1.1 LIGHTWEIGHTING: BACKGROUND

Reducing the weight of military vehicles has been of interest to the U.S. Department of Defense (DoD) for decades. Over the years, many reports and projects have considered lightweight and otherwise advanced materials for use in DoD systems. Historically, reducing the weight—or “lightweighting”—of military land vehicles, maritime vessels, and aircraft has been motivated by the desire to reduce fuel use and costs and the need to improve vehicle transportability.

Reducing DoD fuel consumption and costs remains a critically important reason for lightweighting. The fully burdened cost of fuel for U.S. military operations—including acquisition and transportation costs—approaches $1 billion/day.1 Reducing fuel consumption could also help reduce the risks to personnel and operations associated with supplying fuel to deployed forces.

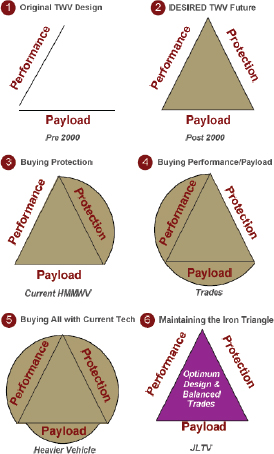

Today, however, there are further motivations for lightweighting military vehicles, as illustrated by the “iron triangle” of requirements shown in Figure 1-1. The military is constantly seeking to balance the three sides of the triangle: performance, protection, and payload. (Not shown is affordability, which is also a crucial consideration.) The current combat situation has made achieving an appropriate balance increasingly demanding, with weight a contributing factor: for instance, the “uparmoring” that has occurred in military ground vehicles deployed overseas over the past decade has resulted in very large weight increases that have, in turn, had adverse effects on vehicle maneuverability and range.2 To the extent that lightweighting can restore some or all of the lost performance, it can help to rebalance the “iron triangle.”

Lightweighting can improve a vehicle’s performance and reduce its support needs. For instance, it can improve maneuverability, transportability, speed, and range—all important attributes for military vehicles. It can also be used to “buy” more payload capacity (weight) in the form of personnel or materiel. For aircraft, lower weight is a critical determinant of performance, payload capacity, maneuverability, and range. For maritime vessels, lightweighting of superstructures improves stability, maneuverability, and speed. These possible improvements illustrate

________________

1 Fuel for U.S. military operations is managed and provided through the Defense Logistics Agency’s Energy Support Center (DESC) group. See http://www.desc.dla.mil/. Last accessed October 19, 2011.

2 M. Grujicic, H. Marvi, G. Arakere, W.C. Bell, and I. Haque. 2009. “The Effect of Up-armoring of the High-mobility Multi-purpose Wheeled Vehicle (HMMWV) on the Off-road Vehicle Performance.” Emerald Insight, Volume 6, Issue 2, pp. 229-256.

FIGURE 1-1 The “iron triangle.” SOURCE: Adapted from G. Bochene, TARDEC, presentation to the 2007 Combat Vehicles Conference, October 24, 2007.

that viewing lightweighting through the lenses of fuel efficiency and transportability alone is too restrictive and fails to capture the full potential for lightweighting to help balance the “iron triangle.”

This potential can be realized through various means. Lightweighting has traditionally been viewed narrowly, as a process of replacing the materials in a system with lighter3 alternatives. Although this is indeed one way of reducing weight, lightweighting can be achieved in many other ways: for instance, by changing structural shape (I-beams, tubular members, and lattices being common examples) or tailoring the spatial configuration of dissimilar materials (as is done with fiber composites and sandwich panels) to make the most efficient use of each material. These strategies are now routinely taught in undergraduate engineering programs, especially in the materials and mechanical engineering fields. Prescriptions for this type of design—using material performance indices, shape factors, and the like—are described in the textbook Materials Selection in Mechanical Design by Michael Ashby.4

Moreover, sophisticated software tools—such as the Granta CES Selector—are available that aid designers not only in selecting the materials and materials processing methods to use, but also in optimizing performance, cost, and environmental properties. They are becoming ubiquitous in academia and the industrial design community.

Lightweighting can be achieved at a systems level, which involves considering the potential for lightweighting from the beginning of the design process. For example, creative architectural designs that involve multifunctionality in components or make use of multifunctional materials can emerge when lightweighting approaches are integrated into the engineering of new systems. A systems-level perspective also incorporates considerations such as the availability of materials and of the manufacturing processes used to produce them and to create shaped parts. The broad view of lightweighting that the committee has adopted is likely to yield the greatest benefits for balancing the “iron triangle.”

Recognizing the substantial remaining potential for lightweighting in air, sea, and land vehicles, especially when approaches beyond just lightweight materials are considered, the Department of Defense (DoD), through the Reliance 21 Community of Interest on Materials and Processing,5 asked the National Research Council (NRC) to assess the current state of lightweighting in land vehicles, aircraft, and maritime vessels and recommend ways in which lightweighting might be better implemented in the future. The statement of task, given in Box 1-1, called for a study that would focus on military vehicles, but also address commercial vehicles.

The Committee on Benchmarking the Technology and Application of Lightweighting was asked explicitly to look beyond materials alone6 and to also consider lightweight design, the availability of lightweight materials from domestic manufacturers, and the performance of lightweight materials and their manufacturing technologies (the technologies used to process and manufacture the materials as well as those used to manufacture components, structures, and other shapes from the materials). It was asked to consider the full “trade space” of attributes—that is, the effect that lightweighting strategies can have on all aspects of vehicle function and performance. The need

________________

3 “Light” and “lightweight” are terms used in this report to denote materials having high specific properties (e.g., high specific strength, defined as strength divided by density) or, more generally, high specific performance. Historically, lightweighting has been achieved by focus on lower-density materials with high property values (e.g., composites). However, the converse is equally viable—using traditional-density materials with enhanced property values, which then allow reduced total weight via reduced cross sections.

4 Michael Ashby. 2011. Materials Selection in Mechanical Design. Edition 4. Burlington, Mass.: Butterworth-Heinemann.

5 Reliance 21 is a management process developed by the Director of Defense Research and Engineering (DDR&E), with the advice of the De fense Science and Technology Advisory Group, involving the science and technology executives of all the military components. It was launched in 2008 as a means of improving coordination and collaboration among the components and reducing unnecessary duplication (Statement of Honorable John J. Young, Jr., Director of Defense Research and Engineering, before the U.S. House of Representatives Committee on Armed Services, Subcommittee on Terrorism, Unconventional Threats, and Capabilities, March 21, 2007, available at http://www.globalsecurity.org/military/library/congress/2007_hr/070321-young.pdf). All the DoD and military service science and technology (S&T) organizations prepare biennial S&T strategic plans that are informed by and harmonized with an overarching DoD S&T strategic plan prepared by the DDR&E (see www.dod.gov/dodgc/olc/docs/TestYoung070321.doc).

6 “Background Information and Study Goals,” presentation to the committee by Julie Christodoulou, Director, Naval Materials Division, Office of Naval Research, July 20, 2010.

Box 1-1

Statement of Task

The committee will assess the current state of lightweighting implementation. To do so, the committee will:

Task I Assess the relevance of the definition of lightweighting within the materials community.

Task II Assess and benchmark the current state of lightweighting implementation in land, sea, and air vehicles in the military and civil sectors, with a primary emphasis on military systems and equipment.

Task III Make recommendations for ways in which the use of lightweight materials and lightweight solutions might be better implemented in military and dual-use systems.

As part of its assessment, the committee will consider:

- The use of lightweight materials and lightweight design.

- The availability of lightweight materials from domestic manufacturers.

- The performance of various lightweight materials and manufacturing technologies.

