Reducing the Major Logistics Demands

An analysis in 2003 by the Army Materiel Systems Analysis Activity indicated that, in the initial phase of Operation Iraqi Freedom (OIF), 51.1 percent of the tonnage moved to the theater was accounted for by water and 38.6 percent by bulk fuel. The Army consumed 1.2 million bottles of water per day. There have been on average 1 casualty per 50 supply convoys in Iraq and Afghanistan. Resupply operations have been identified as a significant contributor to casualties in operations in Afghanistan and Iraq.

There are many technologies that could reduce the logistics burden of the Army. This chapter presents a variety of these. It should be noted that many of the technologies discussed in this chapter are not particularly new. The committee is at a loss for the reason that some of them have not yet made it into the field. The implementation of demand-reducing technologies will have second- and third-order effects that would have to be analyzed and modeled to be completely understood. For instance, take a technology that reduces the demand for fuel. That would take trucks, and soldiers, off the road and out of danger. Fewer trucks mean less fuel consumed in transporting fuel. A reduction in the number of trucks would also result in a reduction in maintenance demands. A reduction in the number of personnel required would mean that less sustainment needs to be provided overall (less food, water, power used, etc.). And so on. Some technologies would also introduce logistics demands that might mitigate their benefit to some degree. For example, using additive manufacturing in the field would introduce a maintenance demand for the machines and associated equipment and would introduce a demand for the raw material used in additive manufacturing. Combined Arms Support Command analyses indicate that the largest future demands will continue to be for fuel, ammunition, and water. Other logistics demands of interest to the Army, even though they are not large by tonnage, are maintenance and critical parts and batteries and soldier load.

The committee notes the need to be cautious when introducing new systems and technologies into the field. The Army has had some successes by fielding fairly-mature technologies to gain operational experience. This has allowed technologies to be refined, aided in the development of better capabilities for soldiers, and has even provided soldiers with new capabilities that they would otherwise have had to wait a long time to access. But introducing technologies before they are sufficiently mature can create many problems. One effort to introduce new capabilities to deployed soldiers, the Rapid Fielding Initiative, fast-tracks equipment and systems to deployed soldiers outside of the normal acquisition process.1 There is anecdotal evidence that this has caused some problems in terms of logistics support. The fast tracking of the procurement system did not allow for proper integrated logistics support planning. Inadequate training, manuals, repair parts, and long-term support resulted in much of this equipment not being deployed properly, only being deployed on a limited basis, or only being used until the unit rotated out of theater but then going unused because the next unit could not operate or maintain the equipment. The committee’s findings and recommendations about introducing new systems and technologies should be viewed in light of these two items.

________________________

1 U.S. Army, “Rapid Fielding Initiative,” http://www.army.mil/aps/08/information_papers/prepare/Rapid_Fielding_Initiative.html, accessed October 15, 2014.

In the following sections, the committee touches on actions it believes could make significant impacts on the water, fuel, and ammunition logistics demands. The committee’s general priorities for investment in these technologies are presented in Tables S-2 and 9-1. The committee is aware that the technologies it discusses in this chapter span a range of maturities. Some are nearly ready to field, others will take more research and development. Some areas are already under active exploration by the Army. Some are efforts underway by other Services. And some may be novel to the Army. Per its tasking, the committee focused on identifying and describing technologies that could reduce the logistics burden. The committee did not receive the level of information that would be necessary to analyze these technologies, identify technical challenges to their adoption, or assess their maturity. Addressing challenges and maturity would be a complicated task as these will vary depending on the specific setting and operational circumstances. For instance, the technology readiness level (TRL) of a technology for a commercial application might be different from the TRL for a military application, due to the special requirements of military settings. And the TRL of a technology for operation on a mature base might be very different from the TRL of that technology when considering an expeditionary environment.

Water is vital to the human body. During the Six-Day War of 1967, Israeli troops, who had adequate field water, suffered minimal casualties from dehydration, whereas Egyptian troops, who experienced severe water rationing, suffered more than 20,000 fatalities from heat stroke (Grandjean, 2005). The quantity of water required by humans depends on a variety of factors, including physical activity, physiology, body weight, ambient temperature, and humidity. There are other water needs of the forward-deployed soldier besides drinking water. These other needs, which can also vary widely depending on temperature, humidity, topography, and activity, include the following:

- Personal hygiene (hand and face washing, sponge baths, teeth brushing, etc.),

- Showers,

- Laundry,

- Food preparation,

- Medical treatment,

- Mortuary affairs,

- Equipment wash down,

- Vehicle maintenance,

- Engineers’ requirement (concrete, well drilling, etc.), and

- Equipment coolants.

These various non-drinking-water requirements can be satisfied by water of differing qualities and by different levels of water treatment. The categories of water quality include these:

- Potable water,

- Untreated source water,

- Untreated grey water,

- Treated grey water,

- Untreated black water, and

- Treated black water.

Satisfying the water demand at the point of need as much as possible would reduce not only the logistics demand, it would also reduce personnel risk. In Iraq, approximately 50 percent of convoy trucks were used to transport bottles of water, amounting to 144 trucks per day.2

Historically, during wars, the wide range of water purification and drilling technologies available to the Army has been used to supply local water to soldiers. The availability of contractor-provided bottled water in peacekeeping missions and initial deployments in the Gulf War and in Iraq, and decisions to not deploy organic Army water production capabilities, have made bottled water the principal water source for deployed forces. The use of bottled water has been so great that the Army procured and deployed expeditionary bottling facilities. These facilities used plastic “blanks” that were formed into bottles on-site and then filled with local water.

When given a choice between water provided by organic Army capabilities and bottled water, bottled water becomes a cultural preference that imposes a large logistics burden. Because water has been bottled from local sources, contamination can enter the bottled water. Also, there has been a problem with bottled water being wasted by people throwing away partly full bottles. While there may be many applications such as medical use and emergency storage that merit bottled water, traditional water carrying methods such as canteens and water sacks offer significant advantages for a leaner and more expeditionary Army. There are many sound alternatives to bottled water, starting with the soldiers’ canteens and extending to on-site water recovery and purification technologies. Simply eliminating the use of bottled water as a mainstay of sustainment would have a huge positive impact on the Army logistics situation, not to mention saving lives by reducing the number of convoys needed to transport water.

Some solutions to the need for water are available immediately or in the near term. Some are longer-term solutions that will require research and development work. Massive resources have been devoted to bottling water and transporting it to the warfighter. The committee believes this to be unnecessary, a self-inflicted wound, and that there are any number of solutions to the water problems available to the Army now. These range from existing Army capabilities and systems to access and purify water, to mature commercial systems, to systems under development.

Water Technologies, Current and Future

There are many ways to satisfy the water demand at the point of need and reduce the amount of water that has to be moved. Currently, the Army relies on reverse osmosis as a way to purify surface or ground water found in the area.

The existing Army equipment for reverse osmosis appears to meet the Army’s company, battalion, brigade, and division water requirements. For water recycling purposes, biofiltration and ultrafiltration methods are effective for pretreating gray water prior to reverse osmosis, which extends the utility of the current reverse osmosis units. Existing reverse osmosis equipment includes the 3,000 gallon per hour (GPH) reverse osmosis water purification unit (ROWPU), the 1,500 GPH tactical water purification system (TWPS), the 600 GPH ROWPU, and the 125 GPH lightweight water purification system. ROWPUs are currently placed with Army Reserve units, making their deployment to rapid expeditionary operations difficult.

There are many areas of the world where water can be relatively quickly and easily obtained from surface sources or from groundwater through by drilling wells. When Allied forces drove across North Africa in the Second World War, they did not have bottled water. They exploited local water sources.

________________________

2 Art Lundquist, Army Institute of Public Health, “Military Field Water,” presentation to the committee on February 5, 2014.

