Electrochemical Prozac: Relieving Battery Anxiety through Life and Safety Research

ALVARO MASIAS

Ford Motor Company

Global interest in electrified vehicles is sparked by both environmental concerns and, in practical terms, the relatively recent application of lithium ion battery technology to automotive applications. Mass adoption of automotive batteries will depend on performance improvements, so methods to optimize the prediction and design of this technology for endurance and safety are an area of active research. New analytical test tools and methods are described in this article, and their refinement and adoption will enhance the ability of lithium ion technology to supplant liquid hydrocarbon fuels in the transportation sector and thus positively contribute to the global environment.

INTRODUCTION

The governments of the United States, European Union, China, and Japan, among others, have announced increasingly strict fuel economy regulations. Thus although the fossil fuel–powered automobile has been the subject of continuous engineering improvement for over 100 years (Ford 1988), electrified automobiles are a key component of virtually all automakers’ current and future product portfolios, and lithium ion batteries are enabling a new generation of electrified vehicles to be commercialized by global automakers.

In this article I explain battery performance requirements for the broad range of electrified vehicles, together with new tools to improve the identification and prediction of failure mechanisms. Safety testing and the results of recent research in this area are also presented.

By addressing the sources of uncertainty in battery failure mechanisms, whether performance (i.e., precise measurement of voltage, current, and time) or

safety (i.e., reaction to various types of mechanical and electrical abuse) related, researchers will enable significant improvements in future generations of battery-powered vehicles.

TRANSPORTATION BATTERY NEEDS

Electrified vehicle designs can be classified by their levels of electrification. In order of increasing power and energy demands, common electrified vehicle features include stop-start (maintaining normal vehicle functions at a stop while allowing the engine to turn off), regenerative braking (converting the kinetic energy of motion into stored electrical energy using the electric machines to supplement friction braking), motor assist, and electric vehicle (EV) drive (EVs run solely on electricity). The ability of hybrid electric vehicles (HEVs), which can convert liquid fuel energy into either mechanical or electrical energy, to perform these functions allows for differentiation between stop-start, mild (<20 kW), strong (>20 kW), and plug-in electric hybrids (PHEVs), which may consume some fossil fuel.

Until recently the performance and maturity of various battery chemistries determined their EV type suitability and commercialization. Now the recent maturation of lithium ion technology is driving a migration away from nickel metal hydride batteries for most HEV and EV applications. But low-temperature, cost, and life challenges prevent lithium ion technology from supplanting lead acid chemistries in the stop-start market.

The various EV types, with their different array of electrified features, place very different power, energy, and cycle life demands on their batteries. For example, a common EV design features more than 80 kW of power and 24 kWh of energy. Cycle life is strongly affected by the extent of the battery capacity used in each cycle. Likewise, designing for high energy has a direct impact on the available power delivery as a tradeoff.

Designing a vehicle battery involves balancing competing performance figures, including energy and power. As a result, several automotive industry and government organizations—the US Advanced Battery Consortium (USABC; information at www.uscar.org), the European Council for Automotive Research & Development (EUCAR; www.eucar.be), and the New Energy and Industrial Technology Development Organization (NEDO; www.nedo.go.jp)—have created EV performance targets for energy and power, designating targets for pack-level specific energy (energy by weight) and power (power by weight).

LIFE PREDICTION

When determining the ability of a battery technology to meet future life requirements a high level of confidence is required. Consequently, qualifying a new technology for production can take several years of validation testing to meet

the typical 10-year/150,000-mile vehicle life requirement. Testing first distinguishes between battery life decay mechanisms (use or calendar dependent) and then assesses the impacts of current levels (low, high) and temperature.

Battery Life Decay Mechanisms

Battery life decay mechanisms can be categorized as calendar or use dependent. The former are tested in high-temperature protocols that take advantage of a battery’s Arrhenius kinetic mechanisms, which lend themselves well to accelerated testing. Cycle life acceleration is more problematic, as its decay mechanism is more difficult to accelerate through established techniques. High-precision battery testing has recently been proposed as a method to accelerate the understanding of cycle life–based decay mechanisms (Smith et al. 2010). To make future life predictions, it is necessary that the precision of the test data be at least as good as the decay per cycle that is being predicted. By closely measuring current, voltage, and time during a battery test, it is possible to achieve the parts per million (ppm) level of measurement precision needed to predict hundreds and thousands of cycles into the future.

