Appendix B

Trip Reports of Technical Experts

Note: The INEEL committee invited several expert consultants to attend its first meeting and to write these trip reports. The opinions, findings, conclusions, and recommendations provided in these trip reports represent the views of the consultants and do not necessarily represent the views of the committee or the National Research Council.

DAVID CLARK

(University of Florida)

This report is based on oral presentations, written documents provided by INEEL and a tour of the INEEL facility. The INEEL's waste consists of about 5,300 m3 of sodium-bearing liquid wastes (SBW) and 4,500 m3 of calcined high-level wastes (HLW) in the form of s olid granules. The SBW is stored in stainless steel tanks. The calcined wastes are stored in stainless steel bins designed to last for 500 years. Present storage facilities for both SBW and HLW are considered interim solutions. It is my understanding that DOE/INEEL is considering six options to permanently immobilize both types of wastes. These can be divided into two categories:

Separation Options

-

Full separations, with grouting of low-activity waste (LAW) and vitrification of high-activity waste (HAW). This option has two phases. In phase 1, the radionuclides, transuranics and fission products will be separated from the liquid SBW and subsequently vitrified and prepared for eventual geologic disposal off-site. The remaining liquid (LAW) will be immobilized in a grout and disposed of at INEEL. In phase 2, the calcine will be dissolved and the radionuclides will be separated and vitrified as in phase 1. Likewise, the remaining liquid LAW will be immobilized in grout.

-

TRU separation/Class A grout + vitrification of Cs and Sr. This option is similar to option 1. The major difference is that the transuranics will be separated from the fission products (Cs and St), placed in 55 gallon drams and sent to the Waste Isolation Pilot Plant (WIPP) for permanent disposal. The Cs and Sr will be mixed with an appropriate borosilicate glass frit, vitrified, and made ready for eventual geologic disposal.

-

TRU separation/Class C grout. This option is similar to option 2. The major difference is that the Cs and Sr will not be vitrified, but will be treated as LAW, immobilized with the other LAW in grout, and disposed of at INEEL.

Nonseparation options

-

Early vitrification (also referred to a direct vitrification). In this option, the liquid SBW and solid calcine will be mixed with an appropriate borosilicate glass frit, vitrified, and prepared for eventual disposal in a geologic repository. Unlike options 1 through 3, the majority of the waste components will be treated like HAW.

-

Direct cementitious. This option is similar to option 4. However, the SBW will be calcined and the calcine will be immobilized in cement instead of in a borosilicate glass. Temperature requirements for this option are considerably lower than for vitrification.

-

Hot Isostatic Pressing (HIP). In this option, all of the SBW will be convened into calcine. All calcined wastes (SBW as well as existing calcine) will be mixed with an appropriate material (soil?) and consolidated under high temperature and pressure into a dense glass-ceramic. The resulting HAW glass-ceramic eventually will be sent to a geologic repository.

Although all six options have the potential to immobilize the wastes, option 1 (Murphy's Option 10, Murphy et al., 1995) involving full separations, grouting of the LAW and vitrification of the HAW appears to be the most favored by INEEL presently, based on the significant reduction in HAW volume that will have to go to a repository, on more even budgetary requirements over the next 20 years, and on total costs. From a total cost perspective, there is only a factor of about two to three difference between the most and least expensive options, and when storage and disposal are eliminated from the equation, the costs of all options are nearly the same.

The separations options will require a dissolution process that will put the solid calcine HAW wastes back into a less desirable liquid form. I have the same concern as expressed by Claude Sombret (1998) with separations. Why go to the trouble of making a calcine and then redissolving it?. Although the volume of HAW will be considerably smaller using the separation approach, the total waste volume (HAW + LAW) most likely will be greater due to the additional volume of solution that must be used in the dissolution process. The separations approach appears to be driven primarily by the estimated (speculated) repository costs, which could change dramatically in the future. If there were additional reasons for separations, such as reclamation of isotopes for various applications, then this approach might become more reasonable. Whereas the options involving separations have merit and can significantly decrease the volume of HAW, it appears that the scale-up separation technology involving dissolution of the calcine has not been adequately demonstrated. I have a more specific concern with options 1 and 2. What happens if the concentrated HAW that is produced in the separations cannot be suitably immobilized in a borosilicate glass that can meet performance standards? If these two options have a high-priority, then much additional work needs to be performed to demonstrate the scale-up of the dissolution/separation process, and to demonstrate that the remaining radionuclides can be incorporated into an acceptable borosilicate glass.

Regarding the nonseparation options, both the early vitrification (frit + calcine) and direct cementitious (cement + calcine) appear attractive due to their simplicity and, in the case of vitrification, its proven track record. The major weaknesses in the direct cementitious option are the unknowns of the process scale-up in a remote facility and the requirement to demonstrate equivalency to borosilicate glass. There are two areas that require significant additional re-

search/development even if early vitrification is the selected option. (D There are differences in the calcine compositions within the different bins. Some thought needs to be given to blending these using a tank similar to the slurry melter evaporator (SME) at Defense Waste Processing Facility (DWPF) to make a more uniform waste stream (perhaps two blends; one high A1 and one high Zr) (2) A database should be established from the literature and other sources of what already is known about vitrification of calcine in borosilicate glass. This information will be useful in developing one or two glass frit compositions, based on calcine compositions that will optimize waste loading while maintaining a low (1,150°C) processing temperature. Lastly, while the concept of a glass-ceramic appears promising, the use of HIP to achieve the product is too complex and scale-up too uncertain to pursue any further.

At the present time, a strong case for separations, based either on a technical or an economic basis, has not been made. Technically, the weak link in these options appears to be the dissolution of the calcine which still is in the exploratory stage of development. It is my opinion that the final decision for a waste form has to be based on the technical merits/issues such as processing simplicity, flexibility of the process, process maturity, and product perform-ante and accept. Early vitrification (i.e., nonseparations) appears to be the best option when all of these factors are considered. However, my recommendation is for the INEEL staff to reduce the number of options to two through careful and detailed analysis of existing data. Additional research and development will need to be performed on both options before a final decision is made. If the early vitrification option is selected as one of the two, I would encourage the INEEL staff to develop strong interactions with the Savannah River Site and West Valley plants (and the French Cogema and Marcoule facilities) in order to take advantage of their ''development" and "operations" expertise. Also, due to the time required to reach a final decision, it probably will be necessary to complete the calcination of the remaining 5,300 m3 of liquid SBW

Regardless of the option selected by INEEL, a more thorough analysis and characterization of the wastes will need to be performed. The product quality cannot be predicted or achieved if the feed stream is not well characterized.

EDWARD J. LAHODA

(Westinghouse)

General Observations

The INEEL effort is severely hampered by a lack of a good, representative sample of the waste tanks containing SBW and the calcine bins. Getting a good analysis of all the tanks and bins should be a top priority. For example:

-

Almost all options are predicated on obtaining an EPA exemption/delisting of the final waste form. It is doubtful that most of the organics listed in Wichmann et al. (1996) will be found if sampling is carried out. The presumed existence of these organics might also explain EPA's push to call the calciner an incinerator.

