2

Development of Vehicle Subsystems

CANDIDATE SYSTEMS

The success of the PNGV program will depend on the integration of R&D programs that can collectively improve the fuel efficiency of automobiles and meet the requirements of comparable size, reliability, durability, safety, and affordability of today’s vehicles. At the same time, the PNGV vehicles must meet even more stringent emission standards and recycling levels and must use components that can be mass produced and maintained in a manner similar to current automotive products.

In order to achieve the Goal 3 fuel economy objective of 80 mpg, the energy conversion efficiency of the chemical conversion system (e.g., a power plant, such as a CIDI engine or a fuel cell) averaged over a driving cycle will have to be at least 40 percent, approximately double today’s efficiency. In addition to improving the energy-conversion efficiency of the power train (including energy converters and transmissions) and reducing other energy losses in the vehicle, achieving the Goal 3 fuel economy objective will require a very large weight reduction (> 40 percent) through new vehicle designs and lightweight materials.

In short, meeting the Goal 3 fuel economy target will require extensive innovation. For example, the primary power plant, when used in a hybrid electric vehicle (HEV) configuration, will have to be integrated with energy-recovery and energy-storage devices. Radically new vehicle structures will be necessary to reduce vehicle weight. The design and performance of essentially every aspect and function of the vehicle, from the passenger heating and cooling systems to the conversion efficiency of the exhaust-gas after-treatment systems, will have to be evaluated for possible energy savings.

Hybrid drive systems, the PNGV near-term power trains of choice, use energy-storage devices to reduce fluctuations in demand on the primary power plant, thereby permitting the use of a smaller power plant operating closer to optimum conditions for increased energy-conversion efficiency and reduced emissions. These storage devices also allow recovery of a portion of the vehicle’s kinetic energy during braking operations.

In this chapter, the committee continues its evaluation of the candidate energy-conversion and energy-storage technologies that survived the 1997 technology selection process, as well as of candidate electrical and electronic systems and advanced structural materials for the vehicle body.

The committee reviewed R&D programs for: four-stroke internal-combustion reciprocating engines, fuel cells, electrochemical storage systems (rechargeable batteries), power electronics and electrical systems, and structural materials and safety to assess their progress toward commercial applicability. In the committee’s opinion, PNGV has continued to make significant progress on the development of candidate systems and the identification of critical technologies that must be addressed to make each system commercially viable.

Indeed, global competitiveness is one of the objectives of the PNGV program. In fact, previous committee reports have specifically addressed the directions and trends of international development programs. The committee is aware that the PNGV partnership continues to maintain awareness of international programs and, in many cases, the USCAR partners are participating in those developments through international operations and coalitions. Therefore, a separate section on international developments has not been included in this report.

INTERNAL COMBUSTION RECIPROCATING ENGINES

The internal combustion engine continues to be the primary candidate power plant for meeting near-term PNGV program goals. To meet the fuel economy target of Goal 3, the internal combustion engine will have to be integrated into an HEV configuration. The CIDI or diesel engine is the most fuel efficient internal combustion engine being developed. Consequently, in the near term, maximizing the efficiency of a diesel engine and integrating it into an HEV will provide maximum vehicle efficiency. However, as will be discussed below, the challenges of meeting the new California Air Resources Board (CARB) and EPA Tier 2 emission standards have called into question the viability of the CIDI engine as the primary energy converter in PNGV’s time frame. As a result of the new standards, the technical team working on the 4SDI (four-stroke direct-injection) engine began focusing more on emissions control research for the CIDI engine. In addition, they are continuing research programs on other combustion systems for internal combustion engines, namely the homogeneous-charge compression-ignition engine, the gasoline direct-injection engine, and the homogeneous-charge spark-ignition engine.

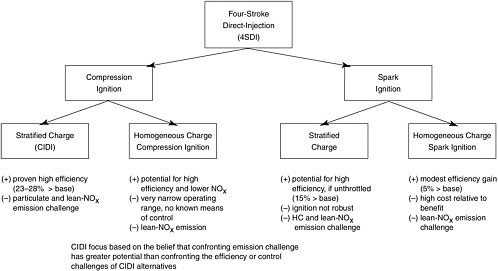

Figure 2-1, which was included in previous committee reports, is a convenient summary of the advantages and challenges of the internal combustion engines being considered as primary energy converters for the PNGV program.

Program Status and Plans

In the past year, the 4SDI technical team has made excellent progress in continuing the development of a power system to meet the PNGV goals. In addition, each USCAR partner developed and built its own concept car. Based on proprietary visits to each partner’s laboratories to be briefed on concept-car programs, the committee recognizes and commends the tremendous and impressive efforts by each USCAR partner to develop and build these concept cars and integrate promising technologies into the vehicles. The extent to which each concept vehicle represents a different approach toward meeting the PNGV goals is testimony to the dedication, creativity, and industry of the USCAR partners.

All three partners are developing diesel-powered electric hybrid systems for their concept vehicles. However, overall vehicle objectives and the logical basis for hybridization vary among the partners, whose approaches to trade-offs among fuel economy, degree of hybridization, emission reduction strategies, attaining manufacturability, and cost reduction are quite different. Because of the importance of these vehicles as a program milestone, a separate section of this report is devoted to them (see Chapter 4).

In addition to proprietary internal work on the concept vehicles, PNGV continued its collaborative programs on precompetitive fundamental technologies, including interactions between fuel composition and engine performance (as recommended in the committee’s fifth review [NRC, 1999]); the fundamentals of combustion, including some very novel concepts; and in response to Tier 2 emission standards, a stepped-up investigation of emission control technologies and sensors. Progress to date and the future plans of the 4SDI technical team are discussed below in three sections: engine-fuel interactions; engine-combustion system developments; and after-treatment and controls and sensors.

Engine-Fuel Interactions

The effects of fuel chemistry and physical properties on engine performance and emissions was the focus of intense activity during the past year motivated by data reported in the literature showing that fuel composition affects nitrogen oxides (NOx) and particulate matter (PM) emissions from a variety of diesel engines (Ryan et al., 1998; Takatori et al., 1998; Tanaka and Takizawa, 1998; Wall and Hoekman, 1984). The data also indicated that fuel composition could affect the performance of exhaust-gas after-treatment systems. However, the extent to which these changes would carry over to a state-of-the-art, highly

controllable engine system in which the engine and fuel have been optimized together was not clear. Similarly, as new exhaust-gas after-treatment systems are developed, it will be important to determine whether they retain their sensitivity to fuel composition. These are the general areas of focus for PNGV’s studies on fuel-engine systems and exhaust-gas after-treatment systems.

PNGV is working cooperatively with the low-emission partnership of USCAR, the fuels industry, the U.S. Department of Energy (DOE), and the national laboratories to evaluate the effects of fuel composition and physical properties on engine performance and exhaust-gas after-treatment conversion efficiencies. The working relationships range from formal (e.g., the Engine Manufacturers Association-EPA-American Petroleum Institute Diesel Fuel for 2004 Program and the DOE Advanced Fuels Technology Initiative) to ad hoc (e.g., arrangements between individual USCAR partners with fuel companies [BP Amoco, Shell, and ExxonMobil] to include fuel composition in their matrix for in-house engine development programs).

Collaborative in-house testing by PNGV teams and their energy company partners is being done on a CARB commercial #2 diesel; a petroleum-based, low-sulfur (<10 ppm), low-aromatic (<9 percent by weight) fuel; a neat Fischer-Tropsch diesel fuel; and an oxygenated fuel made by blending 15 percent dimethoxymethane with the low-sulfur, low-aromatic petroleum-based fuel. Standard fuel properties, such as distillation, cloud point, pour point, density, and viscosity were measured for all of the fuels tested. The choice of fuels was based on practical considerations of what might be feasible to introduce into the current fuel infrastructure.