The Army Geospatial Center’s (AGC’s) Water Resources program is the primary Department of Defense (DoD) entity responsible for military hydrologic geospatial analysis and water detection. Its mission is to tell the Services where they can find water in a given region. AGC is the lead for the Water Detection Response Team, which provides well site analysis for DoD outside the United States. Such site analyses boosted well-drilling success rates from 35 percent to 90 percent.3 AGC also populates, maintains, and disseminates the Water Resource Data Base. This database contains information on existing water facilities, surface water, and ground water for locations outside the United States, focusing on arid and semiarid areas of interest to DoD and on regions of strategic or tactical importance. The data are organized according to military equipment and specifications. The emphasis is on quantity, quality, location, and seasonal availability of each source. Currently, about 35 percent of the world had been mapped. AGC’s Hydrologic Analysis Team is actively engaged in providing water resources support in a variety of locations, but its primary focus is currently the Central Command and Africa Command areas of interest. There are places where there is no groundwater or the groundwater is too hard to reach. Examples of such places are areas with hard rock, such as the Sahara and southeastern Egypt, and high-altitude areas such as mountains.4,5

Depending on climatology and available local sources, there are numerous simple procedures other than drilling wells, tapping surface water supplies, and using host nation water to augment water supplies and produce water in the field. Many are mature and in use in civilian applications. Others could be put to use by the Army with some development work but would not require a full science and technology effort. Several are discussed below.

Deployments near coastlines could be supplied from ships moored along the coast, anchored in harbors, or docked in port. Existing ships have distilling units of between 25 and 50 thousand gallons per day capability (BUPERS, 1966). Some or most of this could be piped ashore. Indeed, in crisis response and humanitarian assistance situations, one reason that aircraft carriers are deployed is their ability to make large quantities of fresh water. Alternatively, tankers could be readily adapted by adding modular reverse osmosis units to produce as much as 10 to 30 million gallons per day.6 Placing these systems in containers could make this approach more flexible. Tankers are ideal as they can supply the necessary power and possess pumps and tanks for prefiltering, polishing, and storing surge water. Currently, there are no specialized water generation ships in the Navy, Marine Corps, or Army inventory. Such vessels could be used for the inexpensive generation of large quantities of fresh water on short notice. In addition to supporting an expeditionary posture for the Army, such vessels could also be used in humanitarian assistance and disaster relief missions, a major U.S military activity in the Asia-Pacific region.

Finding 3-1. Specialized water generation ships have been designed by industry and could provide a useful expeditionary water capability in areas near oceans or seas.

Recommendation 3-1. The Army, working with the U.S. Transportation Command, should consider converting one or more small tankers for desalination of seawater to produce bulk potable water.

________________________

3 Personal communication between Thomas R. Spillman, Chief, Hydrologic and Environmental Analysis Branch, AGC, and Gerald Galloway, committee chair, on June 27, 2014.

4 E-mail communication between Thomas R. Spillman, Chief, Hydrologic and Environmental Analysis Branch, AGC, and Gerald Galloway, committee chair, on June 12, 2014.

5 Personal communication between Thomas R. Spillman, Chief, Hydrologic and Environmental Analysis Branch, AGC, and Gerald Galloway, committee chair, on June 27, 2014.

6 Water Standard information available at http://waterstandard.com/h2ocean-solutions/, accessed August 20, 2014.

One of the simplest water collection methods, conditions permitting, is rain catchment. Gutters and rain barrels can be used on all rigid shelters and tents, and tarps can be specifically arrayed to catch rain water. With sufficient atmospheric humidity, water can be condensed out of the air on tarps and the like. This is already done to some extent, requiring only the adoption of a technique, not research and development. Another technique for generating water is fog collection. Projects in Canada, which use canvas, and in Chile, which use nylon nets, arranged vertically, have produced significant amounts of water via fog collection. In one project in Chile, 100 nets produced an average of 15,000 liters per day. There are such projects in 25 countries worldwide (Cho, 2011).

Atmospheric water generators using cooling condensation are able to extract water from humid air using dehumidifier technology. These generators are more effective at temperatures over 65°F (18.3°C) and relative humidity over 30 percent.7 Another approach for obtaining water from air uses a chemical desiccant to extract water from the air. One company has a system that can produce up to 2,600 gallons of potable water per day. It is self-contained and transportable in an ISO (International Organization for Standardization) marine container, does not draw external power, and works in low-humidity conditions. The current units are powered by generators and thus would induce a fuel burden. A solar-powered version is in development.8,9 The U.S. Army Tank Automotive Research, Development and Engineering Center (TARDEC) continues to explore use of this process.10,11

Finding 3-2. In appropriate climates, use of rain and atmospheric water may satisfy a significant portion of the water demand at the point of need. This can be accomplished with available equipment such as tarps, nets, and rain barrels, and simple changes to tents to collect water.

Recommendation 3-2. The Army should implement and, where necessary, develop methods to harvest water from the local environment, including rain and fog, to meet soldier water needs at the point of need.

Distillation and Nanotechnology

Distillation is another approach to water purification whereby water containing any impurities—chemical or biological—is boiled. The water vapor that is generated is free of most contaminants and can be condensed into pure drinking water. Novel work has been done in this area. One technology is a device called the Slingshot. It is a small still, the size of a small refrigerator, that can distill over 180 gallons of water per day using any feedstock, including black water. Fifteen Slingshot systems tested in Ghana for six months in 2013 provided water for five schools. Plans are in place to place 2,000 of these systems around the world by 2015 (Foster, 2014). This type of system could be a suitable replacement for ROWPUs and other large water purification systems. It is energy efficient, simple, and could save energy—fuel—in the process and possibly have lower maintenance costs.

________________________

7 United Nations, Engineering Standardization and Design Centre Newsletter, http://www.unlb.org/downloads/ESDCNewsletter201208.pdf, accessed October 1, 2014.

8 Aqua Sciences, “Aqua Sciences: Making Water from Air Virtually Anywhere, Saving Lives,” http://www.aquasciences.com/tech_eng.shtml, accessed August 20, 2011.

9 Aqua Sciences, “Compelling Current Product Line,” http://www.aquasciences.com/products_eng.shtml, accessed August 20, 2014.

10 Jay Dusenbury, Deputy for Science and Technology, U.S. Army TARDEC Force Projection Technology, “Reducing the Forward Operating Base Water Logistics Burden,” presentation on May 6, 2009.

11 Office of Management and Budget, “Liquid Desiccant-Based Atmospheric Water Generation without Reverse Osmosis,” http://earmarks.omb.gov/earmarks-public/2008-earmarks/earmark_344860.html, last modified September 4, 2009.

Experimental projects in solar thermal desalination are being carried out in California’s Central Valley by a company called WaterFX. Their system, called Aqua4, technique uses reflective parabolic fabrics to focus sunlight on tubes containing thermal oils. These oils are then used to heat water in evaporators, vaporizing the feed water and forming steam that condenses as freshwater.12 This technology might also be used in addition to desalination to purify water of other chemical or biological contaminants. If the equipment was put into container modules and the parabolic fabric reflectors were made to be easily deployable, then such techniques could be of use to the Army.13

A company called Puralytics is marketing a nanotechnology mesh that uses light to purify water. The technology makes uses of photocatalytic oxidation, photocatalytic reduction, photolysis, photoadsorption, and photo disinfection to either break down contaminants or remove them from water. The technology is advertised to be able to treat contaminants including heavy metals, petrochemicals, pesticides, viruses, bacteria, and protozoa. It does not seem to address minerals in water. The technology is available in reusable bags for personal water purification, an LED-activated filter system, and “lily pads” that float on the surface of bodies of water and purify it.14

Finding 3-3. Distillation may be a simpler, more efficient method of water purification than systems currently used by the Army. It can produce pure drinking water from any water feedstock with any sort of contaminant, including black water. Similarly, nanotechnology solutions may be able to effectively address Army water purification needs in appropriate settings.

Recommendation 3-3. The Army should develop distillation methods to meet soldier water needs at the point of need. The Army should also explore the use of existing nanotechnology solutions for water purification.

