2

Sources, Treatment, and Monitoring Of Spacecraft Water Contaminants

THIS chapter provides an overview of the water reclamation system of the International Space Station (ISS) and a discussion of sources of spacecraft water contamination. Water treatments are discussed in conjunction with contaminant sources, as the treatments also contribute to the contamination. Strategies for monitoring water quality are also discussed.

OVERVIEW

The ISS is expected to operate for many years, with each crew spending up to 6 months onboard. The prohibitive cost of transporting the large amounts of water needed to support the crew and the impracticality of generating water from fuel cells for missions of this length have led to the requirement that the ISS environmental control and life support system (ECLSS) recycle wastewater to provide water of acceptable quality for potable and personal hygiene use and for oxygen generation.

In 1992, the design team for the U.S. space-station life-support systems was directed to assess existing Russian technologies for possible

use in developing life support hardware for the ISS (Mitchell et al. 1994). Many components of Russian life support systems (e.g., atmosphere revitalization and water recovery) already have been operational in microgravity. A means of recovering water from humidity condensate has been in use since the Salyut era of the mid-1970s, and a urine-processing system has operated on the Mir station since 1989.

The life support system for the ISS will be incorporated in several phases of the assembly sequence. Initially, potable water will be produced from humidity condensate by multifiltration treatment by a Russian assembly housed in the Russian service module. Fuel cell water from the U.S. space shuttle will be transferred to the station after docking. This water, stored in special tanks on the station, will provide an emergency supply. The plan will accommodate up to three crew members. An advanced Russian life support system, involving hygiene-water processing and urine processing will be deployed in the Russian life support module (LSM) of the ISS. At approximately the same time, the ability to reclaim potable water from humidity condensate, hygiene wastewater, and urine distillates (via multifiltration and catalytic oxidation) will be incorporated in the U.S. habitation module of the ISS.

Design Drivers

Water reclamation systems intended for the ISS and its programmatic predecessors have been designed to deliver specific amounts of product water (Table 2-1) of specified quality. (At the time the ISS system design was begun, no models were available to predict contaminant loads in water produced by the water reclamation systems. Since then, considerable information has been generated from ground-based and in-flight studies, as described later in this chapter, and a predictive model is being generated (D.L. Carter, Marshall Space Flight Center, personal communication, Oct. 13, 1999).) Other considerations in designing the water reclamation systems included shelf life, resupply-return logistics, crew time needed for maintenance, power needed to operate the system, launch weight, and stowage volume. The processing assemblies for the ISS have been designed to support six crew members after assembly is complete. The product-water tank's capacity will be about 120 lb of processed water.

TABLE 2-1 ISS Water Requirements

|

Purpose |

Amount, lb |

Amount, kg |

|

Drinking, food rehydration, oral hygiene |

6.2/person/d |

2.81/person/d |

|

Extravehicular activity |

20 |

9.05 |

|

High per-person usage |

11.35 over 24 hr |

5.14 over 24 hr |

|

Hygiene |

15.0/person/d |

6.79/person/d |

|

Hygiene (high usage) |

16.0/person over 24 hr |

7.24/person over 24 hr |

|

Life sciences experiments (with animals) |

7.35/d |

3.33/d |

|

Maximum off-line water-quality analysis |

2.2/d |

1.00/d |

|

Nominal off-line water-quality analysis |

1.7/d |

0.77/d |

|

Oxygen generation |

17/d |

7.69/d |

|

Payload experiments |

4.8/experiment d |

2.17/experiment d |

|

The ISS is designed to support six crew members. Source: Segment Specification for the U.S. On-Orbit, SpecificationNumber SSP 41162E, July 1996, p. 273. |

||

Table 2-2 illustrates the water mass balance of the Russian water-processing segments before the completion of the ISS. Total water consumption of a cosmonaut was estimated at approximately 9 lb or 4.1 liters per day (L/d). During the first phase of construction, the Russian service module will reclaim drinking water only from humidity condensate; during the second phase, the service module and the LSM will regenerate potable water from urine. During the second phase, the amount of water supplied by the Russian progress vehicle and the U.S. space shuttle needed to make up the water balance will be lower.

ISS Water-Quality Standards

Standards for recycled water in a closed spacecraft system have been a matter of debate for many years. Because water aboard the U.S. space shuttle is not recycled (it is generated by onboard fuel cells), ex-

TABLE 2-2 Water Mass Balance Estimates of the Russian Water-Processing Segments

|

Water Supply Sources, lb |

||||

|

Water Demand |

(lb/person/d) |

Source |

First Phase (SM) |

Second Phase (SM + LSM) |

|

Drinking, food |

5.5 |

Humidity condensate |

3.3 |

3.3 |

|

Oxygen generation by electrolysis |

2.21 |

Hygiene water evaporation |

0.66 |

0.66 |

|

Personal hygiene |

1.1 |

Water with food |

1.1 |

1.1 |

|

Urinal flush |

0.66/0.22 |

Water from storage system |

4.44 |

0.44 |

|

Water from WRS-UM |

NA |

2.58 |

||

|

Water from CDRS |

NA |

0.95 |

||

|

Total |

9.48/9.0 |

9.48 |

9.04 |

|

|

Water mass balance estimates did not consider evaporation or otherwater losses. 85% of the crew water will be regenerated during phase2, whereas only 43% during phase 1. CDRS, carbon dioxide reductionsystem; LSM, life support module; NA, not applicable; SM, servicemodule; WRS-UM, updated system for water reclamation from urine Source: Modified from Samsonov et al. (1997). The units have beenconverted to pounds for comparison with Table 2-1. |

||||

isting water-quality standards for shuttle water cannot be extended to recycled water, particularly for long ISS missions. In 1986 and 1989, the National Research Council (NRC) Committee on Toxicology reviewed water-quality standards for the National Aeronautics and Space Administration (NASA), and recommend maximum contaminant levels that would protect the health of crews on long space missions (NRC 1986, 1989). This information was used in the design of onboard water treatment and recycling system for the ISS. One critical recommendation was that the integrated ECLSS should be able to assess possible interactions between the air revitalization system and the water reclamation system in terms of contaminants that might arise from one or the other system.

The current requirements for ISS water quality are based on standards from the U.S. Public Health Service (PHS 1962) and U.S. Envi-

ronmental Protection Agency (EPA 1996) for public drinking water. Standards for water quality are described in Appendix A and in other NASA documents (e.g., the International Space Station Flight Crew Integration Standard, SSP 50005, Rev B, Aug. 1995).

Because the Russian segments will initially support water regeneration for the ISS, a review and consensus on Russian water-quality standards is necessary. The standards established for the Mir station generally are less stringent than are U.S. standards: Fewer limits are specified, and those that are specified tend to have higher maximum limits. Also, the disinfectant used for the Mir water-processing system is silver, whereas the biocide for most U.S. systems is iodine. Differences between the two programs in analytical techniques have made direct comparisons difficult; nevertheless, negotiations are currently under way to develop water-quality standards that are acceptable to both partners in the ISS program. Appendix A, Table A-2, compares the proposed standards – which have yet to be accepted officially – of the Russian and U.S. programs.

Some detailed descriptions of the water reclamation systems that are currently operating on Mir, planned upgrades for the Russian segments of the ISS, and the planned U.S. integrated water reclamation system functions are provided in Appendix A.

SOURCES OF SPACECRAFT WATER CONTAMINATION

The water reclamation system for the ISS comprises a unique combination of input and output streams. Waste streams will include urine and urine flush water, humidity condensate, personal hygiene water (body wash), water from general hygiene activities (hand washing, shaving, teeth cleaning), and effluent from the crew health care system (CHeCS). Humidity condensate undoubtedly will have the greatest inherent variability, because it will include contributions from crew metabolism, hygiene activities, food preparation, materials off-gassing, and payload experiments, some of which will involve animals and all of which will vary widely from mission to mission.

The nature of the water sources and the extent of closure in the recycling loop have posed substantial challenges for defining product-water specifications that will protect crew health over long periods. In its

earlier reviews, NRC (1986, 1989) evaluated NASA's plans for potable-water reclamation, including issues on the small volume of water; the complexity and variability of cabin humidity condensate (the principal source of potable water); the tight interface between cabin air and water systems; the treatment processes for urine and hygiene wastewater and the treatment by-products; the potential accumulation of polar, uncharged organic molecules; the need for toxicologic characterization of unique chemical and microbial by-products; and monitoring and analytical capabilities. Since those reviews, considerable progress has been made in the characterization of source-water contaminants.

