4

Motivations and Mechanisms for Cooperation in Defense Technology

SUMMARY POINTS

-

Historically, Japanese licensed production of U.S. systems has evolved as the most common mechanism for U.S.-Japan defense technology collaboration because it represents a compromise between the Japanese preference for indigenous production and the U.S. preference for off-the-shelf sales.

-

Because of growing concerns in the United States over imbalanced flows of technology and the risk of enabling Japanese competition in commercial industries, reliance on licensed production has become increasingly problematic in recent years.

-

Other mechanisms have been pursued, such as integrating Japanese subsystems into systems sold to Japan by the United States, codevelopment, and small-scale collaborative research and development (R&D). Each of these mechanisms could deliver benefits to the United States, but each also involves barriers and potential pitfalls.

The United States and Japan have cooperated in defense technology and defense industrial areas for roughly 40 years. This chapter describes the mechanisms for U.S.-Japan cooperation in defense technology that have been important in the past as well as newer approaches with a focus on the motivations and impacts on the U.S. and Japanese sides. The major mechanism for collaboration is still Japanese licensed production of U.S. systems. Table 4-1 shows that Japan continues to be a large market for U.S. weapons, and that licensing fees constitute a large part of the total flow of income from Japan.

TABLE 4-1 Japan Defense Agency Overseas Procurement, current million dollars

|

From the United States |

||||||

|

Year |

Foreign Military Sales |

Direct Commercial Sales |

Licensing Fees |

Total |

From Other Countries |

U.S. Share, % |

|

1990 |

643 |

313 |

1,556 |

2,512 |

54 |

98 |

|

1991 |

890 |

488 |

1,206 |

2,584 |

84 |

97 |

|

1992 |

755 |

472 |

1,027 |

2,254 |

54 |

98 |

|

SOURCE: Mutual Defense Assistance Office, Tokyo, Japan. |

||||||

POSSIBLE U.S. BENEFITS

From the U.S. perspective, benefits from technological collaboration with Japan in the context of the defense relationship could come in a number of forms, as described below.

“Hard” Technology

This category of benefits can be defined as specific product or process knowledge that can be transferred in a straightforward way, mainly through data exchange. Hard technology is generally proprietary in nature, with transfer occurring through licensing or cross-licensing. Most of the defense technology that the United States has transferred to Japan through licensed production of U.S. systems and other mechanisms is of this type. In the case of the FS-X codevelopment, Japan was provided with about 95 percent of the 10,550-document F-16 technical data package.1 The “flowback” of Japanese improvements made to U.S.-derived technologies is written into government-to-government and many industry-to-industry agreements. For example, Mitsubishi Heavy Industries has transferred data on the FS-X composite wing to Lockheed Martin as flowback. To transfer hard technology effectively, exchanges of technical personnel and other forms of instruction are often required to supplement exchanges of data or drawings.

“Soft” Technology

This term describes knowledge that can be applied in improving quality or productivity but is not specific to particular products or processes. Soft technology includes techniques and practices for managing manufacturing systems and product development processes, which are developed over time in organizations (so-called tacit knowledge). In many cases, soft technology can be described, transferred, or adapted, given a favorable organizational context. One of the best-known examples of soft technology originating in Japan is the Toyota Production System, the set of practices for managing manufacturing.2 Although the transfer of such knowledge is facilitated by direct experience, soft technology of widespread significance tends to quickly become a public good.3

Leverage for Scarce Resources

Collaboration with Japan in defense-related R&D or production could leverage U.S. government or industry resources. For example, collaborative R&D in technical areas of mutual interest might facilitate access to a given scale of R&D effort at reduced cost. Codevelopment of systems or subsystems could leverage government budgets and industry engineering efforts. Licensing income from production of U.S. systems in Japan can be reinvested in developing more advanced technologies.

|

1 |

U.S. Congress, General Accounting Office, U.S.-Japan Codevelopment: Update of the FS-X Program (Washington, D.C.: U.S. Government Printing Office, June 1992), p. 5. |

|

2 |

See Toyota Motor Corporation, The Toyota Production System (Toyota City, Japan: Toyota Motor Corp., 1992). The Toyota Production System, or TPS, is also known as “lean manufacturing.” |

|

3 |

A growing number of U.S. manufacturers are adapting Japanese management practices in manufacturing and product development. See Rajan R. Kamath and Jeffrey K. Liker, “A Second Look at Japanese Product Development, ” Harvard Business Review, November-December, 1994, pp. 154-170. |

Influence and Goodwill

Through the range of interactions and relationships surrounding the security alliance, including collaboration in defense technology, the United States is able to influence aspects of Japanese defense and foreign policies, such as the choice of defense systems. Deployment of common or interoperable systems enhances the effectiveness of joint operations. Technology collaboration might also play a role in enhancing goodwill between the defense establishments and broader publics of the two countries.

MECHANISMS FOR COOPERATION

Japanese Procurement of U.S. Systems: “Off-the-Shelf” and “Blended” Modes

While this form of U.S.-Japan interaction by definition does not involve extensive technology transfer in the traditional sense, it serves as a useful baseline to begin evaluating the motivations and benefits on each side for various forms of interaction and emerging trends. Historically, defense technology transfers from the United States to Japan have occurred in the context of Japanese procurement. As Japan considers a given weapons system, purchase from the United States or other supplier countries represents one option along a continuum that may include licensed production, codevelopment, and indigenous development.

In the case of many off-the-shelf sales, money is simply paid for a given system, with very little technical activity associated with the exchange.4 The benefits to the United States from this arrangement come in several forms. First, the procurement allows Japan to contribute more to its own defense through increased capability. Second, a purchase of U.S. equipment ensures interoperability with the equipment used by U.S. troops already based in Japan as well as those likely to be deployed in the theater during a contingency. Third, the United States avoids several risks sometimes associated with technology transfer through licensed production, including proliferation to hostile countries, future Japanese development of indigenous systems based on the transferred technology, and utilization of transferred technology to compete with U.S. companies in commercial markets. Fourth, the proceeds from weapons sales to Japan help to maintain the U.S. defense technology and manufacturing base.

