Panel I:

The Flexible Electronics Opportunity and Industry Challenges:

Perspectives from Industry

Moderator:

Sridhar Kota

Office of Science and Technology Policy (OSTP)

The White House

Dr. Kota began by thanking the National Institute of Standards and Technology (NIST) for making the workshop possible, and Senator Jeff Bingaman’s office for leadership. He noted that the office where he was working, OSTP, was not a funding agency, but lies within the Executive Office of the President, along with the Office of Management and Budget (OMB) and the National Economics Council. One of its functions is to convey the administration’s priority areas to the federal agencies and to offer budgetary guidance on meeting these priorities. Another objective of OSTP is to promote interagency cooperation through a shared vision, which is “especially useful in a fiscally constrained environment, such as the one we have now, when we really do need to make one plus one equal three, or four.” This shared vision involved not only manufacturing but also many other areas, including energy, climate, health, and space.

He began with a brief review of major features of innovation and manufacturing. He showed a graphic of the innovation cycle that began with basic research, “the great scientific discoveries,” most of which are federally funded. “But that’s only the first step,” he emphasized. “We need to be able to go past that and take the best ideas to prototypes and physical testing. Among all the discoveries, only a few will bear fruit.” Prototyping and testing were followed by the essential step of scaling up, or increasing yield and reliability of a production process. “Once you scale,” he said, “you gain understanding about essential process innovations and product innovations that are needed to feed into the next cycle. Without doing that, no matter how good we are at generating ideas, we just don’t score any runs.”

THE VALUE OF THE “INDUSTRIAL COMMONS”

Developing the skills required for this great overlapping ecosystem of activities, Dr. Kota said, required an “industrial commons” of shared skills, knowledge, and instrumentation. During the recent decades when much manufacturing capability had been outsourced, he said, the capacity of the “industrial commons” in the United States had eroded appreciably, along with our manufacturing leadership.1 “Without the industrial commons, you lose that ability to innovate the next generation of products. And although some people might think otherwise, innovation and manufacturing are closely tied. So the question is, how do we establish and strengthen these commons so that we can create new industries and sustain existing industries.”

He described some of the elements required to create new industries, including innovation, early adoption, and access to capital. Radical technological innovations, he said, emerge from research and development (R&D), primarily the research-dominated R&D funding from the federal government. In the case of federal funding for robotics, for example, there is far more support for research than there is for development. At the other extreme, he said, most of the funding from industry is directed at manufacturing and commercialization, but not at prototyping and the other preliminary steps. This is partly a function of the loss of much of the basic science that was once carried out at Bell Labs and other large, centralized industrial research facilities. The lack of support for activity between R&D and commercialization, he said, creates a problematic innovation gap. “This is where the great ideas coming out of universities need to be translated into products that are actually manufactured here. Closing this innovation gap is a big challenge.”

CLOSING THE INNOVATION GAP

There are different ways to close the innovation gap, Dr. Kota said. One is through strong public-private partnerships that support the kinds of precompetitive research that can be shared by all firms and other parties to the value chain. Doing this, he said, requires careful planning and agreement about how to distinguish appropriate portions of the work.

Another force for closing the gap is existing industries, which provide the incremental innovations and business innovations required to save existing jobs. The government, too, has a role in providing infrastructure and tools, such as automation, resources, and modeling and simulation, as well as a skilled

_______________________

1See Gary Pisano and Wily Shih, “Restoring American Competitiveness,” Harvard Business Review July 2009. The authors define an industrial commons as “engineering R&D, materials, standards, tools, equipment, scalable processes, components, and manufacturing competencies in platform technologies need to product cost-effective, safe and reliable products.”

workforce. These elements are needed to build infrastructure for manufacturing, but they can also have an economy-wide impact. Finally, the structural nonproduction costs are important, including taxes, benefits, energy, and pollution abatement costs.

In accord with the goal of strengthening the industrial commons, he described his own work at OSTP to promote advanced manufacturing in terms of three areas: how to create new industries, how sustain and grow existing industries, and how to coordinate manufacturing better across the federal agencies. Among the topic areas were flexible electronics and nanocellulose materials, which have the potential to revitalize the paper and pulp industry, as well as to create new plastics and composites. He noted that the potential of nanocellulose materials had been clarified over the past 10 years, and that it was “now time for us to scale up and take the best of it and move forward. That’s how we complete the innovation cycle.” Robotics, too, he said, is at “a tipping point,” thanks to advances in sensors and control systems that have taken place in the past 20 years. “Now we have the notion of robots as co-workers, co-inhabitants, and co-explorers, which is very different than the early-style robots” that were much more limited in what they could be expected to do. “The opportunity is there,” he said, “not only to enhance manufacturing, but also to create new industries, especially in health care and defense.”

