THE NATIONAL ACADEMIES

Advisers to the Nation on Science, Engineering, and Medicine

Board on Army Science and Technology

Mailing Address: 500 Fifth Street, NW Washington, DC 20001 www.nationalacademies.org

July 26, 2006

Mr. Michael A. Parker

Director

Chemical Materials Agency

5183 Blackhawk Road Edgewood Area Aberdeen Proving Ground, MD 21010-5424

Re: Review and Assessment of the Proposals for Design and Operation of Designated Chemical Agent Destruction Pilot Plants (DCAPP–Pueblo)

Dear Mr. Parker:

As requested by the Program Manager, Assembled Chemical Weapons Alternatives (PMACWA),1 the National Research Council (NRC) of the National Academies has established committees to review and assess proposals to design and build two different chemical agent destruction pilot plants. (See Attachment A for the statement of task.) The first committee, called the Committee to Review and Assess the Proposals for Design and Operation of Designated Chemical Agent Destruction Pilot Plants (DCAPP–Blue Grass), has already reported to you on the supercritical water oxidation system design proposed for the Blue Grass Chemical Agent Destruction Pilot Plant. This second committee, called the Committee to Review and Assess the Proposals for Design and Operation of Designated Chemical Agent Destruction Pilot Plants (DCAPP–Pueblo), now presents its assessment of the processes in the enhanced reconfiguration building (ERB), the agent processing building (APB), and the biotreatment area (BTA) for the proposed design of the Pueblo Chemical Agent Destruction Pilot Plant (PCAPP) in Colorado.

This study was initiated on May 18, 2006, and had to be completed within 60 days of initiation. In view of the short study schedule and the detailed nature of the task, the NRC selected committee members with extensive past experience in the destruction of chemical weapons. (See Attachment B for committee composition.) The DCAPP–Pueblo committee has reviewed and assessed the proposal submitted by the Bechtel Pueblo Team (BPT) for the design

and operation of the PCAPP. (See Attachment C for all references.) This letter summarizes the committee’s findings. Attachment D contains the full assessment, which is not accessible to the public under Subsection 15(b)(3) of the Federal Advisory Committee Act, 5 U.S.C. App., as amended by the Federal Advisory Committee Act Amendments of 1997, P.L. 105-153, December 17, 1997, 111 Stat. 2689. The NRC has determined that to release this information to the public would disclose information described in 5 U.S.C. 552(b). Attachment E acknowledges the contributions of the reviewers.

BACKGROUND

In July 2002, the Army issued a request for proposals to design, build, operate, and close a full-scale pilot plant facility at Pueblo Chemical Depot. A system contract was awarded to Bechtel Corporation in September 2002. The teaming subcontractors are Parsons Corporation, Battelle Memorial Institute, and the Washington Demilitarization Company, a wholly owned subsidiary of Washington Group International. General Physics Corporation and General Atomics Advanced Process Systems are lower-tier subcontractors. An intermediate design for PCAPP was presented to PMACWA in May 2004. However, when the Department of Defense estimated that the life-cycle cost for this design would be $2.6 billion instead of the targeted $1.5 billion, both it and the Congress requested a redesign of the plant. BPT has produced a modified design to comply with the Department of Defense’s instructions. This assessment focuses on the technical aspects of the systems configurations, the maturity, and the schedule of the proposed modified design. An earlier NRC committee had already completed a report on the original design, Interim Design Assessment for the Pueblo Chemical Agent Destruction Pilot Plant (NRC, 2005), in which it assessed the unit operations and system integration.

The chemical weapons stockpile at Pueblo Chemical Depot contains 105-mm boxed cartridges, palletized 155-mm projectiles, and 4.2-inch mortars, all of which are filled with one of two forms of mustard agent, HD or HT. The physical and chemical properties of mustard agent are given in Table 1.

