EXECUTIVE SUMMARY

The purpose of the Blast Mitigation Program is to develop methods to protect people inside of buildings from terrorist bomb attacks. Although this will be accomplished, in part, by structural hardening and blast mitigation techniques, the focus is on protecting people, not the building or other assets. Two key issues are addressed in the program which are the primary cause of injuries and death in terrorist bombings; structural collapse, and flying debris (i.e., glass, building materials, etc.). Products of the program include better assessment methods which identify potential vulnerabilities, and new methods and guidance on how to reduce these vulnerabilities. The program will develop methods to design new, less vulnerable structures, as well as develop methods to retrofit existing structures to improve their protection levels.

During the first year (FY98), the program has initiated the development of methods to retrofit existing structures to prevent structural collapse. A four story test building has been constructed at White Sands Missile Test Range (WSMR) to examine collapse mechanisms and test retrofit methods. Retrofits using traditional materials, such as concrete and steel, as well as the use of advanced composite materials will be tested. This building has also been used to test mailrooms to protect against package bombs, windows and window retrofit methods, and will hold various walls for additional blast testing. To address roof and load-bearing wall collapse, a reaction structure has been constructed to test retrofit concepts. Tests during FY98 provided baseline structural response information; retrofits will be tested during FY99. Out-year efforts will develop design guidance for retrofitting steel framed structures and other structural types. To address the design of new buildings, in cooperation with GSA, a design methodology to prevent progressive collapse will be developed and tested. Ultimately, guidelines will be produced for the design of all GSA buildings. These guidelines could be used by DoD and other government agencies.

Flying debris, particularly glass, is a major source of injury from terrorist bombings. Methods to predict the response of glass to blast have been limited to estimating glass breakage. The United Kingdom (UK) has developed a Glazing Hazard Guide which defines potential hazard levels from break-safe (little hazard) to high hazard. This guide was computerized as a first step in developing a comprehensive method to predict the hazards and injuries from flying glass. During FY98-99, in cooperation with the UK, ninety-six (96) windows were tested in the building at WSMR to verify the hazard guide at high explosive yields where little data exists. Future efforts will focus on more comprehensive models which predict fragment size, shape, velocity, and distribution from all window types and sizes. This model will be linked to human injury models to estimate hazards and compare the effectiveness of various mitigation techniques.

There are many commercial companies with various products which may help reduce injuries from glass. Unfortunately, there have been very few tests conducted in a consistent manner to evaluate the capabilities of these products. Testing was initiated during FY98 on sixty (60) products to compare their blast performance. The results will

be published on a “Yellow Pages” web page which will help building owners understand the capabilities of, and differences between products. Testing of door and wall products will be conducted during FY00.

Validation tests were successfully conducted in Israel to verify design methods for masonry wall and window retrofits that provide inexpensive systems to reduce debris hazards. The wall system uses fabrics which do not strengthen the wall, but catch the debris thus protecting people inside. The window system uses fragment retention film attached to the glass and a bar across the window which, in combination, catches the glass. Design and implementation guidance has been completed and will be distributed. Additional retrofit methods will be tested during FY00-01.

Tests were conducted in Israel and WSMR on various blast wall designs. New, less expensive, and more aesthetically pleasing designs will be developed during FY99. Tests were also conducted during FY99 to validate blast wall shielding effects.

ASCE

American Society of Civil Engineers

ATF

Bureau of Alcohol, Tobacco, and Firearms

BAA

Broad Area Announcement

CMU

Concrete Masonry Unit

CONWEP

PC code for conventional weapons effects based on TM 5-855-1

CTS1

Full-scale test structure to be built and tested in FY98

CTS2

Full-scale test structure to be built in FY98 and tested in FY99

DoD

Department of Defense

DOE

Department of Energy

DOS

Department of State

DSWA

Defense Special Weapons Agency

FBI

Federal Bureau of Investigation

FCDSWA or FC

Field Command, Defense Special Weapons Agency

FEMA

Federal Emergency Management Agency

FY

Fiscal Year

GSA

General Services Administration

IACRO

Interagency Cost Reimbursement Order

MIPR

Military Interdepartmental Purchase Request

NFESC

Naval Facility Engineer Service Center

NRC

National Research Council

PC

Personal Computer

PHETS

Permanent High Explosives Test Site

SETA

Scientific Engineering and Technical Assistance

SS

US Secret Service

TNT

Trinitrotoluene

TWSG

Technical Support Working Group

UK

United Kingdom

USACE

United States Army Corps of Engineers

USAF/WL

United States Air Force Wright Laboratories

WES

United States Army Engineer Waterways Experiment Station

WSMR

White Sands Missile Range

1. Introduction

The Technical Support Working Group (TSWG) administers, coordinates, and executes a large portion of the US Government Anti/Counter-terrorism Development Program. As a result of recent terrorist attacks against American citizens both home and abroad (World Trade Center, Murrah Federal Building, and Khohbar Towers), the Blast Mitigation for Structures Task (Task T-148F) was added during FY98. The attacks on the U.S. Embassy's in Nairobi and Dar El Salaam further demonstrate the need for blast mitigation techniques. The Blast Mitigation Program is managed by the Defense Threat Reduction Agency (DTRA) and is under the oversight of the Physical Security Subgroup of the TSWG.

2. Background

The protection of occupants of buildings from terrorist bomb attacks can be enhanced by an appropriate balance between better security procedures including the enforcement of increased standoff distances and the use of blast hardening and mitigation techniques. This program addresses only the blast hardening and blast mitigation aspects of the problem including design of blast walls, blast loading modifications, and structural hardening. Although blast mitigation methods show great promise, many of them have inadequate validation testing and some may be too costly to implement on a large scale.

The work conducted in this program will address the major issues related to preventing injuries and deaths from a terrorist bomb attack by developing cost-effective blast mitigation techniques and assessment procedures. The program pulls together both national and international agencies to generate a coordinated effort and leverage resources.

