H

Report of the Panel on Benefits of Fuel Cell R&D

The report presented in this appendix is the product of an expert panel convened by the NRC’s Committee on Prospective Benefits of DOE’s Energy Efficiency and Fossil Energy R&D Programs. The charge to the panel was to complete the preliminary prospective benefits matrix using the guidance from the committee as described in Chapter 2 and Appendix E. The panel had considerable flexibility in determining how to fulfill this charge. This appendix summarizes the panel’s findings on the methodology and process.

Although a member of the committee chaired the panel, the full committee did not participate in the work of the panel. Rather, the committee reviewed the findings of all three of the panels formed for the purpose of this study1 as the empirical basis for developing the methodology and process that the committee recommends in Chapters 3 and 4 of its full report. As a result, the committee’s recommendations may not reflect the specific suggestions or findings of an individual panel.

The committee wishes to emphasize the following points:

-

The three panels did not apply the methodology recommended in Chapters 3 and 4. The committee’s recommended methodology will be applied in Phase Two of this project.

-

The panel reports were prepared for the sole purpose of developing the methodology. As a result, the panel reports are not complete or systematic evaluations of program benefits and should not be interpreted as such.

STUDY SCOPE AND FORMATION OF SUBPANELS

The Panel on Benefits of Fuel Cell R&D evaluated only a portion of the full suite of applied R&D activities related to fuel cells at DOE. A subpanel on vehicle applications was formed to evaluate the fuel cell activities in the Office of Energy Efficiency and Renewable Energy (EE) that included vehicle fuel cell applications but not EE activities involving the distributed generation applications of polymer electrolyte membrane (PEM) fuel cells. The total annual funding requested by the administration in FY 2005 for EE vehicle fuel cell activities was $70 million.2 Likewise, a subpanel on stationary applications was formed to evaluate the $35 million of annual funding for the Solid-State Energy Conversion Alliance (SECA).3 (Total funding for stationary fuel cell activities within the Office of Fossil Energy [FE] was $69 million in FY 2004.)

The findings of the two subpanels will be discussed in their individual reports, presented below. Each subpanel’s report is responsive to the following statement of task:

1. The members of the panel will familiarize themselves with the relevant DOE programs, including the expected progress of the technologies under development, the markets they are intended to enter, and private sector R&D programs whether or not they cooperate with DOE. They will also examine any estimation of benefits provided by DOE.

2. Then the panel will estimate the probability of technological and economic success of the various fuel cell projects under current funding projections. Insofar as possible, they shall also examine alternative funding levels and resulting changes in the rates of progress and the probability of success. The panel shall also note what other development programs must be successfully completed for fuel cells to be successful in the market.

3. The panel shall also estimate how credit should be apportioned between DOE and the private sector’s R&D programs,

|

1 |

The reports of the other two panels—the Panel on Benefits of Lighting R&D and the Panel on Benefits of Sequestration R&D—appear as Appendixes F and G, respectively. |

|

2 |

Patrick Davis, U.S. Department of Energy, “Fuel Cell Subprogram,” Presentation to the panel, July 20, 2004. |

|

3 |

SECA comprises six industry teams that individually plan to commercialize solid oxide fuel cell systems to predefined markets. Additional funding for SECA is provided in program areas outside of the fuel cell activities, for a total of $47 million for SECA-related activities. |

assuming the new technologies are developed and marketed successfully. This exercise should consider the impact of the DOE contributions on when the technologies enter the market as well as the probability of overall success. Insofar as possible, the panel shall perform this exercise for the alternative funding levels considered in Task 2.

4. The panel will then apply the committee’s methodology to estimate the value of the benefits of DOE’s fuel cell R&D programs under several scenarios to be provided by the committee, including economic, environmental, and national security benefits. Environmental and national security benefits may be left in physical units (e.g., tons of emissions or barrels of oil imported) or just described if the economic values have not been determined by the committee. Insofar as possible, the panel shall perform this exercise for the alternative funding levels considered in Task 2.

5. The panel will prepare a report for the committee detailing its analyses, supporting the conclusions, and commenting on the practicality and adequacy of the methodology used to estimate benefits.

REPORT OF THE VEHICLE FUEL CELL SUBPANEL

Objective of Study and Statement of Work

The Panel on Benefits of Fuel Cell R&D assisted the Committee on Prospective Benefits of DOE’s Energy Efficiency and Fossil Energy R&D Programs with the development of a methodology for estimating the benefits of applied R&D. The methodology is to be used for prospectively estimating the benefits of ongoing R&D programs and was developed initially by the committee. The work of the committee is a follow-on to the NRC report Energy Research at DOE: Was It Worth It? (NRC, 2001),4 concerned with retrospectively estimating the benefits of DOE R&D funded between 1978 and 2000.

In this subpanel report, the vehicle fuel cell subpanel estimates the benefits that could be provided by current fuel cell R&D activities at DOE related to vehicle applications. (Stationary applications are considered in the following subpanel report.) The subpanel further provides observations on the merits of the methodology itself, on the basis of the subpanel’s experience applying it to a real-world example.

The subpanel conducted meetings in Washington, D.C., on July 20-21, 2004, and August 18-19, 2004. These meetings included open, information-gathering sessions attended by DOE headquarters staff who briefed the panel on fuel cell R&D programs and resulting benefits. This report of the subpanel is based on information gleaned from these meetings, documents supplied by DOE, and the panel’s knowledge of the subject.

Prospective Benefits Matrix

Cautionary Note

The subpanel cautions against using the prospective benefits matrix that it completed for this study as anything more than an illustrative example of the methodology. The subpanel did not have the resources to generate its own data to evaluate benefits of the vehicle fuel cell program. Furthermore, the subpanel believes that to compare the benefits with the costs of the program requires that all elements of the Hydrogen, Fuel Cell and Infrastructure Technologies (HFCIT) Program5—including R&D on hydrogen production, distribution, and storage and R&D on fuel cells—be evaluated together because of their extreme interdependence.

Having completed its report, the subpanel views as valuable products its assessment of the probability of success for the technical goals of the relevant activities and its suggestions for improving the assumptions used as input to the Energy Information Administration’s National Energy Modeling System (NEMS) and MARKAL models. The subpanel commends DOE for having assembled a comprehensive R&D program, for already having taken measures to correct some of the overly optimistic assumptions that it has made in its benefits analysis, for including go/no-go decision points; and for pursuing R&D in important areas that have received limited attention to date.

Technical Probability

Table H-1 lists the technical goals established by DOE for achieving a production- and market-ready fuel cell vehicle by 2015. Table H-1 also gives the subpanel’s estimates of the probability of success (high, medium, or low) and the reasons for these estimates. Most of the goals appear appropriate, except for the efficiency and cold-start goals, as discussed below. The subpanel’s reservations relate mostly to the lack of data needed to convince its members that the goals will be achieved.

The greatest concerns with respect to technical probability are with cost and durability. The latest cost estimate for an 80 kilowatt (kW) direct compressed hydrogen fuel cell system is $145/kW, based on reduced membrane and platinum cost assumptions (TIAX, 2004). An almost fivefold reduction in cost is required to reach the target of $30/kW. Two components alone already add up to more than this—the membrane ($16/kW) and the electrodes ($22/kW)—and the subpanel has no data to make it optimistic that these costs

|

4 |

The methodology for estimating benefits retrospectively is described in Appendix D of NRC (2001). |

|

5 |

The HFCIT program resides within the DOE Office of Energy Efficiency and Renewable Energy and receives funding from both the Energy and Water appropriation and the Interior and Related Agencies appropriation. The portion of the HFCIT funding related to fuel cell systems derives from the latter. |

TABLE H-1 Fuel Cell Program Probability of Achieving Ultimate Goals

can be reduced sufficiently to meet the system-cost goal while achieving the necessary durability.