-

Thermal options (i.e., vitrification) enjoy an implicit advantage in that they are assumed to destroy the listed wastes allegedly contained in the SBW or calcine.

-

The results of any evaluation of options will enjoy a higher degree of confidence if their analysis is based on a sound waste feed composition.

-

Any potential problems due to the waste composition (i.e., Pu content and buildup) can be identified.

-

INEEL's laboratory and pilot-scale testing efforts are severely limited by the labeling of the waste as extremely hazardous. This label will likely be removed upon sampling.

-

The variability of the compositions of the calcines found in the bins is likely to affect how they are handled for processing. In addition, knowledge of this variability may require use of the unused bin set or even construction of a new bin set to help average out the range of calcine compositions.

The state of development for all the options considered is low. Therefore, the state of the technology development should not be a deciding factor at this time. This is not to say that the INEEL staff does not have technology strengths; they do and these strengths lie in solvent extraction and calcination. It is therefore understandable that the perceived best options at this point should involve the use of solvent extraction. This statement is based on the following observations:

-

The technical basis for the solvent extraction options are 1 liter, limited time tests.

-

The testing on other options has either been suspended for long periods of time or are proceeding at very low levels.

The cost estimates of the different options are probably no better than ± 100 percent for the processing portion of the options and should not be a determinant for the final option. Disposal costs are not likely meaningful numbers. This observation is based in part on:

-

Discounted values were not used. This would tend to 'minimize the effect of disposal costs.

-

The process designs used very conservative (and probably unrealistic) assumptions for operating factors. For instance, if one brought a melter on line, it is not clear why it would be run for only 180 days per year, especially if there was a standby already in line.

-

The process portions of the cost estimates were all within ± $1 billion dollars.

The choice of the final waste form should still be considered an open item. Since the long and arduous task of qualifying the final waste form has not even begun, it might be more reasonable to pick the waste form that is the easiest to produce. Therefore, consideration of a cement form should not be excluded at this early date.

The level of resources available to INEEL should be adequate to do the job.

-

In particular, an A&E with experience in costing vitrification, cementing, and solvent extraction processes at SRS or WVNS could be used for performing reasonable cost estimations. Utilization of SRS or WVNS operating personnel to help set reasonable operating assumptions should be encouraged. Could these personnel be borrowed from the other sites on a temporary basis to help perform the EIS?

-

Use of Hartford, SRS, and WVNS personnel to help develop and implement a sampling plan is encouraged. They have already gone through the agony.

-

Waste-form qualification and product quality performance should proceed using SRS as the model. This effort will likely require years to accomplish and much in the way of resources. Utilization of the SRS experience will hopefully reduce the level of expenditures required.

The concerns as to the institutional memory in terms of operations, design, etc., are well founded. This project will take at least 37 years to complete. This is much longer than a single generation (or maybe even two generations) of engineers is likely to last at this site. Therefore it is imperative that a project management approach be taken as to records generation, keeping, and retrieval now. Given today's technology, all reports, memos, letters and data should be put on a computer database that is backed up with all the normal controls and options (i.e., searching) that are available for any very valuable database. Maintaining written records is nice, but their limited searchability is a critical flaw.

Finally, I believe that the operability and maintainability of any process should be the primary basis for choosing a process. In this regard, simple is good.

In answer to the specific questions in the Statement of Task:

Are the set of treatment options chosen reasonable and are there others that need to be considered?

The options chosen are reasonable. Others that could be considered include:

-

Plasma melting as a replacement for a joule-heated furnace.

-

Glass/ceramic wasteforms not produced by HIP (i.e., Russian technology using thermite reactions).

-

Low pressure/temperature curing of cement type reactions.

-

Calcination of the remaining SBW and long-term storage on site. Although sugar has been the suggested organic additive to reduce the level of emitted NOx and the residual NO3 in the calcine, perhaps some other organic might be used which might have a reduced safety concern. One that comes to mind is acetic acid.

-

Utilization of one the current tanks to make it RCRA compliant might be considered. For instance, if there is a relatively clean tank available, perhaps another tank could be built inside of it. This would save the time and cost of building a brand new tank and of obtaining the required permit.

Are the assumptions, criteria, and methodology used reasonable?

The approach is reasonable. As per the above comments, I think that the process assumptions and costing portions of the analysis can be improved.

Are the environmental and technology risks reasonable?

-

The first priority should be the rendering of the residual SBW liquids to calcine as quickly as possible. Although this may slightly increase overall costs, this will result in a safer site for the long term until the program is completed over the next 30 years.

-

At this point in their development, I do not think that one can differentiate the identified technologies on either a safety or technology risk basis. For instance, until a complete flow sheet with mass and energy balances and at least a conceptual design are produced for each of the options, one cannot determine the costs, development needs or schedule in an adequate manner.

-

Risk assessments do not appear to have been run for any of the options. A risk assessment may be the means to provide the discipline necessary to carry out the EIS since it requires knowledge of the feeds, products, flowsheets, etc.

-

One point to note about the separations portions. Any solvent extraction process will likely add some level of organics to one or more of the streams. Will this be a concern for those options producing a TRU powder waste? Are any of the extractants or diluants considered hazardous, carcinogenic, potentially carcinogenic or mutagenic?

What is the feasibility of the treatment options within the regulatory framework and compliance agreements?

At this time, all appear to be feasible. Note, however, this statement is based on the assumption that reasonable resources are committed to doing the project. It is not wise to skimp during the initial phases where the final option is chosen or the laboratory development work is being done. The production of the EIS is likely to be the cheapest portion of the whole task and will set the course for the whole project to which very much larger sums of money will be committed. The next smallest cost will be the technology development effort. Extensive bench scale and pilot testing will save far more money than their cost.

K. K. SIVASANKARA PILLAY

(Los Alamos National Laboratory)

My participation in the National Academy of Sciences' assessment of the INEEL HLW alternative treatments leads me to provide the following observations and comments.

-

The range of technology alternatives proposed for the long-term management of HLW at INEEL is limited, and all options identified to be included in the upcoming EIS have high risks and high costs. None of these technologies is new or unique. These technologies have been extensively examined under the auspices of the ERDA/DOE in the past and those evaluations could be valuable to INEEL. Prior to the passage of the Nuclear Waste Policy Act (NWPA) of 1982 by the U.S. Congress, there were extensive examinations of waste forms for the stabilization and geologic disposal of liquid HLW from spent fuel reprocessing. The DOE decision to choose glass vitrification technology for immobilization of HLW at Savannah River and West Valley was reached after considerable debate. ERDA/DOE reports published during that period by the Battelle Memorial Institute in Columbus, Ohio on these discussions would be valuable to this exercise.

-

Waste characterization data available to the NAS were mostly deduced from flow-sheet materials balancing, rather than from sampling and chemical analysis. As a result, considerable uncertainties exist in the viability of technology options proposed to meet the regulatory requirements. Identification of both safety and special nuclear material safeguards issues require realistic data on waste form compositions.

-

There is sufficient expertise at INEEL to conduct dissolution and separation of actinides and fission products from fuel materials of various compositions and irradiation history. However, at present there is very limited expertise and capabilities at INEEL to stabilize and manage the separated fractions for geologic disposal.