Low Current

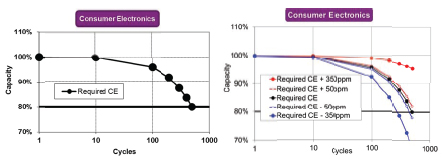

To understand the impact of imprecise battery measurements, the example of coulombic efficiency (CE) in consumer electronic cell life requirements is shown in Figure 1. Coulombic efficiency is defined as the number of electrons that leave a battery divided by the number that entered. Based on this definition, a theoretically perfect battery would have a CE value of unity or 100 percent. If a cell delivered the exact amount of coulombic efficiency (99.954 percent or a deviation of 446 ppm from ideal) required to achieve 20 percent capacity decay in 500 cycles, the curve shown on the left in Figure 1 would be achieved. Exist-

FIGURE 1 Coulombic efficiency (CE) required (L) and impact of tester imprecision (R).

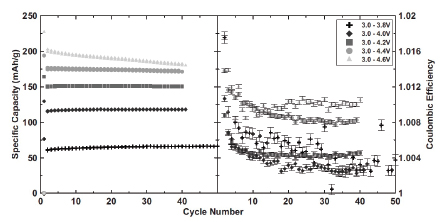

FIGURE 2 Capacity and high-precision coulombic efficiency as a function of charge voltage. Reprinted with permission from Smith et al. (2010).

ing battery testing equipment is subject to CE errors of nearly the same order of magnitude (350 ppm). To be relevant to EVs, where an order of magnitude improvement in cycles to 5,000 is desired, testers would need a corresponding error improvement to approximately 50 ppm. The righthand graph in Figure 1 shows that when the error is of about the same order of magnitude (350 ppm) as the allowable deviation (446 ppm), the predicted future capacity is uncertain. However when the tester error is reduced to 50 ppm, the predicted future capacity can be determined with more confidence.

Recognizing this opportunity for improvement, there has been growing interest in research on high-precision battery testing. Current academic systems have achieved 100 ppm error in terms of coulombic efficiency, with a goal of 10 ppm for future systems (Dahn et al. 2013; Smith et al. 2010). It should be noted that these systems are at low current rates (single-digit amps at the most). The impact of using a 100 ppm system on the imprecision of CE measurements is shown in Figure 2: the closer a battery’s CE gets to unity (right side), the flatter its capacity decay cycle over time (left side).

High Current

Automotive battery testing must demonstrate the capacity to support currents of at least several hundred amps, as would be typical of vehicle conditions. The range of power and corresponding current demands varies by vehicle type. Higher currents are achieved in power characterization patterns ranging from +300 to −120 amps (A) for the various electrified vehicle types. To address the challenges associated with improving the precision of capacity predictions at

higher current and power levels, the Department of Energy’s Advanced Research Projects Agency–Energy (ARPA-E) has awarded a research contract to Ford, Arbin Instruments, and Sandia National Labs to build a commercially viable 50 ppm 200A tester.1 Project progress is described below.

Temperature

Another significant challenge in testing at high currents is mitigation of the resulting temperature changes in the test cells and tester (e.g., shunts and amplifiers). For the test automotive cell, a thermal image can reveal temperature gradients. The order of magnitude of the gradient can vary widely depending on cell design and test pattern run, but its orientation remains the same. At the top of the cell, the connecting terminals serve as excellent thermal wicks (thanks to the highly thermally conductive metals used).

To explore the impact of high current–driven thermal gradients during high-precision testing, the Ford ARPA-E team has been developing thermal control strategies, one of which involves two thermoelectric (TE) heater/cooler assemblies surrounding a single cell. By coupling the intimate cooling capacity of the TEs with feedback (cell temperature) and feedforward (current delivery pattern and resulting cell-driven temperature change), it is possible to neutralize temperature fluctuations during the testing and study their effect (e.g., dV/dT) on precision.

SAFETY PREDICTION

Current and evolving government regulations and industry standards cover all aspects of automotive design. In the United States, these regulations take the form of the Federal Motor Vehicle Safety Standards (FMVSS), of which FMVSS 305 addresses electrified vehicles (Table 1).

As the technology and systems have evolved, FMVSS 305 has been revised numerous times since it was first issued in 2000. With the recent application of lithium ion batteries to automotive applications, the National Highway Traffic Safety Administration (NHTSA) has conducted research on the safety behavior of the technology. One of the NHTSA-sponsored research projects, conducted by Ford in collaboration with Ricardo, an international engineering and environmental consultancy, sought to develop recommendations for vehicle-level safety tests and performance metrics for NHTSA consideration. The project, completed in November 2014, included study of the behaviors of parts (e.g., cell strings, modules, and packs) to determine quantifiable vehicle-level recommended test procedures.