The subpanel set a low to medium probability of success for achieving the durability target (see Table H-1) because no test data at sufficiently severe temperature, duty cycle, and tilt conditions exist to give confidence that the target can be achieved given the sensitivities of current systems to freezing, aridity, impurities, and so on. However, DOE is planning such tests.

The cold-start target raises another concern. It should be set lower with respect to both time-to-start and temperature, and the freezing issue should be addressed head-on to ensure a viable product. Again, the subpanel was told that DOE has plans to address these problems. While the single-point efficiency goal appears likely to be met, an efficiency operating curve goal is needed for evaluating technical and market potential.

Targets for survivability, sensors, and compressors/expanders were not evaluated by the subpanel, as DOE did not supply experimental data.

Other important targets that have not been explicitly addressed by DOE are those for power electronics, electrical motors, and electricity storage devices. DOE stated that these items will be nonissues, as they are being developed for internal combustion engine hybrids. However, while significant progress has been made, the cost of these devices added to that of the fuel cell could make the final product economically unattractive. Also, targets for grade climbing and cabin heating have not been addressed. Finally, the $30/kW target includes hydrogen storage, another area that may require invention to achieve both the performance and cost targets; however, that area is outside the funding being examined here.

Market Probability

Hydrogen fuel cells have undeniable environmental and security advantages if hydrogen can be produced from domestic sources of renewable energy or fossil energy with technologies that handle the carbon dioxide (CO2) released during hydrogen manufacture. However, the security and environmental advantages are irrelevant to fuel cell market penetration, which will depend on the existence of regulatory constraints or government incentives. In a nonregulated market, fuel cells will have to compete first and foremost on cost. The $30/kW target recognizes this imperative, as it is comparable to the cost of internal combustion (IC) engines. Failure to achieve this target is a showstopper if energy prices remain low. Fuel cell vehicles must also provide performance and utility comparable to those of conventional vehicles. Government incentives and/or regulations that promote fuel cell vehicles at the expense of IC engine vehicles could affect market penetration.

Perhaps the greatest market risk for fuel cell vehicles involves the need for widespread availability of hydrogen at a reasonable cost. This is the real showstopper, which DOE is addressing as part of the HFCIT program. It is an enormous technical and financial challenge, which if not met will doom fuel cell vehicles.

Benefits

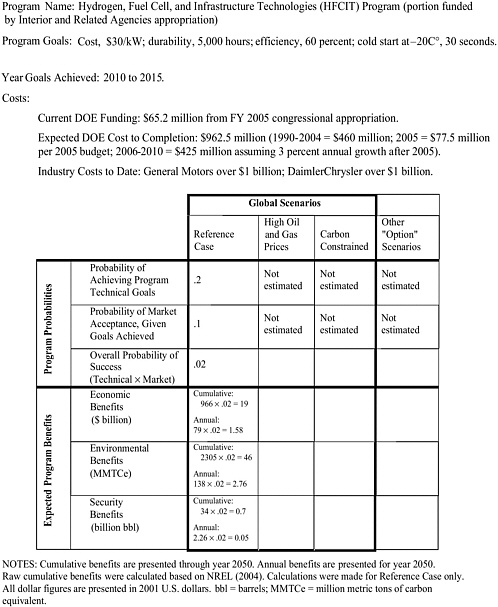

Because of time and resource constraints, the subpanel did not independently calculate benefits. Instead, it used the benefits computed by DOE using MARKAL, despite several concerns over the validity of these calculations for this exercise. The MARKAL model calculated benefits through 2050, by which time it was assumed that fuel cells would have penetrated 38 percent of the vehicle miles traveled and that hybrid vehicles would account for the bulk of the remaining vehicle miles traveled. The NEMS model calculates benefits only through 2025. The matrix (Figure H-1) provides both cumulative benefits and annual benefits in 2050 because the rationale for this program is to provide the means for drastically reducing CO2 emissions and U.S. vulnerability to oil supply shocks.

The subpanel developed the matrix subject to a number of assumptions, boundary conditions, and data limitations, as follows:

-

DOE assumed that all technical goals for the entire HFCIT program—including goals for fuel cell systems and hydrogen infrastructure and supply technologies—will be achieved; fuel cells will be production-ready by approximately 2015.

-

In calculations supplied to the subpanel by DOE, the oil savings and reductions in carbon emissions were evaluated using a scenario in which fuel cell vehicles were given unrealistic advantages over other alternatives, such as hybrid vehicles. (See further discussion later in this subsection.)

-

CO2 sequestration was not included in the calculations of the benefits supplied to the subpanel by DOE.

-

Program costs through 2005 are those provided by DOE for the fuel cell part of the HFCIT program only.

-

Future fuel cell program costs (budgets) to 2010 were estimated assuming 3 percent per year increase.

-

Anecdotal figures (from news articles) for industry R&D expenditures were used.

-

The probability of technical success was set equal to that for the technical goal with the lowest probability of success, 20 percent, for achieving the $30/kW cost target, as the cost probability was estimated assuming that other goals had been met.

-

The probability of market success was set at half that of technical success so as to reflect, among other things, the extreme difficulty of establishing a hydrogen production, distribution, and storage infrastructure. This probability is not based on an analysis of the hydrogen program.

-

Scenarios other than the Reference Case were not examined because data were lacking.

-

All figures are presented in 2001 U.S. dollars.

-

Cumulative benefits (2010 to 2050) for the program were calculated from a third-order polynomial fit of the data in Table 5.29 on page 5-19 of Projected Benefits of Federal Energy Efficiency and Renewable Energy Programs FY2005-2050 (NREL, 2004).

Unfortunately, the benefits calculated by DOE using MARKAL are overstated owing to the use of the following assumptions:

-

Fuel cell vehicles will, by 2040, have 3.4 times the fuel economy of conventional gasoline vehicles of the same vintage. DOE now believes that fuel cell vehicle fuel economy should be lower. Calculations with a new value will not be available until next year (2006) and should be based on consistent technology assumptions for conventional and hybrid vehicles.

-

Gasoline hybrid vehicles were assumed to have only 2.0 times the fuel economy of conventional gasoline vehicles of the same vintage. This automatically made fuel cell vehicles the winner, given their exaggerated fuel economy advantage—3.4 times that of conventional vehicles of the same vintage.

-

DOE’s analysis of the share of energy service demand that would be met by fuel cell vehicles, measured in vehicle miles traveled (VMT), was determined assuming a market in which competition with hybrid electric vehicles exists. For example, in 2050, the share of the VMT for fuel cell vehicles was 38 percent and for hybrid vehicles, 54 percent. In the subpanel’s judgment, DOE did not compare the benefits of the fuel cell program case against the correct baseline—that is, a case in which the next-best alternative succeeds. The

FIGURE H-1 Prospective benefits matrix for the vehicle fuel cell program.

-

subpanel believes that the calculation should be made by comparing a baseline case in which fuel cells do not exist and the next-best alternative is allowed to dominate the market, with a case in which fuel cells and other alternatives compete in the market—the latter case bearing a similarity to DOE’s fuel cell program case. The benefits of fuel cell vehicles in DOE’s analysis (NREL, 2004) were determined on the basis of the savings of the fuel cell portion of the market versus a baseline case in which the fuel economy of the light-duty vehicle fleet increased only 10 percent by 2050.

-

Dates assumed for the introduction of fuel cell vehicles were overly aggressive; DOE also plans to correct this problem.

-

Input assumptions were based on ensuring economic success at a 3-year payback rather than being derived from

-

the cost and performance goals of the program. Thus, rather than estimating the cost of the fuel cell vehicle power train, favorable ratios of fuel cell to conventional vehicle costs and other factors were assumed. A complete analysis of power train cost and performance is needed and appears to be under way at DOE. The results of such an analysis are required as input into the NEMS and MARKAL models.

-

The cost ratios assumed by DOE make little sense, because by 2050 both large and small vehicles represented in MARKAL were assigned approximately the same cost ratio, whereas the subpanel expects larger vehicles to have higher (less favorable) ratios than smaller vehicles: Unlike DOE (TIAX, 2004), the subpanel expects the cost of fuel cells ($/kW) to increase more rapidly with power requirements than the costs of the power train of hybrid or conventional vehicles.