ADMINISTRATION SUPPORT FOR MANUFACTURING

Other new aspects of advanced manufacturing, he said, included the use of modeling and simulation to design materials at the molecular level, at one end of a spectrum; at the other end is the use of multiscale, multiphysics models and algorithms for multicore computations in cloud computing.2 While the value of such processes is becoming clear, he said, few small and midsized manufacturers use the modeling and designing tools that already exist because of lack of expertise and access. OSTP, he said, had been trying to develop ways to make available this ability and access in order to enhance firms’ productivity and competitiveness.

Last year, Dr. Kota noted, the administration signaled its focus on manufacturing by the appointment of Ron Bloom as the special counsel for manufacturing. In addition, the White House and others had requested a special study on advanced manufacturing. OSTP had convened interagency meetings

_______________________

2“Multiphysics treats simulations that involve multiple physical models or multiple simultaneous physical phenomena. For example, combining chemical kinetics and fluid mechanics or combining finite elements with molecular dynamics. Multiphysics typically involves solving coupled systems of partial differential equations.” See Wikipedia, <http://en.wikipedia.org/wiki/Multiphysics>.

with NIST, the Defense Advanced Research Projects Agency (DARPA), and others to identify priority areas.

He said that the administration had released a document in December 2009, Revitalizing American Manufacturing, in which the White House identified seven principles to strengthen the manufacturing base, and addressed various cost drivers such as labor, access to markets, regulation, taxes, technology, and business practices.

He noted the importance of integrating manufacturing with information technology in order to advance process manufacturing and create cyber physical systems. He said that the president’s 2011 budget contained a series of technology investments for this purpose, including a doubling of the research budget for the National Science Foundation (NSF), more basic research funding for the Department of Defense (DoD) 6.1/6.2 basic research, an increase in the budget for the NIST Technology Innovation Program (TIP) to $150 million by 2015, and funding for NSF university innovation centers. It also included measures to ensure better access to capital for businesses, including loan guarantees and a manufacturing tax credit, which achieves a leverage of private-sector returns by a factor of three or four.

Dr. Kota also reviewed excerpts from OMB and OSTP budget guidance to agencies for the fiscal year 2012 budget. In science and technology, he said, six areas were identified: economy, clean energy, health care, climate change, ecosystem diversity, and national defense. He noted that the first one, economy, included promoting sustainable economic growth, and the administration’s priority in advanced manufacturing was the lead priority.

THINGS INVENTED HERE, MANUFACTURED ELSEWHERE

Dr. Kota said that while he did not have technical expertise in flexible electronics, he had learned from experts in industry and academia that the opportunity to advance this field is great. But without policy changes, he said, the “picture was somewhat scary.” By this he meant the specter of “things invented here but manufactured elsewhere; industries we have already lost, and others that are at risk.” Citing recent research by Gary Pisano and Willy Shih, he showed a list of technologies that had been lost to manufacturers abroad, including “fabless” chips, compact fluorescent bulbs, liquid-crystal displays (LCDs) for monitors, TVs, and mobile phones; lithium-ion, lithium polymer, and nickel–metal hydride batteries for cell phones, portable consumer electronics, laptops, and power tools; crystalline and polycrystalline silicon solar cells; desktop, notebook, and netbook PCs; low-end servers; hard disk drives; consumer-networking gear such as routers, access points, and home set-top

boxes; advanced composites used in sporting goods and other consumer gear; advanced ceramics; and integrated circuit packaging.3 Among the opportunities for flexible electronics, he summarized, are the potential for high-tech, high-profit manufacturing, job creation, and low-cost manufacturing of electronics with more flexible substrates—distributed among such application domains as smart phones, health care monitoring, structural health monitoring, smart bandages, and batteries. “This is all exciting stuff,” he said. “Hopefully we still have an opportunity to manufacture them here, in the U.S., so we can reap the benefits of investments in basic research.”

Dr. Kota said there were many opportunities for partnerships as well, among large companies, small companies, and innovative companies of any size, the research universities, and the federal laboratories. Partnerships could affect multiple sectors, he said, and take the form of horizontal consortia, or vertical consortia, as in the case of SEMATECH, or a hybrid. They could also leverage existing research from universities to new clusters, such as the Flexible Display Center at Arizona State University.

The primary challenges for flexible electronics, he said, were similar to those facing any new technology, including packaging, reliability, and yield. The task was to determine which research challenges could be addressed in a precompetitive manner, with benefits for all, and which would be deemed proprietary.

In summary, he challenged the workshop participants with two closing questions. First, what technological breakthroughs are needed to establish and then to sustain the industries that can grow up around flexible electronics? Second, what kinds of public-private partnerships (PPPs), business models, or government policies would enable the United States to gain global manufacturing leadership in this area? “What is at risk, what has been lost, and what are the things we can catch?”

Dr. Kota closed with a quote from President Obama about the technology goals of his administration: “Our goal has never been to create a government program, but rather to unleash private-sector growth.”

_______________________

3Gary Pisano and Willy Shih, “Restoring American Competitiveness,” op. cit.