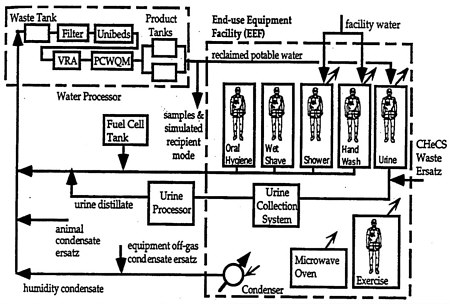

The results described here come from ground-based and in-flight studies (from Spacelab, shuttle, and Mir missions). Two ground-based test beds in particular have generated a wealth of information on humidity condensate, urine distillates, urine off-gassing products, and wash water – the Water Recovery Test (WRT) at NASA's Marshall Space Flight Center in Huntsville, Alabama, and the Early Human Testing Initiative (renamed the Lunar-Mars Life Support Test Project (LMLSTP)) at NASA's Johnson Space Center in Houston, Texas. The Marshall test bed has been used mainly to assess the performance of the various systems intended for environmental control and life support on space stations. Stages 9 and 10, the two most recent versions of this test bed simulate many aspects of the configuration planned for the ISS. Figure 2-1 is a diagram of the Stage 9 water recovery system. Humans participate in the operation of this system through brief visits to the end-user equipment facility, which includes a shower, hand-washing sink, microwave oven, urine collection and pretreatment unit, condensing heat exchanger, and exercise equipment.

The LMLSTP, in contrast, involves human subjects actually living within a closed test chamber that has integrated air and water reclamation systems. Subjects in the chamber donate and use recycled water. Three tests have been completed with this system, the first a 15-d mission involving one crew member, and the second and third involving 30-and 60-d missions, respectively, each including a four-person crew. Results from a 90-d test are not discussed here because water reclamation processes other than those planned for ISS were used.

Some information about flight data is available from the 1985 U.S. Spacelab-3 mission; more recent data were generated through observational studies begun in the 1990s on the space shuttle. The advent of

FIGURE 2-1 The integrated water recovery system used in Stage 9 of the Marshall WRT. CHeCS, crew health-care system; PCWQM, process-control water-quality monitor; VRA, volatile removal assembly. Source: Holder et al. (1995).

U.S.-Russian cooperation has provided an invaluable opportunity to assess the Mir spacecraft water-recycling system, which operates in microgravity. Results from these and other studies form the existing database of the likely chemical constituents of the proposed ISS water system.

The major sources of water and their likely contaminants are discussed below. These include likely constituents of human urine, both before and after treatment; humidity condensates and wash water, and the various sources of chemical contaminants to those streams; and chemical by-products that can form as a result of treatment failures or from the use of biocides.

Human Urine

Untreated Urine

The composition of human urine is extremely complex, and it varies widely according to diet, use of medications, and health status. The

normal constituents of urine include electrolytes, small-molecular-weight proteins, and metabolites of nutrients and drugs. Typical components include salts of iron, sodium, potassium, magnesium, calcium, chlorides, phosphates, citrates, oxalates, and sulfates. Also present are hormones, vitamins, creatinine, uric acid, and carboxylic acids.

Crews in the Apollo, Skylab, and space-shuttle programs have taken drugs to alleviate motion sickness, headache, sleeplessness, constipation, and nasal congestion during flights (Putcha et al. 1994). Because those drugs are likely to be used aboard the ISS, their metabolites will be introduced into the water system via urine. As a result, the chemical composition of urine in the ISS might be somewhat different from the urine used to develop and test ground-based systems where such medications have not been incorporated.

Chemical Treatment and Distillation By-Products

The water reclamation system planned for the ISS uses chemical pretreatment and distillation in treating urine. Oxone (a commercially developed potassium monopersulfate compound) and sulfuric acid are added to the raw urine to stabilize it, to fix ammoniated species, and to control microbial content. Oxone can oxidize chloride compounds in the urine to form chlorine, which will react directly with several organic compounds to form chlorinated hydrocarbons. This process can generate several nonphysiologic chlorination by-products. Cole et al. (1991) have reported off-gassing of cyanogen chloride, chlorinated ketones, and chlorinated nitriles from treated urine, which probably appeared because of high ammonia and amino acid content in the raw urine.

Several distillation technologies have been used in developing the water reclamation system for the space station (including reverse osmosis, thermally integrated membrane evaporation (TIMES), or vapor compression distillation). Early stages of the WRT included TIMES distillation, but later versions included vapor compression distillation, which is the current technology of choice for the ISS. (Urine was pretreated with Oxone and sulfuric acid in both distillation processes.) Despite some minor differences in the composition of the distillate from the two processes, the contaminant load (and its variations over time) were thought to reflect those of the space-station system (Winkler

et al. 1983; Verostko 1986; Cole et al. 1991; Carter and Bagdigian 1993). The TIMES distillate included carboxylates, alcohols, ketones, aldehydes, phenols, nitriles, hydrocarbons, and halogenated hydrocarbons. Most compounds could be traced to human metabolism, but some seemed to have resulted from the urine pretreatment process. The constituents produced by vapor compression distillation in Stages 4 and 5 of the WRT are described by Carter et al. (1992).

Vapor compression distillation also was used to treat urine in the closed-chamber tests at the Johnson Space Center. Compounds found in the urine distillate samples from the 30-d test included: acetic, butyric, formic, propionic, and lactic acids; ethanol; methanol; 1,1-dichloropropanone; and ibuprofen. Formic acid was present in the highest concentration (13,700 micrograms per liter (µg/L)) (Homan et al. 1997; Verostko et al. 1997).

In addition to these results, for the raw distillate of the urine, additional information is available concerning the volatile oxidation products arising from urine pretreatment. In 1989, the NRC expressed serious concerns about concentrations of cyanogen chloride (100 parts per billion (ppb)), reportedly off-gassed in the Marshall WRT study. Off-gassed products from urine treated with Oxone and sulfuric acid (the treatment chosen for the ISS) during a Marshall WRT have been described by Cole et al. (1991). High concentrations of acetone, acetonitrile, methylene chloride, 3-methylbutanal, dimethylamine, propanenitrile, and several other volatile oxidation products were reported. More than a dozen compounds occurred frequently in the off-gassing products from the seven urine samples analyzed.

Humidity Condensate

Humidity condensate will be an important source water – and probably the most variable – in the ISS water reclamation system. Humidity condensate is collected by the cabin heat exchanger, which is controlled by the spacecraft 's air revitalization system. The chemical constituents will include contaminants released into the cabin air from crew activities, such as by-products of metabolism, food preparation, and hygiene activities (including the use of cleansers and disinfectants); from routine operation of the air revitalization system; from materials and hardware off-gassing; from payload experiments, especially

those involving animals; from onboard utility chemicals; and from routine in-flight use of the CHeCS. Some steps in the water recovery process involve liquid-air separations. The air from those steps is vented into the cabin atmosphere and eventually appears in the humidity condensate. As wastewater passes through the multifiltration bed to the volatile removal assembly, for example, small molecular-weight organic compounds in the water undergo catalytic oxidation in the presence of sparged oxygen in a catalytic reactor. Before the effluent is passed to an ion exchange resin, which removes the small-molecular-weight organic compounds, the excess oxygen and other volatile compounds (incomplete oxidation products) are vented to the cabin. Even though some of these airborne contaminants will be removed by “scrubbers ” in the air revitalization system, many will end up in the humidity condensate.

Designing an effective water treatment system requires that the chemical constituents of the source water, and the variability of those constituents, be thoroughly characterized. As a corollary, that system also must include ways to evaluate potential toxicologic hazards posed by consuming the product water. The information available regarding the chemical composition of spacecraft humidity condensates is described below. These results came from test bed studies (the WRT and the LMLSTP) and from postflight analyses of samples collected during actual spacecraft missions. The remainder of this section constitutes descriptions of other environmental contributors to condensate aboard spacecraft.

Condensate Sample Results

Water Recovery Test

The water recovery system of the Marshall Space Flight Center WRT includes a facility that contains a shower, handwash, microwave oven, urine collection and pretreatment unit, condensing heat exchanger, and exercise equipment. Tests in which human subjects use this facility have revealed the presence of low-molecular-weight acids, semi-volatile acids, volatile alcohols, purgeable organic compounds, semi-volatile organic compounds, and glycols in the humidity condensate (Cole et al. 1991). The chemical composition of the condensate was

highly variable, no doubt reflecting variations both in the ubjects ' activities and in the ambient test environment.

Lunar-Mars Life Support Test Project

Part of the 30-d test of the Johnson Space Center's LMLSTP, in which wastewater was recycled throughout the test, included chemical characterization of humidity condensate samples. Results from four sets of samples collected are shown in Table 2-3. Total organic carbon (TOC) in the condensate ranged from 45 milligrams per liter (mg/L) to 65 mg/L, and accountability was 97%. Acetone, 2-butoxyethanol, diethyl phthalate, phenol, alcohols, and glycols were present in high concentrations, as were formaldehyde (7.7-12 mg/L) and ethylene glycol (5-12 mg/L). EPA's recommended lifetime maximum exposures are 1 mg/L for formaldehyde and 7 mg/L for ethylene glycol (EPA 1996).