_____________

1 Information about the project, for which I am principal investigator, is available at ARPA-E, “Ultra-Precise Battery Tester,” http://arpa-e.energy.gov/?q=slick-sheet-project/ultra-precise-battery-tester.

TABLE 1 US Federal Motor Vehicle Safety Standard 305 Requirements

| Section | Requirement | |

| S5.1 | Electrolyte spillage from propulsion batteries | <5L spillage total, 0 into passenger cabin 30 minutes after barrier test |

| S5.2 | Electrical energy storage/conversion device retention | Energy device shall remain attached to vehicle and out of passenger cabin |

| S5.3 | Electrical safety | Maintain isolation >100 ohm/volt with monitoring or >500 ohm/volt without monitoring |

Source: DOT (2008).

The most common way to describe the response of a lithium ion battery to abuse is to use the EUCAR rating system (Table 2), which assigns a score of 0 to 7 for a range of increasingly severe battery responses. For example, a score of 5 denotes a battery that experienced a fire or flame event.

The team performed a rigorous fault tree analysis (FTA) to consider all the possible lithium ion–specific faults a vehicle could experience and produced a ranked list of priority hazards, from which the top three—crush, overcharge, and

TABLE 2 European Council for Automotive Research & Development (EUCAR) Battery Abuse Response Rating

| Score | Title | Description |

| 0 | No effect | No effect. No loss of functionality. |

| 1 | Passive protection activated | Cell reversibly damaged. Repair of protection device needed. But no defect; no leakage; no venting, fire, or flame; no rupture; no explosion; no exothermic reaction or thermal runaway. |

| 2 | Defect/damage | Cell irreversibly damaged. Repair needed. But no leakage; no venting, fire, or flame; no rupture; no explosion; no exothermic reaction or thermal runaway. |

| 3 | Leakage (∆ mass < 50%) |

Weight loss <50% of electrolyte weight (electrolyte = solvent + salt). No venting, fire, or flame; no rupture; no explosion. |

| 4 | Venting (∆ mass > 50%) |

Weight loss of ≥50% of electrolyte weight (electrolyte = solvent + salt). No fire or flame; no rupture; no explosion. |

| 5 | Fire or flame | No rupture; no explosion (i.e., no flying parts). |

| 6 | Rupture | No explosion, but flying parts of the active mass. |

| 7 | Explosion | Explosion (i.e., disintegration of the cell). |

Reprinted with permission from Doughty and Crafts (2005).

short circuit—were selected for procedure development. A global survey of battery regulations and industry standards provided a baseline for the development of draft test procedures, which were then tested at three US locations. The sites evaluated string, module, and pack hardware built up with three types of lithium ion cells. The experimental testing and analysis allowed for significant test procedure refinement and confidence in battery responses.

Battery abuse tests generally fall into one of three categories: mechanical, thermal, and electrical. The following sections present the range of testing for each category and, where appropriate, the results and recommendations of Ford’s research.

Mechanical Abuse

International battery safety mechanical test regulations and standards vary significantly (Table 3). The most common test combines mechanical shock and mechanical integrity testing, in which the battery is typically subjected to a mechanical crush event.

Review of the large number of existing crush-related tests led to selection of the FreedomCar procedure as a starting point (INEEL 2003). The procedure was modified to stratify the battery response by breaking up the crush motion into 20 increments of 5 percent. By crushing in many small steps over approximately one hour, it was possible to determine the impact of a fault as it progressed.

All hardware was able to be crushed to more than 13 percent displacement without a EUCAR 5 (fire or flame) response. The broad plane of the cell had the smallest ranges of response, indicative of testing consistency. Designing a parts-level crush test for the other planes of the cell is nontrivial because of the tendency of hardware to move out of the plane of crush when not constrained in a vehicle. As a result, it was concluded that crush testing should be performed only at the vehicle level and in the same manner as current FMVSS crash tests. If a battery experiences mechanical damage during these tests, the extent of battery crush can be used to assess the result.

Improvements in computing power and modeling capabilities have revolutionized automotive design and in particular crush performance development. Research in this area should seek to couple experimental results with simulations in the hopes of supplanting the need for trial and error experimentation (Sahraei et al. 2014).

