A Viscous Multiblock Flow Solver for Free-Surface Calculations on Complex Geometries

G.Cowles, L.Martinelli (Princeton University, USA)

1 Introduction

The last two decades have brought about many major advances in the ability to predict the steady flow about an advancing ship. Solvers based on several formulations have been developed and validated using experimental data from well known ship forms. Experience has shown that in order to correctly predict the drag of even simple hulls at realistic Froude numbers, the surface cannot be linearized. That is, the dynamic and kinematic conditions must be applied to the fully deformed boundary giving a fully nonlinear update of the free surface. Also, while solution of the inviscid equations can efficiently predict the effects of altering hullform coefficients, in order to accurately predict the total drag, the interaction between the free surface and the viscous layer must be accounted for. This can be done by solving the full Reynolds averaged Navier Stokes equations (RANS) in the entire flowfield in conjunction with a proper model for the eddy viscosity. Lastly, in order to be useful within the time constraints of a typical design schedule, the run time of the solver must be on the order of several hours.

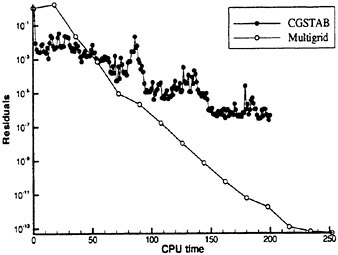

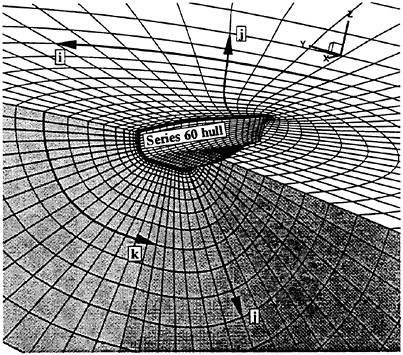

Several of the higher order domain methods include all the necessary aspects described above. However, the quality of the mesh has a large effect on both the convergence and accuracy of these methods. Realistic hullforms can be considerably more complicated than the Wigley hull. Fully appended sailboats and submarines as well as naval combatants with transom sterns give rise to topological constraints which can make it difficult, if not impossible for the grid generator to produce a high quality single block mesh with spacing suitable for Navier Stokes calculations. One solution to this problem is to eliminate the constraints of mapping a single Cartesian domain to the hull by using an unstructured mesh. However the successive generation of high quality, three dimensional unstructured meshes necessary to follow the deformation of the free surface is very expensive and complicated. Also, even with an efficient implementation, the flow solver is only about half as computationally efficient when compared with a structured solver with equal resolution. An alternative route to the improvement of grid quality is to use a multiblock implementation. It can provide exceptional topological flexibility which facilitates a more efficient placement of points as well as smooth the skewness of cells and gradients in spacing.

We decided that in order to begin making routine calculations on realistic ship geometries with run times suitable for use in a design process, a parallel, multiblock implementation was necessary. The strategy was to maintain as many elements of the efficient single processor cell-vertex based solver that was already in place. This vertex formulation [9] had benefitted from several developments. Excellent convergence rates were obtained by using multigrid acceleration, local time stepping, and residual smoothing in the bulk flow. Accuracy stemmed from the utilization of limiters in the free surface dissipation as well as the incorporation of a fully nonlinear free surface boundary condition. As an intermediate step towards our goal, a single block, parallel version of the solver was developed. This required a change from the cell-vertex stencil to a cell-center. This was because in the method of domain decomposition, a cell-vertex scheme requires processors to share flow field values at subdomain faces which can lead to difficulties with implementation at the interface. Details of the method as well as some results can be found in [17]

Once that was in place, a parallel, multiblock version was implemented in which viscous terms as well as a turbulence model are included. The multiblock strategy has only minimal effect on the efficiency of the code. Thus, similar to the single block, parallel version, inviscid flow solutions are achieved in minutes on eight processors. Due to the increased number of grid points, reduced time step, and added work in calculating the viscous terms, solutions of the Navier Stokes equations require a factor of 20 increase in CPU time over

the inviscid case. Thus, converged NS runs require about three hours on eight processors.

The establishment of an efficient baseline multiblock flow solver is extremely important because it enables both sea-keeping analysis and optimization to become practical tools in the design process.

2 Mathematical Models

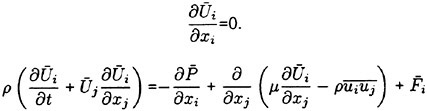

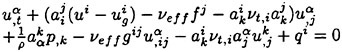

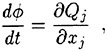

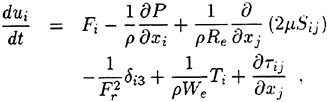

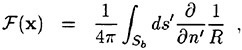

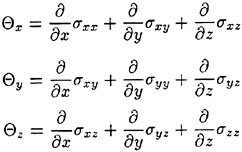

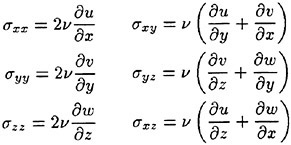

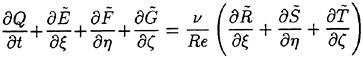

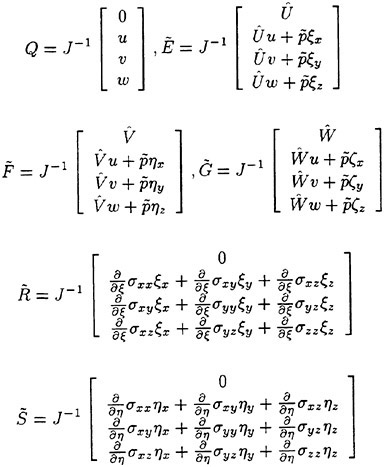

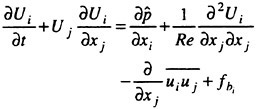

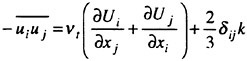

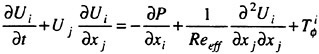

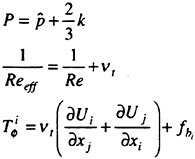

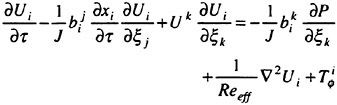

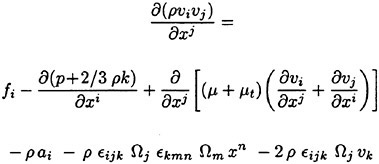

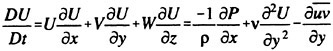

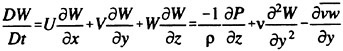

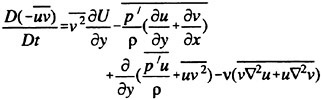

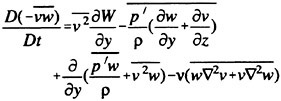

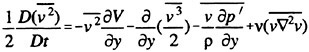

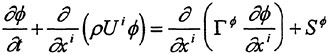

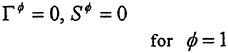

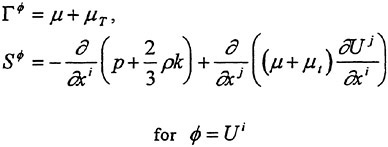

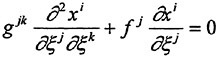

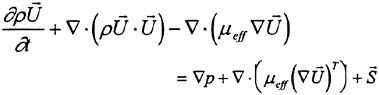

For a viscous incompressible fluid moving under the influence of gravity, the differential form of the continuity equation and the Reynolds Averaged Navier-Stokes equations (RANS) in a Cartesian coordinate system can be cast, using tensor notation, in the form,

Here, ![]() is the mean velocity components in the xi direction,

is the mean velocity components in the xi direction, ![]() the mean pressure, and

the mean pressure, and ![]() the gravity force acting in the i-th direction, and

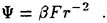

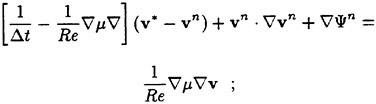

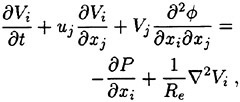

the gravity force acting in the i-th direction, and ![]() is the Reynolds stress which requires an additional model for closure. For implementation in a computer code, it is more convenient to use a dimensionless form of the equation which is obtained by dividing all lengths by the ship (body) length L and all velocity by the free stream velocity U∞. Moreover, one can define a new variable Ψ as the sum of the mean static pressure P minus the hydrostatic component −x3Fr−2. Thus the dimensionless form of the RANS becomes:

is the Reynolds stress which requires an additional model for closure. For implementation in a computer code, it is more convenient to use a dimensionless form of the equation which is obtained by dividing all lengths by the ship (body) length L and all velocity by the free stream velocity U∞. Moreover, one can define a new variable Ψ as the sum of the mean static pressure P minus the hydrostatic component −x3Fr−2. Thus the dimensionless form of the RANS becomes:

where ![]() is the Froude number and the Reynolds number Re is defined by

is the Froude number and the Reynolds number Re is defined by ![]() where ν is the kinematic viscosity, and is

where ν is the kinematic viscosity, and is ![]() a dimensionless form of the Reynolds stress.

a dimensionless form of the Reynolds stress.

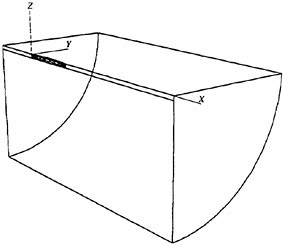

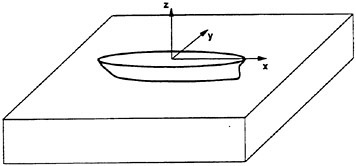

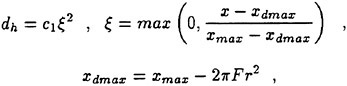

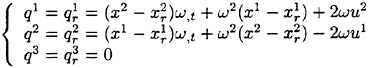

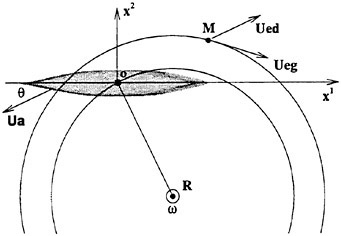

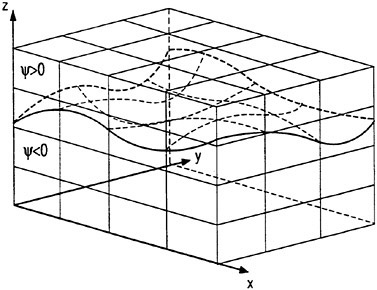

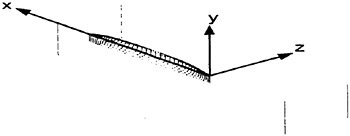

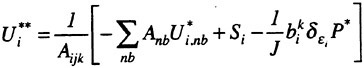

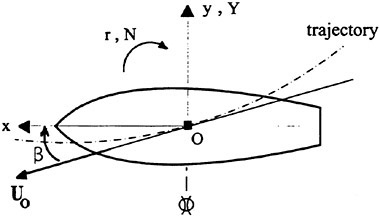

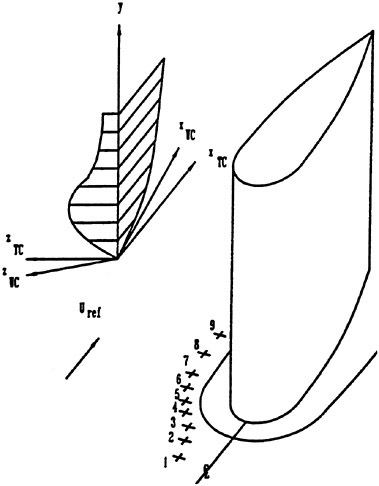

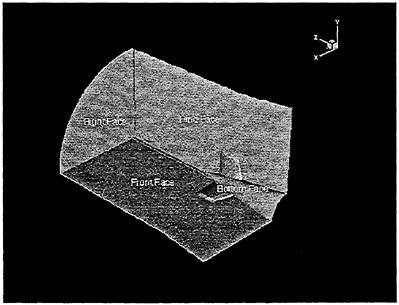

Figure 1 shows the reference frame and ship location used in this work. A right-handed coordinate system Oxyz, with the origin fixed at the intersection of the bow and the mean tree surface is established. The z (x3) direction is positive upwards, y (x2) is positive towards the starboard side and x (x1) is positive in the aft direction. The free stream velocity vector is parallel to the x axis and points in the same direction. The ship hull pierces the uniform flow and is held fixed in place, ie. the ship is not allowed to sink (translate in z direction) or trim (rotate in x−z plane).

It is well known that the closure of the Reynolds averaged system of equation requires a model for the Reynolds stress. There are several alternatives of increasing complexity. Generally speaking, when the flow remains attached to the body,

Figure 1: Reference Frame and Ship Location

a simple turbulence model based on the Boussinesq hypothesis and the mixing length concept yields predictions which are in good agreement with experimental evidence. For this reason a Baldwin and Lomax turbulence model has been initially implemented and tested [5]. On the other hand, more sophisticated models based on the solution of additional differential equations for the component of the Reynolds stress may be required. Notice that when the Reynolds stress vanishes, the form of the equation is identical to that of the Navier Stokes equations. Also, the inviscid form of the Euler equations is recovered in the limit of high Reynolds numbers. Thus, a hierarchy of mathematical model can be easily implemented on a single computer code, allowing study of the controlling mechanisms of the flow. For example, it has been shown in reference [9] that realistic prediction of the wave pattern about an advancing ship can be obtained by using the Euler equations as the mathematical model of the bulk flow, provided that a non-linear evolution of the free surface is accounted for. This is not surprising, since the typical Reynolds number of an advancing vessel is of the order of 108.

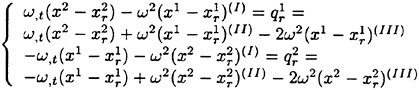

Free Surface Boundary Conditions

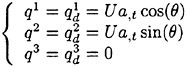

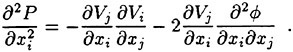

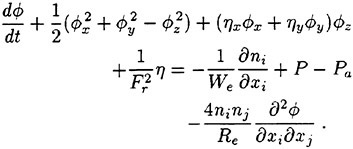

When surface tension as well as tangential stresses are neglected, the boundary condition on the free surface consists of two equations. The first, the dynamic condition, states that the pressure acting on the free surface is equal to the stresses normal to the free surface. It was found that the inclusion of the viscous stresses had little to no effect on the solution since they are of the order ![]() . Thus the dynamic condition that pressure is a constant is a good approximation. The kinematic condition states that the free surface is a material surface: once a fluid particle is on the free surface, it forever remains on the surface. The dynamic and kinematic boundary conditions may be expressed as

. Thus the dynamic condition that pressure is a constant is a good approximation. The kinematic condition states that the free surface is a material surface: once a fluid particle is on the free surface, it forever remains on the surface. The dynamic and kinematic boundary conditions may be expressed as

p=constant

(1)

where z=β (x, y, t) is the free surface location.

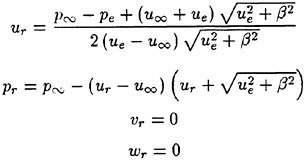

Hull and Farfield Boundary Conditions

The remaining boundaries consist of the ship hull, the meridian, or symmetry plane, and the far field of the computational domain. In the viscous formulation, a no-slip condition is enforced on the ship hull. For the inviscid case, flow tangency is preserved. On the symmetry plane (that portion of the (x, z) plane excluding the ship hull) derivatives in the y direction as well as the υ component of velocity are set to zero. The upstream plane has u=Uo, υ=0, w=0 and ψ=0 (p=−zFr−2). Similar conditions hold on the outer boundary plane which is assumed far enough away from the hull such that no disturbances are felt. A radiation condition should be imposed on the outflow domain to allow the wave disturbance to pass out of the computational domain. Although fairly sophisticated formulations may be devised to represent the radiation condition, simple extrapolations proved to be sufficient in this work.

For calculations in the limit of zero Froude number (double-hull model) the (z=0) plane is also treated as a symmetry plane.

3 Numerical Solution

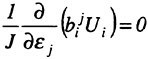

The formulation of the numerical solution procedure is based on a finite volume method (FVM) for the bulk flow variables (u, υ, w and ψ), coupled to a finite difference method for the free surface evolution variables (β and ψ).

Bulk Flow Solution

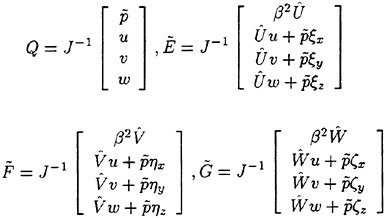

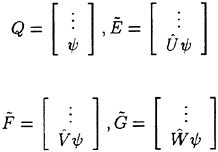

The finite volume solution for the bulk flow follows the same procedures that are well documented in references [1, 2]. The governing set of differential flow equations are expressed in the standard form for artificial compressibility [6] as outlined by Rizzi and Eriksson [7]. In particular, letting w be the vector of dependent variables:

(2)

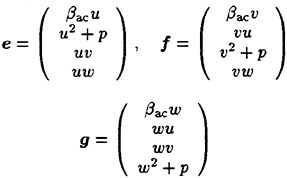

Here f, g, h and fv, gv, hv represent, respectively, the inviscid and viscous fluxes.

