaviour aft of the transom edge.

With this simple modification the transom conditions to be imposed in the first points of the free surface strips aft of the transom are in principle complete for a linearized method. For the second points, in the FSC the same three-point difference scheme is used as everywhere else. This involves again the transom edge height. For all downstream points no modification is needed.

One should notice that in principle this treatment of the transom conditions does not guarantee that the solution satisfies the zero-pressure condition at the transom edge; and if not, it does not satisfy the kinematic condition in the first free surface point either. However, a mechanism that physically governs the transom flow is incorporated. The inherent continuity of solutions of the Laplace equation will make the flow leave the transom more or less tangentially. If the wave elevation in the first free surface points aft of the transom deviates from this tangent, a large streamline curvature at the transom edge results, inversely proportional to the square of the distance from the transom to the first points. This curvature adjusts the pressure at the edge and the wave elevation. Thus upon panel refinement the wave height at the first free surface collocation points will be forced to approach the transom edge. How appropriate this FSC is for finite panel sizes can only be deduced by numerical experimentation. The quality of the linearized predictions will be studied in Section 3.4

The implementation of the transom edge conditions in the nonlinear method is actually quite similar to that outlined above. As again no collocation point can be located at the transom edge itself, the free surface conditions are imposed at a small distance aft of the transom. Again, the free surface slope to be substituted in the FSC is expressed in the difference between the transom edge height and the Bernoulli expression for the collocation point, through one of the alternative expressions. The free-surface boundary conditions are now linearized with respect to the previous iteration; and the iterative procedure will converge to the fully nonlinear solution.

It was found that the convergence of the iterative procedure is excellent. As the transom edge is a fixed point in the result, extremely large errors in the dynamic and kinematic boundary conditions are found initially if one starts from a flat free surface. But the fact that this point is fixed also appears to stabilize the results locally, and convergence presents no problem at all.

Although basically the linearized and nonlinear treatment of the transom conditions is similar, it is a significant advantage of the latter that the nonlinear terms and transfer terms are fully included. These can be very large, in particular for low transom depth Froude numbers, when large vertical velocities and large free surface curvature occur near the transom. Moreover, since the nonlinear method imposes the exact free surface boundary conditions, we can be more confident that the physical mechanisms governing the transom flow are fully included.

3.4 Results

As the actual behaviour at the transom edge in a 3D nonlinear case is not known, I have chosen the following path for verifying the method. I see two possible causes why it might give erroneous results. The first is discretization; therefore careful grid refinement studies have been carried out. The second would be an incorrect modeling of some kind of singularity at the transom edge. The importance of this will be studied by comparing the results found with different assumptions on the flow behaviour at the edge.

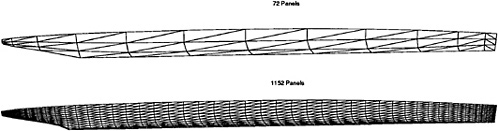

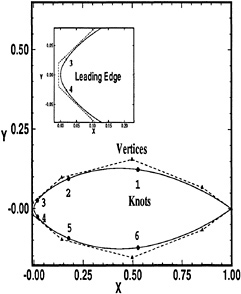

For the panel refinement study, the test case (Fig. 4) is a mathematical hull form with rectangular sections with a rounded bilge; parabolic waterlines in the forebody; an afterbody that is prismatic up to x =0.25 L, and has a bottom slope of 1: 0.16 aft of this point.

Figure 4. Mathematical hull form with transom

The panel refinement study discussed here addressed a case with a Froude number of 0.40 and a transom immersion of 0.01 L. The Froude number based on transom depth is 4.0, which may be just sufficient to make the flow clear the transom.

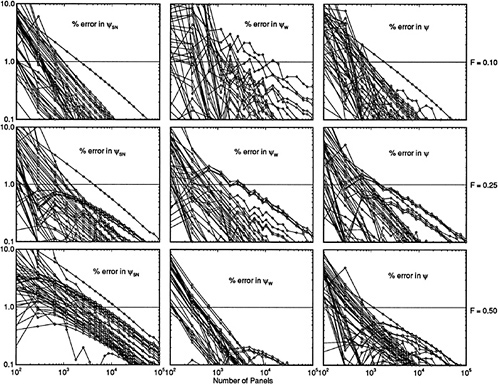

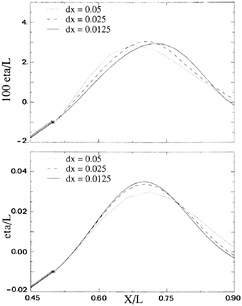

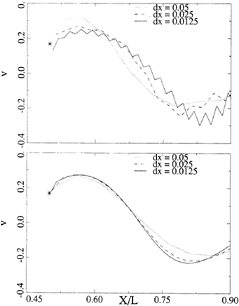

Let us first look at the results of the linearized

Figure 5. Wave profile behind transom, for 3 panel densities; linearized (top) and nonlinear (bottom)

