6

Risk Management

RISK ASSESSMENTS AND HAZARD EVALUATIONS

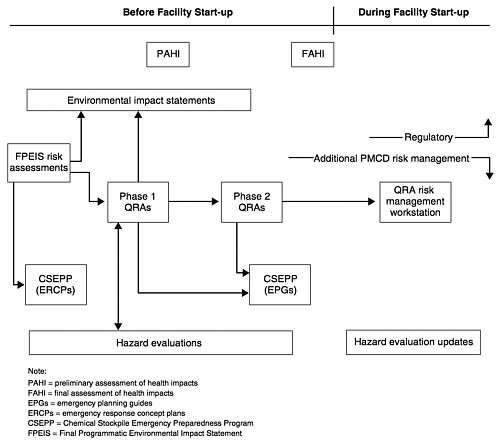

Several of the recommendations in this report deal with concerns about safety and risk. The Army established a procedure in 1997 for dealing with these matters, which was published in A Guide to Risk Management Policy and Activities (U.S. Army, 1997). The Guide calls for the following safety and risk evaluations to be completed at the design stage:

-

hazard fact sheets in support of the final programmatic environmental impact statement

-

Phase 1 and Phase 2 QRAs1

-

appropriate HEs

A health risk assessment (HRA) must also be prepared but has less impact on operational risk and safety. Figure 6-1 is a diagram showing how these analyses and assessments interact.

In previous reports, the committee has stressed that the safety of operations and storage can best be understood and managed based on the results and models developed in a Phase 2 site-specific QRA (NRC, 1993, 1994a, 1996a, 1996b, 1997, 1999a, 1999b, 1999c). The QRA in turn must be based on a thorough understanding of plant hazards identified in HEs, knowledge of operating practice and campaign management, knowledge of agent toxicology, and models of agent dispersion following accidents. Special attention must be paid to unusual design features and particular hazards at each facility.

A key component for the Phase 2 QRA is a detailed, dynamic model of the cascade ventilation system for each facility that can be used to determine possible agent concentration levels at various points in a plant in case of a power failure, interlock failure, or other exigency. Parallel systems and single systems can be compared to define the alternative with the lowest risk, which would then be included in the final plant design. From the information made available during this study, the committee could not be certain that development of these kinds of analyses (leading to a Phase 2 QRA and associated HEs) is proceeding at a proper pace during the design stage. The committee believes that HE and QRA development must be initiated as soon as possible to ensure that the results are available for the final design and operation of the facilities.

Recommendation 6-1. Quantitative risk assessments and hazard evaluations for both the Newport and Aberdeen facilities should be carried out as early as possible during facility design, and the findings from these assessments should be used in both the design and future operation of the facilities to minimize risk and maximize safety.

SCHEDULE RISK

Another risk that must be considered is associated with the schedule of project development and design, construction, start-up, operations, and shutdown. Schedule delays not only affect cost and meeting CWC obligations, but also increase public risk due to continued storage. The committee is particularly concerned about the schedule for the NECDF because of uncertainties associated with the SCWO process. The committee believes the workability of this process may very well be proved out during a pending EST. However, it is not clear if the EST can be completed quickly enough to prevent causing serious delays to the NECDF project. If the EST takes longer than expected, or if further development in

|

1 A Phase 1 QRA evaluates public risks from a proposed facility before it is constructed. A Phase 2 QRA is a detailed evaluation of the risks and consequences of accidental releases of agent to workers and the community based on the site-specific design and operations. |

FIGURE 6-1 Timing of risk management activities. Source: Adapted from U.S. Army, 1997.

some process area is required, continued storage of the agent would be necessary, which would probably increase public risk. The ABCDF schedule is less likely to be delayed because biodegradation is better known and more developed. In 1998, Arthur Anderson reported that although the schedules for all PMCD disposal facilities could conceivably meet PMCD's plans, there was a high probability that the schedules for several facilities, including the ABCDF and the NECDF, would be exceeded (Arthur Anderson, 1998).

Recommendation 6-2. Schedule risk should be evaluated for the Aberdeen and Newport facilities in the context of program implications and public risks and appropriate contingency plans developed if needed.