As noted above, the Army has water purification systems for units of company size and above. However, there is currently no solution for water purification at the platoon and squad levels. Graphene fiber technology shows promise as ultraprecise and ultrafast small filter units. Work in this field is being carried out at the University of Manchester (U.K.) and the Chinese Academy of Science. Filters based on graphene, for instance, are impermeable to all gases and liquids except water, which passes through the filter easily (University of Manchester, 2012). The U.S. Marine Corps and the Army are also working on individual-level water purification systems. The Marine Corps has developed the Individual Water Purification System, which uses a hollow fiber microfilter and a MIOX purifier. The hollow fiber filters out bacteria and protozoa and improves taste and odor. The MIOX filter removes viruses and bacteria. It does not address toxic industrial chemicals or materials.15 The MIOX purifier works by adding a chlorine tablet to the water and letting it sit for 30 minutes before consumption (Sanborn, 2012b). The Army’s individual water treatment device is under development. This unit is meant to be compatible with the modular lightweight load-carrying equipment. The goal of the effort is to develop an individual-level

________________________

12 Aqua4 Information available at http://waterfx..co/aqua4/, accessed August 19, 2014.

13 Solar stills can also be used to generate drinkable water from dirty water, soil, or the atmosphere. Using the solar still concept, J. Liow, a Monash University graduate student, developed a spherical still in 2011. It is about 24 inches in diameter, with a transparent upper half that can produce about 3 liters of potable water per day. Information available at www.jonliow.com/SOLARBALL-Water-Purifier and http://www.gizmag.com/solarballcreates-drinkable-water/18270/. Last accessed on August 19, 2014.

14 See Puralytics, http://www.puralytics.com/html/home.php, accessed November 4, 2014.

15 Art Lundquist, Army Institute of Public Health, “Military Field Water,” presentation to the committee on February 5, 2014.

water purification system that will allow soldiers to drink from indigenous water supplies.16 While initial operating capability was projected for fiscal year (FY) 2014, this is not going to happen. The government intends to consider changes to the requirement and now plans to potentially resolicit the new requirement at a later date.17 Future development efforts will include providing the capability to purify saltwater and brackish water; to improve filter life and flow rate, to lower the pressure drop across the filter; and to achieve full toxic industrial chemical and material removal.18,19 However, these filters currently lack the capability to test and assure that they are effective in removing impurities.

Finding 3-4. Current water filtration systems are focused at the Army’s company level and above. There is a need to develop and field individual water purification filters. Individual water filters would reduce the amount of water that has to be shipped forward.

Recommendation 3-4. The Army should field individual water filters as soon as possible.

The presence of toxins and pollutants is widespread in the ground and surface water in many Pacific countries. Bacteria, protozoa, animal waste, and fertilizers are ubiquitous in the Far East. Currently, the Army’s Public Health Command provides water testing in forward areas. This requires the deployment of special equipment and trained experts. It would be very useful if water testing equipment and training were made available to soldiers to augment those efforts of the Army’s Public Health Command. The committee believes there is a need for a universal, consolidated standard for performance and quality control for water. This would include the development of a risk management plan embracing the following:

- Source and exposure characterization,

- Validation through protocol-driven evaluations,

- An operational control designed proof of concept, and

- Verification monitoring of the efficiency.20

Finding 3-5. Training soldiers in tactical units to perform water quality testing and providing them with suitably simple field equipment would enhance the timely production of safe water in the field.

Recommendation 3-5. The Army should develop a simple, portable water testing device that a squad can use to ascertain whether water is potable without having to wait for specialists to test it.

________________________

16 Program Executive Office Soldier, “On the Move Hydration,” presentation on May 12, 2011, http://nsrdec.natick.army.mil/APBI/Hydration%20Load%20Carrying%20Equipment/Army__Hydration_&_Load_Carriage_Ver_6_MAY_2011.pdf.

17 Personal communication between Donald W. Matts, Jr., U.S. Army Research, Development and Engineering Command, and James Myska, study director, September 11, 2014.

18 Art Lundquist, Army Institute of Public Health, “Military Field Water,” presentation to the committee on February 5, 2014.

19 Program Executive Office Soldier, “On the Move Hydration,” presentation on May 12, 2011, http://nsrdec.natick.army.mil/APBI/Hydration%20Load%20Carrying%20Equipment/Army__Hydration_&_Load_Carriage_Ver_6_MAY_2011.pdf.

20 James Tuten, Product Manager, Force Sustainment Systems, “Contingency Basing and Operational Energy Initiatives,” November 2011, http://www.dtic.mil/docs/citations/ADA558324.

Water from Diesel Engine Exhaust

The exhaust gases from diesel consist mainly of nitrogen, water vapor, and carbon dioxide. Also present are noxious products such as carbon monoxide, hydrocarbon products, nitrous oxides, and particulate matter. It is claimed to be theoretically possible to recover about one pound of water for each pound of fuel burned (Pentland, 2011). This is currently accomplished by a process known as capillary condensation, whereby water vapor in the exhaust is captured by tiny capillaries in porous, tubular inorganic membranes. It is claimed that the water is potable.

Tests of this process were carried out by the Southwest Research Institute and Bend Research under the sponsorship of the U.S. Army Belvoir Research, Development and Engineering Center. Later work (2011) by Oak Ridge National Laboratory further developed the concept. Practically, only about 65-85 percent of the putative pound of water mentioned above is recoverable from diesel exhaust (Boyle, 2011). Committee members have heard anecdotally that this water has a strong bad taste. One member has experienced this directly. A taste problem would be a huge barrier to acceptance of this water by soldiers. Further, current technology for the capillary condensation process adversely impacts weight and power of the engine to which the equipment is attached. The existing technology is also expensive when every diesel engine must be equipped with such a device.

Still, if these shortcomings can be overcome, significant logistical benefits could be realized using this technology. It should also be noted that the water recovered using this technology need not be potable to be usable. Water is also used to wash down equipment, do laundry, and the like. It is possible that water recovered from diesel exhaust might be able to reduce some of the water demand even before it can be widely accepted as drinking water.

Finding 3-6. Water from exhaust is not yet ready to be used as drinking water. There are still many challenges to overcome, not least its taste. Still, it could be used to meet some of the demand for nonpotable water, and if the taste challenge can be overcome, it could have a very great positive impact on the provision of water on the battlefield.

Recommendation 3-6. The Army should continue its research on extracting water from diesel exhaust. It should also explore the use of water recovered with this technology for nonpotable uses. Specific goals, including affordability, minimal weight and power impact, and good taste should be provided to the research community. The Army should also suggest to the Defense Advanced Research Projects Agency (DARPA) that this may be a problem whose difficulty justifies their involvement.

Another obvious way to reduce water demand in either expeditionary or extended operations is by conserving water. Conservation can be accomplished both by simply using less water and by recycling it where possible. Both approaches require water management. This is a five-step process:

- Establish a metric,

- Measure current consumption,

- Establish a baseline,

- Set goals, and

- Monitor usage.

The process necessitates the use of simple water meters, where practicable, and the regular collection of usage data. This would also raise soldiers’ awareness of water conservation.

The Army is already actively working on this issue. The Army Base Camp Integration Laboratory at Fort Devens, Massachusetts, is testing technologies expected to reduce the logistics demand for water

by up to 75 percent through managing water use and employing technologies such as shower water recycling (Quick, 2011; Reinert, 2013).21 To accomplish this bold objective many efforts will be required. There are many opportunities to conserve water. Some are technical opportunities, while others are cultural.

There are many small cultural adjustments that can produce considerable water conservation. Typical techniques used by submariners—turning the water off between wetting down, soaping, and rinsing off and not shaving and brushing teeth under running water—are examples of saving water through cultural changes. Inducing cultural and behavioral changes carry no additional cost for developing and procuring technical solutions. They are essentially free and constitute low-hanging fruit.

Finding 3-7. There is a wide variety of simple cultural and behavioral changes that could produce significant water savings.

Recommendation 3-7. Rather than relying solely on technical solutions for water conservation, the Army should aggressively pursue cultural and behavioral changes that would save water at no additional cost.

