8

Barriers to Implementation of HLW Salt Processing Options

The focus of this concluding chapter is on the third charge of the committee's statement of task (see Chapter 1): “Are there significant barriers to the implementation of any of the preferred alternatives, taking into account their state of development and their ability to be integrated into the existing Savannah River Site (SRS) high-level waste (HLW) system?” Many of the research and development (R&D) barriers to implementation of salt processing alternatives were addressed in Chapter 3, Chapter 4, Chapter 5, Chapter 6, Chapter 7, and will not be repeated here. Instead, this chapter focuses on what the committee considers to be two “global” challenges for selecting and implementing a salt processing alternative: (1) systems integration, and (2) program management.

SYSTEMS INTEGRATION

HLW salt processing is a single but key component of a much larger HLW processing system (see Figure 1.2), and the option(s) selected for processing the HLW salts must be fully compatible with the other system components. The U.S. Department of Energy (DOE) recognized the importance of systems engineering1 to the success of the salt processing program when it asked the committee to comment on systems integration in this third charge. Given the abbreviated schedule for this project, the committee did not have an opportunity to perform a detailed analysis of the HLW system at SRS or the potential for integration of the candidate processing options into that system. The committee did, however, gather much information on this issue through its oral and written communications with SRS staff throughout the course of this study. Much of this information is presented in Chapter 3, Chapter 4, Chapter 5, Chapter 6, Chapter 7, of this report. Based on this information, the committee concludes that

|

1 |

See Systems Analysis and Systems Engineering in Environmental Remediation Programs at the Department of Energy Hanford Site (National Research Council, 1998) for a good discussion of systems engineering concepts. |

systems integration is not adequately implemented in the HLW salt processing options program at SRS.

The committee observed that cesium, strontium, and actinide processing are being treated as individual issues rather than as components of a fully integrated engineered system. The committee did see some evidence that systems engineering approaches are being used at SRS —for example, SRS is considering the potential impacts of waste stream feeds to the Defense Waste Processing Facility (DWPF) in its evaluation of processing options. However, other essential aspects of a systems engineering approach were lacking, especially the integrated consideration of alternative flowsheets for processing the HLW salt solutions.

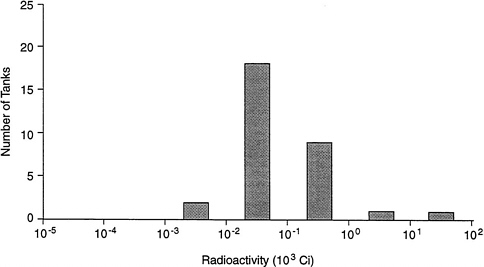

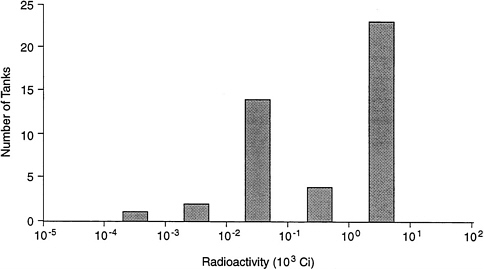

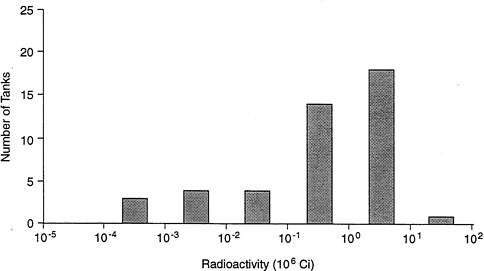

The following example perhaps best illustrates the committee's conclusion on this point: As the committee became better acquainted with the HLW system at SRS, the members realized that the tank wastes were more variable in chemical and radionuclide compositions than they had been led to believe initially. The compositional differences are caused by differing inputs to the tanks from reprocessing operations (see Chapter 1) over the years and by subsequent tank transfers and processing operations. In fact, the tanks contain variable quantities of sludge, saltcake, and supernate, and radionuclide concentrations can vary from tank to tank by several orders of magnitude. This variability is illustrated for some key radionuclides in Figure 8.1, Figure 8.2, Figure 8.3.