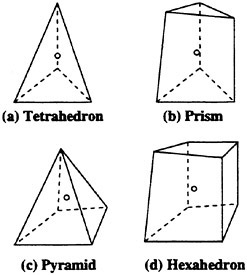

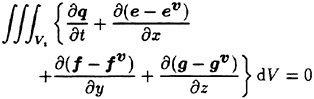

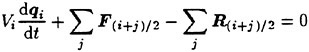

Following the general procedures used in the finite volume formulation, the governing differential equations are integrated over an arbitrary volume V. Application of the divergence theorem on the convective and viscous flux term integrals yields

(3)

where Sx, Sy and Sz are the projections of the area ∂V in the x, y and z directions, respectively. In the present approach the computational domain is divided into hexahedral cells. Two discretization schemes are considered in the present work. They differ primarily in that in the first, the flow variables are stored at the grid points (cell-vertex) while in the second they are stored in the interior of the cell (cell-center). While the details of the computation of the fluxes are different for the two approaches, both cell-center and cell-vertex schemes yield the following system of ordinary differential equations [4]

where Cijk and Vijk are the discretized evaluations of the convective and viscous flux surface integrals appearing in equation 3 and Vijk is the volume of the computational cell. In practice, the discretization scheme reduces to a second order accurate, nondissipative central difference approximation to the bulk flow equations on sufficiently smooth grids. A central difference scheme permits odd-even decoupling at adjacent nodes which may lead to oscillatory solutions. To prevent this “unphysical” phenomena from occurring, a dissipation term is added to the system of equations such that the system now becomes

(4)

For the present problem a fourth derivative background dissipation term is added. The dissipative term is constructed in such a manner that the conservation form of the system of equations is preserved. The dissipation term is third order in truncation terms so as not to detract from the second order accuracy of the flux discretization.

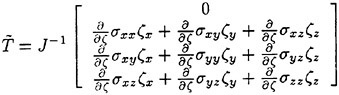

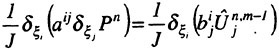

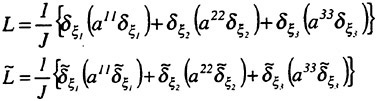

Discretization of the Viscous Terms

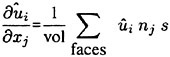

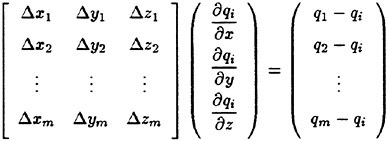

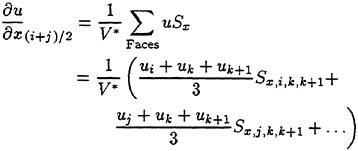

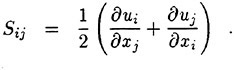

The discretization of the viscous terms of the Navier Stokes equations requires an approximation to the velocity derivatives ![]() in order to calculate the stress tensor. In order to evaluate the derivatives one may apply the Gauss formula to a control volume V with the boundary S.

in order to calculate the stress tensor. In order to evaluate the derivatives one may apply the Gauss formula to a control volume V with the boundary S.

where nj is the outward normal. For a hexahedral cell this gives

(5)

where ûi is an estimate of the average of ui over the face.

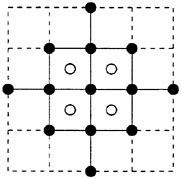

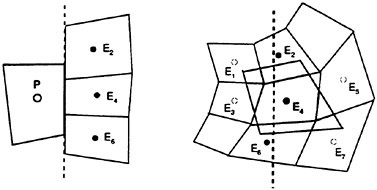

This technique requires motivates the introduction of dual meshes for the evaluation of the velocity derivatives and the flux balance as sketched for for the two dimensional case in figure 2.

Figure 2: Viscous discretization for cell-centered algorithm.

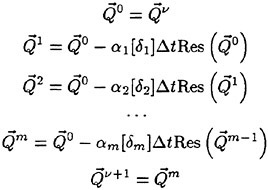

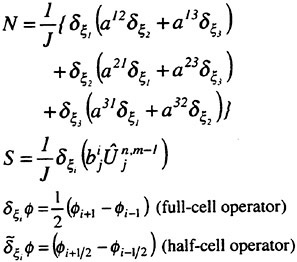

Multigrid time-stepping

Equation 4 is integrated in time to steady state using an explicit multistage scheme. For each bulk flow time step, the grid, and thus Vijk, is independent of time. Hence equation 4 can be written as

(6)

where the residual is defined as

and the cell volume Vijk is absorbed into the residual for clarity.

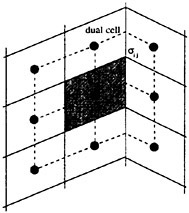

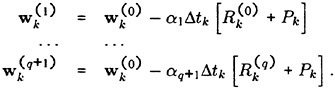

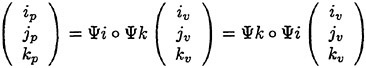

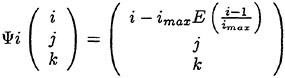

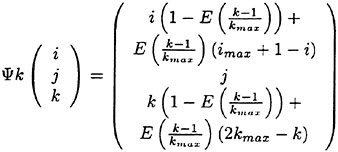

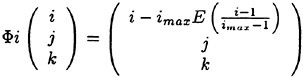

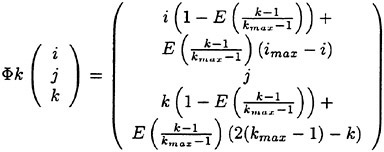

The full approximation multigrid scheme of this work uses a sequence of independently generated coarser meshes by eliminating alternate points in each coordinate direction. In order to give a precise description of the multigrid scheme, subscripts may be used to indicate the grid. Several transfer operations need to be defined. First the solution vector on grid k must be initialized as

where wk−1 is the current value on grid k−1, and Tk,k−1 is a transfer operator. Next it is necessary to transfer a residual forcing function such that the solution grid k is driven by the residuals calculated on grid k−1. This can be accomplished by setting

where Qk,k−1 is another transfer operator. Then Rk (wk) is replaced by Rk (wk)+Pk in the time- stepping scheme. Thus, the multistage scheme is reformulated as

The result wk(m) then provides the initial data for grid k+1. Finally, the accumulated correction on grid k has to be transferred back to grid k−1 with the aid of an interpolation operator Ik−1,k. Clearly the definition of Tk,k−1, Qk,k−1, Ik−1,k depends on whether a cell-vertex or a cell-center formulation is selected. A detailed account can be found in reference [13].

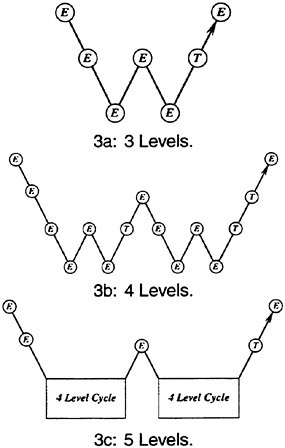

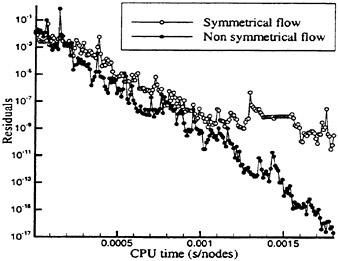

With properly optimized coefficients, multistage time-stepping schemes can be very efficient drivers of the multigrid process. In this work we use a five stage scheme with three evaluation of dissipation [8] to drive a W-cycle of the type illustrated in Figure 3.

Figure 3: Multigrid W-cycle for managing the grid calculation. E, evaluate the change in the flow for one step; T, transfer the data without updating the solution.

In a three-dimensional case the number of cells is reduced by a factor of eight on each coarser grid. On examination of the figure, it can therefore be seen that the work measured in units corresponding to a step on the fine grid is of the order of

and consequently the very large effective time step of the complete cycle costs only slightly more than a single time step in the fine grid.

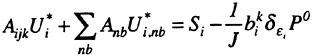

Free Surface Solution

Both a kinematic and dynamic boundary condition must be imposed at the free surface which require the adaption of the

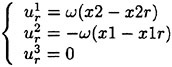

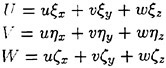

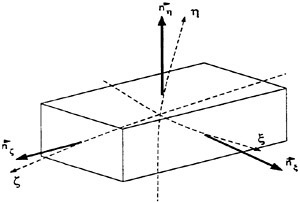

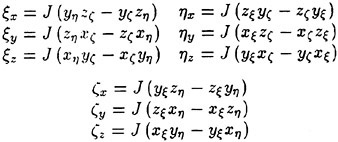

grid to conform to the computed surface wave Since flow values are stored at cell centers, they must be extrapolated up one half cell for solution of the kinematic condition. By introducing a curvilinear coordinate system that transforms the curved free surface β (x, y) into computational coordinates β (ξ, η), equation 1 can be case in a form more amenable to integration. This results in the following kinematic condition:

(7)

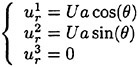

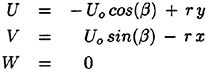

Where U and V are the contravariant velocity components give by:

(8)

(9)

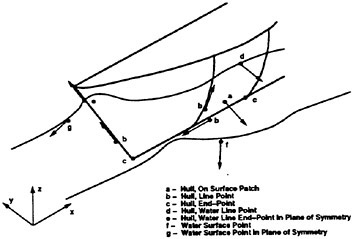

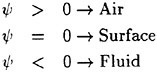

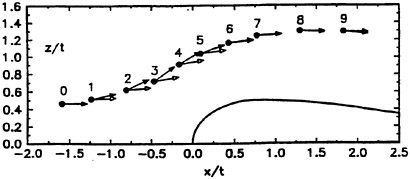

Figure 4 displays the computational stencil for the free surface update. It differs slightly from the bulk flow stencil, owing to velocity values held at the centers of the surface faces, while the free surface heights are held at surface vertices. The integration is a 3 stage Runge Kutta algorithm with dissipation evaluations on all stages.

Figure 4: Free Surface Stencil

In our original method, equation 7 was augmented by high order diffusion [1, 2]. Such a scheme can be obtained by introducing anti-diffusive terms in a standard first order formula. In particular, it is well known that for a one-dimensional scalar equation model, central difference approximation of the derivative may be corrected by adding a third order dissipative flux:

(10)

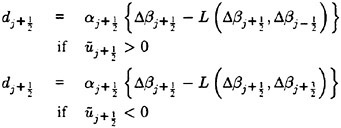

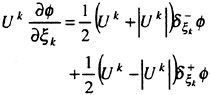

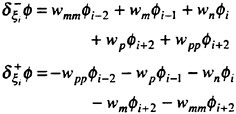

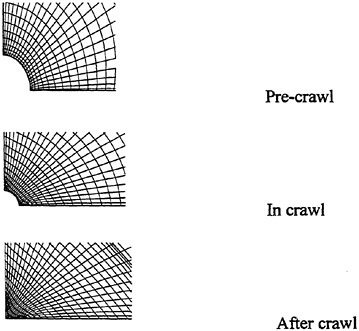

where ![]() at the cell interface. This is equivalent to the scheme which we have used until now to discretize the free surface, and which has proven to be effective for simple hulls. However, on more complex configurations of interest, such as combatant vessels and yachts, the physical wave at the bow tends to break. This phenomenon cannot be fully accounted for in the present mathematical model. In order to avoid the overturning of the wave and continue the calculations lower order dissipation must be introduced locally and in a controlled manner. This can be accomplished by borrowing from the theory of non-oscillatory schemes constructed using the Local Extremum Diminishing (LED) principle [10, 11]. Since the breaking of a wave is generally characterized by a change in sign of the velocity across the crest, it appears that limiting the antidiffusion purely from the upstream side may be more suitable to stabilize the calculations and avoid the overturning of the waves [12]. By adding the anti-diffusive correction purely from the upstream side one may derive a family of UpStream Limited Positive (USLIP) schemes:

at the cell interface. This is equivalent to the scheme which we have used until now to discretize the free surface, and which has proven to be effective for simple hulls. However, on more complex configurations of interest, such as combatant vessels and yachts, the physical wave at the bow tends to break. This phenomenon cannot be fully accounted for in the present mathematical model. In order to avoid the overturning of the wave and continue the calculations lower order dissipation must be introduced locally and in a controlled manner. This can be accomplished by borrowing from the theory of non-oscillatory schemes constructed using the Local Extremum Diminishing (LED) principle [10, 11]. Since the breaking of a wave is generally characterized by a change in sign of the velocity across the crest, it appears that limiting the antidiffusion purely from the upstream side may be more suitable to stabilize the calculations and avoid the overturning of the waves [12]. By adding the anti-diffusive correction purely from the upstream side one may derive a family of UpStream Limited Positive (USLIP) schemes:

Where L (p, q) is a limited average of p and q with the following properties:

P1. L (p, q)=L (q, p)

P2. L (αp, αq)=αL (p, q)

P3. L (p, p)=p

P4. L (p, q)=0 if p and q have opposite signs.

It is well known that schemes which strictly satisfy the LED principle fall back to first order accuracy at extrema even when they realize higher order accuracy elsewhere. This difficulty can be circumvented by relaxing the LED requirement. Therefore the concept of essentially local extremum diminishing (ELED) schemes is introduced as an alternative approach. These are schemes for which, in the limit as the mesh width Δx → 0, maxima are non-increasing and minima are non-decreasing. In order to prevent the limiter from being active at smooth extrema it is convenient to set

where D (p, q) is a factor designed to reduce the arithmetic average, and become zero if u and v have opposite signs. Thus, for an ELED scheme we take

(11)

where

(12)

Properties P1–P3 are natural properties of an average, whereas P4 is needed for the construction of an LED scheme.

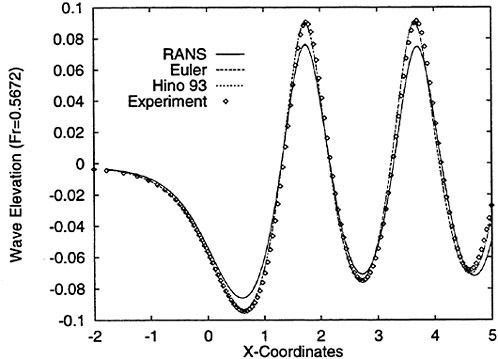

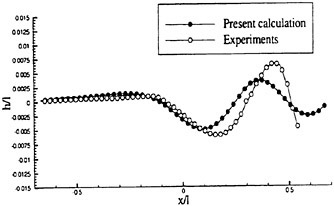

and ∈>0, r is a positive power, and s is a positive integer. Then D (p, q)=0 if p and q have opposite signs. Also if s=1, L (p, q) reduces to minmod, while if s=2, L (p, q) is equivalent to Van Leer’s limiter. By increasing s one can generate a sequence of limited averages which approach a limit defined by the arithmetic mean truncated to zero when p and q have opposite signs. These smooth limiters are known to have a benign effect on the convergence to a steady state of compressible flows. In comparison with experiment, it was found that the waterline profile calculated with ELED was more accurate when compared with LED or fourth differencing [17] [12].

Integration and Coupling with The Bulk Flow

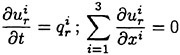

The free surface kinematic equation may be expressed as

where Qij (β) consists of the collection of velocity and spatial gradient terms which result from the discretization of equation 7.

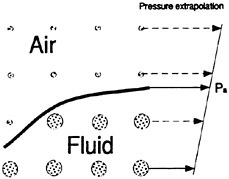

Once the free surface update is accomplished the pressure is adjusted on the free surface such that

The free surface and the bulk flow solutions are coupled by first computing the bulk flow at each time step, and then using the bulk flow velocities to calculate the movement of the free surface. After the free surface is updated, its new values are used as a boundary condition for the pressure on the bulk flow for the next time step. The entire iterative process, in which both the bulk flow and the free surface are updated at each time step, is repeated until some measure of convergence is attained: usually steady state wave profile and wave resistance coefficient.

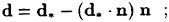

This method of updating the free surface works well for the Euler equations since tangency along the hull can be easily enforced. However, for the Navier-Stokes equations the no-slip boundary condition is inconsistent with the free surface boundary condition at the hull/waterline intersection. To circumvent this difficulty the computed elevation for the second row of grid points away from the hull is extrapolated to the hull. Since the minimum spacing normal to the hull is small, the error due to this should be correspondingly small, comparable with other discretization errors.

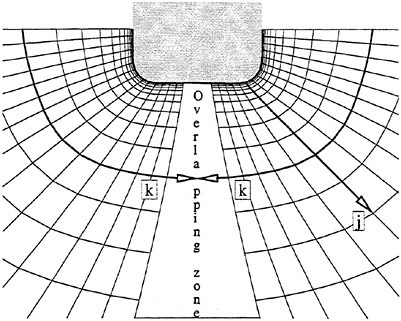

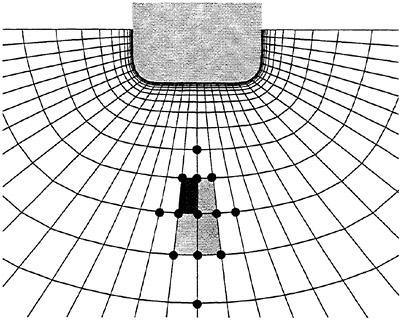

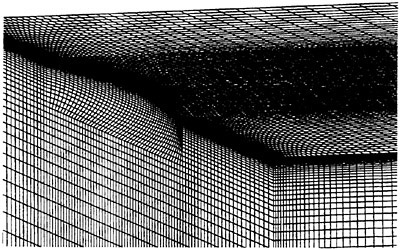

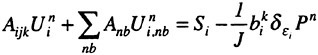

4 Parallel Multiblock Implementation

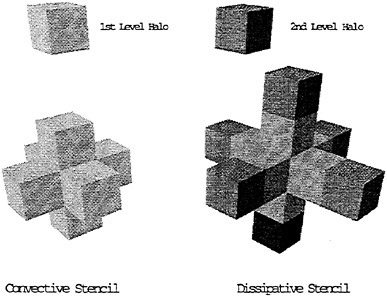

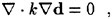

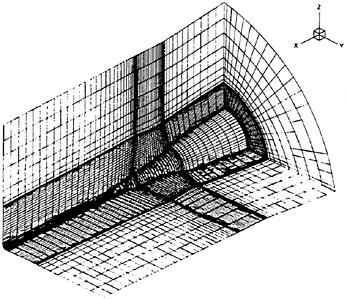

Topological constraints deriving from complex configurations necessitate the integration of a multiblock algorithm into the baseline code. An intermediate step was first taken in the form of a parallel, single block version of the code. Details of this method can be found in [17]. A multiblock strategy has been developed which requires minimum deviation from the parallel single block code. A halo is constructed around each block such that the flow solution within it is transparent to the block boundaries. Since both the convective and the dissipative fluxes are calculated at the cell faces (boundaries of the control volumes), all six neighboring cells are necessary, thus requiring the existence of a single level halo around each block. The dissipative fluxes are composed of third order differences of the flow quantities. Thus, at the boundary faces of each cell in the domain, the presence of the twelve neighboring cells (two adjacent to each face) is required. Figure 5 shows the neighboring cells which are required for the calculation of convective and dissipative fluxes. For each block, some of these cells will lie directly next to an interblock boundary. If the neighboring block is contained in a different processor, it will be necessary to pass the values across processors. With halos properly updated, the blocks

Figure 5: Convective and Dissipative Discretization Stencils.

are simply looped through the single block integrator. Thus, the highly optimized baseline code remains unchanged. The only difference in the integration lies in the implementation of the residual averaging. In the single block case, flow information from the processor’s entire subdomain is used for smoothing. In the multiblock case, only the information from the particular block being processed is utilized for this calculation. The converged solution remains unaffected and thus far, there has not been any significant effect in the rate of convergence.