There is a wide variety of commercially available, simple technical solutions for conserving water at established base camps. These include spring-loaded faucets, reduced-flow shower heads, and the like. On the technology development side, the U.S. Army Engineer Research and Development Center is working to develop an integrated and robust gray water reuse system and intends to have it developed to TRL 6 by mid-FY2016.22 The system involves reusing shower and laundry water by screening, biofiltration, ultrafiltration, high-efficiency reverse osmosis, and disinfection, resulting in water that meets U.S. Army Public Health Command standard IP-31-027. The result is that only 20 percent of the recycled water goes to waste, and only a 20 percent volume of potable make-up water will be required.23 This work will have a significant impact on the demand for the delivery of potable water to base camps. Also, an effective water conservation effort requires measuring the amount of water being used. This would also allow water usage to be managed in response to changing circumstances. The most effective way to do this is to put meters on all water tanks and bladders. These are inexpensive and commercially available.

Finding 3-8. There is a wide variety of technical water conservation solutions. These range from commercially available devices to the system that the U.S. Army’s Engineer Research and Development Center is developing to recycle water in the field.

Recommendation 3-8. Commercially available water conservation devices should be adopted for use as widely as possible. Additionally, development work such as that of the U.S. Army’s Engineer Research and Development Center should be supported and the resulting water recycling systems fielded as quickly as possible.

Finding 3-9. Installing water meters on all water tanks and bladders would allow for the more effective monitoring and management of water usage.

Recommendation 3-9. The Army should install water meters on all water tanks and bladders.

________________________

21 James Tuten, Product Manager, Force Sustainment Systems, “Contingency Basing and Operational Energy Initiatives,” November 2011, http://www.dtic.mil/docs/citations/ADA558324.

22 Technology readiness levels measure the maturity of a given technology development program (NASA, “Definitions of Technology Readiness Levels,” http://esto.nasa.gov/files/trl_definitions.pdf, accessed October 30, 2014.

23 David Horner, Technical Director, Military Engineering Business Area, “ERDC Reduced Logistics R&D,” presentation to the committee on February 5, 2014.

It may be possible to introduce efficiencies into the way water is transported. The benefit here would be more logistical efficiency and, to the extent that fewer trucks might be required, fuel savings. The Army’s traditional method of moving water to the front is with 2,000 gallon tanks called “hippos” (DA, 2007; Brautigam, 2006). When the hippos are empty, they have to be returned to a water source to be filled, consuming truck and fuel resources. The military is now using simple platforms, such as flatbed semitrailers or container flats, to replace single-purpose vehicles. It is possible to leverage this change to improve the efficiency of the water supply chain. Under some circumstances, such as where road conditions permit, bladders with greater capacity than hippos could be used in their place and transported on the simpler flat platforms now in use. Several empty bladders could be returned for refilling on one flat, reducing the truck and fuel resources required to return empties for refilling.

The committee notes that there have been problems with transporting and fully emptying bladders and with stability when transporting partially full bladders. This instability is known as the free surface effect: When the bladders are partially full the liquid can shift freely. The free surface problem in rigid tank containers has been solved with internal baffles. Industry representatives state that the stability problem with bladders has been solved by using an adequate number of fabric straps. The transport of bladders is now commonplace in the container industry, and they are manufactured specifically for 20 foot and 40 foot containers. To solve the problem of fully emptying bladders, if a platform supporting a bladder is resting on a chassis, one need only crank the chassis landing gear up to get 100 percent drainage. If the platform is set on the ground, then one end can be propped up, or it can be on a on a slope or a hill, to achieve 100 percent discharge of the bladder.

Finding 3-10. Using flexible bladders to transport water could simplify the task of returning empties, increasing efficiency, providing greater utilization of flats, and reducing logistics demand for fuel.

Recommendation 3-10. The Army should consider replacement of water tank containers and hippos by more versatile flexible bladders riding on flats.

Depending on the volume of potable and fresh water required, the distance inland, and the mobility of the units, the most efficient method of water transport is by pipeline. Rigid pipeline can be quickly laid from truck-mounted reels. Hoses are less permanent but more easily deployed. Current pipeline solutions can be laid at a rate of 2 or 3 miles per day. A new expeditionary fuel distribution system is in development that could be laid at 15-20 miles per day.24,25 Pipelines, of course, reduce the need for motorized transport of water. There are, however, physical security risks to unattended pipeline laid in potentially hostile territory. These risks can include tampering with and interdicting the pipelines, disrupting the flow of water. These concerns are also shared by commercial pipeline operators, and there are a number of companies that offer pipeline monitoring systems. While these systems likely exceed Army requirements for monitoring pipeline security and integrity, they might prove to be useful starting points for the Army to introduce monitoring into its pipelines in order to detect any compromises in their pipelines, either through natural or man-made causes.26

________________________

24 James Dusenbury, Senior Technical Expert, U.S. Army Tank Automotive Research, Development and Engineering Center, “Force Protection Technology,” presentation to the committee on February 4, 2014.

25 Comments by LTG Raymond Mason, U.S. Army G-4, to AUSA Hot Topics Sustainment Seminar, Sustaining the Force 2025, on May 20, 2014.

26 Examples of commercial pipeline monitoring capabilities can be found at PSI Solutions for Oil and Gas Pipelines, http://www.psioilandgas.com/en/pipeline-monitoring-solutions/pipeline-monitoring-solutions/, and SMARTEC, http://www.smartec.ch/Applications/Pipelines, accessed October 30, 2014.

Finding 3-11. Where appropriate, pipeline is the most efficient method to deliver water to troops and bases. New pipeline systems are under development that will greatly increase the rate at which pipeline can be laid. Also, current pipelines are vulnerable to enemy action. There are commercial solutions available to address pipeline integrity and security, and these might prove useful for the Army to adapt to its needs.

Recommendation 3-11. The Army should develop self-monitoring pipelines that report interdiction, intrusion, tampering, and other detrimental activities. The Army should begin by exploring commercially available applications for pipeline monitoring to see if they can be adapted to its needs.

While watercraft are discussed in Chapter 4, the logistics support of watercraft, including fuel, are not addressed in this report. This report focuses on fuel used by ground and air vehicles.

Fuel is used, broadly, to meet two needs: to power engines (vehicles) and to generate power for camps and tactical units (generators). A significant amount of the fuel consumed during operations in Iraq was for generators. Overall, about 50 percent of the fuel brought onto forward operating bases was used for generating power, for cooking stoves, or for the trucks bringing materiel into and out of the base (Steele, 2014). Anything that significantly reduces the amount of fuel that must be provided to forces in the field will have a significant positive impact on the overall logistics burden.

There is a significant body of Army research into improved energy efficiency in order to reduce fuel demand. This body of work includes research on engine design, electric machines and power electronics, power distribution, alternative power sources, and environmental control systems, and considerable effort has been expended in the area of chemical storage batteries. A summary of current Army work can be found in Box 3-1.

One Army effort to address operational energy is the Joint Operational Energy Initiative (JOEI). This is a partnership between the U.S. Army Program Executive Office Combat Support and Combat Service Support and the U.S. Army Tank-Automotive Research, Development and Engineering Center (TARDEC). JOEI is a system-of-systems modeling and simulation capability. It provides quantitative data and information to support holistic evaluations of changes in energy technologies and usage patterns to determine their impacts on the overall operational energy picture. This information is used to inform current and future doctrine and to provide input to science and technology and acquisition programs, to trade-space studies, and to cost-benefit analyses.27

All of the efforts listed in Box 3-1 are impressive and an important part of the overall research and development strategy to address operational energy and, thus, the fuel issue. This work should be continued. The remainder of this section discusses technologies the committee believes could be particularly effective in reducing the logistics demand for fuel.

One of the most straightforward ways to reduce fuel demand is to develop more fuel-efficient engines. The U.S. Army has been working on the Improved Turbine Engine Program (ITEP) to produce a smaller, lower-cost, 3,000-shaft horsepower engine for the aviation community. The goal is to provide a 50 percent increase in power, reduce fuel consumption by 25 percent, reduce production and maintenance

________________________

27JOEI 2014 abstract, document provided to the committee by U.S. Army Research, Development and Engineering Command, June 9, 2014.