-

Adapting specific technologies for the treatment of HLW forms at INEEL will require experiments with INEEL waste materials, technology developments, and demonstration before determining the feasibility of alternatives. Consultation with experts on vitrification at SRS, PNNL, and West Valley are appropriate at this time.

-

From a first-hand knowledge of the new safety culture at DOE sites and the audits and assessments by DOE/EH, and the Defense Board, it is prudent to avoid wasting resources on technologies involving simultaneous use of high-temperature and high-pressure in processing highly radioactive materials in the canyons.

-

Although vitrification was the technology chosen by DOE in the 1980s for the sty lidification of liquid HLW at Savannah River and West Valley, a pragmatic alternative often proposed is the well-known waste cement technology. For serious consideration of this alternative, the performance requirements and comparisons to criteria developed for glass would need to be investigated if the glass option were not pursued as the baseline for HLW stabilization.

-

Recognizing the existence of negotiated agreements between DOE and the state of Idaho and the mandates of the court order of 1995, it is still prudent to consider the following simple, elegant, and relatively safe management strategy for the calcine waste forms at INEEL. The obligations of the agreement and mandate mentioned above have sufficient room for further negotiation to accommodate such an alternative.

A preferred alternative for the long-term management of existing HLWs at INEEL should be to convert all liquid wastes into calcine using the NWCF and leave the calcined wastes in the silos for several (10 to 20) decades. The natural decay of radioactive nuclides will allow a rather simple and safe disposition option of the long-lived radionuclides and RCRA constituents at the end of that period. The design life of the calcine bins is 500 years and they are sure to last

-

without any major problems during the 10 to 20 decade period. This alternative is not the same as the "no-action alternative" being proposed in the EIS.

It should also be recognized that the waste forms created at INEEL as a result of re-processing the calcines may not be accepted (or acceptable) at the WIPP or the Yucca Mountain facility, if and when they become operational. The consequence of the newly created waste form at INEEL would be worse than the worst scenarios associated with the storage of calcines in the silos for many decades.

The success of the above option will depend on a carefully formulated long-term financing plan to create an incentive for future generations to monitor, protect, and maintain the safety of these silos in good condition.

The reason for removing the calcines from Idaho to protect the Snake River aquifer is not quite justifiable considering the safe configuration of the calcine and the history of its performance in current storage silos. It would be more appropriate to direct attention and available resources to remove the infamous "pit-9" and similar pits from INEEL where solid wastes from Rocky Flats were dumped into open pits. A responsible resource management scenario would also choose the qualified "leave in place" option proposed here for the HLW calcines at INEEL.

-

So far, INEEL had very little problems with the HLW generated during the past 5 decades when compared with other three sites in the United States. At the same time, it should be recognized that privatization efforts within DOE complex have not been great successes. An objective reexamination of the real value added by privatization to INEEL HLW processing is appropriate well before such efforts are initiated.

-

Other issues that were not properly addressed and those that call for near-term examination include:

-

a clear definition of the HLWs and quantifies of such material at INEEL;

-

the commingling of civilian and defense waste streams that may have impact on the acceptance of wastes at the WIPP site;

-

the fissile nuclide composition of wastes and its significance to criticality safety and nuclear material safeguards;

-

a management plan for the RCRA elements, such as Fo, Hg, Cd, etc., in the calcine and their end states (It is estimated that nearly 10 tons of mercury were used to catalyze the dissolution of spent fuels at INEEL. Establishing a material balance for this important RCRA metal as well as others before starting further processing of calcines is essential.);

-

a strategy to manage long-lived radionuclides such as 237Np, various Pu isotopes, 129I, 99'I'c, 59Ni, etc., that are present in the waste forms at INEEL; and

-

an integrated examination of the HLW issues by the three Divisions of DOE (DP, EM, and MD) to arrive at a common strategy to manage the wastes within the DOE complex, including INEEL.

JOHN H. ROECKER

(Westinghouse Hanford Company, consultant)

The author of this trip report participated as a technical expert for the National Research Council Committee on INEEL HLW Alternative Treatments during its review conducted August 17-19, 1998, at Idaho Falls, Idaho. In keeping with the author's area of technical expertise these comments are focused on systems engineering and program management issues.

Systems Engineering

The application of aerospace systems engineering methods to nuclear waste processing is oftentimes made either unnecessarily complex, making it almost useless, or is simplified to such an extent that necessary steps are not performed to a sufficient degree. Considering the information presented, it appears that the INEEL alternative study focused primarily on the alternatives step.

In the application of systems engineering methods to an alternative treatment study, such as the INEEL study, four distinct steps must be performed to produce a product that will withstand critical scrutiny. These steps are as follows:

-

Identification and definition of the initial conditions. In the case of nuclear waste processing this will consist primarily of identifying and understanding the chemical and physical properties of the waste material, but should also included clear identification of any social, cultural, economic, and regulatory issues or conditions that may impact the processing scenarios.

-

Identification and specification of a range of waste disposal end states. This will consist of not only a set of chemical and physical characteristics that the final waste product must fulfill, but again, as in the initial conditions step, social, cultural, and economic (e.g., lifecycle cost) requirements must be defined. It should also be pointed out that it is essential that a range of end states be defined so a spectrum, not just a single set, of disposal scenarios will be examined.

-

Definition of alternative processing functional scenarios. Several sets of functional flowsheets that define various process combinations that will transform the waste from its initial condition into the desired end state need to be developed. All possible combinations of processing functions and all alternative technologies for a specific function should be identified initially. A screening review can be used to eliminate infeasible and impractical scenarios. The screening review should be documented so that review groups, such as this committee, can readily see why a particular scenario has been eliminated.

-

Test alternative scenarios for performance against end-state requirements . Simplified or screening performance assessments should be prepared to provide a measure of how well a processing alternative scenario performs. A few critical radioisotopes and hazardous chemicals can be utilized to develop a high-level performance assessment.

The following specific observations are made with regard to the INEEL systems engineering study:

-

Considering the information provided, it appears that the INEEL effort focused on step 3 of the systems engineering process and that steps 1, 2, and 4 either have not been performed or are incomplete.

-

With regard to the initial conditions, the chemical data presented for the calcine waste was based on calculated flowsheet information. This data needs to be substantiated by analytical laboratory sample results.

-

There is a considerable degree of uncertainty with regard to the quality of the chemical data presented in document (Garcia, 1997). One table was found to contain erroneous data. It was also stated by one of the study participants that the data in (Garcia, 1997) was not used in his study, but rather another set that was documented in the study report. This demonstrates a real need to establish a single source of certified waste characterization data, under configuration management, that is used by all participants.

-

End states need to be specified in terms of specific technical requirements that can be used by chemical process design engineers for development of alternative disposal scenarios. The requirements need to be quantitative not qualitative. Such requirements as "road ready" are not useful to the designer or the reviewer. The specific technical requirements to make the waste "road ready," if indeed that is the desired end-state, need to be defined, documented, and approved by the appropriate participants. When information does not exist, an enabling assumption should be used and a specific plan for resolving the open item defined. The level of detail in the end-state specifications will naturally become more developed and specific as the program matures.