The program is broken into three major areas. The Technology and Construction Methods Evaluations area examines predictive capabilities and vulnerabilities of current construction methods in addition to screening potential mitigation techniques. The Technology Development and Application area determines the blast effects on structures and components, and develops and tests new design and retrofit concepts. Final products include vulnerability assessment methods for calculating blast effects, structural response and human injury. Design guidance will be developed to reduce these vulnerabilities. And finally, the Technology Transfer and Administration area insures that the results of this program are validated, coordinated, and disseminated to the ultimate users, and that the overall program runs smoothly and effectively.

3. Program Objectives

The purpose of the program is to develop methods to mitigate the effects of blast on structures in order to prevent injuries and death. Although structural hardening and blast mitigation techniques will accomplish this, in part, the focus is on protecting people, not the structure or other assets. Injuries and death from bomb attacks on buildings can usually be attributed to three causes: structural collapse, flying debris, and fire/smoke propagation. Since the first two represent the predominant cause of death or injury, particularly from external explosions, they will be the primary focus of the first years of the program.

A primary product of this effort will be methodologies and computer modules for predicting blast environment, structural loading, structural response, and injuries to personnel. These modules will be developed such that they can easily be imported into various vulnerability assessment, design, and analysis tools. These methodologies will be fully coordinated throughout the community so all are using consistent physics formulations. Ultimately, the final product will be the incorporation of economical design changes that enhance blast resistance and reduce the debris hazard into standard building practices.

Specific objectives are as follows:

-

Establish tri-service/interagency workgroups to review and collaborate on the program.

-

Develop cost-effective methods to retrofit existing structures to mitigate the effects of blast.

-

Develop design guidance for new construction to mitigate the effects of blast.

-

Test and evaluate commercial-of-the-shelf (COTS) products for their capability to increase the resistance of a structure to blast effects.

-

Develop industry standard models for the prediction of blast effects on structures and generate computer modules for use by the government and industry.

-

Define and produce joint service/agency design and assessment tools (to be defined by the user community).

-

Develop simplified injury prediction models so that the benefits of blast mitigation design and retrofits can be evaluated in terms of human injury avoidance.

IV. Approach

In the first year, a review of existing methodologies and data will be initiated. Results of this effort will be used to define the state of the technology and will help focus research on critical areas. Potential mitigation materials and technologies will be identified and evaluated for incorporation into a testing program. The testing program will examine the blast response of structural components and entire structures to determine the potential vulnerabilities and hazards to personnel. Mitigation techniques will be developed and

tested for both pre-construction designs as well as post-construction retrofits to existing facilities. All major issues will be worked in parallel to ensure that solutions to key problems are developed quickly.

Because of the complexity of predicting the effects of blast on structures, and the large variations in commercial construction, detailed final guidance will likely take a number of years. To ensure that results and information are made available as quickly as possible, interim guidance will be provided as the program progresses. A newsletter and technical bulletins will be published and distributed to all users to inform them of the progress of the program and to provide interim guidelines.

The blast effects efforts will leverage existing work and available information throughout the blast, shock, and structures communities. Existing facilities and infrastructure will be used to the fullest and duplication of effort will be minimized through cooperative testing. Explosive environment, structural loading, structural response, blast mitigation studies, and forensic investigation efforts will be combined as much as possible in coordinated tests supported by the Federal Bureau of Investigation (FBI), US Army Corps of Engineers (USACE), DSWA, Bureau of Alcohol, Tobacco, and Firearms (ATF), as well as international participants. To ensure the effort is coordinated and meets all agency requirements, ad hoc working groups will be established for each technology area to help guide the program. Overall program review will be provided by a committee established by the National Research Council (NRC) which will also facilitate technology transfer.

In addition, calculations, building structure component tests, individual debris hazard tests, and source characterization tests will be done. A major focus of this research effort will be testing on a full-scale representative test structure (CTS1) built without blast hardening. Retrofit methods to increase blast resistance will be applied to the structure and tested. This and other full-scale structures built during the program will be used as multi-agency test facilities to leverage resources and test requirements. The next year will see continued work on basic blast-structure interactions and the construction and testing of an structure (CTS2) similar to CTS1 but designed, within strict financial limitations, to be blast resistant. The thrust of the third and fourth years of the program will be to build on what was learned in the first two years and insure that the techniques and methodologies get transferred to the design community. Other full-scale structures will be constructed to examine earthquake resistant designs, other construction types, and to test additional blast mitigation techniques.

V. Program Summary. This program will basically have three main parts (A more detailed explanation of each part can be found in Appendix A):

-

Technology and Construction Methods Evaluations. This will include evaluating the effectiveness and appropriateness of current methods for predicting bomb blast effects on structures and the supporting data. In addition, standard design and construction practices will be examined to identify vulnerabilities to blast effects

-

resulting from applying these standards. Finally, potential techniques touted by vendors to mitigate the effects of bomb blasts will be screened to evaluate the potential for further development and/or testing.

-

Technology Development and Application. This will include a detailed high explosive test program which, in addition to basic research in blast-structure interaction, will attempt to resolve any deficiencies noted in part 1. These tests will be planned on both the responses of individual structural components and complete structures to the effects of bomb blasts. Debris hazards caused by the bomb blast and specialized circumstances such as mailroom blasts will also be evaluated in the test program. Studies of the blast loading will also be included in the testing program. This will include looking at the bomb itself (shape, composition, and configuration), its dynamics upon explosion, and the effects of intervening structures (buildings or blast walls) on the blast loading. It will then take the validated results of the research program and either develop new computer-based methodologies or modify existing design programs to take into account the potential effects of terrorist bombs on buildings. This is the most important but potentially the most difficult portion of the entire program. Blast mitigation solutions that are developed must be straightforward, economical, and simple to apply or they will not be used. Results of this phase of the program will also include development/validation of specific retrofit and protective measures designed to mitigate the effects of bomb blasts on existing structures.