Figure 6. Vertical veloctiy behind transom, for 3 panel densities; linearized (top) and nonlinear (bottom)

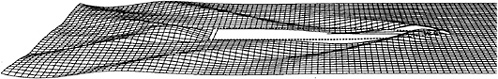

Figure 7. Calculated wave pattern for transom stern hull; nonlinear method

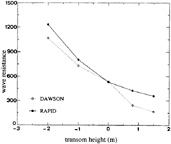

Figure 8. Wave profile for varying transom edge height; linearized and nonlinear method

Figure 9. Wave resistance against transom edge height; linearized and nonlinear method

(DAWSON) code. Fig. 5 (top) shows the predicted free surface shape aft of the transom on the line of collocation points closest to the centerline, for hull and free surface panel lengths of 0.05 L, 0.025 L and 0.0125 L respectively. Some grid dependence appears to be there, with a downstream shift of the wave crest but not too much change in amplitude. Fig. 6 (top) shows the vertical velocity on this same line. The marker indicates the value at the transom edge, deduced from the dynamic condition and the transom slope. The value found on the free surface aft of the transom is too high for the coarser panelings, and too low for the finest distribution. The latter result may be due to the large oscillations in the vertical velocity that are typical for the Dawson-type of discretization at small panel sizes. 80 panels per wavelength is, by the way, not a density one would use in practice. Anyhow, the linearized transom modeling seems to give a qualitatively correct behaviour, but its accuracy is not quite convincing.

For the corresponding nonlinear (RAPID) calculations, the results are shown in Figs. 5 and 6, and Fig. 7. The calculated flow is absolutely smooth and satisfies both transom conditions accurately: no deviation is visible on the scale of the paneling. The convergence of the wave profile for decreasing panel size is very good, and there is hardly any difference between the two finer panelings. In particular the behaviour just aft of the transom is perfect. The vertical velocity converges well and consistently matches the transom edge value indicated.

We thus find that, as panel refinement has very little effect on the solution, we can be confident that the exact FSC's are accurately satisfied in all points on the free surface (not only the collocation points) in the converged nonlinear solution. But an exception must be made for the point right at the transom edge: no collocation point is present here, and if some sort of singular behaviour occurs, panel refinement could in principle give convergence towards an erroneous solution. Therefore the effect of the choice of the flow model at the edge has been considered. But the difference between the results obtained with the Schmidt- and the Taylor expression was only quite local and too small to be distinguished on the scale of the plots. In both cases the calculated vertical velocity was continuous (tangential flow), but with a discontinuous ∂v/∂x and a discontinuous but finite curvature of the free surface streamlines. This does not exactly correspond with the Schmidt theory, but does allow a Taylor expansion.

Since, therefore, the particular assumptions on the behaviour here have only a very small and localized effect, we may conclude that this detail of the modeling is not too important and is very unlikely to lead to an erroneous solution globally. Thus the method proposed is adequate.

Next, we study the effect of the transom depth on the predictions. The draft of the ship is varied to obtain the transom heights—0.02 L, −0.01 L, 0., 0.008 L and 0.015 L (positive is above the still water level). Fig. 8 shows the wave profile on the centerline behind the transom predicted by DAWSON and RAPID. In all cases the free surface correctly starts at the edge. The wave profiles predicted by DAWSON and by RAPID are remarkably close for all immersed transoms. The nonlinear predictions have a somewhat higher and steeper stern wave, with a difference of up to 20 %. The greater the transom immersion, the stronger the nonlinearity. But, fortuitously or not, the several nonlinear contributions, each very large for the large vertical velocities occurring (up to 40 % of the ship speed), appear to cancel to a substantial extent; the difference between DAWSON and RAPID is therefore relatively moderate.