Space Shuttle

Humidity condensate has been collected on relatively few space-shuttle missions, and most of the samples have been collected during the past 4 or 5 years. One exception was the 1985 STS-51B/ Spacelab-3 mission, which included tests with rodents housed in a new holding facility and analyses of the air revitalization system (Verostko 1986). Although the integrity of the samples collected from the mission was questionable, many organic compounds were identified, including alcohols, amides, amines, carboxylic acids, ethers, esters, ketones, phenols, and thiourea. In 1991 and 1992, samples were collected after four Spacelab missions (STS-40/SLS-1;STS-42/IML-1;STS-50/USML-1;STS-47/SL-J); however, the long delays after landing until samples could be collected undoubtedly affected their chemical composition. Finally, routine assessments of atmospheric quality aboard shuttle missions have revealed the presence of a wide spectrum of organic compounds that could well appear in the humidity condensate (James et al. 1994).

The first in-flight humidity condensate samples were collected on two shuttle missions, STS-45 and STS-47, in 1992; additional samples were collected from STS-68 and from the Mir. Organic compounds found in the 9 samples collected on the STS-45 and STS-47 missions are listed in Table 2-4 (Muckle et al. 1993).

TABLE 2-3 Organic Constituents of Humidity Condensate from the LMLSTP 30-d Closed-Chamber Test

|

Compound |

Maximum Concentration (µg/L) |

|

Volatile Organic Compounds |

|

|

Acetonea |

2170 |

|

2-Butanone |

91.71 |

|

Cyclohexanone |

111.11 |

|

Methylene chloride |

1.78 |

|

4-Methyl-2-pentanone |

14.12 |

|

Tetrahydrofuran |

25.22 |

|

Toluene |

1.26 |

|

Extractable Organic Compounds |

|

|

Acetophenone |

56.3 |

|

2-Acetylfuran |

1.1 |

|

Benzaldehyde |

3.8 |

|

Benzoic acid |

29.9 |

|

Benzothiazole |

32.7 |

|

Benzyl alcohol |

21.1 |

|

Benzylbutyl phthlate |

4.9 |

|

Benzyl salicylate |

1.4 |

|

Bis-2-ethylhexyl adipate |

2.1 |

|

Bis-2-ethylhexyl phthalate |

13.2 |

|

2-Butoxyethanola |

3533.8 |

|

2-(2-Butoxyethoxy)ethanol |

136.6 |

|

2-(2-Butoxyethoxy)ethanol acetate |

5.7 |

|

N-Butyl palmitate |

2.5 |

|

Butylated hydroxyanisole (BHA) |

11.7 |

|

n-Butylbenzenesulfonamide |

1.0 |

|

4,4'-Butylidenebis (6-tert-butyl-m-cresol) |

5.7 |

|

3-tert-Butylphenola |

125.3 |

|

Camphor |

1.3 |

|

Caprolactam |

60.1 |

|

Carvone |

13.4 |

|

trans-Cinnamaldehyde |

0.9 |

|

Cyclohexanol |

79.8 |

|

Decamethylcyclopentasiloxane |

1.2 |

|

Decanoic acid |

36.2 |

|

1,4-Diacetylbenzene |

36.9 |

|

Di-n-butyl phthlate |

23.9 |

|

Di-n-butylamine |

10.8 |

|

N,N,-Dibutyl formamide |

23.5 |

|

3,5-Di-t-butyl-4-hydroxybenzaldehyde |

3.1 |

|

2,6-Di-t-butyl-4-methylphenol |

3 |

|

2,4-Di-t-butylphenol |

1.7 |

|

Diethyl phthalatea |

214.9 |

|

Diethylene glycol monoethyl ether |

137.4 |

|

N,N-Diethyl formamide |

28.3 |

|

N,N-Diethyl-m-toluamide |

2.2 |

|

Diisobutyl phthlate |

3.7 |

|

Diisopropyl adipatea |

157.1 |

|

Dimethyl phthlate |

98.9 |

|

N,N-Dimethylacetamide |

47.7 |

|

N,N-Dimethylbenzylamine |

0.3 |

|

N,N- Dimethylformamidea |

311.3 |

|

2,3-Dimethylmaleic anhydride |

1.2 |

|

2,4-Dimethylphenol |

2.0 |

|

Dipropylene glycol methyl ether |

43.7 |

|

Dodecamethylcyclohexasiloxane |

1.0 |

|

Dodecanoic acid |

20.6 |

|

2-Ethoxyethanol |

8.7 |

|

Ethylene glycol monobutyl ether acetate |

17.0 |

|

2-Ethylhexanoic acida |

327.1 |

|

2-Ethyl-1-hexanola |

130.9 |

|

Ethyl 4-hydroxybenzoate |

2.5 |

|

4-Ethylmorpholine |

8.9 |

|

4-Ethylphenol |

3.6 |

|

Furfural |

4.4 |

|

Furfuryl alcohol |

4.7 |

|

Guaiacol (2-Methoxyphenol) |

1.2 |

|

Heptanoic acid |

30.1 |

|

2-Heptanone |

15.9 |

|

1-Hexadecanol |

12.1 |

|

1,6-Hexanediol |

23.4 |

|

Hexanoic acid |

118 |

|

2-Hexanol |

1.6 |

|

γ-Hexanolactone |

3.3 |

|

2-Hydroxybenzothiazole |

3.3 |

|

3-Hydroxy-2-butanone |

136.4 |

|

4-Hydroxy-4-methyl-2-pentanone |

86.1 |

|

Indole |

0.4 |

|

Isophorone |

23.2 |

|

2-Isopropylphenol |

8.2 |

|

3-Isopropylphenol |

28.3 |

|

p-Menth-1-ene-8-ol |

26.2 |

|

Mesityl oxide |

1.0 |

|

3'-Methylacetophenone |

3.5 |

|

3-Methyl-2-cyclohexen-1-one |

2.2 |

|

Methyl-4-hydroxybenzoate |

4.0 |

|

2-Methylphenol |

2.7 |

|

4-Methylphenol |

12.3 |

|

2-Methylpyrazaine |

6.4 |

|

1-Methyl-2-pyrrolidinone |

39 |

|

Methyl stearate |

0.4 |

|

Methyl sulfone |

6.6 |

|

2-Methylthiobenzothiazole |

0.4 |

|

Monomethyl phthalate |

89.7 |

|

Myristic acid |

6.2 |

|

Neomenthol |

83.0 |

|

Nicotine |

2.1 |

|

2-Nitrophenol |

0.6 |

|

Nonanoic acid |

55.9 |

|

Octadecanol |

23.8 |

|

Octanoic acid |

65.5 |

|

4-tert-Octylphenol |

1.3 |

|

Pentacosane |

0.9 |

|

Pentanoic acid |

50.1 |

|

2-Pentanone |

1.9 |

|

sec-Phenethyl alcohol |

3.0 |

|

Phenola |

427.5 |

|

2-Phenoxyethanol |

43.6 |

|

1-Phenoxy-2-propanol |

9.3 |

|

2-Phenylacetic acid |

12.9 |

|

Phenylethyl alcohol |

6.5 |

|

2-Phenylphenol |

0.8 |

|

2-Phenyl-2-propanola |

347.5 |

|

Phthalide |

7.3 |

|

2-Propoxyethanol |

6.1 |

|

Pulegone |

5.9 |

|

Terpinen-4-ol |

3.4 |

|

1-α-Terpineol |

19.7 |

|

1-Tetradecanol |

6.5 |

|

Tetramethylsuccinonitrile |

61.0 |

|

Tetramethylthiourea |

2.6 |

|

Tetramethylurea |

6.1 |

|

Toluene |

3.1 |

|

1,3,5-Triallyl-1,3,5-triazine-2,4,6(1H,3H,5H)-trione |

4.5 |

|

Tributyl phosphatea |

269.2 |

|

Tricosane |

2.2 |

|

Triethylamine |

27.7 |

|

Triethylene glycol methacrylate |

1.7 |

|

Triethyl phosphate |

4.6 |

|

2,2,4-Trimethyl-1,3-pentanediola |

268.8 |

|

2,2,4-Trimethyl-1,3-pentanediol diisobutyrate |

21.7 |

|

Triphenyl phosphate |

2.0 |

|

Tripropylene glycol monomethyl ether |

109 |

|

Tris(2-chloroethyl) phosphate |

2.6 |

|

Undecanoic acid |

7.3 |

|

2-Undecanone |

0.7 |

|

Valeraldehyde |

1.8 |

|

γ-Valerolactone |

1.8 |

|

Vanillin |

1.3 |

|

Alcohols |

|

|

1-Butanola |

1480 |

|

Ethanola |

27,458 |

|

Methanola |

39,498 |

|

1-Propanola |

580 |

|

2-Propanola |

24,670 |

|

Glycols |

|

|

Ethylene glycola |

12,490 |

|

Propylene glycola |

8814 |

|

Aldehydes |

|

|

Formaldehydea |

12,192 |

|

Carboxylates |

|

|

Acetatea |

9.21 |

|

Butyrate |

0.21 |

|

Formatea |

8.84 |

|

Lactate |

0.183 |

|

Propionateb |

0.32 |

|

Amines |

|

|

Trimethylamine |

ND |

|

Nonvolatile Compounds |

|

|

Urea |

0.43 |

|

Total organic carbon |

45,400 to 64,500 |

|

a Contaminant present in four of four samples collected. b Contaminant present in three of four samples collected. ND, target compound was not detected at or above the detection limitfor that method. Source: Homan et al. (1997). |

