2

Background

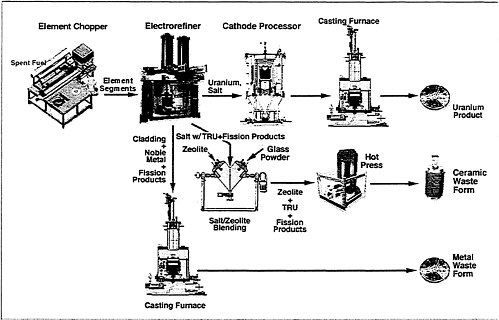

Figure 1 shows a schematic of the electrometallurgical processing technology including the production of two waste streams:1

-

the metallic waste form (MWF) and

-

the ceramic waste form (CWF).

FIGURE 1. EBR-II spent fuel treatment flow sheet.

The MWF is composed of a mixture of an iron-chromium-nickel alloy (“stainless steel”), 5 to 20 weight % zirconium, and up to 11 weight % uranium.2 The MWF also contains noble metal fission products at a combined concentration of 0 to 4 weight % and lower concentrations of actinides including plutonium. The microstructure of the MWF consists of a stainless-steel phase containing ferrite and austinite, and a zirconium-rich intermetallic phase that contains most of the uranium and actinides present in the MWF. The novel structure and composition of the MWF require a verification approach that can demonstrate its suitability as a final waste form for geologic disposal.

The second waste stream is a glass-bonded ceramic waste form (CWF) that will contain the bulk of remaining fission products and transuranic elements, including

|

1 |

This process also produces a uranium stream. ANL does not consider uranium a waste product. |

|

2 |

S. M. McDeavitt, D. P. Abraham, J. Y. Park, and D. D. Keiser, Jr., Metal Waste Form Alloys from the Electrometallurgical Treatment Process, NT Technical Memorandum No. 24, Argonne National Laboratory, Argonne, IL, 1996, pp. 3-10. |

plutonium. This waste form results from the use of zeolite 4A for extraction of fission products and actinides from the internally recycled EMT chloride processing salt.3 Early development of the CWF was based on hot isostatic pressing (HIP) of the zeolite 4A with a borosilicate glass binder to produce a densified waste form. Subsequent R&D showed that a significant fraction of the zeolite 4A was converted to sodalite during HIP. Further evaluation led to the selection of glass-bonded sodalite as the reference CWF.

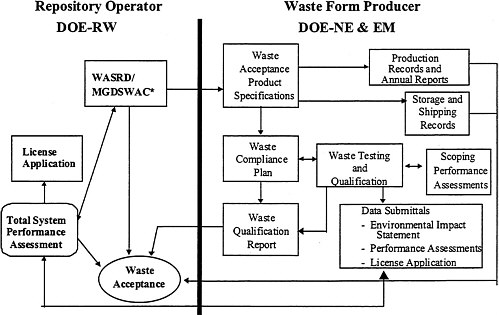

This report provides discussion of critical issues and outstanding questions related to the activities shown in Figure 2 , as well as committee comments and recommendations. This analysis is based on several recent presentations by Argonne National Laboratory (ANL) and documents covering the EMT Program, the committee's continued monitoring of ANL progress during the last 4 years, and published reports on the EMT process. This report assesses the technical consistency and comprehensiveness of the EMT activities that support ultimate acceptance of EMT waste forms by the U.S. Department of Energy's Office of Civilian Radioactive Waste Management.

FIGURE 2. Waste qualification activities involve several organizations. DOE = U.S. Department of Energy; RW = DOE's Office of Civilian Radioactive Waste Management; NE = DOE's Office of Nuclear Energy; EM = DOE's Office of Environmental Energy, WASRD = Waste Acceptance Systems Requirements Document, MGDSWAC = Mined Geologic Disposal Waste Acceptance Criteria.

|

3 |

Waste Form Acceptance Requirements for Molten Salt Electrorefining of Spent Nuclear Fuel, NT Technical Memorandum No. 8, Argonne National Laboratory, Argonne, IL, 1995, pp. 8-9. |