7

Direct Grout Option

The direct grout option was included by the Savannah River Site (SRS) as one of the four short-listed alternative processes primarily because of simplicity, high throughput capacity, lower cost, and extensive operational experience (see Chapter 2). This option was not selected as either the primary or backup option, however, owing to perceived regulatory, political, and public acceptance difficulties. Although this option was considered as “off the table ” by SRS as the committee began its review, the committee nevertheless considered the option in its information-gathering and deliberation activities, primarily because the technical maturity of this option makes it a potential approach should all of the other cesium separation options prove technically intractable or economically undesirable. Concerning the technical maturity of the direct grout option, the committee understands that SRS has never run a large volume of grout mixture with the salt supernate. The objective of this chapter is to provide a brief review and analysis of the direct grout option and to provide recommendations on possible actions.

PROCESS DETAILS

The direct grout option differs from the other three options (crystalline silicotitanate ion exchange, caustic side solvent extraction, and small-tank tetraphenylborate precipitation) in that only the “front-end ” MST treatment is applied to the high-level tank waste. Cesium is not separated from the supernate and is instead sent directly in the salt supernate to the saltstone facility.

This option is referred to as “direct grout” because the salt supernate from the strontium and actinide removal process is incorporated directly into grout with a minimal amount of pre-processing. Indeed, of the four short-listed options considered by SRS, the direct grout option involves the least amount of processing and does not produce a cesium waste stream to the Defense Waste Processing Facility (DWPF). Rather, the cesium remains in the salt supernate and is stabilized by blending it into a grout mixture that is disposed of in concrete vaults located above the current water table in an

onsite shallow land-disposal facility known as the Z-Area saltstone 1disposal facility (see Figure 1.1). After emplacement of the grout, the vaults are covered with nonradioactive grout in preparation for closure—burial under an impermeable cap.

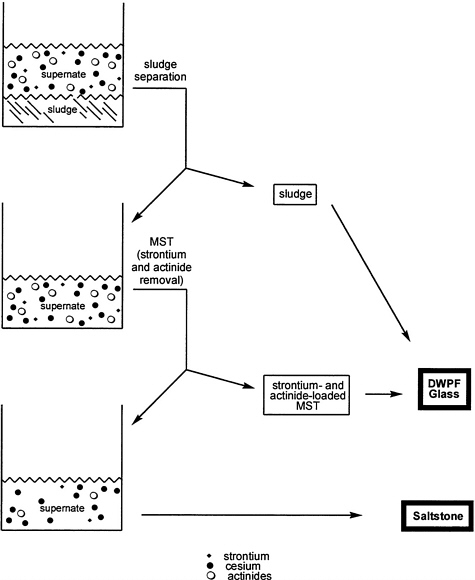

A schematic process flowsheet for this option is shown in Figure 7.1 and comprises the following steps:

-

high-level waste in the tanks is treated with monosodium titanate (MST) to remove strontium and actinides (see Chapter 3 for details of this process);

-

slurry is then processed through a continuous filter to separate the strontium- and actinide-bearing MST solid phase (slurry) from a cesium-bearing salt supernate solution;

-

salt supernate solution is transferred to the onsite Z-Area saltstone production facility, where it is blended into a grout mixture and poured into disposal vaults located at the saltstone disposal facility; and

-

the MST solid phase (slurry) is transferred for immobilization in glass at the DWPF.

In the salt supernate solution to be processed and disposed of in the saltstone production and disposal facilities for the direct grout option, significantly higher concentrations of cesium isotopes are expected than would be handled for the in-tank precipitation (ITP) process. A comparison of concentrations of some materials in the reference salt supernate waste stream used as a basis for saltstone facility operations using the planned ITP process performance parameters (Martin Marietta Energy Systems, Inc., et al., 1992; Stevens, 1999) and anticipated concentrations in a direct grout option supernate stream (Stevens, 1999; Beck et al., 1998) are shown in Table 7.1. A higher concentration of cesium-135 exists in the direct grout waste stream than in the reference salt supernate stream. Cesium-135, with a half-life of 2.3 × 106 years, can be expected to be a contributor to radiation doses for long times following disposal. Cesium-137 also has a similarly higher concentration in the direct grout waste stream than in the reference waste stream. Although having a short half-life of 30 years, cesium-137 is present in such quantities that it will remain a major contributor to the dose for as long as 15 to 20 half-lives (450 to 600 years). Other radioisotopes of concern in long-term safety are not significantly higher in the direct grout waste stream than in the reference waste stream, although actinides in grout will present a long-term problem in meeting safety criteria. The salt supernate may also contain trace levels of hazardous metals (arsenic, barium, cadmium, chromium, lead, mercury, selenium, and silver), but Jones (2000a) notes that these metals will react with the slag components of the saltstone grout mixture to generate a reaction product that is insoluble. Other, more mobile toxic

|

1 |

The term “saltstone” is applied to the grout-salt supernate mixture (a blend of fly ash, slag, and portland cement with the salt supernate) after it is poured into the concrete vaults and cured. |