|

TABLE 2-4 Organic Compounds Found in the Humidity Condensate Samples from the Shuttle Cabin

|

Concentration, µg/L |

||

|

Compound |

Minimum |

Maximum |

|

Volatile Organic Compounds |

||

|

Acetaldehyde |

<10 |

19.8 |

|

Acetone |

12.6 |

68 |

|

2-Heptanone |

0.73 |

7.26 |

|

4-Heptanone |

ND |

6.03 |

|

Methylene chloride |

1.94 |

1,380 |

|

Tetrachloroethane |

2.67 |

10.60 |

|

Toluene |

<0.25 |

1.4 |

|

Semivolatile Organic Compounds |

||

|

Acetophenone |

22 |

108 |

|

2-(2-Butoxyethoxy)ethanol |

2,700 |

3,400 |

|

3-tert-Butylphenol |

36 |

193 |

|

Diethyl phthalate |

480 |

2,200 |

|

N,N-Diethyl-m-toluamide |

126 |

245 |

|

Octanoic acid |

1,500 |

1,800 |

|

Phenol |

35 |

107 |

|

1,3,5,Triazine-2,4,6(1H,3H,5H)-trione-1,3,5-tri-2-propenyl |

480 |

2,300 |

|

Alcohols |

||

|

Benzylalcohol |

59,000 |

369,000 |

|

Ethanol |

6,600 |

126,000 |

|

Methanol |

1,400 |

7,400 |

|

2-Propanol |

1,900 |

43,300 |

|

Glycols |

||

|

Propylene glycol |

29,000 |

72,000 |

|

Organic Acids |

||

|

Acetic acids |

2,300 |

28,520 |

|

Butyric acid |

280 |

900 |

|

Formic acids |

8,900 |

16,900 |

|

Propionic acid |

2,600 |

5,020 |

|

Aldehydes |

||

|

Formaldehyde |

3,300 |

10,400 |

|

Representative results from the characterization of cabin humidityconcentrations from nine samples from two shuttle missions. ND, notdetected. Source: Muckle et al. (1993). |

||

Among the volatile organic compounds present, acetone, acetaldehyde, and methylene chloride were found in significant concentrations. Notably, most of the EPA target compounds were not found, and only methylene chloride exceeded the EPA maximum contaminant limit (MCL) of 0.005 mg/L for potable water. This finding underscores the unique nature of spacecraft source waters. Propylene glycol was the predominant glycol in the in-flight samples. Caprolactam, organic acids (acetic, formic, and propionic), and formaldehyde also were found, the latter in substantial amounts both in the cabin and in the Spacelab samples.

TOC accountability was about 50% for one mission and 75% for the other (Muckle et al. 1993); accountability in a similar study conducted on STS-68 was 86-88% (Straub et al. 1995). In the latter mission, 116 volatile organic compounds, 97 semivolatile organic compounds, caprolactam, urea, several organic acids, and formaldehyde were among the major contributors to the TOC. Alcohols (ethanol and 2-propanol) and glycols were the predominant organic alcohols. Variations in the amount of TOC among missions probably reflect both the shuttle vehicle and the type of payload launched. For example, the condensate taken from the shuttle with a Spacelab contained much higher TOC (Straub et al. 1995).

A discussion of inorganic contaminants found in humidity condensates from shuttle missions are presented later in this chapter, in conjunction with analyses of regenerated water.

Mir Humidity Condensate

In 1995 and 1996, another series of investigations was undertaken to characterize humidity condensate and processed water aboard Mir. Nine humidity ondensate samples were collected, one during Mir-19, four during Mir-20, and four during Mir-21. (Samples from Mir-20 and Mir-21 included those collected during periods in which ethylene glycol leaked from the coolant system into the Mir atmosphere). Results from Mir-19 and Mir-20 are discussed separately from Mir-21, because advances in technology between the two study periods allowed closer examination of short-chain alcohols and urea in the Mir-21 samples.

A wide spectrum of organic compounds was present in the Mir-19

and Mir-20 samples (Pierre et al. 1996). Differences were found between those samples and the earlier shuttle condensate samples in conductivity, turbidity, and anion and cation concentrations. Moreover, about 60 semivolatile compounds identified in the shuttle condensate were not found in Mir condensate, and about 10 compounds were found only in the Mir samples.

Volatile organic compounds common to the Mir and shuttle samples included acetone, 2-butanone, and methylene chloride. Others included acetaldehyde, carbon disulfide, chloroform, diethylether, iodomethane, perfluoro-1,3-dimethyl-cyclohexanone, and o-xylene. Several semivolatile organic compounds were found at concentrations exceeding the minimum detection limits. Those constituents found at the highest concentrations included acetophenone, 3-tert-butylphenol, dioctylphthalate, n,n-diethyl formamide, diethylene glycol monoethyl ether, n,n-dimethyl acetamide, dioctyl phthalate, dipropylene glycol methyl ether, 4-ethylmorpholine, 2-hydroxybenzothiazole, 4-hydroxy-4-methyl-2-pentanone, 1-methyl-2-pyrrolidinone, methylthiobenzothiazole, 2-phenyl-2-propanol, and tetramethylthiourea.

Notably, 72% of the organic carbon in the shuttle condensate samples could be accounted for, but only 21% could be accounted for in the Mir-19 and Mir-20 samples.

Samples from the Mir-21 mission were returned in two batches, one from each of 2 shuttle missions (Pierre et al. 1997). Some volatile organic compounds were present in some samples but not in others, a finding that might reflect the delay between receipt of the two sample batches. Acetone and carbon disulfide were found in all humidity condensate samples. Tetrahydrofuran was found in the Mir-21 samples but not in any samples from the earlier Mir missions. The semivolatile organic compounds benzothiazole, 2-hydroxybenzothiazole, 4-ethylmorpholine, 1-methyl-2-pyrrolidinone, 2-phenyl-2-propanol, 3-tert-butylphenol, n,n-diethyl formamide, tetramethylthiourea, and tetramethylurea were found in all humidity condensate samples. Other compounds (e.g., caprolactam, diethylformamide, n,n-dimethylacetamide, and n,n-dimethylformamide) were found in some samples but not in others. Methanol, 1-propanol, 2-propanol, 2-methyl propanol, and 1-methoxy-2-propanol were the alcohols found in all samples. High concentrations of ethylene glycol were traced to a coolant leak in the thermal control system. Formaldehyde was found in significant

concentrations (32.5 µg/L). The TOC accountability was only 4-7%, although it was 32% and 67% in the two samples that had high ethylene glycol content.

A discussion of the inorganic contaminants found in humidity condensates from Mir are presented later in this chapter, in conjunction with analyses of regenerated water.

Environmental Contributors to Spacecraft Humidity Condensate

Hardware Off-Gassing

Most nonmetallic materials continuously release trace amounts of a wide variety of gases, either through breakdown and subsequent volatilization of the original material or via gradual escape of gases that are trapped in the materials during their manufacture or cleaning. Off-gassed products are of great concern in closed habitats, such as submarines and spacecraft. Compounds off-gassed by articles in spacecraft interiors have included aliphatic hydrocarbons, alcohols, aldehydes, chlorinated hydrocarbons, siloxanes, and carbon monoxide. Even given the constraints on the types of materials that can be flown, gaseous products from the Shuttle and flight articles stored in its lockers could accumulate to harmful concentrations during long missions if they were not removed by the scrubber components of the air revitalization system (Coleman and James 1994).