28 Mary Miller, Deputy Assistant Secretary of the Army for Research and Technology, “Logistics Science and Technology: A 30 Year Look,” presentation to the committee on January 17, 2014.

BOX 3-1

Current Army Research Efforts in Energy Efficiency and Fuel Demand Reduction

• Combining and integrating energy technologies in order to optimize system characteristics in support of military requirements. For example, combining solar photovoltaic and batteries to achieve optimal performance and reduce cost, weight, and complexity.

• Investigating smart-grid control technologies to effectively manage electrical power generation, distribution, and use, thus reducing the need for periodic liquid fuel resupply to base camps.

• Examining innovative alternative energy sources that minimize or replace current hydrocarbon energy systems, perhaps enabling the elimination of fossil fuel based generators.

• Examining lightweight, low-volume, and highly reliable dense power sources and establishing microgrids for recharging portable and mobile batteries.

• Reducing energy demand through the use of light emitting diode lighting and high-efficiency heating, ventilation, and air conditioning (HVAC) systems coupled with modular relocatable thermally insulated structures.

• Examining high-power and high-energy-density batteries and ultracapacitors to provide load leveling and to support various other applications such as transportation and soldier power.

• Investigating photovoltaic cells integrated into military shelters along with additional structural insulation. This lowers the electrical demand by providing a solar shade to the shelter and at the same time produces some electrical power that can be used for powering some electrical units.

• Improving the process efficiency of biofuels and lowering their cost so they are competitive with traditional fuels.

• Investigating waste-to-energy technology to produce synthetic gas that can power standard generators, displacing up to 85 percent of the JP8 (jet propellant fuel, essentially diesel in this use) used to fuel generators, depending on scale.

• Investigating microhydroelectric plants and wind turbines for use in appropriate geographic regions.

• Examining the use of passive solar hot water and solar air heating units made from lightweight plastics.

• Investigating hybrid propulsion systems and fuel cell based propulsion and power generation.

SOURCE: ARCIC (2010).

costs by 35 percent, and achieve a 20 percent longer engine life. The ITEP concept is to design a drop-in replacement engine for the one that currently powers the AH-64 Apache and the UH-60 Black Hawk. The ITEP is part of U.S. Army’s Aviation Applied Technology Directorate Advanced Affordable Turbine Engine program. This program is under the larger research and development umbrella of the Versatile Affordable Advanced Turbine Engines program. The Advanced Turbine Engine Company and GE Aviation are both developing engines for this program: the HPW3000 and GE3000, respectively (Aviation Week, 2013).28 At the time of the writing of this report, engines were being tested as part of this development effort.

The U.S. Air Force has been funding the development of the Adaptive Versatile Engine Technology (ADVENT) engine, which is being optimized for both high speed and high fuel efficiency.

Until now, engines have been optimized for either speed or fuel efficiency, not both. The program goal is to use 25 percent less fuel than the most advanced engines currently on the market or in development (GE Aviation, 2013; Jordan, 2014). Pratt & Whitney and GE are working on the next version of ADVENT, called Adaptive Engine Technology Development, to develop next-generation engines that could provide better fuel-burn rates and operate at higher speeds while also allowing more operating flexibility for pilots.

Finding 3-12. The committee believes that the Improved Turbine Engine Program will provide significant reductions in aircraft fuel consumption and increases in aircraft engine efficiencies.

Recommendation 3-12. The Army should accelerate development and fielding of the Improved Turbine Engine Program.

Finding 3-13. The Air Force’s ADVENT program technologies have the potential to reduce fuel consumption, and their high-efficiency components may also reduce maintenance cost. These engines are likely to have high power density and high fuel efficiency. While the ADVENT program is directed a producing a fighter engine, there may be turbine engine technology synergies that could aid the Army’s Improved Turbine Engine Program.

Recommendation 3-13. Without slowing down fielding of the Improved Turbine Engine Program, the Army should explore the possibility of working with the Air Force and industry partners to combine the relevant technologies of the Adaptive Engine Technology Development program and the Improved Turbine Engine Program to further reduce fuel consumption and improve performance.

The Army is also investing in efficient power trains for ground vehicles. A program called Efficient Power Trains is under way to develop power trains that will provide 15-20 percent increased mission range and increased fuel efficiency. The engines in these power trains will be able to run on a wide variety of fuels, increasing operational flexibility, and will be able to export power off-board. The goal of these efforts is to develop two power trains at TRL 5 by the end of FY2014, one for wheeled vehicles of 25 tons or more and one for tracked vehicles of 30-45 tons. The power trains will use an optimized commercial off-the-shelf engine. An integrated TRL 6 test on an M2 Bradley is planned for FY2017.29

Upgrading the M1 Abrams engine to a more fuel-efficient model is also a worthwhile endeavor. For example, the committee learned that a diesel engine with greater fuel efficiency than the current turbine engine was tested at TARDEC in 2013. The vendor claims that this improved engine will use 207 gallons of fuel per combat day versus the 408 gallons used per combat day by the current engine and that the engine could provide a range of 308 miles on 395 gallons of fuel, versus the 205 miles on 436 gallons for the current engine. The test data are not available to the committee, however. Also, a fair amount of integration work would reportedly be needed to install the engine on the M1 Abrams (InsideDefense, 2013). Additionally, the engine is a diesel engine, not the turbine engine currently on the M1, and that change could have significant operational consequences for the Army. The committee takes no position on whether this particular engine would be an appropriate upgrade of the current M1 engine. The committee does, however, believe significant logistics benefits are to be had by developing a more fuel-efficient engine for the M1 and that, in light of the ITEP program, such an effort is feasible.

As shown in Table 2-1, the Computer Aided Map Experiment (CAMEX) 2008 exercise modeled a heavy brigade combat team as using approximately 338 tons of fuel per day. If improved engines were

________________________

29 Ibid.

developed for the M1 and M2 with savings similar to the 25 percent goal for the ITEP engine, this could save approximately 80 tons of fuel per day.

Finding 3-14. Developing more fuel-efficient engines for the M1 Abrams and the M2 Bradley would result in significant fuel savings for the Army. As indicated in the discussion above, a diesel engine that uses approximately 50 percent fuel has been tested. The M2 uses a diesel engine. The Improved Turbine Engine Program is developing an engine with 25 percent greater fuel efficiency. The M1 uses a turbine engine.

Recommendation 3-14. The Army should develop more advanced engines for the M1 Abrams and the M2 Bradley, with a goal of 25 percent greater fuel efficiency as envisioned by the Improved Turbine Engine Program.

Hybrid Drive Systems for Propulsion

Hybrid vehicle propulsion provides another fuel-saving option that could be combined with the possibility of efficiently providing electric power for off-board applications. They come in two types, discussed in Box 3-2. Hybrid electric propulsion provides about 10-20 percent more efficiency than a diesel-powered alternative for ground vehicles, depending on the propulsion system design. It also offers faster acceleration and maneuvering and a higher degree of fault tolerance through system redundancy and a reduction in moving parts. In addition to improved fuel efficiency, hybrid vehicles might also be used to provide power to soldiers and microgrids in the field.

Owing to the higher fuel efficiency of hybrid propulsion systems, the Army has been looking into hybrid propulsion strategies for several of its vehicles, such the High Mobility Multipurpose Wheeled Vehicle, popularly known as the HUMVEE, and various trucks. TARDEC has done much research and development of technology for the combat and tactical vehicle applications. A number of concerns remain that must be addressed before the technology is adopted by the Army. Some remaining considerations are these:

- Reliability,

- Safety,

- Integration issues (thermal management),

- Cost impacts,

- Logistics impacts (engine, batteries, and power electronics), and

- Training and maintenance.

