III

Tank Waste Retrieval

As shown in Chapter II (Figure II-1), the first major step in the cleanup of the Department of Energy’s (DOE’s) tank wastes is to retrieve wastes from the tank. The effectiveness of waste retrieval technology is central to the committee’s task because it drives the cost, worker risk, and secondary waste production associated with the removal of waste from the tanks. These are key factors in deciding how much waste should be left behind in tanks for on-site disposal. The status, effectiveness, and challenges of waste retrieval technologies are the focus of this chapter.

DOE has developed and deployed a number of technologies for retrieving tank wastes. Because the three sites use similar technologies, this section begins with a generic description of the technologies and approaches used in various stages of the waste retrieval process. Most of this chapter addresses retrieval from the large underground storage tanks at the three DOE sites.

However, the Idaho National Laboratory also has six sets of large stainless steel bins containing reprocessing waste that was converted to a fine granular powder by a process called calcination. The calcined material is very different from the wastes stored in the tanks, and factors affecting its retrieval are discussed in the section concerning waste characterization. The chapter ends with the committee’s findings and recommendations related to tank waste retrieval.

WASTE RETRIEVAL TECHNOLOGIES AND APPROACHES

As described in detail in Chapter II, the waste that is to be retrieved from DOE’s large underground storage tanks can contain three distinct phases: (1) supernatant liquid, (2) precipitated saltcake containing mostly nonradioactive sodium compounds and soluble radionuclides such as cesium-137, and (3) viscous sludge.1 The phases usually occur in this order from top to bottom although the sludge and saltcake may be layered to some extent and both contain interstitial liquids having a composition typical of the supernatant liquid. Other materials may be present in the tank, such as debris and abandoned equipment.

The objective of DOE’s tank cleanup program is to retrieve waste to the maximum practical extent for subsequent processing. However, waste retrieval technologies suitable for removing large amounts of bulk waste are generally not suitable for removing small amounts of residual waste in a tank. Thus, tank waste retrieval technology is discussed in two parts, which address: (1) bulk waste retrieval (including supernatant liquid, saltcake, and sludge retrieval) and (2) retrieval of the residual remaining after bulk waste retrieval.

Bulk Waste Retrieval

Retrieval of the bulk of the tank waste necessarily begins with the supernatant liquid at the top and works down through the saltcake and sludge. The following sections describe the mobilization, collection, and removal of the bulk of these wastes.

Supernatant Liquid

Retrieving the bulk of the supernatant liquid is straight-forward because liquid waste is inherently mobile and can be removed readily by a “transfer” pump, much like a sump pump in a basement (see Figure III-1). The transfer pump is lowered into the tank to remove the liquid through a pipe or hose into a doubly contained underground pipe. The pumps used for this purpose need relatively low power compared to the mixing pumps used to mobilize waste forms such as saltcake and sludge, as discussed below. The technology for retrieving supernatant liquid is efficient and well established, although minor improvements continue to be made as a result of field experience.

FIGURE III-1 The SEEPEX transfer pump before installation. SOURCE: Reynolds, 2004.

Saltcake

Saltcake is composed mostly of readily soluble salts that precipitated because the saturation limit in the supernatant liquid was exceeded due to evaporation. The saltcake is dissolved to prepare it for removal by adding “fresh” water2 to the tank. Although it would be preferable to avoid adding fresh water to the tanks by using already contaminated recycled fluids, these fluids, such as supernatant liquid, are less efficient in dissolving the saltcake because they already contain high concentrations of salts or solids. Both the Savannah River and the Hanford Sites use “inhibited water” or “raw water” to dissolve saltcake. At Hanford Tank S-112, approximately 95 percent of the tank waste inventory was retrieved using saltcake dissolution; additional retrieval using high-pressure (>5000 pounds per square inch [psi]) jets of water is being performed to break up and mobilize the remaining hard heel. The resulting solution is circulated through the tank until the desired specific gravity (usually 1.3 to 1.4) is achieved.3 Tank S-102 is also currently undergoing saltcake dissolution.

Once the saltcake is dissolved, the resulting solution is then retrieved in the same manner as the supernatant liquid. As with supernatant liquid retrieval, this technology is efficient and well established with only minor improvements continuing to be made.

Sludge

Bulk retrieval of the sludge and other solid materials is considerably more challenging than supernatant liquid and saltcake retrieval because the sludge cannot readily be dissolved in water and pumped from the tank; it first has to be mobilized, suspended in the liquid, and collected near a transfer pump. At the Savannah River Site, the sludge is mobilized using large mixer pumps (also called “sluicing pumps” or “slurry pumps”; see Figure III-2) that mix it into a slurry by directing a jet of water into the waste layer.

At the Hanford Site, mixer pumps are planned for retrieval of waste from the newer double-shell tanks. However, the sludge waste in Hanford single-shell tanks is mobilized using different equipment. For structurally sound single-shell tanks, high-pressure jets of water and mixer pumps and transfer pumps, similar to the equipment used for saltcake retrieval, will be used to retrieve sludge. For single-shell tanks with questionable integrity, a vacuum retrieval system in combination with a mobile retrieval system (except for smaller-diameter 200-series single-shell tanks) will be used to retrieve sludge.

The Savannah River and Hanford Sites recognize that using recycled fluids, such as supernatant liquid from the same or surrounding tanks, to mobilize the sludge is better than using so-called fresh water because there is no net increase of waste volume and no subsequent need for evaporation. Moreover, the supernatant liquid has a viscosity 10 to 20 times higher than that of raw water because of its high salt content. The supernatant liquid has self-sealing properties (i.e., it will plug small leaks) and keeps the slurry better suspended. However, if only a small addition of fluid is

FIGURE III-2 Mixer pump used in Hanford Tank AZ-101.

SOURCE: Gasper, 2003.

needed to suspend solids, raw water is used to minimize equipment contamination, worker exposure, and risk of leaks.

The jets from the mixer pumps can be directed to impact various parts of the sludge layer and steer it toward the transfer pump intake. As with the supernatant liquid and dissolved saltcake, a transfer pump is then used to pump the slurry to a double-shell tank or compliant (“new-type”) tank. Eventually, the sludge from different tanks will be sent to processing facilities at the Hanford Site to separate the high-activity fraction from the low-activity fraction of the waste before vitrification, or washed then vitrified at the Savannah River Site.

The primary challenge in sludge retrieval is creating a slurrying jet that has sufficient energy to mobilize and mix the sludge across distances on the order of half a tank diameter (10.7 to 12.2 m or 35 to 40 feet) amidst the internal structures and debris. The Savannah River Site approach has been to build a steel superstructure atop each tank that is sufficient to mount four large (200 to 300 horsepower [hp]) electric motors. Each motor rotates a 12-meter- (40-foot-) long drive shaft having a directional pump attached at the bottom to mobilize sludge into a slurry that can be removed from the tank with a transfer pump. At Hanford, single-shell tank retrieval from tanks with questionable integrity is performed using either installed sluicing jets, the Hydrolaser, the vacuum retrieval system, or a crawler system described later.4

The approach to bulk sludge retrieval described above suffers from two significant shortcomings, the first of which is cost. The typical cost to retrieve the bulk of the waste from a single large tank is about $16 million to $24 million depending on whether there is a need to build a massive superstructure to support the mixer pumps (DOE-SRS, 2005d). The second shortcoming is the occupational dose to workers during mixer pump removal and insertion and during maintenance to repair problems caused by the bearings along the pump shaft.

Calcine

DOE has not yet begun retrieval of the 4,411 m3 of calcine from the bins at Idaho National Laboratory. Technologies being investigated for this purpose are discussed in Appendix G and issues concerning future retrieval are discussed in the section of this chapter dedicated to the adequacy of intank waste characterization for waste retrieval.