The types and amounts of chemicals that could be off-gassed from a payload obviously depend on the nature of that payload, and variations make exact predictions difficult. To assess the effect of a “typical ” off-gas mixture on recycled water, an ersatz mixture was created and added to the humidity condensate in the WRT. The composition of this ersatz test mixture was based on analyses of humidity condensate from Spacelab and shuttle missions (Holder et al. 1995).

Animal Wastes

Life sciences experiments, especially those that involve animals, constitute another source of wastewater contamination. Another mixture

of chemicals (an ersatz solution) representing various contaminants found in animal wastes was created on the basis of results from Spacelab animal experiments missions (Carter et al. 1995). This mixture (Table 2-5) was added to the waste stream of the Marshall WRT, and the same mixture was used during the 60-d closed-chamber trial of the LMLSTP.

Mechanical Leaks

Recycling potable water from a variety of complex sources is expected to be difficult, and leaks from the water reclamation hardware are likely. Moreover, the potential effects of microgravity on component processes, such as air-fluid separators, vapor compression distillation, catalytic oxidation, and urine pretreatment with highly corrosive

TABLE 2-5 Ersatz Animal Condensate Composition

|

Compound |

Concentration, µg/L |

|

Acetaldehyde |

300 |

|

Acetone |

10,100 |

|

Ammonium |

590,000 |

|

Benzoic acid |

850 |

|

Bis-2-ethylhexyl phthlate |

70 |

|

Ethylene glycol |

14,000 |

|

Nickel |

600 |

|

Phenol |

50 |

|

Phosphate |

17,000 |

|

2-Propanol |

11,500 |

|

Protein |

6,080 |

|

Urea |

1,170 |

|

During the ground-based tests, first in the water recovery testsat Marshall then at Johnson, the animal condensate ersatz solutionwas metered into the waste bus 24 hr/d at 0.33 lb/hr to simulatecondensate input from the research animal holding facility on thespace station. It is expected that about 7.92 lb/d would be generatedas animal condensate. Source: Carter et al. (1995). |

|

chemicals, have not been completely identified. Nor are potential system leaks confined to the water system itself. As mentioned above, at least two incidents have taken place on Mir in which ethylene glycol has leaked from the thermal control system. It is not surprising that the humidity condensate collected after one of those leaks (1.8 L of 37% ethylene glycol) contained large amounts of ethylene glycol (149.2, 152.8, and 76.8 mg/L) (Pierre et al. 1996).

Microbial Metabolites

Microorganisms will certainly be present aboard any spacecraft that includes humans and animals. Evidence from Skylab and the space-shuttle missions indicates that the microbial ecosystem aboard spacecraft undergoes substantial increases in number and perhaps diversity over time (Pierson 1994). Many environmental bacteria can produce volatile metabolites that could end up in the humidity condensate. As an example, bags used to store urine samples for a life sciences experiment on a 1994 shuttle mission were found to give off strong odors. A postflight assessment revealed that the combination of noxious chemicals that had been leaching through the bags could well have come from microbial growth in the urine. Volatile microbial metabolites found in urine storage bags include C8-alkane, C9-alkane, bis(methylthio)methane, carbonyl sulfide, dimethylsulfide, dimethyltrisulfide, ethanol, ethylene glycol, propanone, tetrachloroethene, 1,1,1-trichloroethane, and toluene (J.T. James, Johnson Space Center, personal communication, Jan. 10, 1994).

Several high-efficiency particulate filters in the ECLSS are expected to remove most airborne microbial or fungal particulate matter. However, colonization of the filters and degradation by-products of the colonies might well be carried to the humidity condensate if they cannot be removed effectively by trace contaminant control in the air revitalization system.

Another potential source of microbial metabolites is in the multifiltration resin beds, which contain large amounts of organic carbon. Because large quantities of wastewater will pass through them, these beds may provide a matrix – and a rich nutrient source – for microbial growth and potentially for biofilm formation.

Payload Chemicals

Another source of contaminants in the water system during long space missions is the chemicals carried as part of payload experiments. Toxic chemicals are used frequently in materials-processing and fluid-behavior experiments, in biologic studies that require tissue fixation, and in other types of experiments. Although toxicologists review all flight experiments in detail well before launch, assign hazard levels to component chemicals, and recommend levels of containment, the possibility of escape always exists, especially when experimental equipment is being transferred from one container to another or is being heated. Even a chemical judged to be “acceptable” from a toxicologic standpoint can accumulate in the water system if it escapes.

Utility Chemicals

Volatile chemicals used to disinfect surfaces constitute another source of contamination for the humidity condensate. For example, the high alcohol content in the shuttle humidity condensate presumably reflects the use of alcohol-impregnated “wet wipes” for cleaning interior surfaces (Pierre et al. 1996). A biocide will be used on the ISS to clean surfaces, eating utensils, and windows. The current disinfectant of choice for ISS surfaces is a 2400 parts per million (ppm) Barquat 4250Z solution. This agent, a mixture of N-alkyl (C12-C18)-N,N-dimethyl-N-benzyl ammonium chloride and N-alkyl (C12-C14)-N,N-dimethyl-N-ethylbenzyl ammonium chloride, has been found to be effective against Pseudomonos aeruginosa, Staphylococcus aureus, and Salmonella choleraesuis. Other utility chemicals to be considered include glues and adhesives, the off-gas products from which eventually will appear in the water system.

Wash Water and Other Waste Streams

Hygiene Water

Detergents

A major contributor of complex chemicals to the waste stream is hygiene water, which will contain soap, residue from shaving, and chem

icals used for oral hygiene. Ingredients of the detergent chosen for ISS personal hygiene and hand washing are listed in Table 2-6.

Chemicals from Personal Hygiene Products

Other personal hygiene items to be used on the ISS, such as shaving cream, toothpaste, and deodorant or antiperspirant, have yet to be standardized in the space-station program. However, some information on use of these products is available from ground-based test beds. During Stage 7 of the WRT, subjects used commercially available shaving cream and toothpaste during a 50-d water-recycling period. No contaminant build-up was noted from the use of these products (Carter and Bagdigian 1993). No build-up was found from the use of similar products, along with a commercially available antiperspirant during the 60-d LMLSTP.

CHeCS Wastes

Another waste stream input to the water processor is the effluent from the CHeCS. This system will be used to provide several routine monitoring procedures over the course of long flights. An ersatz mixture of these compounds was prepared and added to the waste stream of the Marshall WRT, and the same mixture was used during a 60-d closed-chamber trial of the LMLSTP (Meyers et al. 1997).

TABLE 2-6 ISS Soap Ingredients

|

Ingredient |

Percent |

|

Sodium n-coconut acid-n-ethyl taurate (24% active) |

98.65a |

|

Formaldehyde (formalin 37%) |

0.10 |

|

Lecipur 95f (soybean lecithin) |

0.50 |

|

Luviquat FC-500 (polyquaternium) |

0.75 |

|

a CAS No. 104639, RTECS No. GG6500000. Source: Holder et al. (1995). |

|

Chemicals Formed in the Water Treatment System

Other sources of contaminants in closed-water systems, such as that planned for the ISS, are potential reactions within the system itself. One example noted earlier is the formation of oxidation products from the combination of urine with Oxone and sulfuric acid. Another would be the appearance of chemicals in the treatment train itself that form over long periods of operation, such as fouling in the resin beds. Trimethylamine detected during Stage 10 of the WRT was thought to arise from the reaction of highly basic anions with oxidation chemicals passing through the multifiltration beds or perhaps from large amounts of air being present in the influent to the multifiltration beds (Carter 1997). The bed itself, being a high-carbon source, could form a matrix for biofilm formation. Microorganisms present in the distribution line also could act as a source of microbial metabolites. Biofilms and nonadherent microbial contamination were found in the heat exchangers after a 60-d closed-chamber study in the LMLSTP (D.W. Koenig, Krug Life Sciences, personal communication, April 1997). Even though these organisms were nonpathogenic, they still can produce significant amounts of metabolites. Moreover, the use of biocides in the water system does not preclude the evolution of biocide-resistant species.

System Failures and Incomplete Processing of Influent

Incomplete processing of influent streams can result not only from contaminant overload, but also from mechanical malfunctions of the water system. The design of the integrated system planned for the ISS is extremely complicated, and many components are sensitive to perturbations. The ability to function reliably in microgravity, of course, is critical. Particulate filters are easily clogged. Air-fluid separations are precise processes, and frothing or foaming of detergents will cause poor separations. Poor separation in turn affects the multifiltration beds, causing channeling to adversely affect the flow and the function of the resins, and could even oxidize the resin matrix (e.g., formation of trimethylamine). The vapor compression distillation process depends heavily on motors, complex fluid pumps, and purge pumps to remove

noncondensable gases. Frequent pump failures have been experienced during the LMLSTP system tests, which have led to a mixture of coolant and water being processed (data presented at LMLSTP Phase IIA status meeting, NASA/JSC, April 22-24, 1997). Incomplete processing will produce noncondensable gases that will foul the distillation unit and lead to poor quantitative and qualitative recovery of urine distillate. Finally, the multifiltration beds are designed to remove large-molecular-weight organic and ionic components before the water passes to the volatile removal assembly, which catalytically oxidizes the small-molecular-weight organic constituents. Incomplete processing at the multifiltration beds will overload the volatile removal assembly and catalyst with large-molecular-weight organic compounds, eventually producing incomplete products of oxidation.