The fuels were run in four different state-of-the-art engines by DaimlerChrysler, Ford, and GM at a range of speeds and loads. At the time of this review, the initial testing had been completed and the data were being analyzed. Although the detailed results and conclusions have not been released yet, one conclusion seems apparent. No clearly identifiable practical fuel composition or property will enable the CIDI engine to meet the new emission standards simply through improved combustion. Although control of the fuel composition and/or properties yields some benefits, the gains in a highly controlled and optimized engine were not as large as expected.

The effects of fuel properties on exhaust-gas after-treatment systems are also being investigated. As the committee has noted in previous reports, the PNGV technical team has determined that none of the 4SDI technologies will be capable of meeting the emission standards without extensive exhaust-gas after-treatment (NRC, 1998, 1999). Therefore, determining the effects of fuel properties, especially sulfur content, on the conversion efficiency of the after-treatment devices will be critical.

PNGV’s activities in the last year in this area have been intense. PNGV teams are working cooperatively with the Diesel Emission Control Sulfur Effects

(DECSE) test program, which is attempting to determine the impact of diesel fuel sulfur level on emission control systems. The DECSE program is evaluating the effects of fuel sulfur concentrations ranging from 3 to 350 ppm on NOx absorbers, PM traps, lean-NOx systems, and diesel oxidation catalysts. The data are still being analyzed, but a consensus has already emerged that sulfur degrades the performance of exhaust-gas after-treatment systems.

This consensus is supported by the results of fundamental research on advanced after-treatment technologies at the national laboratories (discussed in more detail below). When researchers incorporate sulfur concentration into their test matrices, the data show a strong correlation between the system conversion efficiencies and sulfur concentration. In general, the less sulfur the better. But, because the cost-benefit analysis of incremental sulfur removal has not been conclusively evaluated, work in this area should be continued.

PNGV plans to continue its very active program in the area of fuel-engine system interactions. Ad hoc working relationships with fuel companies, as well as participation in formal programs, are critical aspects of the program on fuel-engine system interactions. These ad hoc relationships seem to be working well and provide flexibility to the individual companies to pursue appropriate research.

Engine-Combustion System Developments

Understanding the challenges facing PNGV requires understanding the fuel economy and emission characteristics of different engine types. To date, the approach of the 4SDI technical team has been to pursue technologies that promise maximum fuel efficiency and then address the more stringent emission targets. For an internal combustion engine, the maximum work per unit fuel is obtained when the engine is operated in a fuel-lean (i.e., excess air) condition. If the engine load can be controlled by varying the quantity of fuel introduced into the cylinder without altering the amount of inducted air, energy losses associated with drawing air into the engine across a throttle (throttling losses) can be eliminated. Throttling losses in a typical homogeneous spark-ignition engine range from a few percent at high loads to more than 90 percent at very light loads.

The desirable engine attributes described above are inherent characteristics of diesel engines, the most efficient internal combustion engines available. For this reason, as well as because extensive manufacturing and operating experience are available, the diesel engine is the engine of choice as the principal energy converter for the PNGV program. However, because the diesel engine attains lean combustion by maintaining a heterogeneous combustion system, there are large gradients in air-fuel mixtures in the combustion chamber during energy release. As a result, PM forms in fuel-rich regions, and NOx forms in high-temperature stoichiometric regions. The challenge is to control NOx and PM emissions from diesel engines simultaneously.

The implementation of the EPA Tier 2 standards and the necessity of meeting CARB Ultra Low Emission Vehicle (ULEV) II requirements in California, as well as in other states that may choose to adopt them, has significantly increased the challenge of meeting emission regulations with any internal combustion engine, especially a diesel engine. The initial design targets for NOx and PM emissions at the start of the PNGV program were 0.2 g/mile NOx and 0.04 g/mile PM. These targets seemed to be attainable with an advanced technology diesel engine and some exhaust-gas after-treatment. In October 1997, immediately prior to the PNGV technology selection process (downselect), new research targets were introduced, namely 0.20 g/mile NOx and 0.01 g/mile PM. These levels required substantial improvements in the efficiency of combustion and after-treatment systems. At that time PNGV introduced R&D on the effects of fuel composition into the program.

The new EPA Tier 2 standards tighten the emission requirements further. The new standards mandate fleet averages of 0.07 g/mile NOx and 0.01 g/mile PM, including light trucks and sport utility vehicles (SUVs) of up to 8,500 pounds. The Tier 2 regulations set a phase-in time schedule for different classes of vehicles, as well as emission level “bins” into which different vehicles can be grouped, as long as the fleet average emission level is met. This regulatory flexibility is intended to allow for emerging technologies being introduced into the market by giving manufactures time to gain production experience and continue their development. However, for each vehicle that exceeds the fleet average emission level, a number of vehicles with emission levels below the fleet average will have to be sold to maintain the fleet average. Producing ultralow emission vehicles will be a substantial challenge, and, from a business perspective, if the manufacturer’s lightest and most fuel-efficient vehicle, the PNGV vehicle, cannot meet the mandated fleet average, in all likelihood it will not be pursued. Clearly, PNGV needs to reassess the technological avenues and roadblocks to attaining fleet average standards with the diesel-powered HEV and decide whether or not it should be the primary choice for the PNGV vehicle.

In an attempt to put current work on the diesel-powered HEV in perspective, the 4SDI team assessed to what extent the current projections of after-treatment system performance would have to be modified to meet the new emission standards. The results of this sobering exercise are summarized below:

-

With a gasoline port-fuel-injected, stoichiometric, homogeneous-charge engine, the emission standards could probably be met with advanced three-way catalysts of different combinations.

-

With a direct-injection, spark-ignited gasoline engine as the principal energy converter, advanced NOx traps and PM traps would be required.

-

With a diesel engine, exhaust-gas after-treatment systems would require 75 percent and 50 percent reduction efficiencies for NOx and PM, respectively.

-

Because the fuel economy projections are based on extrapolations of emissions reduction technology, the fuel economy penalty associated with meeting the emission standards could not be quantified.1

The immediate effect of the announcement of the Tier 2 standards has been a shift in resources toward after-treatment technologies to reduce emissions and away from improvements in fuel economy. Prior to the announcement, PNGV believed that the best chance of reaching 80 mpg in its time frame was with a diesel engine as the primary energy converter. Based on the current assessment, the challenges of meeting the Tier 2 emission standards with the diesel engine will be enormous, and the technology most likely to meet the new standards is an engine that uses homogeneous stoichiometric combustion, for which the exhaust-gas after-treatment is most advanced. Unfortunately, this type of engine is the least efficient of all of the candidate engines being investigated. Ironically, in the near term, the likely effect of the Tier 2 emission standards will be to promote the development of the less efficient engine systems.

Despite the increased emphasis on emission reduction technologies, which are being pursued primarily through improved exhaust-gas after-treatment systems, the 4SDI technical team has also continued to perfect in-cylinder combustion processes. This R&D is being performed by the PNGV partners in collaboration with DOE national laboratories, the Department of Defense Tank Automotive Command, EPA, AVL List GmbH, FEV, Wayne State University, and the University of Wisconsin at Madison. Projects have been divided into two categories: (1) enabling technologies that will be critical in the near term (less than three years); and (2) technologies that could be important in the longer term (more than three years).

Near-term projects include: the development of advanced fuel-injection systems, studies of the cylinder-to-cylinder distribution and transient response of exhaust-gas recirculation (EGR); the development of pressure-reactive pistons for dynamic changes in the compression ratio; and detailed comparisons of combustion data obtained in an optical research engine, a similar metal engine, and the predictions of sophisticated, three-dimensional computer simulations. The results of these projects during the past year have varied.

To date, using injection-rate shaping and multiple injection events for emissions control have shown no significant reduction in emissions. However, this

technology has not been completely explored. In addition, this technology may have a critical effect on the composition of the exhaust gas that enters the exhaust-gas after-treatment system. A special fuel system using dimethyl ether was successfully constructed and tested, and more extensive testing of this interesting fuel can now be done in a Ford DIATA (direct-injection, aluminum-block, through-bolt assembly) diesel engine.