Technology Advances in Bulk Waste Retrieval

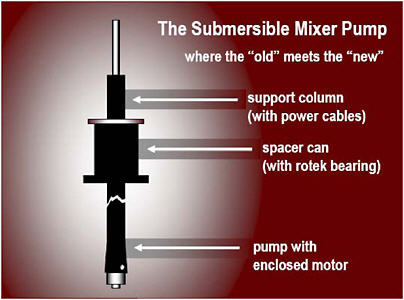

Advancements in technology for retrieval of bulk wastes are directed primarily at making engineering improvements in the large mixer pumps used to mobilize sludge to reduce cost and worker dose through incremental improvements in pump reliability. A notable recent technology at the Savannah River Site that may represent a step improvement in bulk waste retrieval is the “waste on wheels” (WOW) concept for bulk sludge removal. The WOW concept is centered on a specially designed submersible mixer (slurry) pump. This pump is similar to a conventional mixer pump except that a 305 hp drive motor is coupled to the pump and submerged, instead of being attached with a long shaft (see Figure III-3). The submersible mixer pumps are designed to be “self-supporting,” with some tanks requiring “limited” structural steel supports, while others require a more robust structural steel supporting system similar to standard slurry pumps. The amount of structural steel required will depend on a technical evaluation of each tank.

Submersible mixer pumps are designed to be retractable, portable, and reusable. The infrastructure (power, instrumentation) that supports each of these is also designed to be movable; hence, the name WOW. These pumps address the shortcomings of traditional mixer pumps: They eliminate the troublesome 12-meter shaft, have sufficient power and directional control so that the number of pumps used in each tank can be reduced from four to two, and allow bulk waste retrieval in some tanks without having to build a costly steel support structure over the tank. These pumps have been successfully demonstrated in the cold test facility at the Savannah River Site and installed to retrieve waste in Savannah River Site Tank 5 as this report was being written. As a consequence, information on the effectiveness and/or shortcomings of the submersible mixer pump is only just

FIGURE III-3 Submersible mixer pump used at the Savannah River Site Tank 5. SOURCE: Clark, 2005b.

beginning to become available. Additional details are provided in a later section titled Retrieval Experience.

Residual Waste Retrieval

Residual waste is what remains after the application of bulk retrieval technologies described above. Residual waste can be composed of any or all of the following:

-

Liquid and sludge in the bottom of the tank that could not efficiently be recovered using bulk retrieval technology;

-

Radioactive material on the internal surfaces (e.g., walls, cooling coils) of the tank above the level of waste in the bottom of the tank; and

-

Wastes composed of agglomerated materials that resist physical removal techniques to varying degrees. One example of such a material is the zeolite (see Appendix K) in some of the tanks at the Savannah River Site.

Waste remaining in the tank after the residual waste has been removed to the maximum extent practical is referred to as the “heel.” The heel is the fraction of the waste that cannot be further mobilized and removed by practical means and, therefore, will be grouted inside the tank (see Chapter V). The heel is composed mostly of insoluble metal hydroxides, oxides, and (at Hanford) phosphates containing strontium-90 and transuranic isotopes that are often viscous or consolidated into solids that are difficult to remove or located in inaccessible locastions. To limit the amount of waste left in the tanks, the mobilization and collection steps of residual waste (after bulk waste retrieval) are critical to the success of the tank cleanup process.

Physical Technologies for Residual Waste Retrieval

The primary objective of residual waste retrieval technology is to mobilize and collect the waste at a point where it can be removed from the tank while minimizing secondary waste production. A variety of physical mobilization and collection technologies have been developed, and these have been implemented using a variety of deployment technologies. (Table F.2 in Appendix F summarizes the available technologies for residual waste retrieval.)

Physical technologies for mobilizing residual waste and collecting it at a point in the tank that is accessible by a transfer pump include using a combination of the following: hydraulic techniques involving the use of pressurized water; a vacuum; mechanical techniques to dislodge the waste for collection and mobilization. All physical techniques for retrieving residual wastes in tanks require some type of deployment technology. To date the dominant deployment technology for residual waste retrieval has been mechanical arms. The most popular type of arm used at DOE sites is a relatively simple mast inserted through a riser from which an arm containing one or two joints projects and some type of retrieval device extends (see Appendix G).

Chemical Technologies for Residual Waste Retrieval

When physical technologies for retrieving residual waste have not been deemed sufficient, DOE has employed chemi-

cal technologies to remove remaining tank wastes. Tests performed in the late 1970s and early 1980s (Bradley and Hill, 1977; Hill, 1978; West, 1980) proved oxalic acid solutions to be the most effective reagent for dissolving sludge while not corroding the carbon steel tank (see Appendix G).

One reason DOE has cited for not using oxalic acid is a concern that it may compromise nuclear criticality safety.5 Since its interim report, the committee has received additional information from the Savannah River Site staff on criticality concerns. According to the Savannah River Site staff, sludge heels after bulk waste removal may contain enough fissile mass,6 on average, to cause a criticality event (DOE-SRS, 2005e). As DOE recognizes, the available data are inconclusive with regard to the potential for criticality during oxalic acid dissolution because the bulk of the material, including the fissile material, may be removed before the ratio of fissile to poison falls below safe storage limits. Savannah River Site staff told the committee that each tank heel needs to be evaluated before attempting dissolution with oxalic acid to determine whether any potential for criticality exists and if so how to mitigate that risk. The committee has not seen any additional calculations regarding the criticality issues and cannot determine whether the concern is well founded. In Chapter IX, the committee recommends that DOE investigate the matter further.

According to DOE, there are additional downstream complications when using oxalic acid due to the large amounts of acid needed to dissolve the residual sludge. If oxalic acid is added to the sludge before washing, it goes to the evaporator and may precipitate in the feed tank. If oxalic acid is added to the salt tank, it may precipitate and form a hard salt layer that would require additional water to remove.

DOE has indicated that it is planning to use oxalic acid as a final cleaning step at the Savannah River Site on a tank-by-tank basis, taking into account the factors listed above (DOESRS, 2005d). Hanford is not planning at this time to use oxalic acid to clean its tanks.

Technology Advances for Mechanical Residual Waste Retrieval

DOE is considering the use of the Power Fluidic TechnologyTM developed by AEA Technology and a similar Russian Pulsating Mixer Pump technique for residual waste retrieval at the Hanford and the Savannah River Sites (Murray, 2005). This technology involves using two or more nozzles in a tank to establish a “back-and-forth” motion of the sludge and a vacuum induced by fluid flow through a “jet pump system,” as shown in Figure G-6 in Appendix G.

This technology does not have any mechanical devices inside the tank and is supposed to use water more efficiently than conventional mixer pumps. Fluidic technology is claimed to be useful for bulk waste as well as residual waste retrieval and for mixing the grout with waste residuals that cannot be removed further. However, like other technologies, its effectiveness on waste in tanks with vertical cooling coils is uncertain.

Hanford tested a prototype using fluidic technology in a full scale cold test facility, and determined that the complex air and fluid controls and air handling systems would require significant maintenance. Concerns were also raised about radiation exposures to workers and meeting ALARA (as low as reasonably achievable) requirements for operations in the single-shell tank farm system. To the committee’s knowledge, no further deployment of fluidic technology for waste retrieval from single-shell tanks is planned. Use of fluid jets for mixing grout with waste residuals is still under consideration.

GENERAL WASTE RETRIEVAL ISSUES

The discussion above has alluded to future difficulties that can be expected when retrieving waste from DOE’s “complicated” tanks. Some of the important complications are discussed below. In addition to general issues, a number of site-specific issues may limit the extent to which wastes can be retrieved, as discussed in Appendix G.

-

Recalcitrant Waste Deposits: Waste may be encrusted on internal tank surfaces or structures in a semidry form, or it can agglomerate in physical and chemical forms that resist physical removal technologies. These recalcitrant waste deposits must be mobilized before they can be collected and removed from the tanks.

-

Waste Accessibility: To remediate a tank, the waste has to be accessible to waste removal streams or tools. One of the main challenges in waste removal is the number and type of physical obstacles in the tanks and tank design features that complicate waste retrieval operations. The most difficult issue to overcome is likely to be the vertical cooling coils in Savannah River Site tanks, which severely impede the ability to maneuver water jets, mechanical arms, and intank vehicles. The Hanford tanks, although they do not have cooling coils, have other internal obstructions such as the air-lift circulators that were used to stir and suspend the sludge in high-heat tanks.