TABLE 1 Physical and Chemical Properties of Mustard Agents Stored at Pueblo Chemical Depot.

|

Agent Characteristic |

HD |

HTa |

|

Chemical name |

Bis(2-chloroethyl) sulfide or 2,2?-dichlorodiethyl sulfide |

Same as HD with 20 to 40 wt% agent T, Bis[2-(2-chlorethylthio) ethyl] ether |

|

Chemical formula |

C4H8Cl2S |

Not applicable |

|

Molecular weight |

159.07 |

188.96 (based on 60/40 wt%) |

|

Vapor density (relative to air) |

5.5 (calculated) |

6.5 (calculated based on 60/40 wt%) |

|

Boiling point |

218°C (424°F) (extrapolated) |

No constant boiling point because it is a mixture |

BRIEF DESCRIPTION OF THE PROPOSED SYSTEM

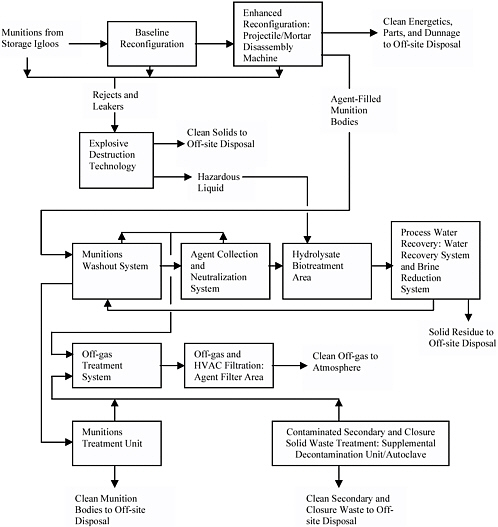

A simplified block diagram of the proposed destruction system is shown in Figure 1. The munitions are transported to the ERB, where they are unpacked. The propellant is removed from the boxed 105-mm projectile cartridges and the boxed 4.2-inch mortar rounds. The 155-mm projectiles are removed from their pallets. All munitions are passed through the projectile/mortar disassembly machines (PMDs), where lifting lugs, fuzes, and bursters are separated from the projectile bodies that still contain chemical agent sealed in the projectile body by the burster well. BPT plans to send noncontaminated energetics2 off-site to an existing permitted disposal facility. At each major step in the disassembly process, the rounds are monitored for agent vapor

leaks. Any leakers (contaminated rounds) or munitions that cannot be opened safely (rejects) are placed into overpacks and sent to a unit that will use explosive destruction technology to destroy them without disassembly.

FIGURE 1 Functional block diagram for the PCAPP intermediate redesign.

Noncontaminated rounds are transported to the APB, where they enter the munitions washout system. For projectiles, the burster well that seals in the chemical agent is rammed into the body to gain access to the agent. For mortars, the base plate is cut off. In either case the agent is then drained out and a high-pressure water jet cleans any remaining solids from the body. The empty metal bodies are sent to the munitions treatment unit (MTU), where they are heated to over 538°C (1000°F) for 15 minutes.

The chemical agent is piped to the agent neutralization system, where it is treated with hot water to neutralize the agent. Caustic is added to raise the pH to 10-12. Because the product of this reaction produces a multicomponent waste stream (hydrolysate) that remains a hazardous material (although it contains no detectable agent), it must undergo further treatment. Biotreatment on-site is the process proposed for treating the agent hydrolysate.

SCOPE AND METHODOLOGY

The committee was directed to assess the technical aspects of the PCAPP redesign, its maturity, and its ability to meet the schedule. The committee interpreted “schedule” to mean the process schedule (i.e., the time duration required to destroy the munitions from the first munition to the last). This excludes systemization and closure. Thus, the process schedule is essentially a function of the throughput rate and the availability of the equipment used in the rate-determining steps in the process.

This assessment is based on data received from PMACWA, the proposed design, the tests and demonstrations performed by BPT in support of the design and documented in the Technical Risk Reduction Project reports, and the presentations given by PMACWA and BPT at the May 18–19, 2006, meeting. It assumed that energetics, dunnage, packing materials, and the other noncontaminated waste will be sent off-site as planned by BPT. The committee assessed biotreatment even though it is possible that the hydrolysate might be sent off-site for treatment. The committee focused on the design of the ERB, the APB, and the BTA. It also assessed the system integration and the plant throughput and availability analysis provided with the proposal with respect to assumed impacts on the process schedule.