Since the sizes of the blocks can be quite small, sometimes further partitioning severely limits the number of multigrid levels that can be used in the flows. For this reason, it was decided to allocate complete blocks to each processor.

The underlying assumption is that there always will be more blocks than processors available. If this is the case, every

processor in the domain would be responsible for the computations inside one or more blocks. In the case in which there are more processors than blocks available, the blocks can be adequately partitioned during a pre-processing step in order to at least have as many blocks as processors. This approach has the advantage that the number of multigrid levels that can be used in the parallel implementation of the code is always the same as in the serial version. Moreover, the number of processors in the calculation can now be any integer number, since no restrictions are imposed by the partitioning in all coordinate directions used by the single block program.

The only drawback of this approach is the loss of the exact load balancing that one has in the single block implementation. All blocks in the calculation can have different sizes, and consequently, it is very likely that different processors will be assigned a different total number of cells in the calculation. This, in turn, will imply that some of the processors will be waiting until the processor with the largest number of cells has completed its work and parallel performance will suffer. The approach that we have followed to solve the load balancing problem is to assign to each processor, in a pre-processing step, a certain number of blocks such that the total number of cells is as close as possible to the exact share for perfect load balancing.

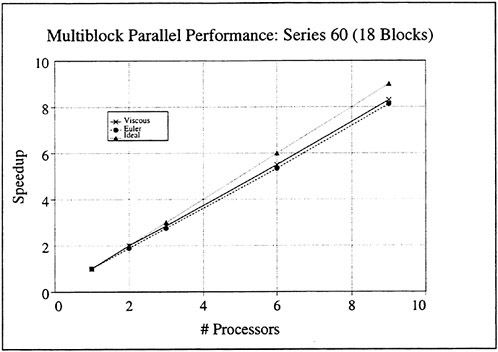

One must note that load balancing based on the total number of cells in each processor is only an approximation to the optimal solution of the problem. Other variables such as the number of blocks, the size of each block, and the size of the buffers to be communicated play an important role in proper load balancing, and are the subject of current study. Figure 20 shows speedups obtained on an 18 block mesh of Series 60 hull. One can see the good scalability of the method. The viscous speedups are closer to ideal due to increased granularity from the added work in calculating the viscous fluxes.