-

Technology Transfer, Computer Support and Administration. Initially this program will primarily include pre-shot calculations and post-shot analysis for tests in part 2 to validate and modify predictive and design methodologies as necessary. In order to achieve the goal of coordinated data and methodologies, key organizations who would use the tools and data developed by this program will need to participate in the data gathering, development and review process. The goal will be to have this involvement conducted under the auspices of a NRC panel and to incorporate these design changes into existing building codes and standards. Some of these organizations may require funding support to participate. This task will also provide that support as well as technical support for the task manager.

VI. Program Management

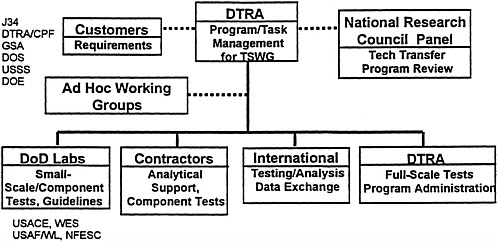

The overall organization is depicted in Figure 1. The Physical Security Subgroup and the TSWG have responsibility for oversight of the program. DTRA provides program development and overall management of the effort as Task Manager for the individual tasks. The Task Manager must prepare individual task plans for each of the tasks contained herein for approval by the Physical Security Subgroup and the TSWG.

Once these task plans are approved, appropriate funds will be provided by the TSWG directly through the use of IACRO's, MIPR's, and contracts (upon availability of funds).

All task plans, briefings, and monthly reports will be generated according to the TSWG Task Manager's Handbook. The Task Manager will also ensure that the program is coordinated with DoD and non-DoD users. This will be done through ad-hoc working groups established for various technology areas.

FIGURE 1. Program Management

There are many US government, commercial, and foreign government performers. The US Army Waterways Experiment Station (WES) is the lead military service laboratory under Project Reliance for Survivability and Protective Construction. They will be used for both explosive testing and methodology development.

DTRA has a considerable testing infrastructure as part of the DTRA Permanent High Explosives Test Site (PHETS) at the White Sands Missile Range (WSMR) where full-scale testing will be performed. This large facility has ample room for a number of full-scale structures and a variety of experiments with virtually no limitation on explosive yield. An opportunity exists to use the test structures to meet other agency requirements, leveraging off of the initial test objectives.

Commercial contractors will be used for much of the analysis work and for some of the component testing. Contractors will be chosen through the Broad Area Announcement (BAA) system and through standard open competition procedures.

Finally, the program will be leveraged through joint efforts with foreign governments. Programs are already underway with Israel and the United Kingdom and an effort will be initiated with Canada.

1. Technology and Construction Methods Evaluations

A. Evaluate Vulnerability Assessment Methods/Data. Methods for predicting bomb blast effects on structures have been developed for many types of common building classes and components. For conventionally constructed buildings, these methods are often based on limited data and in some cases on no test data. The purpose of this task is to perform a detailed assessment of the analytical methods and supporting test data for blast predictions and structural response to determine which methodologies are sound and which need more validation testing and/or development. The methodologies will be researched to determine their origin and the test data used to validate the particular method. Other test data will be sought out to further evaluate the method. Where useful, first principle calculations may be used in this process. Results from this study will assist in establishing test requirements and research priorities.

B. Evaluate Standard Design and Construction Techniques. Although design standards require that structural systems be built to withstand specified loadings and other environmental conditions they leave considerable flexibility for the designer and fabricator in meeting these specifications. To prioritize the development of retrofit techniques and structural systems to be evaluated in the program, an assessment of the various typical structural types (e.g. reinforced concrete frame, steel frame, reinforced concrete flat slab, load bearing masonry), column/beam and column/slab joint designs, and field construction techniques (e.g. locations of cold joints, uniformity of concrete properties) must be evaluated. This effort will consist of a survey of design and construction practice, and analytical investigation of the susceptibility of the various different designs and construction to blast loadings.

C. Identify and Evaluate Potential Mitigation Materials/Techniques. A number of potential techniques to mitigate the effects of bomb blasts on structures have been identified (e.g., earthquake resistance retrofit methods, application of composite materials, energy absorbing materials). There are a number of vendors who claim to have products which will mitigate the effects of blast, but which are untested. These techniques and others may provide cost-effective solutions to this problem. Before expensive testing is performed, a preliminary evaluation will be made to identify the products or techniques that offer the highest potential for success. This evaluation will likely include analysis and small scale or static testing. After successful screening, these potential solutions will be incorporated into the full-scale testing program.

2. Technology Development and Application

The effort described below will leverage off of existing work throughout the blast/shock and structures communities. Existing capabilities will be utilized to the fullest and duplication of effort minimized. The program will leverage blast mitigation efforts with forensics by continuing support for the FBI in developing a better tool for explosive yield estimation and incorporating ATF vehicle debris tests into the structures mitigation effort.

A. Loading Definition. One of the primary issues that will influence the development of protection from terrorist bombs is the proper definition of the bomb environments and corresponding loads. There are several principle parameters that affect the blast loading of structures from a terrorist attack. These parameters include the location of the bomb with respect to the primary target as well as other structures and terrain, the presence of blast walls or barriers, the configuration and orientation of the charge, and the type of explosive. This effort will seek to characterize the effect of these parameters through tests and analysis. The results of this effort will help to identify advantages that may be gained by control of these parameters. They will also help to improve analytical tools that are used to determine the critical loads for design, analysis and retrofitting of facilities.

1) Blast wave propagation in complex geometries. The blast loading on structures in an urban or other area where other buildings will affect the blast pressures is not easily calculated with simplified methods. Three-dimensional hydrocode calculations are required to estimate the effect of other structures. This type of analysis was performed for Eskan Village in Saudi Arabia where average pressure reduction beyond 400 ft were found to be half of those calculated using CONWEP1. This showed that traditional methods might yield very conservative results for high-density areas. This task will address this issue by providing a suite of 3-D and 2-D blast propagation calculations simulating high density building layouts to determine the general trend of pressure and impulse reduction from other buildings.