An instrumentation system for monitoring the transient EGR distribution was developed by FEV this year, which will enable the detailed investigation of the cylinder-to-cylinder distribution of EGR and the transient response of the engine-EGR system. Because EGR is an important method of in-cylinder NOx control, the results of this investigation will be significant.

Through the collaborative efforts of Sandia National Laboratories (SNL), Wayne State University, and the University of Wisconsin at Madison, the program on the optical engine, the metal engine, and advanced simulation is now fully operational. Data showing soot luminosity and liquid fuel distribution were mapped in the optical engine, and tests of EGR tolerance, from zero to the maximum possible amount, were performed in the metal engine. Both of these data sets were used as a basis of comparison for the predictions of the simulation. The objective of the project is to characterize fully the in-cylinder flow field with the effects of swirl and to validate the full combustion simulation.

Projects in the longer time frame include: continued investigation of homogeneous-charge, compression-ignition combustion; studies on advanced variable compression-ratio engines; studies of electromagnetically actuated engine valves (the camless engine); and the investigation of several novel engine concepts. Progress was also made in these projects.

Researchers at the Combustion Research Facility at SNL in Livermore, California, are close to completing a dedicated laboratory for studying the fundamentals of homogeneous-charge, compression-ignition combustion. Some preliminary data have already been obtained. Experiments and comparisons of the results with predictions from detailed chemical-kinetic computer codes are planned for this facility.

PNGV also continues to investigate novel engine concepts, such as a variable compression-ratio small engine that would operate either as a port fuel-injected or gasoline direct-injected engine. The idea behind this concept is to minimize throttling by varying the compression ratio and boost pressure. If perfected, this engine could operate at stoichiometric air-fuel ratios and take advantage of the advanced state of technology in exhaust-gas after-treatment for stoichiometric systems. The results of initial testing of this engine concept at AVL List GmbH have encouraged researchers to design a functional variable compression-ratio mechanism. Other novel concepts being investigated include an engine that could switch between four-stroke operation and two-stroke operation as the power demands on the engine change and a small engine that would

operate at close to full load for normal operation, which is predominantly light load, and operate in “burst power” mode when high power is needed.2

The 4SDI technical team was also involved in the solicitation of competitive bids for the development of emission control for PNGV-sized CIDI engines. Cooperative agreements were awarded in September 1999 to Detroit Diesel Corporation and Cummins Engine Company. The 4SDI technical team supplied the committee with an estimate of the cost and affordability challenge of the proposed engine and emissions control system. The projected cost is $900 higher than the target cost of $2,100 for the combined engine and exhaust control system. The estimate of funding for collaborative research on emission control for PNGV-sized CIDI engines for 1999 was $52 million.

After-Treatment and Controls and Sensors

Meeting the new EPA Tier 2 emission standards will be a major challenge for any internal combustion engine, especially the diesel engine. Any internal combustion engine used as the primary energy converter will require substantial emissions reduction in the exhaust system. Thus, exhaust-gas after-treatment systems will be critical enabling technologies for meeting the PNGV goals. Highly effective exhaust-gas after-treatment is even more difficult for lean combustion processes, which are the most efficient processes.

PNGV has been aggressively pursuing exhaust-gas after-treatment systems in the past year. Participants in collaborative research with the national laboratories and catalyst manufacturers have included: DOE’s Office of Advanced Automotive Technologies; Los Alamos National Laboratory (LANL); Oak Ridge National Laboratory (ORNL); Pacific Northwest National Laboratory (PNNL); SNL; the Low Emission Technologies Research and Development Partnership; and DaimlerChrysler, Ford, and GM. The work performed directly by PNGV and through cooperative research and development agreements (CRADAs) ranged from the fundamental development of catalysts to the testing of multicylinder engines.

SNL continued its testing of platinum-based hydrous metal oxide (Pt-based/ HMO) catalysts with simulated exhaust gas and sulfur dioxide (SO2). A patentable technology, lower light-off temperatures, and a wider temperature window for effective NOx reductions has been transferred to the suppliers. At best, the maximum NOx conversion efficiency was 60 percent; but a significant degradation in performance was observed when SO2 was present in the exhaust.

Suppliers sent a test catalyst with the SNL formulations to ORNL for testing on a Navistar 7.3-liter direct-injection diesel and a Volkswagen (VW) 1.9-liter turbocharged direct injection engines. There were significant differences in the conversion efficiencies of the catalyst for the two engines. For the VW engine, the conversion efficiency was less than one-half of the conversion efficiency for the Navistar engine. An evaluation showed that this difference was not related to the different levels of NOx emitted by the two engines. Further evaluation showed that the hydrocarbon conversion in the catalyst was lower for the VW TDI engine, and there was a buildup of soot at the entry point of the catalyst. Explanations of these phenomena may be relevant to the performance differences in after-treatment systems for larger and smaller (PNGV size) engines. In any case, the tests showed that Tier 2 standards would not be attainable using Pt-based catalysts.

LANL is investigating synthesis and characterization of high-temperature supports and catalysts, including NOx absorber technologies. One goal of these studies is to optimize the support selection, pretreatment, and catalyst selection. More than 170 materials were prepared and 150 screening tests performed. Fifty tests were made to evaluate SO2/temperature/water stability of the materials. LANL has developed several new catalysts, filed patent applications, and is in the process of transferring the technologies to the catalyst suppliers. Although the results of these investigations have been encouraging, the catalysts are still very much in the experimental stage of development. Many questions, such as catalyst stability and overall conversion efficiencies, have not yet been addressed.

PNNL has continued its research on plasma-assisted catalysis, a process in which an electrical potential difference generates nitrogen ions that combine with NO to form molecular nitrogen and atomic oxygen. This system is used to precondition the exhaust gas from the engine before it enters the catalyst after-treatment system. The device was tested with simulated exhaust gas in the exhaust stream of a diesel-powered generator, and at ORNL on an engine dynamometer system. Bench test results of one catalyst showed up to 50-percent conversion of NOx; some NO and unidentified nitrogen-containing species were detected. Results of long-term stability tests (up to eight days) and sulfur tolerance tests (50 ppm SO2) have been very encouraging. Chemical modeling and mechanistic studies of this catalyst have been started. The results, although still in the early development stage, are promising, and the work will be continued for the next year to explore the full potential of this technology. An evaluation of combined NOx and PM reduction using catalyst-in-plasma designs is also planned..

Another approach to eliminating PM from engine exhaust is to use a PM filter. Filter systems physically trap PM and, therefore, require a method of cleaning out the filter. Continuously regenerative traps, which require low-sulfur fuel, are being developed outside of PNGV by catalyst manufacturers. In addition, in the past year, the 4SDI team has investigated the potential of using a microwave generator to initiate the burn-out of PM captured in the filter. The microwave regeneration efficiencies were evaluated under actual diesel engine

operating conditions. A power of 2 kW and a time of three minutes at idle were required for regeneration. The typical engine running time between regeneration cycles was approximately one hour. This technology is considered promising, and work is planned to continue for the coming year.

Closed-loop control of the engine and emission reduction systems will be necessary to meet the new emission requirements. Once the governing fundamental interactions of the subtleties of engine operating characteristics, their resulting impact on emissions, and the performance of the emission reduction systems are understood, it will be necessary to use sensors and control strategies to minimize the exhaust emissions in all operating conditions. For example, the effects of the EGR in-cylinder distribution and the responses of the EGR system to engine transients will be important for optimizing the fuel-engine after-treatment system. Exploiting the tolerance of the engine for EGR in terms of PM and NOx reduction will require a dynamic, closed-loop control system, for which a wide-range oxygen sensor and a dynamic PM sensor would be important enabling technologies. This is an important area for the 4SDI technical team to pursue.

