23

Manufacturing Knowledge and the Arrow of Time

Eugene S. Meieran

Intel Corporation

Although it is difficult to understand the increasingly complex and ever-expanding manufacturing arena, it is essential for a company’s success. The manufacturing process has many facets, and, with the added complexity of globalization of this capability, a company must have a clear and concise path to follow in order to ensure that it remains competitive. One approach to managing this complex environment is to relate things to the different timelines that are important to different stakeholders. For example, university research on future manufacturing needs may have a 3- to 6-year window of opportunity, whereas a factory manager may have a 0- to 1-year window of opportunity for improving day-to-day operations. To put it another way, researchers into manufacturing technology search for the perfect answers whenever. Because time-to-money is increasingly important in manufacturing, however, things need to happen quickly, and manufacturing managers typically search for good enough solutions to their problems now. Time is relative to these two perspectives and the question in this specific situation is how we close the gap between what is perfect and what is good enough.

MANUFACTURING PROCESSES AND TIME

Another way to think about timelines in manufacturing is to consider manufacturing as a process where people operate processing equipment, with the results of this process being the manufactured products. This process has a direct flow, from beginning to end, and the product increases in complexity as the process is carried out. This process is also irreversible, as in the case of entropy, where, for example, if you drop a glass and it breaks, the flow cannot be reversed. Time flows in one direction, from the start of the process to its completion.

The link between the fact that time is relative to different people involved in manufacturing, and the flow of time from the beginning of the process to the end, lies in the expansion of the information universe in which much of the manufacturing processes occur. As in the expanding physical universe, where galaxies and other stellar entities are moving apart at a high rate, the virtual universe is expanding and the manufacturing entities in the virtual universe are moving apart. While the force that holds the physical universe together, gravity and the exchange of gravitons, is not well understood and the future of the physical universe is not known, the “force” in the virtual universe can be thought of as knowledge. Because the exchange of data, or information knowledge, is possible, it is possible to control the complexity and expansion in manufacturing.

New technologies being continuously developed can help us to control our manufacturing destiny. This is important because in our expanding virtual universe, interdependency and interaction between knowledge objects is increasing. The volume of data, information, and knowledge inhabiting this space is also increasing. These interdependencies result in an increasing impact on manufacturers and customers in terms of cost, quality,

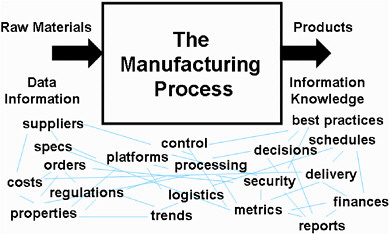

FIGURE 23-1 Illustration of real and virtual manufacturing transformations.

performance, and time.

DATA, INFORMATION, KNOWLEDGE, AND WISDOM

The distinction between data, information, knowledge, and wisdom is important. For example, raw data in a table do not appear to be very useful. We do not know what the numbers mean. Additional reference material can turn data into useful information, for instance, by arranging it spatially into a map.

In the same way, additional information can lead to knowledge, for example, directions from one place to another on the map. The last application to this process is wisdom, which we define as expertise applied to knowledge. For example, a “wise” person could inform us that at rush hour we should use Ray Road rather than Chandler, or that there is a speed trap at Rural and Chandler. This adds richness to the travel guide.

With these definitions in mind, we can now look at the manufacturing process. Figure 23-1 illustrates manufacturing as a transformation: in real space, a transformation of raw materials into products, and, in virtual space, a transformation of data into knowledge or wisdom. The data, information, and knowledge involved in the manufacturing process increase in volume and are interrelated. There are no boundaries between what were once considered to be independent “buckets.” As a result we must continuously create, develop, deploy, categorize, store, apply, and recreate the systems to handle the voluminous data, information, knowledge, and wisdom that apply to and relate these activities to one another. Fortunately, new information and knowledge management technology enables us to do this.

PROBLEMS AND OPPORTUNITIES FACING MANUFACTURERS

With the ever-growing complexities presented in the manufacturing process it is critical to understand both the problems and the opportunities facing manufacturers today. Significant

problems facing manufacturers include decreasing time-to-money, with a resulting need for speedy responses to manufacturing issues; increasing susceptibility to attack and/or security breaches, making swift responses absolutely necessary; a more volatile workforce as a result of globalization and expansion; the exponentially increasing volume of data, information, and knowledge noted above that must be formatted, controlled, and distributed properly and effectively; obsolete and legacy systems that make it difficult to expand, evolve, or grow in an efficient manner; an absence of a well-thought-out architecture or plan, resulting in new pieces of functionality simply being attached to the existing structure; and strong, agile, and globally distributed competition.