The subpanel accounted for the deficiencies listed above (estimates of fuel economy, next-best alternative, introduction dates, and cost) by lowering the probability of market success. Further, it is assumed that hydrogen will be produced, distributed, and stored at a cost competitive with that of gasoline and that hydrogen refueling stations will be widely available. Although the subpanel did not evaluate the hydrogen program, it has serious reservations about the likelihood that all of these assumptions about hydrogen will prove to be correct. The subpanel has attempted to account for these reservations about supply by reducing the probability of market success.

In addition, the following omissions in the analysis were seen as shortcomings:

-

CO2 sequestration was omitted, which can skew both the economic and environmental benefits.

-

The benefits of reaching higher-probability, less-aggressive fuel cell vehicle cost targets were not evaluated.

-

In MARKAL, there were no barriers to entry for fuel cell vehicles beyond economics. Although NEMS includes consideration of a handful of noneconomic factors such as vehicle range and luggage space, neither NEMS nor MARKAL includes consideration of such noneconomic factors as consumer perceptions of safety, risk, reliability, and image.

Because of the uncertainties in the calculated benefits and the unavailability of reliable industry costs, the subpanel did not apportion the benefits between the industrial and federal programs. However, the subpanel does believe that DOE funding is crucial to ongoing fuel cell development.

Probabilities Estimation

The matrix (Figure H-1) gives single-point numerical probabilities for the sake of simplicity. Note that the entire program has been assigned a probability of technical success that is equal to the probability of the goal in Table H-1 having the lowest probability, that is, cost per kilowatt. Table H-1 shows both numerical and descriptive ranges for the subcomponent and performance goals. The subpanel believes that this is justified both because it made separate evaluations of the probability for each goal in Table H-1, assuming the other goals had been met, and because this goal of cost per kilowatt is a showstopper.

Another issue with probability estimation is that the subpanel evaluated only the fuel cell part of the HFCIT program. The fuel cell element and the hydrogen production, distribution, and storage program element of HFCIT are inherently interdependent and should be evaluated as one. The intuition of the subpanel is that the production, distribution, and storage of hydrogen—in view of constraints on cost, environmental impacts, safety, and capital investments—present challenges that may be even more difficult to overcome than those of fuel cell vehicles. This concern about low-cost, clean, and widely available hydrogen was one reason for assigning a very low probability of market success to fuel cell vehicles.

See the discussion in the subsection entitled “Benefits,” above, for additional reasons why technical and market success were unlikely.

Methodological Issues

General

The subpanel had neither the means nor the time to evaluate whether the proposed funding of the fuel cell vehicle projects is realistic, given the technical goals. The panel believes, however, that to attack cost and durability issues and improve the probability of success would require more funding than was devoted to these issues in the past. Whether this additional funding would come from an increase in budget or a reallocation of funds within the current budget level is an open question. The decision recently taken to discontinue the onboard fuel-reformer work could be helpful if those funds—$8.5 million was expended on onboard fuel processing in FY 2004—are reallocated to resolving the fuel cell cost and durability issues.

Comparing the probability-adjusted economic benefits (see Figure H-1) with the program cost suggests that the program is worthwhile, assuming that the fuel cell benefits have not been seriously overestimated (as discussed above). The total estimated program cost (undiscounted) is $962.5 million, with adjusted benefits of $1.58 billion in the year 2050 alone and $19 billion from 2010 through 2050. However, the adjusted environmental benefits (2.764 million metric tons carbon equivalent [MMTCe] per year) and security benefits (0.124 million bbl per day of oil [45 million bbl per year]) of fuel cell vehicles appear insignificant compared with the more than 360 MMTCe per year resulting from the 8 million bbl per day of oil consumed by cars and trucks today. Rather

than being an indication of the low worth of fuel cell vehicles, these results show how important it is for the DOE to help overcome the technical and market uncertainties that have led the subpanel to assign a low overall probability of success of only 2 percent to the program.

A further complication is that the benefits calculated by DOE assumed the success of the entire HFCIT program,6 which includes hydrogen supply, whereas the subpanel’s own benefits evaluation, including assumptions on program costs, were only for the fuel cell portion of the HFCIT program. As stated previously, the subpanel lowered the probability of market success of the fuel cell program to account for the lack of evaluation of the hydrogen program.

Scenarios

The low financial, environmental, and national security benefits in the Reference Case of the vehicle fuel cell matrix also point to the importance of evaluating alternative scenarios. While the subpanel lacked the data to evaluate additional scenarios, the benefits could be evaluated with additional MARKAL runs, which the DOE has planned for 2005.

Aside from the Reference Case, the two additional scenarios—the High Oil and Gas Prices scenario and the Carbon Constrained scenario—are appropriate for evaluating this program, as might be a scenario combining the High Oil and Gas Prices and Carbon Constrained scenarios. DOE should be encouraged to run calculations for these scenarios, as they represent likely future conditions. Results could be significantly different from those obtained in the Reference Case. Perhaps additional scenarios could be included in which the government provides incentives and/or regulations that favor the purchase of fuel cell vehicles and the production, distribution, and storage of hydrogen. Additional scenarios need to be run with fuel cell cost targets of $40/kW and $50/kW, which have a greater probability of being achieved. Combining the results from these runs with previous results would more accurately represent the benefits from fuel cell vehicles and would help clarify the uncertainties in achieving the fuel cell program goals.

Benefits Calculation

The complexity of the energy and vehicle markets makes benefits calculation difficult. The use of models such as NEMS and MARKAL is an attempt to handle this complexity. However, unless the inputs to these models are transparent, reasonable, and validated and have continuity with the available experimental data and program goals, the use of these complex models only hides overly optimistic or erroneous assumptions and yields results that have only the appearance of validity. Unless total transparency of the inputs to the models can be demonstrated, it would be preferable to use simple calculations of the benefits. The subpanel believes, however, that with due diligence and the necessary expenditure of time and funds, transparency can be ensured. Therefore, it is recommended that the models be used, with clear links between program goals and vehicle cost and performance.

Of the two models, NEMS is the more sophisticated, but MARKAL is the only one capable of yielding estimates for most of the period during which fuel cell vehicles are expected to penetrate the market. Consequently, the subpanel concurs with DOE’s use of MARKAL for estimating long-term benefits.7 However, the more complex NEMS is useful in validating the MARKAL results in the overlap years. Further, it is recommended that the models be run for other purposes: to evaluate the fuel cell benefit versus the next-best alternative (instead of versus the baseline case of conventional vehicles), which could be hybrid vehicles or cellulosic ethanol vehicles (DOE claims that comparing one program case with another would be inconsistent with its methodology); to perform analyses of sensitivity to fuel and vehicle costs, vehicle performance, and hydrogen availability; and to run the models with retrospective data to ascertain if they can “predict” the past and thereby increase confidence in them.

Federal Role

Industries here and abroad have extensive and well-funded fuel cell programs, in some cases due to past DOE fuel cell funding. One could argue that fuel cell vehicles can now succeed without a U.S.-government-funded program to increase the probability of success, but this would likely delay their introduction into the U.S. market and could damage the competitiveness of U.S. firms. As discussed above, the probability of market success of fuel cell vehicles is the largest factor that the subpanel found in determining prospective benefits, and DOE has a key role to play in improving the chances for success.

The government is also addressing the problems of hydrogen production, distribution, and storage, which are receiving inadequate attention by the energy industry. The hydrogen part of the program is vital because hydrogen fuel cells have no future without hydrogen fuel’s being widely available at a reasonable price. For the U.S. government to conduct R&D on hydrogen only, without a parallel program in fuel cells, would ignore the interdependence of these programs and would deprive the government of firsthand information about the mutual needs of the programs. The entire

program gives the U.S. automotive industry a strong signal that it should continue its own vigorous R&D efforts. If the government fuel cell program were discontinued, it is likely that the U.S. automotive industry programs would be scaled back.