CHALLENGES AND OPPORTUNITIES FOR THE FLEXIBLE ELECTRONICS INDUSTRY

Ross Bringans

Palo Alto Research Center, Inc.

Dr. Bringans began his review of the field of flexible electronics with a description of the Palo Alto Research Center (PARC) as “different from most institutions in being not truly industry, and not academia.” PARC was established by the Xerox Corporation four decades ago, in 1970, with the objective to “invent the office of the future for Xerox.” In 2002, the parent company transformed PARC into a new subsidiary to work with other entities, including the government and commercial clients. It organized itself into four divisions, two in computer science and two in hardware. In hardware, a chief area of focus was large-area electronics, which included flexible electronics. Several other PARC topics also related to flexible electronics, including microelectromechanical systems, or MEMS; optoelectronics, including activities in laser devices and optical detectors; printing systems, which grew out of the Xerox tradition; biomedical systems; and clean technology, including energy systems.

Another unusual feature of PARC, he said, is its method of doing research as a business; customers include private companies and the government. It operates by partnering with many small companies, including many at the startup stage that consist of “two or three people and an idea.” PARC also incubates businesses on its own, spinning out new companies. Finally, it licenses and transfers technologies from its historical and current portfolios.

The overarching concept behind flexible electronics, he said, is that it replaces traditional means of placing electronics on rigid silicon with something that is much more paper-like or plastic-like and is therefore relatively lightweight and robust. He noted the concept of Nokia, which is that flexible electronics brings the ability to “morph from one shape to another,” which cannot be done with current technology. He also recalled an image from Scientific American, created six years ago, that showed a display going in and out of a cell phone. “You will see that this is not too far from reality.” He cited the “really interesting” prospect of medical patches: thin, flexible material that has the ability to monitor heart rate and other vital signs and communicate those readings to physicians and hospitals. “Something like that would be tremendous,” he said.

Defining Flexible Electronics

Dr. Bringans suggested that flexible electronics might be defined in two ways, according to applications. Many applications are likely to utilize flexibility per se, which in itself is valuable. But he suggested that a second,

larger market would be other electronics that benefit secondarily from the quality of flexibility. This market would create a new industry of electronics that are much lighter and more robust, potentially lower the cost of manufacturing dramatically, and allow custom systems to be manufactured without large new infrastructures. “If you look at it this way,” he said, “it’s pretty clear that it can be a destabilizing technology. And as in all cases of destabilizing technology, the winners are not obviously the incumbents of the previous technology. They could be, but there could be new ones, and the question is where they will be—in Asia, the U.S., Europe, or some mixture.”

He said that “in the spirit of an overview” he would review each of those component areas, or “partitions.” The first included applications that benefited from flexibility.

• Many displays, for example, have added value if they are mounted on curved surfaces and rollable. He noted that Sony earlier this year showed the ability to wrap an active display around a very small diameter. Rollable displays, he said, would naturally be more robust than rigid, flat displays.

• Manufacturers would want to place photovoltaics on curved surfaces—both for practical reasons and for aesthetics. This would increase the number of places such products can be used.

• In making and viewing x-ray images, which is an area of PARC interest, flexibility might allow them to be conformal, surrounding the objects under view; this would also bring robustness.

• The medical device area, he said, was an exciting market, for which both electronic patches and implantables could benefit from flexibility and biocompatibility. He showed an image from the University of Washington of electronic devices embedded in a contact lens.

• “Systems on a foil,” he said, would include wearable, flexible devices that were “designed for people, not imposed upon them.”

A second category, he said, was one that needs the flexible substrates for particular uses but also bring benefits to manufacturing as a whole. The element most often mentioned was roll-to-roll manufacturing. This technique exists now and produces newspapers, packages, and other products at low cost and high volume, and many firms were trying to move that technology into electronics. Another element was light, thin substrates which could lead to ultralight and stackable systems. Flexibility also brings the element of robustness because the products are not brittle. “We like to be able to drop our tablet computers and not have them break,” he said, “and I think that is going to happen. There are many by-products under development that can benefit from both flexibility and

robustness, including RFIDs, photovoltaics, smart labels, lighting, smart phones, and tablets.”

Applications Must Drive the Technology

The perspective of PARC, he said, was that “flexible electronics is a very exciting direction, and there will be a lot of new technologies. We are certain that interesting business opportunities will flow out of that.” He said that these opportunities are beginning to open, particularly in Europe. He also said that “applications will drive the technology. In the end, people are not particularly interested in the technology. It’s kind of cute, but they really want the solutions.” Furthermore, he said, people want not just solutions, but “a convergence of all the solutions in one place, whether it be a smart phone or an iPad.”

Two major barriers stood in the way, however. The first was the commercial challenge of launching the industry. “It’s hard to get something started that’s going to be as large as this,” he said. The second challenge, he said, concerned the role of the federal government. “Where,” he asked, “is the best place to apply its leverage?”