BOX 3-2

Types of Hybrid Power Trains

Hybrid vehicles fall into two general categories, series hybrids or parallel hybrids. In a series hybrid vehicle, the engine drives a generator, which in turn charges the batteries to provide power to an electric motor for propulsion. A series hybrid vehicle is essentially an electric vehicle with a battery being charged on board by the engine-driven generator or by a fuel cell. In a parallel hybrid vehicle, both the engine and the electric motor are used to drive the vehicle.

Presently, TARDEC is pursuing a “crawl, walk, run” approach to developing integrated starter generator technology to provide large amounts of onboard high-voltage power. Mechanically driven devices such as fans and pumps could be electrified and intelligently controlled to gain vehicle efficiency. The final step would be to add a battery (i.e., parallel hybrid drive configuration) for start-stop, silent mobility, and silent watch capabilities.30 The recently cancelled Ground Combat Vehicle was to have been equipped with a hybrid propulsion system. The Army is currently working on hybrid vehicle technology for light tactical vehicles in the Ultra Light Vehicle program.31,32 Army research and development efforts, however, have not yet resulted in an operationally deployed hybrid vehicle.

Finding 3-15. Hybrid propulsion offers significant improvement in fuel economy over conventional vehicles. Hybrids could also be used to transfer power to off-board applications or a base camp microgrid.

Recommendation 3-15. The Army should continue to develop hybrid drive technology and should adopt technologies that have been developed for commercial hybrid vehicles for use in military vehicles.

Another fuel saving technology is auxiliary power units. Currently, onboard electrical vehicle systems are powered by the engine, either when the vehicle is moving or by idling and running the engine to generate electric power. If the required onboard power is generated using more efficient auxiliary power units instead of using the main engine, fuel consumption can be greatly reduced. For example, an independent JP8-fueled auxiliary power unit (separate from the main engine) could save 4,300 gallons a day for a tank brigade. The Army is working to incorporate a 10 kW fuel cell into the M1 Abrams in a planned upgrade in 2019.33

The Army is looking into more than one technology for onboard power generation. In addition to JP8-fueled auxiliary power units, the Army is exploring the use of fuel cells. The use of fuel cells for onboard power generation is two to three times more efficient than using electric power from an engine-driven generator, reducing fuel demand (DOE, 2011). These units provide power to a vehicle without the need for the main engine to be running. One of the fuel cell technologies that the Army is examining is a system based on high-temperature solid oxide fuel cells (SOFCs). These SOFCs can also be combined with lithium batteries as hybrid power system. (Fuel cells are discussed in more depth, and for more applications, below.)

Finding 3-16. Auxiliary power units, particularly those based on fuel cells, are more fuel-efficient than engine-driven generators for onboard power generation, driving down fuel demand.

Recommendation 3-16. The Army should continue its efforts to implement auxiliary power units (APUs) on conventionally propelled vehicles. Moving to non-fossil-fuel APUs such as fuel cells when possible will result in greater efficiencies.

________________________

30 Personal communication between Michael Blain, TARDEC, and Steven Dellenback, committee member, August 7, 2014.

31 U.S. Army, “Ultra Light Vehicle (ULV) Research Prototype,” http://www.army.mil/article/129285/Ultra_Light_Vehicle__ULV__Research_Prototype/, accessed October 30, 2014.

32 “U.S. Army Embarks on the Testing of a Hybrid Ultra Light Vehicle (ULV),” http://defenseupdate.com/20130909_ulv.html#.U86Lr_ldXTo, accessed October 30, 2014.

33 Mary Miller, Deputy Assistant Secretary of the Army for Research and Technology, “Logistics Science and Technology: A 30 Year Look,” presentation to the committee on January 17, 2014.

The military is also beginning to use pure electric vehicles on bases (Robson, 2012). These electric vehicles have predictable usage cycles and can be charged from a central depot, simplifying the installation of the required charging system. Electric vehicles obviously do not directly use fossil fuels, although it is possible that fossil fuels would be used to generate the electricity to charge them. Even with this, electric vehicles are more energy-efficient than those powered by internal combustion engines. Where they can be powered from an existing power grid, as in a friendly host nation, electric vehicles convert 70-75 percent of the grid energy to power at the wheels. For gasoline-powered engines, this figure is only 17-21 percent.34 The situation is different if electric vehicles have to be powered by generators. A gallon of gasoline contains 115,000 Btu of energy, which works out to 34 kWh.35 Assuming a gas-powered generator efficiency of 35 percent, a gallon of gasoline would produce 34 × 0.35 = 11.9 kWh of energy for use in an electric vehicle. Computing from a range of actual vehicle data, an electric vehicle requires an average of 0.27 kWh to travel 1 mile. Using these data, the committee figures that an electric vehicle would get approximately 44 miles of travel distance per gallon of gasoline burned in a generator, i.e., 44 mpg. By contrast, a HUMVEE gets an average of 14 mpg.36 When using the fully burdened cost of fuel, discussed above, it is readily seen that this would not only decrease the logistics burden but also save considerable money that could be applied to other logistics needs.

There are some disadvantages to electric vehicles. Most get 100-150 miles of travel distance per full charge, whereas gasoline-powered vehicles can travel over 300 miles per full tank. Additionally, it can take 4-8 hours to fully charge an electric vehicle, though an 80 percent quick charge may be possible in 30 minutes. Also, their batteries take up considerable volume and weight in the vehicle.37 Given this, pure electric vehicles are not likely to be suitable for the battlefield for some time. They could, however, be used at forward logistics bases in, for example, utility vehicles and forklifts, where their limitations could be more readily accommodated. This could reduce the amount of fuel that needs to be brought forward to support these bases. The greatest efficiencies for electric vehicles would be achieved where they could get their power from a host nation energy grid. They are less, but still considerably, efficient if they have to be powered from generators. It may also be possible to use other energy sources such as solar and wind to generate and store some of the energy needed to charge electric vehicles, further driving down fuel demand.

Finding 3-17. Pure electric vehicles might have some application in forward logistics bases and may further reduce the amount of fuel that must be brought forward to support operations at these bases.

Microgrids, Power Generation, and Distribution

A significant portion of the fuel consumed during operations in Iraq, and in Afghanistan once large bases began to be established, was by generators providing power to facilities and devices. Generators are assigned in a way to ensure that any given unit or function—a headquarters element or housing, say—has its own power generation capability. When all these organizational units started coming together on a base each brought, and ran, its own generators. The result was significant

________________________

34 “All-Electric Vehicles (EVs),” http://www.fueleconomy.gov/FEG/evtech.shtml#end-notes, accessed October 31, 2014.

35 Energy units information available at http://bioenergy.ornl.gov/papers/misc/energy_conv.html, accessed October 31, 2014.

36 “High Mobility Multipurpose Wheeled Vehicle (HMMWV) (M998 Truck),” http://fas.org/man/dod101/sys/land/m998.htm, accessed October 31, 2014.

37 “All-Electric Vehicles (EVs),” http://www.fueleconomy.gov/FEG/evtech.shtml#end-notes, accessed October 31, 2014.

inefficiencies in power generation. In response, the Army began to implement microgrids and smart grids to maximize the efficiency with which electricity is generated, thus minimizing fuel demand.

A microgrid is a locally confined and independently controlled electric power network in which distributed energy resources and loads are integrated. A microgrid has its own power generation sources, and it may or may not be connected to a larger power grid. For established military installations, a microgrid is a contingency source of power to support critical operations in the event of an outage from the main grid. At forward bases, which may not be connected into a larger grid, a microgrid can reduce the number of generators required to provide power, thus increasing efficiency and reducing fuel demand. The Project Manager Expeditionary Energy & Sustainment Systems (Project Manager Mobile Electric Power at the time of the project) implemented a 1 MW microgrid project in Afghanistan that experienced a 17 percent reduction in fuel consumption, an 85 percent reduction in generator operating hours, and 67 percent lower maintenance costs (Lafontaine, 2012a). Microgrid work is also ongoing at the Base Camp Integration Laboratory at Fort Devens, Massachusetts. A 2011 demonstration resulted in a 37 percent decrease in fuel consumption by generators (Lafontaine, 2012b).