Traditionally, Japan has preferred licensed production and indigenous development—procurement mechanisms that its domestic industry can utilize to either obtain U.S. technology or develop indigenous capability —to purchases.5 With downward pressure on the Japanese defense budget and the growing cost advantage of U.S.-produced weapons as a result of the recent yen appreciation, there would appear to be added incentive for Japan to increase purchases of U.S. equipment relative to more expensive licensing and indigenous development options. However, Japanese defense contractors and their allies can also be expected to fight hard to retain as much domestic development and manufacturing as possible. In recent years, AWACS

|

4 |

Soft technology in the form of knowledge necessary to operate the system effectively is transferred. Japan and other countries purchasing U.S. systems are also generally able to buy upgraded versions of the systems. |

|

5 |

In addition to gaining technological and manufacturing base benefits, Japan’s rationale for licensed production or indigenous development has often involved complaints about the high cost of U.S. systems and poor service. See Michael Chinworth, Inside Japan’s Defense (Washington, D.C.: Brassey’s (US), Inc., 1992)., pp. 124-126. |

(airborne warning and control system) and other large off-the-shelf purchases have raised concerns in Japan’s defense industry.6

For the most complex defense systems, or so-called systems of systems, the distinctions between purchases and other forms of collaboration such as licensed production and codevelopment can blur. One recent example is the Japanese procurement of Aegis destroyers.7 The overall battle management system was sold to Japan through the Department of Defense’s (DoD) foreign military sales (FMS) program, so technology transfer in the traditional sense was limited. However, Japan’s Aegis procurement has involved extensive U.S.-Japan technical and engineering interaction because the destroyer hulls and several of the individual weapons systems are designed and manufactured in Japan. The integration of Japanese elements into the U.S.-developed system required the creation of new interfaces to maintain the real-time information management critical to the system’s operation.

The Aegis experience is relevant to future U.S.-Japan cooperation because several of the capabilities that Japan is considering for the future, such as theater missile defense and reconnaissance satellites, have a “system of systems” character and could potentially involve a blending of components developed and produced by the United States, Japan, or both countries. Particularly in cases where one-way technology transfer is not extensive, with this type of “blended” interaction in which U.S. and Japanese technological and engineering contributions are combined within the overall framework of a Japanese purchase of a U.S. system, both countries can achieve clear benefits.

Several factors contributed to success in the Aegis case. To begin with, there was widespread support in Japan for the top-level decision to deploy the system. Aegis allows Japan to fulfill operational roles within the framework of the U.S.-Japan alliance that had been committed to in the early 1980s.8 Building the hulls in Japan and utilizing several Japanese weapons systems—combined with the fact that indigenous development of the entire system was not a realistic option—solidified this support in Japanese industry and government. Also, the U.S. Navy and U.S. contractors had accumulated valuable experience from managing the complex U.S. program for a number of years and were able to effectively apply this experience in working with their Japanese counterparts. It is important to note that several of the political and management factors that contributed to the success of Aegis might not be present in potential areas of future U.S.-Japan collaboration, such as theater missile defense (see Box 4-1 and Appendix D).

In the case of Aegis, the benefits to the United States were not technological—Japan’s deployment of the system constitutes an enhanced contribution to the alliance, the income from the sale strengthens the U.S. defense industrial base, and the outward flow of technology was limited compared to licensed production. In the future the challenge will be to structure such programs so that they do facilitate technology transfer to the United States.

While the main obstacle to sales of U.S. systems is Japan’s reluctance—shared by many other countries—to avoid large foreign arms purchases that do not involve significant Japanese production, development, or learning opportunities, there are other potential obstacles. In some cases, parties on either side may prefer to structure the procurement as a direct commercial sale

|

6 |

National Research Council, Committee on Japan, High-Stakes Aviation (Washington, D.C.: National Academy Press, 1994), p. 29. |

|

7 |

See Appendix E. |

|

8 |

See U.S. Congress, Office of Technology Assessment, Arming Our Allies: Cooperation and Competition in Defense Technology (Washington, D.C.: U.S. Government Printing Office, 1990), pp. 109-110. |

|

Box 4-1 Navy International Programs Office A number of U.S. government organizations have responsibility for aspects of international defense industry cooperation.1 In addition to DoD organizations such as the Defense Security Assistance Agency, the Defense Technology Security Administration, and the Office of the Under Secretary of Defense for Acquisition, the military services play a role as well. The U.S. Navy’s International Programs Office (IPO) deals with a variety of issues associated with the sale of naval weapons systems and the transfer of related technologies. IPO ’s areas of responsibility include export license review, foreign military sales (FMS), coproduction and cooperative development programs, arms control treaty compliance and verification, and advising U.S. defense industries on international marketing. The U.S. Army’s equivalent of IPO is the Security Affairs Command, while the Air Force counterpart is the International Affairs Division of the Office of the Secretary of the Air Force. A wide range of sophisticated naval weapons systems and technologies have been transferred to Japan through commercial sales, foreign military sales, and coproduction agreements. Representative commercial sales include MH-53 and SH-3 helicopters, LM2500 gas turbine engines, and Landing Craft Air Cushion vehicles. FMS sales have included Aegis integrated combat systems, Harpoon antiship and Standard antiaircraft missiles, vertical launch systems, E-2C Early Warning Aircraft, and UYK-43B and -44 computers. In addition, Japan has been permitted to coproduce Mk 46 torpedoes, SH-60/UH-60 helicopters, P-3C Orion antisubmarine aircraft, and Seasparrow and Sidewinder missiles. Finally, the United States and Japan have entered into a cooperative program to develop advanced steel technology under the rubric of the Systems and Technology Forum. Naval commercial programs with Japan (including sales, coproduction, and licensing) have brought in approximately $400 million annually in recent years. Navy FMS programs have amounted to $800 million annually, or about half the total annual FMS to Japan recently.

|

from the U.S. manufacturer, rather than going through the FMS program. For a direct commercial sale, the U.S. contractor obtains an export license from the Department of State, which consults with the DoD ’s Defense Technology Security Agency. In the case of FMS, DoD essentially purchases the system from the U.S. manufacturer and sells it to the foreign government.9

|

9 |

For a general description of FMS and direct commercial sales procedures and issues, see U.S. Congress, Office of Technology Assessment, Global Arms Trade: Commerce in Advanced Military Technology and Weapons (Washington, D.C.: U.S. Government Printing Office, 1991), pp. 56-61. In the case of Japan, resistance to FMS often reflects the preference for licensed production mentioned above. For example, recent MIT Japan Program surveys found that both U.S. and Japanese industry respondents advocate greater DoD flexibility in allowing systems to be licensed produced rather than sold through FMS. See Michael Green, The Japanese Defense Industry’s Views of U.S.-Japan Collaboration: Findings of the MIT Japan Program Survey, 1994, and Matthew Rubiner, U.S. Industry and Government Views on Defense Technology Cooperation with Japan: Findings of the MIT Japan Program Survey, 1994. |

Japanese Licensed Production of U.S. Systems

This has been a common form of U.S.-Japan interaction over the past 40 years. Japan has produced many U.S. aircraft, missiles, and other weapons systems under license.