Another reason for continued DOE funding is that in the national laboratories the U.S. government has unique capabilities, unavailable in industry, to conduct fundamental R&D on key issues such as low-cost membranes, electrodes, and other components, and with respect to hydrogen production and storage.

Finally, if the economics of hydrogen and fuel cell vehicles turns out to be unfavorable but environmental and security concerns compel the government to provide incentives and/or regulations to make them viable, the government would be in a much better position to do this intelligently, having conducted its own R&D and evaluation.

The United States is the world’s largest consumer of petroleum for vehicle operation, and private automobile transportation is uniquely important to both our society and economy. A federal role is essential.

Interpretation and Use of the Matrix

Summary of Findings

The methodology for evaluating the prospective benefits of R&D programs seems adequate, and it should work when all the necessary information required by the methodology is available. However, this is a very calculation-intensive process. In addition, the projects selected for analysis must be independent of other projects. In this case, evaluating the fuel cell program independently of the HFCIT program is inappropriate, as already discussed. Consequently, the matrix is good only for illustrative purposes and not for evaluating the benefits of the program, which was the subpanel’s charge.

The strength of the methodology is that it brings together independent experts with differing backgrounds to do the evaluation, and it relies on a common methodology for all programs. Its greatest weaknesses are that simple-to-use tools for evaluating benefits are not available, and it requires voluminous data.

Once the methodology is established and validated, it would be valuable for use as an internal management tool by DOE. Its use should increase the efficiency and effectiveness of ongoing projects.

Recommendations

The proposed methodology for creating the prospective benefits matrix seems reasonable. However, the process for evaluating, digesting, and analyzing the information necessary to construct the matrix could be improved. The need for this improvement can be illustrated by reviewing how this subpanel operated within the compressed time frame allowed.

The first meeting of the subpanel was chaotic and rushed. The subpanel had been asked to concentrate on reading the material concerning the benefits methodology, and most subpanel members were not prepared to ask DOE staff pertinent and probing questions about the projects and their related costs and benefits. The DOE presentations were glossy but lacked the substance that the subpanel needed to do its job. The presentations were also unnecessarily lengthy, which prevented DOE from covering all of the material in the allotted time. This problem caused the subpanel to receive incomplete information, hindered the digestion of the information, and precluded asking the necessary probing questions.

Several steps can be taken to remedy the type of situation described above:

-

The first meeting of a subpanel such as this one should not involve DOE. Instead, the subpanel should meet alone with NRC staff after having had the opportunity to study and digest the pertinent information. Specifically, this subpanel should have read and digested the information in Hydrogen, Fuel Cells and Infrastructure Technology Program—Multiyear Research, Development and Demonstration Plan (DOE, 2003a) and in Projected Benefits of Federal Energy Efficiency and Renewable Energy Programs FY 2005-FY 2050 (NREL, 2004) before coming to the first meeting.

-

During this first meeting, a subpanel should identify any weaknesses in the selection of the project to be evaluated and should compose a list of additional information to be requested from DOE. As an example, this subpanel would have identified the need to ask DOE about its assumptions for calculating benefits, whether other scenarios had been considered, and whether experimental data or program goals had been used in generating the inputs to the models.

-

After the first meeting, a subpanel would request information and additional work from DOE.

-

The information from DOE should be given to a subpanel prior to the second meeting.

-

During the second meeting, which would include DOE, a subpanel should review DOE’s responses and should ask questions of DOE staff. This would prevent the delivery of canned presentations and irrelevant information.

-

In a subsequent meeting(s), a subpanel should analyze the information and prepare the benefits matrix.

STATIONARY FUEL CELL SUBPANEL REPORT

Objective of Study and Statement of Work

The Panel on Benefits of Fuel Cell R&D assisted the Committee on Prospective Benefits of DOE’s Energy Efficiency and Fossil Energy R&D Programs with the development of a methodology for estimating the benefits of applied

energy research and development. The methodology is to be used for prospectively estimating the benefits of ongoing R&D programs and was developed initially by the committee. The work of the committee is a follow-on to the NRC report Energy Research at DOE: Was It Worth It? (NRC, 2001),8 concerned with retrospectively estimating the benefits of DOE R&D funded between 1978 and 2000.

In this subpanel report, the stationary fuel cell subpanel estimates the benefits that could be provided by current fuel cell R&D activities at DOE related to stationary applications. (Vehicle applications are considered in the preceding report of the other subpanel.) The subpanel further provides observations on the merits of the methodology itself, on the basis of the panel’s experience applying it to a real-world example.

DOE Program and Budget

The DOE FY 2004 budget authority for stationary fuel cell activities within its Office of Fossil Energy (FE) was $69 million. Of this total, $35 million was for the Solid State Energy Conversion Alliance (SECA),9 $9.9 million for advanced research, $10.9 million for fuel cell systems, and $12.9 million for fuel cell/turbine hybrids.10

Although there are many stationary fuel cell technologies,11 FE’s current program focuses on solid oxide fuel cells (SOFCs). The SOFC, having a ceramic electrolyte, operates at temperatures up to 1000°C, which simplifies fuel reforming relative to polymer electrolyte membrane (PEM) fuel cell technology. The waste heat can be utilized in a steam bottoming cycle or for combined heat and power. The SOFC can operate on a variety of fuels, but current units are designated for natural gas.

The program goal of SECA, by 2010, is to produce SOFC modules of 3 to 10 kW capacity at a capital cost of no greater than $400/kW. Along with this goal, the power densities, reliability, and operating characteristics all must be compatible with commercial service in stationary and transportation power applications. The market envisioned for stationary applications of SOFCs is distributed generation, including both residential and commercial combined heat and power. Within transportation applications, the market for auxiliary power units is targeted.12

A longer-term program goal (2012-2015) is to scale up SOFC modules to megawatt-class and run fuel cell/turbine hybrids on a coal-derived slip-stream. By 2015, the goal is to test a SECA 40 MW hybrid at a coal gasifier. Both of these hybrid approaches have the same capital-cost goal of $400/kW as the fuel cell product, but higher thermal efficiency goals.13

SECA comprises six industry teams that individually plan to commercialize SOFC systems to predefined markets. The six industry teams cost-share funding with DOE. In parallel with these industry teams, a Core Technology Program comprises investigators conducting research activities to overcome barriers identified by the industry teams. The intellectual property from the Core Technology Program is available to all in the industry teams.

Benefits Matrix for the SECA Program

The stationary fuel cell subpanel limited its analysis of program benefits to the SECA program, which represents the majority of future funding for stationary fuel cells at DOE. The subpanel used information provided on the DOE Web site, including program descriptions, contractor presentations at program review meetings, and peer review summaries of the DOE program. Other data sources included DOE presentations to the subpanel, DOE responses to specific subpanel member’s questions, and the subpanel’s general knowledge of the subject. The assumptions used for the analyses are discussed below.

Technical Probability

The primary goal of the SECA program by 2010 is to meet the cost target of $400/kW for fuel cell modules having a 3 to 10 kW capacity—this cost target includes the balance of plant, labor, indirect costs, and depreciation.14 The added SECA goal of doubling the efficiency over conventional technologies can only be achieved by employing bottoming cycles, as do fuel cell/turbine hybrids, and maintaining the capital cost goal of the total hybrid system, including the turbine, at $400/kW. It is anticipated that the gas turbine part of the hybrid system will have a cost of less than $400/kW, therefore relaxing the requirement for a $400/kW fuel cell stack; this may facilitate the achievement of the $400/kW goal for the hybrid system.