Dr. Bringans said that PARC had viewed the field of flexible electronics from many angles. Its first approach was to make standard technologies flexible, such as the placement of amorphous silicon on plastic and polycrystalline silicon on thin steel foils. They had also spent a good deal of time exploiting printing technology, especially ink-jet printing, and were now beginning to look into traditional printing technologies, such as gravure. “We’ve done a lot of development in organic electronics,” he said. “Those two sit together well, because many of the organic materials are printable, and many of the printable materials are organic. We are doing basic research, but trying to demonstrate applications at the prototype level.” Those applications include displays, sensors, and systems. He showed an image of a nonflexible x-ray imaging system for looking at improvised explosive devices (IEDs). It was, he said, “basically an imaging x-ray detector that you’d put behind a suspicious object. If you shine x-rays through the object you get a one-to-one image, like seeing it through a window.” PARC was about to start work with partners to develop this imaging device into a flexible and robust system. “This is to show that we have worked from fairly basic materials science all the way through to assembly of fully working systems.”

He showed the example of an all-additive printed array, which functions without photolithography. The patterning is done with ink-jet printing; the metal layers, the semiconductor, and the insulator are all created with solution-based materials and can yield a fully working backplane for display.

Why is this important?, he asked. First, producing a printed array takes many fewer steps than photolithography. For example, a transistor can be made with four steps, yielding four layers if it is all printed in an additive way. Traditionally, depending on the design, making an array by photolithography

can require 16 to 20 steps. The other, perhaps more important, advantage, he said, was that by simplifying the structure to this level, it is possible to contemplate simpler applications, such as smart labels, that might not be feasible as separate industrial technologies.

Sensors to Monitor Brain Injury

A second example, he said, was an effort, funded by DARPA, to use printing technology to develop a blast dosimeter that measures and tallies the cumulative effects of multiple blasts in warfare. “The issue,” he said, “is that traumatic brain injury does not come only from very large explosive impacts; it’s a cumulative effect. There can be as much damage from a sequence of small impacts, or even a very separated series of moderate impacts, as from a large one. We want to develop something like a radiation monitor that soldiers wear on their uniforms or helmets.” These sensors would monitor events of pressure, acceleration, sound, and light, put them into memory for up to a week, and then read them out.

“That sounds straightforward,” Dr. Bringans said, “except for the requirement that the sensors cost a dollar apiece.” The challenge is to find ways to print each of the major circuit components—the ring oscillator, shift register, amplifier, and memory—on a flexible substrate. He said that PARC had been able to develop some sensing from laminated elements that could potentially be produced inexpensively through roll-to-roll techniques. “The next step,” he said, “is to integrate these so the impact measured by the MEMS sensor is amplified by the printed amplifiers and then stored in printed memory cells.” This experience, he said, had confirmed PARC’s view that flexible sensor systems would be important not only for the military but for many applications, such as monitoring elderly people at home.

“The other thing we’ve learned,” he said, “is that hybrid devices are promising, and probably necessary—certainly in the beginning. Some things can be done well with printing and customized circuits, but others make more sense on silicon, such as the communication chips.” He noted also the opportunity to combine the new technologies with traditional printing and manufacturing, such as silicon manufacturing or techniques like lamination.

He said that PARC had also learned the lesson “that putting all this into a system is hard—as is taking it to the next level. To get applications that are inexpensive—the $1 patch—you need a lot of volume. In order to create volume, you need applications. So the big question is, does the whole industry have to wait until a company with enough money and a particular demand will drive the development of not only that particular piece, but also the industry itself. That’s asking a lot, but it seems to be happening.”

His view, he said, is that flexible electronics has “a huge future.” This view, he said, reflected PARC’s activity across the industry and its work with a wide range of partners. “We get a view on this, and what we do is invent, develop, and demonstrate both processes and prototypes, and then put them into applications. Then we ourselves are investing in developing components and trying to partner with manufacturers to move to the next level.” Beyond that stage, he said, it would be interesting to focus on the development of applications. “There’s clearly some funding already for processes and infrastructural capabilities,” he said, “and this needs to be enhanced. But it would be interesting if we could put this together with applications, which you could argue is one of the big missing pieces in the United States.”

Dr. Bringans offered a quote from a report by NSF and Office of Naval Research on the state of flexible electronics: “…the relatively low prevalence of actual manufacturing and advanced systems research and development in the United States has led to an incomplete hybrid flexible electronics R&D scenario for this country….”

“We think that by pushing the applications,” he concluded, “we could really help kick-start this industry, which we all believe is going to be very important.”

IMPACT OF A FLEXIBLE FORM FACTOR FOR DISPLAYS AND LIGHTING

Julie Brown

Universal Display Corporation

Dr. Brown began by introducing her company, which was founded in the mid-1990s as “an innovation gap company.” The original goal of Universal Display Corporation (UDC) was to fund basic research, she said, and to “really inspire innovation.” Two researchers at nearby Princeton University4 had identified the chemistry and technology to make an organic light-emitting diode (OLED) 100 percent efficient, and the company was founded to exploit that discovery. She predicted widespread uses for flexible electronics. “As a person who does not have pockets in her suit to carry a cell phone,” she said, “I look forward to being able to wear one on my wrist. She said that the mission of her own firm was to develop all kinds of organic flexible electronics for displays and lighting.