The committee received, reviewed, and assessed numerous documents and their supporting material. These documents are exempt from public disclosure under Subsection 15(b)(3) of the Federal Advisory Committee Act, 5 U.S.C. App., as cited on page 2. Documents reviewed include, but are not limited to, the following:

-

System design descriptions for the agent collection and neutralization system, autoclave, biotreatment system, brine reduction system, explosive destruction technology, munitions transport and storage system, MTU, munitions unpack and PMD, munitions washout system, off-gas treatment system, residue handling, and supplemental decontamination unit;

-

Other technical information on the cavity access machines, explosive destruction technology, munitions handling robots, MTU, prototype PMD, and secondary waste streams and waste container traffic;

-

An engineering study of on-site materiel transfer alternatives for munitions delivery and secondary waste handling;

-

The throughput and availability analysis for PCAPP;

-

The PCAPP plot plan;

-

The facility design description, general arrangement, and equipment arrangement for the ERB; material, process, and other flow diagrams; and the secondary waste stream summary for the ERB;

-

The general arrangement and equipment arrangement for the APB; technical information on the various cavity access machines to be used in the APB; process and other flow diagrams; and the secondary waste stream summary for the APB;

-

Process flow diagrams for the BTA;

-

Process flow diagrams for the off-gas treatment system; and

-

PCAPP redesign briefings by BPT.

The committee held two meetings. At the first, the committee received briefings by PMACWA and BPT, and considerable discussion took place between the committee and the subject matter experts. Follow-on exchanges with the contractor took place electronically in response to the committee’s additional questions. The second meeting focused on finalizing the written assessment.

GENERAL FINDINGS AND RECOMMENDATIONS

The following general findings and recommendations summarize the conclusions of the committee regarding the design proposal. The supporting narrative for these findings is given in Attachment D of the report.

Finding 1. Based on the design and testing information and data presented, the committee’s assessment is that the proposed design will destroy the chemical weapons effectively with little technical risk, provided that the testing of first-of-a-kind equipment is completed successfully. The committee agrees with:

-

using an explosive destruction technology to destroy leakers and rejects;

-

sending noncontaminated energetics and dunnage off-site for disposal or recycling rather than processing on-site, greatly simplifying the process with no adverse environmental impact;

-

using commercially available equipment for treating metal parts;

-

using the supplemental decontamination unit and autoclave for decontaminating secondary wastes to the new airborne exposure limit standards.

Recommendation 1. The Bechtel Pueblo Team should proceed with a rigorous testing program for the first-of-a-kind equipment and system integration, and should address the other points raised by the committee in this proposal review, in order to ensure the success of the project.

Finding 2. The Pueblo Chemical Agent Destruction Pilot Plant design could be further simplified by treating agent hydrolysate off-site if institutionally feasible.

Recommendation 2. If institutionally feasible, the opportunities for off-site hydrolysate treatment should be investigated. A first and necessary step in this investigation would be to

assess the amount of trace contaminants, such as heavy metals, that an off-site facility would have to process and their impact on the treatment of the hydrolysate.

Finding 3. The schedule presented to the committee seems longer than necessary for the following reasons: (1) the availabilities assumed for Pueblo Chemical Agent Destruction Pilot Plant process equipment are low in comparison with those for industrial equipment; (2) the processing rates used are lower than the design rates; and (3) more significantly, the long ramp-up rates specified for each campaign are longer than necessary, given the time already included in the schedule for systemization. Furthermore, the committee observes that information from the contractor indicates that the state permitting authorities do not require such long ramp-up rates.

Recommendation 3. Once the overall Pueblo Chemical Agent Destruction Pilot Plant system has demonstrated its ability to perform the individual operations effectively and safely and personnel are properly trained, the facility production rate should be increased.

Finding 4. There is a mismatch between the processing rates of the munitions washout system (MWS) and the other components of the Pueblo Chemical Agent Destruction Pilot Plant system. This could be resolved by either increasing the MWS capacity or by decreasing the capacity of the other steps. The former would shorten the schedule, while the latter would not affect the schedule.