Some of the benefits that have traditionally accrued to the United States from Japan’s licensed production of U.S. weapons systems are comparable to the benefits from a purchase—expanded Japanese capability, income for U.S. manufacturers (albeit without manufacturing base benefits of U.S. production), interoperability, influence, and goodwill. 10 The United States might also benefit from the flowback of Japanese improvements derived from licensed technology.11 However, licensed production involves several risks for the United States that do not arise in sales of equipment.

First, there are traditional security and proliferation concerns—that U.S. weapons technology licensed to Japan might leak to third countries that could utilize it contrary to U.S. interests. There have been cases over the years of Japanese companies violating export controls, including the recent notable case of Japan Aviation Electronics selling missile parts, including parts made under U.S. license, to Iran.12 Although such cases are disturbing, it does not appear that they are widespread.

Another risk is that Japanese licensees may use the expertise and manufacturing base established through licensed production to develop indigenous systems and subsystems, displacing U.S. companies in later procurements. A 1992 General Accounting Office report documents that Japanese firms cited their experience in F-15 licensed production to demonstrate their capability to supply the FS-X program.13 The down side of this market risk has been experienced by U.S. firms but has been largely limited to the Japanese defense market to date because of Japan’s proscription of arms exports.14 This could change if the arms export ban is lifted in the future. In several areas of defense systems, notably aircraft and missiles, Japan has pursued a strategy of moving from purchasing U.S. systems to licensed production to indigenous development.15

A final risk of licensed production, from the U.S. standpoint, is that the technology and expertise transferred to Japanese companies will be utilized to compete with U.S. companies in nondefense areas. The long-term impact of the flow of U.S. technologies accompanying Japanese licensed production has been a topic of interest, concern, and debate for some time, with aircraft

|

10 |

There are, however, doubts about the degree of interoperability that can be maintained in a licensed production program. This is particularly true in the case of a complex system, such as the F-15, in which Japan produces replacement parts and may not incorporate all the engineering changes that have occurred over the course of the U.S. program. See Chinworth, op. cit., pp. 129-131. |

|

11 |

A number of U.S. companies involved in defense technology cooperation with Japan report that flowback occurs regularly, but most do not consider it a major motivation for cooperating. See Rubiner, op. cit., p. 14. |

|

12 |

See Jeff Shear, The Keys to the Kingdom: The FS-X Deal and the Selling of America ’s Future to Japan (New York: Doubleday, 1994), p. 282. |

|

13 |

U.S. Congress, General Accounting Office, Japanese Firms Involved in F-15 Coproduction and Civil Aircraft Programs (Washington, D.C.: U.S. Government Printing Office, 1992), p. 10. |

|

14 |

For several examples, see Chinworth, op. cit., pp. 120-124. |

|

15 |

The technological capabilities of Japan’s defense industry are more impressive in areas where commercial capabilities have been brought to bear and are generally lagging or uneven in the most specialized, advanced defense equipment. See Arthur Alexander, Of Tanks and Toyotas: An Assessment of Japan’s Defense Industry (Santa Monica, Calif.: RAND Corp., 1993). |

being a particular focus.16 Drawing on the work of the individual scholars and groups that have examined the historical context and trends, it is possible to draw several lessons from the experience of Japanese licensed production that can be applied to future U.S.-Japan collaboration.

An important distinction to make in evaluating the impacts of licensed production on Japan’s aircraft-related technological and industrial capabilities is between the benefits that are clearly technological and those that accrue from the manufacturing opportunities afforded by licensed production itself.

The manufacturing base benefits of licensed production for Japan’s military and commercial aircraft capabilities have been and still are extremely critical. Licensed production of U.S. military aircraft has served as a foundation for the development of the Japanese aircraft industry. This activity sustained the growth of the industry through the 1960s and 1970s, when the only commercial aircraft activities were the ill-fated YS-11 and some minor subcontracting. The biggest benefit to Japan’s aircraft industry, therefore, has been licensed production’s crucial role in building and sustaining the engineering and manufacturing base of the heavy industrial manufacturers that serve as prime contractors for most Japanese aircraft programs and the entire supplier infrastructure. Licensed production has also benefited sectors other than aircraft. Licensed production and Japan ’s own indigenous weapons and technology programs have also delivered significant benefits for Japan’s machinery industries and overall manufacturing and technology base, particularly in the 1950s and 1960s when defense products accounted for a significant share of total manufacturing activity.17

Purely technological contributions to Japan’s capabilities in military aircraft have been important but have not yet propelled Japan into the “big leagues” of the global aerospace industry. Japan has independently developed a series of trainers and day-fighters. These have performed well, and the experience from licensed production must have been a help. But these aircraft have not exhibited cutting-edge design and integration capabilities. In the view of some experts, the experience of the FS-X program, discussed in more detail below, indicates that Japanese industry still had not acquired these skills by the late 1980s.18

In several specific areas the technological benefits of military licensed production programs for Japan’s commercial aircraft industry are clear and compelling. This is particularly true for engines and some subsystems. Ishikawajima-Harima Heavy Industries first made long shafts in F100 licensed production and now dominates the worldwide commercial market for this component.19 Blade casting is another example of a jet engine technology that was transferred through licensed production and is now utilized in commercial products.s20 The General

|

16 |

Among the sources that cover the topic are G. R. Hall and R. E. Johnson, “Transfers of United States Aerospace Technology to Japan, ” in R. Vernon, ed., The Technology Factor in International Trade (New York: National Bureau of Economic Research, 1970); U.S. Congress, General Accounting Office, U.S. Military Coproduction Programs Assist Japan in Developing Its Civil Aircraft Industry (Washington, D.C.: U.S. Government Printing Office, 1982); Michael Chinworth, Inside Japan’s Defense (Washington, D.C.: Brassey’s (US), Inc., 1992); Richard J. Samuels, Rich Nation, Strong Army: National Security and the Technological Transformation of Japan (Ithaca, N.Y.: Cornell University Press, 1994); and National Research Council, High-Stakes Aviation, op. cit. |

|

17 |

Samuels, op. cit., particularly Chapter 6. |

|

18 |

National Research Council, High Stakes Aviation, op. cit., p. 45. |

|

19 |

Ibid., p. 138. |

|

20 |

There are also examples of aircraft technologies in which U.S. restrictions on technology transfer provided impetus for Japanese companies, sometimes in conjunction with the Japan Defense Agency, to develop indigenous capabilities. In many cases these capabilities represented improvements on technologies transferred by the United States in earlier programs. See Michael Chinworth, Inside Japan’s Defense, op. cit., especially Chapter 4 and Chapter 5. |

Accounting Office report cited above also found that several Japanese suppliers participating in the F-15 program supply similar components in Boeing commercial programs.21