The history of displays, she suggested, might be said to have started with the first symbols scribbled on a rock, which evolved eventually into the portable convenience of newspapers. The other key element of lighting

_______________________

4Steven R. Forrest and Mark E. Thompson, who have collaborated in patenting numerous organic thin-film devices, worked with UDC in developing the firm’s technology.

technology, she continued, began with the fire that produced light, then became portable with the use of lanterns. She compared the cathode ray tube of the 20th century to the stone, only to be replaced by “beautiful LCD technology,” which has become the first truly portable display technology in its use for laptop computers. Today, she said, the technologies of both the newspaper and the portable display are poised to converge in OLED technology. “We’re moving very quickly toward having the technology pieces in place,” she said. “We’re actually building flexible displays today for our government customers.” UDC began its research in this field in the late 1990s, she said, in response to early work at DARPA on flexible displays. UDC now works with the U.S. Army. It is also conducting lighting research supported by the Department of Energy (DoE).

Rollable and Almost Paper-Like Displays

As the technology moves ahead, she said, consumers will want not only the flexibility and convenience of a newspaper, but the vivid color and energy efficiency of cell phones. She noted the design concepts being discussed by Nokia, Sony, and other companies, which envisioned products that will not only be vivid and efficient, but also nonbreakable, thin, and rugged.

To date, Dr. Brown said, beautiful products are being designed with electrophoretics, or e-ink, which produces a thin and potentially flexible technology. The goal is to advance this technology with a technology platform and manufacturing process that will add more essential features, including full color, vivid images, video rate display, and “green low power.” These features can then be combined with the manufacturing capability to make “rollable and almost paper-like displays.”

She noted that the current generation of cell phones, such as the Galaxy S, already generates vivid color by combining flexible silicon backplanes with OLED front planes. They also have low power consumption, which grew out of the work by Forrest and Thompson, who identified the chemistry and technology needed to achieve 100 percent efficiency for OLEDs in turning electricity into light. UDC has a pilot manufacturing line outside Princeton, with the objective of producing “light without heat.” With additional improvements in phosphorescent technology, the power consumption of OLED lighting will continue to decline.

The “big win” for OLED technology, she said, would be to develop the process that allows it to be placed on a flexible substrate. Her company already employs a designer, she said, whose job is to imagine future uses for flexible OLEDs beyond the current cell phone.

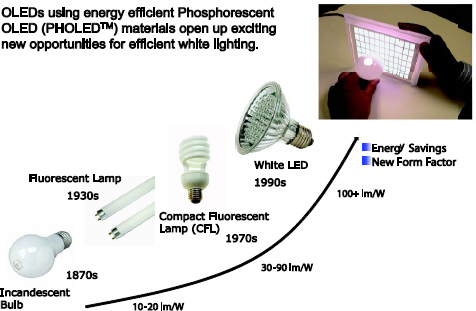

FIGURE 1 Evolution of lighting.

SOURCE: Julie Brown, Presentation at September 24, 2010, National Academies Symposium on “Flexible Electronics for Security, Manufacturing, and Growth in the United States.”

Rugged Enough to Absorb Hammer Blows

Dr. Brown said that the company’s core OLED technology sits on a flexible substrate about 100 microns thick and is rugged enough to absorb hammer blows. Development of the technology began in DARPA and moved into the Army, and UDC had been funded by the Army to build full-color, active-matrix OLED flexible displays. UDC works with L-3 Communications and several other partners who were responsible for the backplane and systems integration. UDC had delivered the first units to the Army in Fort Dix the previous August for field testing, with good early results. “They had all our units laid out on the table with streaming video from the UAV [unmanned aerial vehicle] above the tent,” she said. “So we have flexible electronic technology now being fed into the military.”

In addition to the goal of producing a better technology, she said, the lighting industry as a whole is “focused on green—on energy efficiency, which is a huge issue here in the U.S. and globally.” Lighting currently consumes 22 percent of the total electricity generated in the United States, she said, and 8 percent of the total energy. “Right now, whether we’re talking about an inorganic LED or an organic LED, all the technology development is going after lumens per watt. And the numbers are getting better. Programs in lighting are heading toward 100 lumens per watt.”

She said that one application with high potential is transparent light sources on pieces of flexible material. She showed an example of white OLEDs for applications in ceiling systems. UDC, in partnership with Armstrong Industries, had built a fully integrated OLED ceiling system that plugs into the Armstrong Tech Zone Ceiling using 24-volt rails. “My OLED plugs in,” she said, “and saturates the camera with bright light.” She said that flexible lighting would provide great opportunities to bring together diverse manufacturing expertise with end uses. “Lighting is really different from the display industry,” she said. “A lot of people involved in lighting are doing infrastructure development. And today the technology blocks are in place: flexible encapsulation, low-power OLED, flexible substrate.”