Recommendation 4. The mismatch in processing rates between the munitions washout system and other Pueblo Chemical Agent Destruction Pilot Plant system components should be resolved.

Finding 5. The Bechtel Pueblo Team (BPT) has close relations with the Colorado regulators, and the Pueblo Citizen’s Advisory Commission has been very effective in obtaining public support. The committee thus believes that BPT will not encounter serious permitting problems.

Recommendation 5. The Bechtel Pueblo Team should continue to work closely with the Colorado Chemical Demilitarization Citizens’ Advisory Commission’s Permitting Working Group and all other stakeholders to expedite the planning, development, and implementation of the permitting process.

Attachment A

Statement of Task

Contractual Statement of Task

The NRC will establish an ad hoc Committee to Review and Assess the Proposals for Design and Operation of Designated Chemical Agent Destruction Pilot Plants (DCAPP Committee). This new committee will receive, review, and assess the proposals submitted by the Bechtel National, Inc. for the Pueblo Chemical Agent Destruction Pilot Plant in Pueblo, Colorado, and the Blue Grass Chemical Agent Destruction Pilot Plant in Richmond, Kentucky, to consider the technical aspects of systems configurations, maturity, and schedule. The committee will provide a review to the Army of these proposals to advise them in their procurement decisions regarding award of the task order.

Plan of Action

In response to the request by the Department of Defense and the Program Manager, Assembled Chemical Weapons Alternatives, the National Research Council established the Committee to Review and Assess the Proposals for Design and Operation of Designated Chemical Agent Destruction Pilot Plants (DCAPP-Pueblo Committee) to receive, review, and assess the proposals submitted by the Bechtel Pueblo Team for the Pueblo Chemical Agent Destruction Pilot Plant in Pueblo, Colorado. The committee considered the technical aspects of systems configurations, maturity, and schedule of the enhanced reconfiguration building (ERB), the agent processing building (APB), and the biotreatment area (BTA).

Attachment B

Roster and Biographies

ROBERT A. BEAUDET, Chair, University of Southern California, Los Angeles

CHARLES BARTON, Iowa Department of Public Health, Des Moines

JOAN B. BERKOWITZ, Farkas Berkowitz & Company, Washington, D.C.

WILLARD C. GEKLER, Consultant, PLG, Inc., Los Alamitos. California

MARTIN GOLLIN, Carmagen Engineering, Inc., St. Davids, Pennsylvania

DAVID S. KOSSON, Vanderbilt University, Nashville, Tennessee

JOHN MERSON, Sandia National Laboratories, Albuquerque, New Mexico

CHANDRA ROY, Exponent, Inc., Irvine, California

STANLEY I. SANDLER, University of Delaware, Newark

MICHAEL K. STENSTROM, University of California, Los Angeles

Staff

BRUCE A. BRAUN, Director, Board on Army Science and Technology

MARGARET N. NOVACK, Study Director

DETRA BODRICK-SHORTER, Administrative Coordinator

JAMES C. MYSKA, Research Associate

LaVONNE WILLIS, Senior Program Assistant

BIOGRAPHIES

Robert A. Beaudet received his Ph.D. in physical chemistry from Harvard University in 1962. From 1961 to 1962, he was a U.S. Army officer and served at the Jet Propulsion Laboratory as a research scientist. He joined the faculty of the University of Southern California in 1962 and has served continuously in the Department of Chemistry since that time. He also has served on Department of Defense committees addressing both offensive and defensive considerations surrounding chemical warfare agents. He was chair of an Army Science Board committee that addressed chemical detection and trace gas analysis. He also was the chair of an Air Force technical conference on chemical warfare decontamination and protection. He has participated in two NRC studies on chemical and biological sensor technologies and energetic materials and technologies. Most of his career has been devoted to research in molecular structure and molecular spectroscopy. Currently, Dr. Beaudet is chair of the Committee on Assembled Chemical Weapons Alternatives Program. Previously, he served on the NRC’s Board on Army Science and Technology (BAST), on the NRC Committee on Review of the Non-Stockpile Chemical Materiel Disposal Program, and as a BAST liaison to the Committee on Review and Evaluation of the Army Chemical Stockpile Disposal Program (Stockpile Committee).