At this time, the only NOx conversion system with the requisite reduction level is a urea-selective catalytic reduction (SCR) system, which would require a urea transport infrastructure and onboard transport of the reductant. Despite the complexity of both the infrastructure and the onboard auxiliary storage system, the fact that this technology is being investigated is indicative of the monumental challenge facing PNGV.

Issues of Concern

The 4SDI technical team has made excellent progress. Nevertheless, in the short term at least, the more stringent emission standards bring into question the viability of the most efficient power plant as a primary energy converter for the PNGV vehicle. Thus, PNGV faces a dilemma: the most efficient power plant faces the most significant technical challenges in meeting the emission standards.

No doubt, lean exhaust-gas after-treatment systems will require breakthroughs to attain the conversion efficiencies required to meet the standards. In fact, new measurement systems will have to be developed to measure the extremely low PM levels mandated by the regulation. At a minimum, the after-treatment system will add complexity and probably weight to the vehicle. The operating characteristics of the engine to facilitate the after-treatment operation by maintaining the appropriate temperature and exhaust-gas composition will most likely reduce fuel economy because lean combustion exhaust-gas after-treatment systems require a reductant (usually fuel) or auxiliary power (for plasma generation). Systems models will be essential for quantifying the fuel economy penalties for various strategies of meeting the emission standards.

A second ramification of the Tier 2 emission standards is the inclusion of SUVs, which weigh up to 8,500 pounds, in the regulated fleet average emission

standards. Although SUVs are not PNGV-type vehicles, the potential of improving their fuel economy with PNGV technology has not gone unnoticed. However, the very technology being considered for transfer to these vehicles (i.e., highly efficient automotive-size diesel engines) faces the daunting challenge of meeting the new emission standards. Projections by the 4SDI technical team of the after-treatment conversion efficiencies necessary for SUVs were 90 percent for NOx and 80 percent for PM. Even though the Tier 2 standards allow some vehicles to exceed the mandated average levels, the fleet average emission level is so low that, with current and projected technologies, manufacturers may not be able to produce a sufficient number of vehicles with low enough emissions to offset emissions from SUVs. Therefore, SUV manufacturers are not likely to introduce PNGV engine technologies unless they will be able to attain the fleet average emission levels with them. Achieving an acceptable level of confidence for the emission control technology performance would require breakthroughs for lean combustion after-treatment technologies.

At this point in the PNGV program, meeting the emission targets with the CIDI engine is speculative. It seems clear that the sulfur level in the fuel will have to be reduced, but an acceptable level has not yet been quantified. Fuel composition will be critical, but compositions and properties have yet to be determined. In addition, technological breakthroughs in exhaust-gas after-treatment systems will be necessary for the most efficient energy converter to remain a viable option for a PNGV vehicle.

As PNGV continues its development activities, it will be critical to quantify and compare the fuel economy penalties associated with engine systems that are projected to meet the emission standards. An effective method to accomplish this would be to use the systems models to predict the optimal power train configuration for each engine type and after-treatment system that would meet the emission standards. The fuel economy of the different configurations could then be compared. However, before this can be done, emissions models will have to be developed and incorporated into the systems models. The development of emission models represents a critical need.

Recommendation

Recommendation. PNGV should continue its aggressive pursuit of lean combustion exhaust-gas after-treatment systems. The program should also pursue detailed systems modeling that could quantify the fuel economy penalty associated with using different technologies to meet the new Tier 2 emission standards. The modeling should also address how power train hybridization could be used to reduce emissions and what effects changing the primary energy converter would have on fuel economy trade-offs necessary to meet emissions standards.

FUEL CELLS

From the beginning of the PNGV program, fuel cells represented one (perhaps the only) energy converter technology that could simultaneously provide sufficiently low emission levels and sufficiently high energy conversion efficiencies to meet the emission and fuel economy objectives of Goal 3. However, the immature status of proton exchange membrane (PEM) fuel-cell stack technology (the technology under development for automobiles), coupled with the need for suitable subsystems (e.g., liquid-fuel processor, air-management system, etc.), virtually guaranteed that the development of the fuel cell would be on a longer time scale than most other candidate technologies considered in the PNGV program.3

Because of the rapid pace of achievements, as well as the potential for near-zero emissions and high energy conversion efficiency, the fuel cell has been retained as an important PNGV technology. However, because of the longer time scale, fuel cells were not considered for the “deliverable” PNGV concept cars introduced in 2000, for which the much more mature CIDI engine was selected by all three automakers as the near-term energy converter of choice. In fact, the CIDI engine in an HEV configuration was projected to yield average energy conversion efficiencies almost as high as those of hydrocarbon-fueled fuel cell vehicles, while meeting (albeit with some difficulty), the EPA emission requirements in force when the PNGV program began. However, as discussed in the previous section, the much more stringent emissions regulations have increased the challenge and cast serious doubts on the ability of the CIDI engine to meet the new emission levels in the time frame of the PNGV program. If the CIDI engine cannot meet the emission standards, and if the spark-ignited direct-injection engine cannot be modified to achieve efficiency levels close to those of the CIDI engine while meeting new emission requirements, then the fuel cell will certainly become more important for meeting PNGV’s objectives. Although not considered “deliverable” concept cars, Ford has an operational version of a pressurized hydrogen P-2000 fuel cell vehicle, and GM has shown a fuel cell version of the Precept with a proposed hydride-hydrogen storage system at the North American International Automobile Show (see Chapter 4). The P-2000 fuel cell vehicle does not have the energy-saving refinements of the Ford Prodigy concept car, and the GM fuel cell Precept is not yet operational. DaimlerChrysler is also working on a fuel cell-powered version of its PNGV concept vehicle.

Three fuels remain under primary consideration for fuel cell vehicles: hydrogen, methanol, and gasoline. The primary focus in the PNGV program has been

on gasoline. Of the three, hydrogen is the preferred fuel for the fuel cell energy converter; it allows almost instant start-up and load-following, as well as the highest system efficiency with no need for a fuel processor system. However, it is difficult to store enough hydrogen energy on board an automobile for a 350-mile range, there is virtually no infrastructure for distributing hydrogen fuel, and it is more expensive per unit of energy than the other two fuels.

Gasoline has the advantages of an extensive existing infrastructure, the highest energy storage density, and the lowest unit energy cost. However, from the standpoint of the fuel cell energy converter, it presents the greatest challenges because it requires a high-temperature fuel processor with extensive carbon monoxide (CO) “cleanup,” which leads to start-up and transient delays, as well as significant efficiency losses.

Methanol falls between hydrogen and gasoline in many ways. It has an energy storage density about half that of gasoline but about five times that of hydrogen gas pressurized to 3,500 psi. It can be reformed at a much lower temperature than gasoline thus easing the start-up and transient problems somewhat and providing a slightly higher system efficiency. Hydrogen is nontoxic but has by far the widest flammability limits and the lowest ignition energy of the three fuels.

At present, virtually 100 percent of both methanol and hydrogen are produced from natural gas, although each could be produced from other feedstocks (although at higher costs). Methanol is already being produced at pilot plants from coal and could be produced from other materials, such as wood, grain crops, and even municipal or agricultural wastes. Hydrogen can be produced from any hydrocarbon, as well as through electrolysis of water (although it takes more energy to produce hydrogen this way than is returned as useful work by the fuel cell).

Almost all of the experimental fuel-cell vehicles currently operating use gaseous hydrogen as the fuel stored on the vehicle. A few vehicles are operating on methanol, and none is operating on fully integrated gasoline systems. The challenge of a fully integrated system is clearly related to the technical difficulties associated with using the respective fuels in efficient systems that are compatible with automobile requirements.

The committee’s review this year has revealed several success stories associated with R&D on fuel cell technologies. Nevertheless, some previously identified problems persist, and some of the “fuzzy” problems are beginning to come into focus. The automotive companies and researchers are optimistic that the major problems will be resolved through focused R&D on evolutionary, rather than revolutionary, improvements.