FIGURE 8.1 Histogram showing the variation of strontium-90 activity in soluble radionuclides in the high-level waste tanks at Savannah River. SOURCE: Data from Fowler (2000); see Table 1.2 of this report.

FIGURE 8.2 Histogram showing the variation of alpha activity in soluble radionuclides in the high-level waste tanks at Savannah River. SOURCE: Data from Fowler (2000); see Table 1.2 of this report.

FIGURE 8.3 Histogram showing the variation of cesium-137 activity in soluble radionuclides in the high-level waste tanks at Savannah River. SOURCE: Data from Fowler (2000); see Table 1.2 of this report.

These observed intertank variabilities led the committee to pose the following questions about implementation of each salt processing option:

-

Should all tanks be subject to the same processing operations? Although the average concentrations of soluble radionuclides in the tank waste appear to be above saltstone limits (see Table 7.1), the concentrations of soluble radionuclides in some of the tanks (see Table 1.2) fall below the supernate waste stream limits for the saltstone facility—suggesting that the contents of some tanks could be sent directly to grout with little or no radio-nuclide removal. Thus, instead of blending tank wastes to produce a feed that might allow all tank contents to be treated by a single process, as is now planned, would it be advantageous to tailor processing based on chemical and radionuclide contents of individual tanks? For example, could tank wastes with little or no cesium be processed only to remove strontium and actinides—essentially, the direct grout option discussed in Chapter 7? Alternatively, could tank wastes with low strontium and actinide concentrations be processed only to remove cesium? Indeed, could tank wastes with low actinide, strontium, and cesium concentrations be sent directly to the saltstone facility after minor waste conditioning (e.g., filtration)?2 Although this tailored approach might require additional regulatory approval and perhaps some facility modifications (e.g., the construction of additional waste transfer lines), it might allow the tank wastes to be processed on a faster schedule, thereby reducing costs and freeing up tank storage space for ongoing HLW processing operations. Indeed, using this approach, SRS might be able to process some tank wastes before a cesium processing option is selected and implemented, because the saltstone facility already exists. Once a cesium processing option is implemented, SRS could focus its processing efforts on the high-cesium tanks, which would produce the cesium feed stream that may be used later this decade to immobilize excess weapons plutonium.

-

Should the actinide and strontium processing step be performed prior to cesium removal? Only for the tetraphenylborate (TPB) process have advantages been presented by SRS for the MST operation as a front-end step (see Chapter 3). For other process options, the committee sees no advantages in removing these radionuclides in a front-end operation and believes that there may, in fact, be a significant disadvantage: shielding requirements are higher, thereby increasing the hazard, cost, and time of processing. The removal of cesium in a front-end step could result in much reduced radiation fields, allowing strontium and actinides to be removed in a smaller, less expensive facility. As noted previously, the MST processing step might be skipped altogether for tank wastes with low strontium and cesium concentrations.

Recommendation: SRS should implement a more fully integrated systems engineering approach for processing HLW salt solu-

|

2 |

Dilution of the supernate during salt processing operations could further reduce the radionuclide concentrations shown in Table 1.2, thereby allowing more tank waste to be sent to the saltstone facility without the need for extensive radionuclide separations. |

tions. To this end, SRS should consider (1) tailoring the processing operations to tank waste contents, with the goal of reducing processing time and costs and freeing up tank space, and (2) changing the order of processing to remove radionuclides from the HLW salt solutions, with the goal of reducing processing hazards, costs, and time.

PROGRAM MANAGEMENT

As noted in several chapters of this report, the committee has concluded that SRS generally appears to have a good understanding of the technical uncertainties that must be resolved before a HLW salt processing option can be implemented, and the committee has recommended approaches to and conduct of R&D work to resolve these uncertainties. Assuming that this R&D work is adequately funded and the appropriate people are identified to perform this work, the main barrier to the successful implementation of a salt processing option then involves two management issues: (1) ensuring that the R&D work stays properly focused on the right problems; and (2) ensuring that the salt processing program uses the information gathered by the R&D program to make appropriate selection and implementation decisions. The remainder of this chapter addresses these issues.