-

A range of end states, not just those that satisfy the baseline, need to be defined so that both the decision maker and regulator will have a full spectrum of alternative disposal scenarios to consider. Expenditures of large sums of resources for little, if any, risk reductions are not worthy endeavors when less costly alternatives with acceptable environmental risks are available.

-

Several waste disposal processing scenarios have been evaluated by INEEL. However, without seeing a clearly defined range of end-states for the waste, it is probable that all practical alternative scenarios have not been considered.

-

Specific technologies familiar to INEEL personnel have been selected for the alternative disposal scenarios evaluated. However, it is not clear what consideration, if any, has been given to alternative technologies for a specific processing function. A range of technologies for each processing function needs to be evaluated to ensure that the most cost effective and most appropriate technology is selected.

-

There was no evidence presented that any screening-level performance assessment work has been performed to date. This is necessary so poor-performing disposal scenarios can be eliminated while work is continued on those alternatives that produce acceptable environmental risks.

Management Issues

-

Aggressive plans of action for resolving the "incidental waste" and "equivalency" issues are needed. If an unfavorable ruling is obtained on either of these issues, several current planning assumptions may be adversely impacted which could in turn affect the alternative selection. Timely resolution of these issues is necessary so the alternative selection decision process can proceed with certainty. Also, considerable effort by INEEL personnel may be required to provide sufficient information to the regulators. This effort needs to be incorporated into the INEEL program planning.

-

The continued use of the existing stainless steel tanks as an alternative to building costly new tanks needs to be evaluated. It appears that the existing tanks are sound and would continue so for some time in the future. An evaluation to determine whether the environmental risk from continued use warrants the considerable expenditure required.

-

Some top-level schedule evaluation for each alternative evaluated is necessary. Simply stating end dates does not provide much insight for the decision-maker into the schedule feasibility of an alternative. This is important for all alternatives, but particularly those requiring extensive technology development.

-

There was not much information regarding maintainability, operability, flexibility, and reliability presented. These items have to be factors considered in selecting a technology alternative. There are several examples throughout the industry of failed plants and/or processes because these items were not adequately considered.

-

The current assumption by INEEL personnel is that the facility(ies) will be privatized rather than government-owned contractor-operated (GOCO). However, most, if not all, of the information presented was developed using a GOCO approach. A privatization approach may well change the technical alternative, unless it is dictated by the request for proposal (RFP), and it will certainly change the cost profiles. If the technical approach is dictated by the RFP, it may unduly impact the bidding process. A determination on the privatization vs. contractor issue needs to be made and a consistent set of planning assumptions issued and utilized in the alternative selection process.

[Note: A detailed discussion of the application of the systems engineering methodology to a nuclear waste disposal program can be found in the National Research Council (NRC) publication An End State Methodology for Identifying Technology Needs for Environmental Management: With an Example from the Hartford Site Tanks (NRC, 1999)].

ERNEST RUPPE

(E.I. DuPont, retired)

Quality of the presentations and tours associated with the HLW disposal situation at INEEL was uniformly high and assisted the technical experts significantly in assessing the technology and situation.

In general, the problems at the site, though not simple, are in many ways more straightforward than at many other DOE sites:

-

clear liquid wastes,

-

sound tanks that do not leak, and

-

calcine that is an excellent, handleable waste form for the interim.

Though it does not meet the present legal agreements, retention of all the waste at the site in this form in the well-designed bins provided for it is a solution which has a great deal of merit, obviating the personnel and transportation exposure and expense associated with any of the other plans.

Sorting out a preferred alternate from the EIS will of necessity be strongly influenced by the relative state of development of the options, some of which have lain dormant for a long time, presumably due to lack of funding.

There are several problems common to all of the alternatives:

-

All have regulatory problems of one kind or another, but they have in common the need for delisting of RCRA components. All could founder on these. It appears that an aggressive approach to this problem, probably by DOE HQ with EPA, is needed. The regulators should all want to facilitate safe disposal of the waste, which will require the delisting. Hand in hand must go an aggressive sampling and analysis program, utilizing methods developed at other sites. This is necessary both for flowsheet development and to support the delisting effort, which will not have a high probability of success with the current kitchen-sink list.

-

All alternatives need performance assessment and end-state analysis work. Waste-form qualification criteria/equivalence to existing vitrified products will take a long time based on Savannah River experience. It should be undertaken promptly for any alternatives to be actively pursued.

-

The fate of low concentration but long-lived and active actinides in the wastes (technetium, ruthenium, and plutonium) must be determined.

Looking at the particulars of some of the processes presented:

Full Separations/Baseline Case

This is similar to work done elsewhere, and the separations steps are most familiar to Idaho personnel. Calcining the remaining SBW and redissolution of all the calcine followed by the vitrification is clearly a very expensive process. It appears to be the most developed option of those presented, but much development effort is still needed. Though some demonstration on the l-kg scale has been made, extended rum of the liquid-liquid contactor system using real

materials must be done to determine whether there are problems from buildup over extended recycle. Vitrification development is still at a very early stage, and, based again on Savannah River experience, will require a major effort.

Other options are all at a lower state of development because they are, in general, unique to INEEL and apparently are not active tine to funding/staff limitations. Extensive development work is needed to seriously consider any. All have the common problems mentioned above. Though no staffing tables were presented, the overall impression was left that this work was not likely to be funded in the short-term future.

Early Vitrification Option

This option is attractive because it avoids the redissolution and separations of the first alternative, but again much demonstration is needed, including developing, characterizing, and qualifying the waste form. The volume downside will be discussed later in connection with costs. The waste form is most similar to ''conventional."

Direct Cementitious Option

Direct grouting is attractive, except for the extreme volume downside attributed to it. The process cost appears very high, with the reasons not obvious.

TRU Separations

There are many known technologies here but also new ones to be developed. The option has not only the delisting problem common to all options but also the HLW reclassification, which is at least semantic but will be viewed critically. WIPP acceptance will also need to be developed.

HIP

Though HIP is used elsewhere for other purposes, it is difficult to envision hot cell operation of this complex technology at large physical size and 20,000 psi, 1050°C.

Based on experience in both high pressure and canyon operations, major practical and safety problems are apparent. It would be a very difficult development, and therefore low priority is recommended.

The glass-ceramic form, however is quite attractive. Are not other mutes to it developable?

Finally, looking at the cost summary presented, volume and disposal costs drive these totals completely. The range of process costs shown is essentially the same within the limits of their accuracy. Thus the cost comparison hangs on use of the proper disposal cost value. This could range from incremental cost (considering previous expenditures, a sunk cost) to full cost. Alternatively if the waste is to go to a second repository, then replacement cost is appropriate. Further study, discussion, and agreement on this is needed.

Overall, the common problems noted at the beginning need to be pursued vigorously no matter which alternative is selected from the EIS.

BARRY SCHEETZ

(The Pennsylvania State University)

Introductory Comments

The visit to INEEL was very enlightening and indeed very useful in expanding my background knowledge of the site, facilities, and progress that has been made. The personnel at LITMCO and Idaho DOE should be complemented on their efforts in providing us with data and information that will be invaluable in our process for making recommendations.