Chemicals Added to Retard Bacterial Growth

Iodine

Microbial growth and biofilm formation are controlled in the U.S. water system by adding iodine to processed water. About 5 ppm iodine is imparted by a microbial check valve, a polishing ion exchange bed that contains iodinated resin (see Appendix A), which is placed after the volatile removal assembly in the treatment stream. Iodine is added before water is diverted either to the use tank (assuming it meets the criteria of the process control water-quality monitor) or to the potable-water waste-processing stream for reprocessing (if it fails quality criteria). Just as chlorinated by-products can form during disinfection of public water systems, residual iodine can react with a variety of small organic compounds, like phenols, to form iodinated organics while the water is being stored in the ISS. Iodinated organics, like trihalomethanes, can cause adverse health effects (Thorstenson et al. 1987). Even though iodinated organics have not been found in the product water in the Marshall WRT, numerous iodinated organics can form from several organic precursor compounds (Barkley et al. 1992; 1993). High concentrations of phenol, 2-methyl phenol, 3-tert-butylphenol, and 2,4-di-t-butylphenols were found in the cabin humidity condensates from shuttle and Spacelab missions (Muckle et al. 1993); these compounds are potential substrates for the formation of iodinated adducts (Barkley et al. 1992). The adverse health effects from io-

dine and its by-products have yet to be systematically addressed. Because of the potential for adverse effects from iodine and iodine species, the medical sciences division of the Johnson Space Center has recommended that concentrations of those compounds be reduced at the point of use. Iodine and iodine species have been removed during recent space-shuttle missions by using an iodine removal and mineral injection system or by using activated carbon and ion exchange resins pumped between the shuttle water tank and the galley. Such procedures could become a medical operations requirement for ISS missions.

Silver

The Russian water system uses silver as the residual biocide for processed water. The Russian system was designed to impart silver at concentrations of 0.05-0.5 mg/L of potable water. Water of acceptable quality (i.e., conductivity <150 microsiemens per centimeter) from the humidity condensate processor passes through a conditioning bed, where magnesium, calcium, and other minerals are added for palatability. This proprietary conditioning bed also adds silver to the water. Silver is also added via a silver ionizer to water that is transported from the ground to Mir. The treated water is stored in Rodnik tanks and transported by the Russian Progress resupply vehicle. The crew uses the water without further processing.

Another source of silver in the water system is the condensing heat exchanger, which collects the humidity condensate. Because the heat exchanger could well support microbial growth, it contains silver components as biocides. Analyses of Mir humidity condensate have not shown significant amounts of silver to be present. For example, 3 samples from Mir-20 had 55-100 µg/L of silver; 1 sample from Mir-21 had about 500 µg/L; others had no detectable silver. Silver is not analyzed in shuttle humidity condensate samples (Pierre et al. 1996).

REGENERATED WATER

Inorganic Contaminants

A review of federal safe drinking-water standards and health advisories indicates that several inorganic metals and anions and cations can

pose risks ranging from simple aesthetic effects (taste, odor, color) to adverse health effects. In the shuttle, potable water is generated electrolytically and concentrations of metal ions are extremely low. This is not the case with the ISS design. There are concerns that the water reclamation process and wastewater treatment processes will result in corrosion and leaching of metal components during storage in potable-water distribution systems. In addition, iodine added to the water as a disinfectant could exacerbate corrosion. The ISS water-quality requirements table (see Appendix A, Table A-1) lists several inorganic compounds and the maximum concentrations to protect crew members from experiencing any potential toxic effects. The multifiltration beds in the Mir condensate processor assembly and the Unibed assembly proposed for the U.S. water processor systems, which are made up of combinations of several strong and weak anion and cation exchange resins, were intended to remove inorganic species. Analysis of waste-water samples, and analysis of humidity condensates from several shuttle missions (Muckle et al. 1993; Straub et al. 1995), shuttle-Mir missions (Pierre et al. 1996, 1997), and various WRT samples (Carter and Bagdigian 1993) for inorganic contaminants clearly show the presence of various metals and anions and cations. A brief summary of findings from these studies is given below.

Shuttle Humidity Condensates

Samples of humidity condensates from the space shuttle, not processed for crew use, were collected from STS-45, STS-47 (Muckle et al. 1993), and STS-68 (Straub et al. 1995) and analyzed for the presence of metals, anions, and cations. Zinc was found in substantial concentrations in both the cabin (10-20 mg/L) and the Spacelab condensates (40.5 mg/L in STS-50, USML-1) (Muckle et al. 1993). Other metals found in the cabin condensates were silicon, nickel, and lithium. It was proposed that the shuttle humidity condensate heat exchangers were the source for these metals. The concentrations differed with the mission and with the age and condition of the heat exchanger. For example, the amounts of nickel in STS-45 (11th mission) humidity condensates were significantly greater than were those in STS-47 (second mission) samples. Silicon was found to come from the water separator filter. Similarly, substantial amounts of zinc were found in condensates from

STS-68 (17-28.5 mg/L). The STS-68 condensates had nickel, copper, lithium, and manganese at low concentrations (< 0.2 mg/L each) but at higher concentrations than reported from previous missions. The anions present in significant concentrations were chloride (0.9-1.8 mg/L) and nitrite (0.45-0.72 mg/L). Ammonium was the major cation in the shuttle condensate at 11-18 mg/L.

Mir Humidity Condensates and Mir Reclaimed Water

As a part of water-processing systems development, and to help determine the quality of the raw source water from missions of long duration, humidity condensate samples and samples reclaimed from these condensates using the Mir condensate processors were collected from several shuttle-Mir missions, starting in March 1995 (named as Mir-18, Mir-19, Mir-20, Mir-21, etc.). The analysis of Mir-20 humidity condensate samples are presented in Table 2-7. A composite summary of inorganic ion concentrations in the humidity condensate samples collected from all the shuttle-Mir missions (Mir-18 to Mir-25) is presented in Table 2-8.

TABLE 2-7 Components of Humidity Condensate from Mir-20

|

Concentration, µg/L |

||

|

Component |

Minimum |

Maximum |

|

Ammonium |

4,930 |

61,800 |

|

Calcium |

730 |

2,490 |

|

Chloride |

320 |

1,120 |

|

Lithium |

510 |

640 |

|

Magnesium |

340 |

1,150 |

|

Nitrate |

470 |

2,100 |

|

Potassium |

450 |

570 |

|

Silver |

55 |

100 |

|

Sodium |

1,250 |

9,380 |

|

Sulfate |

240 |

1,010 |

|

Source: Pierre et al. (1996). |

||

TABLE 2-8 Inorganic Compounds with Significant Concentrations in Mir Missions

|

Concentration, µg/L |

||||

|

Compound |

Minimum |

Maximum |

Mean |

Frequencya |

|

Recycled Water |

||||

|

Barium |

ND |

2,440 |

189.7 |

18/22 |

|

Chloride |

ND |

13,000 |

3,640 |

20/23 |

|

Fluoride |

ND |

3,680 |

206 |

12/23 |

|

Iron |

9.3 |

265 |

64.4 |

22/22 |

|

Manganese |

ND |

51.7 |

9.2 |

21/22 |

|

Nickel |

5.6 |

157 |

31.3 |

22/22 |

|

Potassium |

ND |

2,770 |

621 |

16/25 |

|

Silver |

8.4 |

674 |

113.6 |

28/28 |

|

Sodium |

ND |

5,970 |

1,560 |

24/25 |

|

Sulfate |

ND |

27,600 |

3,690 |

14/23 |

|

Humidity Condensate Samples |

||||

|

Ammonia (as N) |

ND |

48,000 |

24,960 |

26/28 |

|

Barium |

ND |

13,920 |

635.7 |

21/23 |

|

Calcium |

ND |

6,110.0 |

952.8 |

21/28 |

|

Chloride |

ND |

16,800 |

1,750 |

23/28 |

|

Magnesium |

ND |

6,570.0 |

614 |

23/28 |

|

Nickel |

10.2 |

14,700.0 |

1,400 |

23/23 |

|

Nitrate as NO3-N |

ND |

8,170.0 |

456.8 |

7/28 |

|

Potassium |

ND |

20,400 |

1,800 |

15/28 |

|

Sodium |

ND |

123,400 |

8,280 |

27/28 |

|

Sulfate |

ND |

114,000 |

6,270 |

17/28 |

|

a Number of times detected/total number of humidity condensate samples analyzed from Mir 18-25 missions. ND, not detected. Source: Pierre et al. (1996, 1997, 1999). |