It should be noted that achievement of each of these two cost goals, for turbine or fuel cell, is a very formidable task. The most difficult problem in achieving the goals of the SECA fuel cell distributed generation program is to reach the overall cost of $400/kW at the targets for efficiency, availability, stability (life), operability (cycles), and power

|

8 |

The methodology for estimating benefits retrospectively is described in Appendix D of NRC (2001). |

|

9 |

Additional funding for SECA is provided in program areas outside the fuel cell activities, for a total for SECA-related activities of $47 million. |

|

10 |

Sam Biondo, U.S. Department of Energy; “U.S. DOE FE Fuel Cell Program,” Presentation to the panel, July 21, 2004. |

|

11 |

DOE has previously funded the development of phosphoric acid fuel cells and molten carbonate fuel cells for stationary applications. A complete description of stationary fuel cell types can be found in Chapter 3 of The Hydrogen Economy: Opportunities, Costs, Barriers, and R&D Needs (NRC, 2004). |

|

12 |

Mark Williams, “Overview of DOE FE Fuel Cell Program,” Presentation to the panel, July 21, 2004. |

|

13 |

Ibid. |

|

14 |

Sam Biondo, U.S. Department of Energy, “U.S. DOE FE Fuel Cell Program,” Presentation to the panel, July 21, 2004. |

density (compactness). Current costs of SECA fuel cell systems must be reduced by a factor of 10 or greater.

Incremental technical progress is being made on critical components and packaging, but little information has been made available to the subpanel regarding the present status of or path toward the primary program goal of a 5 kW, $400/kW module. Phase One final reports from each of the six SECA teams are due early in 2005. The intermediate program goal for the end of Phase One is the design of a product that has the potential to be manufactured in large quantities at a cost of $800/kW. In addition, each contractor team must deliver an operable prototype of its design to DOE for testing at the National Energy Technology Laboratory (NETL).

The cost of the fuel cells depends on a complex combination of the cell configuration (flat plate versus tubular, and no seal versus sealed), the materials (the electrolyte, anode, cathode, interconnect, collector, support), the fabrication process, and the operating conditions, particularly the temperature and current density. The system costs include not only those for the cells but also those for fuel processing, air supply, heat removal and utilization, insulation, power conditioning, and control. Reducing the combination of all of these costs is indeed a formidable problem and not a matter of a single breakthrough. Effective systems engineering may thus be the most important breakthrough needed for stationary fuel cells.

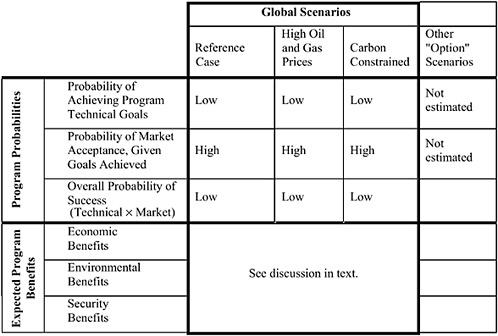

Furthermore, the impact of component performance improvements on total system cost is not clear, which makes it difficult to assess the relative importance of various R&D activities and to estimate the probability of success. The details of how the cost goal will be achieved by the six industry teams are proprietary and were not available to the subpanel for evaluation. When this information was requested from DOE, the response was “Actual costs for the SECA fuel cells are proprietary” and “Details regarding where they are relative to the targets cannot be made public.” Based on the subpanel’s own knowledge of this technology, it seems unlikely that the cost goal will be met while simultaneously achieving all of the other required technical specifications—that is, efficiency, fuel utilization, current density, lifetime, availability, degradation rate, transient response, fuel type, number of thermal cycles, and low emissions. In addition, the interdependency of these parameters should not be over-looked, since optimizing the performance of one attribute may be detrimental to another. For these reasons the probability of achieving SECA program goals was determined by the subpanel to be low (see Figure H-2).

Market Probability

Achieving the project goals for fuel cells would compete extremely well against the next-best alternative for distrib-

FIGURE H-2 Prospective benefits matrix for the Solid State Energy Conversion Alliance (SECA) program.

TABLE H-2 Characteristics of Fuel Cell Distributed Generation Versus Next-Best Technology

uted generation, as shown in Table H-2. The probability of market acceptance was judged to be high (see Figure H-2).

It should be noted that achievement of the project goal of $400/kW for fuel cell/gas turbine hybrids would necessarily entail increased thermal efficiency of the fuel cell and turbine units. At higher efficiencies, these units consume less fuel and do not require as large a coal gasification plant, if one is required. This would allow coal-fueled gasification-based technologies and natural-gas-based technologies to significantly penetrate the market for central-station-generated power.

As gas prices rose, the fuel savings compared with those from other options would increase the level of market penetration. If carbon taxes were in place, the level of market penetration would increase relative to the Reference Case.

Overall Probability

The overall probability of success is low for the $400/kW goal (see Figure H-2). If the $400/kW goal is relaxed, the probability of technical success increases; however, higher costs would increase the market risk. A compromise between cost and market risk could result in significant market penetration.

Economic Benefits

The subpanel employed two simplistic methods to compute potential economic benefits of the SECA program. These methods provide a quick check on the benefits derived by DOE from runs made with the very sophisticated NEMS model. The objective was to determine if the benefits estimated by DOE and the subpanel were in the same ballpark.

Economic benefits were calculated for the three global scenarios: the Reference Case, the High Oil and Gas Prices scenario, and the Carbon Constrained scenario. The results are summarized in Table H-3. These three global scenarios share the same capital cost savings, the details of which are discussed in the “Benefits Calculation” subsection, below. The fuel price is assumed to be $4.6 per million Btu in the Reference Case. In the High Oil and Gas Prices scenario, the fuel price is assumed to be 63 percent higher. The Carbon Constrained scenario includes low and high carbon taxes of $50 and $150 per ton, respectively.

Environmental Benefits

The environmental benefits of SECA fuel cell systems in natural-gas-fired commercial distributed-generation (DG) and utility DG systems are as follows:

-

Reduced emissions of pollutants: SO2, NOx, particulates, mercury, and so on;

-

Reduced emissions of CO2 resulting from the increased efficiency of electrical generation and from the recovery and use of reject heat in commercial DG applications; and

-

Reduced consumption of water.

These reductions are particularly pronounced relative to coal-fired, conventional utility power generation but less

TABLE H-3 Benefits Calculations for Solid State Energy Conversion Alliance (SECA) Program for Three Global Scenarios

|

|

Global Scenario |

|||

|

Reference Casea |

High Oil and Gas Pricesb |

Carbon Constrainedc |

||

|

Low |

High |

|||

|

Method 1 |

||||

|

Capital cost benefit |

13.5 |

13.5 |

13.5 |

13.5 |

|

Fuel benefit |

6.0 |

9.9 |

7.1 |

13.1 |

|

Total benefit |

19.5 |

23.3 |

20.5 |

22.6 |

|

Method 2 |

||||

|

Total benefit |

24.6 |

34.4 |

27.3 |

32.7 |

|

NOTES: Totals may not add due to rounding. All costs are in billions of 2002 dollars. aFuel price assumed to be $4.6 per million Btu. bFuel price assumed to be 63 percent higher. cIncludes low and high carbon taxes of $50 and $150 per ton, respectively. |

||||

pronounced relative to conventional gas-fired generation and distributed cogeneration and to the DOE FE integrated gasification combined cycle (IGCC) and advanced turbine technologies now under development.

The NEMS program that was used to estimate the prospective benefits of the SECA subprogram does not quantify the SECA program’s environmental benefits except for the reduction of CO2 emissions (NETL, 2004). Rather, NEMS determines a mix of fuels and generation technologies to satisfy the power market, based on national SO2, NOx, and mercury emissions caps of the Clear Skies Initiative.15 The combined economic and environmental benefits of introducing the SECA technology into the market are thus summarized in the cumulative benefits of reductions in the overall electric power and natural gas fuel costs to the nation—that is, reductions below the Reference Case of the Annual Energy Outlook. Cumulative benefits have been calculated using NEMS for six different cases (see Table H-4). The six cases correspond to two different assumptions regarding R&D success (either all of DOE FE R&D power programs achieve their performance and economic goals and enter the market, or only the SECA program achieves its goals and enters the market) for each of three scenarios (Clear Skies; expensive natural gas; and restricted CO2).