- The trade space (that is, the impact that use of lightweight materials will have on the required performance and function of various systems, platforms, and components) for determining the value of lightweighting.

for a systems-level approach, wherein lightweighting is considered from the beginning of the design process, provided important context for the committee’s work.

1.3 COMMITTEE’S APPROACH AND REPORT OUTLINE

To stay within the constraints of available time and resources, the committee chose to focus its efforts as indicated below:

- The committee considered its primary topic to be military vehicles. Although it drew on experience with lightweighting in civilian vehicles, it did not address these vehicles in detail.

- The committee did not have the resources to perform a comprehensive assessment of the state of lightweighting across the services, or to “benchmark” lightweighting implementation.7 It instead reviewed illustrative examples of lightweighting in military and civilian systems as a way of identifying qualitative lessons for future efforts. It also outlined some barriers that impede lightweighting as well as opportunities for further lightweighting.

- The committee considered the “trade space” of vehicle attributes qualitatively. A quantitative assessment of the value of lightweighting would require development of a set of performance metrics that describe quantitatively the changes in each attribute for a unit change in weight. Examples of metrics include fuel use and expenditures over the life of the vehicle; the frequency and cost of repairs; the number of occupants or amount of payload and armaments that can be carried; the transportability of a vehicle (e.g., whether it can be carried on a certain platform); the maximum speed and range; and resistance to blast and other threats. In this context, it is clear that no single performance metric can fully describe “the value of a pound saved.”

________________

7 By definition, benchmarking requires quantitative measurement of performance. Acquiring the data needed for such measurements was not feasible, not only because of the limited time and resources available to the committee, but also, and more importantly, because of the proprietary nature of the requisite information.

- The committee considered the development of vehicle and body armor to be outside the study scope. It focused on the structural elements of vehicles and their components. Lightweighting can facilitate the use of heavier armor, but the report does not discuss this in detail. (Nor does it discuss other non-structural elements such as energy storage systems, electronics, cables, cartridge cases, and so on.) Optimizing vehicle attributes within the “iron triangle” will require consideration of the full system, including all vehicle internals as well as vehicle armor and perhaps even the weight of body armor worn by vehicle occupants.

For a recent assessment of opportunities for developing advanced materials for use in vehicle and body armor systems, see the NRC report Opportunities in Protection Materials Science and Technology for Future Army Applications.8 - The committee drew heavily on earlier studies. Numerous reports over the past decade have advised the DoD on topics related to lightweight or otherwise advanced materials. Other reports have addressed related topics, such as technology transition and systems engineering, that are central to the broad view of and approach to lightweighting that the committee has adopted. Later in this chapter, the committee summarizes the key findings and recommendations of some of those studies.

In summary, the committee’s approach was to provide an overview of lightweighting considerations for military vehicles, and to supplement that overview with detailed examples from the military and commercial sectors, with some assessment of “lessons learned.” This report brings together a range of pertinent information that the committee hopes will be useful in efforts to foster better implementation of materials and design for lightweighting of military vehicles.

To assess the relevance of the definition of lightweighting within the materials community, the committee considered the multiple objectives that military air, sea, and land vehicles are obligated to meet and the varied benefits that lightweighting can confer. Based on these factors and its own collective experience, the committee developed a working definition of lightweighting, presented in the next section, that reflects a broad view of lightweighting and provides the framework for this study. The subsequent section contains a qualitative assessment of the relative importance of lightweighting for different types of vehicles. The remainder of Chapter 1 introduces some key topics in lightweighting and reviews the findings of earlier studies, as described under item 5 above.

To assess and benchmark the current state of lightweighting implementation in land, sea, and air vehicles, with a primary emphasis on military systems and equipment, the committee reviewed examples of lightweighting, the barriers that impede use of this approach, and some opportunities for further lightweighting. The assessments for air, sea, and land vehicles appear in Chapters 2-4.

After considering air, sea, and land vehicles separately, the committee returned to some of the points introduced in Chapter 1. Chapter 5 expands on some topics that cut across all vehicles, in some cases identifying areas where further work is needed. That review, together with the assessment in Chapters 2-4, laid the groundwork for the committee’s formulation of recommendations for ways in which lightweighting might be better implemented. These recommendations are presented in Chapter 6.

1.3.1 Approaches for Chapters 2 Through 4 on Air, Sea, and Land Vehicles

As noted earlier, weight is a critical determinant of aircraft performance, payload capability, maneuverability, and range. Optimizing the weight of aircraft relative to other performance elements (and costs) has been a focus of the aircraft industry, both commercial and defense, for decades. Therefore, the chapter on aircraft comes first, followed by the chapters on maritime vessels, and land vehicles. Chapter 2 provides detailed discussions of some topics, such as the use of composites; these discussions are referred to in Chapters 3 and 4.

Each of the three chapters addresses Task II for the type of vehicle (air-, sea-, or land-based) discussed as well as the bulleted items (see Box 1-1) that the committee was asked to consider. The first four sections of each

________________

8 NRC. 2011. Opportunities in Protection Materials Science and Technology for Future Army Applications. Washington, D.C.: The National Academies Press. Available at http://www.nap.edu/catalog.php?record_id=13157. Last accessed on November 17, 2011.

chapter review (1) how and why lightweighting is used and the status of metrics; (2) barriers and keys to success in lightweighting, including some brief examples; (3) opportunities for lightweighting via new materials, designs, and manufacturing processes, focusing on the near term; and (4) long-term challenges to lightweighting. Each chapter ends with examples of vehicle development and the role of lightweighting therein. As noted above in describing the committee’s approach to this study, these examples take the place of a full benchmarking effort. They are reviewed as illustrations of how lightweighting has been attempted and sometimes achieved and what lessons might be learned from the experiences.

Chapter 3 covers heavy ships as well as lighter maritime craft, for all services. Chapter 4 focuses on heavy military combat vehicles, although it does provide an example of systems engineering as applied to a commercial product, the Ford F-150 truck. Chapter 2 on aircraft has much more coverage of commercial applications and concentrates primarily on composites (although other materials are discussed).

Finally, lightweighting also applies to unmanned vehicles. For robotic vehicles (air, sea, and land) as for manned vehicles, lightweighting serves to improve performance as well as transportability, which in this case can extend to “man-portability.”

The committee did not do a full review of unmanned vehicles. It does provide examples of unmanned air vehicles but did not review unmanned maritime vehicles (surface and underwater) or unmanned ground vehicles. In the committee’s view, for land and maritime applications, balancing the sometimes-competing requirements (performance, survivability, operational supportability, and so on) is currently most important for occupied vehicles. Hence, these are the focus of Chapters 3 and 4. Unmanned air vehicles (UAVs), which have been in use for some time, are discussed in Chapter 2.

The notion of lightweighting is seemingly simple. At its core, lightweighting is the process of reducing weight for the purpose of improving performance. However, as noted above, it goes far beyond simply using low-density and otherwise lighter and high-performance materials to improve fuel efficiency. Indeed, it encompasses a wide range of implementation strategies—the use of low-density materials being only one possibility. For example, lightweighting can be accomplished by efficient utilization of materials through judicious materials selection and design optimization—that is, finding the best material in the best geometric configuration for each part of the system. It can be accomplished by developing components that serve multiple functions, thus simplifying design, or by improving manufacturing methods so as to enable the use of new materials. In the committee’s view, establishing and maintaining a broad vision of what constitutes lightweighting are necessary to achieving the greatest benefits.

The committee views lightweighting as a means of not only reducing fuel consumption and costs and the associated logistical requirements but also achieving a variety of desirable features. The definition of lightweighting established by the committee and used in its assessments is shown in Box 1-2.