Charles Barton received his Ph.D. in toxicology from the University of Louisiana. Dr. Barton is currently the Iowa state toxicologist at the Iowa Department of Public Health. In addition to

being a certified toxicologist, he is certified in conducting public health assessments, health education activities, and risk assessments; in emergency response to terrorism and emergency response incident command; and in hazardous waste operations and emergency response. In his position as the state toxicologist, Dr. Barton serves as the statewide public health resource, providing health consultations and advice to other environment and health-related agencies as well as to health-care providers and to business and industry representatives. He currently directs, or has directed, a host of Iowa Department of Public Health programs, including programs for PCBs, radon, water treatment system registration, hazardous substances emergency surveillance, hazardous waste site health assessment, risk assessment for the Superfund program, the Iowa toxicology program, and many others.

Joan Berkowitz is currently managing director of Farkas Berkowitz & Company. She graduated from the University of Illinois with a Ph.D. in physical chemistry. Dr. Berkowitz has extensive experience in the area of environmental and hazardous waste management, a knowledge of the technologies available for the cleanup of contaminated soils and groundwater, and a background in physical and electrochemistry. She has contributed to several of the Environmental Protection Agency studies, been a consultant on remediation techniques, and assessed various destruction technologies. Dr. Berkowitz is the author of numerous publications on hazardous waste treatment and other environmental subjects.

Willard C. Gekler is currently an independent consultant working for his previous employer, ABS Consulting, Inc. He graduated from the Colorado School of Mines with a B.S. in petroleum refining engineering and pursued graduate study in nuclear engineering at the University of California at Los Angeles. Mr. Gekler’s extensive experience includes membership of NRC’s ACWA committee and of the Mitretek Systems expert panel reviewing the quantitative risk assessments and safety analyses of hazardous materials handling, storage, and waste treatment systems for the Army’s Anniston, Umatilla, Pine Bluff, and Aberdeen chemical agent disposal facilities. He also participated in a consequence screening assessment for the Newport Chemical Disposal Facility. Previously he was project engineer for various nuclear test facility designs and for development of facility design criteria for the Johnston Atoll chemical agent disposal system. His expertise is in hazard evaluation, quantitative risk analysis, reliability assessment, and the development of databases for risk and reliability. Mr. Gekler is a certified reliability engineer and a member of the Society for Risk Analysis, the American Institute of Chemical Engineers (AIChE), and the American Nuclear Society (ANS).

Martin Gollin graduated from Loughborough University of Technology in England with a B.S. and an M.S. in chemical engineering. He is currently a consultant affiliated with Carmagen Engineering, Inc. He has worked for an engineering contractor (Davy McKee), an R&D company (Dynatech), and an operating company (ARCO Chemical). He has extensive experience in process engineering, capital projects, commissioning, process safety, environmental processes, relief system design, and heat transfer. He has held positions in engineering design and engineering management. He was the EH&S manager for a $1 billion grass-roots project in the Netherlands and was a member of the AIChE’s Center for Chemical Process Safety and of the panel that wrote the book LOPA—Layer of Protection Analysis. He is a member of the Research and Evaluation of International Technologies for the Destruction of

Non-Stockpile Chemical Materiel and has also been a member of several other NRC committees. His consulting work involves projects for the Centers for Disease Control and Prevention, petrochemical companies, and pharmaceutical companies and he has presented two courses (“LOPA” and “Process Design for Safe Operations”) for the American Institute of Chemical Engineers.

David S. Kosson is chairman of and professor in the Department of Civil and Environmental Engineering and professor of chemical engineering at Vanderbilt University. Previously, he was professor of chemical and biochemical engineering at Rutgers. He has a B.S. in chemical engineering, an M.S. in chemical and biochemical engineering, and a Ph.D. in chemical and biochemical engineering from Rutgers, The State University of New Jersey. Dr. Kosson has carried out research and published extensively on subsurface contaminant transport phenomena; leaching phenomena; physical, chemical, and microbial treatment processes for hazardous waste; and waste management policy. He has been a member of the NRC Committee on Alternative Chemical Demilitarization Technologies, the Panel on Review and Evaluation of Alternative Chemical Disposal Technologies, and the Committee on Review and Evaluation of the Army Chemical Stockpile Disposal Program, where he served as chair for 2 years.