For the cases with the transom above the still water level however, the difference between DAWSON and RAPID is much larger. The rooster tail suddenly disappears in DAWSON as soon as the transom edge comes above the still water line. As the still water level is of little meaning for the local flow, there is no physical explanation for this drastic change. As opposed to this, in RAPID the height of the rooster tail continuously decreases, which must be the proper behaviour.

Similarly, all RAPID calculations display the correct free surface slope at the edge, corresponding to a tangential flow off the hull; while in the DAWSON predictions only the cases with the transom edge on or below the still water level have the correct slope. The same tendencies are found in the predicted wave resistance (Fig. 9). For DAWSON, a contribution

has been added, which in an ad hoc fashion accounts for the absence of hydrostatic pressure on the transom. Although entirely inconsistent, this correction appears to bring the resistance fairly close to the nonlinear result (which does not require such a correction because the total pressure is integrated over the hull). At zero transom immersion the two predictions are almost equal. The cases with transom above the still water surface again show a deviation in the DAWSON results.

The explanation of the bad linearized predictions for transoms above the still water level is of course that the hull must be cut off at the undisturbed water level in a linearized method. The hull paneling then ends at some point ahead of the transom. While the transom conditions in the first free surface collocation points can be imposed just as well if the transom height is positive, no boundary condition can be imposed on the part of the hull bottom above the still water level. But, because of the double-body linearization and the symmetry with respect to the still water level, imposing no boundary condition is the same as imposing a zero vertical velocity on this part of the water surface! This may be an acceptable approximation for cases with small buttock angle near the transom, but not for the present case where the vertical velocity should be around 0.16.

Summarizing, for the cases studied the results with the linearized method appear to be quite reasonable for all immersed transoms, with a moderate deviation due to nonlinear effects; but for transoms above the still water level the representation of the flow off the transom edge is relatively poor.

The RAPID solutions however are very accurate and satisfy all boundary conditions to the degree to be expected. Even for transoms above the still water level the hull shape near the transom is completely taken into account. Optimization of the transom immersion and stern shape seems to be possible now throughout the practical range.

Remains the question to what extent the transitions to the other flow regimes (dead water and early detachment) are indicated by the nonlinear calculations. As expected, the transition to a dead-water zone is not indicated as no criterion for the inception of wave breaking is included. In [25], the nonlinear stern waves behind a flat bottomed semi-infinite two-dimensional body have been studied theoretically, and it was derived that a solution with the free surface detaching from the transom edge exists only for a transom depth Froude number exceeding 2.23; and that breaking occurs for all Froude numbers below 2.26. Hoping to find anything particular I made calculations for a flat-bottomed finite-length 3D ship with a transom depth Froude number of 2.0. But again a converged solution was obtained, and no particular indication of non-existence was found. However, the result (Fig. 10) was markedly three-dimensional, so the theory of [25] does not apply and probably nothing more could be expected.

Figure 10. Calculated wave pattern for a flat-bottomed hull at transom depth Froude number 2.0

The transition to a detachment ahead of the transom is indicated by the calculations, although rather indirectly. For the highest position of the transom edge considered here, the pressure along the bottom of the hull falls below zero before the transom is reached. But on that part of the boundary only a hull condition is imposed, and passing the zero pressure level has no effect. One has to watch the pressure distribution on the hull, and as soon as this falls below zero the regular flow type is to be attempted. Geometric complications currently prevent the RAPID code to make this switch without any user intervention; and at this moment the degree of generality of the code is still insufficient to deal with regular flow around flat sterns with extremely blunt waterlines. These restrictions will hopefully be eliminated in the near future.

4. VALIDATION STUDIES

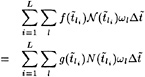

While [16] focused on the theoretical background of the RAPID-approach and discussed several studies of the numerical accuracy, grid independence and so on, in the meantime a number of validation studies has been carried out in which the predictions were compared with experimental data. Because of the availability of very detailed and accurate measurements, we first consider two standard test cases.

4.1 Wigley hull at Fn=0.316

For this case, data from the ITTC Cooperative Experimental Program are available. A comparison has been made of the wave profiles with zero trim and sinkage. Calculations were made with 624 panels on the port half of the hull and two different free surface panelings, with 1148 and 2312 panels, respectively, in an attempt to elucidate the cause of the general underprediction of the bow wave height in all published results for this particular case.