However, more questions were raised during the presentations than could be answered within the time frame of the presentations and allocated discussion time. Many of these questions concerned fundamental assumptions that were made and the detailed rational behind the assumptions, for example, the issue of dioxane in the off-gas stream of the calciner. No clear explanation was given for the assumptions that it would be(is) present in the full-scale calcination process, especially since we were informed that no off-gas characterization has been performed. The consequences of proceeding with remedial actions based upon these assumptions are significant, not only in terms of project costs but also in the selection of a process flow sheet as well as regulatory involvement. Similarly, the assumption that all of the RCRA listed wastes that came onto site can be identified in the calcine, significantly and detrimentally influences the regulatory environment within which the calciner will continue to operate. The fear is that we heard what we were supposed to hear.

Discussion

In the early 1950s when the operators of INEEL made the decision not to commit to neutralization of their process wastes but to go with volume reduction via calcination, they made the most enlightened decision of all of the Atomic Energy Commission's facilities. Today some 40+ years later, their action still stand as a testament to good scientific reasoning; for instead of setting here today with a legacy of 56,000,000 gallons of corrosive, aqueous, mixed salt waste, we have 5,000+ m3 of flowable, dry, granular, non-corrosive solids.

Separations

This approach is based upon a 1995 programmatic decision with its assumptions of for-cost and waste volume reduction based on Yucca Mountain National Nuclear Waste Repository, even though the waste from this project is designated to go to the second national repository. From the data present to this review committee, it appears that the desire to reduce the volume of HLW from 5,000+ m3 to 210 m3, irrespective of the consequences of this action, has driven the decision to justify this course of action.

It is apparent that the process technology is based upon strengths of the IN-EEL (separations). However, data that we received were lacking in the foresight to determine the fate of volatile hazardous and radioactive species such as Tc, Ru, and I in the proposed process; as if the technology was first selected and the process made to fit the technology. It appears that the data presented to us came from multiple sources with sometimes conflicting and, certainly, variable quality. Further progress will be impaired by lack of detailed knowledge of the compositions of the wastes; most information is currently based only on flowsheet calculations.

No discussion was provided to describe the nature of the projected 32,000 m3 of "grout" that would contain the LLW residue from the separations process, nor the 70 tons of Cd and 12 tom of Hg that it would contain. No mention of the enormous volumes of nitric acid that would be required to take the calcine back into solution nor to its disposition were made. Although concern for the Snake River aquifer was presented as a significant motivating force for the removal of HLW, it should also be a motivating force for the removal of heavy metals as well. We have been presented with no information regarding the regulatory implications or stewardship requirements of building and operating a mixed-waste repository (landfill) that will remain within the state of Idaho. Are we to assume that the state of Idaho is aware of the implications of the construction and maintenance of such a LLW repository and concur with this action? We can only be left with the impression that these major considerations are in their infancy in development.

Furthermore, the separate operational steps associated with the proposed process is more complex (dissolution + separations + vitrification + grouting)than any of the proposed alternative approaches presented to us. The doctrine, "keep it simple" should be practiced.

Nonseparation Approaches

From these discussions, several very important statements were made. First, the fact that it is readily possible to homogenize the calcine immediately simplifies all alternatives processing. Instead of dealing with multiple, different calcines, only one will need to be addressed which should greatly simplify process designs. Second, we learned that up to 10 percent of SBW was already being mixed with existing calcine during its processing on a routine basis. Therefore, the further extension to include all denitration of the SBW and denitration of the residual nitrate in the calcine is readily feasible.

Three alternative approaches for the immobilization the SBW and calcine wastes were presented; but the alternatives were either dead for so long a period of time that their status is questionable, or the alternatives are so new that adequate funding has not been allocated for their development. In either case, we are left the conclusions that neither separations nor nonseparations options are well developed at this time.

Direct Vitrification

Direct formation into a glass was evaluated for approximately a 10-year period from 1976 to 1986, during which time the concept had advanced to the point that at least one full-scale glass log was produced. In the intervening year, West Valley and Savannah River have come on line with the production of full-scale radioactive glass waste forms. Scale-up and melter designs that have proven reliable can be implemented from the experience of these other sites. Development of frit compositions and evaluation of the resulting products are still needed especially in light of the stated ability to readily homogenize the calcine. Dealing with a single waste composition instead of as many as six variations greatly simplifies the processing flow-sheets and minimizes the possibility of error.

Hot Isostatic Pressing Into Glass-Ceramic

Hot Isostatic Pressing (HIP) has been developed at INEEL for nearly 2 decades. The data presented for this process appeared to be very positive, suggesting that both high waste

loading and the formation of durable waste forms is readily achievable. The most significant disadvantage that appears to be of concern by other members of this review committee is the high operating pressure of the hot isostatic press. There was strong sentiment, expressed by several members of the committee who have direct operational experience, that such a system, with these very high pressures, would not be feasible to implement in a hot-cell environment. However, Argonne National Laboratory-West is actively pursuing the use of a hot isostatic press in their waste-form development. They have adequately demonstrated to another NAS review committee, on several occasions, the efficacy of placing a hot isostatic press, of up to 24 inches in diameter, into a hot-cell environment. Their schedule has advanced such that their objective is to place a full-scale hot isostatic press into a hot cell within 2 years.

Cementitious Waste Form

The data presented with respect to a cementitious waste form represent a minimal level of activity over the past 5 years. The cementitious waste form alternative that was presented to us in this review is not a conventional portland cement-based waste form. It is a cementitious material that is based on the alkaline activation of pozzolanic aluminosilicate materials. All development has been made with the availability of materials and the implementation of common industrial practices in mind. The cement hydrates to a C-A-S-H, x-ray amorphous solid, at room temperature rather than C-S-H that occurs with portland cement. When cured at temperatures in the range of 90°C to 175°C, the resulting product hydrates into a crystalline form, which possess a zeolite struck. Another unique aspect of these cements is that they have been designed to also posses the bulk chemistries that will allow them to be formed into glass-ceramics via HIP. HIP of this vitrifiable hydroceramic has been demonstrated to be achievable at 850°C and 2K psi to 5K psi while at the same time e eliminating the difficulty in canister filling that is associated with the addition of dry powders to the HIP cans. The resulting product is a glass-ceramic not unlike that obtained in the HIP program. Waste loadings between 35 percent and 50 percent are achievable. It should be emphasized that the cementitious waste form before HIP can also meet durability requirements and may serve in its own right as a waste form while still maintaining the flexibility to be converted into a glass-ceramic (see Appendix A for a list of references).

The Fluor-Daniel report that was commissioned by INEEL to review this technology suggest that it could address the entire calcine problem in a much shorter time interval and at a cost that is a fraction of the $3 + billion earmarked for separations.

Recommendations

Operating Assumptions

Some basic assumptions must be adopted (a) Since this waste will be going to the second generation national nuclear waste repository, for which no specifications have yet been established, "volume" should not be a driving issue. (b) Within the error of current estimates, there were substantially no differences in the cost associated with separations and all nonseparations approaches. (c) Separation of the high-level fraction of the waste is unnecessary, more complex, and should be discouraged. (d) Based on the second assumption, the calcines should be manipulated to ensure homogenization. (e) The current SBW and the calcine should be concurrently processed to remove the nitrate-load in the SBW and to reduce the residual nitrate in the calcines. (f) A processing approach should be adopted that meets minimal disposal require-

ments and is the simplest to operate. (g) Concerns over regulatory definitions of wastes should not drive the final decisions since these are likely to be modified.