Box 1-2

Committee’s Definition of Lightweighting for Military Systems

The committee developed the following broad definition of lightweighting:

Lightweighting is the process of reducing the weight of a product, component, or system for the purpose of enhancing certain attributes, notably (1) performance, (2) operational supportability, and (3) survivability.

Note that, although this definition also applies to civilian vehicles, the main focus of the report is military vehicles, and so the attributes of interest and the wording used are tailored for military applications.

Each category of vehicle attributes is broad in scope:

- Performance includes vehicle speed, maneuverability, payload capacity (in terms of weight), and range. In this context, lightweighting is assessed on the basis of the degree to which these attributes are enhanced when lightweighting materials and design are used.

- Operational supportability refers to the ease and cost associated with support of vehicle operation. It encompasses fuel consumption as well as transportability, durability, reliability, maintainability, and repairability. These attributes are related to performance, but are of critical importance to overall system effectiveness, and so must be concurrently or iteratively optimized with other key system attributes. Long-term sustainment (support of fielded systems and their subsequent life cycle product support, as well as modernization of legacy systems) also falls into this category, although the committee did not assess sustainment needs.

- Survivability, in principle, could be considered under performance. However, the committee treated it separately because of its crucial importance to military systems and the strong correlation between weight and survivability for some vehicles. Survivability includes attributes such as resistance to blast and ballistic threats, tolerance of damage and environmental conditions, and avoidance of detection.

Lightweighting can confer other benefits not called out specifically in the committee’s definition—notably, flexibility and adaptability. One example is the Army’s A+B approach, wherein the base vehicle, denoted “A,” can be equipped with various armor packages, denoted “B.” This approach allows not only for the armor packages to be matched to the current threat levels but also for rapid integration of new armor packages as technologies improve or threats evolve. One negative consequence of this approach is that the vehicle will not be optimal for conditions demanding high speed and maneuverability but requiring only light armor, because the base vehicle must be sufficiently robust (and hence, usually, heavier) to bear heavier armor under other circumstances.9 To the extent to which the base vehicle can be made lighter, this disadvantage can be reduced.10

Legacy systems will undoubtedly be used in the future under conditions that push the envelopes of their original designs. Similarly, future systems will necessarily be designed based on the performance, operational, and survivability requirements set at the time of design. The inevitable evolution in the conditions under which the vehicles will be employed emphasizes the need for flexibility and adaptability in their design—e.g., through designing so as to facilitate component replacement or other types of upgrades—to allow the military to respond rapidly to changing threats and priorities and carry out long-term sustainment as efficiently as possible.

It is now widely recognized that taking fullest advantage of lightweighting requires a systems-level approach.11

In making its assessments of lightweighting in air, sea, and land vehicles, the committee assigned qualitative rankings of the importance of each general class of attribute to each class of vehicle, with 1 the most important and 3 the least important. These rankings, summarized in Table 1-1, were developed based on the presentations made to the committee at its meetings and the collective experience of committee members. They represent the committee’s view at the time this report was prepared.

Under the committee’s broad definition, lightweighting demands a true systems approach. Focus on only one vehicle attribute may result in a weight reduction but miss the more significant benefits that could be attained through a more systematic consideration of lightweighting throughout a vehicle systems design cycle. A systems approach to design might consider:

- Materials with high specific strength or performance (low-density materials are a subset of this category);

- Creative architectural and component designs that make the most efficient use of materials;

- Integration of materials selection with novel design concepts to achieve multifunctionality;

________________

9 “Ground Systems Integration Domain (GSID) Materials for Ground Platforms,” presentation to the committee by Lisa P. Franks, U.S. Army, Tank and Automotive Research, Development and Engineering Center, Research, Development and Engineering Command, September 2010.

10 This is also true for reducing the weight of armor, but as noted earlier, armor is beyond the scope of this study.

11 See, for example, Center for Automotive Research, 2011, “Automotive Technology: Greener Products, Changing Skills Lightweight Ma terials & Forming Report.” May. Available at http://drivingworkforechange.org/reports/lightweightMaterials.pdf.

TABLE 1-1 Lightweighting Attributes and Their Relative Importance for Land Vehicles, Maritime Vessels, and Aircraft

| General Attributes | specific Attributes | Relative Importance | ||

| Land Vehicles | Marine Vessels | Aircraft | ||

| Performance | • Speed • Maneuverability •Payload • Range |

Primary 2 |

Primary 2 |

Primary 1 |

| Operational supportability | • Fuel consumption •Maintainability • Durability •Reliability •Repairability • Sustainment |

Secondary 3 |

Secondary 3 |

Primary 2 |

| Survivability | • Ballistic impact resistance •Explosion resistance •Damage tolerance •Observability |

Primary 1 |

Primary 1 |

Secondary 3 |

NOTE: These rankings represent the committee’s view at the time this report was written. 1, 2, and 3 represent the committee’s assessment of the relative importance of each attribute for a given transport platform. For example, for land vehicles, survivability is the most important of the three attributes, and operational support capability is least important (although it is still important in absolute terms). “Primary” and secondary represent the relative importance of an attribute across air, sea, and land vehicles. For example, operational support capability is a primary consideration for aircraft but of secondary importance for land vehicles and marine vessels. Note also that the “Aircraft” category contains all aircraft flown by the military: fighters, transports, and UAVs. This aggregation lowers the ranking of survivability from what it would be for fighter and attack aircraft alone.

- New or advanced manufacturing methods that enable the use of new designs, materials, and materials combinations as well as the reduction in manufacturing defects (thus improving durability and service life); and

- More aggressive design strategies to optimize structure and function, based on (a) optimization of system design and topology using available or new technologies and components, and (b) improved understanding of response and failure mechanisms of materials and improved associated physics-based computational models.

Although the committee found good examples of vehicle lightweighting in all three areas (air, sea, and land), there is still much that can be done. Viewing lightweighting broadly, and at the systems level, may help bring these opportunities to light.

1.5 KEY TOPICS IN LIGHTWEIGHTING

This section introduces topics that apply to all vehicles and are mentioned in the air, sea, and land chapters. Chapter 5 discusses some of these topics in greater depth.

1.5.1 Systems Engineering, Design, and Optimization

As mentioned above, and discussed in the review of earlier reports that appears later in this chapter, it is widely recognized that taking the fullest advantage of strategies such as lightweighting demands a true systems approach. Importantly, a systems approach to lightweight design need not be materials-centric: it extends to how materials are arranged, topologies optimized, and functionalities combined. Many of the innovations in lightweight construction

are concerned with putting material where it is most beneficial, and advances in system design and topology can yield improvement in performance even absent the incorporation of new materials. For example, advances in the performance of America’s Cup yachts have stemmed in large part from changing the shape of the boat. Multifunctional structures—such as those that provide both structural support and protection from fire—reduce “parasitic” weight (e.g., for elements that protect against fire but have no other function). Improvements in manufacturing of large components from particular materials can allow those materials to be used for additional applications.

Systems-level design requires simultaneous consideration of all the ramifications of changes in materials or design and the corresponding trade space—that is, how various performance and other attributes change relative to one another in response to a material or design change. It also requires definition of the relative importance (or weighting) of the attributes in order to develop optimal designs.

In its definition of lightweighting (see Box 1-2), the committee separated vehicle attributes into the three categories of performance, operational supportability, and survivability for discussion purposes and to illustrate the challenges involved in optimizing the “iron triangle” of requirements (see Figure 1-1). However, it notes that such optimization will always have to be done concurrently for all important attributes—and that systems engineering may in fact consist of sequential analyses for different attributes, followed by iterations in design and configuration, until all key requirements are satisfied or optimized for the desired system.