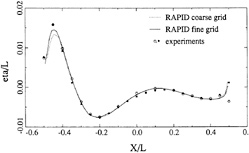

Fig. 11 shows that for both panelings the agreement of the calculated and experimental hull wave profile

is almost perfect, and far better than in most calculations published before. Grid dependence is only visible in the immediate vicinity of the bow, were the wave height is again slightly underpredicted. Further study, preferably for a simplified test case, must show whether this local effect is a consequence of incomplete resolution or of the possible bow singularity discussed before.

Figure 11. Hull wave profile; Wigley hull, Fn= 0.316

Fig. 12 compares the wave profiles on the line of collocation points adjacent to the hull and centerline as predicted by DAWSON, RAPID, and the first RAPID-iteration which is a Neumann-Kelvin linearization. Substantial differences are observed. Notwithstanding the slenderness of the vessel, the nonlinear method brings about a distinct improvement.

Figure 12. Wave profile, Wigley hull, Fn=0.316

4.2 Series 60 Cb=0.60 at Fn=0.316

For this case a very extensive set of measurements is available, which have been carried out at IIHR [26]. A large number of longitudinal and transverse cuts has been measured. A disadvantage of these data is that they apply to a very small model of 3 m length, in a narrow towing tank (Rn≈4 . 106). Initial calculations were made using 24*25 hull panels. Three free surface panelings have been tested: Grid I with 10 strips on each side of the hull and a panel length of 5 % of the transverse wave length; Grid II with 20 strips of 5% panels; Grid III with 10 strips of panels with a 2.5% length.

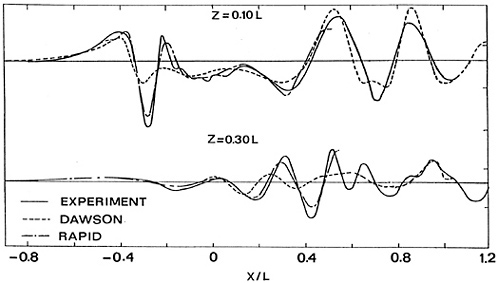

Fig. 13 compares the Neumann-Kelvin, Dawson and Rapid predictions for 2 longitudinal cuts. They all reasonably well correspond with the data, the Neumann-Kelvin results (in the present implementation) giving the worst agreement, with some phase shift in particular. While the nonlinear effects are not too large here, RAPID consistently gives the best agreement. An exception is the flow aft of the stern. The bad correlation in this region can safely be attributed to viscous effects; calculations for a displacement body in [25] in fact indicate a very important effect on stern wave amplitude.

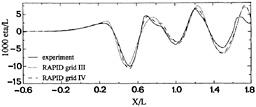

The comparison of the nonlinear results on the 3 free surface grids showed that the first grid was somewhat less accurate, and slightly reduced the bow wave height due to an insufficient resolution. Grid II and III gave largely equivalent results, but at greater distances from the hull Grid III was marginally better due to the slightly smaller numerical damping. As the main difference between the data and the nonlinear calculation, a small, very short wave component was observed, generated at the bow and riding on top of the pattern of longer wave components. The length of this diverging wave was about 0.2 L, and the corresponding angle of the wave is 71 degrees. Although such a component is usually meaningless from the resistance point of view, the question was posed whether this deficiency was due to wave breaking, an unresolved strongly nonlinear effect or simply a lack of resolution.

Therefore grid IV has been generated, having 17 strips on the free surface and 56 panels per transverse wavelength. Besides, the hull paneling was refined to 56*15 panels. As Fig. 14 illustrates, the short wave component now actually enters (most clearly at x=0.6–0.9), and has an approximately correct phase and position, but not an entirely correct amplitude. While it apparently still is distorted by the poor resolution, this result definitely suggests that even this detail is fully contained in the mathematical model, and just requires a very fine discretization to turn up in the prediction. This short wave is, however, something of theoretical interest only.

Figure 13. Longitudinal cuts, linearized and nonlinear; series 60 Cb=0.60, Fn=0.316

Figure 14. Grid dependence of short wave component; series 60 Cb=0.60, Fn=0.316

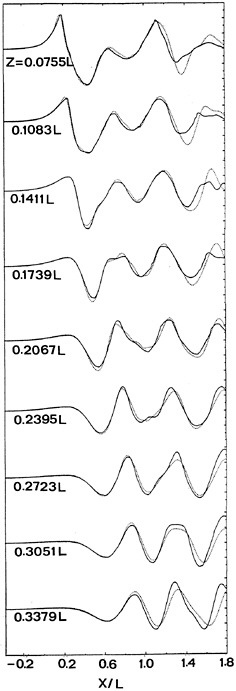

Fig. 15 shows the comparison of the calculation on the finest grid and the experiment, for 9 longitudinal cuts. It is noted that at the outer longitudinal cuts the agreement is not quite as good. However, these cuts are located around z=0.30L, which may have been too close to the wave absorber (at z=0.40L) and the tank wall (z=0.50L). Everywhere else the agreement is, in my opinion, extremely good and these are probably the best results for this case ever published up to now.