Support for Alternatives Studies

With these fundamental assumptions in mind, several alternative approaches to handling the calcine now become viable but, because of the program's direction in the past 3 years, have not received the necessary funding to advance their state of development. In order to meet court-ordered deadlines, funding for these programs should be released immediately.

Ranking of Alternative Processes

Two previous independent commissions were charged with evaluating INEEL wastes with the objective of making recommendations as to types of waste forms that should be/could be implemented. In 1979, an NAS committee, chaired by Rustum Roy, concluded that immobilizing the calcine in a cementitious matrix was the most desirable approach to pursue. In 1981, another committee with much broader representation, chaired by Roy Post, evaluated 31 differ-em waste forms and independently ranked them (Post, 1981). Again in the mw numerical ranking, a cementitious waste form, FUETAP developed at Oak Ridge National I.aboratory in the mid-to late-1970s, was selected as the most desirable waste form.

The calcine, although designated HLW by its point of origin, is indeed a rather mild waste, at 40 watts/m3, which would qualify as an "intermediate" level waste by U.K. standards. We can look to other organizations internationally (i.e., BNFL) and learn that wastes with this level of activity are routinely and successfully immobilized in a cementitious matrix.

The advantages of going to the process flowsheet discussed in this review are: (a) low temperature processing, (b) established "off-the-shelf' technology for processing concrete, (c) track record, (d) minimal op-steps, (e) flexibility to form hydroceramic initially which could differ processing into a glass-ceramic to some later date if desirable, and (f) the calcine waste becomes an integral component of the wasteform (i.e., soda, which is among the most difficult elements to immobilize, is necessary to initiate the hydration reaction).

The disadvantage of a hydroceramic at this stage is directly associated with the state of maturity of this specific formulation/process, although laboratory-scale development has proven successful. The process as it now stands has received virtually no attention. Funding for this process was less than $100 K from INEEL, in total.

The HIP process at INEEL has received a great deal of attention for nearly 2 decades and could complement the hydroceramic approach. HIPing a hydroceramic would resolve two of the major difficulties associated with the HIPing of powders by (a) eliminating the can-fill difficulties and (b) significantly reducing the P and T processing conditions. HIP is a viable alternative accepted by the NAS review committee for Argonne National Laboratory-West (ANL-W). A cooperative program should be established between INEEL and ANL-W, such that they would work together on the implementation of this technology.

Direct vitrification has also received a good deal of attention and in light of a homogenized feed, which would eliminate the need for multiple frits, should be evaluated.

Finally, a very promising option should be considered that would complete the calcination of the SBW and revert to permanent storage on site. With minor modifications (i.e., mounding earthworks around the above-ground silos for enhanced protections against the elements) to the existing bin sets, which already possesses a 500-year design life, they would form the basis for long-term storage/disposal. This alternative is not within the guidelines of court-ordered closures and shirks the government's responsibility to the state and people of Idaho and should only be considered as a "last resort" option.

Miscellaneous observations

It should also be emphasized that the resources to address the issue of alternatives to separation appear to be available at IN-EEL. To aid in the control of costs, outside contractors should be utilized where applicable. For example, we heard that the costs of modification of the calciner to meet clean air standards was a rote-limiting step and would cost perhaps a $100 million; while at the same time, a complete proposal for an entirely new calciner, specifically designed for handling SBW, including all of the emissions controls to met EPA requirements and at the total cost of $45 million, is available.

ANNE E. SMITH

(Charles River Associates)

Focus on Issues Related to Costs and Trade-Offs

The INEEL is in the process of developing cost and performance/risk estimates for a range of alternative processes for long-term management of the HAW at INEEL. To some degree, costs and cost-risk trade-offs will almost certainly be key considerations in the final decision, and this trip report focuses on those issues.

Although the official cost estimates for the final decision are not yet available, several preliminary and related cost estimates were cited among the presentations and reports that I reviewed. Some of these were quite detailed and some were "back of the envelope." It is important to recognize that these various cost estimates were never intended to be of comparable quality or mutually consistent. However, the differences among them have been useful for helping identify some specific cost-analysis issues that could benefit from general guidance. I have grouped the issues that I identified into the following five areas:

-

Discounting

-

Requirements for Completeness

-

Addressing Uncertainties

-

Role of Privatization in Costs

-

Assessing Trade-offs in a Multi-Attribute Setting

The comments that I provide below are not intended as criticism of any existing work. Rather, I am highlighting areas where there appeared to be a lack of consistent opinion or uncertainty about the most appropriate technical approach. I provide suggestions for approaches that are consistent with sound economics, and also adapted to highlight and address specific aspects of this waste management decision.

Discounting

The various cost estimates reviewed take different approaches to presenting treatment costs that occur over long periods of time. Some estimates "discount" costs and some do not. These inconsistencies can be explained by the different intended uses of the cost information in each document. The most important point here is that discounting should be used when the purpose of the cost results is to compare among the waste treatment options, with the ultimate goal of selecting a single alternative. Given that there were a number of questions at the August meetings regarding what discounting means, why we do it, and how we do it, I will provide a more detailed discussion of these points in this section.

A dollar to be spent in 10 years is usually viewed as less of a financial concern than a dollar to be spent today. There are many reasons that a given absolute amount of money declines in value over time. Most commonly one thinks of inflation. However, even if there is no inflation (or if the costs have already been adjusted to remove the effects of inflation), future dollars have less value, dollar for dollar, than current dollars. One reason is that people simply prefer choosing consumption now over consumption at some later date (when they may be less able to enjoy the experience, or may perhaps even die before then). Another very important reason is that if a dollar expenditure is put off, then the extra dollar available today may be invested in alternative activities that are productive (i.e., have financial returns). A productive

investment means that more than one dollar of wealth will be available when the original dollar is to be expended at a later date. Hence, spending the dollar later will seem "less expensive" because the total wealth available to pay for it is larger.

"Discounting" is the process by which dollars spent in a future are converted into a comparable "present value." To compare the costs of alternatives that will involve expenditures at varying points in time, first all of the expenditures should be converted to a common "present value," then summed up to obtain an estimate of the total present value of the cost stream. If R is the annual discount rate, and H is the number of years into the future that expenditures on a project will occur, then

Some of the existing INEEL cost estimates use discounting. For example, the "Murphy report" (Murphy et al., 1995) uses an annual discount rate of 2.8 percent, applied to costs that do not include inflation. This contrasts to the budget estimates presented for the "Baseline" in the Ten-Year Plan (DOE, 1998). The latter report not only does not discount costs, but in fact escalates the on-going costs by 2.7 percent per year. How can these both be right?. The answer lies in the specific use of the information in each report. The Ten-Year Plan is part of a budget document, intended for forecasting dollar amounts of future budget requirements. This "budget perspective" does not purport to provide a total social cost of the baseline strategy, and it does not compare the cost of the baseline to the costs of other options. It does not matter for purposes of congressional budget requests whether a future budget dollar is worth less than a current budget dollar. In fact, one can argue that a constant-dollar-amount budget allocation is easier to achieve than an allocation that is lower in present value, but increases over time in terms of dollars per year. It is also more important that the budget projection be presented in the dollar amounts that will actually be needed and requested. If these projections were presented in terms of discounted present values, this would only lead to confusion and increased probability of a failure to achieve the necessary funding when the future year comes. Thus, it makes sense that budget planning, once an alternative has been selected, be done without discounting future costs, and also that it provide for expected inflation in wages and cost of materials.