2) Blast wall effectiveness. Blast walls and barriers modify the blast propagation from a bomb detonation. The Army and Air Force Security Engineering Manual (TM 5-853, AFM 88-56) contains a methodology for calculating the reduction in blast pressure and impulse behind a blast wall. The formulations are, for the most part, based upon small-scale tests conducted at WES. These formulations were never validated with full-scale experiments and are limited to certain geometries and charge sizes. For instance, the minimum height of a blast wall for a 5,000-pound bomb using these formulas will be 14 feet. This task proposes to extend the limits on the geometry of the problem through a calculational effort followed by some validation tests.

The overall effectiveness of barriers is also a function of their potential for creating hazardous debris. A recent DSWA sponsored test indicated that a reinforced concrete wall failed in a manner as to cause a significant debris hazard out to several hundred feet.

|

1 |

PC-based computer code that provides conventional weapons calculations based on the equations and curves of TM 5-855-1 “Fundamentals of Protective Design for Conventional Weapons” |

Tests need to be performed with various wall designs and threat levels to determine the most cost-effect ways to eliminate the debris hazard, yet still deflect the blast pressures.

B. Structural Collapse. Progressive collapse of structures has been the leading cause of death from bombings. This may continue to be a problem, particularly in urban areas where little or no standoff for buildings may be available. Column failure was the primary cause of structural collapse in the bombing of the Murrah Federal Building. A FEMA/ASCE report2 on the Oklahoma City bombing suggests that 85% of the floor space would have been saved if the columns did not fail. This report recommends incorporating techniques used for earthquake protection (e.g. column jacketing, use of special moment frame and dual systems) into the structure for blast protection. Although seismic loading is different than blast loading, some of the methods, modified to resist blast conditions, may provide adequate protection for a modest investment. Testing is needed to verify this belief and to develop design guidance.

A number of types of structures are susceptible to collapse. Retrofit methods for flat-slab structures, load-bearing walls, and lightweight steel roof systems will be developed first. Other structures will include blast-resistant designs, moment-resistant frames, and steel frames. Specific discussions on each are contained below

1) Flat-Slab Structures

Flat-slab structures are very common in low seismic zones. Story heights can be smaller since there are no beams to interfere with overhead utilities. These structures will typically have less capacity to resist blast loads because of the weak column/slab joint. For this reason, this structural type was chosen to be examined first. If retrofit methods work on this structural class, they should work on others.

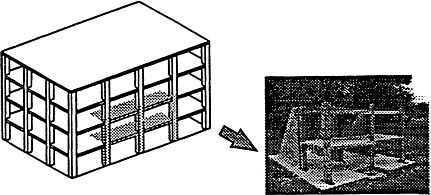

The general approach taken to develop retrofit methods is to first design and construct a full-scale flat slab test structure (CTS-1). The basic structure was designed to ACI code (This was constructed during FY98). The structure will be tested during FY99 to a blast load which will cause severe damage, and possibly collapse a portion of the structure. The remaining structure will then be retrofitted and re-tested to the same blast environment to demonstrate the effectiveness of the retrofit techniques. This effort is supported by first-principal calculations, scale model testing, and laboratory tests.

Figure 1: Typical Flat-Slab Structure

a. Scale-Model Testing

|

2 |

Oklahoma City Bombing: Improving Building Performance through Multi-Hazard Mitigation, FEMA 277/August 1996. |

Scale-model testing was conducted during FY98 to help understand potential failure modes of the structure, and to determine the structural loading. This effort is complemented with first prinicple numeric simulations of the structural response. These efforts will help insure the success of the full-scale structure test. Potential failure modes include column failure, slab failure due to uplift, or punching shear of the floor at the column. The structural loading of the column and the floor slab is complicated by the failure of the exterior wall. If the wall fails quickly, relative to the blast load duration, the blast will clear quickly and the column will have less impulse applied. If the wall fails slow, relative to the blast duration, the column will experience more impulse because the blast can not clear quickly. Another complicating factor for floor loading, is the effect of the exterior wall failure on the blast. Typical calculations assume a non-responding exterior wall.

Figure 2 shows the section of the building to be modeled, and a picture of the test article and the reaction structure. The test article simulates the center column of the building (2 storries), the floor slab (for 1 bay), and the perimeter beam. The weight of the floors of the multi-story building is simulated with a weight placed at the top of the stub column.

Five tests were conducted. The first simulated a 1000 lb bomb at 20 feet from the building. In this test the structure suffered minor damage. In the second test, the bomb was moved in to a simulated stand-off of 14 feet. In this case, some permanent deformation took place (see figure 3). There was no exterior wall in either of these tests (bare column only).

Figure 2: Scale-Model Component Test Atricle in Reaction Structure

Figure 3: Test 2, Bare Column, Moderate Damage

The third test was identical to the second except the in-fill masonry walls were added. These walls do not strengthen the structure, but delay the clearing of the blast wave so the column sees more impulse. The time it takes for the walls to break apart will affect the

clearing time. Post-test examination of the structure and the pressure measurements show that the wall does breakup relatively slowly and the impulse on the column was greater, resulting in severe damage to the column. No slab uplift occurred since the blast did not enter the building until the pressures were substantially reduced (see figure 4).

Figure 4: In-Fill Walls, Severe Damage to Column

The fourth test modeled the real building exterior walls with an opening for the windows. The response of the column was expected to be somewhere between the bare column test and the test with the solid in-fill walls. The results showed a that the column received almost as much damage as the column in the solid wall test (see figure 5). In addition, the floor received severe damage. It is believed that the underside of the second floor was in direct sight of the charge and the blast was delayed to the top of the second floor by the walls. This resulted in greater differential pressures.