A fuller discussion of systems engineering appears in the review of previous studies later in this chapter, and also in Chapter 5. This topic is also mentioned in Chapters 2-4; Chapter 4 contains an example of full systems engineering design: the Ford F-150 truck. Chapter 5 also discusses work in structural design or topology.

1.5.2 Development Cycles for Materials and Vehicle Systems

The time required to develop new materials and their processing technologies, and certify new materials for use in military vehicles, generally exceeds that required to develop and certify a new vehicle. Specifically, a critical limitation to the introduction of new materials into military vehicles is the extended period required for materials development and qualification. The time required can vary widely—from 2 to 3 years for derivative materials on an expedited schedule, up to a decade or longer for significant new or emerging materials or processes. In cases where a new class of material is under development or where new infrastructure is required to produce the material or structure, the time period can extend well beyond 10 years,12 often as long as 15 years13 and even up to 20 years when a new, advanced material system is involved.

As discussed in Chapters 2-4, the time to develop a new vehicle can be much shorter, although this is not always the case. The reasons for the lengthy materials development and qualification cycle are described in a 2003 NRC report:

At the front end of the development cycle is the arduous task of creating a material with superior properties. Not only must the composition of the material be established, but—of equal importance—so must the process by which the material is made. Processing of structural materials is critical because the microstructure developed during processing is a primary determinant of the resultant mechanical properties. Complicating the design process is the fact that a material has many mechanical and physical properties, e.g., elastic modulus, yield strength, ductility, fracture toughness, fatigue resistance, density, weldability, and corrosion resistance. Improvement of one property often causes degradation of another. Hence material design is a compromise. Traditionally, the development cycle is long because it involves sequential synthesis of the material and then extensive testing of many properties and combinations.14

The lengthy materials development cycle means that new materials and process technologies must be suitably mature at the time of preliminary design to ensure that the target vehicle will be manufactured within the required timeframe; otherwise, sometimes-costly risk mitigation strategies must be implemented. An adequate,

________________

12 NRC. 2004. Accelerating Technology Transition: Bridging the Valley of Death for Materials and Processes in Defense Systems. Washing ton, D.C.: The National Academies Press. Available at http://www.nap.edu/catalog.php?record_id=11108. Last accessed November 17, 2011.

13 NRC. 2003. Materials Research to Meet 21st Century Defense Needs. Washington, D.C.: The National Academies Press. Available at http://www.nap.edu/catalog.php?record_id=10631. Last accessed November 17, 2011.

14 Ibid.

stable supply of materials must be established, together with adequate manufacturing capability to produce useful forms of these materials, in order to ensure that the capability exists for streamlined incorporation (also called “insertion”) of lightweight materials into designs.

In addition, the current acquisition process for military vehicles is expensive and lengthy.15 Examples include the F-22 Raptor (19 years)16 and the F-35B (9 years, although not a function of technical barriers).17 The time and expense involved stem from the extensive validation and certification required for new materials and processes as well as the exhaustive testing of full-scale systems that must be done. Because the consequences of failure are severe, the principal decision makers tend to be strongly risk-averse.

The time required to design and certify vehicles and products is generally much shorter. The product design and development cycle outpaces the materials development cycle by a significant margin, leading to a mismatch that hampers the insertion of new materials into engineering products.

The “gated” processes that are followed for development of new products or systems, such as the process specified by the Defense Acquisition Guide and DoD Instruction 5000.02, require technologies to be relatively mature before insertion at the initiation of a program. The considerable time and cost required to reach the requisite maturity level for a new material must occur in the preacquisition phase, before a program is actually initiated. This often exacerbates the extent to which the development and qualification cycles for materials and vehicles are “out of sync” with one another, making it even more difficult to insert new materials early in the design cycle.

A more comprehensive discussion of this issue is contained below in the committee’s review of earlier reports. It is also discussed in Chapter 5, where some strategies to ameliorate this mismatch are identified.

1.5.3 Integrated Computational Materials Engineering

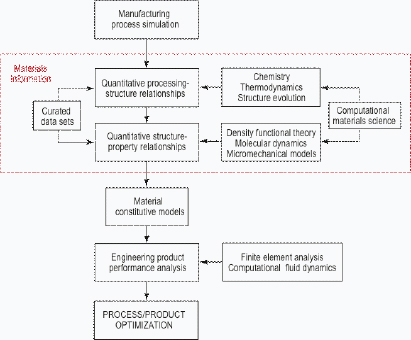

Integrated computational materials engineering (ICME), and its development over the past 10 years, is discussed in detail in the next section, under the review of earlier reports. ICME tools are discussed further in Chapter 5. In the context of materials and process develoment, ICME is the analog to systems engineering (Section 1.5.1) in vehicle design. For ICME, the “system” is the set of manufacturing processes, materials systems, and engineering applications.

The primary potential of ICME is more efficient and robust engineering of products, manufacturing processes, and materials.18 Efficiency can take the form of reduced development time, reduced development costs, or better matching of materials and needs. ICME allows quantitative tradeoffs between material properties and manufacturing capabilities. It can lead to the development of new engineering products using existing materials, refinement of existing materials and manufacturing processes, or development of new materials and manufacturing processes. The use and further development of these tools for military purposes would be expected to benefit the development and improvement of commercial air, maritime, and land vehicles.

1.5.4 Physics-Based Models of Material Behavior

Future military technologies will place increasing demands on materials in extreme service environments— notably, under high levels of stress, strain, strain rate, temperature, and heat flux. Tremendous progress has been made over the past two decades in the development of finite element codes for thermostructural analysis. Significant advances have also been made in the development of continuum-level constitutive laws for inelastic deformation, damage evolution, and rupture. Together, the finite element codes and the constitutive laws have proven effective in analyzing structural response over a wide range of loading conditions. Notwithstanding this progress, there remain

________________

15 See, for example, NRC, 2011, Evaluation of U.S. Air Force Preacquisition Technology Development, Chapter 2, pp. 33-61. Washington, D.C.: The National Academies Press. Available at http://books.nap.edu/catalog.php?record_id=13030. Last accessed November 17, 2011.

16 Andrew McLaughlin. 2006. “F-22A Raptor—No Longer a Fair Fight.” Australian Aviation, April, pp. 55-61. Available at http://www.ausairpower.net/AA-Raptor-0406.pdf. Last accessed June 21, 2011.

17 Bill Sweetman. 2011. “F-35B Put on Probation; New Bomber to Go.” Aviation Week, Jan. 7.

18 NRC. 2008. Integrated Computational Materials Engineering: A Transformational Discipline for Improved Competitiveness and National Security. Washington, D.C.: The National Academies Press. Available at http://www.nap.edu/catalog.php?record_id=12199.

large gaps in the understanding of the underlying physical processes that operate in complex multiphase systems, especially at very high strain rates and in the shock domain. New information-rich experiments and corresponding material models are needed. Specific areas that require attention include:

- The linkage of strength, damage evolution, and fracture to material chemistry, processing history, and microstructure;

- Techniques to bridge time and length scales in material models; and

- New numerical techniques to model the pertinent physical processes with high fidelity and exploit the computational power now available to the DoD.

The U.S. Department of Energy has sponsored extensive work in physics-based modeling and simulation at its national laboratories, much of it to provide assessments of material and structural behavior for nuclear weapons in the absence of testing. The fundamental physics codes developed for this purpose are relevant for all materials design efforts. For example, work at Sandia National Laboratories has resulted in open-source tools for molecular modeling that have been used extensively and are continuously updated to add more fundamental physics information and to increase computational speed. Continued progress on such physics-based modeling and simulation is needed.