It is curious that NEMS makes projections of positive national electric power and gas cost benefits for the SECA technology in only two of the six cases in Table H-4. These cases, both of which assume that all of FE’s programs succeed, are as follows: (1) the Clear Skies Initiative is adopted and the natural gas supply is constrained and (2) the Clear Skies Initiative is adopted and CO2 emissions are also limited. NEMS projects that SECA fuel cell DG capacity installations, if all FE R&D technologies succeed, will be 50 to 70 gigawatt (GW) by 2025, at a cost of $20 billion to $35 billion for the various scenarios (NETL, 2004, pp. 38 and 75). No NEMS projections are presented concerning SECA fuel cell installations if SECA is the sole successful FE R&D technology.

NEMS projects that SECA fuel cell distributed generation systems can reduce CO2 emissions by 383 MMTCe if all FE R&D programs succeed and if natural gas supply is not constrained, or by 21 MMTCe if only the SECA program is commercialized and, again, if natural gas supply is not constrained. Otherwise NEMS calculates no CO2 emissions reductions attributable to the SECA program.

NEMS does not consider water use in its calculations. Utility power plants in general use 3 to 5 pounds of water per kilowatt-hour for cooling. Water is increasingly becoming a scarce commodity in portions of the United States. SOFC DG systems, such as those being developed by SECA, use no water.

TABLE H-4 Benefits Calculated by DOE for All Combinations of Global Scenarios and R&D Success

Security Benefits

SECA technology could reduce U.S. dependence on foreign sources of natural gas through increased efficiency and greater use of domestic fuels. It would also provide a more secure energy infrastructure through distributed generation, which reduces vulnerable transmission and distribution networks. Rapid deployment of distributed power generation systems would be possible in the event of catastrophic grid failure due to natural or deliberate causes.

Methodological Issues

The subpanel thought that the primary SECA goal of $400/kW was unrealistic. This value, which is used in all benefits calculations, results in overly optimistic outcomes. That being said, a more modest goal of $600/kW or $800/kW probably would lead to adoption of SECA technology and market penetration.

SECA funding levels appear to be matched to the desired program goals. Higher funding levels are not likely to increase the probability of attaining program goals.

Benefits Calculation

As noted, the subpanel developed two methods of its own for the calculation of economic benefits. The fuel cell or fuel cell/turbine hybrid units deliver economic benefits in the form of fuel savings and reduced capital costs measured against the next-best alternative. The results of the two methods furnish the data on economic benefits shown in Table H-3. For Method 1, shown in Tables H-5 and H-6, the installed DG fuel cell capacity (cumulative by 2025) was taken from calculations made by DOE using NEMS. The subpanel assumed that this capacity would be added at a constant rate, starting in 2016 and ending in 2025. Thus, the average number of units in service during this period is one-half the total capacity in 2025. The length of service for each unit was assumed to be 5 years. All of these fuel cells are used in the natural-gas-fueled DG market. None of the fuel cells or hy-

TABLE H-5 Method 1 for Calculating Benefits

|

|

Savings ($ million) |

|||||||||

|

Reference Case |

High Oil and Gas Prices |

Carbon Constrained |

||||||||

|

|

Total Capital + Fuel |

|||||||||

|

Unit Cost ($/kW) |

Unit Capacity (MW) |

Installed Capacity (GW) |

Capital Cost |

Fuel Cost |

Total Capital + Fuel |

Total Fuel |

Total Capital + Fuel |

Total Fuel |

Low Carbon Tax |

High Carbon Tax |

|

400 |

<1 |

4.00 |

2,400 |

958 |

|

|||||

|

~1 |

60.40 |

8,456 |

3,890 |

19,506 |

6,046 |

23,317 |

9,857 |

20,557 |

22,660 |

|

|

~10 |

18.60 |

2,604 |

1,198 |

|

||||||

|

600 |

<1 |

3.00 |

1,200 |

719 |

|

|||||

|

~1 |

31.40 |

−1,884 |

2,022 |

2,057 |

2,741 |

3,785 |

4,469 |

2,534 |

3,487 |

|

|

~10 |

0.00 |

0 |

0 |

|

||||||

|

800 |

<1 |

2.50 |

500 |

599 |

|

|||||

|

~1 |

13.20 |

−3,432 |

850 |

−1,483 |

−1,449 |

−570 |

2,363 |

1,231 |

−727 |

|

|

~10 |

0.00 |

0 |

0 |

|

||||||

|

NOTES: All costs in millions of 2002 dollars. Installed capacities and savings are cumulative from 2016 through 2025. $/kW = dollars per kilowatt; MW = megawatt; GW = gigawatts. See also Table H-6. |

||||||||||

brids is used in combined heat and power applications, natural-gas-fueled central station applications, or coal-fueled central station gasification plants. For Method 2, shown in Tables H-7 and H-8, the total market for DG in any given year, starting in 2011, was assumed to be 25.78 GW,16 and the penetration of the DG market by fuel cells was assumed to be 10 percent. A capital charge rate multiplier was included to represent a depreciated flow of capital services.

Interpretation and Use of the Matrix

Common Elements in Prospective and Retrospective Benefits Matrixes

The proposed matrix for the evaluation of prospective benefits (Figure ES-2) is a modification of the matrix used to evaluate the benefits of past DOE programs in retrospect (Figure 2-1). The common elements of these two matrixes are the economic, environmental, and national security benefits, realized either in retrospect or projected for the future. Ideally the economic benefits can be expressed in dollars. NEMS defines these as the cumulative savings in electrical energy and natural gas costs to the nation resulting from the penetration into the market of commercial and utility DG systems based on SECA fuel cells. The investment costs involved with manufacturing and purchasing and installing these SECA fuel cell systems are a factor in the determination of overall economic benefits to the nation.

The environmental benefits of SECA fuel cell distributed-power generation might be expressed quantitatively in terms of cumulative reductions in the following:

-

SO2, NOx, particulate matter, and mercury pollutant emissions;

-

CO2 production; and

-

Water consumption.

These benefits will accrue to the extent that the natural-gas-fired SECA fuel cell power generation replaces coal-fired generation and/or improves the overall efficiency of natural

TABLE H-6 Inputs and Assumptions Used in Method 1

TABLE H-7 Method 2 for Calculating Benefits

gas utilization by means of combined heat and power production. If market prices are established for the various emissions and for CO2 capture and sequestration, it might also be possible to monetize these environmental benefits. The problem is that NEMS assumes that the national emissions are capped; therefore, the introduction of SECA DG shifts the balance of emissions amongs emitters, but it does not reduce overall emissions nationwide. The environmental benefits are captured in the overall effect of SECA fuel DG on the costs of electricity and gas to the nation.

The security benefits of the program can be described in terms of the reduction in the vulnerability of the power supply associated with centralized power generation, transmission, and distribution. This benefit is difficult to quantify.

The matrix for retrospective evaluation of DOE program benefits also considers options and knowledge benefits, including educational benefits. These considerations disappear from the prospective benefits matrix. Certainly these benefits exist, and their consideration might be included in the prospective benefits matrix. The retrospective matrix also includes a cost factor associated with each benefit. It is not clear how program and investment costs are distributed among the benefits categories, and they are advisedly omitted from the prospective benefits matrix proper but included in program and investment costs listed in the prefatory text of the matrix.

TABLE H-8 Capital Costs and Heat Rates Used in Method 2

|

Heat Rate (Btu/kWh) |

Capital Cost ($/kW) |

||

|

Fuel Cell |

Next Best |

Next Best |

Fuel Cell |

|

5,924 |

8,900 |

630 |

400 |

New Elements in the Prospective Benefits Matrix

The proposed prospective benefits matrix quite properly includes two important additional elements for consideration, as follows:

-

The probabilities of successfully achieving the technical goals, including cost, and the market goals of the program.

-

The global scenarios reflecting external factors that might affect the market for the technology.