Program Status and Plans

Primary activities in the past year have been focused on the following areas:

-

fuel processors (including systems integration)

-

stack electrodes

-

air-management systems

-

cost reductions

Fuel Processors

Fuel processing (converting a hydrocarbon fuel to hydrogen aboard the vehicle) is probably the most challenging technical problem facing fuel cell developers. The reformation of fuel, including gasoline, into a hydrogen-rich reformate has been demonstrated using steam, autothermal, or partial oxidation (POX) reformers. Of these, POX reformers have received the lion’s share of attention (and funding) primarily because they are expected to have the shortest start-up time. Unfortunately, they also yield the smallest quantity of hydrogen per unit of fuel consumed along with copious amounts of CO, which must subsequently be removed through a combination of shift reaction to additional hydrogen and “CO cleanup” systems. These subsystems add to the start-up time (because they must also be heated), which further lowers hydrogen yield because air bled into the process gas to oxidize CO also oxidizes some of the hydrogen. These subsystems also increase costs. Even with POX processors, because of the need for shift conversion, air bleed, and preferential oxidation, the minimum start-up time from ambient temperature ranges from five to ten minutes, and the system takes a significant toll on overall energy conversion efficiency.

The major government-supported fuel processing R&D includes industry programs at Epyx Corporation/A.D. Little; McDermott Technology, Inc./Catalytica, Inc.; and Hydrogen Burner Technology, in addition to programs at Argonne National Laboratory (ANL), PNNL, and other national laboratories. R&D by Epyx/A.D. Little has resulted in a 10-kilowatt-electric (kWe) (closer to 15-kWe according to Epyx) multifueled reformer based on existing designs followed by a “new” CO cleanup section. This processor has been coupled with a 10-kW Plug Power, Inc., PEM stack. Once steady-state performance was satisfactory, the fuel processor/stack combination was tested with gasoline and several other alternative fuels at various steady-state operating conditions.

The tests demonstrated the operation of a stack for relatively long periods of time (hundreds of hours) at various steady-state power levels fueled by reformate obtained through an efficient conversion of a variety of hydrocarbon fuels. Also, steady-state emission levels were far below EPA Tier 2 standards. However, the start-up time for the fuel processor from ambient temperature was about seven minutes, the test processor was not an “integrated” system, and the stack and fuel processor were operated separately. No system transient capability was shown, and the relatively high projected federal test procedure cycle emission levels (based on start-up and limited transient processor data) indicated that a new tail-gas combustor, which utilizes gas discharged from the stack, would be necessary.

As part of the same Epyx/A.D. Little project, a 50-kWe fuel processing system is under development that will be integrated into a 50-kWe Plug Power, Inc., fuel cell stack. The intent is to create an integrated system with interactions and feedbacks between fuel processor and stack that can be studied in detail. The 50-kWe integrated system is expected to be operational by the summer of 2000.

Two other PNGV-sponsored industrial projects are under way, both to develop 50-kWe fuel-flexible processors. The McDermott Technology project was begun in late 1999, and the Hydrogen Burner Technology project is in the process of “performance mapping” to characterize the system.

As noted in the committee’s fourth report, significant private sector investments are also being made worldwide in fuel cell programs for vehicles, and substantial analytical and experimental capabilities are being developed by private industry for long-range development of fuel cell systems (NRC, 1998). Additional activities have been initiated recently. For example, International Fuel Cells (IFC) has reorganized its existing facility in South Windsor, Connecticut, and added new leased space to house a PEM system development project. New research facilities are being dedicated at IFC to PEM stack development, as well as fuel processing for hydrogen, methanol, and petroleum-based hydrocarbon fuels.

Another impressive industrial fuel cell development project is under way at the GM Global Alternative Propulsion Center (GAPC) near Rochester, New York. In addition, there is an operation of similar scope in Mainz-Kastel, Germany, and a smaller operation at the GM Technical Center in Warren, Michigan. Like IFC, GAPC has virtually all new R&D facilities devoted to the development of PEM fuel cell components and systems. GAPC is also working with hydrogen, methanol, and hydrocarbon fuels.

In addition to the projects sponsored by PNGV, IFC has delivered three Series 200 ambient-pressure 50-kW units to undisclosed automotive companies. Presumably these units are configured to operate with hydrogen fuel. (IFC is also working with at least two other automotive companies.) IFC has delivered a 5-kW system to BMW as an auxiliary power unit that also uses hydrogen (liquid) fuel. Apparently, IFC has also successfully operated Series 200 units with gasoline over a range of conditions, including transients (although not as a fully integrated system), and is currently developing the Series 300, which is expected to have better overall efficiency, a faster start-up time (two to four minutes), and better specific power. IFC is also working on Series X for the 2005 time frame, which is expected to meet or approximate PNGV 2004 performance and cost targets.

GAPC has successfully operated (and continues to operate) a fully integrated 30-kW methanol system. It has also developed and is currently operating all of the major components of a complete gasoline-fueled PEM system. Although this system is not yet operating as a fully integrated unit, full integration is expected very soon.

GAPC has taken a comprehensive approach that involves joint activities with dozens of potential suppliers. “Four win” criteria have been developed for product success: (1) the customers (performance, cost, safety, etc.); (2) GM and automotive suppliers; (3) energy companies; and (4) society at large (low emissions, fuel conservation, etc). GAPC indicates that, although some serious problems are still unresolved, the technology is expected to be ready by 2004. Large-scale production will probably not be feasible for an additional four to six years.

All of the major processor, stack, and systems development projects are currently working toward approximately 50 kW as a nominal design power level. This power level, which is insufficient for a nonhybrid vehicle configuration, is based on the assumption that liquid-fueled systems will require hybridization to shorten start-up times, transient response times, and even overcome cost barriers, a correct assumption based on the current state of the technology. However, hybridization also represents increased vehicle power-train complexity and weight. Therefore, as the cost per kilowatt for fuel cell systems declines and system response improves, the hybridization is likely to be eliminated and the design power level significantly increased (perhaps doubled or more) by the developers.

Two of the national laboratory programs have shown promising results to date. ANL has developed a new catalyst that can operate at higher temperatures (~700°C) than conventional catalysts and does not have to be protected from exposure to air during or after shutdown. These characteristics could be beneficial in reducing processor size, complexity, and start-up time in an autothermal reformer.

PNNL has successfully used microchannel technology to develop ultra-compact reactors and heat exchangers. The results of their efforts have revived interest in steam reforming, which is more efficient than alternative reformer concepts but was believed to be incompatible with automotive applications because of limited heat transfer rates. Results to date appear to confirm the potential for dramatic reductions in fuel processor size and to show fuel conversions (with iso-octane) approaching 90 percent. However, fuel conversions will have to be much higher (> 99 percent), or a technique for separating out the unreacted fuel will have to be used, to avoid damaging the stack.

Stack Electrodes

Efforts to improve stack electrodes are generally focused on the following objectives:

-

increasing CO tolerance

-

reducing precious-metal loading

-

improving manufacturability

Increased CO tolerance equates to lower demands on the fuel processing cleanup sections with corresponding increases in system efficiency (reduced fuel consumption) and decreases in processor weight, volume, cost, and start-up time. To date, the most successful efforts have come either through heavier precious-metal loadings (with corresponding higher electrode costs) or through a higher cell operating temperature (with corresponding durability and life reductions using currently available membrane materials).

Efforts to increase CO tolerance, primarily at LANL, have been focused on improving alloy electrocatalysts, air bleeding, anode design, and increasing stack temperatures. Although CO tolerance has been increased with these technologies, they require either precious-metal loadings (higher costs) or reduced efficiency (air bleed). Operation at an elevated temperature (120°C to 150°C) is likely to mitigate these problems but will require pressurization to maintain water content; in addition, no known membrane materials have adequate lifetimes at elevated temperatures.