1.5.5 Material Properties and Testing

Introduction of new technologies into complex systems typically requires significant experimental testing from the level of material samples (often called “coupons”) to components to subsystems. While modeling can accelerate this process, ultimately the new technology must be tested in field conditions as part of a complete system. As noted previously, the mechanical properties of materials are affected by process variations and by the defects induced during their processing. As a result, the as-manufactured properties of materials can differ from properties determined in the laboratory.

For structural materials, the usual development of material properties begins with coupon-level tests to gauge basic physical and mechanical properties. If these data look promising, fabricated panels representative of candidate structure are made and tested. These test data substantiate the coupon test data and provide confidence in the accuracy of design analysis methods.

Subsequently, subscale or full-scale candidate parts are made of the new material for component testing. Throughout this process, the manufacturing processes used to make these test articles may not be the actual production processes. The final design data are developed from test specimens made from material processed using actual production methods. These data are validated through testing of full-scale subsystems incorporating the new material manufactured using the actual production processes.

1.5.6 Uncertainty, Risk, and Design Factors

A key issue with the use of new materials is the use of larger design factors (also referred to as safety factors and knockdown factors) that can increase the weight of a component over that needed to satisfy design requirements. Several concerns and uncertainties drive the increase in design factors. These include:

- Uncertainty in properties of materials (especially local variability in properties);

- Concern over the potential for unknown susceptibility to fatigue or environmental effects;

- Variability in manufacturing processes;

- Difficulty in detecting manufacturing defects in heterogeneous materials by inspection; and

- Shortcomings in the non-destructive evaluation (NDE) techniques that could detect manufacturing defects as well as in-service damage.

A particularly fruitful area for research and development is NDE techniques and technologies. For example, NDE of heterogeneous materials such as fiber composite laminates is challenging. Large defects can be induced

during the manufacturing of large composite parts, in which differential thermal expansion can result in fiber rumpling and a loss of local tensile stiffness, or low thermal conductivity of the matrix can lead to regions of incomplete matrix cure or regions of exothermic runaway and over-cure. These are all very difficult to detect and characterize with today’s NDE tools.

The processing issues and poor control of microstructure in anisotropic metals such as magnesium or titanium present another class of problems for which a new generation of NDE tools is needed. These tools could be developed for better control of the manufacturing process (to reduce variability), which would reduce the need for costly inspections after manufacturing. Associated issues and challenges, and approaches for overcoming barriers, are discussed in Chapter 5.

1.5.7 Materials and Materials Availability

As discussed in Chapter 5, two cornerstones of lightweighting are (1) low- or reduced-density, high-specific-performance19 alloys, and (2) fiber-reinforced composite materials. High-strength steels are also important, because even modest improvements in steel strength can have a large impact due to the large amounts of steel used in military vehicles. Some alloys, such as those based on aluminum, are readily available. They are used widely in industry in sufficiently large volumes to support the operations of multiple suppliers.

The availability of other materials critical to lightweighting, however, is limited, or the materials are prohibitively costly. Moreover, the specialized manufacturing capabilities needed to create some of these materials, or to form them into useful structural shapes, are, in some cases, in short supply. These concerns are mentioned in Chapters 2-4 and discussed further in Chapter 5.

1.5.8 Mechanisms for Technology Transition

As is discussed above, acceleration of the insertion or transition of new materials and technologies into products and into use is needed. Three DoD mechanisms for doing this are accelerated insertion of materials, advanced technology demonstrations (and advanced concept technology demonstrations), and ManTech. An NRC report, Accelerating Technology Transition: Bridging the Valley of Death for Materials and Processes in Defense Systems, addresses many of the issues involved. A DoD initiative, Accelerated Insertion of Materials, is highlighted in that report.

The advanced technology demonstration (ATD) is a process for managing science and technology programs that brings together all the involved communities—scientific research, technology design and development, end users, and others—to accelerate the maturation of technologies. According to the DoD’s Manager’s Guide to Technology Transition in an Evolutionary Acquisition Environment:

The collaboration and coordination result in early interaction and exchange among the communities, permit experimenting with technology-driven operational issues, weed out unattainable technologies as early as possible, and result in more focused requirements and capability documents …. ATDs require planning, review, and approval at the Service or agency level. ATDs have a finite program duration, agreed-upon exit criteria, and typically require transition plans. Accordingly, ATDs require technologies that are mature enough to provide a capability that can be used or demonstrated during the demonstration period.

The ATD team evaluates technical feasibility, affordability, compliance with operational and technical architectures, operation and support issues, and user needs as early as possible. This fully integrated approach and focus on operationally sound capabilities ensures that militarily significant capabilities can be developed, evaluated, and transitioned to the warfighter rapidly.20

________________

19 Specific performance (e.g., strength) is performance divided by density.

20 DoD. 2005. Manager’s Guide to Technology Transition in an Evolutionary Acquisition Environment. Version 2.0. Ft. Belvoir, Va.: Defense Acquisition University Press. Available at http://www.dau.mil/pubscats/PubsCats/Managers_Guide.pdf.

ATDs are reviewed and approved by the services and funded with service science and technology funds. Specific ATD projects are described in Chapters 2 and 3, and the ATD process is discussed more fully in Chapter 5.21

A related approach, the advanced concept technology demonstration (ACTD), is designed to expedite the transition of maturing technologies from the developers to the users. ACTD projects emphasize assessing and integrating technology rather than developing it. The goal is to put a prototype into the field and help the end user evaluate it under realistic conditions, and so the program works with fairly mature technologies.22

The DoD’s Manufacturing Technology Program (ManTech) is aimed at reducing technology acquisition and total ownership costs by developing, maturing, and transitioning key manufacturing technologies. The program “matures and validates emerging manufacturing technologies to support low-risk implementation in industry and DoD facilities … and addresses production issues from system development through transition to production and sustainment. The focus is on rapid responses to immediate manufacturing needs.” 23

1.6 CHALLENGES AND OPPORTUNITIES: FINDINGS OF RECENT STUDIES

Numerous reports over the past decade have advised DoD on topics related to lightweight or otherwise advanced materials. Others have addressed related topics relevant to the committee’s broad definition of lightweighting. Among them are several NRC reports published over the past 8 years, including the following:

- Materials Research to Meet 21st Century Defense Needs (2003),24

- Use of Lightweight Materials in 21st Century Army Trucks (2003),25

- Accelerating Technology Transition: Bridging the Valley of Death for Materials and Processes in Defense Systems (2004),26

- Managing Materials for a Twenty-first Century Military (2008),27 and

- Integrated Computational Materials Engineering: A Transformational Discipline for Improved Competitiveness and National Security (2008).28

The key findings and recommendations of these reports are summarized below. Several of the topics covered in these summaries are treated in more detail in Chapter 5 and form part of the foundation for the committee’s findings and recommendations. Also described below are the results of some additional relevant reports.

1.6.1 Materials Research to Meet 21st Century Defense Needs

Opportunities for materials research that could lead to revolutionary defense capabilities by about 2020 were described in the 2003 report Materials Research to Meet 21st Century Defense Needs.29 Among the classes of

________________

21Chapter 5 of this report also notes that the DoD has other technology transition mechanisms available.

22 DoD. 2005. Manager’s Guide, p. 3-3: “ACTDs should consider manufacturing and sustainment issues as a part of their programs. The long-term success of ACTD initiatives can be improved by considering all of the manufacturing, sustainment, and operational and support issues.”

23 DoD. 2005. Manager’s Guide, p. 3-7. Further information on DoD’s ManTech Program is available at http://www.dodmantech.com/program/index.asp. Last accessed October 19, 2011.