The technical and cost goals of the SECA program have been set by DOE. These goals presumably reflect what might be reasonably expected from the program and/or what is required for the program to achieve notable economic, environmental, and security benefits in the market. Achievement of such notable market benefits frequently requires a significant stretch beyond reasonably expected goals. But great stretches logically result in lower probabilities of reaching the goals. Establishing for a program a realistic balance between goals and the probability of reaching these goals requires careful consideration.

The market goals for the SECA program have been established by NEMS. NEMS projects market penetration of SECA commercial and utility DG systems based on its model of the U.S. economy, including its power and fuel supply markets; on the technical and cost goals established for the SECA systems; and on various scenarios regarding environmental regulations and the natural gas fuel supply situation in the nation. NEMS is a complex economic model, and its interactions and its projections are not transparent. For example, it is not clear what significant criteria have been established for acceptance of the SECA technology by potential commercial and utility DG customers and what share of the market will be captured by competing technologies, such a small gas turbines, for commercial and utility distribution systems.

The probabilities of achieving technical and market goals are key in assessing the benefits, and thus the prospective benefits, of the SECA R&D program. Establishing values for these probabilities requires observers who are informed and objective but still intuitive. The stationary applications subpanel of the Panel on Benefits of Fuel Cell R&D was objective and willing to employ intuition, but the time available for group investigations was wholly inadequate for establishing a claim that the subpanel members were informed. The subpanel therefore recommends against publishing any matrix that it has produced.

The probability of achieving technical and economic goals of the program obviously depends on the persons and organizations involved in the work, on the organization and conduct of the effort, and on the resources provided, primarily the funding. The SECA program involves six industrial organizations, each dedicated to producing, within 10 to 12

years, a complete power generation system of 3 to 10 kW and meeting the SECA technical and cost goals. Parallel efforts certainly enhance the probability of success. These industrial organizations are assisted in their work by a large number of smaller projects carried out by a variety of organizations, universities, and national laboratories. The SECA program, funded at $35 million per year, devotes 60 percent of these funds to the industrial organizations and 40 percent to the supporting efforts. Presumably, a reduction in program funding would be accommodated by eliminating one or more of the industrial efforts and trimming the supporting efforts, not by proportionate reductions in all of the industrial efforts, slowing the program. In any case, a careful continuing observation and study of the overall SECA program would be required in order to provide a meaningful estimate of the probability of achieving program goals. Such a study would be greatly facilitated by the establishment of technical milestones intermediate to the performance goals set out for the three phases of the SECA program.

The probability of achieving acceptance in the market projected by NEMS is dependent on a judgment concerning the effectiveness of NEMS in projecting future markets. Further study of the details of the input to NEMS, on the assumptions, on the calculations, and on the results, is required in order to render a meaningful estimate of the probability of attaining market acceptance at the predicted levels.

Three global scenarios concerning external factors that might affect the market for the technology have been envisioned in the prospective benefits matrix. These scenarios are applied in sequence to determine their cumulative effect on the market and economic benefits. But frequently it is the unforeseen crises that most seriously affect the future. Disruption of the oil supply owing to international conflicts and to rapidly rising demand in the Far East might result in pressures on the natural gas and electric power supply in the United States. And these pressures in turn might result in profound, but difficult to predict, changes in the market for natural-gas-fired DG.

Concerns

The stationary fuel cell benefits subpanel was concerned that numerical information provided in a prospective benefits matrix might be used in a routine, unthinking way to rate, to compare, to initiate or terminate programs, or to adjust their funding. For example, numerical guesses of the probabilities of achieving program goals and market acceptance of the SECA program might be combined with financial benefits (in terms of cumulative fuel and natural gas savings to the nation through 2025) to provide an “expected” value of the program. This value then might be used together with the program cost (and perhaps also the investment costs involved in the manufacture, procurement, and installation of SECA distributed generation systems) to determine a rate of return for program investments. And this single numerical value might in turn be used without further thought or consideration to rate the program.

Filling Out the Matrix

Several preparatory steps might be taken prior to filling out a prospective benefits matrix. DOE’s program manager should do the following:

-

Provide and explain the technical and cost goals of the effort,

-

Recount a history of goals previously achieved,

-

Describe the target market for the developed technology,

-

Project cost data concerning R&D program funding, and

-

Describe the national security benefits.

The NEMS programmers (or perhaps the programmers of other, similar economic models, such as MARKAL) should project the market, the economic and environmental benefits, and the associated investment costs based on input from a program manager, on scenarios mutually agreed upon, and on data input concerning competing technologies.

Informed, objective (disinterested), and intuitive reviewers should, after consultation with the DOE program manager and the NEMS programmers, consider, report, and comment on the probabilities associated with achieving the following:

-

The program technical and cost goals based on the projected R&D program and its funding, and

-

The projected market with the associated economic and environmental benefits, assuming that technical and cost goals are met.

It is clear that the reviewers need to have knowledge and understanding of both the R&D program and of the NEMS projections if the probabilities that they provide are to be meaningful.

Uses of the Matrix

It is hoped that the process of periodically filling out a prospective benefits matrix will promote communications among DOE program managers, NEMS program managers, and the informed, objective observers who will assist in the process of promoting, guiding, and funding the program.

The benefits matrix may also assist those who, at higher levels of responsibility, are comparing the merits of various programs and are concerned with funding decisions. The subpanel cautions, as noted above, against using the numbers of the prospective benefits matrix as the sole source of guidance in program decisions. The very important goal and market probability estimates are imprecise at best, as are the

descriptions and unexpressed probabilities of various scenarios. The security benefits are also unquantified; and the options and the knowledge benefits are undescribed and unquantified. The various political aspects of the program and its support are not even contemplated. At best, the examination and contemplation of a set of prospective benefits matrices—filled out consistently and, it is hoped, periodically—may serve as one factor in the comparison of programs competing for support.

Summary of Panel Findings

The panel’s calculations reveal significant benefits for the DOE SECA program, which are consistent with DOE’s predictions. This latter result is not unexpected, as the subpanel assumed that all program goals were achieved and used DOE and NEMS data for inputs to its benefits calculations. Probabilities, which are needed to adjust calculated benefits to realistic values, are impossible to determine without access to proprietary information, which was not available to the subpanel. As the primary objective of the SECA program is cost reduction and all economic benefits derive from this, it is essential to know the current and projected costs of all components, processes, and other factors as the program proceeds. In addition, the subpanel needed to know how technical progress in specific areas impacts the SECA module cost at the system level. The core program, which consumes 40 percent of the budget, must be accountable to the overall program goal of cost reduction. Currently, it is impossible to determine the extent of risk reduction that this program offers, although it is clear that good scientific and technical progress is being made.

The subpanel understands that it was not charged with performing a program review; however, these issues need to be understood in order to independently establish probabilities and benefits. The results of the current exercise simply underscore what DOE has already published and provide little added value. If this methodology is employed in its current form, the consumer of the product might assume that the matrix is an independent assessment by the NRC. This would be an erroneous and unfortunate conclusion.

The subpanel recommends that in the future subpanels work with NRC staff to develop a strategy for obtaining the necessary information to perform its work based on the statement of task. Once these data are obtained, it should be a relatively simple matter to complete the matrix. Most of this activity could be completed by e-mail, with perhaps one meeting with DOE to clarify issues and allow the subpanel to discuss the program and develop an analytical strategy for completing the matrix.

