4

Safety Programs and Performance

The Stockpile Committee has been concerned with the CSDP's safety performance since its early evaluations of operational verification testing (OVT) at JACADS and has made many recommendations for improving safety, including the development of a well qualified and trained workforce and the establishment of a safety culture. This chapter revisits the recommendations discussed in Chapter 3 that pertain to worker safety and the implementation of sound industrial safety practices. These include: (1) putting a high priority on the development and implementation of the overall safety program [S-1]; (2) setting management goals for high levels of safety and environmental performance in all work areas and giving these goals at least equal weight with production goals [S-2]; and (3) developing strong safety management systems [S-10].

OVERSIGHT

When Congress authorized the destruction of the chemical agent and munitions stockpile in 1985 (PL 99-145), the law specified that destruction should be accomplished in a way that ensured the safety of the public, workers, and the environment. As part of its oversight responsibility, the Stockpile Committee has expressed continuing concerns over safety and has made many observations and recommendations in several reports for improving safety at specific sites and at the programmatic level. A summary of relevant observations and recommendations follows.

In an NRC letter report, Evaluation of the Johnston Atoll Chemical Agent Disposal System Operational Verification Testing: Part I, issued in July 1993, the committee made the following recommendation:

The Army should use systemization of the Tooele Chemical disposal facility to implement improvements relating to safety, environmental performance, and plant efficiency. These improvements should be made at Tooele prior to initiating the destruction of agents and munitions (NRC, 1993).

In April 1994, the Stockpile Committee completed its evaluation of OVT at JACADS and issued Evaluation of the Johnston Atoll Chemical Agent Disposal System Operational Verification Testing: Part II, which contained the following findings and recommendations (NRC, 1994b):

Overall safety management. Many OVT incidents [observed failure events] involved human error indicative of deficiencies in procedures, training, or management priorities.

Enforcement of safety requirements. Safety violations observed during OVT, . . . are serious problems that require changes in training, job priorities, and management accountability.

Recommendation 1. Give safety considerations priority over production goals.

Recommendation 5. Develop systems to improve overall management of safety.

In March 1996, the committee issued Review of Systemization of the Tooele Chemical Agent Disposal Facility, the continuation of several earlier NRC reports, with the intention of (1) reviewing the completion of testing of certain secondary systems that had not been completely tested at JACADS, (2) reviewing the changes implemented by the Army in response to earlier recommendations pertaining to the TOCDF, and (3) providing an overview of the status of the facility at the end of the systemization period (NRC, 1996a). The following excerpts from this report are related to safety issues:

Personnel Issues (Recruitment, Training, Turnover). Training in process operations and agent operations appears to be thorough, but training in general safety practices requires improvement.

A General Observation. There appears to be a general belief at the TOCDF that safety practices are primarily for agent

operations. As a result, the emphasis on safety has been focused on agent-related issues with less emphasis being given to industrial safety practices.

Recommendation 1. Development and implementation of the overall safety program at the TOCDF must be given high priority.

Recommendation 2. Safety and environmental performance goals should be given at least equal weight with production goals in establishing award fee criteria.

Recommendation 10. High quality, adequately staffed management systems must be completely implemented (including procedures for testing critical equipment; all necessary operating, maintenance, and emergency procedures; management of change procedures; training and cross-training programs; programmatic lessons learned activities; subject area reviews; and other safety oversight activities).

Safety at the TOCDF became a public issue when two former employees released detailed allegations that safety programs and performance were deficient. As a result of these allegations, seven independent assessments of the safety program at the TOCDF have been conducted:

-

a courtesy chemical surety inspection by the U.S. Army Inspector General Agency, August 15–18, 1994 (U.S. Army, 1994a)1

-

an investigation by the Army Safety Office into 119 safety-related deficiencies alleged by a former EG&G safety and security manager (U.S. Army, 1994b)

-

a review of the 119 alleged safety-related deficiencies by the Army Chief of Engineers for design implications (U.S. Army, 1994c)

-

a report by an independent evaluation team led by the Director of Army Safety (U.S. Army, 1997b)

-

a joint review by the PMCD and EG&G Management Assessment Team (U.S. Army, 1997c)

-

a report by AMH Consulting (commissioned by EG&G) (AMH Consulting, 1996)

-

a report by IHI Environmental and Ralston Consulting Group (commissioned by the Utah Citizens Advisory Commission) (IHI, 1997)

ASSESSMENT OF PROGRESS AND CURRENT STATUS

In general, the Stockpile Committee believes that TOCDF operations are being conducted in a way that protects the public. All of the independent assessments conducted at the site reached the same basic conclusion. The following discussion points out opportunities for further improvement.