5 Results

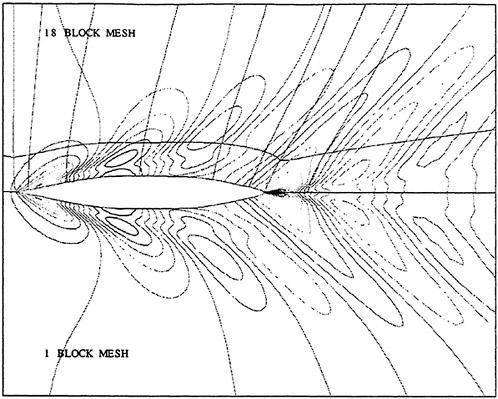

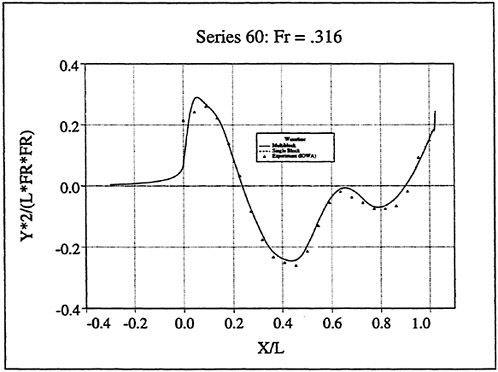

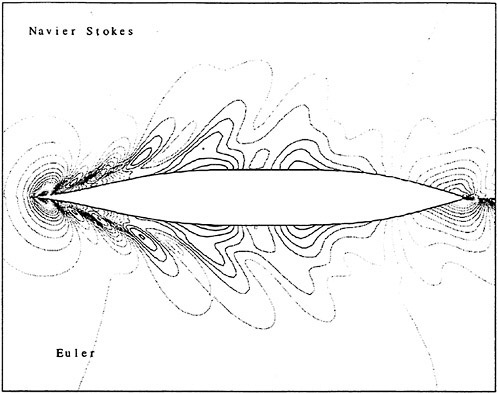

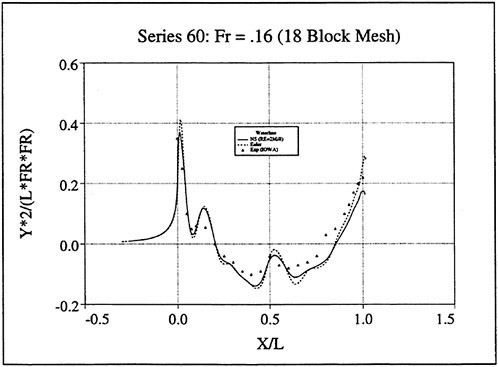

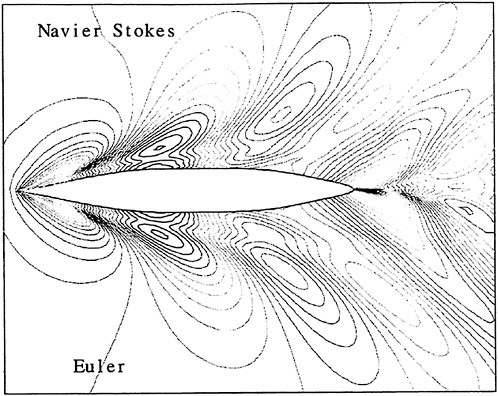

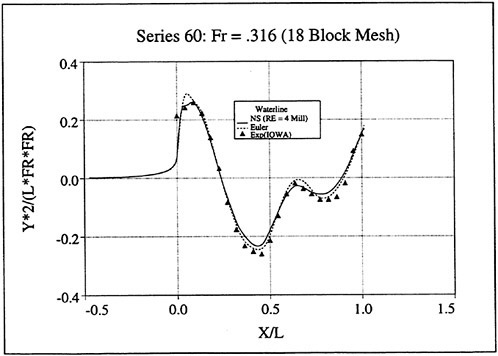

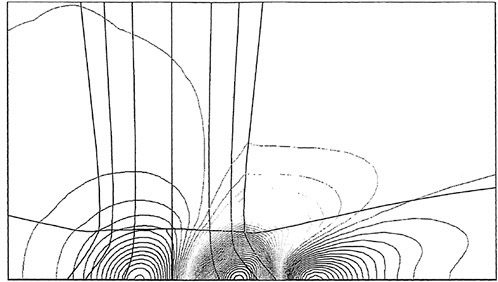

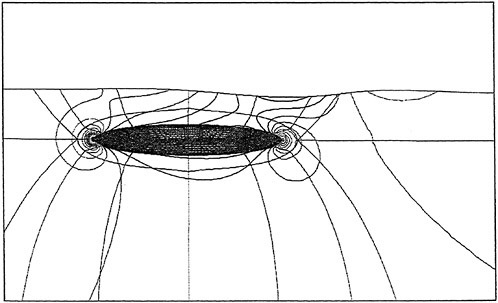

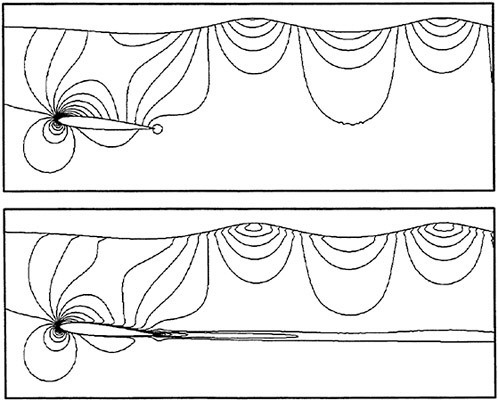

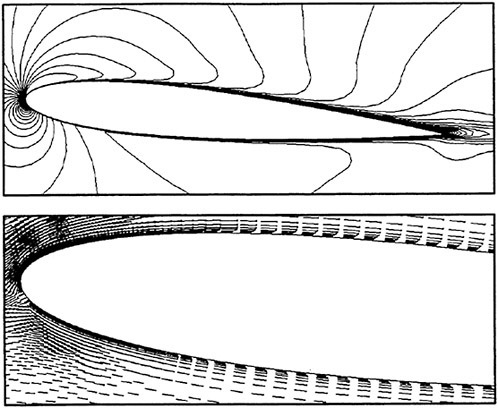

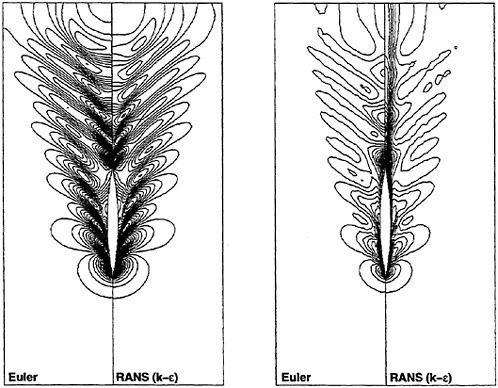

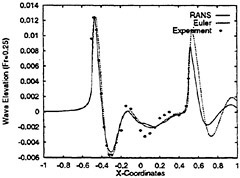

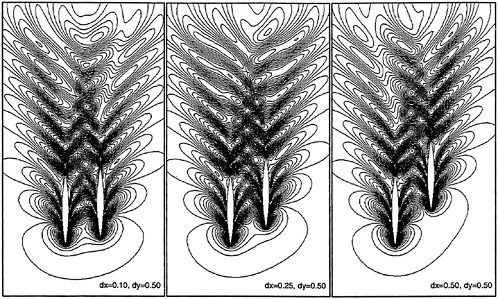

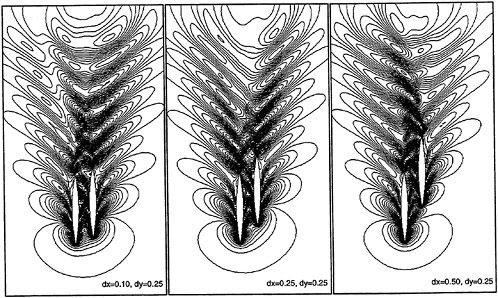

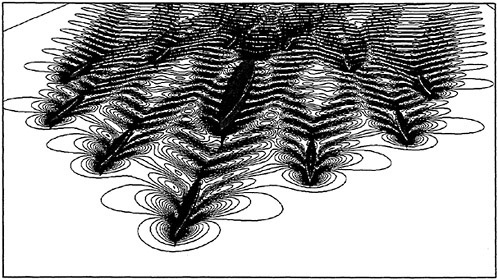

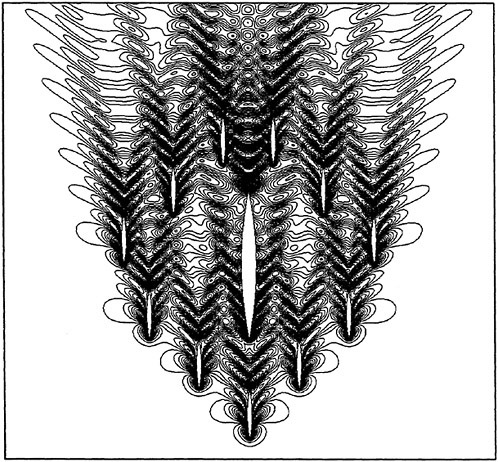

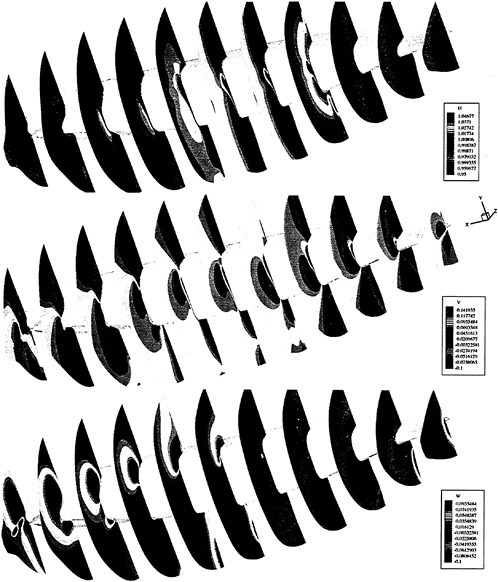

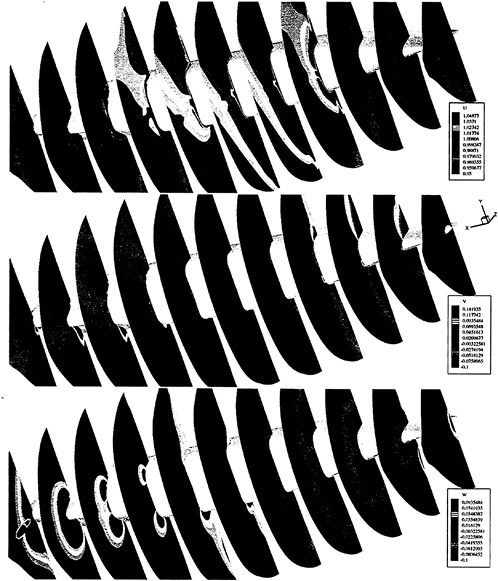

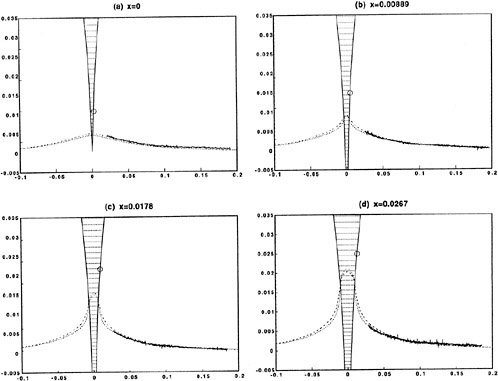

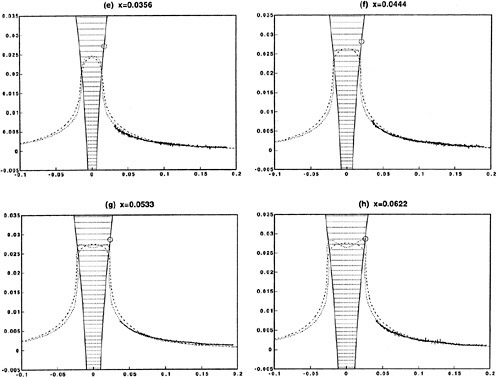

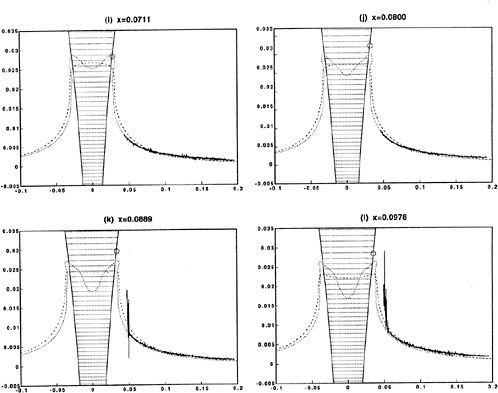

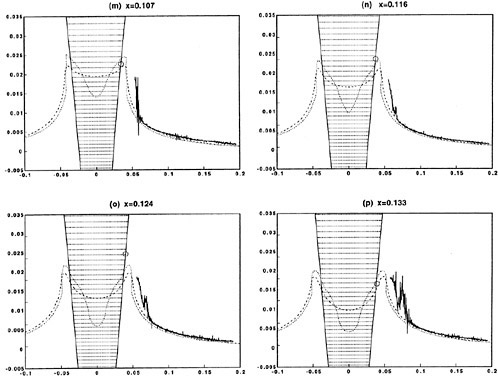

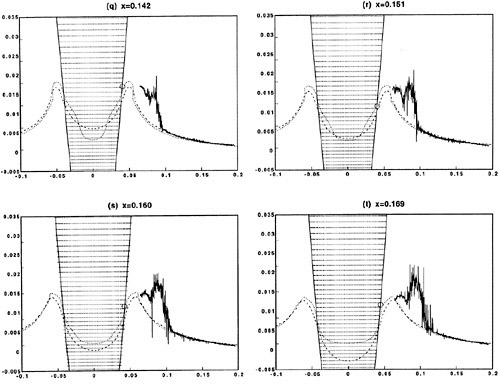

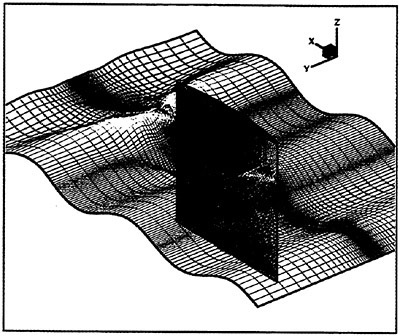

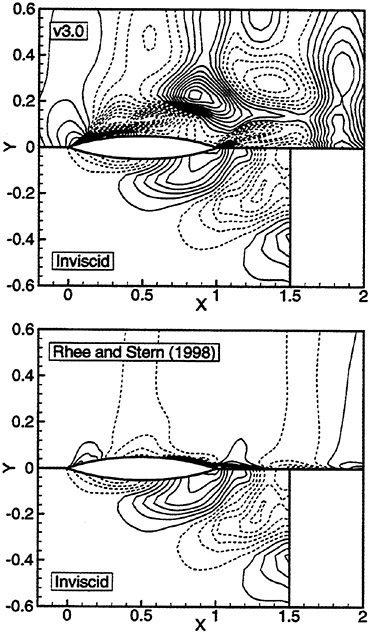

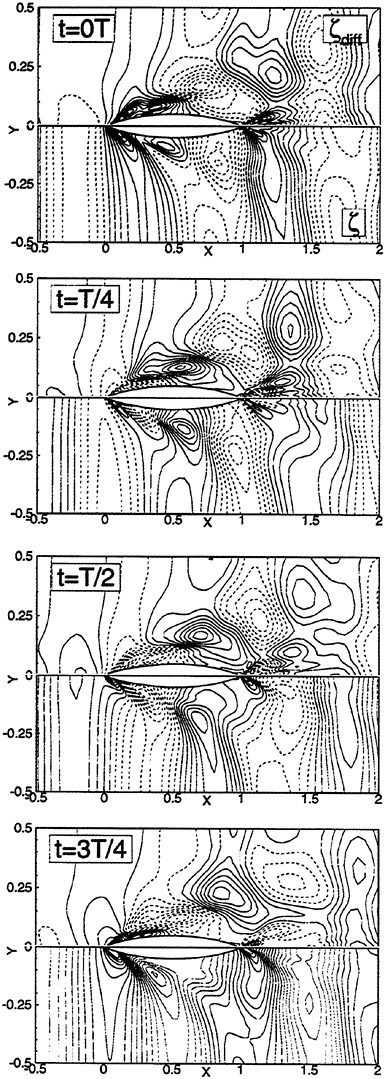

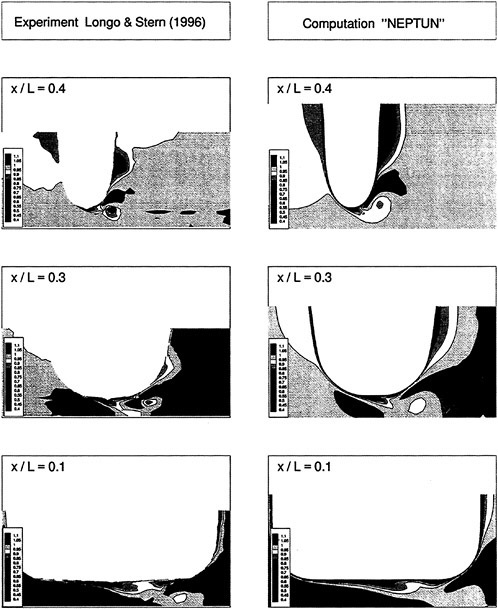

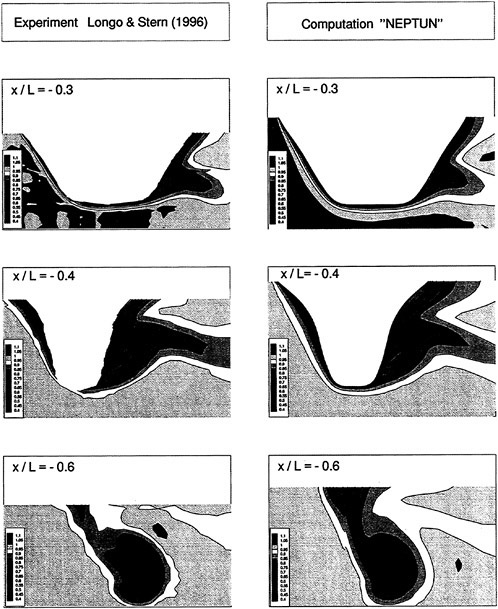

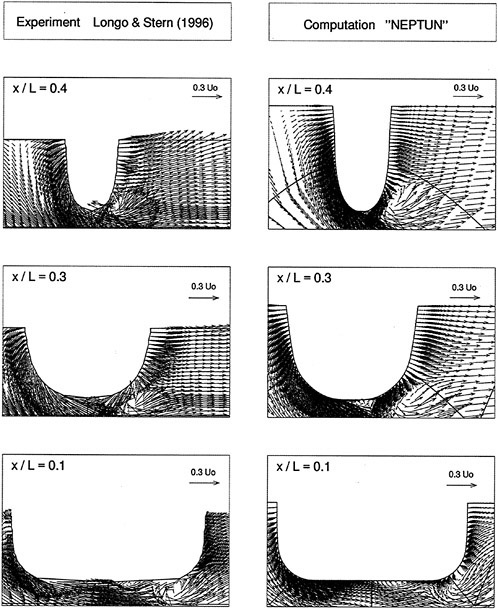

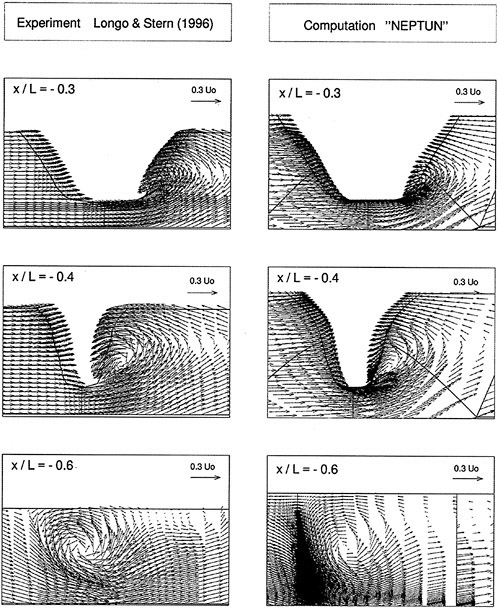

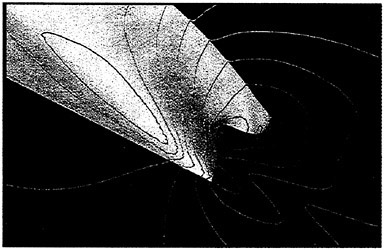

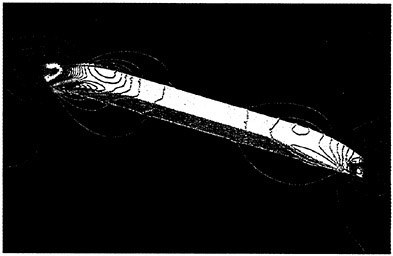

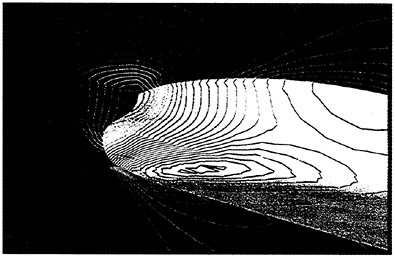

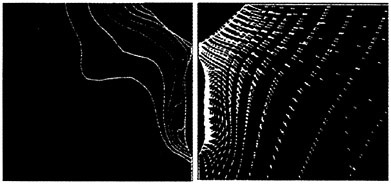

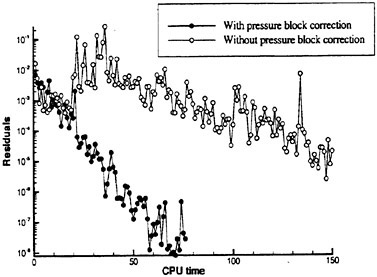

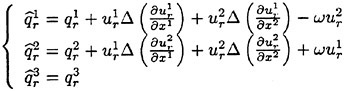

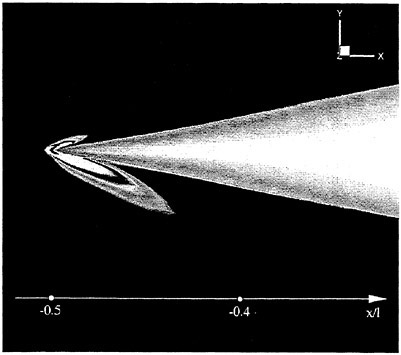

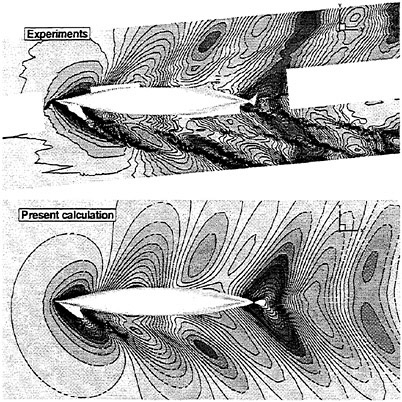

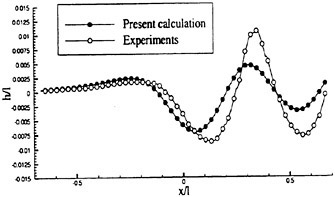

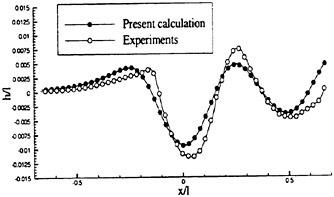

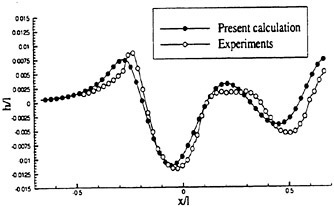

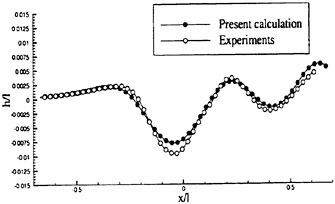

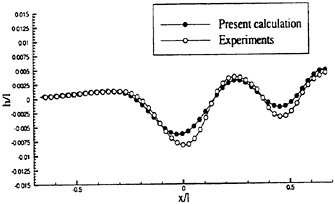

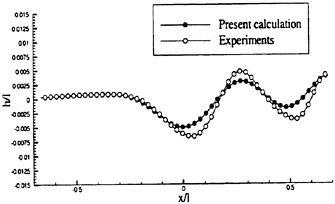

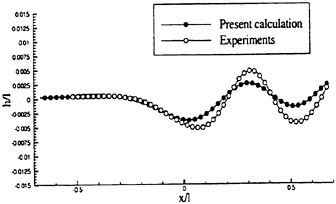

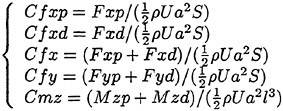

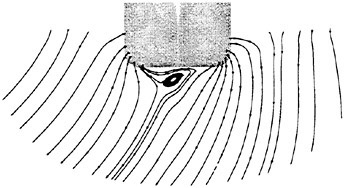

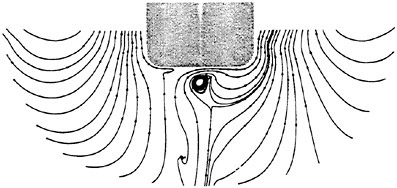

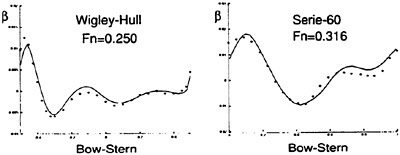

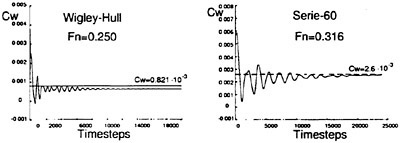

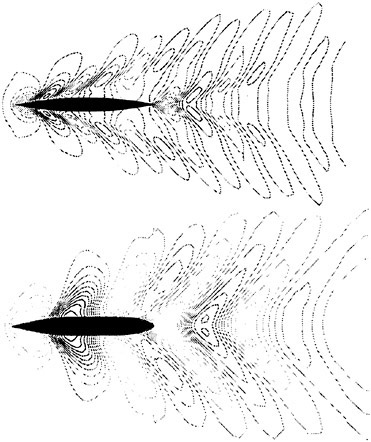

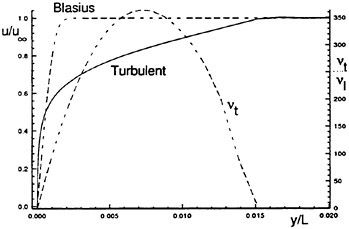

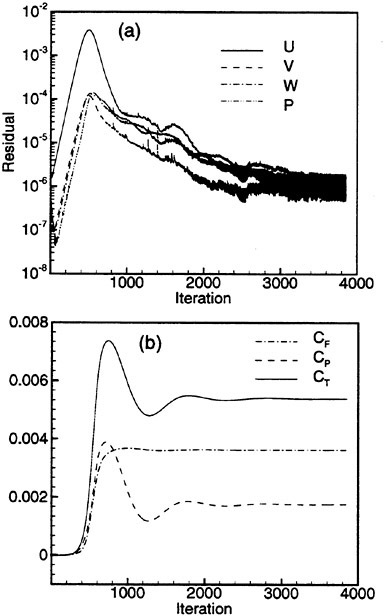

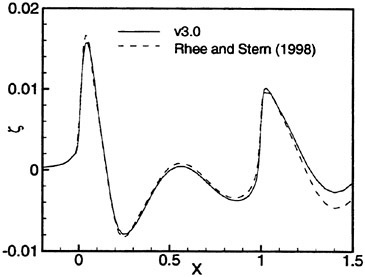

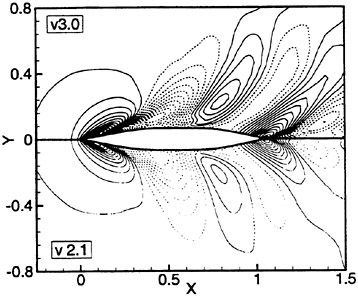

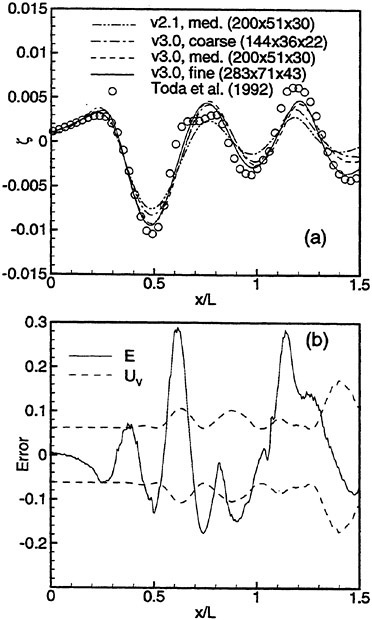

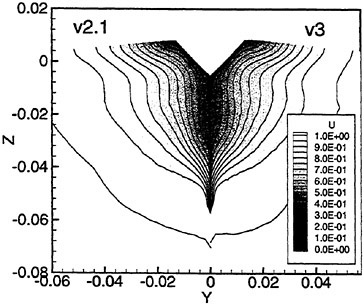

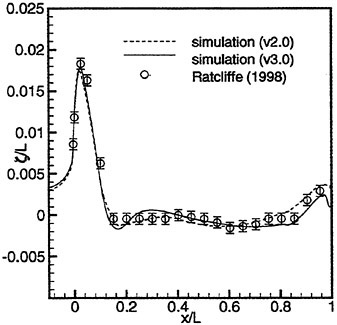

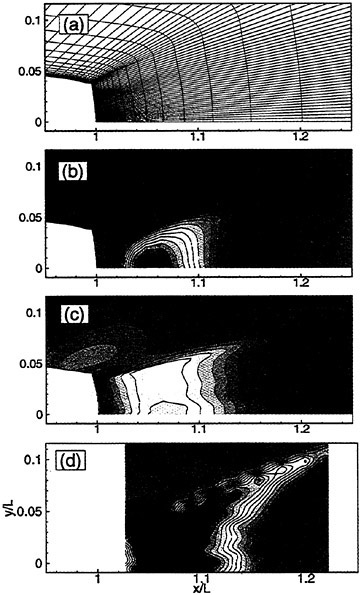

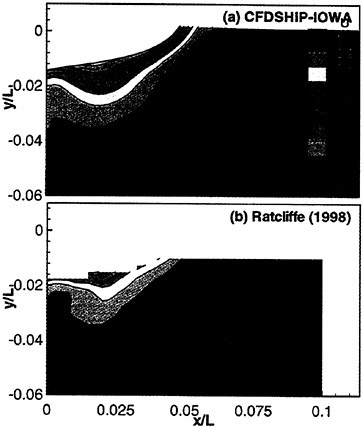

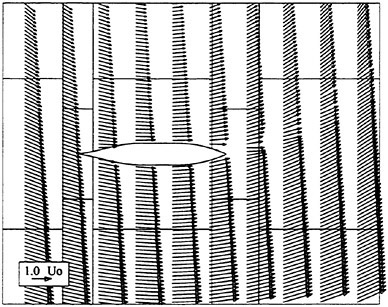

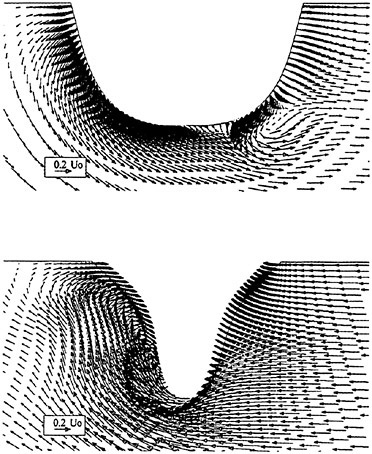

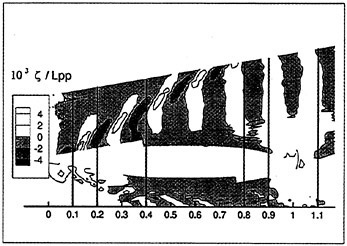

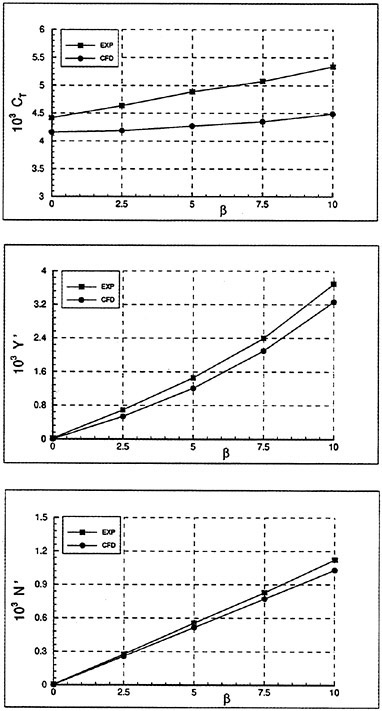

Figures 6 and 7 show overhead wave contours and waterlines for inviscid solutions of the Series 60 at a Froude number of .316. They serve to validate the multiblock code by comparison with both experiment and the previously developed single block parallel code. In order to validate the viscous solver, calculations were performed on the Series 60 hullform for comparison with the experimental data from Iowa [19]. Figures 8 and 9 show overhead wave contours and waterlines for both viscous and inviscid solutions of the Series 60 at Froude=.16. Figures 10 and 11 show wave elevation contours and waterlines for the Series 60 hull at Froude=.316. The Reynolds numbers for these calculations were 2 million and 4 million respectively, corresponding to the Iowa data. The grid spacing near the hull on the NS mesh is such that y+values in the first cell normal to hull reside in the range .75<y+<1.5.