Also the hull wave profile (Fig. 16) corresponds quite well with the data. Grid IV represents some improvement compared to grid III; this is likely to be primarily a result of the finer hull paneling. The maximum bow wave height is accurately predicted on both grids, but the high wave elevation right at the fore perpendicular is not reproduced. As this appears to have no effect in the nearby longitudinal cut, this probably has been a very thin fluid or spray sheet in the experiment.

Summarizing, in general an excellent agreement has been obtained for this case. Panel refinement makes the results converge towards the experimental data, even for details such as the short diverging waves. There is no trace of any unresolved “strong nonlinearities ” in the near field having an effect at greater distances from the hull.

Figure 15. Longitudinal cuts, calculated (Grid IV) and experimental; series 60 Cb=60, Fn=0.316

Figure 16 Hull wave profile, series 60 CB=0.60, Fn=0.316

4.3 Container ship

Of course further validations for more up-to-date hull forms are desired and will be carried out. Also, it is useful to compare linearized and nonlinear pedictions for ships exciting more diverging waves, as experience has shown that these tend to be rather poorly represented in linearized methods. Whether this is caused by numerical dispersion or damping or by the linearization was not quite clear until recently.

Our test case is a container ship with a bulbous bow, running at Fn=0.24. Two longitudinal cuts were measured during the towing tests at MARIN. DAWSON and RAPID calculations have been carried out. However, as the ship has a transom stern above the still waterline and stern sections with a very large slope, at the moment of making these calculations we were forced to modify the afterbody in the RAPID calculations. As the primary interest was in the forebody design, this was an acceptable change; but consequently the RAPID stern wave predictions cannot be compared with the data and have not been plotted. In DAWSON the transom flow model has been applied with a positive transom edge height.

Fig. 17 shows the predicted and measured longitudinal cuts for the full-draught case. At z= 0.10 L, RAPID obviously gives a far better prediction of the amplitude of the diverging bow wave system, which is severely underestimated by DAWSON. Further downstream, RAPID consistently improves upon the DAWSON results. But DAWSON is doing well for the rather transverse waves generated at the stern, notwithstanding the deficiencies in the modeling. In the second longitudinal cut, at a distance of 0.30 L from the centerplane, the agreement is slightly worse, and the bow wave system soon mixes up with the stern waves that prohibit further comparisons. But again here, RAPID is substantially closer to the data.

Figure 17. Longitudinal cuts for container ship, full draught

The first iteration of RAPID (a Neumann-Kelvin approximation) was quite similar to the DAWSON results, which proved that the underprediction of diverging waves is caused by neglecting nonlinear effects and not by numerical dispersion or insufficient resolution in the DAWSON results. The same has been found for other cases. It appears that the short diverging waves have a stronger tendency to steepen than the long transverse waves, and thus display stronger nonlinear effects.

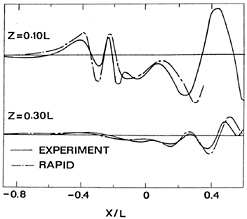

For the same vessel in ballast condition the top of the bulbous bow is at 1.2 m above the still waterline (which is 15 % of the stagnation height). An important practical question is then, whether it still becomes completely immersed at the service speed; if not, a significant resistance penalty can be incurred.

This cannot be studied using a linearized method. Inherent to the linearization is the transfer of the boundary condition towards the undisturbed free surface. The greater part of the bulbous bow is above that surface and plays no role in the calculation. Therefore the predicted bow wave form is unrealistic. The same is true if the top of the bulbous bow is extremely close to the undisturbed waterplane [16]. In RAPID however, the free surface boundary conditions are applied at the actual wave surface. If the bow becomes completely submerged due to the bow wave elevation, its effect is fully included in the mathematical model. The only precaution needed is to start with an increased draught to make the bow fully submerged, and to gradually reduce this draught in the course of the iteration until the equilibrium position is reached.