24 NRC. 2003. Materials Research to Meet 21st Century Defense Needs. Washington, D.C.: The National Academies Press. Available at http://www.nap.edu/catalog.php?record_id=10631. Last accessed November 17, 2011.

25 NRC. 2003. Use of Lightweight Materials in 21st Century Army Trucks. Washington, D.C.: The National Academies Press. Available at http://www.nap.edu/catalog.php?record_id=10662. Last accessed November 17, 2011.

26 NRC. 2004. Accelerating Technology Transition: Bridging the Valley of Death for Materials and Processes in Defense Systems. Washing ton, D.C.: The National Academies Press. Available at http://www.nap.edu/catalog.php?record_id=11108. Last accessed November 17, 2011.

27 NRC. 2008. Managing Materials for a Twenty-first Century Military. Washington, D.C.: The National Academies Press. Available at http://www.nap.edu/catalog.php?record_id=12028. Last accessed November 17, 2011.

28 NRC. 2008. Integrated Computational Materials Engineering: A Transformational Discipline for Improved Competitiveness and National Security. Washington, D.C.: The National Academies Press. Available at http://www.nap.edu/catalog.php?record_id=12199.

29 NRC. 2003. Materials Research to Meet 21st Century Defense Needs. Washington, D.C.: The National Academies Press. Available at http://www.nap.edu/catalog.php?record_id=10631. Last accessed November 17, 2011.

Box 1-3

Multifunctional Materials

The following description is excerpted as indicated below.

One way to reduce weight and volume is by using materials that can perform at least two functions (e.g., stealth and structural support). Multifunctionality can be thought of on two scales: (1) mesoscopic (e.g., coatings) or macroscopic (e.g., load-bearing), and (2) microscopic or nanoscopic, in which multiple physical phenomena are produced through molecular design or architectural texture.

The concept of multifunctionality encompasses many classes of materials and applications: Structural materials may be self-interrogating or self-healing, provide stealth, or protect against enemy fire; microscopic materials or systems may combine sensing, moving, analyzing, communicating, and acting.

The concept of multifunctional materials applies to all the major classifications of materials (polymers, metals, ceramics), but by its very nature it is most prevalent in composites of these materials.

One way to achieve multifunctionality is through functionally graded materials that have properties and material constituents on one surface that differ from those on another surface, or are stratified through the interior of a part.

Any material classified as “smart” or “intelligent” is also multifunctional, usually due to microstructural/molecular level response characteristics that manifest as macroscopic actuation ability with electric, magnetic, or thermal input.

An important global issue related to multifunctionality is therefore the understanding and modeling of materials in a hierarchical fashion to address key length scales.

______________________________

SOURCE: NRC. 2003. Materials Research to Meet 21st Century Defense Needs. Washington, D.C.: The National Academies Press. Available at http://www.nap.edu/catalog.php7record_ict10631. Last accessed November 17, 2011.

materials examined, the ones most relevant to the present study were structural and multifunctional materials (see Box 1-3).

The study concluded that the research area of highest priority is materials design by computation (see Box 1-4), which would provide the capability not only to design better materials but also to better understand their behavior, to design better structures with them, and to shorten the development cycle from concept to implementation by eliminating much experimental synthesis and testing.

However, to replace experimentation, computational tools must be reliable: they must consistently predict a suite of mechanical, physical, and thermodynamic properties of materials. The most challenging tasks on the path to robust computational materials design over the next two decades were identified as prediction of equilibrium phase stability in multicomponent materials; prediction of thermomechanical processing transitions (including nonequilibrium phase transformations and microstructure evolution); and prediction of mechanical behavior. Although not couched in the same terms, these elements form the basis for ICME—a concept described in detail in Section 1.6.5 of this chapter.30

Another issue identified in the 2003 study is service-induced material changes. If materials and structures are to be designed for performance, it is necessary to understand the evolution of their properties and performance during use. This approach highlights the need for science-based constitutive theories of property evolution as well as the need for virtual engineering and simulation during design. The advantages of such an approach would be reduction of materials and system development cost and acceleration of the development cycle.

The 2003 study’s Panel on Structural and Multifunctional Materials focused on materials in which one

________________

30 NRC. 2008. Integrated Computational Materials Engineering: A Transformational Discipline for Improved Competitiveness and National Security. Washington, D.C.: The National Academies Press. Available at http://www.nap.edu/catalog.php?record_id=12199.

Box 1-4

Materials Design Assisted by Computation

The following description is excerpted as indicated below.

In the design of materials assisted by computation, the goal is to implement new materials by integrating constitutive models into a framework that employs finite element method (FEM) calculations. The first-level potentials (electron, atom, dislocation, and microstructure) have to be described to yield time, temperature, and size-dependent models of material behavior for all classes of materials, monolithic and composite. This effort will require more precise understanding of physical phenomena and better computer equipment that can extract the important data from a calculation and also analyze these first-level data. A successful effort would predict possible material properties before development costs are incurred and predict material properties and behavior so that the cost of characterization (e.g., temperature dependence of polymer-based materials) could be reduced. This would not only reduce costs but also accelerate material development, especially the introduction of new materials and materials systems into DoD systems.

______________________________

SOURCE: NRC. 2003. Materials Research to Meet 21st Century Defense Needs. Washington, D.C.: The National Academies Press. Available at http://www.nap.edu/catalog.php7record_ict10631. Last accessed November 17, 2011.

might expect major (20-25 percent) performance improvements over the next 20 to 25 years, with “performance improvement” referring to improvement over the current state of the art in six areas: strength, toughness, stiffness, density, environmental resistance, and high temperature capability. The 2003 study concluded that the greatest opportunities exist in composite materials (viewed in broad terms as hybrid multimaterial systems, not simply conventional fiber-reinforced composites) rather than monolithic materials. Because of their multiphase nature and fabrication methods, composite materials offer simple routes for embedded sensors, actuators, and other elements that provide multifunctionality.

Finally, the 2003 study identified the need for integration of non-destructive inspection and evaluation into the design of materials and structures to allow for continuous monitoring of the health of all newly designed structures. Health-monitoring sensors integrated into structures would have to be very small and to be incorporated into the internal structure in places that would be difficult to examine with an outside source.

1.6.2 Use of Lightweight Materials in 21st Century Army Trucks

A study focused specifically on lightweight materials for future military trucks, Use of Lightweight Materials in 21st Century Army Trucks,31 was motivated by the Army’s requirements for improved vehicle transportability and mobility. The requirements mandated that Army trucks consume less fuel, undergo significant weight reduction, have reduced logistical footprints, and require less maintenance. The principal findings and recommendations fell into three categories.

First, the study identified promising materials and processing routes that could be developed and deployed over various time periods. The opportunities in the short and medium term included high-strength and stainless steels for truck frames; magnesium extrusions, superplastically formed aluminum, ultrahigh carbon steels, advanced aluminum alloys, and polymer-matrix composites for secondary structural elements; and aluminum and magnesium alloys as well as metal- and polymer-matrix composites for drive-train components. The key material class featured for longer-term development was titanium (for armor plate and springs).

Second, the study highlighted the need to develop databases of the properties of these materials and to develop

________________

31 NRC. 2003. Use of Lightweight Materials in 21st Century Army Trucks. Washington, D.C.: The National Academies Press. Available at http://www.nap.edu/catalog.php?record_id=10662. Last accessed on November 17, 2011.

models for their processing and for predicting the performance of the resulting components. Again, some of the elements of ICME were emerging and being recommended for future research.