The budget perspective should be contrasted to the cost perspective, which is the proper perspective to use in deciding among the HLW management options. In this type of analysis, the goal should be to understand the total social costs of each alternative, regardless of whose budget the costs fall under or when the expenditures will be incurred. Thus, costs in fu-tare years should be deflated to present values and then summed up over the full time horizon. The time horizon to use should be long enough that it accounts for all the cost ramifications of each of the options. In this particular case, final disposal in most of the options is not expected until after 2065. Thus, the cost analysis for each option should extend about 75 years into the future.

The choice of discount rate to use varies with the context of the decision, and depends on the alternative uses of the funds if they are not spent today. Private corporations use "hurdle rates" that require that investments under consideration be assessed using discount rates from 10 to 25 percent per year. These hurdle rates include adders for private-entity concerns with risk, etc., and are not a good model for use in social investment decisions. For government investments, expenditures might be funded by Treasury Bills, which have an inflation-adjusted

("real") rate of return of about 3 percent per year. Alternatively, lower government expenditures might mean lower taxes, which in mm would mean greater consumption and investment by the private sector. This would suggest a discount rate between 3 and 8 percent.1 Thus, the 2.8 percent discount rate used in the Murphy report is on the low end of the range that should be considered for the INEEL decision.

The present value can be quite sensitive to the choice of discount rate, so it will be reasonable to consider the effect on cost comparisons of discount rates over the range of 3 to 8 percent. A numerical example might be useful here. Consider two simplistic examples of management options. Option A involves an expenditure of $3 billion now and disposal costs of $0.5 billion 70 years later. Option B is cheaper up front ($0.5 billion now) but with a larger volume to dispose ($5 billion 70 years hence). Without considering discounting, the total costs of Option B appear to be $2 billion more than the costs of Option A. With a discount rate of 3 percent, a dollar to be spent 70 years from now is comparable to 17 cents to be spent today, and the present value of Option A is $3.1 billion, higher than that of Option B, which is $1.3 billion. The large differences in costs in the distant future may become insignificant in the comparison of the options. A potentially higher discount rate would only reinforce this finding. Thus, uncertainty about the precise discount rate to use may be less important to the INEEL decision than simply ensuring that some reasonable positive discount rate is used.

Requirements for Completeness and Consistency

Given that the INEEL HLW treatment decision is being made in the social interests, and not in the private interests of any specific entity or group of people, the comparison among the options should also account for all associated costs, regardless of the specific government budget that costs will fall under. Similarly, if there were any potential expenditure that would be borne by a non-DOE or nongovernment entity, this also should be encompassed in the cost estimate. Thus, the "cost perspective" may again result in quite different (higher) costs than one would obtain from a installation-specific "budget perspective" such as is reflected for INEEL in the Ten-Year Plan.

Two specific examples of completeness needs came to light during the August presentations: contingency costs and disposal costs.

Contingency costs are provisions for unforeseen costs or technical difficulties that cannot be anticipated in a standard engineering cost estimate. Although the specific form of the added cost is unknowable in advance, these are real costs, in that they are almost certain to occur due to one or more reasons. Accepted contingency factors are based on historical experience, and although there is some uncertainty in the precise magnitude required for any individual project, their expected impact on total costs is large: 20 to 30 percent typically. To exclude them from a cost estimate is to create an incomplete cost estimate.

Disposal costs are definitely part of the project costs that should be included in comparison of INEL waste management options. These were excluded from the budget estimates of the Ten-Year Plan, but these must be included for the comparison among possible alterna-

tives. Several people at the meetings noted that the disposal costs are the real drivers in the total costs. For example, the last page of the second package of slides handed out at the August meeting shows a "preliminary cost summary." If the options on this slide are ordered in terms of "total costs," and also in terms of "disposal costs," the same ranking is obtained. However, there are reasons why disposal costs may not be as significant as this would suggest:

-

First, this slide has not presented present values of costs. Even with a fairly low discount rate of about 3 percent, disposal costs would be discounted by a factor of 3 to 6, relative to the waste treatment costs.

-

Second, the cost-per-ton assumption for disposal of the final waste form might be overstated. This assumption has been based on the total costs of getting the Yucca Mountain repository into functional status, divided by the tons of waste that can ultimately be disposed in Yucca Mountain. Since Yucca Mountain is the first such repository, it may have involved substantial start-up costs that would not be fully repeated with future repositories, possible expansions of capacity at Yucca Mountain, or future acceptable methods for HLW disposal. A member of the public who spoke at the August meetings argued that costs per ton for disposal of HAW should be based on the incremental cost necessary to dispose the incremental tons, and that these costs would be only $1,000/ton, a factor of 300 less than the unit disposal costs being used by DOE at this time. I agree that the cost per ton should be based on the incremental costs of disposing of HAW rather than the average cost based on the first increment represented by Yucca Mountain. I disagree, however, that this mental cost will be as low as $1,000/ton. New repositories or new disposal capacity will require additional costs above and beyond the engineering cost of transporting and placing the waste canisters in a deep repository. Conceivably, furore repository capacity may be more costly to set up and approve than Yucca Mountain has been. However, a better estimate of the disposal costs that attempts to eliminate any "onetime" aspects of the Yucca Mountain costs would be a good idea and could help define a range of cost estimates for the important disposal cost component.

Despite the uncertainty about their overall contribution to total costs, disposal costs should be included in the cost estimates for each alternative.

Consistency is required in cost estimates as well, for completeness. The costs (and feasibility) of some alternatives are less certain than for other alternatives. Costs may be higher than a point estimate that would be developed with current information if there are technical complications that cannot be easily mounted. They may be lower than a current point estimate would indicate because processes may be better optimized. The cost estimate range will tend to be larger for less mature treatment technologies. Completeness demands that ranges of costs be provided to help normalize for the "maturity" of the various cost estimates.

Addressing Uncertainties

Uncertainty is obviously a key feature of cost estimates for unproven technologies and activities that are spread out over many decades. None of the cost analyses presented at the August meetings have effectively described the uncertainties in ways that can help in the decision making, and a better job will be required in this area. Uncertainty can be incorporated into an evaluation in manageable ways. Two key principles are (1) focus on uncertainties might affect the relative ranking of options (e.g., uncertainties that significantly affect the costs of some options but not all); and (2) explore significant key assumptions in a "what-if" mode.

In the first category, one might include uncertainties that are driven by significant differences technological maturity among the options, as described in the previous section. Similarly, uncertainties in disposal costs may be important in differentiating among options.