Japan has utilized licensed production of U.S. weapons systems to build and sustain industrial and technological capabilities that can be applied in both military and commercial production, a strategy that has been relatively successful.22 However, it is notable that the basic technology in other specific commercial aircraft component areas where Japanese companies are very competitive today—fuselage panels, composite materials, and flat panel displays—did not come through military licensed production. Existing Japanese capabilities—some developed in other industries —were enhanced and developed primarily through links with U.S. commercial aircraft manufacturers. Still, military production affords Japanese industry opportunities to further refine technologies, and to apply these refinements to civilian markets. One recent example is the multifunction display that Yokogawa Electric developed for the FS-X. Yokogawa reportedly plans to apply the technology to civilian markets. 23

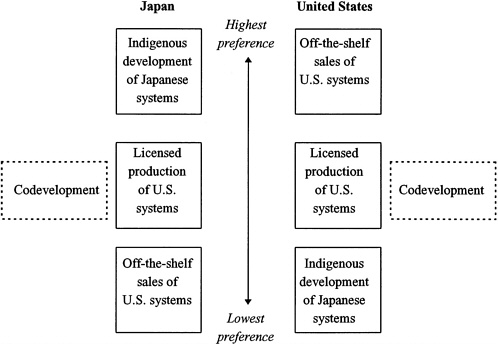

Figure 4-1 shows the traditional preferences of Japan and the United States toward various collaborative mechanisms and illustrates why licensed production has often been utilized as a compromise between U.S. and Japanese preferences. The key questions for the future are how U.S. and Japanese objectives are likely to mesh and the implications of trends in both countries for U.S. strategy making toward licensed production. As has been pointed out, the United States may no longer have a compelling interest in a rapidly growing Japanese military capability. Therefore, the U.S. government’s incentive to use licensing as an inducement for Japanese procurement of a given system might be expected to diminish. On the other hand, U.S. defense companies might have greater incentive to license systems to Japan as the U.S. defense budget remains lean.24

DoD’s Technology-for-Technology (TFT) initiative implies that traditional licensing deals in which technology flows only to Japan may no longer be acceptable. Economic security and technology reciprocity concerns could constitute an obstacle on the U.S. side to cooperation in the future, particularly if these concerns are not taken into account in U.S. planning. An interagency process to assess the impacts of major defense technology transfers was stipulated in the Defense Authorization Act of 1989, but in the first major test, the FS-X (see Box 4-2), conflicts between various U.S. interests were not resolved in an effective way, leading to a contentious process. DoD has recently implemented organizational changes to ensure adequate consideration and consultation, but these new arrangements have not yet been tested in a major U.S.-Japan program.25

Japan must balance competing interests as well. As has been noted, it has pursued a strategy of producing and developing indigenously where possible, even if domestic weapons cost more and do not perform as well as imported systems. Barring a major shift in the external

|

21 |

U.S. Congress, General Accounting Office, op. cit., p. 10. |

|

22 |

This is covered in great detail in Samuels, op. cit. |

|

23 |

“Minsei Bunya ne Tenyo,” (Applying to Civilian Sector), Nihon Keizai Shimbun, June 19, 1995, p. 13. |

|

24 |

See Michael Green, The Japanese Defense Industry’s Views of U.S.-Japan Defense Technology Collaboration: Findings of the MIT Japan Program Survey, op. cit., and Rubiner, op. cit. |

|

25 |

See “Industrial Capabilities for Defense,” in Department of Defense, Director, Defense Research and Engineering, Defense Science and Technology Strategy (Washington, D.C.: U.S. Government Printing Office, 1994), pp. 12-16. |

FIGURE 4-1 Traditional U.S. and Japanese preferences for interactive mechanisms.

SOURCE: National Research Council Defense Task Force.

environment, it will be more difficult to pursue this strategy in the future. There will be continuing pressure on the defense budget no matter how the current political turmoil plays out. These pressures will likely be intensified by Japanese defense budget practices which have delayed payments for current procurements and left major obligations to arms makers for the out years.26 Japan is currently developing a number of indigenous systems for which there are existing U.S. substitutes. Licensed production costs more than purchasing from abroad but could maintain the manufacturing base at a lower cost than indigenous development.

One area where these trends might have important future implications is fighter aircraft. Japan is nearing completion of FS-X development, with test flights scheduled to begin in autumn 1995. The major decisions on the number of planes that will be built, or even whether the FS-X will enter production, were under discussion at the time of this writing. In recent years Japan has had an indigenous aircraft development project of some sort ongoing at all times in order to maintain its base of engineers and designers. These indigenous military aircraft projects included the F-1 fighter, the C-1 transport, and the T-2 and T-4 trainers. Now under discussion are plans to develop a technology demonstration fighter to occupy engineers after the end of FS-X development. 27 Currently, the licensed production of the F-15 is the mainstay of the Air Self-Defense Force, and procurement of the FS-X would supplement that.

|

26 |

See Chinworth, op. cit., pp. 50-55. |

|

27 |

“Yuranki o Dasshita Jieitai” (Self-Defense Forces Pass Through Period of Uncertainty), Nikkei Business, October 31, 1994, pp. 38-40. |

Beyond the next few years, however, the concrete demand for fighter aircraft in Japan is unclear. In the United States the F-22 is now entering production, but projected procurement has been cut with the end of the Cold War. A slowdown in the pace of global technological development in fighters means that from a purely military standpoint the rationale for more capable Japanese fighters is hard to make. It might be some time before Japan is opposed by a country with fighters as capable as the F-15.

The plan to develop a technology demonstration fighter can give Japan flexibility in this uncertain environment. If nothing else, the program will maintain the technology base of skilled engineering and design know-how. Japan’s military needs may be adequately met for the foreseeable future by F-15s, T-4s and possibly FS-Xs, in which case the technology demonstrator might not be followed up by an indigenous development or licensed production program. In addition, just as the Japan Defense Agency’s (JDA) Technical Research and Development Institute (TRDI) focused on R&D programs in the late 1970s and early 1980s aimed at technologies that the United States did not release to Japan—the so-called black boxes—in the F-15 licensed production program, the technology demonstrator could be aimed at achieving greater bargaining power if licensed production of the F-22 is judged to be desirable down the line.28 The project also keeps the option of indigenous development open. Finally, some of the technologies reportedly targeted for the demonstrator —such as fly-by-light actuation—are relevant to future commercial aircraft programs.29 Japanese aircraft makers and government officials are still considering the development of a 100-seat commercial transport in cooperation with foreign companies.30

The plans for a technology demonstrator indicate that despite the current budget situation and uncertain security environment Japan is determined to maintain its skill and technology base in fighter aircraft, which has allowed it to effectively produce advanced foreign designs and to indigenously develop less capable aircraft. It is possible that Japan, which has tried where possible to build technological capabilities across a range of weapons systems, will in the future narrow the focus and continue to combine indigenous development and assimilation of U.S. technology as appropriate. It is likely that some of the many indigenous projects that are being investigated and developed will be dropped. Whether Japan opts for licensed production, seeks codevelopment, or purchases foreign systems to fulfill some of those plans is uncertain.