John A. Merson is currently a senior manager in the Geoscience & Environment Center at Sandia National Laboratories. His experience at Sandia has included research, development, and application of energetic materials and components within the nuclear weapons stockpile. He has been responsible for surveillance, chemical compatibility, energetic material characterization, and advanced component development and production. He has designed components for DOE, DOD, and NASA programs. Dr. Merson received a B.S. and M.S. in chemical engineering from the University of New Mexico and a Ph.D. in chemical engineering from Arizona State University. He is a member of the AIChE and other professional societies.

Chandra M. Roy is a managing engineer in Exponent’s mechanics and materials practice in Irvine, California. Dr. Roy specializes in the application of qualitative and quantitative risk assessment methodologies to engineered and business systems and processes. He also conducts consequence analysis for the release of hazardous chemicals. He has conducted source term analysis, dispersion analysis, and fire and explosion analysis for accidental releases of airborne chemicals. Additionally, he is skilled in the analysis of failure and incident data for use in risk modeling. He is also familiar with a wide range of chemical processes and has experience in the operational management of the chemical process industry. He has authored or coauthored several technical publications and presented a number of papers and short courses. Dr. Roy received a Ph.D. in chemical engineering and an M.S. in nuclear engineering from the University of California, Santa Barbara, M.S. in chemical engineering from Pennsylvania State University, and a B.E. in chemical engineering from the University of Roorkee, India.

Stanley I. Sandler, NAE, holds the Henry Belin du Pont Chair and is director of the Center for Molecular and Engineering Thermodynamics at the University of Delaware. His extensive research interests include applied thermodynamics and phase equilibrium, environmental engineering, and separations and purification. Dr. Sandler graduated from the University of

Minnesota with a Ph.D. in chemical engineering. He is a recipient of the Warren K. Lewis Award and other awards from the AIChE and the American Chemical Society.

Michael K. Stenstrom is a professor in the civil and environmental engineering department at the University of California, Los Angeles. He has a Ph.D. in environmental systems engineering from Clemson University and is a registered professional engineer in California. He teaches undergraduate and graduate courses in water and wastewater treatment, mathematical modeling of environmental systems, and laboratory analysis. Prior to joining UCLA, Dr. Stenstrom was with Amoco Oil Company, where he performed research to improve petroleum refinery wastewater treatment facilities for five Amoco refineries. He is very familiar with the design and operation of municipal treatment systems and industrial treatment and pretreatment systems. He is the recipient of numerous awards, including the Harrison Prescott Eddy Prize for innovative research.

Attachment C

References

Abercrombie, P.L. 2003. Physical Property Data Review of Selected Chemical Agents and Related Compounds, Updated Field Manual 3-9, ECBC-TR-294, September. Aberdeen Proving Ground, Md.: Chemical Materials Agency.

ANL (Argonne National Laboratory). 2003. Transportation Risk Assessment: Options for the Off-Site Shipment and Disposal of Residual Wastes from the Destruction of Chemical Weapons at the Pueblo Chemical Depot, April. Available online at <http://www.cdphe.state.co.us/hm/pcd/pcdtransportassessment.pdf>. Last accessed June 16, 2006.

BPT (Bechtel Pueblo Team). 2005. Test Report for Bench-Scale Evaluation of HT, HD, and Energetics Hydrolysis and Biotreatment, Pueblo Chemical Agent Destruction Pilot Plant (PCAPP) Project, Rev. 0, April 15. Aberdeen Proving Ground, Md.: Program Manager for Assembled Chemical Weapons Alternatives.

BPT. 2006a. Design Criteria for Plant Process, Pueblo Chemical Agent Destruction Pilot Plant (PCAPP) Project, Rev. 0, May 23. Aberdeen Proving Ground, Md.: Program Manager for Assembled Chemical Weapons Alternatives.