A Need for Global Relationships

Dr. Brown said that from both national and international perspectives, there is great momentum toward development of technology for flexible displays. In the United States, this momentum has been initiated within the U.S. government, and leadership is apparent in other sectors, as seen in the Flexible Display Center in Arizona and small firms such as the Arsenal Company. At the same time, she said, the relationships required to build an industry are global.

Within the United States, she said, military applications are being launched first and are beginning to point at directions for commercialization. She added that the emerging industry can take advantage of the many manufacturing technologies related to flexible electronics that are already in place. Another pressing task is to begin to prioritize and integrate issues at the systems level and “talk about how are we actually going to use these flexible systems. There are a lot of very important mechanical and electrical issues to solve.”

While acknowledging that she was “not a public policy person,” she suggested that a flexible OLED lighting would need incentives to bridge the gap between prototyping and marketing. OLED lights were not likely to launch at a price of $2 or $3, she estimated, but at $20 or $30. Lower prices would require both incentives and collaboration among the DoE and potential users. She urged more collaboration between “good work being done in the DoE and various partners, especially U.S. infrastructure companies, universities, and government agencies.” A goal of such partnerships, she said, is to regard OLED lighting as an overall system. For flexible displays, she suggested that mandating both efficient lighting and wall plug applications, such as television monitors, would inspire new applications and advance the industry.

From a global perspective, she said she saw a huge amount of research, development, and prototyping of OLED lighting displays in Asia, especially in Taiwan, China, Korea, and Japan, with China emphasizing mass installations.

The Chinese government, she said, was determined not to miss an opportunity for leadership in OLEDs as they may have done in LCD technology. Likewise, she said, European countries were vigorously working on technologies of flexible lighting.

She concluded with the opinion that “for all of this, the big win is in the flexible organic electronics. There’s a technology platform out there, there’s a commercial need, and there’s a lot of progress being made. This is a huge opportunity, and an exciting new area.”

Discussion

In response to a question about cost, Dr. Brown said that estimated costs for manufacturing on glass, including the glass and the electrodes, were about $600 per square meter, with the main cost for the substrate. Using a metal foil or plastic substrate would drive the cost down, she said, and some industries were experimenting with these technologies. The organic materials for R&D, she said, were produced by her company, which bought the substrates commercially. The large lighting companies preparing to launch products were finding materials overseas.

PLASTIC DISPLAY RESEARCH AT HEWLETT-PACKARD

Carl Taussig

Hewlett-Packard Company

Dr. Taussig, director of advanced display research for Hewlett-Packard Company (HP), said that he had “a visceral reaction to the terms flexible electronics and flexible displays. For me personally, and for HP, it has been about low cost, and flexibility is a nice side effect of very-low-cost manufacturing using roll-to-roll processing.”

He said that HP was one of the world’s largest purveyors of displays, selling about 65 million displays last year as part of most of the products made by the company, including not only computers, laptops, and handhelds but also network switches, printers, and many other products.

When HP was studying the future of displays, he said, the company realized that plastics were going to have a huge effect on the display industry. He said that the primary function of plastics would be to enable low-cost, roll-to-roll manufacturing. Other benefits flowed from the fact that plastics are not glass. “If we’d had a choice,” he said, “we wouldn’t have used glass as a substrate in the first place. It’s friable, it’s heavy, and it’s rigid. Plastic is lightweight, unbreakable, and conformable. These are great benefits and make it suitable for high-volume, low-cost manufacturing.”

LCD as an “Entrenched Competitor”

Among other factors driving the trend toward plastics, he said, was that many emerging display technologies were inherently better suited to a plastic substrate. An example was OLEDs, which could usually be manufactured at the low temperatures compatible with plastics and bring the additional benefit of a simple, efficient stack structure. This alone might be sufficient to replace the entrenched liquid-crystal industry, he said, noting that OLED had been considered the “next display technology” since the mid-1990s. A reason it had not emerged, he suggested, is that an entrenched competitor, such as liquid crystal, continues to evolve, making it difficult for a new and even superior technology to take its place. However, he suggested that the new opportunity presented by plastics might be sufficient to bring change.

Another emerging technology that appears to be compatible with plastics is ultra-low-power displays, such as e-ink, or reflective electro-optic devices. These are potentially bistable and may need no power to maintain a static image. Helping to drive introduction of these new displays is a worldwide desire to have increased mobility and to be able to have information available and visible everywhere, even outdoors in bright sunlight.