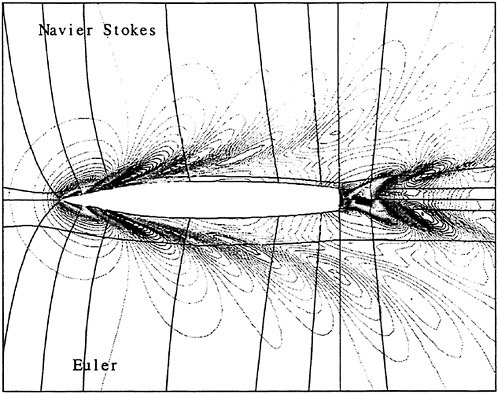

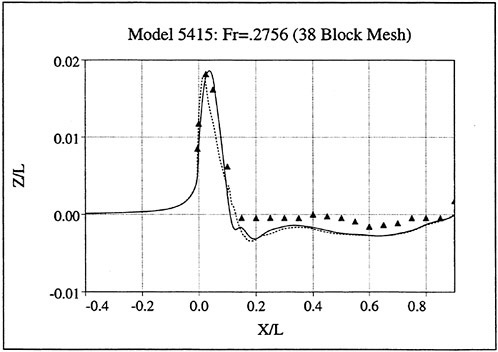

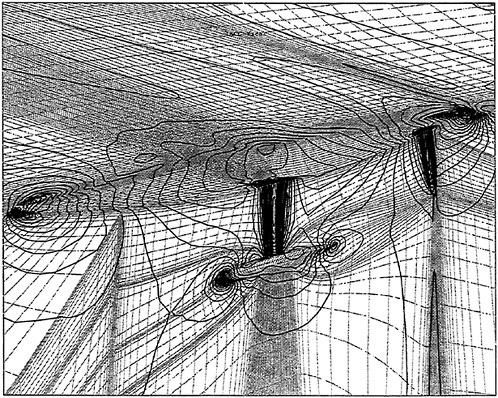

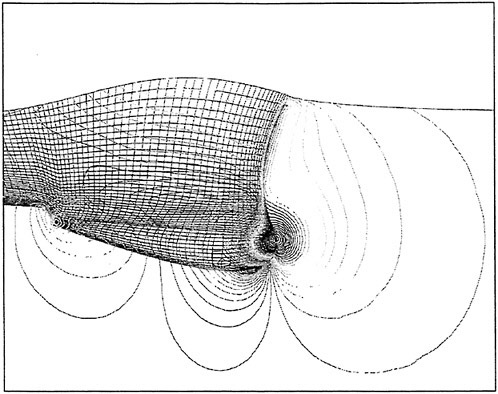

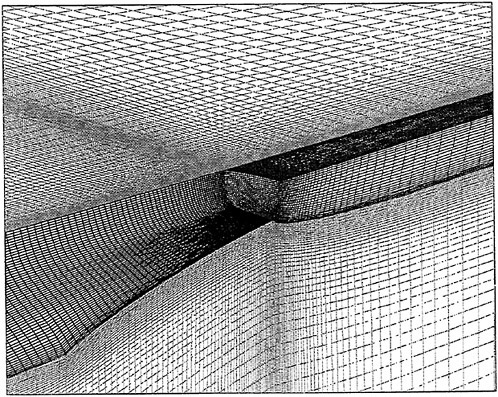

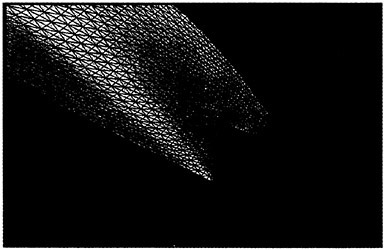

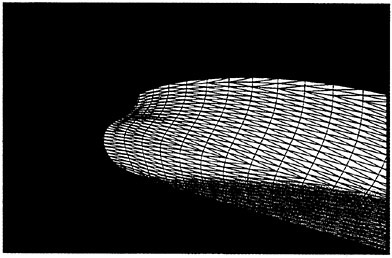

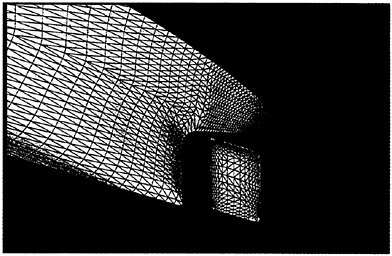

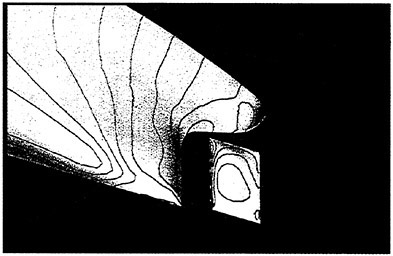

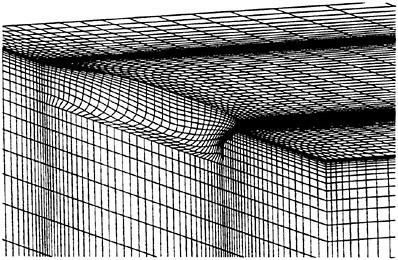

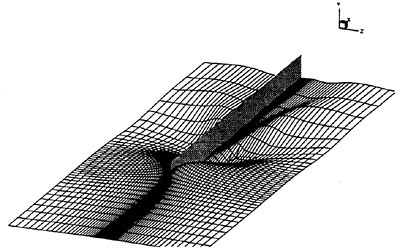

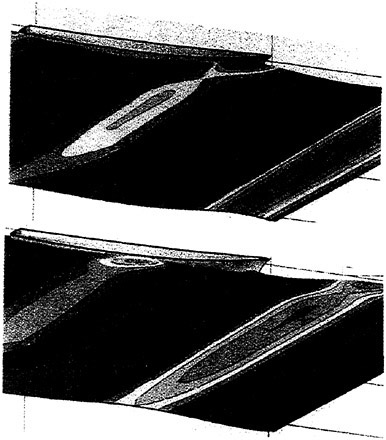

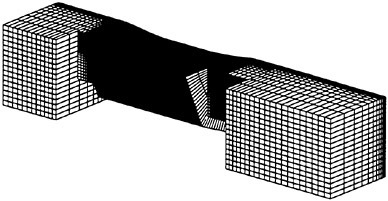

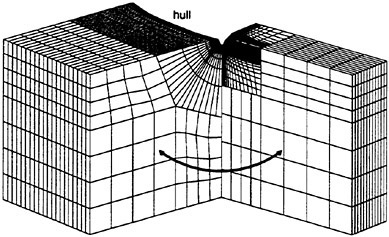

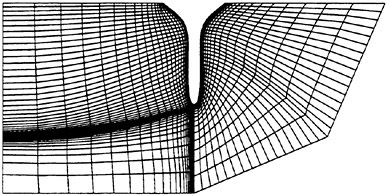

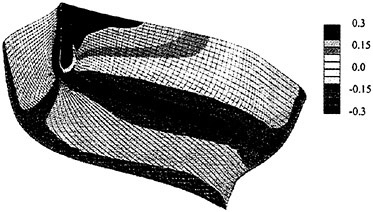

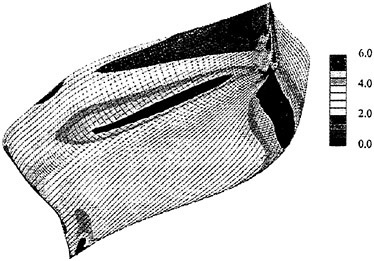

Figures 12 and 13 show overhead wave contours and waterlines for viscous and inviscid solutions of the model 5415 geometry at a Froude number of .2756 (20 Knots full scale). The Reynolds number was 12 million, corresponding to the test data taken at David Taylor Model Basin. Since the hullform has a transom stern, attempts to use a single structured block result in very skewed cells at the intersection of the and the symmetry plane aft of the boat. With a multiblock implementation however, a second block can be fitted to the transom and extended to the outflow plane. Figures 18 and 19 show details of the transom block as well as pressure contours on the sonar bulb.

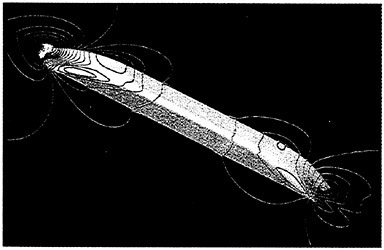

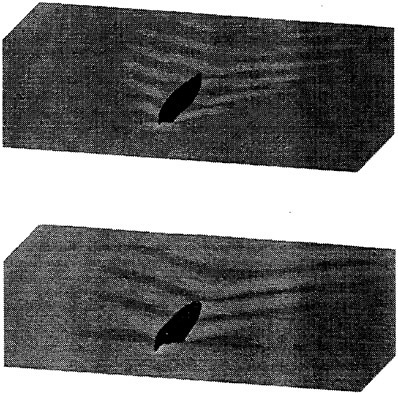

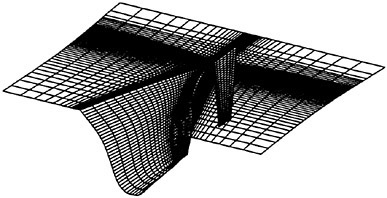

As a preliminary investigation of the application of our method to underwater vehicles, several calculations on a 6:1 ellipsoid were performed. A 1.25 million point mesh consisting of an inner O-H-O layer wrapped in an H-H-H shell was generated. The use of multiple layers facilitates adjustment of the spacing in the boundary layer without affecting the stretching in the far field. Figures 14 and 15 show pressure contours on the ellipsoid moving at a length-based Froude number of .62 and a depth/L of .18. The Reynolds number for this calculation was 4 million.

Initial analysis of an IACC racing yacht has also begun. Figure 16 displays the pressure contours on a double model IACC hull. The mesh topology is similar to the submarine. A O-H-O layer encompasses the hull while a H-H-H completes the far field. This topology was chosen because it will facilitate the addition of keel and rudder to the bare hull.

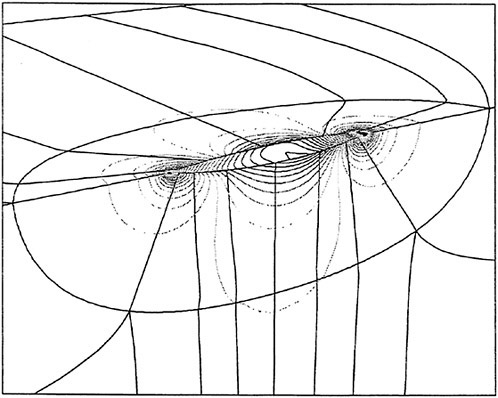

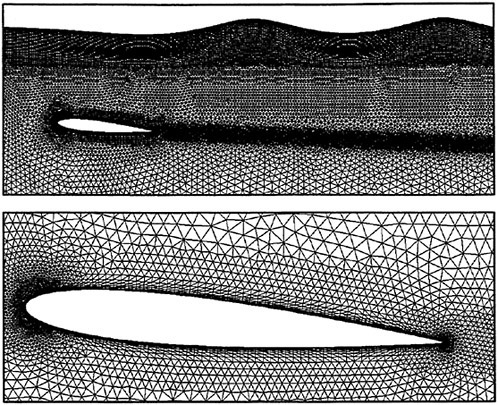

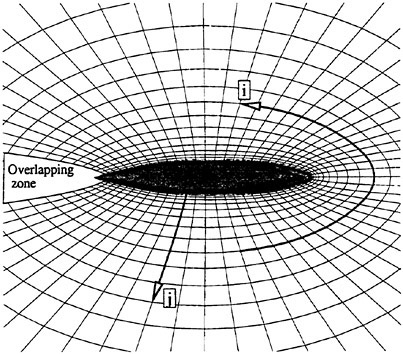

Figure 17 shows an inviscid single block solution on another IACC hull. One can see the highly skewed elements which result from using a single block on a fully appended hullform. Complex configurations such as this sailboat were a primary motivation for the implementation of multiblock.

Conclusion

A cell center, viscous, parallel multiblock version of the code has been developed and implemented. Inviscid flow solutions on the order of half an hour for a grid size of one million mesh points have been achieved on 16 processors of an IBM SP2. Viscous solutions on a mesh of same dimensions demand a factor of 5 increase in CPU work. Future efforts will concentrate on reducing the discrepancy in calculation time between the inviscid and viscous solutions. Progress towards improved dissipation and smoothing in the bulk flow to accelerate convergence has already begun. Additional speedup will be acquired by improving the pseudotime interaction between the bulk flow and the free surface; specifically at the intersection of the waterline and hull. Finally, a more realistic and robust turbulence model needs to be implemented. Even without these forthcoming improvements, however, the current version still provides turn-around times of 2 hours on 16 processors, rendering the Navier-Stokes solver suitable for utilization in design.

REFERENCES

[1] Farmer, J.R., Martinelli, L., and Jameson, A., “A Fast Multigrid Method for Solving the Nonlinear Ship Wave Problem with a Free Surface,” Proceedings, Sixth International Conference on Numerical Ship Hydrodynamics, pp. 155–172, 1993.

[2] Farmer, J.R., Martinelli, L., and Jameson, A., “A Fast Multigrid Method for Solving Incompressible Hydrodynamic Problems with Free Surfaces,” AIAA Journal, v. 32, no. 6, pp. 1175–1182, 1994.

[3] Jameson, A., “Optimum Aerodynamic Design Using CFD and Control Theory,” Proceedings, 12th Computational Fluid Dynamics Conference, San Diego, California, 1995

[4] Jameson, A., “A Vertex Based Multigrid Algorithm For Three Dimensional Compressible Flow Calculations,” ASME Symposium on Numerical Methods for Compressible Flows, Annaheim, December 1986.

[5] Baldwin, B.S., and Lomax, H., “Thin Layer Approximation and Algebraic Model for Separated Turbulent Flows,” AIAA Paper 78–257, AIAA 16th Aerospace Sciences Meeting, Reno, NV, January 1978.

[6] Chorin, A., “A Numerical Method for Solving Incompressible Viscous Flow Problems,” Journal of Computational Physics, v. 2, pp. 12–26, 1967.

[7] Rizzi, A., and Eriksson,L., “Computation of Inviscid Incompressible Flow with Rotation,” Journal of Fluid Mechanics, v. 153, pp. 275–312, 1985.

[8] Martinelli, L., “Calculations of Viscous Flows with a Multigrid Method,” Ph.D. Thesis, MAE 1754-T, Princeton University, 1987.

[9] Farmer, J., “A Finite Volume Multigrid Solution to the Three Dimensional Nonlinear Ship Wave Problem,” Ph.D. Thesis, MAE 1949-T, Princeton University, January 1993.

[10] A.Jameson, “Analysis and design of numerical schemes for gas dynamics 1, artificial diffusion, upwind biasing, limiters and their effect on multigrid convergence,” Int. J. of Comp. Fluid Dyn., To Appear.

[11] A.Jameson, “Analysis and design of numerical schemes for gas dynamics 2, artificial diffusion and discrete shock structure,” Int. J. of Comp. Fluid Dyn., To Appear.

[12] J.Farmer, L.Martinelli, A.Jameson, and G.Cowles, “Fully-nonlinear CFD techniques for ship performance analysis and design,” AIAA paper 95–1690, AIAA 12th Computational Fluid Dynamics Conference, San Diego, CA, June 1995.

[13] A.Jameson, “Multigrid algorithms for compressible flow calculations,” In Second European Conference on Multigrid Methods , Cologne, October 1985. Princeton University Report MAE 1743.

[14] L.Martinelli and A.Jameson, “Validation of a multigrid method for the Reynolds averaged equations,” AIAA paper 88–0414, 1988.

[15] L.Martinelli, A.Jameson, and E.Malfa, “Numerical simulation of three-dimensional vortex flows over delta wing configurations,” In M.Napolitano and F.Sabbetta, editors, Proc. 13th International Conference on Numerical Methods in Fluid Dynamics, pages 534–538, Rome, Italy, July 1992. Springer Verlag, 1993.

[16] F.Liu and A.Jameson, “Multigrid Navier-Stokes calculations for three-dimensional cascades,” AIAA paper 92–0190, AIAA 30th Aerospace Sciences Meeting, Reno, Nevada, January 1992.