BPT. 2006b. System Design Description (SDD) for Munitions Unpacking and Projectile Disassembly, System Number B01, Rev. D, April 20. Aberdeen Proving Ground, Md.: Program Manager for Assembled Chemical Weapons Alternatives.

BPT. 2006c. Enhanced Reconfiguration Building General Arrangement Plan, Rev. F, March 24. Aberdeen Proving Ground, Md.: Program Manager for Assembled Chemical Weapons Alternatives.

BPT. 2006d. Process Flow Diagram, Agent Collection and Neutralization System, Agent Neutralization Reactors, Rev. 0, April 27. Aberdeen Proving Ground, Md.: Program Manager for Assembled Chemical Weapons Alternatives.

BPT. 2006e. System Design Description (SDD) for Agent Collection and Neutralization, System Number B04, Rev. C, January 27. Aberdeen Proving Ground, Md.: Program Manager for Assembled Chemical Weapons Alternatives.

BPT. 2006f. System Design Description (SDD) for Autoclave, System Number B24, Rev. C, April 21. Aberdeen Proving Ground, Md.: Program Manager for Assembled Chemical Weapons Alternatives.

BPT. 2006g. Process Design Throughput and Availability Analysis, Pueblo Chemical Agent Destruction Pilot Plant (PCAPP) Project, Rev. C, May 18. Aberdeen Proving Ground, Md.: Program Manager for Assembled Chemical Weapons Alternatives.

Earley, J.P., M.A. Guelta, and J.R. Mashinski. Undated. Biological treatment of agent and energetics hydrolysates generated from the washout of mustard (HD) munitions. Available online at <http://www.focisinc.com/pdf/Article_Bio_Treatment_of_Ag.pdf>. Last accessed July 10, 2006.

NRC (National Research Council). 2005. Interim Design Assessment for the Pueblo Chemical Agent Destruction Pilot Plant. Washington, D.C.: The National Academies Press.

U.S. Army. 1988. Chemical Stockpile Disposal Program Final Programmatic Environmental Impact Statement. Aberdeen Proving Ground, Md.: Chemical Materials Agency.

Attachment D

Assessments

The assessments contained in this attachment are not be open to the public under Subsection 15(b)(3) of the Federal Advisory Committee Act, 5 U.S.C. App., as amended by the Federal Advisory Committee Act Amendments of 1997, PL 105-153, December 17, 1997, 111 Stat. 2689. The National Research Council has determined that to release this information to the public would disclose information described in 5 U.S.C. 552(b).

Attachment E

Acknowledgment of Reviewers

This report has been reviewed in draft form by individuals chosen for their diverse perspectives and technical expertise, in accordance with procedures approved by the National Research Council’s (NRC’s) Report Review Committee. The purpose of this independent review is to provide candid and critical comments that will assist the institution in making its published report as sound as possible and to ensure that the report meets institutional standards for objectivity, evidence, and responsiveness to the study charge. The review comments and draft manuscript remain confidential to protect the integrity of the deliberative process. We wish to thank the following individuals for their review of this report:

John Costolnick, Exxon Chemical Company (retired)

Michael R. Ladisch, NAE, Purdue University

Peter Lederman, Hazardous Substance Management Research Center (retired)

Harold D. McKinney, Professional Engineer

Douglas Medville, MITRE (retired)

George Parshall, NAS, E. I. du Pont de Nemours & Co. (retired)

William Rhyne, Consultant, ABS Consulting, Inc. (retired)

Leigh Short, Independent Consultant

Although the reviewers listed above have provided many constructive comments and suggestions, they were not asked to endorse the conclusions or recommendations, nor did they see the final draft of the report before its release. The review of this report was overseen by Hyla Napadensky, Napadensky Energetics, Inc. (Retired). Appointed by the NRC, she was responsible for making certain that an independent examination of this report was carried out in accordance with institutional procedures and that all review comments were carefully considered. Responsibility for the final content of this report rests entirely with the authoring committee and the institution.