Third, the study suggested that the DoD procurement process be modified so that the important performance attributes of trucks would be explicitly defined for original equipment manufacturers. For example, if reduction of the logistical footprint is important, this attribute and a method for measuring it must be defined; if the total cost of ownership is important, this attribute, too, should be defined. Weighting factors for each of the performance metrics also need to be defined. The study recommended further that the Army develop and adopt a consistent life-cycle costing methodology for evaluating alternative technologies and that life-cycle cost be heavily weighted in selection decisions.

1.6.3 Accelerating Technology Transition

Published in 2004, the NRC report Accelerating Technology Transition: Bridging the Valley of Death for Materials and Processes in Defense Systems addressed best industry practices for the accelerated transition of new materials and processes into application.32 Case studies included Formula 1 racing cars and America’s Cup racing boats. In these cases, the risk/reward balance favored early adoption of emerging materials technology, encompassing new materials, manufacturing processes, and modeling. The report also reviewed some successes in the military’s adoption of technology that were achieved when strong champions shepherded the acquisition process.

The report identified as attributes of successful integrated development teams (1) a “viral”33 development process featuring rapid iteration aided by modeling and broad communication, (2) design to high-level functional (performance) requirements rather than detailed specifications, and (3) effective and flexible team building. The report surveyed the methods, tools, and databases that have supported accelerated technology transition and identified the achievements demonstrated by the aerospace industry in the Accelerated Insertion of Materials (AIM) initiative as the best example of industry practice (see Box 1-5 and additional discussion in Chapter 5).

Echoing two previous NRC studies of materials and manufacturing, Accelerating Technology Transition identified computational materials engineering as the greatest opportunity for accelerating transition. The study recommended a national initiative in computational materials engineering featuring (1) wider dissemination of information on current capabilities, (2) deliberate transformation of computational materials science tools to engineering tools, (3) broader development of fundamental databases, and (4) infusion of a stronger design culture in academic institutions. This recommendation was one more step in the direction of the 2008 ICME study and recommendations, described in Section 1.6.5.

1.6.4 Managing Materials for a Twenty-first Century Military

“Since 1939, the U.S. government, using the National Defense Stockpile (NDS), has been stockpiling strategic materials for national defense.”34 In light of dramatic changes in the U.S. economic and national security environments, the NRC was charged with conducting a study to assess the effectiveness of current policies and legislation regarding management of such materials. Published in 2008, Managing Materials for a Twenty-first Century Military35 assessed the continuing need for and value of stockpiling and identified alternative strategies to ensure the availability of strategic materials to the DoD and its suppliers. The major risks to ensuring the supply of these materials include the increasing global demands for materials, a diminishing domestic supply and processing capability, and the ever-increasing risks of disruptions in global supply chains.

________________

32 NRC. 2004. Accelerating Technology Transition: Bridging the Valley of Death for Materials and Processes in Defense Systems. Washing ton, D.C.: The National Academies Press. Available at http://www.nap.edu/catalog.php?record_id=11108. Last accessed November 17, 2011.

33 In the report, development is termed “viral” to denote that the process “is infectious, providing a seemingly effortless transfer of informa tion and products to others in the team; exploits common motivations and behaviors that are reinforced by the team members’ behaviors; takes advantage of other team members’ resources and knowledge to find solutions; and scales easily from small- to large-scale implementation.”

34 NRC. 2008. Managing Materials for a Twenty-first Century Military. Washington, D.C.: The National Academies Press. Available at http://www.nap.edu/catalog.php?record_id=12028. Last Accessed November 17, 2011.

35 Ibid.

Box 1-5

Accelerated Insertion of Materials Program

The following description is excerpted as indicated below.

The AIM [Accelerated Insertion of Materials] program is a strategic initiative spearheaded by the U.S. Defense Advanced Research Projects Agency (DARPA) and the U.S. Office of Naval Research (ONR). The AIM program initiative created a new materials development methodology that accelerates the insertion of new materials in order to achieve parity with the engine/platform development/design cycles. The AIM program demonstrated application of integrated science-based mechanistic models in (a) accelerated process optimization at the component level, (b) efficient process scale-up with associated reduced risk, (c) accurate forecast of manufacturing variation with fusion of minimal datasets to enable early adoption, and (d) linking of validated models for process/property tradeoffs in system-level design.

______________________________

SOURCE: Accelerated Insertion of Materials, QuesTek Innovations website, available at http://www.questek.com/accelerated-insertion-of-materials.html.

The principal finding of the study was that the operation of the NDS in its present form is disconnected both from current national defense needs and from national defense strategies and priorities. Its ineffectiveness was attributed to a number of deficiencies in its structure and operation, including inadequate information about the specific material needs of the DoD and the availability of strategic materials in either domestic or offshore markets. The NDS process was described as being “episodic rather than dynamic” and one that is no longer responsive to changes in world markets in real time.

The study concluded with a recommendation that the Secretary of Defense establish a new system for managing the supply of strategic materials. In taking a lesson from the private sector, the system would embrace the concepts of supply-chain management and only sparingly resort to stockpiling. The supply-chain management would require better assessment of risks of disruption, an ability to anticipate vulnerabilities in the supply chain, and strategies to ensure that the supply chains remain resilient to disruption. This strategy would require more effective information-gathering tools to identify which materials are critical to defense needs (by, for example, annual reporting from the services and the defense agencies), assessment of the availability of these materials both domestically and abroad, the potential for market and geopolitical disruptions, and the demands placed on targeted materials in the non-defense industrial sectors of the United States and other commodity-consuming nations.

A noteworthy development since the publication of that report has been recent work under the Defense Production Act (DPA) Title III. The mission of the program is to “create assured, affordable, and commercially viable production capabilities and capacities for items essential for national defense.”36 The Title III Program is a DoD-wide initiative under the Director of Defense Research and Engineering (DDR&E). The Air Force serves as executive agent. A category of projects under Title III involves critical technology areas in which U.S. industry leads with respect to research and development but runs the risk of being outpaced by foreign industry in developing production capabilities. In both cases, Title III support encourages and enables domestic firms to improve capabilities to produce higher-quality, lower-cost materials.

1.6.5 Integrated Computational Materials Engineering

Integrated Computational Materials Engineering: A Transformational Discipline for Improved Competitiveness and National Security, published in 2008, defined integrated computational materials engineering as “the

________________

36 Further information on the DPA Title III program is available at http://www.wpafb.af.mil/library/factsheets/factsheet.asp?id=10904 and at http://dod-executiveagent.osd.mil/agentListView.aspx?ID=20. Last accessed October 19, 2011.

FIGURE 1-2 Integrated computational materials engineering (ICME) flow chart showing how knowledge from different domains is combined to provide manufacturing history-sensitive properties as input for engineering product performance analysis. SOURCE: Adapted from John Allison, 2011, “Integrated Computational Materials Engineering: A Perspective on Progress and Future Steps.” Journal of the Minerals, Metals and Materials Society, Vol. 63, No. 4, pp. 15-18, DOI: 10.1007/s11837-011-0053-y. April. Available at http://www.springerlink.com/content/t77k837710154345/.

integration of materials information, captured in computational tools, with engineering product performance analysis and manufacturing-process simulation.”37 ICME enables the integration of manufacturing and design via advanced materials models. Its key elements are depicted in Figure 1-2. The report highlighted a number of realized and potential benefits stemming from the use of ICME, the most significant being reductions in development time and cost for new manufacturing processes, new engineering products, and new or improved materials.