FIGURE 7.1 Schematic flow sheet for processing high-level tank waste at Savannah River using the direct grout option.

chemical constituents (primarily nitrates and nitrites) are expected to be present in similar concentrations to those evaluated and found acceptable by Martin Marietta Energy Systems, Inc., et al. (1992). Therefore, they are not expected to present a significant safety issue.

Jones (2000a) noted that the mixing of the direct grout supernate waste stream with the grout-making materials results in a dilution of the salt supernate by a factor of 1.8. Thus, the cesium-137 in the grout can be calculated to be about 2.2 × 108 nCi/L.

TABLE 7.1 Comparison of the Reference Salt Supernate Waste Stream, Direct Grout Salt Supernate Waste Stream, and Current State Permit Limits for the Saltstone Facility

|

Waste Component (half life, years) |

Reference Salt Supernate Streama |

Direct Grout Supernate Streamb |

Current State Permit Limitsc |

|

Sodium salts (nitrate, nitrite, sulfate, aluminate, phosphate, carbonate) and NaOH |

4.5-5.0 molar |

5.8 molar |

no limits |

|

Cs-135 (2.3 × 106) |

5.3 × 10-2 nCi/L |

8.0 × 102 nCi/L |

no limits |

|

Cs-137 (30) |

2.7 × 104 nCi/L |

4.0 × 108 nCi/L |

1 × 106 nCi/L |

|

Sn-126 (105) |

1.8 × 102 nCi/L |

2.2 × 102 nCi/L |

no limits |

|

Tc-99 (2.1 × 105) |

8.9 × 104 nCi/L |

1.1 × 105 nCi/L |

3 × 105 nCi/L |

|

Total alpha activity |

0.4 nCi/g (4.8 × 102 nCi/L)d |

limit <20 nCi/g |

10 nCi/g |

|

a Nominal concentrations in salt supernate stream generated from the planned (and now abandoned) in-tank precipitation process and treatment with MST (Martin Marietta Energy Systems, Inc., et al., 1992, Tables 2.6-1 and 2.6-2, nominal blend; Stevens, 1999, b Nominal concentrations in salt supernate stream that has not been treated with the in-tank precipitation process but has been treated with MST (Stevens, 1999, p. 9). Limit for total alpha activity in the salt supernate set by SRS at <20 nCi/g to meet the limit of 10 nCi/g for the saltstone disposal facility vaults (Jones, 2000b). c Limits from the wastewater permit issued by the South Carolina Department of Health and Environmental Control (SCDHEC). For radionuclides, SCDHEC requires that the average saltstone concentration not exceed the limits for Class A low-level waste as defined by the U.S. Nuclear Regulatory Commission (USNRC) in Code of Federal Regulations, Title 10, Part 61.55 (10 CFR 61.55). d Value in nCi/L from Martin Marietta Energy Systems, Inc., et al. (1992, Table 2.6-2); value in nCi/g = nCi/L ÷ 1230 g/L (density of reference salt solution) (J. Sessions, Westinghouse Savannah River Company, personal communication, May 23, 2000). |

|||

OBSTACLES TO SUCCESSFUL IMPLEMENTATION

The SRS views the primary obstacles to success of the direct grout option to be potentially major regulatory and political ones as opposed to technical problems (Westinghouse Savannah River Company, 1999a). Successful implementation of this option would depend on SRS's ability to surmount, at a minimum, the following two challenges:

-

the ability to obtain an incidental waste declaration for the direct grout supernate (Appendix D); and

-

the ability to obtain a permit from the State of South Carolina Department of Health and Environmental Control (SCDHEC) to allow higher concentrations of radionuclides to be disposed of in the saltstone disposal facility.

Surmounting these challenges is viewed by SRS as highly uncertain (Westinghouse Savannah River Company, 1999a).

Waste resulting from reprocessing spent nuclear fuel that is determined to be incidental to reprocessing (Appendix D) can be managed as transuranic (TRU) or low-level waste, depending of the radionuclide composition of the waste. If the high-level waste at SRS were to be declared as incidental and to be processed to remove strontium and actinides (for example, by using MST as shown in Figure 7.1), the supernate could then be managed as low-level waste. Incidental waste must meet the following three criteria to be classified as low-level waste (U.S. Nuclear Regulatory Commission, 1999):

Criterion 1: The waste must receive processing to remove key radio-nuclides to the maximum extent that is technically and economically practical.