The experience with in-tank precipitation (see Chapter 4) illustrates how unanticipated technical “surprises” can upset even seemingly well-planned projects. Given the large volume and the chemical complexity of tank waste at SRS, such unexpected problems are possible and perhaps even likely in the future. Consequently, a primary objective of the R&D program on alternatives should be to bound performance over the range of waste and operating conditions likely to be encountered during future processing operations. This will enable engineers to design and implement a process that can accommodate such future surprises without major upsets to the high-level waste system.

The R&D program will likely be conducted at several sites across the country, and competent technical leadership will be required to ensure that this program is properly focused and coordinated. The committee does notbelieve that the R&D program management should reside solely at SRS,because that site does not have the full range of technical capabilities required to direct and evaluate the required R&D work. The committee had contact with many technical staff at SRS during the course of this review and found them, on the whole, to be a capable and dedicated group. Nevertheless, considerable experience is present at several other DOE sites (e.g., experience with cesium removal at Hanford Site and Oak Ridge National Laboratory). SRS should take greater advantage of this knowledge and experience. This work has been and will most likely continue to be carried out at a number of companies, universities, and national laboratories. The committee believes that the personnel who oversee and evaluate this work should have the similar range of technical expertise as the experts who actually perform the R&D. DOE Order 435.1 specifies that leadership and responsibility for

waste management at this site resides at SRS, but close cooperation must be in place between the site and DOE Headquarters to achieve some of these objectives.

Recommendation: The committee recommends that SRS charteran external technical oversight group to guide, evaluate, and provide direction to the R&D to be carried out under this program. The groupshould have the same range of technical expertise as those performing the R&D work. Group members should be selected based on technicalknowledge and R&D experience and should, to the extent possible, befree from professional and organizational conflicts of interest. Thisgroup should be chartered to keep the R&D focused on resolving thetechnical uncertainties with the processing options so that the down-selection process can proceed in a timely manner.

Similarly, the committee believes that strong and technically informed programmatic management will be needed to select and implement a HLW salt processing option at SRS. The committee understands that the salt processing program at SRS is under pressure to implement a processing option as soon as possible. Each year of program slippage has the potential to: (1) add almost $400 million to the project cost, merely from the expense of operating and maintaining the tank farms in their current condition; (2) increase the potential hazards posed by leaks to the environment from aging waste tanks; and (3) increase the likelihood that the site will run out of tank space, requiring either a curtailment of HLW operations or initiation of an expensive program to construct additional tanks.

The committee recognizes the inevitable conflicts between the objectives of taking adequate time to conduct sufficient R&D to ensure that the processing option(s) selected will do the job well, and the competing objective of completing the project in the shortest time at the most reasonable total cost. The committee also recognizes the complications introduced into R&D planning and execution by the annual budgeting system used by the U.S. government. Neither the high-risk-of-failure option (“go quickly”) nor the zero-risk-of-failure option (“wait until all needed data are obtained, even if it takes forever”) can be allowed to prevail. The challenge is to manage the R&D program, hot and cold demonstration testing, pilot plant operation, and process selection and implementation in ways that minimize total costs without incurring unacceptable risks, either safety or fiscal.

The successful implementation of a processing option will require strong and technically informed management of the HLW salt processing program. The committee did not see such management in place at SRS during the course of this study. Indeed, as the study progressed, it became increasingly difficult to determine who was in charge of managing this program. In the committee's view, such management is best provided by a team of experienced technical managers.

Recommendation: DOE and SRS should appoint an appropriately expert technical team with the responsibility and authority with adequate funding to manage the HLW salt processing program. This team should be charged with assuring that R&D and analysis of the alternate processing options are carried out as long as needed to reduce risk to an acceptable level—but no longer. The team should decide when enough information is available to allow selection or exclusion of any process, what demonstrations —hot or cold—should be conducted, what pilot plants are needed, and if so, when. The team should also be responsible for selecting the size and throughput of the production facility, since that decision also impacts both costs and risks.