2

Alternative Technology Research and Development Program

The alternative technology research, development, test and evaluation (RDT&E) program, which was authorized by Congress in 1994, focuses on the following basic technologies:

-

“Stand-alone” neutralization (for example, chemical hydrolysis). This process will be used to detoxify the chemical agents by chemical treatment and convert them into products that can be treated in a hazardous-waste treatment, storage, or disposal facility. The conversion may involve immobilization of the neutralization products in a matrix such as concrete or bitumen.

-

Neutralization followed by biodegradation. In this process micro-organisms are used to convert the neutralization products into innocuous materials that may be considered hazardous wastes.

Stand-alone neutralization of the volatile GB nerve agent was carried out on a large scale at the Rocky Mountain Arsenal in the 1970s, but there has been much less experience in neutralization of mustard blister agents and VX nerve agent, the materials stored in bulk at Aberdeen and Newport, respectively. Neutralization of these agents has been studied extensively in the context of decontaminating equipment under battlefield conditions (Yang et al., 1992), but the process is less well developed for demilitarization applications. Only laboratory and small-scale pilot demonstrations have been conducted (NRC, 1993b). Biological degradation of neutralization products has been studied only in the laboratory. The RDT&E program also is carrying out a survey of the stockpile condition at Aberdeen, Newport, and Tooele (where pilot testing may be conducted) and of methods to decontaminate ton containers concurrently with process development for agent destruction. This survey is required to understand the extent to which agent has reacted or gelled during storage, which may impact agent-destruction processes. Furthermore, ton container decontamination and either metal recycling or disposal will be essential for success of the overall system.

An immediate goal of the RDT&E program is to determine whether either alternative technology offers sufficient advantages to justify the cost of building and operating a pilot plant and to justify facing the risks associated with delaying the destruction of the chemical weapons stockpiles. Because information on both alternative technologies is so limited, it is necessary to study them in the research laboratory and to develop process data in a bench scale semi-works (20–30-gallon reaction vessels). These studies will identify preferred chemical reactions and biological species for neutralization and neutralization-biodegradation. They are intended to enable an early decision between the two technologies. The experimental program will also provide the basic data needed for design, permit acquisition, and construction of a pilot plant if there is a positive decision to build and operate such a demonstration facility. Simultaneously, as part of the comprehensive program, the Army will survey the physical and chemical characteristics of the agents to be destroyed at Aberdeen and Newport. Other activities include agent-specific and technology-specific hazards analyses, development of appropriate monitoring techniques, and evaluation of means to dispose of the waste products from the two neutralization-based technologies.

The following sections discuss technical aspects of neutralization and biodegradation, as well as the mechanism and time frame for decision-making, and provide more detail on the experimental and engineering aspects of the Army's program.

CHEMISTRY AND BIOLOGY OF ALTERNATIVE PROCESSES

The NRC Stockpile Committee's report, Recommendations for the Disposal of Chemical Agents and

Munitions (NRC, 1994b), recommended accelerated research and development on four neutralization-based systems for agent destruction:

-

neutralization followed by burning the neutralization products in an existing incinerator;

-

neutralization followed by supercritical water oxidation to “mineralize” all the constituents of the agents;

-

neutralization followed by wet air oxidation with subsequent bio-treatment to complete the oxidation of the organic products; and

-

neutralization followed by biodegradation to produce innocuous products.

In each of these proposed systems, neutralization (for example, chemical hydrolysis) serves to detoxify the agent and permits complete destruction in a subsequent, more complex step. The Army has gone further by considering neutralization with disposal of residues as hazardous wastes as a “stand-alone” technology for demilitarization, not just detoxification. However, the Army also chose to evaluate the neutralization/biodegradation option as an integrated system for complete demilitarization of the agents.

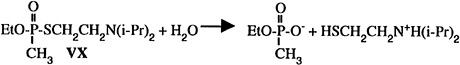

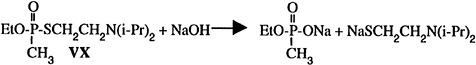

Five neutralization chemistries have been pursued at the laboratory scale (see Table 2-1); three of these are being tested on a larger scale (U.S. Army, 1995b):

-

simple hydrolysis of VX by prolonged reaction with water under mild conditions;

-

hydrolysis of VX by hot water or hot aqueous NaOH; and

-

hydrolysis of mustard by hot water or hot aqueous NaOH.