In the second category, there may be some assumptions that affect all of the cost estimates in a similar manner, but which may have dramatic effects on costs. One example that comes to mind is the assumption that DOE will successfully get a delisting of hazardous wastes. Ail of the cost estimates depend significantly on this single assumption, yet there appears to be a significant risk that delisting will be denied. A most informative element of the cost analysis would be an exploration of what would happen to the waste management options and decision if delisting were to be denied. What would the alternatives look like? How would this event alter the comparison among the options? Would one option suddenly appear much more advantageous? Would some options become anathema? This type of ''what-if" analysis need not be highly quantitative, as long as the options are carefully scrutinized for pitfalls and advantages, and the implications of this assumption for costs are openly discussed.

Another important assumption appears to be that the designation of the calciner as a hazardous waste incinerator, with attendant upgrading costs and waste management delays, is mutable. I should think that this decision, which appears to be fairly poorly thought out by regulators, could be reopened if a good risk-risk comparison were made to support the discussion. An important question in my mind is how the costs and options being considered might be altered if the calciner could be run without major upgrading until the remaining liquid wastes are calcined.

An important feature of a good uncertainty analysis is that it highlights the most salient aspects of the decision and targets them for greater discussion and exploration. Doing so may lead to better alternatives generation. For example, in the August meetings, it became apparent that there are really two basic options, and that focusing too heavily on detailed comparisons among all of the waste treatment options may be missing a more important aspect of this decision, which is whether or not to treat and remove the calcined wastes at all.

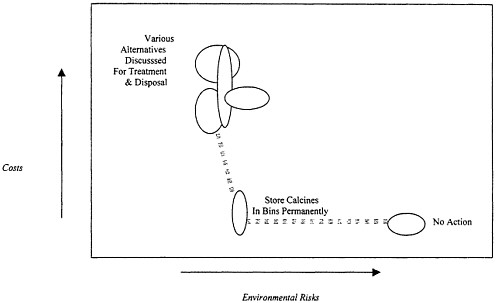

Figure B-1 illustrates the nature of the INEEL decisions in terms of a cost and risk trade-off. (Risk is defined strictly in terms of environmental risks in Figure B-1.) A balloon illustrating the range of cost and risk uncertainties represents each of the options. "No action" has low but non-zero costs. The option to finish calcining the wastes and to store them permanently in the existing bins will probably give a substantial risk reduction, possibly with minor increases in costs. (Although there are costs to calcining, the life-cycle costs might be reduced due to lesser monitoring and maintenance needs compared to the "no action" alternative.) The next increment in action is conversion of the wastes into a stabilized form and off-site disposal. All of the technologies discussed at the August meetings are associated with this general type of action. As can be seen, they all appear to involve very large cost increases and probably mini-real further environmental risk reductions. This figure highlights the basic fact that there may be too much attention being given to defining and analyzing all the conceivable "stabilize and remove" options and too little attention to intermediate alternatives. Some intermediate alternatives that could be considered might be (a) upgrades to the calcined wastes and/or the bins to make them lower-risk as a permanent configuration, and (b) waste vitrification, but with on-site permanent storage. Although these may not be considered politically or legally acceptable at this time, it is not possible to know whether these intermediate options deserve further regulatory consideration unless their cost and risk attributes are explored in more careful detail.

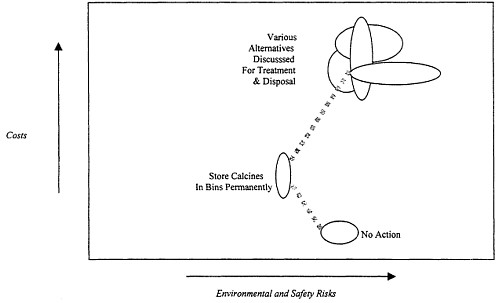

Figure B-1 gives the sense that there really is a cost-risk trade-off to decide on. However, there are more dimensions to risk than just the environmental. There are safety concerns associated with the treatment activities, and the safety risk almost certainly increases with the amount of treatment. Figure B-2 illustrates a possible cost-risk curve when risk is redefined to include both environmental and human safety risks, If information available today were summa-

rized in this form (Figures B-1 and B-2 are hypothetical and purely meant to illustrate methods for thinking about trade-offs), the debate may be better targeted to finding "better" options, and this might lessen the importance of obtaining precise cost estimates for the waste treatment technologies. The differences among the treatment alternatives described in August may start to seem relatively minor compared to the basic questions of whether the attendant incremental risk reduction is worth the incremental cost, and whether there might be intermediate solutions providing more reasonable trade-offs.

Role of Privatization in Costs

A few times during the August meeting, the discussion came around to the possibility of this waste treatment activity being privatized. Privatization is assumed in the Ten-Year Plan for budget purposes, with an attendant assumption that costs will be reduced by 20 percent over the existing estimates. I do believe that privatization can lead to cost decreases over a non-privatized clean up. However, I do not believe that engineering cost estimates will be decreased by 20 percent, or any other arbitrary factor. Rather, privatization may only reduce the chance that actual costs will exceed the estimates.

I could go into some depth about why these factors should not be used. However, we should also note that these factors would apply to all of the options equally. An across-the-board scaling down of cost estimates will not affect the cost ranking of the alternative approaches. It is therefore not important to dwell on numerical assumptions. Rather, it should be noted that the benefits of privatization derive from the way that a carefully thought-out privatization scheme creates management flexibility and incentives to make good use of that flexibility. The longer privatization is delayed in the process of deciding how to best manage the INEEL wastes, the less the opportunities to gain from its potential benefits. The current plan assumes privatization will only occur after the particular waste treatment technology has been identified and developed. At that point many of the potential benefits of privatization may have been lost.

I therefore suggest that if privatization is to be attempted that DOE seriously consider the merits of speeding this process up. I also recommend that attempts to incorporate the effects of privatization into cost estimates be avoided: it won't improve the cost estimates, and it won't substantively affect the decisions among alternatives.

Assessing Trade-Offs in a Multiattribute Setting

Everyone recognizes that neither costs, nor risks, nor cost-risk trade-offs alone will determine the best alternative. There are other attributes, sometimes less quantifiable, that people consider important as either leading terms or modifiers to the decision among alternatives. The "Murphy report" (Murphy et al., 1995) provides an assessment of alternatives that accounts for the role of multiple attributes and alternative values among different interested parties. This report is a good example of some of the things that can be done to help illuminate options that are robust across a range of criteria and a range of value systems, without resorting to the controversial and sometimes "black-box" approach known as "multi-attribute utility analysis" (MAUD).

I recommend that multiattribute summary presentations also be used for the final INEEL waste treatment decision, when the time comes to integrate all of the technology information. The approach initiated in the Murphy report can serve as a starting point. I also point to some additional tools and techniques that can help in visually representing the ways that different alternatives make trade-offs among multiple decision-relevant attributes. In the past, I assisted

the U.S. EPA in developing and applying visual multiattribute assessment techniques to large, long-term decisions such as regional adaptation strategies for climate change. The approach was facilitated by a PC tool called TEAM (Tool for Environmental Assessment and Management), which EPA distributes. However, the concepts are simple, relying on visual techniques for representing relative and qualitative summaries of how various alternatives perform with respect to multiple different decision criteria. The usefulness of a PC tool is that it provides automatic access to alternative visual display formats and allows groups of users to explore the implications of alternative weighting of attributes in the visual display.