At the same time, opportunities in manufacturing are constantly emerging. Lower-cost processes and faster technologies to cope with legacy environments are becoming readily available. Interoperability and testbed standards allow us to figure out how to make all the systems work together. New approaches in learning technologies and teaching bring people into manufacturing and train them or take people already in manufacturing and retrain them with the new technology. New collaboration capabilities exist, both virtual and real. This new type of collaboration creates a whole new environment. New materials are continuously being developed, and faster computers and better communication capabilities make it easier to design complex products.

Globalization can be defined as the physical separation of people, e.g., by distance and time zones, and the virtual separation of people due to culture, values, and languages. Collaboration technology can be applied to issues arising from globalization, but this begs the question of how people collaborate in the first place. How does electronic/virtual collaboration differ from face-to-face meetings or audio conferences? New types of collaboration will generate new norms and new societies. These exciting issues must be addressed in order to continue on the path of successful manufacturing.

Fortunately, there are many resources available to the manufacturing community, including:

-

Academia (universities, community colleges);

-

National labs;

-

Consortia (partnerships between industry, national labs, academia);

-

Suppliers;

-

Internal expertise; and

-

Professional societies.

The difficulty arises in linking these collective sources of expertise together rather than just summing up each individual’s knowledge. The establishment of a resource for sharing expertise would enable projects to be undertaken more productively and efficiently.

IMPORTANCE OF ARCHITECTURE AND PLANS

In order to achieve the desired outcome of efficient manufacturing processes, a defined architecture/plan must be developed. An example is the Winchester Mystery House, built by the wife of the inventor of the Winchester Repeating Rifle. Additions to this house were haphazard and were made without any specific plan (it was believed that as long as the house was under construction, Ms. Winchester would not pass away). The house is a maze of different shapes and functions, with redundancy, poor connectivity, random and useless stairways, doors leading

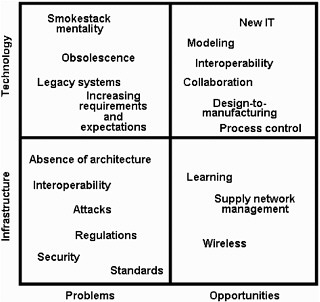

FIGURE 23-2 Information management issues related to creating an integrated architecture for improving manufacturing performance.

nowhere, and windows opening onto blank walls. It is possible to live in this house, but it is not a very functional or efficient design. Westminster Abbey, on the other hand, is a well-known and beautifully designed structure. Construction of Westminster Abbey took years of preparation and planning with a clear focus on architecture and function. It is considered to be an efficient use of space and an inspiring building. Too often, our approach in manufacturing is to build suites of applications reminiscent of the Winchester Mystery House, with patchy and inefficient interfaces. Our effort should be to develop a Westminster Abbey-type approach, with a truly integrated and well-thought-out architecture.

Figure 23-2 illustrates some of the information management issues related to the creation of an integrated architecture. The elements in the matrix represent knowledge objects that should be addressed in order to improve manufacturing performance. This matrix points to the following manufacturing issues (not prioritized) that must be addressed in order to improve performance:

-

Interoperability/interoperability standards;

-

Pervasive and adaptive process control;

-

Advanced learning technology;

-

Global collaborative capabilities;

-

Enterprise-wide supply network management;

-

Knowledge management and navigation tools;

-

Security and other protection systems;

-

Modeling and simulation technology;

-

Wireless and remote communication;

-

Software to enhance moving from ideas to products; and

-

Incorporating intelligence into processes and products.

CONCLUSIONS

Manufacturers are facing significant issues such as equipment and process obsolescence; sophisticated competition; globalization of customers, facilities, and suppliers; rapid change; increasingly complex human factors; and increasingly complex products, logistics, and processes. These issues must be addressed and resolved by a company if it is to remain competitive. Fortunately, emerging manufacturing technologies and capabilities can help address these issues and open the door for new opportunities. In particular, data, information, and knowledge management capabilities will enable leveraging of these opportunities to handle ever more complex manufacturing processes. Indeed, such capabilities provide the foundation for a new manufacturing paradigm. Previously, manufacturers depended heavily on the creation and distribution of energy and power, as well as on product movement. Today, manufacturers exist in an era of knowledge, wisdom, and information creation and distribution.

Manufacturing operations use as much information as they do raw materials and create at least as much knowledge as they do products. Our expanding use of data, information, and knowledge appears to be the only way to cope with the exploding complexity and interdependencies within the physical manufacturing environment. Emerging information technologies appear able to satisfy most foreseeable manufacturing needs. To be successful, however, requires collaboration between laboratories, suppliers, universities, competitors, manufacturers, and funding agencies. Highly competitive manufacturing must also be highly cooperative manufacturing. Even modest investments in crosscutting technologies, infrastructure development, research and development, and collaboration can have a significant impact on our leadership position and economy.