PANEL MEMBERS BIOGRAPHICAL INFORMATION

Martha A. Krebs (chair) is president of Science Strategies, a consulting firm. She was founding director of the California NanoSystems Institute at the University of California at Los Angeles and the University of California at Santa Barbara. Previously, she was a senior fellow at the Institute for Defense Analyses (IDA), where she led studies in R&D management, planning, and budgeting. She has extensive experience regarding DOE’s basic and applied energy programs. Dr. Krebs also served as DOE assistant secretary and director, Office of Science, responsible for the $3 billion basic research programs that underlie the department’s energy, environmental, and national security missions. She also had the statutory responsibility for advising the Secretary of Energy on the broad R&D portfolio of the department and the institutional health of its national laboratories. She has been associate director for planning and development, Lawrence Berkeley National Laboratory, where she was responsible for strategic planning for research and facilities, laboratory technology transfer, and science education and outreach. She also served on the House Committee on Science, first as a professional staff member and then as subcommittee staff director, responsible for authorizing DOE non-nuclear energy technologies and energy science programs. She is a member of Phi Beta Kappa, a fellow of the American Association for the Advancement of Science, and a fellow of the Association of Women in Science, and she received the Secretary of Energy Gold Medal for Distinguished Service (1999). She is a member of the National Research Council’s Board on Energy and Environmental Systems and its Board on Chemical Sciences and Technology. She received her bachelor’s degree and Ph.D. in physics from the Catholic University of America.

Rakesh Agrawal (NAE) is Air Products Fellow at Air Products and Chemicals, Inc., where he has worked since 1980. His research interests include basic and applied research in gas separations, process development, synthesis of distillation column configurations, adsorption and membrane separation processes, novel separation processes, gas liquefaction processes, cryogenics, and thermodynamics. He has broad experience in hydrogen production and purification technologies. His current interest is in issues involving energy production, especially from renewable sources such as solar. He holds 116 U.S. and more than 300 foreign patents. Dr. Agrawal has authored 64 technical papers and given many lectures and presentations. He chaired the Separations Division and the Chemical Technology Operating Council of the American Institute of Chemical Engineers, and also a Gordon conference on separations. He was a member of the NRC Committee on Alternatives and Strategies for Future Hydrogen Production and Use. Dr. Agrawal received a B.Tech. from the Indian Institute of Technology, in Kanpur, India; an M.Ch.E. from the University of Delaware; and an Sc.D. in chemical engineering from the Massachusetts Institute of Technology.

David H. Archer (NAE) is an adjunct professor at Carnegie

Mellon University. He is a retired consulting engineer with the Westinghouse Electric Corporation, and has extensive expertise in the design and evaluation of innovative fossil-fueled power generation systems. His work has included basic studies of flame behavior as well as the applications of combustion turbines, high-temperature fuel cells, gasifiers, fluidized-bed combustion, and hot gas cleaning. He has served on a number of NRC committees, including the Committee on R&D Opportunities for Advanced Fossil-Fueled Energy Complexes. He joined Westinghouse in 1960. Dr. Archer holds a B.S. in chemical engineering from Carnegie Mellon University and a Ph.D. in chemical engineering and mathematics from the University of Delaware.

Richard Bellows is principal of Richard Bellows Advanced Energy Systems, LLC, a consulting company specializing in fuel cells, fuel processing, and systems analysis. Prior to that, he had been manager, Advanced Technology Group for Fuel Processing at United Technologies Corporation, and senior scientist, among other positions, at ExxonMobil Research and Engineering. He has been active in the area of fuel cells, advanced batteries, and fuel processing more than 30 years. He is credited with 27 patents in the areas of advanced batteries and electrochemical devices, fuel processing, separation processes, and flow measurement. Dr. Bellows has written extensively on fuel cells and fuel processing and has addressed many conferences. He has a Ph.D. in chemical engineering from the University of California at Berkeley and a B.S. from the University of Rochester.

James H. Fletcher is an assistant professor in mechanical engineering at the University of North Florida. His previous positions include those as lead engineer, Bus Systems Group, UTC Fuel Cells; department head, Systems Engineering, XCELLSiS-USA; engineer, University of Florida; systems engineer, Advanced Vehicle Group, Georgetown University; and research assistant, Mechanical Engineering, University of Florida, among others. Dr. Fletcher has worked on fuel cell technology and other energy-related technology for about 15 years. He has conducted system modeling, testing, refurbishment, and operation of fuel cell bus endeavors, and systems engineering for developing hydrogen proton exchange membrane (PEM) fuel cell engines for automotive applications. He is currently director of the Clean and Renewable Energy Laboratory (including refurbishment and operation of one of the first-generation fuel cell buses) at the University of North Florida and also works with the Fuel Cell Laboratory at the University of Florida. His expertise is in mechanical engineering, fuel cell power trains for vehicles, and systems engineering of fuel cell power trains. He has Ph.D., M.S., and B.S. degrees in mechanical engineering from the University of Florida.

David Friedman is research director for the Union of Concerned Scientists’ (UCS) Clean Vehicles Program. Before joining UCS in 2001, Mr. Friedman worked for the University of California (UC)-Davis in the Fuel Cell Vehicle Modeling Program, developing simulation tools to evaluate fuel cell technology for automotive applications and contributing to the UC Davis FutureCar team on a high-efficiency hybrid electric family car. He previously worked at Arthur D. Little researching fuel cell, battery electric, and hybrid electric vehicle technologies, as well as photovoltaics. Mr. Friedman is the author or co-author of more than 30 technical papers and reports on advancements in conventional, fuel cell, and hybrid electric vehicles and alternative energy sources with an emphasis on clean and efficient technologies. He earned a B.S. in mechanical engineering from Worcester Polytechnic Institute and is currently (2004) finishing his doctoral dissertation on transportation technology and policy at UC Davis.

Nicholas E. Gallopoulos is retired from General Motors (GM) Research Laboratories, where he spent most of his career. Positions that he held at GM Research Laboratories included, among others, department head, Engine Research Department; department head, Environmental Science Department; assistant department head and research engineer/group leader, Fuels and Lubricants Department. He has extensive experience on research and development to improve conventional spark ignition engines and on R&D to investigate the potential of new engine concepts. Mr. Gallopoulos was responsible for selecting the engine for the vehicle that General Motors developed as part of the government-industry Partnership for a New Generation of Vehicles (PNGV) Program. He has extensive expertise on advanced engines and alternative fuels for personal transportation vehicles. He was also active with Robert Frosch, a member of the National Academy of Engineering, in founding the field of industrial ecology. While at GM, he helped formulate energy policies in the 1970s and 1980s concerning fossil fuel and other resources, and he provided technical support for GM policy on global warming. He has a B.S. degree from Texas A&M University and an M.S. degree from Pennsylvania State University, both in chemical engineering.

Allan D. Murray is president of Ecoplexus, Inc., an automotive technology services company. Previously, he spent most of his career and has held a number of positions at Ford Motor Company, services as including technology director for the Partnership for a New Generation of Vehicles (PNGV) Program, a government-industry partnership to develop advanced, affordable fuel-efficient vehicles; and as manager, Technology Strategy, Plastic and Trim Products Division. As technology director of the PNGV program, Dr. Murray he led government-industry research and development teams pursuing advanced vehicle construction, power trains, fuel cells, batteries, and power electronics. In his other positions he also led development of leading-edge automotive plastic and composite products, processes and methodologies. He has extensive experience in bringing advanced

automotive technologies and products from concept through production, and has a broad-based knowledge of automotive systems and economics. He served as chairman and president of the nonprofit Michigan Materials and Processes Institute, was the first automotive engineer elected a fellow of the Society of Plastics Engineers, and is a member of the Society of Automotive Engineers. He has a Ph.D. and M.S. in metallurgical engineering and materials science from Carnegie Mellon University, a B.S. in metallurgical engineering from the University of British Columbia, and an M.B.A. from Wayne State University.

Robert J. Nowak is a consultant and former program manager at the Defense Advanced Research Projects Agency. He has directed and supported research in fuel cells, batteries, capacitors, energy harvesting, fuel processing, thermal energy conversion, micro-engines, hydrogen storage, biofuel cells, sonoluminescence, and biomolecular motors. Dr. Nowak received his B.A. and M.S. degrees in chemistry from Oakland University and his Ph.D. degree in chemistry from the University of Cincinnati. He was selected as National Research Council Postdoctoral Fellow at the Naval Research Laboratory in 1979.