Criterion 2: The waste must be shown to be managed to meet safety requirements comparable to the performance objectives set out in 10 CFR Part 61, Subpart C.

Criterion 3: The waste must be incorporated in a solid form at concentrations that do not exceed the concentration limits for Class C commercially generated low-level waste. However, the U.S. Department of Energy (DOE) may establish alternative requirements for waste classification and characterization on a case-by-case basis.

Radionuclide concentrations for the direct grout option calculated by SRS might in some cases exceed the current state permitted limits for the saltstone facilities (see value for cesium-137 in Table 7.1). To implement this option, a change in permit would also be necessary (Stevens, 1999). It is not clear whether regulators and the public would be willing to permit onsite disposal of the waste even if it were declared as incidental. Jones (2000a) noted that, under the permit for the saltstone disposal facility issued by SCDHEC, the average concentration for saltstone must not exceed the limits currently specified by the USNRC for Class A radioactive low-level waste. The direct grout option would be intended to produce Class C low-level waste (see Table 7.2).

Finally, there may be an internal DOE barrier to the selection of this option in any but as a last-resort case. A portion of the cesium-containing waste stream to be removed from the high-level waste supernate is planned for use in DOE's program to immobilize excess weapons-grade plutonium at SRS2. If the direct grout option were selected, cesium (or some other highly radioactive material) for the immobilization program might have to be obtained from another source (e.g., the cesium capsules stored at the Hartford Site in Washington).

|

2 |

Under current plans, plutonium will be formed into ceramic forms (puck-shaped) and placed into steel cans. These cans will in turn be placed inside DWPF canisters, surrounded with molten high-level waste glass, and sealed. The cesium from the high-level waste will be incorporated into this glass to provide a radiological barrier against theft and clandestine use of the plutonium (see National Research Council, 1999a). |

TABLE 7.2 Limits for Class C Low-Level Waste

|

Waste Component (half life, years) |

Class C Low-Level Waste Limitsc |

|

Sodium salts (nitrate, nitrite, sulfate, aluminate, phosphate, carbonate) and NaOH |

no limits |

|

Cs-135 (2.3 × 106) |

no limits |

|

Cs-137 (30) |

4.6 × 109 nCi/L |

|

Sn-126 (105) |

no limits |

|

Tc-99 (2.1 × 105) |

3 × 106 nCi/L |

|

Total alpha activity |

100 nCi/g |

|

SOURCE: Code of Federal Regulations, Title 10, Part 61, Subpart C. |

|

ANALYSIS

The direct grout option could be implemented with currently available technologies. The SRS has already demonstrated that it can process salt supernate from the ITP process to make grout (see Chapter 4). Because cesium is in the supernate, the saltstone production facility would need to be upgraded for possible maintenance and failures of the processing and transfer systems in a highly radioactive environment, but the committee believes that the necessary shielding and remote handling technologies are available for this application. Thus, the committee sees no significant technical hurdles to the implementation of this option unless the concentrations of radionuclides and their total amount in the grout exceed the limits for Class C low-level waste. The committee understands that there remains a fundamental issue as to whether 10 CFR Part 61 can be reasonably applied to wastes that incorporate the large inventory of cesium that would be present, about a thousand times larger than what was considered in the environmental impact statement analyses for Part 61. The total cesium-137 activity in the approximately 5.2 × 105 cubic meters of grout that would be produced would be about 210 million curies3 (Stevens, 1999, p. 9-10).

The committee views the regulatory hurdles as probably insurmountable at this time, especially with respect to the incidental waste determination. To declare the waste as incidental (see Appendix D), DOE Order 435.14 requires that the “waste must receive processing to remove key radionuclides to the maximum extent that is technically and economically practical ” (italics added for emphasis). A decision to declare the waste as incidental would

|

3 |

This value is inconsistent with the total amount of Cs-137 (89 × 106 Ci) in the soluble radionuclides in the tanks as reported by Fowler (2000) and shown in Table 1.2 of this report. |

|

4 |

DOE Order 435.1 (entitled Radioactive Waste Management) sets out the criteria and requirements used to manage and dispose of DOE-generated or DOE-controlled waste. |

represent a regulatory affirmation that processing options to remove the cesium are technically and economically impractical. This DOE order requires that the evaluation process be well documented and provide clearly traceable argument that alternative approaches eliminated are not practical.