Figure 5: Exterior Wall With Window Opening, Severe Damage to Column and Floor

The last test was designed to maximize the uplift by leaving the bottom bays without walls and constructing solid walls on the second floor. The test results showed that the floor did receive severe uplift damage, and the column on the second floor received severe damage (similar to other solid wall test).

Figure 6: Solid Wall on Second Floor, Severe Floor and Column Damage

The results of these tests, combined with the computational effort, provide greater confidence for the full-scale tests. After completion of full-scale tests, an evaluation will be made as to the usefulness of performing more sub-scale tests to understand structural behavior in a wider variety of structural details and blast loads.

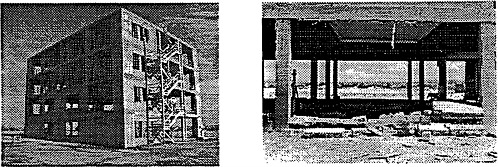

b. Full-Scale Structure Tests (CTS-1)

During FY98, a full-scale test building was constructed (CTS-1) at the White Sands Missile Test Range (WSMR) to examine structural collapse and to test retrofit methods to prevent it. Analytical studies were conducted which indicate that seismic retrofit techniques, adapted for blast loads, show promise. The types of retrofit methods being considered are composite (fiber reinforced plastic) column and floor wraps and steel column jacketing. Potential retrofit designs were developed during FY98 (Karagozian & Case contract).

A calibration test was conducted in August 1998 to provide confidence in ability of computational methods to predict structural response. Three tests are planned for FY99. The first test, which was conducted during April, was designed to cause severe damage to a column which could result in partial collapse of the building. Pre-test predictions suggested that collapse would not occur. On the other hand, if the building did not have an edge beam, or if the edge beam was somewhat weaker, collapse would occur. The test results matched the predictions extremely well. The prediction indicated a 7.5 inch deflection of the column, the actual deflection was 10.5 inches. The results provide confidence that the analytical codes can provide reasonable predictions of expected damage.

Figure 7: Pre and Post-Test Pictures of Calibration Test

Retrofits will be applied to the two adjacent columns and they will be tested to the same environment as the severely damaged column. Hopefully, this will demonstrate the ability of the methods to protect the columns. In order to develop design guidance for a variety of structural details, further testing is required and the designs need to be refined. The next section describes the effort which will result in final design guidance.

Two additional tests are planned to demonstrate structural collapse and the ability to prevent it using retrofit techniques. The first test will be a larger bomb placed between two columns. With two columns severely damaged, partial collapse will likely occur. The next test will be conducted on the other side of the building to demonstrate the adequacy of the retrofit methods.

c. Retrofit Techniques Using Composite Materials

Concurrently, an effort will be conducted to refine the use of composites for retrofitting columns, beams, walls, floors, and structural connections. The final product will be guidelines to allow engineers to design appropriate retrofits for a particular building and a given threat. It is expected that this task will be completed during FY00. (The contract is under negotiation and is expected to commence in July 99)

2) Load-Bearing Wall Structures

a. Damage Prediction Methodology

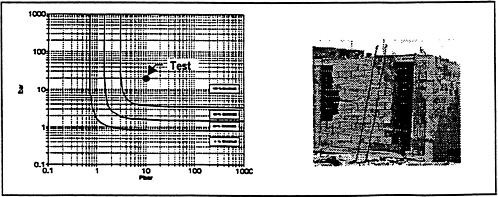

Masonry is the one of the most common building materials for both in-fill and load-bearing walls. These walls are also very susceptible to collapse because of their relatively weak capability to resist horizontal loads, and because of the large surface area to attract blast loads. Analysis methods for masonry walls have been developed for some masonry wall configurations, but only limited validation testing has occurred. Figure 8 shows an example where the FACEDAP methodology over predicts the amount of damage by a factor of 5. The graph shows a prediction of collapse while the test wall was only partially

Figure 8: Masonry Wall Damage Validation Test

damaged. A design using this method would result an excessively conservative and costly retrofit. Another example is documented in the referenced report3. The investigators in this report discovered that the FACEDAP methodology does not predict damage well and modified the method to better model the behavior observed in the tests. Many common wall configurations (e.g., cavity walls) have not been tested and methodologies are required.

Different types of walls will be tested including reinforced concrete, unreinforced and reinforced concrete masonry units (CMU), brick, and cavity walls. Some retrofit methods to strengthen walls have been identified as having potential benefits but testing is needed to verify this. The solutions identified to-date are limited and expensive. New retrofit techniques that will be examined and tested include using composite materials, shotcrete and reinforcing, and other methods. The data from these tests will be used to develop and validate computational codes and provide recommendations of the best and most cost-effective solutions.

b. Load-Bearing Wall Retrofit Development

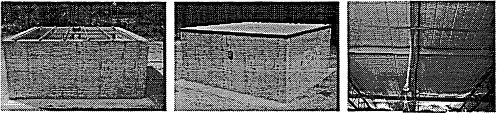

A multi-use reaction structure was constructed at Tyndall AFB during FY98. This reaction structure is capable of holding both roof systems and load-bearing walls for testing. Load-bearing control walls will be tested during FY99. Retrofit methods will be developed simultaneously and tested during FY99. Design guidelines will be developed by th US Army Corps of Engineers, Protective Design Center and published during the first half of FY00.

In addition to the above effort, a retrofit method was submitted during the FY98 BAA process. The proposal describes the development of a lightweight precast panel which would be attached to the exterior wall of a building. The attachments consist of shock-absorbing dampers. This concept shows promise and will be developed during FY99-FY00.

3) Roof Systems

Some common types of roof systems, such as lightweight steel bar joists, often fail during a terrorist bombing while the walls survive. There where three examples of this in the Oklahoma City bombing.