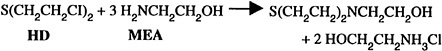

The products of these three reactions seem to be good candidates for biodegradation, which would satisfy both the Chemical Weapons Convention (CWC) irreversibility requirement and many environmental regulations concerning waste disposal. Two additional options, neutralization of HD with monoethanolamine and oxidation with ammonium persulfate, were studied but subsequently dropped because these products had operational drawbacks not encountered with the neutral or alkaline hydrolysis reactions being studied.

One of the most critical aspects in evaluating an agent-destruction process is the nature of the waste products and emissions from the process. The baseline system produces large volumes of gaseous emissions, primarily carbon dioxide and water along with trace amounts of products of incomplete combustion, acid gases, and compounds resulting from recombination of combustion products. Large quantities of salts (i.e., carbonates, chlorides, fluorides, phosphates, and sulfates) are collected from evaporation of the effluents from the gas-scrubbing equipment. Neutralization processes yield similar amounts of salts in combination with relatively large amounts of organic materials and small amounts of gases. Because the neutralization temperatures are below 100º C, there is little or no formation of worrisome materials, such as chlorinated dioxins or furans, even when destroying chlorine-rich materials such as mustard agent (ca. 40 weight percent chlorine). For stand-alone neutralization, methods for disposal of the organic compounds remaining in the reaction mixture along with the salts must be considered.

In choosing between the reactions of Table 2-1 , prime considerations are the extent of agent destruction and the nature of the liquid effluents. For example, data obtained to date indicate that the simple hydrolysis of VX (reaction 1) accomplishes substantial detoxification of the agent, but that low levels of VX may remain even after weeks of reaction at room temperature. Some posttreatment to reduce the VX concentration may be needed to prepare the hydrolysate for biological treatment. Heating, reaction with caustic (reaction 2), or treatment with the enzyme organophosphorus hydrolase (Kolakowski et al., 1994) may suffice. Although conditions for biodegradation of the hydrolysis products have not been established, the simple hydrolysis reaction opens interesting possibilities for destruction of VX stored in bulk. If pilot tests of the hydrolysis of VX within standard ton containers are successful, a relatively rapid and inexpensive detoxification of the VX stockpile at Newport might be possible. Hydrolysis of the agent in its current storage container would reduce the storage risk at the site substantially. Final treatment or disposal of the hydrolysate could be deferred for some time if a Resource Conservation and Recovery Act storage permit could be obtained.

Hydrolysis of mustard (reaction 3) is effective as the first step in an integrated neutralization-biodegradation system. The recent observation that mustard dissolves in and reacts rapidly with hot water is encouraging. The agent is converted fairly cleanly to thiodiglycol (TDG) in contrast to the mixture of products obtained from caustic hydrolysis. Further treatment is needed because

TABLE 2-1 Neutralization Reactions Under Study

|

Destruction of VX Nerve Agent |

Conditions |

Products/comments |

|

|

Neat VX reacted with 7 wt.% water at 25 ºC for 6-10 weeks |

99.9% destruction of VX; product near neutral pH; must be diluted with water for bio treatment. |

|

|

VX added to vigorously stirred, hot, excess aq. NaOH. Rapid reaction to yield viscous liquid product mixture. |

>99.999% destruction of VX; product is alkaline and must be neutralized and diluted before bio treatment. Ratio of S-containing products partially controllable. |

|

|

||

|

Destruction of HD Mustard Agent |

||

|

|

Neat HD (1%) added to hot water. Rapid reaction to give clear solution. |

>99% destruction of HD. Product a candidate for mineralization or (after neutralization) bio treatment. |

|

|

Reaction at 60-90 ºC. |

Mixture of HD product and MEA·HCI: needs dissolution in water before bio treatment. |