[17] G.Cowles, and L.Martinelli “Fully Nonlinear Hydrodynamic Calculations for Ship Design on Parallel Computing Platforms,” Proc. 21st International Symposium on Naval Hydrodynamics, Trondheim, Norway, June 1996

[18] G.Cowles, and L.Martinelli “A Cell-Centered Parallel Multiblock Method for Viscous Incompressible Flows with a Free Surface,” Proc. 13th AIAA Computational Fluid Dynamics Conference, Snowmass, Colorado, July 1997

[19] Y.Toda, F.Stern, and J.Longo “Mean-Flow Measurements in the Boundary Layer and Wake and Wave Field of a Series 60 Cb=.6 Ship Model for Froude Numbers .16 and .316 IIHR Report No. 352, Iowa Institute of Hydraulic Research, August 1991

DISCUSSION

H.Haussling

Naval Surface Warfare Center, Carderock Division, USA

The authors have demonstrated what appears to be a very efficient, parallel code for obtaining free-surface RANS solution. However, the results presented for Model 5415 indicate that the code is predicting a dry transom when measured data and other RANS computations indicate a wet transom. One possible explanation for this is that the solution is missing a significant part of the slowing of the flow in the boundary layer. Such a bias would lead to higher than realistic velocities near the transom and hence a solution behavior more like a higher speed than that being run.

DISCUSSION

H.Raven

Maritime Research Institute, The Netherlands

I am interested in the flow off the transom shown in Fig. 12. In your presentation, the transom appeared to be dry. Does this agree with the experiment at this speed? What happens if you reduce the speed in your calculation (Euler and RANS)?

AUTHORS’ REPLY

The dry transom is a result of the mesh treatment at the stern of the ship. At low speeds, the flow aft of the transom has a slight unsteady character. The viscous terms and turbulence model have been validated in several applications.2,3 The main intention of the current work is to focus on schemes which capture the detailed wave structure at a range of Froude numbers. In order to focus on the free surface, a steady velocity field must be provided. When the study is completed, the full approximation will resume.

DISCUSSION

R.Lohner

George Mason University, USA

This is a very impressive piece of work, combining:

-

Advanced finite volume solvers for the incompressible RANS equations with fully nonlinear free surface boundary conditions;

-

Efficient multigrid acceleration to steady state;

-

Multiblock spatial discretization to handle geometrical complexity;

-

Parallel computing; and

-

Validation through comparisons to experimental data.

As in any paper, there are some minor flaws that could be improved. Of these, the ones that I consider significant are as follows:

1. The statement that the generation of proper unstructured grids for free surface hydrodynamic problems is complicated and expensive is not true. One does not need to generate a new mesh as the solution evolves. All that is required is mesh movement. This distinction is not immediately evident for structured grids, but greatly facilitates the use of unstructured grids in this context. We refer the authors to the following two references:

Lohner, R., Yang, C., Onate, E. and Idelssohn, S. 1997 An Unstructured Grid-Based, Parallel Free Surface Solver. AIAA-97–1830.

Lohner, R., Yang, C. and Onate, E. 1998 Viscous Free Surface Hydrodynamics Using Unstructured Grids. Proc. 22nd Symp. on Naval Hydrodynamics.

(Bear in mind that the author uses unstructured grids routinely for these types of problems; i.e., take this comment with a grain of salt.)

2. The argument is made that multiblock grids reduce skewness, yet the mesh shown in Figure 17 shows a considerable degree of skewness. Perhaps one should say that the main advantage of multiblock is that it can discretize complex geometries where a uniblock approach is impossible.

3. For the Baldwin-Lomax model, are the normals forced to be aligned with (sometimes very curved) gridlines? If so, is this not highly inaccurate? If not, are the normals and their information passed across multiblock boundaries?

4. The section covering the results obtained using this method can be improved substantially. For example, any explanation why the RANS results in Figures 9, 11, 13 are just as good as the Euler results when compared to experiments? (Except for the first wave, which is always

improved with RANS due to the finer spacing normal to the wall). We have observed the same phenomenon for some of our calculations. Are the experiments flawed? Also, more discussion on gridsizes, convergence rates, timings, set-up times, etc.

Overall, an excellent piece of work. What next?

AUTHORS’ REPLY

-

The work time in the deformation of the structures grid is negligible relative to the calculation time. Following the fully deformed free surface mesh with an unstructured grid is considerably more complicated and somewhat more expensive. The statement in the paper was based on the author’s experience with 2-D unstructured methods for unsteady wave problems.1 However, having seen some of Professor Lohner’s work from the aeronautical side of his research regarding the motion of unstructured grids around twisting, falling, and exploding objects, I realize that his grid motion methods must be very efficient.

-

In regard to the comment that the mesh in Figure 17 is actually quite skewed; yes, it is. The intention of its inclusion in the paper was to show the difficulties that arise from using a single block topology mesh for a fully appended sailboat.

-

When generating the mesh, care is taken to maintain that the grid lines extend from the boat along the normal. In the turbulence model, distance from the wall is dotted with the normal. For our implementation, we feel that this is the best way to ensure that the resulting scheme follows the model as closely as possible to maintain accuracy. The information is not passed across block boundaries. Therefore care must be taken that the inner layer of blocks adjoining the hull completely include the boundary layer such that the eddy viscosity vanishes at the outer face.

-

There are some differences between the Euler and viscous waterlines due to differing velocity fields adjacent to the boat. The largest distinction is not displayed in the waterline comparisons but can be seen in the overhead comparisons. In the Euler case, the unphysical tangency condition imposed on the stern of these ships can cause the wave just aft of the transom to be much larger than the stern wave resulting from a viscous calculation.

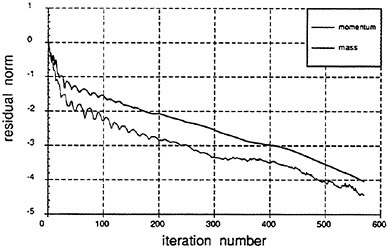

Following the discusser’s advice, I will elaborate on some of the practical concerns of the code. The grid sizes for the three cases presented in this paper—the Series 60, Model 5415, and Elipsoid—are as follows: 920,000 pts (18 blocks), 1.1 million pts (38 blocks), and 1.3 million PTSA (44 blocks). A single node of an IBM SP2 requires a minute for one iteration of the Euler equations on a million point mesh. The calculations of the viscous fluxes require an additional 15% work. Speedups of over 8X have been obtained on 9 processors. The communication procedure is very fast; however, a proper load balance is important as well. In most cases, the deviation from exact balance does not exceed 5%. Euler calculations require about 350 iterations for convergence, while Navier Stokes require approximately double that number. Thus convergence of a viscous calculation can be achieved in a few hours. An inviscid flow solution on a one million point mesh is completed within an hour. However, this solution can be achieved using far fewer grid points. Setting up a calculation requires constructing a grid and running the preprocessor to set up the communication and boundary condition arrays for each processor. Grids are developed using Gridgen to define the boundaries and an in-house solver for the interior points. They require anywhere between 2 days and a week to build. The preprocessor requires less than a minute to perform its duties.

References

1B.Liou, L.Martinelli, T.Baker, and A. Jameson, “Calculation of Plunging Breakers with a Fully Implicit Adaptive Method,” AIAA paper 98–2968, AIAA 29th Fluid Dynamics Conference, Albuquerque, NM, June 1998.

2Farmer, J.R., Martinelli, L., and A.Jameson, “Multigrid Solutions of the Euler and Navier-Stokes Equations for a Series 60 Cb=.6 Ship Hull for Froude Numbers 0.160, 0.220, and 0.316,” Proceedings, CFD Workshop Tokyo 1994, Tokyo, Japan, March 1994.

3Belov, A., “A New Implicit Multigrid-Driven Algorithm for Unsteady Incompressible Flow Calculations on Parallel Computers,” Ph.D. Thesis, MAE 1636-T, Princeton University, 1997.

Navier-Stokes Computations of Ship Flows on Unstructured Grids

T.Hino (Ship Research Institute, Japan)

Abstract

An unstructured grid method for simulating three-dimensional incompressible viscous flows is presented. The governing equations to be solved numerically are the Navier-Stokes equations with artificial compressibility. The spatial discretization is based on a finite volume method for an unstructured grid. Second order accuracy in space is achieved using a flux-difference-splitting scheme with the MUSCL approach for inviscid terms and a central difference scheme for viscous terms. Time integration is carried out by the backward Euler method. The linear system derived by the linearization in time is solved by the Gauss-Seidel iteration. For the analysis of high Reynolds number flows, the k-ω-SST two equation turbulence model is used. The turbulence equations are solved in a similar way as the Navier-Stokes equations. The computational results for viscous flows around ships demonstrate the capability of the method to simulate complicated flow fields with reasonable accuracy.

1 Introduction

Computational fluid dynamics (CFD) analysis is now being used as a practical tool to predict flows around complex configurations. However, as configurations become complex, the efforts required for grid generation increase greatly. This is particularly true in case that conventional structured grids which are based on regular arrays of hexahedral cells are used. One way to overcome this difficulty is the use of multiblock grids which consist of either overlapping or non-overlapping blocks of structured grids. In this case, both a grid generation code and a flow solver must be able to handle special procedures for multiblock boundaries.

The other way is unstructured grid methods (1, 2) which employ irregularly connected cells of various shapes. Unstructured grid methods offer greater flexibility for handling complex shapes than structured grid counterparts. Even though unstructured grid generation around a complex configuration is as difficult as structured grid generation, a flow solver can be simplified because all the topological informations are kept in grids.

Unstructured grid methods were developed initially for solving compressible inviscid flow equations (3). Then the methods have been extended to compute viscous flows. Incompressible flow solvers have also been developed based on a pressure correction method (4) or on an artificial compressibility method (5).

In the CFD applications for ship hydrodynamics, there are increasing needs for flow predictions around more complex configurations, because practical ships are usually equipped with stern appendages, a rudder and a propulsor. Therefore, a 3D unstructured grid Navier-Stokes solver is expected to be a powerful tool in practical ship hydrodynamics as well as in other fluid engineering fields.

Hino developed unstructured grid methods for 2D incompressible inviscid flows with a free surface (6) and for 2D turbulent free surface flows (7) using an artificial compressibility approach. For 3D, Löhner et al. (8) developed an unstructured grid Euler solver based on pressure correction approach and computed free surface flows around ships. Also, Hino (9) developed a 3D unstructured Navier-Stokes solver based on artificial compressibility method and applied it to viscous flow simulations around a ship. The present study is the improvement of the method in (9). The spatial discretization and the turbulence model are modified to enhance accuracy and robustness of the scheme.

In Section 2, the governing equations are given and the spatial discretization is described followed by the explanation of the time integration scheme. Then the boundary conditions for numerical computations are briefly shown and the turbulence model used is presented. In Section 3, the numerical results with the present method are shown for flows around a ship hull and a ship with a rudder configuration. Finally, the concluding remarks are given in Section 4.

2 Numerical Scheme

2.1 Governing Equations

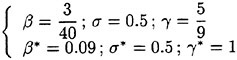

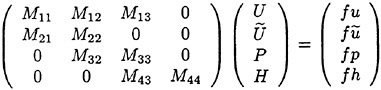

The governing equations to be solved are the three-dimensional Reynolds averaged Navier-Stokes equations for incompressible flows. With the introduction of artificial compressibility, they are written

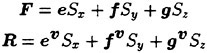

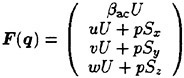

in a vector form as

(1)

where

is the vector of flow variables which consist of p, pressure and (u, v, w), the (x, y, z)-components of velocity. The inviscid fluxes e, f and g are defined as

where βac is a parameter for artificial compressibility. ev, fv and gv are the viscous fluxes defined as

where

In the above expressions all the variables are made dimensionless using the reference density ρ0, velocity U0 and length L0. R is the Reynolds number defined as U0L0/ν where ν is the kinematic viscosity. νt is the nondimensional kinematic eddy viscosity determined by a turbulence model.

2.2 Spatial Discretization

(1) Finite volume formulation

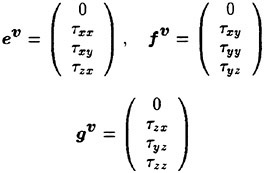

Spatial discretization of the present scheme is based on a finite-volume method for an unstructured grid. Cell shapes the present solver can cope with are tetrahedron, prism, pyramid or hexahedron and face shapes are either triangular or quadrilateral as shown in Fig. 1.

These four types of cells give larger flexibility in handling complex geometries. In particular, it is suitable for a hybrid grid approach in which prisms and hexahedra are placed in the region close to a solid wall for the efficient resolution of boundary layers while tetrahedra and pyramids are used to tessellate the remaining region in a flexible manner. A cell centered layout is adopted which means flow variables q are defined at the centroid of each cell and a control volume is a cell itself. yields

Fig. 1 Cell shapes.

Volume integration of Eq. (1) over a cell yields

(2)

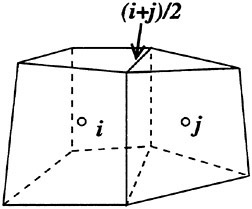

The first term in the integral can be expressed as the product of the cell volume Vi and the time derivative of the cell averaged value of flow variables qi, since the grid is stationary in the current applications. The remaining terms are converted into surface integration over cell faces using the divergence theorem. This yields the semi-discrete form of the governing equation as follows.

(3)

where i is a cell index and j is the index of next cells of the cell i. (i+j)/2 denotes the face between cells i and j as shown in Fig. 2

Fig. 2 Definition sketch of cell and face index.

F and R are the inviscid and viscous fluxes defined as

where (Sx, Sy, Sz) are the (x, y, z)-components of the area vector of a cell face in the direction from the cell i to the cell j.

(2) Discretization of inviscid fluxes

Components of the inviscid fluxes F are

where U=uSx+vSy+wSz. The inviscid fluxes are evaluated by the upwind scheme based on the flux-difference splitting of Roe (10). In the scheme, the numerical fluxes are computed as

(4)

where qR and qL are the flow variables on the right and the left sides of a cell face, respectively. |A| is defined in the following way. First, let A be the Jacobian of the inviscid flux F at a cell face:

where the flow variables at the cell face q(i+j)/2 are evaluated by the simple average of the right and the left side values, i.e.,

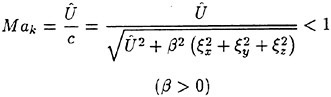

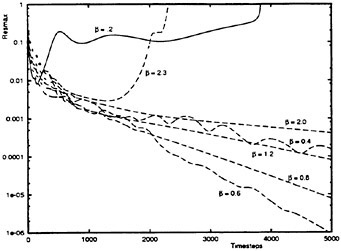

The eigenvalues of A are U, U, U+c, U−c where c is the pseudo-speed-of-sound defined as

By using the right-eigenvector R, A can be expressed as

where Λ is

Finally, |A| is given by

with

To achieve the second order accuracy in space, the MUSCL approach is used in which the flow variable q is reconstructed as a linear polynomial function inside each cell using the cell centroid values. Let the scalar quantity q be a component of q and q is assumed to be linearly varying in the vicinity of the cell i, i.e.,

(5)

where ∇qi=(∂qi/∂x, ∂qi/dy, ∂qi/∂z)T is the gradient of q at the cell i and xi is the coordinates of the cell centroid i. This equation is applied to the cell j which is adjacent to the cell i, which yields

or

A similar equation can be written for all the neighbor cells of i, thus,

(6)

where

The above equation (6) gives the overdetermined system for ∇qi and the least squares solution can be obtained by solving it via QR decomposition. Finally, qR and qL are extrapolated using the gradient with the limiter function as follows

(7)

where x(i+j)/2 is the coordinates of the center of face (i+j)/2.

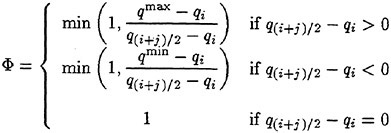

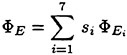

The limiter function Φ is used to enforce the monotonicity of the reconstruction. The form proposed by Barth (12) is used in the present scheme

which is written as

where qmax and qmm are the maximum and the minimum values of q at the cell i and its neighbors.

(3) Discretization of viscous fluxes

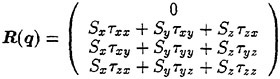

Viscous fluxes components are written as

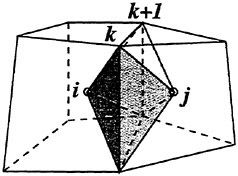

The computation of R(i+j)/2 requires velocity gradient on a cell face. These are computed again by applying the divergence theorem to another control volume surrounding a cell face as shown in Fig. 3.

Fig. 3 Control volume for the evaluation of velocity gradient.

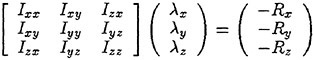

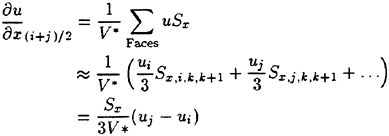

The values of q at the centroids i and j as well as at the nodes surrounding the face (i+j)/2 (k, k+1…) are used for the surface integration. For example, ∂u/∂x is computed as

(8)

where V* is the volume of the current control volume and Sx,α,β,γ is the x-component of the outward area vector of the face formed by the nodes α, β and γ. This formulation is equivalent to centered differencing in the structured grid case and is second order accurate.

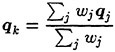

The velocity values at the nodes k, k+1 etc. are computed from the values at the cell centroids by the Laplacian weighted average (13) as follows

where the summation is for all the cells that share the node k. The weight wj is computed as

where λx, λy, λz are the solution of

with

This formulation gives the exact values for linearly varying functions and is second order accurate.

2.3 Time Integration

Since the artificial compressibility is introduced into the governing equations, incompressible flow fields can be obtained only as a steady state limit. Therefore, transient solutions are not physically valid. The time integration in the present scheme is thus the way to drive solutions to a steady state and time accuracy of the scheme is not important.

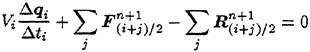

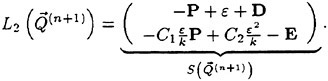

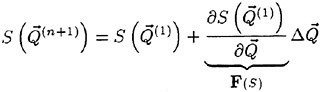

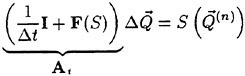

The first order backward Euler scheme is used for the time integration in which the governing equation is written as

(9)

where

and the superscripts denote the time step. Δti is time increment in local time stepping in which Δti is determined cell by cell in such a way that the CFL number is globally constant as follows

where CFL is the CFL number. The summation of the denominator is taken over all faces of the current cell.