Reducing precious-metal loading was a major goal when loadings were as much as an order of magnitude greater than they are with current technology; at that point corresponding high projected costs (as well as availability) were potential showstoppers. As loadings were dramatically reduced, membrane and projected manufacturing costs became priority issues. Now, as projected membrane costs have plummeted and the feasibility of low-cost molded plates and high-volume production of membrane electrode assemblies have been demonstrated, precious-metal loading has again become a limiting cost factor (although much less than it was).

Efforts to reduce precious-metal loadings have been directed mostly toward alternative catalysts and improving the use (surface structure) of precious-metal catalysts. R&D, primarily at LANL, has resulted in continuing improvements in the past year but no major breakthroughs. The noble-metal requirement for the fuel cell stack, based on current technology, is more than an order of magnitude greater than for current automobile catalytic converters. If noble metal is also used in the fuel processor, substantially more would be required. The lack of sufficient noble metal could be a problem for large-scale production.

Air-Management Systems

Air management has evolved into a high-priority issue because the first phases of developmental contracts by five organizations have not produced a single system that meets all of the important targets simultaneously. Smaller high-speed centrifugal machines do not provide the necessary efficiency or pressures at reduced airflows (reduced power output). Variable-displacement machines and “scroll” designs have performed well over a range of rates but are large and bulky. Twin-screw devices provide satisfactory pressure and airflow but are noisy

and inefficient. The remainder of work in this area is focused on developing a novel air bearing for the rotating parts.

An independent panel sponsored by ANL to review compressor/expander technologies is working with DOE to study the air-management problem and current R&D. Meanwhile, various developers are continuing to improve the current technologies. In addition, work is continuing at IFC, national laboratories, and, probably, all major private sector developers on ambient-pressure PEM fuel cell systems that would eliminate the need for compressor/expander subsystems.

One of the issues coming into focus through more detailed system studies is high overall-mission thermal efficiency. A LANL study showed that to achieve the 2004 target of 48 percent overall system efficiency at 25 percent of peak power (where most operation is expected), will require a cell voltage of 0.9 V (Milliken, 1999). Therefore, the cell voltage at rated power (50 kW) would be about 0.77 V, which is much higher than was previously assumed (about 0.55 to 0.60 V). Unfortunately, the power density of the stack is much lower (perhaps 30 percent lower) at the higher voltage, thus implying the need for a larger stack. Therefore, stack efficiency will have to be increased, most likely through improvements in cathode performance. Experience also highlights the need for more and better systems analysis.

Cost Reduction

A cost study by A.D. Little based on apparently realistic assumptions and state-of-the-art technology puts the projected high-volume “factory cost” of the complete automotive (hydrocarbon fuel) fuel cell system at $294/kW, more than double the 2000 PNGV goal of $130/kW (Milliken, 1999). The stack was about half of the projected cost ($140/kW); precious metals in the stack accounted for almost $60/kW. Another concern is that projected demands for platinum (and other precious metals) could exceed the world supply if fuel cell vehicles eventually replace internal combustion engine vehicles. A similar concern was raised in the 1970s when catalytic converters were first introduced. This worry turned out to be a nonissue, however, as improvements in technology dramatically reduced the demand for precious metals, and supplies were increased. It is too early to tell if similar developments would occur with fuel cells.

Areas of Concern

Even though efforts are continuing or being initiated in all essential areas, the following significant issues must be addressed:

-

Costs. Even though projected costs have been reduced dramatically in the past few years, they are still approximately double the PNGV target for 2000 and about six times too high for a cost-competitive power plant.

-

Lack of an integrated system. Hydrocarbon fuel processors have supplied hydrogen-rich fuel gas to PEM stacks, but the only complete integrated systems have been fueled by hydrogen or methanol, neither of which may be acceptable in the marketplace because of consumer resistance or infrastructure problems. This is a critical issue because liquid hydrocarbon fuels (e.g., gasoline) are believed to be extremely important for consumer acceptance in the marketplace.

-

Fuel processing systems. The best efforts to date have not resulted in a fuel processing system that can meet the required start-up times. The demonstrated systems do not have attributes (e.g., size, shape, weight, cost) that would be compatible with production vehicles. In addition, no fuel processing system has been successfully integrated into a complete fuel cell “engine.”

-

Systems studies and trade-offs. Because consistent targets are necessary for orderly technological development, the best analysis tools and available information should be used to determine the relative importance of apparently conflicting targets. For example, how important is the cell voltage required to meet efficiency targets at 25 percent of rated power compared to the weight, volume, and cost targets? Similar questions could be asked about the fuel processor. Assuming that all targets cannot be met, what are the relative penalties for meeting or not meeting each one in relation to the others?

-

Air management. None of the technologies under development appears to be capable of meeting all targets simultaneously, which clearly suggests that an ambient-pressure system should be pursued. However, with ambient-pressure systems, meeting stack efficiency targets is likely to result in even lower power densities. Thus, more emphasis should be placed on efficient pressurization systems.

In summary, fuel cells will remain very important to the PNGV program—especially as Tier 2 emission regulations are implemented. Significant technical progress continues to be made, but some important technical issues and many cost issues persist. The emergence of large-scale industry efforts by both system developers and potential suppliers in the United States will undoubtedly hasten the reality of fuel cell vehicles for consumers and should be considered a major accomplishment of the PNGV program. PNGV’s experience with fuel cell development suggests that DOE should return to supporting high-risk, high-payoff R&D and focus less on supporting hardware development.

Recommendations

Recommendation. In the area of fuel cell development, PNGV, and especially the U.S. Department of Energy, should emphasize high-risk, high-payoff research

in critical areas, such as fuel processing, carbon monoxide-tolerant electrodes, and air-management systems.

Recommendation. PNGV should conduct trade-off analyses to establish relative priorities for fuel cell technical targets and cost targets.

Recommendation. PNGV should consider conducting a comprehensive assessment of the consequences of fuel choices for fuel cells and their impact on PNGV’s direction and ultimate goals.

ELECTROCHEMICAL ENERGY STORAGE

In the simplest HEV drive train, the battery stores vehicle kinetic energy captured in regenerative braking and provides stored energy to start the vehicle’s combustion engine and assist the engine during acceleration. Overall vehicle energy efficiency compared to a conventional vehicle is enhanced if braking energy can be recovered and if the engine can be operated at a nearly constant power level. This is the basis for the HEV, which stores energy for use in various parts of the drive cycle. Energy storage can also compensate for a slow-response engine, such as a fuel cell with a fuel processor. Some energy storage systems may allow an HEV to operate as a zero-emission vehicle that can run on stored energy alone for a certain distance. Also, the emissions and fuel economy with an internal combustion engine should be improved if the engine load varies over only a narrow range. Batteries designed for high specific power are the most likely means of energy storage. PNGV eliminated flywheels and electrochemical capacitors for energy storage in HEVs during the technology selection process in 1997.

The HEV power train chosen by most automotive manufacturers engaged in HEV development requires a battery with relatively small energy storage but very high power capability. At the outset of the PNGV program, the goals for battery specific power and power density were far above what was commercially available. Table 2-1 summarizes the battery performance and cost targets for the low energy storage power-assist mode and the dual mode. Power-assist and dual modes refer to different degrees of hybridization. In the power-assist mode, the power goes directly from the primary power plant to the wheels, with some power peaks being supplied by the energy-storage subsystem. In the dual mode, the primary power plant is run substantially at a constant power level, with all fluctuations being supplied by the energy-storage system (see the committee’s fourth and fifth reports, for more extensive discussion [NRC, 1998, 1999]). The battery in a dual-mode HEV can provide the energy for propelling the vehicle while the slow-response energy converter (e.g., a fuel cell with a fuel processor) is warming up.