|

|

Reaction in water in two stages: 25 ºC to sulfoxide; 90 ºC to salts and CO2 |

Complete mineralization of the agent; large amounts of sulfate coproduct. |

TDG is a “scheduled precursor” that can be reconverted to agent easily. The product solution from the simple reaction with water is strongly acidic because hydrochloric acid is formed as a coproduct. The highly corrosive hydrochloric acid can be neutralized as it forms during hydrolysis without generation of excessive amounts of byproducts. (Hydrolysis with excess alkali generates undesirable byproducts via dehydrochlorination of the HD and the derived sulfonium salts.) The product solution must be neutralized prior to biological treatment because the biodegradation requires a fairly dilute solution near neutral pH. Preliminary studies of the biodegradation of this hydrolysate are encouraging. Mixed microorganisms from a municipal waste-treatment plant appear to oxidize TDG efficiently; however, suitable analytical procedures and disposal processes for the resulting biomass and reaction solution must be developed.

All neutralization systems for destruction of mustard must deal with agent decomposition products, such as gels and solids, that accumulate in storage containers with time. These cause handling problems both for the neutralization process and for emptying the storage containers in preparation for disposal. Residual solids in the containers may retain significant quantities of agent and complicate the decontamination of the drained containers. Such problems are less prominent with the nerve agents, but effective decontamination treatments must also be developed to facilitate the final disposition of the VX ton containers.

In principle, biological processes can be used in many ways in the chemical demilitarization program. Microorganisms have been shown to cleave key chemical bonds in both GB and VX nerve agents. None seems to grow in the presence of mustard agent, which blocks critical metabolic processes. Even with nerve agents, however, the technology for complete destruction of agent has not developed to the point that it can be considered as a stand-alone demilitarization process. It is in the degradation of organic products derived from hydrolysis of VX and mustard that biological treatments are most likely to be useful. Indeed, biological treatment of effluents may be critical to the viability of neutralization processes (NRC, 1994b).

As noted earlier, the biological oxidation of TDG from mustard hydrolysis seems promising. Sewage sludge from a municipal waste-treatment plant, which contains a broad range of microorganisms, oxidizes TDG to carbon dioxide, water, and sulfate (Lai et al., 1994). The efficiency of the process is likely to improve as the bacterial culture adapts to using TDG as its primary organic nutrient for growth. The disposal of the products resulting from TDG oxidation will have to meet environmental regulations for both the water solution and the solid biomass (sludge consisting largely of bacterial cells). The biodegradation of the products of VX hydrolysis may be more difficult, but there are encouraging leads. A particularly important lead is the identification of microorganisms that cleave the methyl-to-phosphorus bond in methylphosphonic acid derivatives (Schowanek and Verstraete, 1990). The importance stems from the fact that the phosphonic acid is a product of the hydrolysis of both GB and VX and is especially difficult to degrade by chemical means (Gloyna, 1993). Cleavage of the carbon–phosphorous bond may be a requirement for “irreversible” destruction of nerve agents, depending on how the language of the CWC treaty is interpreted. Enzymes are also known to oxidize other components of the VX hydrolysate, but the complete degradation of the organic products has yet to be demonstrated.

If an integrated neutralization-biodegradation system is chosen for development, the design and operation of the biological reactors may draw heavily on the engineering of municipal and commercial waste-treatment plants. The extensive nonmilitary experience with such facilities could accelerate the design and permitting phases of implementation.

DECISIONS ABOUT ALTERNATIVE TECHNOLOGIES

The Army must make many critical decisions during the development of alternatives to incineration for destroying its stockpiles of chemical agents. During the research and development program, a series of choices are needed to determine the “best available technologies ” for mustard and for VX. Even with the options limited to stand-alone neutralization and neutralization/biotreatment systems, the choices among the reactions in Table 2-1 are complex. Each of the “best available technologies” must be able to meet the technical and regulatory criteria identified in later chapters. Each must also be evaluated relative to the congressional mandates about safety, cost, environmental effects, and schedule as well as the treaty requirements for irreversible destruction. The Army will make the decisions necessary to arrive at “best available

technologies” through a disciplined decision process known as “trade-off analysis.”