The committee began its ongoing dialogue with TOCDF management and the Army regarding safety performance at the site before the commencement of agent destruction. Numerous site visits by the Stockpile Committee, its subgroups, and individual committee members have focused on safety and the Army's progress in developing a safety culture. Several visits included meetings with employees and representatives of the Employee Safety Committee. The Stockpile Committee has systematically communicated its safety concerns to both the site management and the Army through recommendations in its reports.

In response to the committee's observations and recommendations, and out of desire to improve safety performance, management personnel at the TOCDF have developed a TOCDF Safety Culture Plan and have implemented several programs and initiatives to ensure that a "safety culture" is developed and sustained at the site (U.S. Army, 1997d). The safety culture plan includes comprehensive timelines and milestones, as well as interim goals and objectives. Key elements of the plan are described below.

Implementation of the Safety Training Observation Program

TOCDF management has purchased (from DuPont) and begun the implementation of the Safety Training Observation Program. This program focuses on training managers, supervisors, and employees to observe people and their work environments in terms of safety in order to identify and correct unsafe practices and conditions. The Safety Training Observation Program emphasizes the positive aspects of safety training and behavior and has been used successfully by many companies as a tool for driving behavioral change.

Occupational Safety and Health Administration Voluntary Protection Program

The Voluntary Protection Program developed by the Occupational Safety and Health Administration

(OSHA) is a performance-oriented program that identifies the key elements of safety and health programs and provides measurement criteria for assessing them. The primary elements of this OSHA program are: management leadership, employee involvement, work site analysis, hazard prevention and control, and safety and health training. Each of these elements has a number of associated sub-elements. The Voluntary Protection Program is largely a self-assessment program, but it does provide for external audits. The TOCDF has completed its assessment of current status, and plans for corrective action have been generated. The TOCDF management has submitted an application for the facility to obtain Voluntary Protection Program status.

Safety Metrics

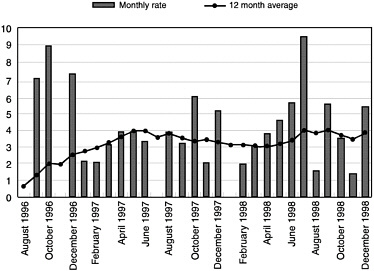

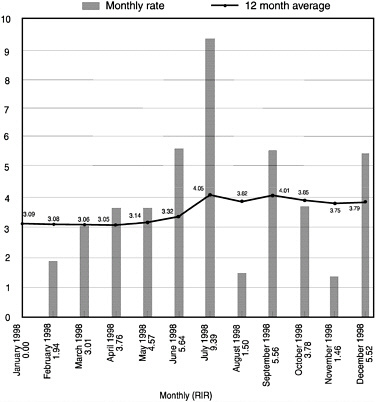

Recordable Injury Rate

The recordable injury rate (RIR), which can be used for comparisons with other industries, represents injuries and illnesses per 200,000 hours worked as defined by OSHA. The TOCDF management uses a 12-month moving ("rolling") average as its primary metric for tracking RIR (see Figures 4-1 and 4-2). The RIR is also tracked monthly and on a trimester basis, with the latter used to determine award fees. Since the commencement of agent operations, the rolling RIR at the TOCDF has been consistently higher than 3.0 and in some instances has exceeded 4.0. These values are within the range of the chemical industry as a whole but are not close to the best in the industry (< 1.0). Nor are they the best in the CSDP (the rate at JACADS was less than 2.0 during the same time period).

In keeping with its mandate to provide maximum protection, and with effective utilization of lessons learned and successful implementation of Safety Training Observation Program and Voluntary Protection Program, the management and staff at the TOCDF should strive to achieve a rolling RIR comparable to the best performing companies in the chemical industry.

Lost Workday Cases

TOCDF management tracks hours since last lost workday case as a measure of performance. This measure can also be tracked as cases with days away. The record through December 1998 was 478 days worked without a lost workday case. The 1998 lost workday case rate was zero.

Figure 4-1 TOCDF recordable injury rate (RIR) 12-month rolling average since the start of agent operations. Source Evans, 1998b.

Figure 4-2 TOCDF 12-month recordable injury rate (RIR) rolling average and monthly RIRs from January 1998 to December 1998. Source. Evans, 1998b.

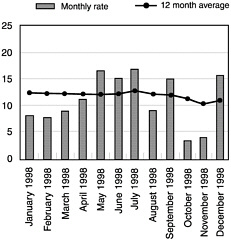

Total Number of Injuries

This measure is documented monthly by type—lost workday injury, recordable injury, and first-aid injury; the total for all three types is also tracked. Figure 4-3 shows the 12-month rolling average for all injuries. Although the trend for total injuries has been generally downward, this is largely because there have been fewer first-aid cases. The number of more serious recordable injuries has not decreased.