Figure 9: Roof failure in Oklahoma City Bombing

During FY98, a reaction structure was built at Tyndall AFB to hold roof test articles. The reaction structure has one removeable wall

|

3 |

Validation of Component Vulnerability Curves for Unfilled Masonry Walls and Steel Joists, Karagozian & Case, TR-96-30.2, 7 January 1997. |

which will provide a place to test load-bearing walls also. Two control roofs were tested during FY98 to moderate and severe damage levels. During FY99, another control test will be conducted to which is expected to achieve collapse of the roof. Retrofit methods will then be tested to prevent roof collapse. Design guidance will be developed during FY99 and will be published early in FY00. In the outyears, other roof types will be investigated.

Figure 10: Reaction Structure With Test Article - Pre and Post-Test

4) Seismic Designed Structures

Another class of structures to be investigated are structures designed to resist seismic loads. These structures are common throughout California, and are becoming more common in other areas of the world. Although blast loading is significantly different than seismic loads, seismic designs are more robust, provide more ductility, and are expected to be more resistant to blast. It should be noted that seismic design is not the same as a blast design. If one were to design specifically for blast, the resulting design would not be the same as a structure designed for seismic loads.

5) Blast-Resistant Designed Structures

It is considerably cheaper and easier to design a new structure for blast resistance than to retrofit an existing structure. Structural details, such as continuity of steel in joints, or steel in the top of a slab to resist uplift, are often the difference between progressive collapse of the structure, and limiting damage to a local area. A blast-resistant structure was designed to a threat level of 1,000 lb TNT at 20ft. The structure was designed using the TM5-1300 methodology. The structure will be constructed during FY99 and FY00 and tested during FY00. This testing will validate this methodology.

The General Services Administration (GSA) has initiated an effort to develop design guidelines to prevent progressive collapse from a bombing. The guidelines will be written so engineers without blast design experience will be able to develop adequate designs. Although blast loads are directly considered in the design process, the robustness of the resulting building will prevent progressive collapse. This effort guideline development effort will be finished during FY99. A building will be designed and constructed using the developed guidelines, and will be tested during FY01.

6) Other Structural Types

Other structural types, such as steel frames, will be examined in the out-years. Some of these types will be identified through Task 1.A, and through vulnerability assessment reports which reveal an inadequacy in analysis capability, and a deficiency in retrofit options.

C. Debris Hazards

Flying debris (e.g., glass, walls, overhead lights and utilities, other building components and furnishings) is the leading cause of injuries in terrorist bombings. Hazardous debris is generated at large distances from the detonation location and can injure hundreds of people, or even kill. Although glass is a major contributor to the debris problem, architects, building owners, and tenants like the openness of large windows. In addition, airblast entering a building can cause overhead utilities to fall, interior walls to fail, and office furnishings can become hazardous missiles.

There are three objectives in the debris problem. The first is to develop an injury prediction methodology. If preventing injuries and death is the main objective of the Blast Mitigation Program, the ability to quantify the vulnerability of facilities in terms of injury is required. Once a vulnerability is determined, the benefits of potential mitigation techniques is required in terms of injuries or deaths prevented. This will allow a risk assessment to be performed which incorporates the cost and benefits of a particular solution.

The second objective is to test and evaluate commercial-of-the-shelf (COTS) products. There are numerous vendors that have products that may increase the protection level of a facility. Unfortunately, most of the products have had little or no realistic blast testing. In addition, the tests that have occurred have not been conducted in a way to provide direct comparisons with other products. An effort is underway to test these products to generate consistent data.

The last objective is to develop retrofit methods to reduce injuries from flying debris where no cost-effective commercial products exist. During FY98, two methods were tested, and design guidance developed, to reduce injuries from broken glass and masonry walls. These methods and others will be described below.

1) Windows

a. Hazard Prediction Methodology

When performing vulnerability assessments, the metric that needs to be used is the extent of injuries and deaths of the occupants of buildings. In order to accomplish this, a hazard

prediction methodology is required. This prediction method needs to take into account all blast environments and window properties, and must be able to predict the benefits of various retrofit options.

At the beginning of FY98, there were two basic methods for calculating window damage. The first is a methodology that calculates probability of breakage for a number of glass types. This methodology falls short by not being able to predict the post-breakage behavior of the glass (e.g., how far does the glass travel, what does the debris field look like). Another methodology was developed in the United Kingdom (UK) which predicts hazard levels for glass subjected to various blast conditions. This methodology is a series of pressure-impulse (P-I) diagrams (lines of equal hazard level plotted in terms of pressure and impulse from various charge sizes and ranges). Three hazard levels are described. The first is break-safe where the glass breaks but either stays in the window frame or falls inside or outside the window. The second is low hazard where the glass travels into the room but not at high velocity. The third is high hazard where the glass travels at high velocity – hits a wall 3 meters into the room at least ½ meter above floor. Although this methodology can not be used to directly predict injuries, it is a good first step toward a complete methodology. The UK Glazing Hazard Guide was developed in paper form as a series of charts.

During FY98, this method was automated and coded as a computer module for use by various vulnerability codes (e.g., it has been incorporated into AT-Planner). It has been incorporated into the WinDAS database as a standalone glazing hazard assessment tool. The WinDAS database has all of the available data on window tests, as well as a guide on how to assess window hazards and how to design and retrofit to reduce potential hazards.

Most of the data from which the Hazard Guide was developed was at small yields (100 pounds or less). There is a substantial need to obtain data for higher yields. A test was conducted during FY98 to gather data on a variety of glass types to obtain this data at a higher yield. The explosive charge size was chosen as 5,000 pounds of C-4 to ensure that the hazard level is on the peak pressure asymptote of the P-I diagram. The test was conducted at the CTS-1 structure. Forty-two windows were tested in the building and another six in cubicles. Most of the windows responded as expected with a few exceptions. The toughened glass consistently performed better than expected. In addition, the retrofit concepts performed somewhat better than anticipated. And lastly, some methods for attaching window film, in a daylight application, to the frame show promise (the frames blew in so the tests were inconclusive). This data will be incorporated into the WinDAS database during FY99. Modifications will be made to the UK Hazard Guide which incorporates this data.