Two general approaches are possible. Japan could continue the course of spending more on defense R&D, including technology development and prototyping, in an environment of flat or declining overall procurement. In this case, procurement might focus on spending more to bring key indigenous programs into production, while fulfilling other needs through purchases from the United States and perhaps other overseas suppliers. This would imply less licensed production activity than is currently taking place. A second possibility is a greater emphasis on maintaining the defense manufacturing base, which could imply a move away from indigenous systems to greater licensed production, with a defense R&D emphasis on subsystems that could be incorporated into licensed systems and used as bargaining leverage in negotiating technology

|

28 |

For details on TRDI’s efforts to build Japan’s technology base for development of the FS-X, see Samuels, op. cit., pp. 233-236. |

|

29 |

Nikkei Business, op. cit. |

|

30 |

Japan’s ambition to join the front ranks of the commercial aircraft industry continues to face challenges, as seen in the prospects for the 100-seat YSX. Uncertainties about the market, possible competition and gaining foreign cooperation on favorable terms threaten the project. See Hirofumi Matsuo, “China-Korea Aircraft Plans Threaten YSX,” The Nikkei Weekly, July 17, 1995, p. 17. |

|

Box 4-2 The FS-X Program Sweeping conclusions about the FS-X are premature, since the development phase is only now reaching a conclusion, and critical issues such as the actual performance and procurement of the aircraft have yet to be resolved. The process of structuring this U.S.-Japan codevelopment program marked something of a watershed in Japan’s security policies and U.S.-Japan relations. Soon after the launch of F-15 licensed production in the late 1970s, the Japan Defense Agency, Air Self-Defense Force, and industry began considering options for replacing the domestically-developed F-1 fighter. Japanese industry and some elements in the government began the process with a presumption in favor of a domestically developed fighter. Increasing domestic content, gaining greater managerial control over the program than was possible in a licensed production arrangement, and controlling costs (the costs of licensed U.S. aircraft increased by an average factor of four with each program from the F-86 to the F-15) were all considerations. Perhaps the most important factor was an underlying sense that Japan’s position in the aircraft industry was fragile, and that passing up domestic development would consign Japan to a follower role forever.1 By the time serious feasibility studies were launched in 1986, the momentum in Japan for a domestic aircraft was quite strong. During 1986 DoD became increasingly concerned with the specifications and low development cost estimates, and began a more aggressive push for the FS-X to be based on an existing U.S. design. In October 1987 the United States and Japan reached an agreement to “codevelop” an FS-X based on the General Dynamics F-16 design. Through late 1987 and 1988 a memorandum of understanding (MOU) for the development program was negotiated and then was signed in late 1988. With the Bush administration coming into office in early 1989, congressional concerns over the FS-X agreement were raised in confirmation and other hearings. Contentious debate over the agreement continued through the spring of 1989, with opponents arguing that F-16 technology transfers would contribute to Japanese competitiveness in commercial and military aircraft—to the long-term detriment of U.S. industry —that off-the-shelf Japanese procurement of F-16s would cut the huge U.S. trade deficit with Japan while addressing Japan’s security needs more economically, and that Japanese technical capabilities were not high enough for the flowback provisions to deliver many benefits to the United States. U.S. proponents argued that significant U.S. participation in the FS-X program was better than none at all, that Japanese procurement of unmodified F-16s was not a realistic scenario, and that flowback would bring considerable benefits. In the end congressional opponents were not able to stop the FS-X agreement but were able to force DoD to gain a “clarification” of several key points. First, the Japanese explicitly committed to a 40 percent U.S. work share during the development phase and to providing access to Japanese-developed technologies. Second, the denial of several key F-16 technologies —including computer source codes, software for the fly-by-wire flight control system, and other avionics software—was made explicit. The episode threw into sharp relief the contrast between the contentious divisions over Japan policy in the United States and the much more united front—albeit with some bureaucratic infighting—that Japan presents to the United States in bilateral negotiations. In addition, the contention left heightened resentment on both sides. |

|

The first FS-X prototype was “rolled out” in January 1995. Development was delayed during 1991 and 1992—in part because of sanctions placed on Japan Aviation Electronics after it was found to have violated export controls.2 Japanese decisionmaking on FS-X production and negotiation of a U.S.-Japan MOU on the production phase (assuming the fighter goes into production) lie in the future. One complication is possible disagreement over development issues, particularly flowback. The original development MOU defined four areas of nonderived technology, meaning that U.S. companies could license technologies in those areas for a fee, but would be entitled to Japanese developments in other areas at no charge.3 Although the FS-X is politically dormant as this is written, Japan is reportedly seeking to reclassify a number of technologies as nonderived, a move that could reignite controversy.4 Keeping in mind the remaining uncertainties, it is possible to draw the following preliminary conclusions about the FS-X program: (1) contention surrounding the negotiation and clarification of the development MOU serves as an important warning—the exercise strained mutual trust and left significant constituencies on both sides thinking that the agreement represents a “giveaway” to the other side; (2) despite controversial beginnings and delays, outlined above, the industry-to-industry relationships, including the flowback of composite wing technology to Lockheed Martin ’s Fort Worth division from Mitsubishi Heavy Industries, are reported to be working effectively; (3) notwithstanding the flowback data, the major benefit to the United States from the program is the licensing and sales income for participating U.S. companies, rather than technology flow from Japan5; (4) U.S. government and industry structures designed to manage traditional international security and defense industry relationships were shown to be inadequate to reconcile trade-offs between the various fundamental U.S. interests at stake; and (5) as a result of the FS-X experience, both countries will likely be wary about pursuing codevelopment in the future. The FS-X case highlights several of the central questions with which this study is concerned, including whether traditional licensed production arrangements with Japan involving one-way technology flows continue to serve U.S. interests and how U.S. government and industry should organize themselves to integrate and pursue a broader set of U.S. interests.

|

transfers. It is possible that for some areas and systems Japan will pursue a technology-oriented strategy and that in others it will pursue a manufacturing-oriented strategy.31

U.S.-Japan Codevelopment of Defense Systems

This is a collaborative mechanism with which the United States and Japan have had little experience thus far. The only example is the FS-X fighter, which is quite different from most codevelopment programs, as described below. Codevelopment is an increasingly popular form of international collaboration in weapons development worldwide, but most of the successful (as well as unsuccessful) examples to date come from Europe.32 There are also important differences between the FS-X and European codevelopment programs, such as the Anglo-Italian-German Tornado fighter. For example, in European programs all of the countries participating in development and production normally enter the venture with an intention to procure the system, and the program is generally integrated from the concept evaluation stage. In the case of the FS-X, American F-16 technologies were used as a basis for the program, Japan has taken the leading role in development, the U.S. side receives licensing income and flowback, and the fighter—if it does go into production —will be procured only by Japan.