TABLE 2-1 Design Targets and Current Performance for Short-Term Energy Storage

|

|

PNGV Targets |

Current Performance |

||

|

Power Assist |

Dual Mode |

Li-iona |

NiMHb |

|

|

Pulse discharge (constant for 18 s) (kW) |

25 |

40a |

|

|

|

Maximum regenerative pulse power (at start of a 10 s trapezoidal pulse) (kW) |

30 |

40 |

|

|

|

Available energy (kWh) |

0.3 |

1.5a |

|

|

|

Energy efficiency (%) |

> 90 |

> 95 |

90 |

88 |

|

Calendar life (years) |

10 |

10 |

3 |

5 |

|

Maximum mass (kg) |

40 |

65 |

|

|

|

Maximum volume (L) |

32 |

40 |

|

|

|

Production costs @ 100 k/y ($) |

300 |

500 |

|

|

|

Minimum operating temperature (°C) |

–40 |

–40 |

–25 |

okd |

|

Maximum operating temperature (°C) |

52 |

52 |

50 |

okd |

|

Available specific energy (Wh/kg) |

7.5 |

23.1 |

23 |

15 |

|

Specific power (18 s) (W/kg) |

625 |

615 |

625 |

400 |

|

Cost/available energy ($/kWh) |

1,000 |

333 |

1,041 |

1,064 |

|

Available energy density (Wh/L) |

9.4 |

37.5 |

29 |

23 |

|

Cumulative contractsc ($ millions) |

|

|

55 |

8.1 |

|

aRevised downward during the year. bCost, specific energy, and energy density refer to dual mode. cIncludes 50% cost sharing on industrial contracts. dOperates at the required temperatures. Source: PNGV, 1999a; Haskins, 1999. |

||||

PNGV is developing both lithium and nickel metal hydride (NiMH) batteries for HEVs. NiMH cells and modules for HEVs have reached technological maturity but fall somewhat short of meeting the power-assist targets. Hopes have been pinned on lithium or lithium-ion (Li-ion) batteries for high energy and energy efficiency, but NiMH batteries are still a less risky backup system for nearer term deployment in concept vehicles. The approximate status of these battery systems in terms of the PNGV goals is shown in Table 2-1.

A key requirement and development target is the capability of the hybrid battery to provide an available energy of 300 Wh while weighing no more than 40 kg. Available energy is energy that can be delivered while simultaneously meeting the pulse-power targets for discharge and regeneration (acceleration of a 1,000 kg vehicle to 100 km/h requires 0.1 kWh for the kinetic energy alone). Meeting the cost and life goals remains a major challenge.

Program Status and Plans

Accomplishments

The life projection has been improved to three years for the Li-ion system, but it is still based on an accelerated testing schedule. As understanding of the HEV system has improved, the goals for the battery have been modified. For example, the PNGV targets for available specific energy have been reduced compared to last year’s targets (NRC, 1999). Some goals on the cell level are now the same for the dual mode and the power-assist mode, which means that developers can concentrate on one cell design. Because the power/energy ratio is different for the two modes, a larger range of state-of-charge can perhaps be used in the dual mode; that is, the PNGV target “energy utilization factor,” the ratio of available energy to rated energy, can be 0.378 for the dual mode as compared to 0.141 for the power-assist mode. However, the required specific power is still the same for the two applications. Goals have also been modified to allow for power fade during the life of the battery.

The SAFT Li-ion program and the PolyStor Li-ion program, which have been ongoing for one or more years, include the development of 50-V modules. A VARTA Li-ion program has been terminated, but a number of new contracts involving new developers for lithium battery development for HEVs have been initiated. Hydro-Québec, which is working on a lithium polymer system, and Delphi, which has a Li-ion, gelled-electrolyte system, have been added. VARTA, the principal developer of the NiMH system has delivered and tested 50-V modules. (The battery in Ford’s concept vehicle is based on this technology.) GM-Ovonic has been added to develop an NiMH system. Another small project by Electro Energy to explore the potential of a bipolar NiMH system has also been initiated.

The Advanced Technology Development program at the national laboratories is looking into the root causes of cell failure of Li-ion batteries. Substantial resources have been devoted to producing test cells of about 1 Ah with non-proprietary chemistry. These cells are tested for different regimes of cycling and temperature and subsequently examined by various diagnostic techniques (including calorimetry, microscopy, and impedance as well as techniques for documenting chemical and structural changes in electrodes) to identify the inherent causes of cell failure and capacity fading. The program also addresses approaches, such as improved materials and electrochemistry and low-cost packaging, for reducing cell costs. Developers are working on safety and the control and balance of series-connected strings of cells.

A detailed cost analysis was performed on the more developed systems to provide a firmer basis for cost projections and to indicate how costs might be reduced. The cost of both the NiMH and Li-ion systems exceeds the PNGV cost goals by about a factor of three.

Assessment of the Program

The modules and cells developed as a result of PNGV joint activities with the battery developers are not necessarily being used in vehicles. Nevertheless, the program has advanced HEV battery technology substantially. The automotive companies have made their own arrangements with battery suppliers for systems in their concept vehicles, which enables them to use systems analysis to coordinate the battery technology requirements and performance with other parts of the vehicle in a proprietary setting. As a consequence, the PNGV program should focus on generic issues, such as producing systems with good performance and dealing with issues of life, cost, and safety, as well as control of series strings and thermal management.

Safety is still a concern with Li-ion systems. Overheating leads to substantial electrolyte venting, and flames are difficult to extinguish. Projected costs are too high by a factor of three, and calendar life is a serious issue.

The NiMH system has longer life, largely avoids safety problems, and should be more benign in control and balance of series strings. Projected costs are still too high by a factor of three, and the system does not provide quite enough available energy or power.

International Developments

Japanese battery companies are the world leaders in the development and commercialization of advanced high-power batteries for HEVs. Their leadership, based on the technology and manufacturing basis established over the past decade in NiMH and Li-ion batteries for consumer applications, is now driven by competition for the emerging HEV battery market represented by the Toyota Prius and Honda Insight HEVs.

Nickel Metal Hydride Batteries

Panasonic Electric Vehicle Energy (PEVE) established the world’s first commercial production of an HEV battery. PEVE’s HEV-6.5 technology has been used in the Prius as a 1.9-kWh, 22-kW battery weighing 44 kg; performance falls about 20 percent short of the key specific power target of PNGV. Recently, PEVE completed the development and established a production line for advanced-design NiMH HEV battery modules. Prius HEVs will soon be equipped with 40-module, 40-kg batteries that will deliver pulse power of more than 30 kW, thus exceeding the PNGV performance target. These batteries are likely to meet PNGV cycle-life targets and will have significantly improved life at elevated temperatures. Also, in mass production, the cost will be below the approximately $1,000/kW for the first-generation Prius battery.

Lithium-Ion Batteries

Other leading Japanese battery companies are concentrating on the development of Li-ion batteries for HEV applications. Sony, Shin-Kobe (part of Hitachi), and JSB have pilot plants for Li-ion cell fabrication and are offering preprototype cells and/or modules for evaluation. All of these technologies meet or exceed PNGV’s specific power targets and are claimed to have very long cycle life over narrow ranges of depth of discharge; calendar life is not fully established but is likely to be much longer than three years if the batteries are operated in the HEV mode and at temperatures below about 45°C. The positive electrode in all of these technologies is based on lithium manganese oxide spinel, the lowest cost material among currently established positive materials. It is not clear at present whether the cost of mass-produced Li-ion HEV batteries would be lower than the cost of NiMH batteries. (The unit costs projected for both Li-ion and NiMH batteries are well above the PNGV targets.)

Recommendation

Recommendation. PNGV should continue to work on cell chemistry of lithium-battery systems to extend life and improve safety, while continuing to lower costs. PNGV should continue to refine performance and cost targets as overall vehicle systems analysis determines the optimal degree of vehicle hybridization. PNGV should also support efforts to apply the materials improvements achieved in the program to improve lithium battery technology and to validate improved performance, life, and safety.