-

In-tank Debris: Most underground storage tanks, especially at Hanford and Savannah River Site, contain objects labeled as debris. These can include failed pumps, instrument trees, sluicers, hoses, and miscellaneous items. Some items have been left in place (e.g., suspended from the top of the tank), while others (such as tapes for measuring waste depth) have been dropped into the tanks. If heel retrieval systems that use vehicles or mobile in-tank systems

-

are to be deployed, debris may become a problem even if these systems are capable of removing or moving this debris around the tanks.

-

Residual Waste in Pipelines and Ancillary Equipment: The large underground storage tanks that are the primary focus of retrieval are interconnected by myriad pipelines and ancillary equipment, such as small underground storage tanks, pumps, valve boxes used to transfer tank wastes among the large tanks, and other hardware used in waste retrieval operations. As a part of routine practice, the majority of pipelines and ancillary equipment has been or will be flushed with nonradioactive water. Consequently, the remaining waste is expected to contain amounts of radionuclides that are small relative to what is being left in the tanks. Foremost among the challenges associated with the pipelines, is the fact that some of them became plugged during use so they could not be flushed to remove most of the residual radionuclides. DOE is inclined to propose that most pipelines and ancillary equipment be flushed and grouted in situ, while it considers exhumation of plugged pipelines where necessary (Harbour et al., 2004; Schaus, 2005).

-

Leaks to the Environment: To varying degrees, all three DOE sites have inadvertently released waste contained in tanks into the environment. Such releases raise two issues: (1) the degree of retrieval from the tanks that should be required, given the amount of radionuclides in the immediately surrounding environment, and (2) the application of removal to the “maximum extent practical” to leaked radionuclides.

EVALUATION OF RETRIEVAL TECHNOLOGY STATUS

The purpose of this section is to evaluate the status of retrieval technologies by drawing on the discussion in the foregoing sections.

Technology Availability

Table F-2 in Appendix F summarizes the main waste retrieval tools in DOE’s “toolbox.” The waste retrieval tools are grouped in broad classes (see column 1, Appendix F) because each site has developed or is using modified versions of the techniques. The table also indicates if and where a device was deployed or tested.

Retrieval Experience

All three DOE sites have operational experience retrieving liquid wastes from many tanks as a result of years of moving waste among the tanks as a part of day-to-day operations in the tank farms. There is no estimate of the amount of liquid waste that has been retrieved but such operations are considered routine. Table F-1 in Appendix F shows the status of tank waste retrieval operations at the three sites.

Both Hanford and Savannah River Site staff have some experience retrieving saltcake wastes (Idaho tanks have no saltcake) although not nearly as much as with liquids. In some cases, higher-pressure liquid jets and higher dissolution temperatures have been needed to overcome endothermic reactions and some complex waste chemistry solid-liquid equilibrium issues. However, DOE has substantial operating experience in dissolving saltcake and retrieving the resulting liquids.

The Savannah River Site has some operational experience with sludge removal. Sludge removal operations began in 1969 at the Savannah River Site for tank space management, to test waste retrieval technologies, or to retrieve sludge for processing and immobilization in the Defense Waste Processing Facility (Saldivar, 2002; DOE-SRS, 2005a). However, past sludge removal operations were not carried out with the purpose of removing waste from a tank “to the maximum extent practical.” That is, there is much more experience with bulk retrieval of sludge than with residual waste retrieval. Savannah River Site tank retrieval experience is summarized as follows:

-

Tank 16 was taken out of service because of leaks and became the first case in which DOE attempted to completely remove the bulk of the waste from a tank at the Savannah River Site. In 1979 254 m3 (67,000 gallons) were removed with hydraulic techniques, and 5.3 m3 (1,400 gallons) were removed in 1980 with chemical cleaning. There was minimal saltcake in this tank. The slurry pumps were extremely effective in removing the sludge. Oxalic acid was used to remove the residual waste. This tank has cooling coils.

-

Waste has been retrieved from Tanks 17 and 20, and these tanks have been filled with grout. Tank 20 contained very little sludge, while Tank 17 contained a minimal amount of sludge and no zeolites. Neither of these tanks has cooling coils.

-

Waste has been retrieved from Tanks 18 and 19. DOE has submitted a draft waste determination necessary to allow these tanks to be closed (DOE-SRS, 2005a). Tank 19 contained very little sludge and a substantial amount (49.2 m3 [13,000 gallons]) of zeolites, while Tank 18 contained substantial amounts of sludge and minimal amounts (7.6 m3 [2,000 gallons]) of zeolites. Neither of these tanks has cooling coils.

-

Waste retrieval from Tank 5 began in October 2005 and is ongoing. Bulk waste retrieval ended mid-December 2005. The submersible mixer pump used on this tank is described above (Figure III-3). The volume of wet solids remaining after the first phase of bulk waste retrieval in Tank 5 is between approximately 68 m3 (18,000 gallons) as calculated and 93 m3 (24,500 gallons) as estimated from mapping the sludge mound at the bottom of the tank (Daily, 2005a). Most of the remaining solids were located in the northwest quadrant of the tank where an array of cooling coils partially obstructed the mixer discharge jets. This is the first tank with cooling coils that has undergone bulk retrieval

-

operations since Tank 16. A second mixing campaign was initiated in late November 2005 using a new mixer orientation to focus on the remaining solids (Purohit, 2005). An additional 7.6 m3 (2,000 gallons) of sludge were removed in the second sludge retrieval campaign (Daily, 2005b). The submersible mixer pumps have been taken out of Tank 5 and installed in Tank 6 for bulk waste removal. Waste removal activities in Tank 5 will resume following completion of waste removal from Tank 6. Heel removal and cleaning of Tank 5 will follow completion of the bulk waste removal phases.

-

Tank 6 is also undergoing waste retrieval (February 2006). As noted above, the submersible mixer pumps have been removed from Tank 5 and installed in this tank. Waste removal activities in Tank 6 are anticipated to occur through April 2006. This tank also has cooling coils.

In summary, after Tank 16, Savannah River Site staff chose to begin waste retrieval from relatively uncomplicated tanks to obtain experience and is now proceeding to work on the more complicated Tank 5. Removal operations in Tank 5 and Tank 6 are DOE’s first attempt to retrieve substantial quantities of sludge from tanks containing vertical cooling coils. Tank 5 is a leaking tank, with 13 known leak sites, although there is no significant waste accumulation in the tank annulus. A new leak appeared within two weeks of initiating sludge removal operations but only as a wet spot on the tank’s outer wall. Leaks are monitored with video cameras in the tank annulus; however, only 25 percent of the annulus surface is visible because of the location of the cameras and risers.

Tank 4 is the next Savannah River Site tank to be cleaned; it also contains sludge and cooling coils. The order in which waste is retrieved from the tanks depends on the feed blending requirements for the Defense Waste Processing Facility.

The Hanford Site has somewhat less operational experience with sludge removal than Savannah River. Hanford experience is as follows:

-

Tank C-106 had a significant amount of sludge removed (187,000 gallons) during the 1997-1998 campaign using sluicing techniques. Sludge removal was enhanced using modified sluicing and chemical dissolution (additional 32,500 gallons) in the 2003 campaign.

-

Sludge removal using modified sluicing started in November 2005 and is in progress in Tank C-103 (75,000 gallons of sludge initially).

-

Hanford gained experience removing hard deposits of saltcake in Tank S-112 by using water jets to break them up, facilitating dissolution.

-

Waste retrieval using the vacuum retrieval system is deemed complete in Tanks C-202 and C-203 (both 208.2 m3 [55,000-gallon] tanks).

-

Waste retrieval using the vacuum retrieval system is under way for Tank C-201 (started in October 2005).

-

Waste retrieval from Tank C-204 will begin in April 2006.

-

Removal of 302 m3 (80,000 gallons) of sludge from Tank C-108 has slated to start late in 2005 using the modified sluicing technique.

-

Removal of 302 m3 (80,000 gallons) of sludge from Tank C-101 using the Mobile Retrieval System is planned but a date has not been set.