At first glance it would appear that both the United States and Japan would have increasing motivation to pursue codevelopment, owing to the budget constraints in each country. For example, a number of U.S. weapons programs have been delayed or canceled in recent years. 33 It is conceivable that one or more of them might fit in with Japanese operational requirements or ongoing development programs. U.S.-Japan codevelopment could be a solution for bringing some of these programs forward.

However, even if the United States and Japan can define a mutual interest in one or more such systems, there would be several obvious challenges in structuring a program. First, the unequal technological levels of U.S. and Japanese defense companies, combined with differences in most U.S. and Japanese requirements, would stand in the way of forming “consortia of rough equals” along the lines of European programs.34

Perhaps a more promising codevelopment model would be a U.S.-led effort in which Japanese companies play the role of key subcontractors, developing and producing subsystems for weapons that would be procured and fielded by both sides. 35 This would be analogous to the

|

31 |

Private advisory committees to the JDA issued reports recently on defense production and defense technology. Boei Sobihin Chotatsu Kondankai (Advisory Committee on Defense Equipment Procurement), Boei Sobihin Chotatsu Kondankai Hokokusho, December 1993, notes the difficult environment for defense production and recommends adopting stable, medium-term budgeting plans to aid industry planning, streamlining the acquisition process, and increasing the use of items with commercial specifications. Boei Sangyo Gijutsu Kondankai (Advisory Committee on Defense Industry Technology), Boei Sangyo Gijutsu Kondankai Hokokusho, March 1994, also recommends stable planning, and calls for more effective U.S.-Japan cooperation. The latter report identifies four key defense technologies that Japan should focus on for the future: software, sensors and data-processing, robots, and materials. |

|

32 |

American companies have been involved in some codevelopment programs, such as the AV-8B Harrier II with Britain. See Richard A. Blitzinger, “The Globalization of the Arms Industry: The Next Proliferation Challenge, ” International Security, Fall 1994, pp. 170-198. |

|

33 |

John Mintz, “Defense Memo Warns of Cuts in Programs,” The Washington Post, August 22, 1994. |

|

34 |

European weapons consortia have had a high rate of failure. There are indications, however, that the success rate may be improving with experience. |

|

35 |

According to a recent MIT Japan Program study, Japanese defense contractors believe that U.S.-Japan cooperation in developing subsystems is a promising mechanism for enhanced interaction. See Green, op. cit. |

approach used by Boeing, General Electric, and Pratt & Whitney in structuring international commercial airframe and jet engine programs. In this case, however, Japan’s arms export ban could complicate or prevent Japanese-developed or manufactured parts from being incorporated into systems procured by the United States, making such cooperation less attractive for Japanese industry (see Box 4-3).36 If systems-level codevelopment focused on JDA requirements, it would almost ensure asymmetries—Japan would inevitably be providing most or all of the funding. On this basis, codevelopment would probably resemble a licensed production program with more scope for technological contribution by Japan (similar to FS-X), rather than an integrated collaborative effort in which both sides have a comparable stake. In this circumstance it would be difficult to avoid the traditional pattern of one-way technology flow.

Notwithstanding these sorts of obstacles, one area for U.S.-Japan cooperation in defense technology that has been discussed recently is theater missile defense (TMD) (see Appendix D). The basic objective of TMD is to provide protection for U.S. and allied forces and civilian populations against ballistic missile attacks in a limited region. Some analysts also believe that credible TMD capabilities can deter possible adversaries from expensive efforts to develop and deploy ballistic missiles. Concern about possible ballistic missile threats in Japan has been prompted primarily by the activities of North Korea.37 In addition to concerns about its efforts to produce nuclear weapons, North Korea is developing ballistic missile capabilities that would enable it to attack Japan. Furthermore, while Japan currently enjoys stable relations with Russia and China, both nations possess nuclear ballistic missiles capable of striking Japan. Japan, because of its relatively small geographic area, is well suited to TMD; indeed, for Japan a TMD system would approximate national missile defense.

The United States has made significant investments in technologies related to missile defense over many years. Three programs form the core of U.S. near-term plans to introduce more advanced ballistic missile defense systems. Patriot antitactical ballistic missile (ATBM) capabilities will be improved with upgraded software, electronics, and missiles incorporated into the PAC-3 expected in late 1998 or early 1999. Navy Aegis destroyers are expected to be equipped with extended-range missiles modified to perform the “lower tier” ATBM role in 1999. Theater high altitude area defense (THAAD) missile systems coupled to long-range, ground based radar for ballistic missile defense beyond the range of Patriot are expected to reach Army field units in 2001. 38

Limited funding and technical uncertainties have delegated three other ballistic missile defense programs to longer-term development. The Corps SAM (surface-to-air missile) program would provide mobile ATBM capabilities to U.S. Army forces. Either sea-based THAAD or the addition of Aegis ATBM missiles with LEAP (lightweight exo-atmospheric projectile) capabilities would give the Navy “upper tier” ATBM capability expanding the range of coverage beyond the currently planned Aegis ATBM system. Finally, several options exist for a boost/ascent-phase ballistic missile intercept capability.39

|

36 |

This sort of arrangement appears to work very well in commercial aircraft production. See Box 4-3 for a discussion of Japan’s arms export controls. |

|

37 |

Susumu Awanohara, “My Shield or Yours?”, Far Eastern Economic Review, October 14, 1993, p. 22. |

|

38 |

David Hughes, “BMDO Under Pressure to Set TMD Priorities,” Aviation Week and Space Technology, January 17, 1994, pp. 49-50. |