The work to date by SRS seems, at this stage, to indicate just the opposite. That is, the documentation reviewed by the committee indicates that SRS views cesium removal as practical, using the small tank tetraphenylborate (TPB) process, but the committee notes that costs associated with cesium removal are slightly more than those associated with the direct grout option (Independent Project Evaluation Team, 1999; Stevens, 1999). Regardless of the committee's opinion of the validity of those conclusions, the fact remains that, from a regulatory perspective, current documents provide evidence that it is technically practical to treat the high-level waste at SRS to remove cesium. As such, if the cesium removal process selected can be shown to be, in the words of DOE Order 435.1, “economically practical,” the waste cannot be declared as incidental waste, and therefore, the direct grout option cannot be implemented under current conditions.

If, in the future, SRS is not able to implement the current primary and backup cesium processing options for technical or economic reasons, then it might be possible to make a case that the salt supernate waste should be declared as incidental and to implement the direct grout option. At that point, however, SRS might face a number of additional and possibly insurmountable hurdles to implementation. A potentially significant hurdle is safety: SRS would have to demonstrate that the waste would meet the long-term performance objectives contained in DOE Order 435.1.

Cook (1998) has argued that it is likely that the performance objectives could be met (see Appendix E), assuming that the performance assessment5 used for the analysis is similar to that used for the Z-area saltstone performance assessment (Martin Marietta Energy Systems, Inc., et al., 1992; Westinghouse Savannah River Company, 1998b). Barring an actual analysis, however, the ability of the site to meet these performance objectives remains uncertain. The direct grout waste stream is unusually high in long-lived radionuclides for a near-surface disposal facility. In particular, the concentration of cesium-135 in the direct grout supernate waste stream represents a long-term safety concern.

Discussants at a joint National Research Council and DOE Workshop on Barrier Technologies for Environmental Management (National Research Council, 1997) identified two key problems relevant to buried waste that could impact the direct grout option: (a) insufficient knowledge of effective lifetimes for barrier materials and systems, and (b) a dearth of barrier performance monitoring data. However, the material to be interred in the saltstone disposal facility would be a processed, solidified waste, unlike the materials typically found in radioactive waste burial sites. Other factors that must be considered in analysis of the direct grout option, especially over the long

|

5 |

The performance assessment estimates long-term saltstone behavior by assessing the probability and consequence of major scenarios by which radionuclides can be released to the environment. |

periods of time that wastes will exist, include stability of the thermally loaded grout and the concrete vault, possible leaching of radionuclides into the surrounding soil and groundwater, variability of the climate and the water table, natural hazards such as earthquakes and floods, and institutional stability and human intrusion.

FINDINGS AND CONCLUSIONS

Based on the foregoing discussion, the committee identified three findings and conclusions with respect to the direct grout option:

-

The committee has identified a potential major obstacle to implementation of the direct grout option: the level of cesium-137 that would be incorporated in the grout is several orders of magnitude higher than the current state permit limits (see Table 7.1), based on average tank compositions (see Chapter 8). Nevertheless, this option has the fewest technical uncertainties of the four options currently under consideration by SRS.

-

The major obstacles to implementation of this option appear to be regulatory and political. First, the committee believes that it is unlikely that the direct grout waste stream could be categorized as “incidental” given that current SRS documents provide evidence that the waste is practically and economically treatable. Second, it is not clear whether regulators and the public would be willing to permit onsite disposal of this waste even if it met incidental waste criteria.

-

The direct grout waste stream is unusually high in long-lived radionuclides for a near-surface disposal facility. The ability of the site to reliably meet long-term safety performance objectives remains uncertain.

RECOMMENDATIONS

Based on these findings and conclusions, the committee offers two recommendations, directed primarily at top-level DOE managers:

-

The direct grout option should be considered as an option of “last resort.” It should be used only in case all of the other cesium processing options under consideration by SRS prove to be technically or economically impracticable and after reexamining other potentially viable options that had been previously discarded. The direct grout option should not be discarded, however, until another option has been implemented successfully.

-

DOE should hold preliminary “good faith” discussions with regulators, the SCDHEC and the U.S. Nuclear Regulatory Commission, to determine whether onsite disposal of incidental waste would be possible should the other cesium processing options be found to be impractical. Given DOE's concerns about the tight schedule for the cesium separations program in light of its tank space management problems (see Chapter 1 and Chapter 8), DOE will

-

need to move expeditiously to implement the direct grout option should the other options fail. Therefore, these preliminary discussions should begin immediately. Before considering implementation of the direct grout option, a thorough performance assessment would have to be conducted to determine its feasibility.