Because of the number of tanks and waste types present at this site, the sludge removal experience gathered thus far is not necessarily representative of the type of waste retrieval challenges faced when cleaning the site’s 18 tank farms. To date, all experience has been in a few tanks inside just two of these tank farms.

The Idaho site has retrieved waste from 7 of the 11 1135.6 m3 (300,000-gallon) tanks and from all 4 of the 113.6 m3 (30,000-gallon) tanks (see Table F.1 in Appendix F for details). The other tanks are still being used to hold sodium-bearing waste awaiting immobilization. The site has successfully deployed the same retrieval techniques (pumping and water washing) for the tanks thus far and plans to use the same technology for all of the remaining four tanks.

Retrieval Effectiveness

The most important measure of retrieval effectiveness is the amount of radioactive material left in the tank for on-site disposal (i.e., increasing retrieval effectiveness leaves decreasing amounts of radioactive material). While bulk retrieval may remove most of the radionuclides, the effectiveness of bulk retrieval technologies is essentially irrelevant to determining the amount of radionuclides left in a tank. As a consequence, this section focuses on the effectiveness of residual waste retrieval technologies. The effectiveness of DOE’s retrieval efforts that have been completed at Hanford, the Savannah River Site, and Idaho National Laboratory is summarized in Table F-1 in Appendix F.

Based on the information in Table F-1, it is evident that waste retrieval has been very effective for certain tanks. For example, the heels in Savannah River Site Tanks 17 and 20 and all of the Idaho National Laboratory tanks cleaned to date each contain less than 3,000 Ci (1. × 1.11 × 1014 Bq). Indicators of more effective retrieval appear to be (1) the absence of solid materials such as sludges and (2) the use of chemical cleaning on deposits where the chemicals would be expected to be effective. Experience with cleaning tanks with oxalic acid indicates that it is not universally effective in reducing the amount of radionuclides remaining in the tank. For example, it appears to be effective on many sludges but not on zeolite deposits.

Indicators of less effective retrieval appear to be the presence of recalcitrant solid materials, especially zeolite deposits containing relatively high concentrations of cesium-137. It is too soon to tell how the general and site-specific

issues discussed above will affect retrieval effectiveness because retrieval from tanks having such materials is just beginning.

In summary, each tank is essentially unique in terms of waste type, tank design, and history. DOE’s bulk waste removal strategy is sensible and has thus far been successful. DOE is learning from experience, improving its understanding of the unique conditions in each tank as it progresses with tank cleanup, and developing and adapting technology to accommodate these differences. DOE is to be commended for exchanging technical information among sites to allow lessons learned to be incorporated in the program. Activities such as the yearly Hanford and Savannah River Site technical exchange meetings, the workshop on lessons learned from the closure of Tanks 17 and 20 at the Savannah River Site in 1998, frequent conference calls, and activities previously undertaken by the Tanks Focus Area are helpful. The Savannah River Site is also planning a technical workshop in March 2006 to identify technologies, including commercially available ones that could be implemented for the heel removal and tank cleaning activities for Tanks 5, 6, and others, with emphasis on techniques that minimize secondary waste volume generation.

The Tanks Focus Area was a particularly helpful approach for centralizing information and lessons learned for all DOE tank sites. The Tanks Focus Area was a user-driven, needs-based program within DOE’s Environmental Management Office of Science and Technology.7 This program performed research, development, and deployment activities on tank waste characterization, monitoring, safe waste storage, retrieval, closure, pretreatment, and immobilization. The Tanks Focus Area’s reports and the Innovative Technologies Summary Reports (the latter was another initiative of DOE’s Office of Science and Technology) are still available on the Internet and provide a valuable although somewhat dated centralized information database on DOE’s tank waste sites, including lessons learned.8 (See further discussion in Chapter IX.)

Tank Waste Retrieval Operations at Other DOE Sites

DOE has two additional sites at which radioactive waste has been stored in underground tanks: (1) the West Valley Demonstration Project (WVDP), New York, and (2) Oak Ridge National Laboratory, Tennessee. Table III-1 summarizes the main features of the tanks at these two sites, which are discussed briefly below. More detailed descriptions of the tank cleanup efforts at these sites can be found in Appendix G. Some of the information is based on data published in 2002.9 Since then, most of the waste at the two sites has been retrieved and the remaining out-of-service tanks at Oak Ridge have been closed. DOE reports that retrieval of high-level waste from the West Valley Demonstration Project tanks was completed in 2002 and the residual sodium-bearing wastewater was retrieved from the two largest underground tanks in 2003. The wastes at these sites have some characteristics in common with wastes at the Savannah River Site and Hanford, although the tanks in New York and Tennessee are not as large as the largest tanks at the Hanford and Savannah River Sites (see Table III-1).

West Valley Demonstration Project

Between 1966 and 1972, the West Valley Demonstration Project plant generated approximately 2,317 m3 (612,000 gallons) of high-level waste. This waste consisted of 2,271 m3 (600,000 gallons) of alkaline plutonium-uranium extraction (PUREX) sludge and supernatant liquid and approximately 45 m3 (12,000 gallons) of acidic thorium extraction (THOREX) waste. The site had two tanks for these waste streams, and two additional tanks were used for secondary waste streams during waste processing. The retrieved wastes were immobilized in a vitrification facility, which operated between 1996 and 2002. The vitrified high-level waste canisters are intended for disposal in a geologic repository.

Oak Ridge National Laboratory

The liquid low-level radioactive waste system at Oak Ridge National Laboratory (ORNL) dates back to the mid-1940s when ORNL was constructed as part of the Manhattan Project. ORNL was a pilot site for Hanford chemical processes and had approximately 390 m3 (103,000 gallons) of sludge stored in a system consisting of nine large Gunite10 tanks and numerous smaller metal tank systems (Lewis et al., 2002a). In addition, the tanks contained small quantities of dried waste that had the consistency of chalk. The Gunite tank sludge (solids) contained approximately 85,000 Ci (3.1 × 1015 Bq). This radioactivity came from uranium, plutonium, thorium, and other long-lived isotopes, as well as from the high concentrations of cesium-137 and strontium-90, which have relatively short half-lives. The tanks also contained organic materials in trace amounts and other heavy

|

7 |

DOE’s Office of Science and Technology along with the Tanks Focus Area were disbanded in 2002 when the Office of Environmental Management was reorganized. |

|

8 |

Tanks Focus Area reports are available at http://www.tanks.org and the Innovative Technologies Summary reports available at http://apps.em.doe.gov/OST/mainpubs.asp. |

|

9 |

DOE provided data on West Valley and Oak Ridge in addition to the data taken from the cited references. Not all of these data agree, as reflected in differences between the numbers in Table III-1 and the text. The committee did not research or examine them further because these sites are not the focus of this study. |

|

10 |

Gunite is a mixture of Portland cement, sand, and water sprayed over a wire mesh and reinforcing rod frame. |

TABLE III-1 Tank Waste Retrieval Programs at the West Valley Demonstration Project, New York and Oak Ridge National Laboratory, Tennessee

|

|

West Valley Demonstration Project |

Oak Ridge National Laboratory |

|

Number of tanks to close |

4 |

67 (does not include tanks currently in active service) |

|

Tank types and material |

2 carbon steel tanks (8D-1 and 8D-2) and 2 stainless steel tanks (8D-3 and 8D-4) |

Various configurations of tanks. Includes 16 Gunite tanks; the remainder are stainless steel tanks (horizontal and vertical orientations that are direct buried, located in vaults, or in building basements) |

|

Tank sizes |

57 to 2,839 m3 (15,000 to 750,000 gallons) |

0.76 to 644 m3 (200 to 170,000 gallons) |

|

Tank diameters |

21 m (70 feet) carbon steel tanks 4 m (12 feet) stainless steel tanks |

1 to 15 m (3 to 50 feet) |

|

Tank conditions |

No leakers |

No leakers; however, many inactive tanks collected in leakage prior to closure |

|

Waste types |

Alkaline (neutralized PUREX waste) in 8D-1 and 8D-2; acidic (THOREX waste) in 8D-4; decontamination process solutions in 8D-3 |