POWER ELECTRONICS AND ELECTRICAL SYSTEMS

The technology selection (downselect) process in 1997 resulted in all three USCAR partners adopting an HEV configuration for their PNGV vehicles. The cost, volume, complexity, and weight of the electrical and electronic systems in an HEV are substantially greater than in a conventional, nonhybrid car powered by an internal combustion engine. Consequently, the chances of an HEV design achieving the PNGV cost and fuel economy goals depends to a great extent on the power electronics and electrical systems meeting their targets. Table 2-2 shows the present values and the 2004 PNGV target values (Malcolm et al., 1999). The targets are extremely aggressive, and meeting them will require breakthrough developments in both component and manufacturing technologies.

Program Status and Progress

The Electrical and Electronics Systems Technical Team (EE Tech Team) has implemented an aggressive and diverse R&D program to meet the electrical and

TABLE 2-2 Current Specifications and Target Specifications for Power Electronics

|

Component |

Specific Power (kW/kg) |

Efficiency |

Cost ($/kW) |

|

Power electronics |

|||

|

Today |

4 kW/kg |

95% |

$10/kW |

|

2004 target |

5 kW/kg |

97–98% |

$7/kW |

|

Motor/generator |

|||

|

Today |

1.5 kW/kg |

92% |

$6/kW |

|

2004 target |

1.6 kW/kg |

96% |

$4/kW |

|

Source: Malcolm et al., 1999. |

|||

electronic systems targets. The committee compliments the EE Tech Team on the comprehensiveness and relevance of its program, as well as its organization and management. The program has three elements: power electronics development, electric motor development, and system development.

The power electronics component of the program includes the development of an automotive integrated power module (AIPM), the development of new thermal management techniques and materials, and the investigation of new materials and manufacturing processes for passive energy-storage components, particularly capacitors. Three contracts have been awarded for the development of an AIPM, and each of the contractors—Semikron, Silicon Power Corporation (SPCO), and SatCon—has projected that the PNGV cost targets can be met. Semikron expects to employ existing power electronics technology in a high-volume, low-cost process. SPCO is focusing on unique packaging and silicon device technology. SatCon intends to meet the AIPM objectives by employing flip-chip packaging technology and creative thermal management designs.

The national laboratories have a large number of ongoing research programs on dielectric materials and capacitors. The EE Tech Team has reviewed these programs and is in the process of developing a road map to meet PNGV’s passive component needs by leveraging these programs.

The programs on electric motors are focused primarily on investigating materials and manufacturing processes that could reduce costs. Other activities include the assessment of accessory drives4 and studies of different machine types that could be made practical by low-cost power electronics, such as switched reluctance and high-speed machine designs. A major element of this part of the program is the development and demonstration of an automotive electric motor drive (AEMD). The goal is to use the AIPM as part of a complete motor drive

system. Two teams have been selected for this work, one led by Delco Remy International and the other by Delphi Automotive Systems. The Delphi team has proposed using the AIPM in combination with an alternating-current (AC) induction motor; the Delco Remy team will use a direct-current (DC) brushless motor.

Projects on system development are focusing on integrated packaging of the power electronics and machine, as well as the modeling of system cost.

Assessment of the Program

The EE Tech Team has done an excellent job of identifying the key barriers to meeting the PNGV cost and performance targets for the electrical and electronic systems and of leveraging ongoing work by industry, universities, and the national laboratories.

As the committee has stated previously, the functional specifications of the power electronics and electrical systems have been met (NRC, 1999), and the remaining challenges include meeting the physical (packaging), efficiency, and, particularly, cost targets.

In its fifth report, the committee expressed its concern about the PNGV’s prospects for meeting its cost targets for power electronics and motors. The extensive discussion of this issue will not be repeated here (NRC, 1999). The contractors for the development of AIPM and AEMD all claim they can meet or exceed the cost targets, but the EE Tech Team and the committee have been shown little supporting data for these claims. The committee was shown drawings of proposed AIPM designs but no detailed cost analyses. The committee reviewed production cost goals for SatCon’s proposed design, which showed that the current cost of $20 to $30/kW is expected to be reduced to $5 to $9/kW in the final production prototype. This implies a substantial reduction in component cost, as well as manufacturing process cost. However, this projection is predicated on developments by component suppliers, whose level of confidence regarding the success of these developments was not clear. For example, the EE Tech Team expects that the cost of the high-voltage bus capacitors will be reduced from $0.20/microfarad (μF) to $0.02/μF but did not explain how this would be achieved (Malcolm et al., 1999).

In fairness to the EE Tech Team, many cost projections must be taken on faith because they depend on developments that are under way but not yet demonstrated. However, given the importance of the electrical and electronic systems to the viability of the entire PNGV vehicle, the EE Tech Team must always be aware of progress toward cost goals and must communicate this information to the systems analysis team.

In its fifth report, the committee recommended that the EE Tech Team perform an analysis of electrical accessory loads to verify system needs. The vehicle engineering team has taken the responsibility for reducing energy consumption at the vehicle system level, and the EE Tech Team intends to initiate a program to

develop efficient motors for accessories. However, to the committee’s knowledge a system level study of electrical requirements has not yet been done.

Recommendations

Recommendation. The Electrical and Electronics Systems Technical Team should closely monitor the progress toward meeting the cost goals of the automotive integrated power module and automotive electric motor drive and update and communicate realistic expectations for costs in 2004 to the systems-analysis team.

Recommendation. The Electrical and Electronics Systems Technical Team, in collaboration with the vehicle engineering team, should undertake a comprehensive study to identify the electrical load requirements of the accessory system. Although the details of the accessory system will differ among the three USCAR partners, the impact of the accessory load is important enough that it should be considered explicitly by the systems analysis team.

STRUCTURAL MATERIALS AND SAFETY

The reduction of vehicle mass through improved design, lightweight materials, and new manufacturing techniques is one of the key strategic approaches to meeting the PNGV Goal 3 fuel economy target. To achieve the 80 mpg target, systems analyses showed that a 40-percent reduction in vehicle weight would be necessary, together with: 40 to 45 percent power train energy conversion efficiency, 70 percent efficiency5 for regenerative braking, improved driveline efficiency, and reduced aerodynamic drag. At the same time, the baseline vehicle performance, size, utility, and affordable cost of ownership must be maintained.

The substantial vehicle weight reduction targets for various subsystems (Table 2-3) would result in an overall reduction in curb weight of 1,200 lbs (40 percent), and a 2,000 lb vehicle.

Materials Selection, Design, and Manufacturing

In its search for lightweight materials that would enable the targeted large weight reductions (50 percent for the body-in-white [BIW],6 for example), PNGV has focused on materials with densities substantially lower than the density of

TABLE 2-3 Weight-Reduction Targets for the Goal 3 Vehicle

|

Subsystem |

Current Vehicle (lbs) |

PNGV Vehicle Target (lbs) |

Mass Reduction (%) |

|

Body |

1,134 |

566 |

50 |

|

Body-in-White |

590 |

|

|

|

Chassis |

1,101 |

550 |

50 |

|

Power train |

868 |

781 |

10 |

|

Fuel/other |

137 |

63 |

55 |

|

Curb weight |

3,240 |

1,960 |

40 |

|

Source: Adapted from Stuef, 1997. |

|||

steels used in the baseline vehicle (NRC, 1998, 1999). Components and BIW structures fabricated primarily from aluminum, glass fiber-reinforced polymer composites (GFRP), and carbon fiber-reinforced polymer composites (CFRP), including hybrid structures (NRC, 1999), are being investigated. Lower density materials entail an incremental increase in cost compared to the baseline steel BIW and closure panels, probably on the order of $1,400 (Schultz, 1999), depending on several variables. The cost penalty for CFRP BIW would be substantially higher.