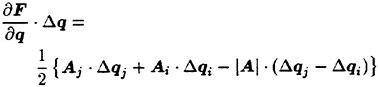

The linearization of the inviscid flux Fn+1 with respect to time is made as follows

When the Jacobian ∂F/∂q is evaluated, the flux F is computed with the first order upwind scheme by setting

i.e., the inviscid flux is approximated by

Thus, ∂F/∂q · Δq is expressed as

where

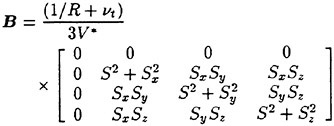

In the similar manner the viscous flux is linearized in time as

For the evaluation of the Jacobian ∂R/∂q, the velocity gradients are approximated by neglecting the contribution from the values at the nodes qk etc. That is, Eq. (8) is replaced by

where Sx is the area vector component of the face (i+j)/2 as defined earlier. Using the similar approximation for the other velocity gradients, R can be expressed as

where

with

Thus, ∂R/∂q · Δq becomes

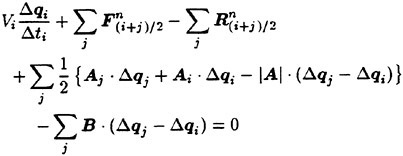

Eq. (9) now becomes

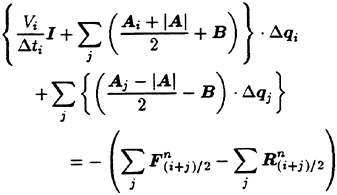

(10)

The delta terms are rearranged into the form as follows

(11)

The equation above is a linear equation with respect to Δq. In order to solve this equation, the Symmetric Gauss-Seidel (SGS) iteration is adopted. To achieve fast convergence, the cells are ordered from upstream to downstream in the preprocessing stage. The Gauss-Seidel sweep is carried out from the upstream cell to the downstream first, then the second sweep follows in the reverse order. The following sweeps change the direction alternately.

2.4 Boundary Conditions

The cell faces on the boundaries are classified as the boundary faces. The boundary conditions

are implemented by giving the appropriate fluxes on the boundary faces based on the following conditions:

Solid wall:

Inflow:

Outflow:

Side:

Symmetry:

Symmetric Conditions

In case of the Dirichlet conditions, the fluxes can be computed using given values, while in case of the Neumann conditions, the flow variables on the face is set equal to those at the cell that contains the current face. In the time integration process, all the boundary conditions are treated implicitly.

2.5 Turbulence Model

A turbulence model is essential for simulating high Reynolds number flows of practical interests. There exist a number of turbulence models. They range from simple algebraic models or one- or two-equation models for the eddy viscosity concept to Reynolds stress models for the second order closure. However, no model has been proved to be universally applicable to general fluid engineering problems. In practice, a turbulence model must be selected based on the characteristics of a flow field of each problem. Ship flows, particularly stern flows, are extremely complicated, because they are essentially three dimensional separated flows with strong longitudinal vortices and free surface effects cannot be neglected in some cases. From the practical point of view, it is important that CFD computations can accurately simulate a propeller inflow, that is, a wake behind a ship hull. However, these extremely complicated ship flows are beyond the capability of most of existing turbulence models.

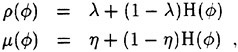

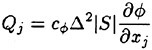

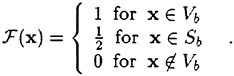

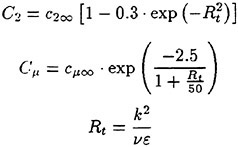

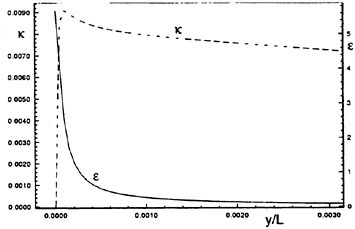

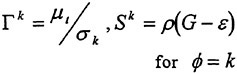

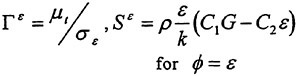

In the previous version of the present method (9), the Spalart-Allmaras one-equation model (14) is used as a turbulence model. Since the wake distribution for a tanker model simulated with the Spalart-Allmaras model showed poor agreement with the measurement (9), the k-ω-SST two-equation model by Menter (15) is newly adopted in the present scheme. This model uses the original k-ω model of Wilcox (16) in the inner region of the boundary layer and the standard k-∈ model in the other region in order to remove the dependence on the free stream condition of the original k-ω. The further modification which accounts for the effect of the turbulent shear stress transport is incorporated into the model. Since Deng et al. (17) showed that the original k-ω turbulence model well predicted the wake pattern behind a tanker hull, the present model is expected to work equally well for ship flows.

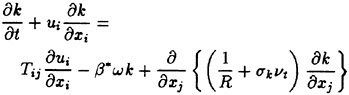

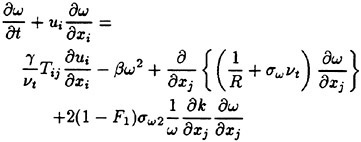

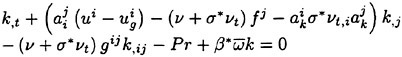

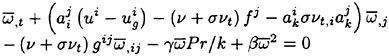

The model consists of the two transport equations, one for the turbulent kinematic energy k and the other for the turbulence frequency ω. The equations are written as

(12)

(13)

where Tij is the turbulent shear stress tensor defined as

The blending function F1 which is 1 in the inner region and 0 in the outer region is defined as follows;

with

where d is the distance to the closest wall and

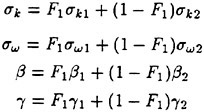

The constant σk σω, β and γ are computed using the blending function F1 as

The constants for the inner region are based on the k-ω model with the modification for SST and are given as:

σk1=0.85, σω1=0.5, β1=0.0750, β*=0.09

The constants for the outer region come from the standard k-∈ formulation and these are:

σk2=1.0, σω2=0.856, β2=0.0828, β*=0.09

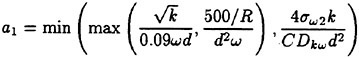

Finally, the turbulent kinematic eddy viscosity is computed by

where Ω is the magnitude of the vorticity and

The function F2 is given by

and

The boundary conditions for k and ω are as follows

Solid wall:

(where Δd is the distance to the centroid of the next cell from the wall)

Inflow:

Outflow:

Side:

Symmetry:

Symmetric Conditions

The numerical method employed for the solution of turbulent equations is similar to the one for flow equations except that the advection terms are evaluated by the first-order upwind scheme.

3. Results

3.1 A Tanker Hull

The first application is a three dimensional flow field around a ship hull form. A ship model is a VLCC hull with a bulbous bow called SR196A. The Reynolds number based on the length between perpendiculars Lpp is 4.0×106 which corresponds to a model scale.

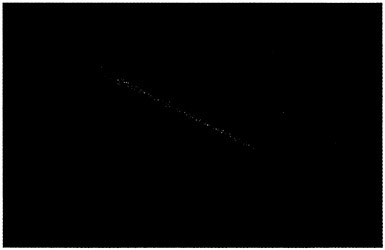

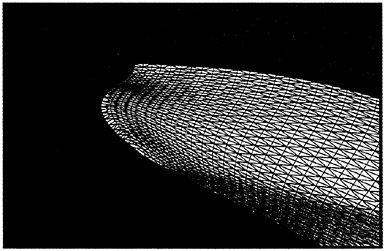

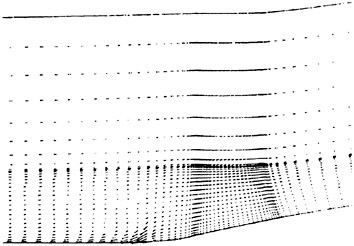

Fig. 4 Partial view of unstructured grid around a tanker hull.

Fig. 5 Magnified view of grid at the bow.

Fig. 6 Magnified view of grid at the stern.

The grid used is based on the 97×41×65 structured grid of O-O topology. The unstructured grid is generated from this grid by dividing all

the hexahedral cells of the structured grid into two prisms. The grid consists of 491,520 cells, 1,245,184 faces and 258,505 nodes. The partial views of the grid is shown in Fig. 4. Figs. 5 and 6 are the magnified views of the bow and stern regions, respectively Distributions of triangular faces on a body can be observed.

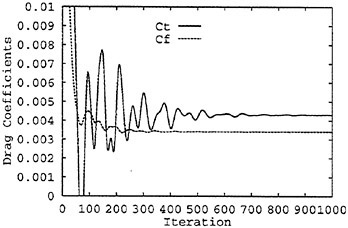

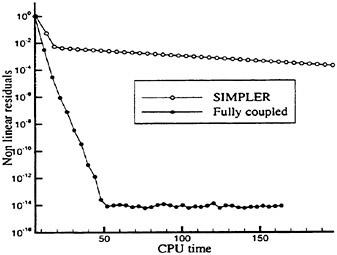

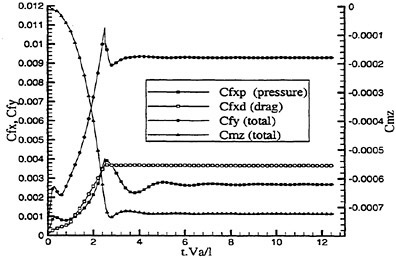

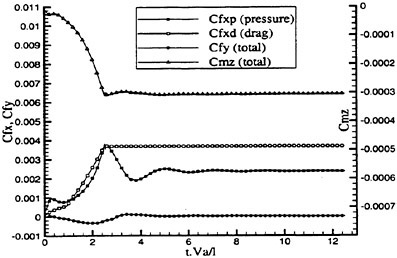

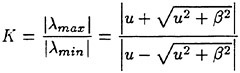

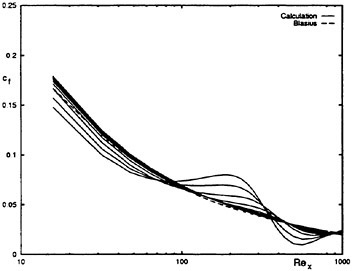

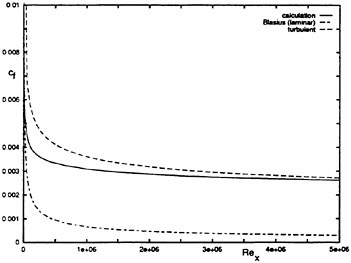

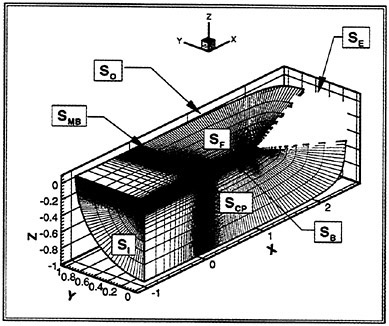

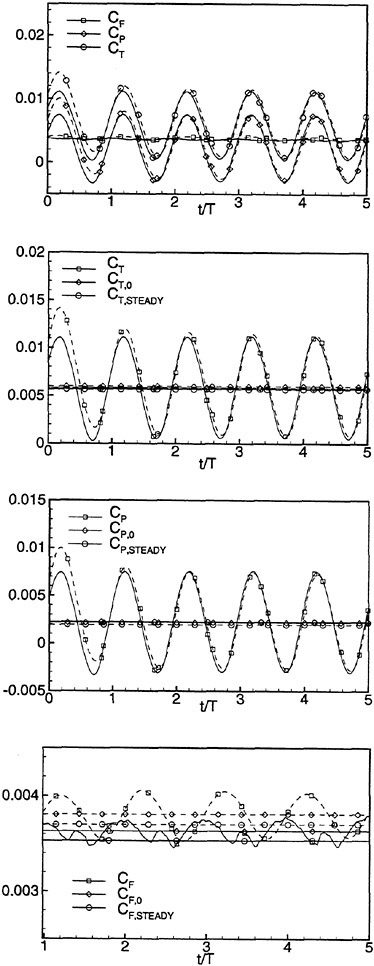

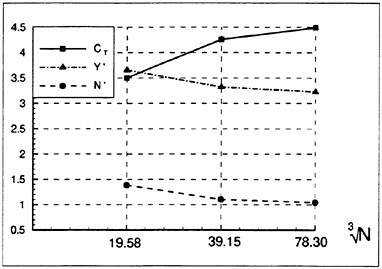

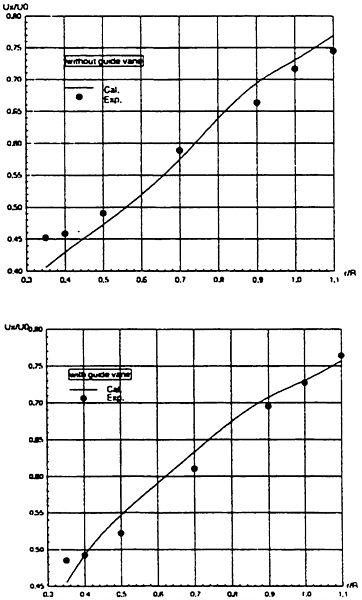

The computation starts using local time stepping with initial CFL of 10 and CFL is increased linearly up to 100 in the first 200 steps. The history of the total drag coefficient ![]() and the frictional drag coefficient

and the frictional drag coefficient ![]() where S is the wetted surface area is shown in Fig. 7. It is seen that the converged solution with engineering accuracy is obtained with about 1,000 iterations.

where S is the wetted surface area is shown in Fig. 7. It is seen that the converged solution with engineering accuracy is obtained with about 1,000 iterations.

Fig. 7 History of drag coefficients.

Computed drag coefficients are shown in Table 1 together with the experimental data which is estimated as the form factor K=0.32 based on the Schoenherr friction line. The total drag is estimated by the present computation slightly lower than the experimental value while the frictional component agree well with the Schoenherr value.

Table 1. Drag coefficients of SR196A

|

|

Total Drag |

Frictional Drag |

|

Computed |

4.32×10−3 |

3.41×10−3 |

|

Experiment |

4.52×10−3 |

3.42×10−3 |

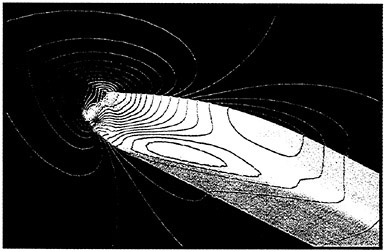

Computed pressure distributions on a ship hull and symmetric planes are shown in Figs. 8, 9 and 10. A high pressure zone at the bow and low pressure zones near the fore and aft shoulders can be seen. Also, low pressure regions appear at the bilge in the bow and the stern where streamlines turn around the bilge and velocity magnitude becomes large. These features off pressure distribution are typical for a ship of this kind.

Fig. 8 Computed pressure distribution around a tanker hull.

Fig. 9 Computed pressure distribution at the bow of a tanker hull.

Fig. 10 Computed pressure distribution at the stern of a tanker hull.

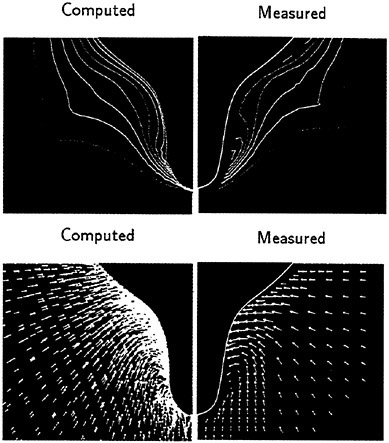

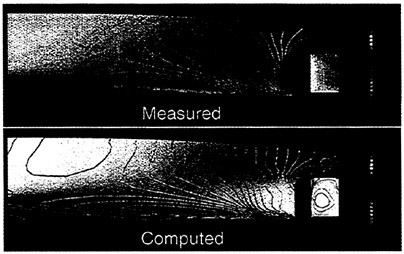

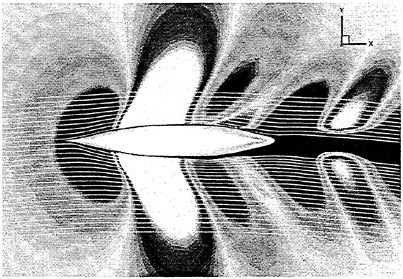

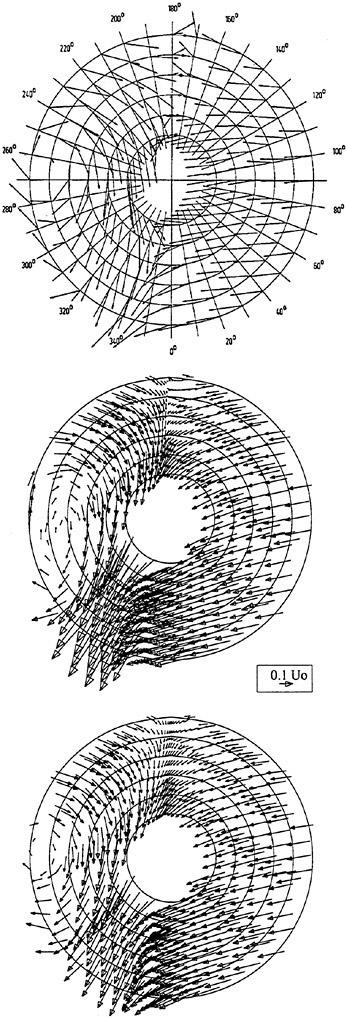

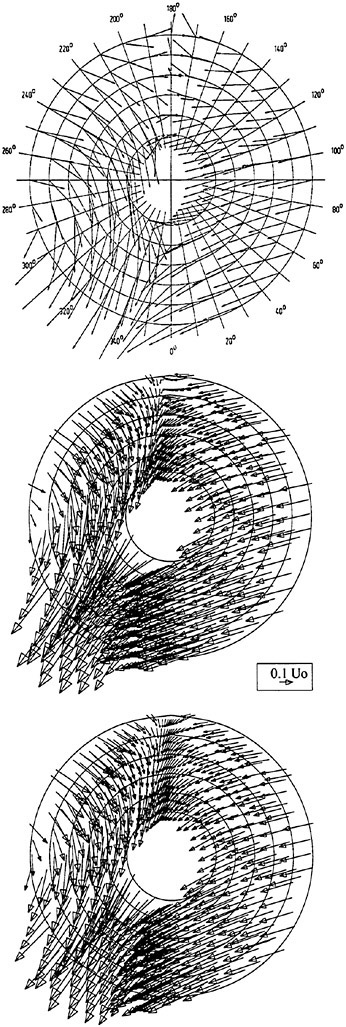

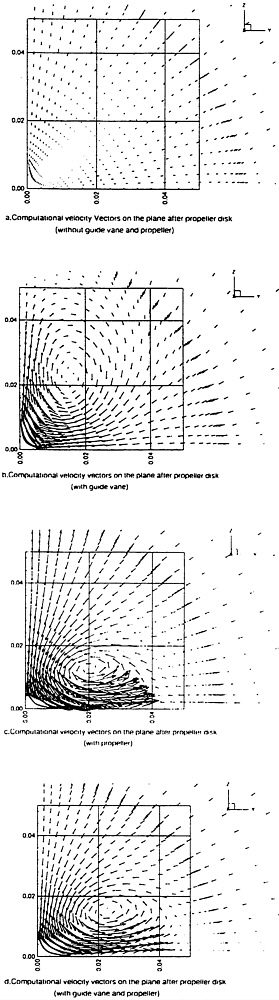

For this hull, Suzuki et al. (18) measured velocity fields using a hot wire probe in a wind tunnel. Fig. 11 and Fig. 12 show the comparison of the computed velocity distributions with the measured data.