Dr. Taussig also described a clear opportunity to enhance the capabilities of existing form factors for displays used in appliances already on the market. Once a technology is developed that has the attributes of plastics, such as very low cost and very large area, it would be possible to extend flexible lighting to billboards, food packaging, “talking cereal boxes,” apparel, and many other products. He noted the plans of Nike to instrument running gear with a display that sends information to the wearer from other parts of one’s apparel. He noted that most of the work in this area had been funded by the government for military applications. The support of government had made it possible for even a very large company such as HP to benefit from the leverage of public-private partnerships to work with e-Ink, Power Film Solar, and other companies. He said that his company saw this as a change from “simple, segmented, fixed-pattern enunciators” into a “cross-point addressing structure that could be passively addressed, and then into an active-matrix technology.” Each of these would have its own development trajectory, as well as trade-offs in difficulties and technologies that need to evolve.

Faster Electrophoretic Displays and Roll-to-Roll Manufacturing

HP Labs focused on two aspects of this change, he said. The first was current reflective displays, which hold advantages in mobility applications, such as e-ink, which he called a “tremendous and exciting product. It uses incredibly low power, and you can see it in bright light.” In two areas, he said,

improvement would be desirable. The first would be to speed the uptake and develop a color version. Because it is an electrophoretic display, it functions by moving pigment particles in a solvent. This process, which is dominated by viscous forces, is inherently slow. In addition, the technology is based on the motion of oppositely charged pigments within a microcapsule. This allows for two kinds of charge, and only two options for the pigments—black and white. The simplest way to render these pigments in color is to place a color filter in front of them, subdivide the pixel into red, green, and blue subpixels, and turn off the blue and green channels to gain a saturated red. This technique, however, results in a dim and washed-out display.

The other major thread of HP research, he said, is roll-to-roll electronics. Developing this feature—not flexibility or any other qualities—was the company’s initial motivation in entering flexible electronics. It wanted to learn how to make the product with the lowest possible manufacturing costs at high volume. “We’ve been working on this for the last 10 years,” he said, “and maybe for the last six years with a focus on displays.”

The Color Reflective Problem

Dr. Taussig returned to the color reflective problem, saying that he had referred to “side-by-side color,” in which a color filter is placed in front of a black-and-white light valve. This technique is fundamentally limited, he said, because it subtracts much of the available light. And in a reflective system of this type—unlike the transmissive or emissive system of OLEDs or LCDs—the problem cannot be solved by increasing the back light or the current; the only light available is what is reflected from the ambient. Side-by-side color essentially gives away 67 percent of that amount, yielding a dim display. An alternative is to stack layers, which HP has been investigating. A difficulty with this approach is that it involves a number of interfaces, and the light has to go through each of them and return. About 2 to 3 percent of the light is lost at each interface, and when light must pass through 20 or 30 interfaces, only about 50 or 60 percent of total reflectivity remains.

A major innovation his company had made in reflective displays, he said, was to place selective mirrors within the stacked system, which causes the light to be intercepted as soon as possible within the stack. This means that the light does not have to travel all the way through the stack, losing a small amount at each mirror. In addition, he said, HP researchers had made this into a “transflective” system. That is, the mirrors also transmit 10 percent of the backlight—more than the transmission of a conventional LCD.

He showed a video clip of this system, featuring a stacked color reflective system developed in the HP Labs, and behind it an e-ink display. The black-and-white performance of the system was similar to that of e-Ink in terms of contrast and brightness, he said, but the HP system also had “a reasonably wide color gamut,” which he noted was almost as fast as video. He said that the

metrics they used to evaluate the system were those developed in the printing industry

The problem with a stacked display, he continued, is that it uses at least three displays, which is more expensive than a side-by-side design. A simpler approach to reduce cost is to develop a process called photoluminescent enhancement. Here, luminescent materials capture the shorter-wavelength light and reemit it in the longer-wavelength portion of the spectrum. This effectively produces light that is “redder than red”—200 percent or more of the original light. “This may give us an intermediate step at a reasonable cost point,” he said. “We can then use approaches like ink-jetting to put these photoluminescent materials into wells that we’ve defined with an imprinting structure.” He said that HP is working with the Flexible Display Center in Arizona and with e-ink to demonstrate color filters made by this approach. Compared to conventional ink-jetting, he said, the photoluminescent system, in template wells, gave “much better resolution.”

Dr. Taussig also showed an e-ink–based display, with e-ink as the front plane and an HP roll-to-roll backplane behind it. His firm had worked for years with a company called Power Film Solar to develop a one-third-meter-wide pilot line at the HP Palo Alto research facility, which makes the backplanes. The technology had been licensed to Power Film, which had formed a subsidiary called Phicot, Inc., a recipient of Army Research Laboratory funding, to make a self-powered, wrist-worn cuff display for the military. The technology, known as self-aligned imprint lithography, or SAIL, had been successful enough to win awards, he said.