Low-level waste liquids, low-level and transuranic sludges |

|

Waste volumes |

2,317 m3 (612,000 gallons) |

1,893 m3 (500,000 gallons) |

|

Radionuclide contents |

300,000 Ci not including short-lived decay products. |

5,500 Ci |

|

Internal obstructions |

Significant (complex bottom structural grid work and some in-tank hardware) |

In-tank hardware, including structural supports, piping, and instrumentation |

|

Status of retrieval |

More than 97% of long-lived radionuclides removed.a |

Interim CERCLA closure complete for 67 inactive tanks (1995 through 2005). Retrieval and disposal of sludge from active (i.e., in-service) Melton Valley storage tanks to be completed as part of Transuranic waste programb,c,d,e |

|

Bulk waste retrieval methods |

Mobilization pumps, sluicing, and pumping |

Sluicing (using nozzles, lances, and borehole miner) or mixing (using fluidic pulse jet, pulsed air, pulsating mixer pump, and Flygt mixers) and pumpingb |

|

Residual waste retrieval methods |

Flushing, acid washing, robotics, and sluicing |

Mixing (Flygt mixers and fluidic pulse jet), sluicing (borehole miner, high-pressure nozzles, and lances), and confined sluicing |

|

Closure schedule |

Not yet finalized; closure expected to take up to 20 years |

67 Federal Facility Agreement Category C and D tanks (inactive tanks) closed through 2005; remaining active service tanks will be scheduled for closing as storage mission is completed |

|

Maximum tank age (years at closure) |

More than 50 |

More than 50 |

|

Site- and tank-specific considerations and uncertainties |

Corrosion; “bathtub ring” along the walls of 8D-2; 8D-1 contained spent zeolites (3 m3 of solids);d,e water in vaults |

Waste not classified as high-level; in-tank chunks of Gunite; various types, sizes, and configurations of tanks |

|

NOTES: CERCLA = Comprehensive Environmental Response, Compensation, and Liability Act. DOE provided the data in this table and the committee did not research or examine them further because these sites are not the focus of this study. a Waste retrieval status as of February 2, 2006, from DOE-WV, 2006. b Waste retrieval status information from DOE-ORNL, 2005. c Elmore and Henderson, 2002a. d Bamberger et al., 2001. e Hamel and Damerow, 2001. SOURCE: Adapted from Elmore and Henderson, 2002a. |

||

metals. Groundwater had leaked into the tanks, adding approximately 1300 m3 (345,000 gallons) of water. This water accumulated on top of the sludge in an aqueous supernatant layer. The supernate and the tank walls contained an additional estimated 15,000 Ci (5.6 × 1014 Bq). In tank cleanup operations, ORNL constituted a test bed for a number of retrieval technologies considered for deployment at other sites.

Comparing Table III-1 with Table II-5, which lists information about the tank wastes at the Savannah River Site, the Hanford Site, and Idaho National Laboratory, shows the similarities and the differences among the tank types and types of waste at Oak Ridge and West Valley. The experience with Silo 3 calcine retrieval at the Fernald Environmental Management Project discussed in Appendix G also bear some similarities to Idaho National Laboratory’s calcine retrieval, although the radioactive contents of calcine are very different. Given the differences in the physical and chemical properties of the waste and tank designs, not all the experience gathered at these other sites is relevant to the three sites addressed in this report. However, sharing lessons learned and communication among the sites may still be helpful as DOE continues its cleanup mission.

Cost of Bulk and Residual Waste Retrieval Using Physical Techniques

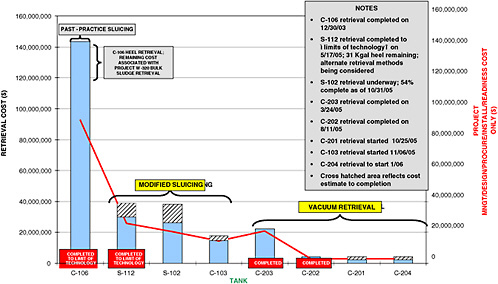

The cost of waste retrieval includes costs for bulk waste retrieval and costs for residual waste retrieval. Despite the relatively limited number of waste retrievals that have been completed, the cost of waste retrieval has decreased substantially as a result of learning from experience. The best example of this occurred at Hanford (see Figure III-4) where the combined cost of the first retrieval effort on a large tank (C-106) was about $140 million, whereas the comparable costs of more recent retrievals ranges from $20 million to $40 million. The projected cost for the next group of tanks (208.2 m3 [55,000-gallon]) is around a few million dollars each and estimated to be about $15 million for a large tank.

The first cost decrease in Figure III-4 (from Tank C-106 to Tanks S-112 and S-102) is attributable to switching from “past-practice” sluicing, which used very large volumes of water, to “modified sluicing,” which uses water more efficiently to target, mobilize, and collect the sludge. The second cost decrease (to Tanks C-201 through C-204) is attributable to moving from permanently installed equipment and pipelines to portable modules that are reusable (to some extent),

FIGURE III-4 Waste retrieval costs and status at Hanford as of November 17, 2005. SOURCE: Quintero, 2005a.

and the use of temporary above-ground transfer lines that substantially reduce infrastructure costs. The third (projected) cost decrease appears to be driven by a transition from existing hydraulic technologies (e.g., water jets) to the reusable Mobile Retrieval System (see Appendix G), which further reduces water usage by employing a vacuum device combined with a mechanical vehicle to push waste. It should be noted that in all cases, most of the cost is attributable to moving equipment to a tank and installing it, not to retrieval operations per se. The estimated cost for retrieving waste from the larger 100-series tanks using the Mobile Retrieval System is about $20 million per tank. However, the cost savings realized so far do not necessarily reflect substantive cost savings in waste removal operations in the future, given the limited number of tanks that have been completely cleaned to date.

Retrieval at the Savannah River Site began with modified sluicing for bulk waste retrieval. As a consequence, combined retrieval costs are comparable to those at Hanford and range from $23 to $34 million per tank excluding costs for chemical cleaning. As previously mentioned, the Savannah River Site has just begun retrieving waste from Tank 5 using a submersible mixer pump. This technology is expected to reduce the retrieval cost to a range between $6 and $14 million. The cost reduction is attributable to the pump’s added effectiveness compared to the long-shaft mixer pumps, so that the number of pumps required in each tank is reduced from four to two; also to the use of the submersible pumps in multiple tanks, which reduces the cost per tank. The spread in cost range is attributable to the need for superstructure above the tanks: tanks with small amounts of sludge do not require a superstructure, whereas tanks with large amounts of sludge would require such a superstructure (DOE- SRS, 2005d).

The design safety analysis at the Savannah River Site requires an evaluation for hydrogen gas release from tanks containing sludge when mixing-removal operations are planned. Safety analyses assume that the quantity of sludge in the tank dictates the amount of hydrogen gas retained in the sludge (same number of grams of hydrogen per inch of depth). Mixing the sludge releases gas that is otherwise held up in the sludge. There is a limit to the allowable rate of hydrogen released. The submersible mixer pumps mix everything above them and are assumed not to mix sludge 30-45 cm (12 to 18 inches) below. To reduce the gas release rate, submersible mixer pumps are suspended closer to the top of the sludge and work their way down. Suspending the submersible mixer pumps at different heights requires a superstructure. In the case of Tank 5, because of its gas release calculation, all of the sludge could be mixed simultaneously. Therefore, the Tank 5 submersible mixer pumps could be lowered to the tank bottom. In some of the other tanks (e.g., Tank 4), the gas release calculation from sludge mixing may dictate that submersible mixer pumps cannot be lowered to the tank bottom, and therefore some superstructure will be required to support them at different levels of mixing.

At the Idaho National Laboratory, waste has been retrieved from seven 1136 m3 (300,000-gallon) tanks and four 114 m3 (30,000-gallon) tanks from 2002 to 2005 at a total (development plus operations) of $35 million. This yields an average cost of $7 million per tank, although this number is likely to decrease slightly because some of the development costs will be allocated to the four remaining tanks where retrieval has not yet been completed. Although many of the Idaho tanks have cooling coils on their bottoms, the relatively low retrieval costs can be attributed to the favorable physical characteristics of the waste (i.e., absence of hard sludges, solid particles easily washed from walls and suspended in the tank liquids).