Fig. 11 shows the data at S.S. 1/2. In the measurement, the swirling motion can be seen in the region close to the keel where the axial velocity is small. The present computation reproduces this phenomenon although the extent, is smaller than the measurement.

Fig. 11 Velocity distributions at S.S. 1/2. Axial velocity contours and crossflow vectors: present computation (left) and measurement (right) (18).

Fig. 12 Velocity distributions at S.S. 1/8. Axial velocity contours and crossflow vectors: present computation (left) and measurement (right) (18).

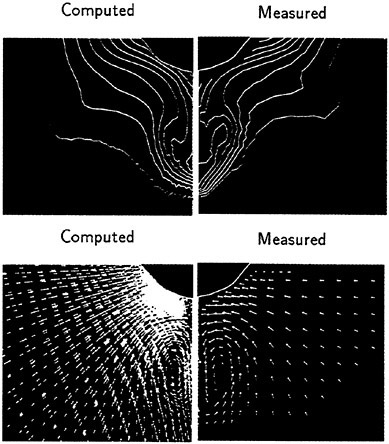

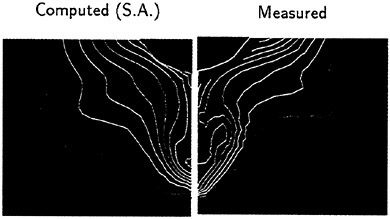

In Fig. 12 the velocity distributions at S.S. 1/8 is shown. The measured wake contour shows the so-called ‘hook’ shape which corresponds to the strong longitudinal vortex. The computed velocity distribution agrees reasonably well with the measurement. The ‘hook’ shape of the contour line is reproduced to some extent and the locations of vortex core are in good accordance with the measurement, although the computed result is still too diffusive. Fig. 13 shows the result with the Spalart-Allmaras turbulence model which is computed by the method described in (9) using the structured grid of 113×41×41 points. It is seen that the ‘hook’ shape is not simulated well with this model. The performance of the present k-ω-SST turbulence model is almost the same as the original k-ω model used by Deng et al. (17).

Fig. 13 Velocity distributions at S.S. 1/8. Axial velocity contours: computation (left) using Spalart-Allmaras model with structured grid and measurement (right) (18).

3.2 A Tanker Hull with a Rudder

The second application is for a moderately complicated configuration of a ship hull with a rudder. A ship model is a VLCC hull called “Ryukoumaru”. For this hull form the extensive experimental data is available (20) including the flow measurement of the full scale ship (300 m long) and the medium scale experimental ship (30 m long) in addition to the usual tank tests of the model (7 m long). The Reynolds number of the computation is set 6.8×106 which corresponds to the model scale.

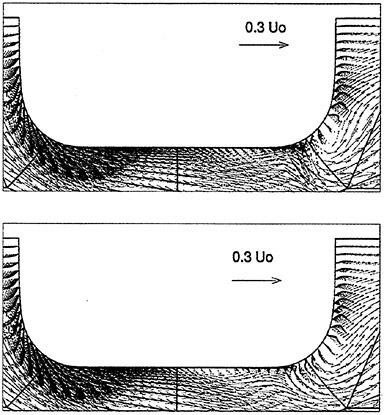

The unstructured grid is constructed from the structured grid of 101×31×41 points with H-O topology. Again, all the cells of the unstructured grid are prismatic obtained by dividing the hexahedral cells of the original grid. The number of nodes is 128,371 and cells and faces are 240,000 and 611,200, respectively.

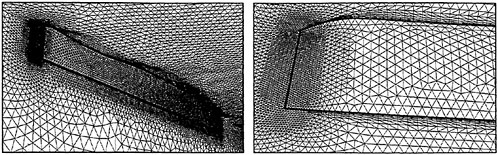

The grid is shown in Figs. 14, 15 and 16. Since the grid topology is different from the first example, the triangle faces are placed on both a ship hull and a y symmetric plane. At the stern region, the multiblock configuration of the original structured grid can still be observed. In order to cope with a ship with a rudder by a structured grid, the multiblock capability should be added to a grid generation code and to a flow solver (21). On the other

hand, the present unstructured solver can handle this grid as well as the previous grid without any modification.

Fig. 14 Partial view of unstructured grid around a ship with a rudder.

Fig. 15 Magnified view of grid at bow (a ship with a rudder).

Fig. 16 Magnified view of grid at stern (a ship with a rudder).

Computed pressure distribution is shown in Figs. 17, 18 and 19. Contour lines occasionally show unnatural kink. This is supposed to be a plotting problem. The high pressure region can be seen in the leading edge of the rudder in Fig. 19. The pressure distribution on a ship hull in Fig. 19 is not so different from that of Fig. 10, that shows a hull surface pressure is insensitive to the presence of a rudder.

Fig. 17 Computed pressure distribution (a ship with a rudder).

Fig. 18 Computed pressure distribution at bow (a ship with a rudder).

Fig. 19 Computed pressure distribution at stern (a ship with a rudder).

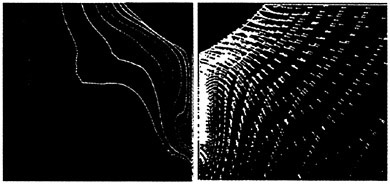

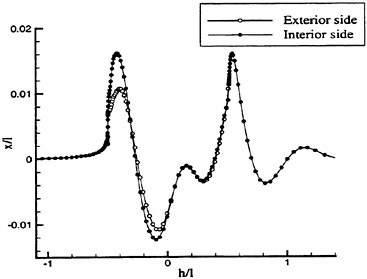

Fig. 20 shows the comparison of the hull surface pressure distribution of computation and the experiment (22). Good agreement can be seen between the two pressure patterns. The extent of the low

pressure zone at the bilge and the high pressure region at the edge of stern overhang are well simulated by the present solver.

Fig. 20 Comparison of measured (top) and computed (bottom) pressure distributions on a ship hull.

Figs. 21 and 22 show the velocity distribution on the propeller plane and on the aft perpendicular section. The wake distribution on the propeller plane does not show the so-called ‘hook’ shape clearly. The pattern is rather similar to the one with the Spalart-Allmaras models shown in Fig. 13. The difference between Figs. 21 and 12 seems to be due to the grid topology. In the O-O topology shown in Fig. 6, the grid spacing just behind the hull is as small as the other cells next to a hull. On the other hand, in the H-O topology shown in Fig. 16, the grid spacing behind the hull is a few orders magnitude larger than the usual minimum spacing in the wall normal direction. The boundary values of the ω on the wall are very large and ![]() since ω is responsible for a near wall damping of the eddy viscosity. The free stream value of ω, on the other hand is

since ω is responsible for a near wall damping of the eddy viscosity. The free stream value of ω, on the other hand is ![]() . Therefore, ω must decreases rapidly inside the boundary layer. The large grid spacing behind a hull with the H-O topology (Fig. 16) may not be fine enough to resolve the steep gradient of ω in this region. Further investigations are needed to clarify this issue.

. Therefore, ω must decreases rapidly inside the boundary layer. The large grid spacing behind a hull with the H-O topology (Fig. 16) may not be fine enough to resolve the steep gradient of ω in this region. Further investigations are needed to clarify this issue.

Fig. 21 Computed velocity distributions at propeller plane. Axial velocity contours and crossflow vectors

In Fig. 22, the wake is divided by the rudder. At the leading and the trailing edges of the rudder, the grid spacing is again very large and the same problem as above may arise. By using a truly unstructured grid with the control of the minimum spacing on the wall, these problems can be avoided.

Fig. 22 Computed velocity distributions at AP section. Axial velocity contours and crossflow vectors

4 Concluding Remarks

An unstructured grid method has been developed for simulating three-dimensional incompressible viscous flows around a complex configuration. The numerical method solves the Navier-Stokes equations with artificial compressibility using a finite volume method on an unstructured grid. Time integration is carried out by the backward Euler method. The derived linear system is solved by the Gauss-Seidel iteration. The k-ω-SST two equation turbulence model is used for high Reynolds flow simulations.

Three dimensional computations are carried out for a tanker hull and a tanker with a rudder configuration. Both results show reasonable agreements with the experimental data and the applicability of the present solver has been proved. The k-ω-SST turbulence model shows promising performance with respect to the prediction of the wake pattern when used with the appropriate grid.

Future plans include the application to truly unstructured grid cases and the extension to free surface flows.

Acknowledgment

The author would like to thank Dr. M.Hinatsu of Ship Research Institute for providing the structured grid and the informations of the experiments for a ship hull with a rudder configuration. Also, discussions and suggestions from members of the CFD group at Ship Research Institute are gratefully acknowledged.

REFERENCES

1. Mavriplis, D.J., “Unstructured Grid Techniques”, Annual Review on Fluid Mechanics, Vol. 29, 1997, pp. 473–514.

2. Venkatakrishnan, V., “A Perspective on Unstructured Grid Flow Solvers”, AIAA Journal, Vol. 34, No. 3, March 1996, pp. 533–547.

3. Jameson, A. Baker, T.J. and Weatherill, N.P., “Calculation of Inviscid Transonic Flow Over a Complete Aircraft”, AIAA Paper 86–0103, 1986, American Institute of Aeronautics and Astronautics.

4. Chen A. and Kallinders Y., “Adaptive Hybrid (Prismatic/Tetrahedral) Grids for 3-D Incompressible Flows”, AIAA Paper 96–0293, 1996, American Institute of Aeronautics and Astronautics.

5. Anderson, W.K., Rausch, R.D. and Bonhaus, D.L., “Implicit/Multigrid Algorithms for Incompressible Turbulent Flows on Unstructured Grids”, Journal of Computational Physics, Vol. 128, 1996, pp. 391–408.

6. Hino, T., Maritinell, L. and Jameson, A., “A Finite-Volume Method with Unstructured Grid for Free Surface Flow Simulations”, Proceedings of the Sixth International Symposium on Numerical Ship Hydrodynamics, Iowa City, 1993, pp. 173–193.

7. Hino, T., “An Unstructured Grid Method for Incompressible Viscous Flows with a Free Surface”, AIAA Paper 97–0862, 1997, American Institute of Aeronautics and Astronautics.

8. Lohner, R., Yang, C., Oñate, E. and Idelssohn, A., “An Unstructured Grid-Based, Parallel Free Surface Solver”, AIAA Paper 97–1830, 1997, American Institute of Aeronautics and Astronautics.

9. Hino T, “A 3D Unstructured Grid Method for Incompressible Viscous Flows”, Journal of the Society of Naval Architects of Japan, Vol. 182, 1997, pp. 9–15.

10. Roe, P.L., “Characteristic-Based Schemes for the Euler Equations”, Annual Review on Fluid Mechanics, Vol. 18, 1986, pp. 337–365, (1986).

11. Barth, T.J., “A 3-D Upwind Euler Solver for Unstructured Meshes”, AIAA Paper 91–1548-CP, 1991, American Institute of Aeronautics and Astronautics.

12. Barth, T.J. and Jespersen D.C., “The Design and Application of Upwind Schemes on Unstructured Meshes”, AIAA Paper 89–0366, 1989, American Institute of Aeronautics and Astronautics.

13. Rausch, R.D., Batina J.T. and Yang H.T.Y., “Spatial Adaption Procedures on Unstructured Meshes for Accurate Unsteady Aerodynamic Flow Computation”, ΑΙAA Paper 91–1106, 1991, American Institute of Aeronautics and Astronautics.

14. Spalart, P.R. and Allmaras S.R., “A One-Equation Turbulence Model for Aerodynamic Flows”, La Recherche Aérospatiale, No. 1, 1994, pp. 5–21.

15. Menter, F.R., “Two-Equation Eddy-Viscosity Turbulence Models for Engineering Application”, AIAA Journal, Vol. 32, No. 8, August 1994, pp. 1598–1605.

16. Wilcox, D.C., “Reassessment of the Scale-Determining Equation for Advanced Turbulence Models”, AIAA Journal, Vol. 26, No. 11, November 1988, pp. 1299–1310.

17. Deng, G. and Visonneau, M., “Evaluation of Eddy Viscosity and Second-Moment Turbulence Closures for Steady Flows Around Ships”, Proceedings of the Twenty-First Symposium on Naval Hydrodynamics, 1997, pp. 453–467.

18. Suzuki, T., Okuni, T., Nozawa, K. and Suzuki, H., “Characteristics of Turbulent Boundary Layer in a Stern Flow Field with Longitudinal Vortices”, Proceedings of the Twenty-Seventh Symposium on Turbulence, 1995, pp. 133–136 (in Japanese).

19. Hino, T., “Viscous Flow Computations around a Ship Using One-Equation Turbulence Models”, Journal of the Society of Naval Architects of Japan, Vol. 178, 1995, pp. 9–22.

20. Ogiwara, S., “Stern Flow Measurements for The Tanker ‘Ryuko-Maru’ in Model Scale, Intermediate Scale and Full Scale Ships”, Proceedings of CFD Workshop Tokyo 1994, Vol. 1, 1994, pp. 341–349.

21. Hinatsu, M., Hino, T., Kodama, Y., Fujisawa, J. and Ando J., “Numerical Simulation of Flow around Ship Hull with Rudder in Self Propulsion Condition”, Transaction of the West Japan Society of Naval Architects, No. 90, 1995, pp. 1–10 (in Japanese).

22. Hinatsu, M., Takeshi, H., Fujisawa, J. and Tsukada, Y., “Pressure Measurement around Full Ship Stern in Self Propulsion Condition”, Proceedings of the Sixty-Fourth General Meeting of Ship Research Institute, 1994, pp. 205–206 (in Japanese).

DISCUSSION

K.Mori

Hiroshima University, Japan

Is your point that the grid arrangement is more important than the turbulent model to realize the “hook-shaped” wake contour?

AUTHOR’S REPLY

It is the turbulence modeling that is responsible for reproduction of the wake distribution. Some turbulence models require the grid property suitable for the models in order to work as designed. In the case of the present paper, the k-w-SST model appears to work well only when used with a grid of O-O type topology, although further verification is needed. In summary, to simulate flow fields accurately, one needs (1) an appropriate turbulence model, (2) a grid which is suitable for the turbulence model used and, of course, (3) a reliable flow solver.

Viscous Free Surface Hydrodynamics Using Unstructured Grids

R.Löhner, C.Yang (George Mason University, USA)

E.Oñate (Universidad Politécnica de Catalunya, Spain)

ABSTRACT

An unstructured grid-based, parallel solver has been developed for solving viscous free surface hydrodynamics problems. The overall scheme combines a finite-element, equal-order, projection-type three-dimensional incompressible flow solver with a finite element, two-dimensional advection equation solver for the free surface equation. The solution is marched in time until a steady state is reached. The unstructured grid enhances geometrical flexibility when treating complex geometries, and the parallel implementation permits fast turnaround of numerical simulations. A number of flows of practical interest are analyzed to demonstrate the numerical performance of the present approach.

1. INTRODUCTION

The prediction of the Kelvin wave pattern and wave resistance of ships has challenged mathematicians, hydrodynamicists and naval architects for over a century. Only in recent years has the rapid development of computer hardware and software enabled large-scale computer simulation of steady ship waves.

The Boundary Element Method is a widely used approach for the prediction of the ideal wave pattern of ships advancing with constant forward speed. There exist two main types of elementary singularity in the solution schemes of this method. The first class of schemes uses the Kelvin wave source as the elementary singularity. The major advantages of such a scheme are the elimination of the integration over the free surface from the resulting boundary integral equation and the automatic satisfaction of the radiation condition. However, this scheme cannot be extended to include nonlinear wave effects. The theoretical background of this method was reviewed by Wehausen (1970), while computational aspects can be found in the literature and in a series of Ship Wave Resistance Workshops (Workshop on Ship Wave Resistance Computations, 1979, 1983). Noblesse et al. (1996) recently developed a new theoretical formulation, called Fourier-Kochin theory, which offers an alternative way of solving steady wave problems using this class of elementary source. The second class of schemes uses the Rankine source as the elementary source. This scheme was first presented by Dawson (1977). The Dawson method has been applied widely as a practical method for predicting wave resistance, and many improvements have been made to account for the nonlinear effects. Among them a successful example is the Rankine Panel Method (Dawson, 1977; Xia, 1986; Jenson and Soding, 1989; Kim and Lucas, 1990; Reed et. al., 1990; Nakos and Sclavounos, 1990; Raven, 1992; Beck et. al., 1993; Soding, 1996; Raven, 1996; Janson and Larsson, 1996). Considerable effort has been devoted to increasing efficiency and accuracy, resulting in the so-called patch method, desingularized method, RAPID method and etc. From the point of view of ship design, the Rankine Panel Method still has an unacceptable sensitivity to numerical parameters such as the domain size and paneling.