RAPID here predicted that the bulbous bow would just emerge above the wave surface, by some 0.20 m. But as the free surface panel size was fairly large compared to the dimensions of the bulbous bow there was a risk of insufficient resolution of the large gradients that can occur above such bows. In fact, the towing test showed that an extremely thin sheet of water just wetted the upper side of the bulb. Immediately downstream a deep wave trough next to the hull was formed, and breaking phenomena affected the wave pattern. The less accurate prediction (Fig. 18) therefore comes as no surprise, although the major aspects of the wave pattern are captured.

The calculations for this container ship thus show that also for fairly slender vessels at moderate speed, nonlinear effects can be surprisingly large in some respects, and for diverging waves in particular. The nonlinear code gives a much better agreement with the experimental data, and additionally it permits to make calculations for surface-piercing bows; but resolution of the rather violent flow features here requires care.

Figure 18. Longitudinal cuts for container ship, ballast draught

4.4 Frigate

In order to specifically test the transom flow modeling, linearized and nonlinear calculations have been carried out for a frigate-type hull with a wide transom, for which older experimental data were available. However, the Froude number based on the transom immersion was only 2.65, and this may well have been a case with a dead-water zone. Moreover, wave breaking near the corners of the transom was observed in corresponding wake survey data. A good agreement could therefore not be expected. As a matter of fact, both the DAWSON-and the RAPID-predictions showed a largely sinusoidal wave aft of the transom, while in the experiment a rather disturbed free surface with modest wave amplitude was observed. Accordingly, the magnitude of the diverging wave from the transom edge was substantially overestimated by both codes, and by RAPID in particular. On the other hand the diverging waves from the bow were again much better represented in RAPID. This case, therefore, turned out to be less appropriate for testing an inviscid potential flow model. Further validations will be carried out in the near future.

5. CONCLUSIONS

This paper has described part of the recent progress in the development of the RAPID-method towards a generally applicable ship design tool. In particular, attention was paid to the convergence of the iterative procedure and the applicability to flows with wave breaking; to the modeling of the flow off an immersed transom stern; and to some of the validation studies. Main conclusions are:

-

The method does not require any smoothing, filtering or damping and usually converges reliably to machine accuracy. The convergence problems typical of most steady nonlinear free surface flow solvers do not occur unless in exceptional cases.

-

A converged solution is also obtained for cases in which extensive wave breaking will occur in real flows, such as full hull forms at high speed. A separate criterion for the inception of wave breaking and a model for its effect on the flow field would be required to complete the flow picture in such cases.

-

It is argued that vorticity physically plays no role in the flow off a transom stern. The implementation of transom conditions in linearized and nonlinear methods is discussed an studied numerically. The linearized form appears to give reasonable results; the nonlinear method satisfies the transom conditions most accurately and shows very little grid-dependence. Optimization of the transom stern shape now seems possible, even for transoms above the still water line.

-

Comparisons with experimental data show that even for slender ships nonlinear effects are larger than was expected before. Diverging waves in particular are much better predicted by RAPID. Including nonlinear terms consistently improves the results. With sufficiently dense panelings very good agreement with experiments can be achieved, even for short wave components. For bulbous bows very close to the wave surface, resolution of small-scale flow phenomena requires care.

-

Future work will be directed to further experimental validation, improving the numerical and computational efficiency, and extensions to more complicated stern shapes.

ACKNOWLEDGEMENT

Computing time was provided by the Dutch National Computing Facilities Foundation (NCF) under project SC-232. Part of the development described in this paper was supported by the Netherlands Foundation for the Coordination of Maritime Research CMO, under project 91/92 B 3.15. This support is gratefully acknowledged.

REFERENCES

[1] Dawson, C.W., “A Practical Computer Method for Solving Ship-Wave Problems”, Proc. 2nd Int. Conf. Num. Ship Hydrodynamics, Berkeley, USA, 1977.

[2] Raven, H.C., “Variations on a Theme by Dawson”, Proc. 17th Symp. Naval Hydrodynamics, The Hague, Netherlands, 1988.

[3] Raven, H.C., “Adequacy of Free-Surface Conditions for the Wave-Resistance Problem ” Proc. 18th Symp. Naval Hydrodynamics, Ann Arbor, USA, 1990.