Cost of Additional Residual Waste Retrieval

One important factor in determining whether radionuclides have been removed to the maximum extent practical is the cost of retrieving additional residual waste from the tanks when the limit of the baseline technology has been reached. Savannah River Site staff has developed cost estimates for additional waste retrieval from Tanks 18 and 19 using three different approaches: (1) additional hydraulic sluicing using a closed loop similar to that in the Mobile Retrieval System now being deployed at Hanford, (2) an intank vehicle similar to the vacuum device now being deployed at Hanford as part of the Mobile Retrieval System, and (3) chemical cleaning with oxalic acid. The additional cost for such cleaning is estimated to range from $10 to $15 million per tank if a tank has been taken “out of service.” This estimated cost for chemical cleaning can be compared to the estimated cost for chemical cleaning of Tank 16 ($250,000) and a 1999 estimate of about $1 million.

The significant increase in the recent estimate for Tanks 18 and 19 is due to the fact that these two tanks have been taken out of service, which means substantial efforts are required to reverse preparations made for closure (e.g., reconnecting support equipment and utilities) and additional safety and operational constraints. These same assumptions were used for the other two alternatives. Presumably, the cost of applying chemical cleaning to a tank that is still in service would be closer to $1 million than to $10 million given the additional safety requirements that were introduced since oxalic acid was applied to Tank 16 (Hill, 2005).

At the Hanford Site, costs for additional waste retrieval from Tank C-106 have been estimated to be $1.24M to $2.97M per m3 ($35,000 to $84,000 per cubic foot), or a total of $5.7M to $13.5M, depending on the retrieval technology if it is assumed that approximately 4.5 m3 (160 cubic feet) of waste would be removed (Sams, 2004). This assumption was made for purposes of analysis only and is by no means assured if the additional technology were to be actually deployed.

At the Idaho National Laboratory, development and deployment of a new technology for retrieval of additional residual waste is estimated to cost slightly more than development and deployment of the existing tank cleaning system. The cost of the new technology (mechanical, chemical, or arm based) was estimated by applying an escalation rate of 10 percent to the tank waste retrieval cost to date, yielding $38.5 million per tank. Idaho National Laboratory believes the actual cost would likely be higher because the new technology may not be able to use much of the existing infrastructure at the site. A large fraction of the cost is independent of the technology used to retrieve waste because it involves the preparation of plans and other documentation, testing, readiness reviews, equipment mobilization, installation, demobilization, and leak detection and monitoring during waste retrieval.

Worker Dose Estimates During Retrieval

Cleaning up large underground tanks is a hazardous operation even for tanks that do not contain radioactive waste (Cole, 1992). The additional cumulative worker doses resulting from further retrieval efforts is estimated to be 7,150 millirem (mrem or 71.5 millisieverts, mSv) for 11 1135.6 m3 (300,000-gallon) tanks11 at the Idaho National Laboratory and ranges from 4,500 to 7,500 mrem (45 to 75 mSv) per tank at the Savannah River Site (DOE-ID, 2005a; DOE-SRS, 2005a). The larger values at the Savannah River Site are presumably a result of the substantial effort that would be required to prepare a “ready-for-closure” tank for retrieval operations. Site staff are still analyzing the information on worker dose risks gathered during waste retrieval (e.g., through radiation surveys and job task analysis). Hanford does not have worker dose estimates for waste retrieval. Information on worker doses during retrieval from Tank C-106 is not readily available because waste retrieval operations comprised many activities spread over a 7 to 10 years and the site did not keep track of cumulative worker dose at that time. It is possible to reconstruct the cumulative worker dose for the entire period, but the information has not yet been compiled (Quintero, 2006).

Estimated Dose to the Public from Closed Tanks

The reduction in dose to the public from retrieving additional residual waste has been estimated by DOE for both the Savannah River Site and Idaho National Laboratory tank waste determinations (DOE-SRS, 2005a; DOE-ID, 2005a) and for Tank C-106 at Hanford (Sams, 2004). The estimates are based on the extent to which the dose rate to a hypothetical member of the public would be reduced by removing or reducing the radionuclide inventory in the tank and multiplying this by an assumed 50 years of exposure to yield the dose avoided by an individual. If 100 percent of the residual waste were to be removed by additional retrieval, a situation that is not actually possible because of limitations on the efficiency of separations, the avoided all-pathways dose to an adult residing in proximity to the F Area Tank Farm at the Savannah River Site is 2 mrem for Tank 18 and 0.45 mrem (4.5 mSv) for Tank 19 (DOE-SRS, 2005a).12 The Idaho Section 3116 waste determination for its tank farm estimates that the remaining radioactivity in the tank farm poses a potential radiation all-pathways dose to a member of the public on the order of 0.5 mrem (5 mSv) per year, with approximately half of the dose due to tank heels. Removing all tank residuals would achieve a dose reduction of approximately 0.25 mrem (2.5 mSv) per year, or 12.5 mrem (125mSv) over 50 years, regardless of cost (DOE-ID, 2005a).

The Hanford Site estimates that removing an additional 4.5 m3 (160 cubic feet) of residual waste from Tank C-106 would reduce the all-pathways doses from the current residual volume (10.5 m3 [370 cubic feet]) from 2.5 × 10−3 to 1.39 × 10−3 mrem per year (2.5 × 10−5 to 1.39 × 10−5 mSv per year) calculated at the fence line of Area C (Sams, 2004, p. 2-37). Therefore, the avoided dose over 50 years would be 0.05 mrem (or 1.11 × 10−3 mrem [1.11 × 10−5 mSv] per year over 50 years) for Tank C-106. Hanford estimates that this further waste reduction entails an incremental lifetime cancer risk reduction of 8 × 10−9 at a cost of $5.7 million to $13.5 million. The avoided dose over 50 years at each site is significantly different because of differing natural settings (e.g., different hydrogeology) and assumptions used in the underlying performance assessments (see Chapter VI).

Adequacy of In-Tank Waste Characterization for Waste Retrieval

Waste retrieval requires knowledge of physical data about the waste (e.g., density, particle size, viscosity, fraction of solids) to facilitate pumping and to avoid plugging the pipelines. Such knowledge is gathered relatively easily by grab sampling. DOE’s approach has been thus far to begin waste retrieval with the knowledge available on the waste and adapt retrieval technologies to the conditions encountered in the tanks.

One case that may prove to be more complicated than anticipated is retrieval of calcine waste at the Idaho National

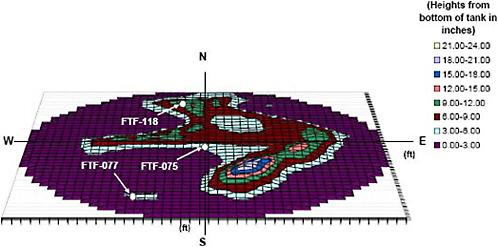

FIGURE III-5 Residual material configuration and sample locations for Tank 19 at the Savannah River Site. SOURCE: DOE-SRS, 2005a, p. 66.

Laboratory. (Retrieval of calcine is discussed at greater length in Appendix G.) DOE plans to retrieve this granular powder from the stainless steel silos (bin sets) by reversing the process by which it was emplaced: vacuuming it from the bins through the risers at the tops. DOE conducted a successful test with simulated waste: caked calcine was readily dislodged by physical contact with the vacuum head, and the calcine could be transported pneumatically. However, whether the actual calcine will behave like the simulant after residing in the bins for several decades is uncertain. Retrieval of a different calcine from a silo at DOE’s Fernald site proved challenging because of compaction. A previous National Research Council (NRC, 1999b, p. 22) report states that, given the little characterization information about the Idaho calcine (see Chapter II),

it would be difficult to conclude that there would be no problem with pneumatic retrieval. Indeed the committee believes that there will be problems but that they can probably be handled. However, this eventually might require mechanical operations to aid particle flow and more elaborate retrieval methods (e.g., a manipulator arm) than simple pneumatic transfer.