One shortfall of the UK Hazard Guide is that the P-I diagrams were developed for certain thicknesses and sizes of windows (these correspond to the size of the test specimens used in the UK). Although the dimensions of most windows are reasonably close to one of the windows in the Hazard Guide, a better solution is to non-dimensionalize the guide so any size or thickness of glass can be evaluated. An effort was conducted during FY98 to examine the feasibility of accomplishing this for annealed glass. This project was a success so the plan is to extend this effort to other glass types. This effort will not be initiated until FY00 due to funding constraints.

The automation of the UK Glazing Hazard Guide is an interim step toward developing a complete hazard and injury prediction method. Glass size, shape, velocity, and debris pattern need to be estimated for incorporation into an injury model. During FY99, a method developed for the Air Force Space Command will be investigated as a base code for predicting the glass debris field. At present, this code calculates the glass shard size, and velocity for annealed glass, but has not been validated. A complete method is expected to take about two years to develop. To gather data to validate the model, the holograph system developed by the Air Force to examine fragment from penetrating munitions will be used.

The last area that needs improvement is the design of proper frames and anchorage systems. Frames and anchorage systems have been tested to some degree, but better design guidance is required

b. Retrofit Method Development

A commonly known approach to retrofitting windows is to apply fragment retention film (FRF) (e.g., mylar®) in a daylight application (FRF is applied to window in exposed areas only, not attached in the frame). When this approach is taken, the glass fails at roughly the same pressure level, but the glass travels into the room as one whole piece held together by the film, and not as pointed shards which can cause severe cuts. The filmed glass also travels at a slower velocity than individual shards at the same pressure level would have. Although daylight applications of FRF provide some hazard reduction, injuries still can occur.

One method to obtain additional protection to a window with a daylight application of FRF is the use of a “catch bar”. This method uses a bar attached across the filmed window to catch the window after it breaks. During FY98, proof-of-concept tests were conducted (which were successful). A design methodology was then developed, and validation testing was conducted in Israel. The US Army Corps of Engineers Protective Design Center developed an Engineering Technical Letter (ETL) to provide complete guidance on how to design and construct this retrofit method (the ETL is currently under review in the Corp of Engineers). This method does provide an additional increment of protection, but can be overwhelmed by a large blast load. Protection levels, up to about 10 psi can be achieved with 10 mil or thicker films.

Another method to reduce glass hazards is to attach FRF to the frame. In this case, the film acts as a membrane and the blast pressures must be high enough to exceed the strength of the film or the frame if the glass were to become a hazard. This method has the advantage over a catch bar in that the it does not allow airblast to enter the building and create more debris from internal building components and furnishings. A couple of methods are being evaluated for attaching the film to the frame. One method is to apply high-strength structural silicone caulk to the film/frame. Another method is to mechanically attach the film to the frame. This was successfully tested in the Divine Buffalo 9 test. A design methodology will be developed during FY00.

c. Commercial-of-the-Shelf Products

The window industry has been involved in the development of blast resistant glazing for a number of years. Many of the glazing units are adaptations of ballistic glazing. Other products are available which include window films, curtains and shades, laminated glass, and different glass material compositions. Testing standards have been developed in the US but do not provide realistic blast simulations and therefore do not provide an adequate basis for evaluation. The wide variety of products makes comparisons between the these products difficult. Although the glazing industry has performed some blast testing, usually with very low charge sizes (e.g., .0.25-1.0 lb), there is no consistent basis to compare products. The Blast Mitigation Action Group (BMAG) was established to evaluate commercial products. This group is chaired by WES and has members from various government agencies (i.e., DTRA, Army, Air Force, Navy, Secret Service, Capital Police). The group developed a testing criteria and protocol which was presented to the glazing industry (Protective Glazing Association) for evaluation. Industry was generally pleased that the government established criteria for them to design to. The government has agreed to test industry products in a shock tube at Wilfred Baker Associates. The shock tube was chosen to perform the tests because it provides a good, consistent simulation of blast loads, and is less expensive than open-field testing. The simulated blast threat was chosen to be 1,000 lb TNT at 150 and 275 feet (peak reflected overpressures of 10 and 4 psi respectively) (a typical window breaks at less than 1 psi). The manufacturers were given the opportunity of providing up to three products for testing. During FY99, 60 products were tested. A “Yellow Pages” Internet web page was developed, and is available on-line, which lists all known manufacturers of blast mitigation products and will provide test data to government personnel with an appropriate password. Additional tests on window products will be conducted during FY00. The testing will be expanded to include door and wall products.

2) Exterior Walls (non-load-bearing)

a. Walls Without Openings

During bombing events, exterior walls often fail and become debris hazards to the occupants of a building. Failure of walls also provides for venting of airblast into the structure which can further add to the debris problem by translating office equipment and

furnishings as well as non-structural building components (e.g., overhead utilities, partition walls, etc.). To protect people inside of structures, exterior walls may either need to be strengthened, or prevented from entering the building after failure by a debris catching method.

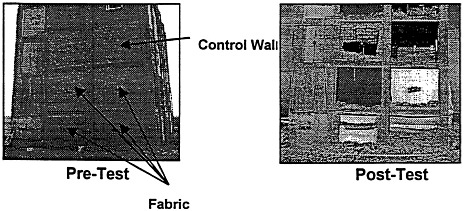

During FY97 (under DTRA/WES joint program), proof tests were conducted to examine the use of high strength fabrics to catch wall debris from masonry walls. The tests were successful and a design methodology was developed during FY98. Further tests were conducted in Israel during FY98 to validate the design methodology. The methodology was successfully validated and was documented in an ETL which was published in early FY99. Figure 12 shows the results of the test.