[4] Zandbergen, P.J., Broeze, J., and Van Daalen, E.F.G., “A Panel Method for the Simulation of Nonlinear Gravity Waves and Ship Motions”, in: Advances in Boundary Element Techniques, Springer Verlag, 1992.

[5] Xü, H., and Yue, D., “Computations of Fully Nonlinear Three-Dimensional Water Waves”, 19th Symp. Naval Hydrodynamics, Seoul, South-Korea, 1992.

[6] Cao, Y., “Computations of Nonlinear Gravity Waves by a Desingularized Boundary Integral Method,” Ph.D.Thesis, Univ. of Michigan, Ann Arbor, 1991.

[7] Ni, S.-Y., “A Method for Calculating Nonlinear Free Surface Potential Flows using Higher-Order Panels”, in: Ph.D.Thesis, Chalmers Univ., Gothenburg, Sweden, 1987.

[8] Larsson, L., Kim, K.J., and Zhang, D.H., “New Viscous and Inviscid CFD-Techniques for Ship Flows”, Proc. 5th Int. Conf. Numerical Ship Hydrodynamics, Hiroshima, Japan, 1988.

[9] Kim, Y.-H., and Lucas, T., “Nonlinear Ship Waves”, Proc. 18th Symp. Naval Hydrodynamics. Ann Arbor, USA, 1990.

[10] Kim, Y.-H., and Lucas, T., “Nonlinear Effects on High Block Ship at Low and Moderate Speed”, 19th Symp. Naval Hydrodynamics, Seoul, South-Korea, 1992.

[11] Delhommeau, G.,” Computation of Nonlinear Wave and Wave Resistance”, Proc. 7th Int. Workshop on Water Waves and Floating Bodies”. Val de Reuil, France, 1992.

[12] Xia, F., “A Study on the Numerical Solution of Fully Nonlinear Ship Wave Problems ”, in :Ph.D.Thesis, Chalmers Univ., Gothenburg, Sweden, 1986.

[13] Jensen, G., “Berechnung der Stationären Potentialströmung um ein Schiff unter Berücksichtigung der nichtlinearen Randbedingung an der Wasseroberfläche”, Ph.D.Thesis, IfS Bericht 484, Hamburg, 1988.

[14] Jensen, G., Bertram, V., and Soding, H., “Ship Wave-Resistance Computations”, Proc. 5th Int. Conf. Numerical Ship Hydrodynamics, Hiroshima, Japan, 1988.

[15] Raven, H.C., “The RAPID Solution of Steady Nonlinear Free Surface Problems”, Proc. 7th Int. Workshop on Water Waves and Floating Bodies, Val de Reuil, France, 1992.

[16] Raven, H.C., “A Practical Nonlinear Method for Calculating Ship Wavemaking and Wave Resistance”, 19th Symp. Naval Hydrodynamics, Seoul, South-Korea, 1992.

[17] Bertram, V., Laudan, J., and Jensen, G., “Validation Gives New Insights into Nonlinear Inviscid Flow Computations ”, 8th Int. Workshop on Water Waves and Floating Bodies, St John's, Canada, 1993.

[18] Duncan, J.H., “The Breaking and Non-Breaking Resistance of a Two-Dimensional Hydrofoil ”, Jnl. Fluid Mechanics, Vol.126, 1983, pp.507–520.

[19] Tulin, M.P., and Cointe, R., “A Theory of Spilling Breakers”, Proc. 16th Symp. Naval Hydrodynamics, Berkeley, 1986.

[20] Lin, W.M., Newman, J.N., and Yue, D.K.P, “Nonlinear Forced Motions of Floating Bodies”, Proc. 15th Symp. Naval Hydrodynamics. Hamburg, Germany, 1984.

[21] Van Daalen, E.F.G., “Numerical and Theoretical Studies of water Waves and Floating Bodies ”, Ph.D.Thesis, Twente University, Netherlands, 1993.

[22] Reed, A., Telste, J., Scragg, C, “Analysis of Transom Stern Flows”, Proc. 18th Symp. Naval Hydrodynamics, Ann Arbor, USA, 1990.

[23] Tulin, M.P., and Hsu, C.C., “Theory of High-speed Displacement Ships with Transom Sterns”, Jnl. Ship Research, Vol.30–3, 1986, pp. 186–193.

[24] Schmidt, G.H., “Linearized Stern Flow of a Two-Dimensional Shallow-Draft Ship” Jnl. Ship Research, Vol.25–4, dec. 1981, pp. 236–242.