The committee agrees with this assessment. Previous studies (NRC, 1999b; CRESP, 2005) have concluded that the calcine in the bins can be safely stored for hundreds of years because of the absence of water in the bins, the stability of the calcine, and the dry environment. As a consequence, addressing the disposition of the wastes contained therein has justifiably been accorded a lower priority in the face of more pressing issues at the Idaho National Laboratory and other DOE sites. The committee identifies the calcine retrieval and bin disposition as issues for further examination.

Adequacy of Retrieved Waste Characterization to Support Operations and Disposal of Retrieved Wastes and Heels

Characterization of heels is necessary to determine their chemical and radionuclide composition (actinide content, alpha, gamma, and beta emitters) to calculate the “source term” in the performance assessment of the tank once closed. Tank heels left in the tanks must also be characterized to demonstrate that the waste has been adequately removed and that the residues can be left in the tanks. Heel characterization is performed by visual inspection through cameras, sampling, special analysis,13 and predictions based on knowledge of wastes that were sent to the tank (process knowledge). Figure III-5 shows an estimate of the residual waste at the bottom of Tank 19 at Savannah River after residual waste removal based on a visual inspection.

Obtaining, packaging, shipping, and analysis of each sample resulted in personnel radiation exposure. Tank 19 sample dose rates were as high as 8,000 mrem (80 mSv) per hour dose to the hands and 4,000 mrem (40 mSv) per hour dose to the whole-body. The total whole-body worker dose received from the three solid samples was approximately 200 mrem (2 mSv). Tank 18 sample dose rates were as high as 150 mrem (1.5 mSv) per hour dose to the whole body. The total whole-body worker dose received from the six solid samples and the one liquid sample was approximately 120 mrem (1.2 mSv) (DOE-SRS, 2005a, p. 63). Detailed discussion of tank heel sampling can be found in the performance objective demonstration document for Tanks 18 and

19 (Buice et al., 2005). The heel sampling campaign at the Savannah River Site showed that the heel contains less radioactive material than the bulk of the waste because it was thoroughly rinsed by waste slurring and tank washing. Those rinses removed some of the soluble radionuclides, which decreased the radioactive inventory and leachability of the heel compared to the bulk waste.14 The time that water would be in contact with the waste in post-closure degradation scenarios is, however, much greater than the duration of tank cleaning operations; thus, even low leach rates for long-lived radionuclides, such as technetium-99 and neptunium-237, can result in groundwater contamination. Both the reduced release rates and the duration of contact with water are important factors in determining residual risks to a member of the public and hence how clean is clean enough.

Evaluation of How Clean Is Clean Enough?

Up to this point the sites have used similar information to decide when to cease retrieving waste. All three sites use the amount of solids removed from the tanks per cycle of mixing and pumping as the main criterion for determining that waste has been removed “to the maximum extent practical.” The solids removal rate is usually high at the beginning of waste retrieval, regardless of the technique used, but as retrieval proceeds and there are fewer solids to recover, it decreases and eventually becomes constant at a low value. At some point, considerations such as the amount of secondary waste generated versus the amount of solids removed, cost, worker dose, and tank space limitations justify a decision to stop waste removal.

At the Savannah River Site, 46 cycles of sluicing and pumping were applied to remove the zeolite from Tank 19 and six cycles for Tank 18. Once the removal rate decreased significantly and went below 200 gallons of solids per cycle and 5,000 gallons of solids per cycle for Tank 19 and Tank 18, respectively, waste removal was deemed complete. The Draft Section 3116 Waste Determination reads (DOE-SRS, 2005a, p. 91):

a number of obstacles prevented further residual waste removal. The obstacles fell into three categories: (1) fast-settling zeolite resins, (2) general tank access limitations and obstructions, and (3) mounds of insolubles. In addition to those obstacles, FFA [Federal Facility Agreement] requirements [i.e., tank closure milestones] for closure of Tank 19 and Tank 18, as well as tank space constraints were additional factors that prevented further residual waste removal.”

However, the committee observes that if one retrieval method shows diminishing effectiveness, other methods may still prove effective. Simply repeating a procedure 46 times does not demonstrate that all practical efforts have been made. Also, constraints imposed by closure schedules should not be an important consideration in selecting retrieval methods if scheduling interferes with effective waste removal.

At the Hanford Site, before DOE can make a waste determination concerning classification of the residual waste, it must meet the waste retrieval requirements specified in the Tri-Party Agreement (TPA). The TPA directs DOE to “remove as much tank waste as technically possible, with tank waste residues not to exceed …” 30 cubic feet (.85 m3) in the small 200-series tanks and 360 cubic feet in the large 100-series tanks. Then, to make a determination that the waste is not high-level waste under DOE Order 435.1, DOE must, among other things, demonstrate that the residues remaining in the tank “have been processed, or will be processed, to remove key radionuclides to the maximum extent that is technically and economically practical.”

To meet this criterion, DOE must remove waste from the tanks to the maximum extent that is technically and economically practical because radionuclides generally cannot be removed from the tanks without removing other wastes as well. The metric that Hanford uses to decide when to cease retrieving residual waste is the volume of waste being retrieved versus the amount of new waste being created.

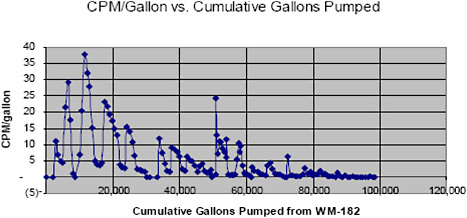

At Idaho National Laboratory, the waste retrieved from the tank was monitored for its radioactivity until it reached an asymptotic value (see Figure III-6). Visual examination (comparison of waste levels in the bottom of the tank to the thickness of known benchmarks) and waste sampling are also used at the three sites to assess the progress of waste retrieval.

In the two recent tank waste determinations at the Savannah River Site and Idaho, DOE presented (although in a somewhat qualitative way) its trade-offs among some of the key technical factors that lead it to conclude that enough waste has been retrieved from Tanks 18 and 19 at the Savannah River Site and will be retrieved from the entire tank farm in Idaho. DOE also made similar trade-offs in the documents recently submitted to the U.S. Nuclear Regulatory Commission (USNRC) showing how waste removal from Tank C-106 at Hanford has reached the technology limit, as required by the Tri-Party Agreement (Sams, 2004). In essence, DOE separately compares the estimated cost (dollars) and worker dose (millirem) from additional retrieval for each tank to the estimated dose to a hypothetical member of the public over 50 years (millirem) that would be avoided by the additional retrieval. This comparison (a ratio) is used as the primary justification in the Savannah River tank waste determination for waste having already been retrieved to the maximum extent practical (Gilbreath, 2005).

As stated previously, the 50-year avoided all-pathways dose to a member of the public residing in the proximity of the tanks ranges from 0.45 to 2 mrem (4.5 to 20 mSv) for the

FIGURE III-6 Radioactivity (counts per minute per gallon) measured during cleaning operations at the Idaho National Laboratory.

SOURCE: DOE-ID; 2005a, figure 13, p. 53.

Savannah River Site, and 12.5 to 23 mrem (125 to 230 mSv) for Idaho National Laboratory,15 and is 0.05 mrem (5 × 10−4 mSv) for the Hanford Site. The cost per avoided unit of dose ranges from about $5 million per mrem to more than $30 million per millirem at the Savannah River Site, from $1.7 to $3.08 million per millirem at Idaho National Laboratory, and from $100 to $240 million per millirem to further remove waste from Tank C-106 at Hanford. The Idaho waste determination reports that the average worker dose for cleaning and closing the 11 1135.6 m3 (300,000-gallon) tanks is expected to total about 7,100 mrem (71 mSv) for all occupational exposure. The ratio of increased worker dose to avoided 50-year dose to the public ranges from about 2,000 mrem (20 mSv) to more than 16,000 mrem (160 mSv) at the Savannah River Site and between 309 and 568 mrem (3.1 to 5.7 mSv) at Idaho. Both ratios assume that all of the residual waste is recovered. Similar information is not available for the Hanford Site because worker doses received during cleanup of Tank C-106 are still not available.