||||

Detailed inorganic analysis was not carried out on the reclaimed water from Mir-18, Mir-19, and Mir-20 due to limited sample volume. Chloride, nitrate, sulfate, sodium, ammonium magnesium, and cal-

cium were found. A detailed analysis of condensates and reclaimed water was carried out during Mir-21. The results on the inorganic constituents measured in the Mir-21 humidity condensate samples indicate that most of these compounds were found at concentrations of less than 5 mg/L, except ammonia (as nitrogen), which was detected in one sample at 15.3 mg/L and another at 26 mg/L (as ammonium). Significant concentrations of barium, iron, copper, nickel, and zinc also were found. The zinc concentrations reached a maximum of 5.3 mg/L in one sample. Zinc was detected at concentrations of up to 28.5 mg/L in shuttle condensate (Straub et al. 1995). A composite summary of ionic species identified in the Mir-18 to Mir-25 reclaimed water samples shows the presence of chloride, fluoride, sulfate, calcium, silver, nickel, barium manganese, potassium, and sodium (Pierre et al. 1996, 1997, 1999). Those results are included in Table 2-8.

LMLSTP 60-d Product Water

Results of the inorganic analysis on the reclaimed water from the Johnson Space Center 60-d closed-chamber study (LMLSTP Phase IIA) show most of the inorganics well below NASA limits. Only copper, iron, manganese, nickel, and lead were found at significant concentrations, and nickel, copper, manganese and lead exceeded NASA limits (maximum 265, 2170, 71, and 54 µg/L, respectively) (M.E.Homan, J.R. Schultz and R.L. Sauer, NASA/JSC, personal communication, 1999). A cursory examination of shuttle, Mir, and ground-based test samples indicates a significant variation in the amount of inorganic constituents in humidity condensate and wastewater. In general, the concentrations in the reclaimed water indicate that the various ion exchange resins included in the processing train (multifiltration bed or Unibed), removed these inorganic constituents to maintain concentrations below the NASA water-quality specifications. Disinfectant iodine concentrations and those for products such as iodides are not included in the tables. The presence of silver in the product waters of Russian Mir missions results from the use of silver as a disinfectant in reclaimed water and in water transported via the shuttle.

Nevertheless, the concern that some inorganic metal ions will accumulate in the water is warranted because of the possibility of corrosion over time – especially in the presence of iodine.

Organic Contaminants

Humidity Condensate in Mir

Analysis of regenerated hot water collected from point-of-use ports on Mir-18 and Mir-19 indicated that the water processor could produce water from condensate that met joint U.S.-Russian specifications for water quality. Nevertheless, TOC, turbidity, and phenol in these samples exceeded the water-quality specifications for the ISS (Pierre et al. 1996). Acetone, bromodichloromethane, chloroform, 1,4-dichlorobenzene, meta- and para-xylene, and dichlorofluoromethane were the volatile organic compounds found. Formaldehyde was found in samples from only one of the two missions. Table 2-9 lists the organic compounds in Mir-regenerated water and their frequency of occurrence.

The organic carbon balance of the regenerated hot water of the two samples from Mir-18 was 0.47% and 4.58%. From three Mir-19 samples, it was only 3.3%, 4.0%, and 6.2%.

Two samples of processed water were collected from the galley cold-water ports on Mir-21 (Pierre et al. 1997). Of the organic compounds detected in these samples, carbon disulfide was the only volatile organic compound found in all samples tested; in contrast, acetone, methylene chloride, and trichloroethene were found in one sample but not in the other. Several semivolatile organic compounds found in processed water from previous Mir missions were also found in samples analyzed from this mission.

The recovery of TOC in these two samples again was poor – 0.94% for one sample and 12.19% for the other. Explanations offered by the project investigators for the poor recoveries include low amounts of TOC in the product-water samples, small sample volumes, and relatively high detection limits for many components. These factors could combine to produce artifacts in sum calculations for recovery estimates by not accounting for numerous organic species that could be present just below detection limits.

LMLSTP 60-d Product Water

The 60-d Johnson Space Center chamber study, in which four humans used regenerated air and water, was intended to provide a typi-

TABLE 2-9 Organic Compounds in the Processed Water Samples from a Representative Mir Mission

|

Concentration, µg/L |

|||

|

Compound |

Minimum |

Maximum |

Frequencya |

|

Benzothiazole |

1.6 |

110.7 |

6 |

|

Bis-2-ethylhexyl phthalate |

0.4 |

27.9 |

6 |

|

Di-n-butyl phthalate |

0.1 |

1.4 |

6 |

|

Diethyl phthalate |

0.1 |

3.4 |

6 |

|

2-Hydroxybenzothiazole |

1.1 |

6.8 |

5 |

|

2-Mercaptobenzothiazole |

8.8 |

41.8 |

5 |

|

2-Methylthiobenzothiazole |

2.2 |

48.5 |

5 |

|

Toluene |

0.8 |

1.9 |

5 |

|

Urethane |

0.4 |

1.9 |

5 |

|

Acetone |

8.89 |

49.6 |

4 |

|

N-Butylbenzenesulfonamide |

0.5 |

2.7 |

4 |

|

Carbon disulfide |

5.2 |

9.6 |

4 |

|

Decamethylcyclopentasiloxane |

0.8 |

5.6 |

4 |

|

Indole |

0.1 |

0.3 |

4 |

|

Phenol |

0.9 |

1.2 |

4 |

|

N-Phenyl-2-naphthylamine |

0.2 |

11.7 |

4 |

|

1-Tetradecanol |

1.8 |

6.2 |

4 |

|

2,2,4-Trimethyl-1,3-pentanediol diisobutyrate |

0.1 |

0.1 |

4 |

|

Acetate |

0.131 |

1.49 |

3 |

|

Benzyl alcohol |

0.9 |

1.9 |

3 |

|

2,4-Di-t-butylphenol |

1 |

1.3 |

3 |

|

Octamethylcyclotetrasiloxane |

0.9 |

1 |

3 |

|

Trichloroethene |

1.8 |

2.3 |

3 |

|

Acetophenone |

0.1 |

41 |

2 |

|

Ethanol |

160 |

2,447 |

2 |

|

Formaldehyde |

22.4 |

63.4 |

2 |

|

2-Phenylphenol |

0.2 |

3.2 |

2 |

|

Phenyl sulfone |

0.1 |

75.1 |

2 |

|

Tetramethylthiourea |

0.3 |

24.6 |

2 |

|

Tris-2-chloroethyl phosphate |

0.9 |

0.8 |

2 |

|

Acetaldehyde |

50.85 |

50.85 |

1 |

|

Benzoic acid |

4.6 |

4.6 |

1 |

|

Butylated hydroxyanisole (BHA) |

3.5 |

3.5 |

1 |

|

3-tert-Butylphenol |

113.4 |

113.4 |

1 |

|

Caprolactam |

27.4 |

27.4 |

1 |

|

1,4-Diacetylbenzene |

5.6 |

5.6 |

1 |

cal demonstration of ISS technology with integrated air and water systems. Because of this, evaluations of the regenerated water contaminants in the product water will provide a better definition of the technology performance (risk mitigation) and a more accurate description of the water contaminants. The compounds identified and the number of occurrences during the 60-d test are presented in Table 2-10. The main purpose of the sorting is to rank the compounds for toxicity evaluation and to assess the processing system to take measures to eliminate contaminants of concern or to control their presence if the source is known. Highly sophisticated onboard monitoring hardware for full characterization will not be available, because of logistical and funding considerations, so the philosophy of the program will be to limit potentially toxic substances entering the system in the first place if the processor can not remove them effectively. The results indicate that the TOC range exceeded NASA's requirement of 0.5 mg/L 16 times, and that values were above 1.0 mg/L five of those times. Acetone and toluene are the only two volatile organic compounds seen of the 57 targeted compounds. Acetone was found four times, but toluene was found in 34 of 68 samples. Among the low-molecular-weight polar hydrophilic compounds that are difficult to remove, formaldehyde was found 30 times; the concentrations, however, were well below the EPA health advisory limit of 1000 µg/L. Other organics – methanol, 1-propanol, 2-propanol, ethanol, and 1,2 propanediol – either were not found or were found infrequently. The results indicate efficient functioning of the volatile removal assembly.