Although the report states that the benefits of ICME are clear, the discipline is in its infancy and there are a number of barriers, both technical and cultural, to widespread development and application. The report recommended that future activities in this area focus on the integration of tools and their use for engineering of materials and structures, rather than on computational materials science per se. The report also indicated that high-quality, information-rich experiments are critical to the successful calibration, verification, and validation of ICME tools. While physics-based material models are important in the longer term, partial solutions and empirical models have proven to be effective for development of useful ICME tools. Nevertheless, the need for new physics-based models should not be overlooked. Indeed, efforts on model development should be pursued in parallel with emerging ICME activities and key advancements in models fed into the ICME pipeline when appropriate. The report also

________________

37 J. Allison, D. Backman, and L. Christodoulou. 2006. “Integrated Computational Materials Engineering: A New Paradigm for the Global Materials Profession.” JOM. November, pp. 25-27.

concluded that curated knowledge bases38 are essential for archiving and disseminating the information required for development of a widespread ICME capability.

In benchmarking best practices, the committee found that development of ICME requires cross-functional teams focused on a common goal—what the report termed a “foundational engineering problem.” Foundational engineering problems are those for which a particular combination of manufacturing process, materials system and engineering application can be specified (even in rather broad terms) and for which all aspects of the problem are amenable to computational modeling and analysis. As defined in the report, foundational engineering problems are essentially demonstration projects. They are “foundational” in the sense that they begin to lay the foundation for future larger-scale development and more widespread implementation of ICME tools as well as the infrastructure for educating a future workforce that can effectively exploit these tools.

The report noted that the DoD has played a leadership role as an early champion of ICME and recommended that that role be expanded, in particular by establishing a long-range, coordinated DoD multi-agency program. The specific recommendations to DoD were to (1) identify and pursue foundational engineering problems to accelerate the development and application of ICME to critical defense platforms, and (2) develop an ICME infrastructure of pre-competitive material process-structure-property tools and databases for defense-critical systems.39

Recent Activity on ICME

A number of concrete outcomes have taken place since the release of the 2008 ICME report. The first World Congress on ICME40 was organized and held July 10-14, 2011, in Seven Springs, Pennsylvania; Northwestern University41 began offering both a certificate program and a new MS program in ICME starting in 2010-2011; and the Materials and Manufacturing directorate of the U.S. Air Force Office of Scientific Research (AFOSR) recently developed a plan to use ICME as an essential organizing concept, adopting ICME throughout its research and development program.42 The moves by the DoD and the research and engineering community to embrace ICME and take concrete actions in response to the recommendations is of particular importance for implementation of lightweighting in DoD vehicles.

In addition, two recent NRC reports—Research Opportunities in Corrosion Science and Engineering (2011)43 and Opportunities in Protection Materials Science and Technology for Future Army Applications (2011)44—feature ICME prominently.

- The Corrosion Science report postulates grand challenges that involve applying ICME tools and approaches specifically to the problem of corrosion. It notes that computational materials design tools are emerging in physical and mechanical metallurgy but are lagging with respect to corrosion behavior.

- The Protection Materials study sought to uncover opportunities for development of advanced materials that are custom-designed for use in armor systems, which are in turn designed to make optimal use of the new materials. Addressing both personnel protection and vehicle armor, the report recommended that the

________________

38 “Curated” knowledge bases are managed, centrally available, and standardized collections of data and information, in which the pedigree of all content is documented.

39 NRC. 2008. Integrated Computational Materials Engineering: A Transformational Discipline for Improved Competitiveness and National Security. Washington, D.C.: The National Academies Press. Available at http://www.nap.edu/catalog.php?record_id=12199.

40 For more information on the first World Congress on ICME, see http://www.tms.org/meetings/specialty/icme2011/home.aspx; last ac cessed October 19, 2011.

41 For more information on Northwestern University’s ICME graduate programs, see http://www.matsci.northwestern.edu/gradinfo.html. Last accessed October 19, 2011.

42 See, for example, Katherine Stevens and Chuck Ward, “Air Force Adoption of ICME for Materials and Manufacturing R&D,” presentation at the annual TMS meeting, 2011.

43 NRC. 2011. Research Opportunities in Corrosion Science and Engineering. Washington, D.C.: The National Academies Press. Available at http://www.nap.edu/catalog.php?record_id=13032. Last accessed on November 17, 2011.

44 NRC. 2011. Opportunities in Protection Materials Science and Technology for Future Army Applications. Washington, D.C.: The National Academies Press. Available at http://www.nap.edu/catalog.php?record_id=13157. Last accessed on November 17, 2011.

DoD pursue an initiative in protection materials by design that would make use of advanced computational and experimental methods.

During the course of the present study, President Obama announced the 10-year Materials Genome Initiative, a “new, multistakeholder effort to develop an infrastructure to accelerate advanced materials discovery and deployment in the United States.”45 The initiative is expected to “better leverage existing Federal investments through the use of computational capabilities, data management, and an integrated approach to materials science and engineering”;46 to advance ICME tool development significantly; and to provide a materials innovation infrastructure and work-force development. Development of ICME capabilities aimed at materials problems of pressing national importance is explicity included.

1.6.6 Other Reports on Simulation-Based Engineering

More recently, two additional relevant reports—the first, funded by the NSF, Inventing a New America Through Discovery and Innovation in Science, Engineering and Medicine: A Vision for Research and Development in Simulation-Based Engineering and Science in the Next Decade,”47 and the second, from the National Science and Technology Council (NTSC), Simulation-Based Engineering and Science for Discovery and Innovation48—echo many of the findings and recommendations of the 2008 ICME report.49 In the context of materials engineering and manufacturing, the reports cite success stories in which high-end manufacturers (including Goodyear, Ford, and Alcoa) employed computational modeling for product and process design, enabling reduced design cycle time and reduced costs associated with development, certification, and re-engineering while improving performance and efficiency. The reports also note that, in general, the simulation-based capabilities in materials science and engineering have lagged behind their counterparts in areas such as structural engineering, product design and weather and climate modeling. One of the consequences has been that the product design and development cycle now outpaces the materials development cycle by a significant margin, leading to a mismatch that hampers the insertion of new materials into engineering products. One of the related deficiencies identified in the reports is the lack of a comprehensive toolbox of validated physics-based material models that have the capabilities to span the pertinent range of time and length scales. The reports further emphasize the need to support education in simulation-based engineering and science across the entire age spectrum: from elementary, middle, and high schools to undergraduate and graduate university programs to continuing education for those practicing in the field.

1.6.7 Commonality in Recommendations of Previous Reports

Although each of the studies described was seemingly distinct from the others, the present committee was struck—as were the committees that produced some of the previous reports—by the similarities in the findings across the studies. However, it is often extremely difficult to attribute specific policy or procedural changes to individual report recommendations, especially as such changes may have resulted from multiple inputs and may occur years after a report is issued. The committee was also struck by the observations of those committees of the seeming lack of action in response to many of the previous report recommendations.

________________

45 Office of Science and Technology Policy. 2011. “Materials Genome Initiative for Global Competitiveness.” June. Available at http://www.whitehouse.gov/sites/default/files/microsites/ostp/materials_genome_initiative-final.pdf.

46 Ibid.

47 NSF. 2010. Inventing a New America Through Discovery and Innovation in Science, Engineering and Medicine: A Vision for Research and Development in Simulation-Based Engineering and Science in the Next Decade. Available at http://www.nsf.gov/mps/ResearchDirectionsWorkshop2010/RWD-color-FINAL-usletter_2010-07-16.pdf. Last accessed on November 11, 2011.

48 NSTC. 2010. Computational Materials Science and Chemistry: Accelerating Discovery and Innovation through Simulation-Based Engi neering and Science. Report of the Department of Energy Workshop on Computational Materials Science and Chemistry for Innovation. U.S. DOE, Office of Science. July 26-27. Available at http://science.energy.gov/~/media/bes/pdf/reports/files/cmsc_rpt.pdf.