|

39 |

Ibid. |

|

Box 4-3 Japanese Restrictions on Weapons Exports Although Japan’s “three principles” governing arms exports and subsequent policy statements are not legislation, they have been in force for a number of years and carry considerable political force. In 1967 Prime Minister Sato declared the three principles, stating that arms exports would not be permitted to: “(1) Communist bloc countries; (2) Countries to which the export of arms is prohibited under United Nations resolutions; and (3) Countries which are actually involved or likely to become involved in international conflicts.”1 The 1967 declaration was supplemented in 1976, when Prime Minister Miki announced the “Unified Government View of Arms Export,” which reaffirms the three principles and goes on to state that “the export of arms to other areas which are not subject to the three principles shall be restrained in line with the spirit of the Constitution and Foreign Exchange and Foreign Trade Control Law. . .” and that “equipment related to arms production shall be treated in the same category as ‘arms’.”2 This statement also defines “arms” to mean “what military forces directly use for combating.” In 1981 both houses of the Japanese Diet adopted a resolution reaffirming the three principles and calling for institutional improvements to deal with arms exports in light of “instances which contravened the stated government policy.”3 In 1983 an exchange of notes between the United States and Japan was completed, allowing for the transfer of Japanese military technology, along with articles necessary to make technology transfer effective, to the United States as an exception to the three principles.4 Japan’s export controls are administered by the Security Export Controls Division of the Ministry of International Trade and Industry (MITI). Although a wide range of U.S. policymakers and other experts agree that continued Japanese adherence to the three principles is consistent with U.S. interests, the experience of the National Research Council Defense Task Force members and expert briefings during the course of the present study raised two areas in which the implementation of Japanese policies can act as a barrier to cooperation. The first area involves cases in which U.S. companies have wanted to incorporate Japanese components based on commercial technology into their defense systems or subsystems, but where a minor modification of the component was necessary for the defense application. Japan’s enforcement of its export controls allows for minor modifications on a case-by-case basis.5 However, the Defene Task Force is aware of instances in which American companies have been told by Japanese counterparts that components embodying commercial technology with minor modifications for a defense application would be prohibited. In several cases, the U.S. company followed up by pursuing a technology license, which is clearly allowed under the exchange of notes, but was refused due to the Japanese counterpart’s concerns that the licensed technology would be utilized to make competing commercial products.6 It is the impression of a number of U.S. and Japanese observers that Japanese companies may invoke the three principles when collaboration with U.S. defense contractors is not desirable for other reasons. 7 An underlying technology might have been developed in order to manufacture commercial products for a large market. The market represented by a component sale to a U.S. defense system might be quite small in comparison, but developing the component could require a considerable engineering effort. Japanese companies were reluctant to develop flat panel displays for the U.S. companies supplying avionics for the Boeing 777, a purely commercial |

|

venture that also required a significant engineering effort for a limited market.8 Due to the political sensitivity Japanese companies feel to becoming known as “arms makers,” many firms are reportedly reluctant to do business with JDA, let alone DoD. In at least one case of refusal on the part of Japanese companies to transfer technology to U.S. companies in which the “three principles ” have been implicated or invoked, it appears that concerns about potential competitive utilization of the technology may have been involved. For example, Mitsubishi Heavy Industries (MHI) rebuffed McDonnell Douglas’s effort in the 1980s to license technology connected with the LE-5 engine for Japan’s H-I rocket, ostensibly because the technology might be used to launch military spacecraft.9 However, as the technology’s application in Japan was purely commercial, a very strict interpretation of the principles would have been required to restrict such a license. Procedures for transfers of military technology to the United States also existed at this point, and could have been utilized had it been necessary to classify the technology as military. In another case in the early 1980s, General Motors expressed interest in licensing technology used in the production of MHI’s 74-type tank, particularly the sophisticated hydraulic suspension systems and transmission, but was also rebuffed.10 In this case, which involved clearly military technologies, MHI was reportedly reluctant to provide a test case for the MOU allowing transfer of military technologies to the United States, which had been concluded a short time before. In any case, a number of cases —both those that have been made public and those which the companies involved appear unwilling to disclose—demonstrate a pattern of reluctance on the part of Japanese companies to license military and dual-use technologies to the United States. For the purpose of enhancing U.S.-Japan cooperation and for DoD and U.S. industry planning, a more transparent way of determining which Japanese exports might violate the principles could facilitate expanded industry-to-industry interactions, particularly in pursuing opportunities to incorporate Japanese commercial technologies in U.S. military systems. Options for achieving this are discussed in Chapter 6. Current interpretation of the three principles can also act as a barrier to the transfer of Japanese military technologies through the procedures established in the 1983 exchange of notes. As noted earlier, this change has not resulted in a significant flow of technologies from Japan to the United States. This is due not only to the limited nature of Japan’s defense technologies but also to the understanding that Japanese defense technologies transferred to the United States will not be retransferred in any form to third parties. For example, if Japan develops an improved component or subsystem for a U.S. system that it is producing under license, it would seem to be in the spirit of the exchange of notes that the United States could obtain this improved technology, manufacture a component or subsystem based on the technology, and incorporate it into the U.S. system. However, for systems commonly subject to FMS sales—and many of the systems Japan is producing are—the retransfer restrictions make this awkward or impossible. Under the present system, in order to accommodate Japan, the United States would have to maintain inefficient production and supply of less capable FMS versions of the parts and subsystems in question in addition to the improved versions incorporating Japanese technology. Naturally, the U.S. military and U.S. industry might be less motivated to pursue cooperation with Japan in upgrades knowing that difficulties could arise down the road. The United States routinely imposes similar retransfer restrictions on its allies. |

|

Options for ameliorating this barrier are considered in Chapter 6 of this report. Any solution would have to address legitimate Japanese concerns and establish a system for royalty payments to Japanese companies. With tightening defense procurement budgets in Japan, possible policy changes related to the three principles are under active discussion in Japan. The Japan Federation of Economic Organizations (Keidanren) has provided the impetus for this discussion.11

|

Japan already possesses or is procuring some rudimentary elements of a TMD system, but these systems would have to be upgraded to perform TMD functions.40 U.S.-Japan collaboration in the ballistic missile defense area goes back to the late 1980s, when several Japanese companies received contracts from DoD as part of the WESTPAC project, an initial study of ballistic missile defense requirements in the Western Pacific. 41 Last year, U.S. defense officials reportedly proposed a series of four possible TMD “options” to Japan.42 More recently, a U.S.-Japan joint study of Japan’s TMD needs was launched under the leadership of JDA.43

The United States has several important interests at stake in TMD cooperation with Japan. First, Japanese deployment of TMD would contribute to the defense of Japan—for which the United States shares responsibility —and would protect U.S. forces in Japan as well as Japanese

|

40 |

Awanohara, op. cit. |

|

41 |

Hironobu Sakamoto, “Japanese Firms Win SDI Research Contracts,” Japan Economic Journal, December 17, 1988. |

|

42 |

Naoaki Usui, “Japan Tackles Antimissile Options,” Defense News, August 29, 1994, p. 1. |

|

43 |

“Raigetsu TMD Kenkyu-shitsu,” (Next Month TMD Study Group), Nihon Keizai Shimbun, March 27, 1995, p. 2. |

citizens. Credible capabilities could also help deter Asian countries from developing ballistic missiles and weapons of mass destruction. A second interest is possible technological benefits from joint development and related activities. If Japan decides to deploy TMD and wishes to license produce some of the component systems, resulting in a significant transfer of technology to Japan, the United States would likely pursue a reciprocal flow of technology from Japan to the United States.44 This could take place through cooperative R&D on undeveloped systems, or insertion of leading edge Japanese technology into the TMD system. Finally, Japanese procurement would benefit the United States by allowing U.S. development costs to be spread over a larger production volume, and some savings could be realized if agreement can be reached on U.S.-Japan codevelopment of one or more of the component systems.