A smart grid is a modernized electrical grid that uses information and communications to enhance its efficiency, reliability, and economy and the sustainability of the production and distribution of electricity. A smart grid facilitates integration of renewable energy sources, demand side management, and microgrid components into the overall energy picture, providing opportunities for significant efficiency increases in power generation and usage. It gathers information such as the behavior of energy suppliers and consumers and acts on that information in an automated fashion to balance supply and demand, thus increasing overall system efficiency.

The integration of solar, wind, fuel cells, and other power generation systems, along with advanced storage solutions, is enabling hybrid systems with diesel generator sets to rapidly expand at low cost. Simulation models such as JOEI (discussed above) are an important instrument for incorporating the modular building blocks of generation and storage to match site-specific energy requirements.38

Finding 3-18. Microgrids provide energy security for military facilities to assure reliable power without relying on a larger utility grid.

Finding 3-19. Microgrids and smart grids reduce the amount of fuel required to generate electric power by networking generators into a system in order to maximize efficiency, reducing fuel demand. Microgrids can also be used to help integrate renewable energy resources (e.g., wind and solar) into the grid, further reducing fuel demand.

Recommendation 3-17. The Army should expand its microgrid and smart grid deployment activity, focusing on incorporating fuel cells and renewable energy sources such as photovoltaic-based power generation systems for on-site power generation applications.

Alternative Energy Sources and Energy Storage

There are a number of technologies for power generation and storage that could at least partially replace generators and their associated fuel and maintenance demands, and thus be logistically beneficial to the Army. The ones that promise to have the most impact are discussed below.

________________________

38 Alan Nanco, Manager, Military and Energy Systems Analysis, Sandia National Laboratory, “Defense Energy Summit DOE National Lab Programs: Supporting DoD Energy Missions Sandia’s Defense Energy Security Capabilities and Projects,” presentation given on November 13, 2013. Available at http://www.defenseenergy.com/program/slides/Alan_Nanco.pdf.

Fuel cells can be used in a variety of military applications, providing power ranging from few watts of power for individual soldiers to large amounts of power for facilities, bases, and tactical vehicles. Compared with diesel- or JP8-powered generators, fuel cells are lighter and are estimated to be in excess of 80 percent more efficient than generators. Fuel cells could be additional source of power for troops for various applications.

A particularly useful type of fuel cell is the SOFC, mentioned above. Fuel can be generated for SOFCs through either external or internal reforming processes.39 Any hydrocarbon fuel can be used for generating the required hydrogen onboard the vehicle. SOFCs do not need pure hydrogen, unlike proton exchange membrane fuel cells, which do (Angelo, 2014). Additionally, proton exchange membrane units cannot tolerate carbon monoxide in the fuel, while for SOFCs it could be part of the fuel along with hydrogen. Also, SOFCs are more sulfur-tolerant than other types of fuel cells. This flexibility and robustness could make them attractive for military applications. The Army is already doing some work with SOFCs. Some cooperative efforts have been conducted with the Air Force.40 In 2013 the Army’s Communications-Electronics Research, Development and Engineering Center demonstrated a 10 kW tubular SOFC power system. It had a dry weight of 960 lb and a volume of 38 cubic feet, compared with 1,100 lb and 41 cubic feet for the 10 kW Tactical Quiet Generator Set (CERDEC, 2013).The Army Research Laboratory has also developed a technology to reduce the sulfur in fuels so they can be more readily used by SOFCs.41

Finding 3-20. The Army is appropriately engaged in fuel cell research for onboard power generation in transportation applications.

Recommendation 3-18. The Army should continue to explore the possibility of using fuel cells wherever appropriate and to deploy them in the field.

The military is increasingly investing in solar energy as an effective alternative to traditional energy sources in a number of ways, a trend that, if continued, could significantly impact the demand for fuel. It has utilized large, centralized utility-scale solar projects to power bases; smaller distributed-generation systems to power buildings and homes; and portable solar systems to provide energy in the field. Examples of these include a 2 MW solar installation at Fort Carson, Colorado, solar panels on military housing units, and portable solar systems in Afghanistan.

Solar energy based systems using flexible photovoltaic (PV) arrays are significantly more portable and rugged than traditional crystalline or polycrystalline PV units. Flexible solar arrays can be emplaced in tarps to provide some energy in remote settings or integrated into solar shields for field shelters, which would have the double benefit of generating power and providing cooling to the shelter. These lightweight solar electric systems can be rolled up for storage or transportation and unrolled for use

________________________

39 An external reforming process generates fuel outside the fuel cell. In an internal reforming process the fuel is generated inside the fuel cell (Fuel Cell Today, “Fuel and Infrastructure,” http://www.fuelcelltoday.com/applications/fuel-and-infrastructure, accessed October 30, 2014).

40 Thomas L. Reitz, Chief, Thermal and Electrochemical Branch, Energy/Power/Thermal Division Propulsion Directorate, Air Force Research Laboratory, “Solid Oxide Fuel Cells (SOFC) as Military APU Replacements,” presentation given January, 2010. Available at http://www1.eere.energy.gov/hydrogenandfuelcells/pdfs/aircraft_7_reitz.pdf.

41 U.S. Army, Army Research Laboratory, “Creating Desulfurized Fuel for Fuel Cells Technology,” Fact Sheet, http://www.arl.army.mil/www/pages/945/docs/powerenergy/ARL_08-25_TFS_Bi-layer_Sorbent-Public_Web.pdf, accessed October 31, 2014.

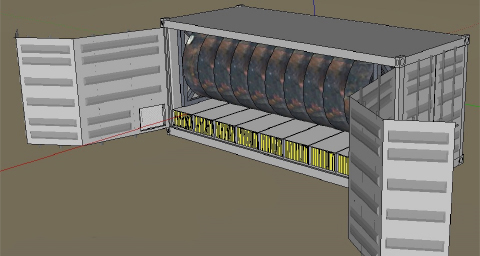

as needed. For the military, the ability to roll up an array of PV panels and carry them from location to location is an additional benefit in developing these products. These cells can provide power at 2 g/W. In general, there is a continuum of possible applications, from high-efficiency, low-cost wearable configurations to containerized rolls that produce 100 kW of energy. An example of containerized rolls is shown in Figure 3-1.

FIGURE 3-1 A containerized system of 100 kW rolls of flexible photovoltaic cell arrays. SOURCE: Courtesy of John Hingley, Founder, Renovagen Ltd. Additional information is available at http://www.renovagen.com.

Finding 3-21. Flexible photovoltaic cells could be an integral part of the electricity supply for a wide variety of applications, including tensioned awnings of photovoltaic cells and spools that are delivered in containers. This could improve expeditionary operational energy capabilities and reduce the requirements for fuel delivery to a given location.

Small Modular Nuclear Reactors

Where operational and security considerations permit, small modular nuclear reactors (SMRs) could replace generators for large bases in rear areas. SMRs, as defined by the Department of Energy, produce 300 MWe or less of energy. They are built in factories and can be transported by truck or rail.42 In the context of this report, SMRs for deployment to a staging area or forward operating base, there are emerging reactor design concepts that could be made transportable to the point of need by C-17s or via sea and land in just a few shipping containers. As described in Pfeffer and Macon (2001), an SMR could also be deployed to a remote theater on a barge. In addition to electricity, SMRs can be used to produce hydrogen, and subsequently alternative liquid fuels, as well as potable water. Many ground vehicles can be converted to run on alternative liquid fuels such as methanol. An SMR could also produce hydrogen for use in fuel cells; however, the storage and transportation of hydrogen in its elemental form can be difficult due to its combustible nature. In peacetime, SMRs could be used for humanitarian assistance and disaster relief, generating electricity and producing potable water.

________________________

42 Department of Energy, “Small Modular Nuclear Reactors,” http://www.energy.gov/ne/nuclear-reactortechnologies/small-modular-nuclear-reactors, accessed March 30, 2014.