Kilometers of Material

Dr. Taussig then described the HP approach to roll-to-roll manufacturing that combined all the lithography processes used in one kind of display. The roll was able to produce kilometers of material at a time. His company, he said, was also interested in adapting these paper-like displays, using reflected but high-performance lighting displays, and in leveraging the developments in OLED lighting. “We see that as the first opportunity to get this stuff commercialized,” he said, adding that other groups, including UDC and General Electric, had demonstrated a roll-to-roll process for making white OLEDs. “We’d like to take that white OLED developed by others for a lighting application,” he said, “and turn it into a display. The challenge there is whether we can process this material afterward when it is manufactured and laminated to a roll-to-roll backplane.”

To advance from the technology of e-ink displays, he said, it was necessary to enhance the performance of the pixel circuit. “They’re a little more complicated when you’re driving an OLED,” he said. His lab had been using

metal oxide semiconductors, which have about 10 times the mobility of amorphous silicon. He showed an early prototype of such a product, a nonaligned roll-to-roll process for assembling a white OLED with a roll-to-roll process backplane, in this case amorphous silicon.

Dr. Taussig closed with a plea for more public-private partnerships in the United States. He said that he firmly believed that even a very small investment on the part of the federal government, if designed properly, can “make an enormous difference in the commercialization of technologies in the United States.” Without such support, he said, “it is virtually impossible to contemplate initiating a manufacturing-based industry in the U.S. because of pressure from overseas, where firms have the support of their governments to make these things happen. As a group, it’s incumbent on us to make that different.”

DISCUSSION

A questioner noted two opinions about the appropriate level of government investment in flexible electronics. One was the need for large investments in infrastructure to move consumer-oriented products into the marketplace, from photovoltaics and other similar areas. The second was the need for only a small government investment, primarily to stimulate the formation stage of the industry. He asked for some more context on those opinions.

Dr. Brown said that she favored a new government initiative to help companies bring flexible OLED lighting, and perhaps flexible solar photovoltaics (PV), into the marketplace. This would mean initiatives in manufacturing and related technologies. She said that she was not calling for large government investments as much as a different type of support. She noted that DoE gave a great opportunity to UDC and its partners by providing funding to initiate OLED manufacturing plants in the United States. This allowed the company to attract a desirable subcontractor from India, Moser Baer, in setting up the plant in the United States. “What I see missing,” she said, “is bringing in the designers and end users and initiatives for energy efficiency, and integrating everything with industry programs.”

Dr. Taussig said that the relatively modest investments that the government had made to date had been important in the early phases of technology development and had catalyzed significant results. “I expect that in that chasm between universities and industrial research labs and then mass production, there needs to be a mechanism to bootstrap that in a similar way. That is where the process falls down.”

Dr. Schen, of NIST, said that his institute was involved with small to medium-sized manufacturers in the United States. He asked about the ability of U.S. firms to compete with China, where the government is investing significantly in flexible substrate technology. A critical need in the United States, he said, was for help in generating high-volume manufacturing “so that

John Smith Incorporated doesn’t have to compete with China Incorporated. I understand that the substrates are coming from overseas now. Our research from the universities and research labs is excellent, but when it comes to manufacturing, somewhere the link is broken.”

Dr. Kota said that the subsidies offered by China and other countries include buildings, 10-year tax holidays, and other help, but that “this is not the world we operate in.” The United States makes significant investments in basic research, he said, but its free-market principles do not usually include a role for direct subsidies. Rather than seeking to compare itself to countries using subsidies, he said, the United States might better address the gap between research and manufacturing through public-private partnerships. A second point worthy of discussion, he said, was the issue of market failure in technology development. This term is often used to describe the private sector’s reluctance to invest in complex functions, such as roll-to-roll processing, if a single company or even industry does not expect to reap a sufficient return on the required investment. In such cases, he said, when research in key platform technologies might benefit multiple industries, such as lighting and displays, the federal government may have a legitimate role.

Dr. Wessner noted that the Obama Administration, especially through the Department of Energy, had targeted substantial funding for technology research in areas of great promise, such as batteries. Two elements of concern for such technologies, he said, are (1) how to drive the supply into production and (2) how to drive the demand for the product. DoE policy, he said, had been effective in demonstrating that the chief barrier to establishing new businesses in the United States was no longer low wages, but the cost of capital. “That is a new area of global competition,” he said, “that we have been slow to participate in.”

Dr. Brown agreed that the United States should not emulate the kinds of support initiatives featured in China, but do a better job of integrating products and moving them into the market. “Whether in solar energy, display, lighting, or other areas,” she said, “I think we have a great opportunity to place the same emphasis as other countries, in flexible electronics, but working at product integration. There are lots of flexible substrate systems in the U.S. that could be integrated, and a lot of opportunity.”

James Sturm of Princeton University commented that there is a “missing piece: the focus should be on applications.” Dr. Bringans said that he favored the model of ARPA-E that had emerged in the energy area, which seemed effective in many ways, such as raising the “technology readiness level” (TRL) of a technology. “We sometimes talk just about putting big consortia together,” he said, “when in fact things can be jump-started by pushing them beyond what is normally people’s comfort zone in R&D more toward