[25] Vanden-Broeck, J.-M., “Nonlinear Stern Waves”, Jnl. Fluid Mech., Vol.96, part 3, pp.603–611.

[26] Toda, Y., Stern, F., and Longo, J., “Mean-Flow Measurements in the Boundary Layer and Wake and Wave Field of a Series 60 Cb=.6 Ship Model for Froude Number 16 and 316”, IIHR Report no. 352, Iowa, USA, 1991.

DISCUSSION

by Professor P.D.Sclavounos, MIT

1. Schmidt (1980) proves in his paper that for overhanging sterns, the coefficient C2 in the local expansion near the stern vanishes, thus establishing that the curvature of the wave profile is preserved in this case.

Author's Reply:

See common response for the above at the end of this section.

2. My question pertains to your experience with regard to the prediction of the wave resistance with your nonlinear method. Have you experienced improved predictions in the wave resistance which result from improved wave profile calculations?

Author's Reply

It has been found that slow-ship linearized methods:

-

generally predict the resistance reasonably well for relatively slender vessels at fairly high speed, with substantial wave making, but often underestimate the resistance otherwise;

-

generally predict a negative wave resistance for full hull forms at low Froude numbers. As shown in [3] this may be a result of a spurious momentum flux through the calculated free surface owing to the slow-ship linearization of the free surface boundary condition. One thus expects an improvement for a nonlinear method.

Current experience with RAPID indicates that:- for slender ships at high speed, the resistance prediction is good but not much different from that of a linearized method; -in some cases dominated by diverging waves, the resistance predicted by RAPID was much closer to experimental values;- for slow ships at low speed, the resistance is not consistently negative anymore, but it is hard to obtain an accurate prediction from pressure integration over the hull. This is due to the fact that, contrary to a linearized method, a nonlinear method requires the hydrostatic+hydrodynamic pressure to be integrated over the hull, which at low Froude numbers is a badly conditioned calculation.

More validations are, however, required. The accuracy of the resistance predictions, and possible alternative expressions for it, will be studied in the near future.

DISCUSSION

by Dr. D.Nakos, Intec Software & Consulting

In case that one of your iterations (towards the nonlinear solution) indicates that the flow separates at the stern before the ship transom, do you correct the assumed separation line?

Author's Reply:

See common response for the above at the end of this section.

DISCUSSION

by Dr. S.Kinnas, MIT

I would like to congratulate Dr. Raven for his impressive work. It appears to me that the detachment of the transom stream-surface is similar to the smooth detachment condition (Villat-Brillouin condition) for cavity flows, in which the cavity detaches at a point where the slope as well as the curvature are continuous. What are the author 's comments to this? Is this an adequate condition or we must consider the viscous flow in front of the detachment point similar to what is done for cavity flows by Arakeri, Frank, & Michel?

Author's Reply:

See common response for the above at the end of this section.

DISCUSSION

by Professor E.O.Tuck, University of Adelaide, Australia

I compliment the author on an excellent paper. My comment relates only to the minor matter raised at the end of it concerning transom sterns which are well above the undisturbed water level. This causes no extra difficulty with RAPID, apparently, which is as it should be. The only problem with this case is that the con-

verged results from RAPID passes a physically-unacceptable region of pressure less than atmospheric, just ahead of the transom. In practice, the flow would have detached prior to reaching the transom, perhaps quite next to the station where in the non-physical case studied, the pressure first goes negative (relative to atmospheric). In a similar planning context, I have had success in finding the actual detachment contour by iteration, the aim being to converge towards a final detachment contour or artificial transom on which not only the pressure but also the pressure gradient is zero. This is equivalent to requiring continuity of curvature, as well as slope, at detachment.

Author's Reply:

See common response for the above at the end of this section.

Author's Reply to Professors Sclavounos, Nakos, Kinnas, and Tuck

All above discussers address the problem of modeling the detachment of the free surface from a smooth surface, the bottom of a flat hull with the transom far above the undisturbed water level. If in a numerical solution the pressure on the hull falls below atmospheric pressure, this early detachment of the free surface may be supposed to occur physically. To model this, one should modify both the location of the detachment line and the assumed free surface behavior there. As mentioned in my paper this is not being done yet, and I had not yet given much thought to the details of this problem. The comments of the discussers are, therefore, welcomed.