If the analysis of laboratory and bench-scale test results indicates that a technology may meet the criteria mentioned above, the Army must demonstrate the efficacy and reliability of the system in a pilot plant. The process for deciding whether to carry out a pilot-scale demonstration is the central focus of this report. Based on initial analyses by the Army (U.S. Army, 1994a), the demonstration may cost as much as $200 million, depending on the specific technology chosen. The pilot operation will not be undertaken unless it is likely that the chosen alternative can be used at Aberdeen or Newport or both. Because the expense is so large, the decision will be made by the Defense Acquisition Board after review by the Army Systems Acquisition Review Council. Both decision panels use highly structured methodology developed for the purchase of major weapons systems.

Proceeding with a pilot-scale demonstration facility embraces a number of decisions about the demonstration's character, size, and location. A neutralization facility will likely use reactors that treat a fixed quantity of agent in a batch or semi-batch mode rather than operating continuously as do the incinerators in the baseline system. The batch technology permits holding the liquid effluents from the reactor until they can be analyzed, thus ensuring that they meet criteria for the next step in the process or for disposal. The volume of liquid agent to be processed at one time might range from 150 gallons (the contents of a 1-ton container) to 500 gallons or more. The quantity may be governed by safety considerations or by the rate at which agent must be processed in order to meet the overall schedule for stockpile destruction. The NRC recommended in Recommendations for the Disposal of Chemical Agents and Munitions (NRC, 1994b) that the demonstration at the pilot facilities be carried out on essentially the same scale as the final demilitarization facility. For a batch process, the “full-scale” facility might comprise several batch reactors of the size used for the demonstration. This approach would significantly reduce the technical risk in implementation of the alternative process.

The NRC formally recommended that the demonstration of an alternative technology be carried out at the Chemical Agent Munitions Disposal System (CAMDS) facility rather than at a storage site (NRC, 1994b). The CAMDS facility at Tooele, Utah, has the appropriate physical infrastructure, analytical facilities, and experienced personnel to conduct a demonstration of alternative processes. Conversely, placement of a pilot unit at Aberdeen or Newport could facilitate the transition from demonstration to implementation at the site. The Maryland Citizens Advisory Commission has indicated its receptivity toward siting a demonstration facility at Aberdeen.

In order to proceed to implementation of an alternative technology, the demonstration facility must show efficacy in agent destruction, reliability and safety in operation, and generation of final products that can be disposed of in accordance with the relevant environmental regulations. Monitoring systems for gaseous, liquid, and solid process streams and effluents must be demonstrated in order to meet process control and disposal requirements. The operation of the pilot unit will also generate the information needed for design and operation of a complete demilitarization system.

ALTERNATIVE TECHNOLOGY RDT&E PROGRAM ELEMENTS

The RDT&E program is intended to provide the data needed to decide whether to demonstrate an alternative system to use in place of the baseline system at Aberdeen or Newport or both. Many of the activities are being carried out simultaneously, but the following phases are evident:

-

laboratory-scale research to identify the most promising chemical and biological processes for further development;

-

bench-scale tests (20–30-gallon reactors) to evaluate the chosen chemical and biological reactions, identify engineering characteristics of the processes, and generate data needed to design demonstration facilities;

-

analytical studies to identify and quantify the products of neutralization and biodegradation (This research complements interactions with relevant regulatory authorities. It must show the ability to analyze for chemical agents and environmentally degrading products down to legally specified threshold levels.); and

-

design studies for a pilot plant (500–20,000-gallon reactors) to demonstrate the best available technology on approximately 150-gallon lots of agent.

Simultaneously with the RDT&E program, the Army's Product Manager for Alternative Technologies and Approaches (formerly the Applied Technology Branch) is surveying the chemical and physical status of the mustard and VX stored at Aberdeen, Newport, and Tooele and the condition of the storage containers. Technology for draining, decontaminating, and disposing of the containers is also being studied.

All of these activities are aimed at generating the information required for the Army Systems Acquisition Review Council and decisions by late 1996. An outline of the data needed is presented in Chapter 4. The NRC has tentatively ageed to evaluate the adequacy of the research and development results, while the Army prepares for the Army Systems Acquisition Review Council and Defense Acquisition Board reviews.