Figure 12: Fabric Wall Retrofits

b. Walls With Openings

The fabric catch method works extremely well for masonry walls without openings. Unfortunately, most walls also contain windows. Retrofitting walls with windows is a much more difficult problem. Either the window, frame, frame anchor, and wall need to be strengthened, or a catch mechanism installed which must be able catch the whole system. In most situations, the building occupants do not want the window covered.

During FY98, one method was tested using a geo-grid material in Israel and using a composite glued to the wall. The geo-grid allows some visibility through the window while the composite blanket did not. Neither method, as applied, was looked good. The geo-grid did not perform very well while the composite did.

During FY99, two contracts will be let which will provide concepts for retrofitting specific EUCOM and State Department facilities (see Technology Transfer Section). These contracts will provide retrofit new retrofit ideas which will be validated with testing.

Other combinations of efforts (composites, windows, frames) will provide other solutions over the next few years.

3) Building Internals

Interior building components such as overhead utilities, internal partitions, and office furnishings, can become debris hazards following a bombing. Such injuries were observed in the Oklahoma City bombing as well as in the Nairobi bombing where numerous deaths occurred. In earthquake prone areas, better attachment methods are required for overhead utilities. Some of these methods, and others, may provide increased protection from these hazards with minimal cost.

To develop injury prediction methodologies and methods to reduce injuries, office and housing areas will be tested in the Divine Buffalo test series starting in FY99. Testing will continue during future tests to collect additional data and examine other retrofit techniques. The product from this effort will be better debris hazard models and methods to reduce debris. Some of the methods are expected to be no-cost, smarter ways to arrange offices, to lessen the objects that may become debris hazards, and to arrange furniture to keep people away from highest airblast (e.g., keep beds away from windows). A video will be produced to describe some of these procedures.

D. Human Injury Prediction

Human injury is the yardstick by which vulnerabilities to terrorist bomb attacks are measured. When vulnerabilities are identified, numerous solutions are often available which provide different levels of protection. Since there is often inadequate funds to provide complete protection from any terrorist threat, risk assessments which examine cost and benefits must be developed. The benefits are described in terms of human injury. At present, injury models for blast focus on overpressure and human translation while most injuries result from flying debris. Models are required to estimate injuries from all major contributors.

1) Injury Case Studies of Terrorist and Other Bombings

The examination of injuries from previous bombing is useful for a number of reasons. First, the cause of injuries can be determined which can lead to improvements in buildings to prevent these types of injuries. In addition, data from bombing can be used to develop or validate injury prediction methods. One must be careful not to rely only on previous bombing events for injury prediction methods since, in terrorist bombings, the bomb type, yield, and configuration is usually not know precisely, and must be estimated based on observed damage.

To examine injuries following the bombing of the Murrah Federal Building, the Blast Mitigation Program contracted with the Oklahoma State Department of Health to complete a database of injuries sustained following the attack. Survivors of the attack

were interviewed to determine the locations of the people, the types of injuries they received, and the causes of those injuries. This database was linked to AutoCAD and Arcview computer codes to provide a capability to plot the results of a query on a map of the city, and place people in proper locations is certain highly damaged buildings. The effort was completed during January 1999.

This database will be expanded with data from the Khobar Towers bombing. This effort began during May 1999 by contacting survivors with a survey. This effort will be completed during FY00. In addition, data from World War II and accidental explosions will be gathered and added to the database.

A simplified, quick running injury model will be developed using the data in the database. The method will be backed up with a more detailed method for a more refined analysis and for comparisons of various retrofit options.

2) Comprehensive Injury Model

A contract will be let during FY99 to develop a comprehensive injury model. Existing methods from the military and auto safety industry will be assembled with blast effects codes (overpressure, debris, etc.) to generate the model. After completion of the model, mitigation methods can be evaluated and compared to determine their capability at reducing injuries. This is a three year effort to be completed during FY02. The model will be put into modular format for input into various vulnerability codes.

D. Internal Detonations. A requirement has been identified to protect mailrooms and other readily accessible areas of buildings, such as lobbies, from small bombs either carried or delivered to office buildings. Techniques will be investigated to obtain different protection levels ranging from fully containing an explosion, to allowing blast venting into limited local areas. Potential methods including reinforced concrete walls, sacrificial walls, masonry walls with debris catchers, application of composite wallpaper, and others will be investigated. This task will take advantage of the full-scale test structures and will work in conjunction with the DOE mailroom initiative. The goal is to develop cost-effective methods to protect against such bombs.

1) Mailroom Protection

During FY98, a simulated mailroom was constructed in the CTS-1 structure. This mailroom used typical masonry walls found in many buildings (i.e., unreinforced 6 inch CMU, two layers of bricks, and lightly reinforced CMU). The exterior wall was designed to be light weight to blow out quickly. This type of design provides a low level of protection from a letter bomb (ref 1). The bomb was placed in an x-ray cabinet (from another TSWG project) which was supposed to contain fragments but not the gas pressure. The exterior wall was blown out and two of the interior walls fell over. The lightly reinforced wall remained in-place. The test verified the Security Engineering Manual at low level of protection. The next step is to test various retrofits and new

designs for greater protection. The threat will be 2 pounds of TNT equivalent explosives. The tests will be conducted at the Chestnut Site and Kirkland Air Force Base. A reaction flame will be constructed and tests conducted during the summer of 1999. Design guidance will be developed during FY00.

Figure 13: DB-2 Mailroom Test

3. Technology Transfer and Administration

There are a number of mechanisms being used to get the technology to the users. First, each military service has a quick method to distribute engineering technology (i.e., Engineering Technical Letters, Technical Data Sheets). All products from this program will be distributed through this method. A longer-term effort is underway to develop a Military Handbook on Security Engineering. The information from this program will be incorporated into this joint service publication.

The technology developed in this program needs to be transitioned into commercial practice. A National Research Council panel was established to perform program review and develop a technology transfer strategy.