Of particular interest is that compounds that were found often – such as iodoform, diiodomethane, di-n-butyl phthalate, ethylhexyl phthalate, and toluene – that are potentially of concern to health were found at low concentrations. The potential for the formation of halomethane-type compounds with iodine as the disinfectant is clearly indicated. In general, the lessons learned in the 60-d chamber test in the areas of component functioning and the efficiency of contaminant removal systems to potable-water quality will help NASA finetune the design and build a robust and dependable system for long space missions.

Stage-10 WRT

The Marshall Space Flight Center WRT Stage-10 was conducted for 128 d in a recipient mode of operation, in which reclaimed water was

TABLE 2-10 Organic Contaminants in Processed Waters During the 60-d Johnson Space Center Chamber Study

|

Concentration, µg/L |

|||

|

Compound |

Minimum |

Maximum |

Frequencya |

|

Iodoform |

1.6 |

4.8 |

40 |

|

Methyl sulfone |

0.6 |

54.5 |

38 |

|

Di-n-butyl phthalate |

0.1 |

2.3 |

36 |

|

Toluene |

1.01 |

9.53 |

34 |

|

2-Ethyl-1-hexanol |

0.4 |

12.4 |

33 |

|

Formaldehyde |

2 |

13.8 |

30 |

|

Benzaldehyde |

0.1 |

0.8 |

24 |

|

1-Methyl-2-pyrrolidinone |

0.3 |

7.4 |

21 |

|

Benzyl alcohol |

0.8 |

7 |

21 |

|

Diiodomethane |

0.4 |

1.8 |

19 |

|

Diisopropyl adipate |

0.4 |

0.9 |

17 |

|

Dodecamethylcyclohexasiloxane |

0.5 |

1.7 |

13 |

|

Acetate |

0.14 |

3.97 |

11 |

|

Bis-2-ethylhexyl phthalate |

0.1 |

1.7 |

11 |

|

4-Hydroxy-4-methyl-2-pentanone |

0.6 |

3.4 |

10 |

|

Methanol |

101 |

233 |

8 |

|

1-Formylpiperidine |

0.1 |

0.6 |

7 |

|

Squalene |

0.9 |

3.9 |

6 |

|

Decamethylcyclopentasiloxane |

0.1 |

0.2 |

5 |

|

Diethyl phthalate |

0.2 |

0.4 |

5 |

|

Lactate |

0.18 |

1.1 |

4 |

|

Oxalate |

0.23 |

0.41 |

4 |

|

sec-Phenethyl alcohol |

0.1 |

0.2 |

4 |

|

Acetone |

4.64 |

6.3 |

3 |

|

Acetophenone |

0.1 |

0.3 |

3 |

|

Benzothiazole |

0.1 |

0.7 |

3 |

|

Pentacosane |

0.3 |

1.2 |

3 |

|

Phenol |

0.7 |

1 |

3 |

|

2-(2-Butoxyethoxy)ethanol |

0.4 |

0.8 |

2 |

|

2-Butoxythanol |

3.1 |

3.2 |

2 |

|

2-Ethylhexanoic acid |

1.7 |

2.1 |

2 |

|

Monomethyl phthalate |

4.8 |

4.8 |

2 |

|

N,N-Dimethylbenzylamine |

0.6 |

0.6 |

2 |

|

Octamethylcyclotetrasiloxane |

0.4 |

0.6 |

2 |

|

Octanoic acid |

2.6 |

2.9 |

2 |

|

Tris-2-chloroethyl phosphate |

0.9 |

1.5 |

2 |

|

Benzylbutyl phthalate |

3.6 |

3.6 |

1 |

|

Bis-2-ethylhexyl adipate |

0.8 |

0.8 |

1 |

|

n-Butyl palmitate |

5.3 |

5.3 |

1 |

|

Butyl stearate |

10.7 |

10.7 |

1 |

|

1,4-Diacetylbenzene |

0.3 |

0.3 |

1 |

|

Neomenthol |

0.2 |

0.2 |

1 |

|

2-Phenyl-2-propanol |

0.5 |

0.5 |

1 |

|

2-Propanol |

154 |

154 |

1 |

|

Tetramethylsuccinonitrile |

0.4 |

0.4 |

1 |

|

Tributyl phosphate |

0.5 |

0.5 |

1 |

|

Urea |

302 |

302 |

1 |

|

Total organic carbon |

87 |

1,850 |

|

|

a Frequency of detection in 68 samples. Source: J. Schultz and colleagues, Wyle Laboratories, personal communication,Sept. 1997. |

|||

returned to test subjects for use. The water recovery system processed pretreated urine flush water; an ersatz sample of CHeCS waste; ersatz animal condensate; humidity condensate; ersatz equipment off-gas; ersatz fuel cell water; and wet shave, personal hygiene, and oral hygiene water. The results in general indicated no accumulation of contaminants in the product water (Carter 1997). When they become available, detailed analysis data on organic species will be reported.

The issues involved with developing appropriate water-processing hardware and treatment technologies are complex. Because of the unique nature of the input water to the ISS water processor system, NASA has placed strong emphasis on characterizing the nature of potential contaminants and on assessing variations in the influent streams as thoroughly as possible. Several efforts have been made to predict the chemical makeup of source waters to the ISS water processor system.

Ground-based test beds, such as the WRT and the LMLSTP, can simulate only some aspects of ISS input water. Humidity condensate samples have been collected from a few space-shuttle and Mir missions, but the constituents of these spacecraft samples have not been compared with those of the ground-based test beds. A composite compila-

tion of wastewater data from various sources has been attempted (Carter 1998).

Despite substantial variability in TOC accountability between shuttle and Mir missions, and the very poor accountability from the Mir product water (partly due to detection limits issues), the results gathered so far from ISS simulated wastewater streams and in-flight raw and processed water samples indicate that the organic compounds that are present are vastly different from the list of target compounds developed by EPA for public drinking water.

MONITORING WATER CONTAMINANTS

Conductivity is the only process control monitoring currently done aboard Mir in its condensate processor system. During the ISS early assembly phase, to monitor the water quality, the Russian segment service module will accommodate U.S.-provided water-quality monitoring hardware for in-flight off-line monitoring with provisions for archiving water samples for ground-based analysis. The U.S. program proposes several strategies for water monitoring after the ISS is assembled.

Source-Water Monitoring

As noted by the NRC (1992), the drivers for designing and operating any potable-water processor will depend on the organic and inorganic constituents of the raw source water. Adequate specifications for ensuring the quality of the reclaimed or recycled water do not exist outside of NASA, and thus attention must be directed to the definition of source water. Because the content of source waters aboard` spacecraft cannot be predicted reliably from ground-based experiments, the NRC recommended that actual humidity condensate and other raw waters be collected from short- and long-term space flights. The waters should be thoroughly analyzed, and their variability should be clarified. This task also is important in terms of defining potential health hazards from the use of water aboard spacecraft.

Described below are monitoring strategies derived from continuing tests of isolated and integrated water-recovery systems conducted at

the Marshall Space Flight Center (Bagdigian et al. 1991; Carter et al. 1992; Homan et al. 1994; Holder et al. 1995), analyses of humidity condensate collected from the space shuttle (Muckle et al. 1993; Straub et al. 1995) and from Mir (Pierre et al. 1996), and analyses of samples from a human-rated life-support chamber (the LMLSTP) (J Schultz, Wyle Laboratories, personal communication, Sept. 1997).

In-Line Monitoring and Process Control

Conductivity is the only aspect of water quality that is monitored routinely aboard Mir and planned for the early phase 2 of the ISS assembly in the Russian service module. In the current proposed configuration of the ISS, an in-line process control water-quality monitor (PCWQM) will assess conductivity, iodine, pH, and TOC. (Product-water TOC should be less than 0.5 mg/L.) If the parameters are within acceptable limits, the effluent is transferred to the potable-water subsystem; if not, the water is shunted upstream of the multifiltration subsystem for reprocessing (see Appendix A, Figure A-3). Current plans for monitoring ISS water quality after completion of the ISS (plans that are subject to revision) are ouflined in Appendix A, Table A-3.

Off-Line Monitoring

The ISS will have one tank, and if the water limit fails the criteria by the on-line monitor it will be reprocessed.

At present, only conductivity and other surrogate quality measures can be used for routine in-line water-quality monitoring. (A water-quality monitor that can measure conductivity, TOC, and iodine – all pass/fail criteria for potability – has been tested successfully in Stage 10 of the Marshall WRT (Carter 1997).) A comprehensive evaluation (complete characterization) of the product water might be needed after every recycling to ensure that the technologies can effectively remove compounds that are potentially hazardous to the health of crew members. Even though organic and inorganic constituents will be removed by the series of granular activated-carbon and ion-exchange beds, and low-molecular-weight compounds will undergo catalytic oxidation at the volatile removal assembly, trace contaminants could produce io-