The DoD has been using small reactors for many years to provide power in remote locations and to power ships and submarines. With the primary focus on supplying power in remote areas, the Army Corps of Engineers maintained a Nuclear Power Program from 1952 until 1977, building stationary nuclear reactors at Fort Belvoir, Virginia, and Fort Greeley, Alaska, and “portable” nuclear reactors at Sundance, Wyoming, Camp Century, in Greenland, and McMurdo Sound in Antarctica (Magnuson, 2013; Pfeffer and Macon, 2001). The MH-1A Sturgis demonstrated the feasibility of putting a nuclear reactor on a barge. The Sturgis, the last nuclear power plant built and operated by the Army, provided electric power to the Panama Canal from 1968 to 1976. The U.S. Navy, operating more than 500 reactor cores in over 200 nuclear-powered vessels,43 has accumulated more than 6,200 reactor-years of operational experience without a radiological incident.

Following several well-publicized catastrophic nuclear power plant failures, concerns over nuclear power safety have severely constrained development of new SMR concepts. However, there is evidence this is changing. For example, in 2010 the Defense Advanced Research Projects Agency (DARPA) issued a request for information on deployable reactor technologies for generating power and logistic fuels (DARPA-SN-10-37).44 The goal was to

Create a fieldable design that could be deployed to maritime and/or ground based forward operations to provide on-site power and fuel production capability in regions not connected to a robust grid and/or not easily accessible for fuel resupply.

According to the request for information, designs of interest would support an electrical load of 5-10 MW and would also produce 15,000 gallons per day of mobility fuel (e.g., JP-8) from a broad range of hydrogen and carbon feedstocks.

DoD has recently funded studies on the use of SMRs on DoD installations, including the 2011 Center for Naval Analyses study Feasibility of Nuclear Power on U.S. Military Installations (King et al., 2011) and the National Defense University’s (NDU’s) Institute for National Strategic Studies paper Small Nuclear Reactors for Military Installations: Capabilities, Costs, and Technological Implications (Andres and Breetz, 2011). The Center for Naval Analyses study showed how SMRs can contribute to DoD missions by increasing energy assurance at DoD installations at the same time as they reduce carbon emissions and reliance on fossil fuels for electricity. The NDU paper looks at the potential utility of SMRs from two perspectives: grid vulnerability (for U.S. military installations) and operational vulnerability (for deployed forces). From an operational perspective, the NDU paper suggests that SMRs could be instrumental in addressing DoD’s challenge of fuel supply at forward operating bases but cautions that SMR designs have not yet been licensed by the U.S. Nuclear Regulatory Commission for commercial use let alone military applications.

More recently, the Defense Science Board was asked by the Under Secretary of Defense for Acquisition, Technology and Logistics, to form the Committee on Energy Systems for Forward/Remote Operating Bases. In a February 2014 memo providing the terms of reference for the study, the committee was directed to

Examine the feasibility of deployable, cost-effective, regulated, and secure small modular reactors with a modest output electrical power (less than 10 megawatts) to improve combat capability and improve deployed conditions for the Department of Defense (DoD) (Kendall, 2014.)

The committee is not aware of any current SMR designs that would meet Army requirements for use as a transportable nuclear power source. The committee does believe, however, that, given Army-

________________________

43 World Nuclear Association, “Nuclear-Powered Ships,” http://www.world-nuclear.org/info/Non-PowerNuclear-Applications/Transport/Nuclear-Powered-Ships/, accessed March 30, 2014.

44FedBizOps.gov, “Request for Information (RFI) on Deployable Reactor Technologies for Generating Power and Logistic Fuels,” Solicitation Number: DARPA-SN-10-37, changed May 05, 2010, http://www.fbo.gov/index?s=opportunity&mode=form&id=6a303cc531086d5b4f3cdf374e9b219c&tab=core&_cview=1.

issued specifications, there are technologies that could be modified to produce a safe, secure, and transportable design that would produce electricity and process heat that could be used to produce alternative liquid fuels and potable water.

This committee did not have the expertise to study the current state of nuclear power technology, Army requirements for SMRs, or risks, costs, and benefits associated with deployment of SMR technologies. However, transportable nuclear power plants were considered in some detail in the 1999 National Research Council report Reducing the Logistics Burden for the Army After Next: Doing More with Less (NRC, 1999). It is clear now, as it was in 1999, that SMR technologies, if developed to a point where they are deemed sufficiently safe and ready for deployment into an operational theater, would represent a game-changer for Army logistics by eliminating a significant fraction of current fuel requirements.

Finding 3-22. Deployable small modular reactors offer the promise of game-changing impacts to Army logistics if deployed at large bases in rear areas.

Recommendation 3-19. The Army should stay abreast of Department of Energy and Department of Defense research and development initiatives for small modular reactors (SMRs). Army logistics planning should include the possibility that SMRs will provide abundant electrical power, fuel, and water for its deployed forces.

Ammunition is the third greatest logistics burden after water and fuel. There are some immediate and near-term approaches the Army can use to address the ammunition logistics demand and some other options that could have a significant impact when the Army replaces its small arms.

Any consideration of Army munitions naturally divides into two categories: small-caliber rounds (e.g., .50 caliber, 7.62 mm, and 5.56 mm) and larger rounds, such as artillery ammunition. To reduce the ammunition logistics burden, it is necessary to either reduce the number of rounds being used, ammunition weight, or both.

The dominant demands for small-caliber ammunition are for .50 caliber, 7.62 mm, and 5.56 mm rounds. For infantry logistics, it may be useful to view 10 kilograms as comprising 660 rounds of 5.56 mm ammunition, 280 rounds of 7.62 mm ammunition, or 85 rounds of .50 caliber ammunition. This does not include the weight of packaging materials and shipping containers. As shown in Box 3-3, a tremendous amount of ammunition is produced in the United States.

BOX 3-3

The Ammunition Industrial Base

Most Army small-caliber ammunition is manufactured by a government-owned, contractor-operated plant in Lake City, Missouri. This plant can produce 85 million rounds of .50 caliber, 230 million rounds of 7.62 mm, and 1.2 billion rounds of 5.56 mm ammunition annually. During Operation Iraqi Freedom and Operation Enduring Freedom, total ammunition demands have exceeded these capacities by about 15 percent, and the balance has been contracted out to private producers, as are much smaller quantities of eight other types of small-caliber ammunition, such as customized Special Operations Forces ammunition, representing less than 5 percent of total demand (U.S. House of Representatives, 2005).

Caseless, Polymer-Cased, and Case-Telescoped Ammunition

Caseless, polymer-cased, and case-telescoped ammunition have been tested by the Army and Marine Corps as part of the Lightweight Small Arms Technology program. Caseless rounds have no steel or brass case. In polymer-cased ammunition plastic replaces the steel or brass case. Case-telescoped ammunition packages the bullet partially or entirely in the propellant, resulting in a more compact round; individual rounds weigh only 40-50 percent as much as conventional cartridges, and their ballistic performance is no different from that of conventional rounds. Unfortunately, these rounds require the procurement of redesigned carbines and machine guns, but the designs exist and have been successfully tested (Sanborn, 2012a). A 40-50 percent reduction in weight per round is a significant reduction in the ammunition logistics burden and in the soldier’s load.45

Finding 3-23. A 50 percent reduction in ammunition weight will have an associated reduction in logistics demand.

Recommendation 3-20. As the Army considers replacing small-caliber arms, it should pursue caseless, polymer-cased, or case-telescoped small-caliber ammunition.

It appears to be possible to replace lead bullets with copper bullets that would provide increased consistency in terms of effectiveness. Copper bullets can be machined with much more precision that swaged ones.46 This reduces ballistic wobble during flight and produces much more consistency. The Army has introduced the M855A1 5.56 mm Enhanced Performance Round into Afghanistan for the M16 and M4 carbines. This round replaces a legacy lead-core bullet with one having a copper core. In tests, the improved rounds are more consistent from shot to shot and more effective. This can serve to reduce the number of rounds that need to be fired and, thus, delivered. The weight per bullet is about the same, but the bullet is slightly longer (Lopez, 2011).