Safety Training Observation Program

Observations from the Safety Training Observation Program are tracked as the overall safe percent of total observations during each month. This metric, which was initiated at the TOCDF in late 1997, has averaged about 86 percent.

Other Metrics

The top five unsafe acts or conditions identified via the Safety Training Observation Program are tracked monthly. This metric is very useful for identifying areas that require more training, corrective action, or changes in procedures.

In general, the Stockpile Committee believes that the current metrics used at the TOCDF are all relevant and appropriate. As safety performance improves, some of them will become less meaningful; at that point they should be complemented with additional metrics relevant to the stage of development of the TOCDF safety culture.

Figure 4-3 Total injury 12-month rolling average for the TOCDF.

Source. Evans, 1998b.

Employee Involvement

A key feature of a safety culture is the active involvement and commitment of all employees. The TOCDF management has established an Employee Safety Committee and has involved all employees in the Safety Training Observation Program and Voluntary Protection Program. Safety has also been included in job descriptions, and safety responsibilities, including training, are clearly defined. Management has also established reward and recognition programs for contributions to safety by employees. Safety messages and news are also included in employee communications, such as the ''DEMIL-TRIB" newsletter. These regular formal and informal communications about safety can help to create an environment in which safety is highly valued.

Management Involvement and Commitment

After persistent urging from the Stockpile Committee and in the aftermath of allegations of poor safety practices by two former employees, management at the TOCDF has implemented a number of programs and procedures to improve safety. These activities are intended to establish a safety culture with equal emphasis on agent-related safety and general industrial safety and to balance production goals with safety goals.

One of the committee's continuing concerns has been that safety at the TOCDF has been primarily focused on agent-related issues and that traditional industrial safety practices and procedures have been neglected (NRC, 1996a). During visits to the TOCDF, the committee noted some improvements in this area, but progress has been slow. Many unsafe conditions and actions have been documented through the Safety Training Observation Program and observed by committee members during site visits. Failure to wear required protective equipment, poor housekeeping, and the existence of other unsafe conditions may be considered minor infractions, but the committee believes that they indicate the lack of an established safety mindset at the TOCDF and reflect negatively on management's commitment to establishing a true safety culture.

Although the absence of a pervasive safety culture with equal emphasis on agent-related and nonagent-related safety matters is unlikely to change public risk estimates, it could significantly increase worker risk. The establishment of a safety culture at the TOCDF will require continuous active involvement, knowledge, awareness, and a highly visible commitment by management to all aspects of the safety program—including management training and development. The committee notes that safety is included in all job descriptions and is clearly identified as an expectation for all managers and supervisors. Although progress in this area is diffi-

cult to assess, the committee believes that sustained improvement will only be possible with strong management involvement and commitment.

Criteria for Award Fees2

A growing body of evidence shows that chemical operations with a strong safety culture also have the highest productivity. The committee's recommendation that safety be given at least equal weight with production in establishing criteria for award fees has been satisfactorily addressed at the TOCDF and JACADS. However, considering that baseline incineration system facilities are currently under construction at three additional sites, the committee believes that modifying the criteria for award fees to include programmatic safety performance would enhance the overall CSDP and facilitate communications among disposal sites. Also, the committee believes that as new facilities are brought on line, their safety performance should reflect the lessons learned from other facilities. That is, at the start of operations, the performance metrics of the new facility should be equal to or better than those at operating facilities.

Programmatic Lessons Learned Program

In 1995, the Army implemented the PLL Program to facilitate the transfer of information from one site to another. Although TOCDF safety lessons learned are frequently included in PLL communications, a review of incidents in 1997 revealed that only about 27 percent of safety incidents (most of which were agent-related) were included in the PLL. In contrast, about 70 percent of operating and permit incidents were included. The committee reiterates its prior recommendation that agent and industrial safety be given equal emphasis.

SUMMARY

Overall, the committee is satisfied that its recommendations are being addressed and that progress has been made toward creating an environment conducive to the development of a safety culture at the TOCDF. Nevertheless, the committee also notes that safety performance at the TOCDF (as measured by RIRs, the frequency of unsafe actions identified by the Safety Training Observation Program, and such occurrences as the error in maintenance that resulted in a contained GB spill) has not improved significantly. A better balance between agent and industrial safety and strong management involvement and commitment will be necessary to meet the goals of the Safety Culture Plan (U.S. Army, 1997d).