On this basis, DOE determined that the risk reduction does not justify further waste removal from Savannah River Site Tanks 18 and 19. The committee notes that the risk-benefit assessment used as a rationale for the waste determination at the Savannah River Site did not discuss the assumptions about the “dollar value” of a dose or provide any framework to compare the doses and costs calculated for additional waste retrieval to doses and costs in different scenarios (e.g., doses to the public after only the waste that is easy to retrieve is removed). The Idaho waste determination reaches the conclusion that further waste retrieval is not necessary in a different way (DOE-ID, 2005a, p. 58):

[W]ith typical average doses to the public from natural sources and medical treatment in the range of 300-400 mrem per year, it is not judged practical or cost effective to reduce the estimated dose from [the tanks] by such a small amount.

The Hanford Site compares the additional waste retrieval costs for Tank C-106 to human health risk reduction (expressed as incremental lifetime cancer risk) based on residual waste volume in the tank (Sams, 2004). The cost ratios for the Savannah River Site were based on what DOE considers conservative assumptions but could be considerably lowered with foresight — for example, by undertaking additional residual waste retrieval before preparing the tank for closure. Additional discussion of doses to the public from the tank heels and assumptions used in the tanks performance assessments is provided in Chapter VI.

For completeness, at Oak Ridge National Laboratory the criteria for stopping waste retrieval were to leave (1) no visible sludge; and (2) residual dirty water in bottom of tank roughly equivalent to the water that would be added during decontamination of retrieval equipment during retraction. At the West Valley Demonstration Project site, flushing effectiveness was monitored using sampling, radiological dose rate changes, and visual inspection. The heels in the tanks were then characterized as described above to determine whether they meet the Class C criteria. Three important operational criteria that determined whether residuals were removed to the maximum extent practical were (1) the chances for melter or major equipment failure during waste retrieval; (2) loss of qualification of vitrified high-level waste form; and (3) significant increases of glass volume.

The committee observes that the question, How clean is clean enough? has both policy and technical dimensions because it involves trade-offs among risks to workers, the public, and the environment and cost. In theory, some combination of residual waste retrieval technologies could continue to be applied until the radionuclides in the waste residuals are reduced to negligible levels. In practice, the possibility of removing radionuclides to this extent is counterbalanced by diminishing returns; reduced leachability of residual radionuclides,16 limits on funds; the dose to workers that occurs during retrieval efforts; the potential for or reality of leaks to the environment during retrieval; and the generation of increasing amounts of secondary waste. There are also nontechnical factors to be considered such as stakeholder values (see discussion in Chapter VIII). Data on the costs and worker doses associated with each tank cleaning option were scant. Input to decisions about the maximum extent practical and ALARA would be improved if DOE kept careful records of costs and worker doses as progress is made on these first tank cleanings and closures.

Part of the answer to the question, How clean is clean enough? is provided by performance assessments to evaluate whether waste left in the tanks meets the performance objectives set forth in the legislation, DOE orders, and federal facility agreements governing waste removal (see Chapter VI). As discussed in Chapters VI and VIII, results in the performance assessment are based on assumptions and scenarios that take place over long periods of time and involve great uncertainties. Assumptions about the duration of institutional controls are a particular case in point. If DOE’s assumptions about institutional controls are not correct, members of the public could reside near the closed tanks or low-activity disposal site within a few hundred years, and doses to the public could be sufficiently large enough that the cost and worker risk associated with additional retrieval might be justified. The issue of how long institutional controls are assumed to keep people away from the closed tanks is a matter of policy that cannot be resolved scientifically.

Another part of the answer to the question, How clean is clean enough? is provided by DOE and its contractors through a discussion of technology limitations. Waste retrieval from DOE tanks is a one-of-a-kind and first-of-a-kind endeavor. There is no other activity that can serve as a benchmark for estimating radiation exposure to workers, technology possibilities and limitations, cost estimates, time lines, and so forth. The regulators and stakeholders have to rely on DOE for such inputs to the decision about whether waste has been retrieved to the maximum extent practical. Deciding the appropriate balance among these competing factors is the essence of deciding whether radionuclides have been removed to the maximum extent practical and, thus, that the tank is “clean enough” to proceed to closure.

Therefore, the debate often revolves around what “retrieval to the maximum extent practical” means and whether further decreasing the estimated risks to the public by retrieving additional waste from the tanks justifies additional worker exposure and retrieval costs. Because of the variability of the physical, chemical, and radiological characteristics of the residual waste in each tank, such decisions must be made on a tank-by-tank basis.

FINDINGS AND RECOMMENDATIONS

Finding III-1: Retrieval of waste from each tank is essentially unique in terms of waste types, tank design, and history. DOE is learning from experience, improving its understanding of the unique conditions in each tank as it progresses with tank cleanup, and developing and adapting technology to accommodate these differences.

Recommendation III-1: Depending on the particular requirements of individual tanks, DOE should select and use the most effective sequence of waste retrieval tools from the available suite of tools to ensure that waste is removed to the maximum extent practical. When the limit of a given technology is reached, DOE should evaluate the need to use other waste retrieval tools.

Finding III-2a: Sequential application of available waste retrieval technologies, such as sluicing of bulk waste and the use of pressurized water jets, in-tank vehicles, vacuum devices, or chemical cleaning, has been very effective in retrieving waste from some tanks at all three sites, with residual waste inventories amounting to a few thousand curies or less in a large tank.

Finding III-2b: Available waste retrieval technologies have been less effective on other tanks, primarily those that contain sludges that are thick and difficult to mobilize and solid deposits such as zeolites that can be dislodged but are difficult to remove.

Finding III-2c: DOE will face additional challenges as it continues its tank retrieval efforts. The primary challenges are a forest of vertical cooling coils that will impede the access and maneuverability of retrieval devices in most of the tanks at the Savannah River Site and the potential for additional waste leakage to the environment from tanks at Hanford as water is introduced to retrieve wastes. A combination of such technologies as leak detection, waste mobilization, and waste removal devices that use little water could address the Hanford challenges and are now being deployed. Solutions to the challenge at the Savannah River Site must await the results of ongoing retrieval efforts to better characterize the nature and extent of the problems posed by the coils.

Recommendation III-2: During tank cleanup and closure operations, DOE should continue to adapt and develop effective technologies for waste retrieval with emphasis on tanks with obstructions and recalcitrant waste. (See also Recommendation IX-2 in Chapter IX.)

Finding III-3: DOE has estimated the cost, public dose avoided, and worker dose increase from deploying residual waste retrieval technologies to determine that radionuclides have been recovered to the maximum extent practical. Long-term risks are based on the results provided by the performance assessment and the assumptions in it, particularly those about the duration of institutional controls. If DOE’s assumptions about institutional controls are not correct and members of the public reside near the closed tanks within a few hundred years, doses to the public could be sufficiently large that the cost and worker risk associated with additional retrieval might be justified. The issue of how long institutional controls are assumed to keep people away from closed tanks is a matter of policy that cannot be resolved scientifically. (See Chapter VI, Recommendation VI-2, which is based on Finding III-3 and Finding VI-2.)

Finding III-4: DOE has pneumatic technology for retrieving calcine from the bins at the Idaho National Laboratory and has successfully demonstrated this technology on simulated waste, including caked waste and waste exposed to humid conditions that could cause agglomeration. However, the exact characteristics of the waste in the bins is not precisely known and DOE may face challenges (such as very hard calcine deposits) when it proceeds with retrieval. Because the waste is in a very stable storage situation that could remain for decades if not centuries, DOE has deferred retrieval of this waste or even decisions regarding it in favor of addressing higher priorities at DOE sites.

Recommendation III-4: DOE should continue modest efforts to anticipate calcine characteristics and develop appropriate retrieval technologies for these situations.

Finding III-5: DOE is to be commended for exchanging technical information among sites to allow lessons learned to be incorporated in the program.

Recommendation III-5: Activities such as the yearly Hanford and Savannah River Site technical exchange meetings, technical workshops on tank waste retrieval and tank closure, frequent conference calls, and activities previously undertaken by the Tanks Focus Area are helpful and should be continued.