Although U.S.-Japan cooperation in TMD has a compelling logic and the possible benefits to both sides are clear, there are a number of potential challenges that must be overcome to structure a mutually beneficial program. One set of obstacles on the Japanese side is related to the lack of a political consensus in favor of deploying a ballistic missile defense system.45 Other obstacles are related to more narrow defense issues. For example, deployment of TMD by Japan would likely require a new level of interservice cooperation within the Self-Defense Forces. Further, the program would likely involve substantial purchases of U.S. equipment, even if some component systems are license produced. In a time of tight budgets, it would be more difficult to acquire other systems with strong constituencies in the Self-Defense Forces.

Pursuing a consistent and balanced U.S. strategy toward cooperation could be difficult in light of the various interests and stakeholders involved on both sides. For example, the friction resulting from the early link between TMD and DoD’s TFT initiative illustrates one potential point of contention.46 At subsequent stages of discussion, U.S. efforts to negotiate a reciprocal technology flow could be resisted or misrepresented in Japan. Another possible challenge could arise if a U.S. approach focusing on the security and cost-spreading benefits of Japanese participation results in an agreement that draws opposition within the United States because of a perceived continuation of one-way technology transfers to Japan.47 It appears that close coordination and advance work by the U.S. government and U.S. industry to develop possible areas for Japanese technical contributions will be necessary. Absent careful planning, there is a danger that, as in the FS-X negotiation, the effort to cooperate with Japan could put strains on the U.S.-Japan relationship without advancing other significant U.S. interests.

Although TMD could be a promising area for U.S.-Japan technology collaboration, it illustrates the major challenges and risks facing both countries in building a new security and defense technology relationship for the post-Cold War era.

|

44 |

When the possibility of implementing the DoD’s TFT initiative through TMD cooperation was raised by the United States early in the discussions of TMD, it was resisted by some on the Japanese side. Partly as a result, the TFT and TMD discussions were “delinked.” See Barbara Wanner, “Washington Pushes for Expanded U.S.-Japan Defense Technology Exchanges,” JEI Report, April 8, 1994, p. 6. |

|

45 |

There is also debate in the United States concerning the scope of ballistic missile defense efforts that are permissible under the ABM Treaty with Russia, and whether a modification of the treaty should be pursued. |

|

46 |

“Gokai oi seniki misairu boei” (Misunderstanding Surrounds TMD), Nihon Keizai Shimbun, November 3, 1993, p. 2. |

|

47 |

Possible Japanese financial contributions are discussed in Barbara Opall and Naoki Usui, “DoD Courts Japan for Sea-Based Defense,” Defense News, June 6-12, 1994, p. 1. |

Cooperation in the Development of Subsystems, Military Technologies, and Upgrades of Systems Deployed by Both Countries

Cooperation in developing subsystems, military technologies, and upgrades of systems deployed by both countries are closely related mechanisms. The scale of a given project is generally much smaller than the large licensed production, codevelopment, and other programs discussed above.

The Systems and Technology Forum (S&TF) is the institutional setting for the United States and Japan to explore and develop possible projects. As part of the DoD’s TFT Initiative, recent efforts have focused on revitalizing S&TF to explore opportunities for cooperation in military and dual-use technologies of interest to DoD and JDA. Table 4-2 shows collaborative projects currently under way or under discussion.

Since Japan and the United States deploy many of the same systems, and the development of new systems is slowing, the development of new subsystems or subsystem improvements to upgrade and retrofit older weapons with modern technology is one area of possible cooperation that has a strong fundamental logic. For example, at the S&TF meeting of December 1994, the two countries discussed joint upgrades to the F-15 fighter. Japan has shown interest in introducing more advanced electronics into the fighter’s control system.48 The two countries also deploy the Patriot missile, the P-3, and other systems in common.

However, there are barriers to utilizing this mechanism to what would appear to be its full potential. For example, the export of U.S. manufactured items incorporating Japanese military technology is restricted under current policies. Since many of the systems the United States deploys in common with Japan are subject to FMS, incorporating Japanese technology might require the United States to maintain two subsystems manufacturing and maintenance capabilities—one for the newer, presumably more capable subsystem incorporating Japanese technology for U.S. procurement and one for the older subsystem to be used for FMS.

Most of the other projects that are ongoing or under discussion through S&TF, such as the ducted rocket engine, eye-safe laser, and ceramic tank engine, accomplish their collaboration through joint visits by military and industry researchers, data exchange, and joint development of demonstrators. Up to this point, this interaction has consisted of relatively small-scale joint R&D projects and therefore should not be expected to serve by itself to redress the imbalance in U.S.-Japan technology flows.49

However, the potential exists to build collaborative R&D in defense technologies into a more effective mechanism in the future than it has been up to now. With longer development and procurement cycles, greater emphasis in the United States on the development of weapons by teams of U.S. companies, and ongoing tight defense R&D budgets, U.S. companies are finding it increasingly difficult to support long-term R&D on enabling technologies for future defense systems. Japanese companies may be facing some of the same problems as a result of tight defense budgets. Collaboration between U.S. and Japanese companies in R&D on enabling technologies could prove to be an important mechanism for leveraging scarce resources in the future. The key will be to focus S&TF or some other forum on industry-to-industry

|

48 |

The two countries have established a working group to discuss F-15 upgrades. See “Military Technology on Agenda,” Nikkei Weekly, December 12, 1994, p. 2, and “F-15 kaizo e semmon-in” (Working Group for F-15 Upgrades), Nihon Keizai Shimbun, December 15, 1994. |

|

49 |

Michael J. Green and Richard J. Samuels, U.S.-Japan Technology Cooperation: Ten Guidelines to Make it Work (Cambridge, Mass.: MIT Japan Program, 1994), pp. 6-7. |

collaboration. Building an effective program or set of programs will likely require a patient effort on both sides. Chapter 6 will review options for removing barriers to greater collaboration in upgrading subsystems and for encouraging beneficial collaborative R&D in defense technologies.

TABLE 4-2 U.S.-Japan Collaborative Technology Projects Under the Systems and Technology Forum (S&TF), Current and Under Discussion