Thermal Abuse

There is considerable variability in the use of thermal testing protocols (Table 4), with only two—the thermal shock and fire exposure tests—close to a consensus position among the regulatory and standards agencies.

TABLE 3 Mechanical Safety Test Matrix

| Test type | Industry standard | Government regulation | ||||||||

| Freedom Car | SAE J2929 | SAE J2464 | ISO 12405-1 | ISO 12405-3 | UN 38.3 | ECE R100 | Q/C-T 743 | KMVSS 1.48 | ||

| Mechanical integrity | • | • | • | • | • | • | ||||

| Mechanical shock | • | • | • | • | • | • | • | |||

| Penetration | • | • | • | |||||||

| Immersion | • | • | • | • | • | |||||

| Rollover | • | • | ||||||||

| Drop | • | • | • | • | • | • | • | |||

| Vibration | • | • | • | • | • | • | ||||

Note: ECE=Economic Commission for Europe, ISO=International Organization for Standardization, KMVSS=Korea Motor Vehicle Safety Standards, Q/C-T=China Industry Standard, SAE=Society of Automotive Engineers, UN=United Nations.

TABLE 4 Thermal Safety Test Matrix

| Test type | Industry standard | Government regulation | ||||||||

| Freedom Car | SAE J2929 | SAE J2464 | ISO 12405-1 | ISO 12405-3 | UN 38.3 | ECE R100 | Q/C-T 743 | KMVSS 1.48 | ||

| Thermal stability | • | |||||||||

| Fire expposure | • | • | • | • | • | • | ||||

| High-temperature storage | • | • | • | |||||||

| Cycle w/o thermal control | • | • | • | • | • | |||||

| Thermal shock | • | • | • | • | • | • | • | |||

| Humidity exposure | • | • | • | |||||||

| Passive propagation | • | |||||||||

Note: See Table 3 for abbreviations.

Thermal shock testing typically involves exposing a battery pack to a cycle of warm and cold temperatures and then evaluating its performance, making it more of a durability evaluation procedure than an abuse failure investigation tool.

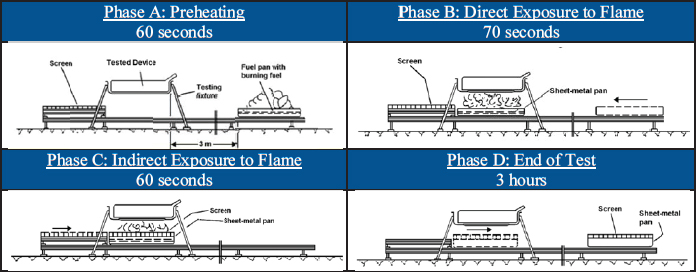

For fire exposure investigation, an ECE regulation (R34) that calls for a fire exposure test on plastic fuel tanks in vehicles has been referenced, and the test, adapted for battery abuse testing, incorporated in a new regulation (R100) (Figure 3). It involves first directly exposing a battery to a burning pool of liquid fuel (Phase B) and then indirectly through a screen of refractory bricks (Phase C) and evaluating the hardware response (Phase D).

Electrical Abuse

The electrical subcategory of battery safety testing (Table 5) shows the greatest consistency of application: all the reviewed regulations and standards feature overcharge, short circuit, and overdischarge tests. There are minor differences in test details (e.g., in current, duration, or resistance), but the general procedures are similar.

The Ford team investigated battery responses to overcharge and found that attempts at discretizing the moment of battery response led to a start-stop approach to overcharge electrical energy delivery using twenty 5 percent state of charge intervals. No hardware had an event before it reached 134 percent overcharge. Thus, in the unlikely event that a vehicle allowed an overcharge to occur, the state of charge can be used to assess the test’s outcome.

Short circuit abuse testing of batteries commonly uses shunts of specific resistances (e.g., 10mΩ), irrespective of the test hardware details. This approach ignores the Ohm’s law behavior of the short circuit reaction, which dictates that the severity of the short is dependent on the relative resistance of the hardware to the shunt. By exploring a range of relative resistance values it is possible to correlate test current and shunt resistance to the likely test outcome. Review of a vehicle battery’s internal resistance and limits imposed by the pack’s fusing is informative of the likely abuse response.

CONCLUSION

The success of long-term vehicle electrification efforts will depend heavily on the performance of their batteries. Batteries appropriate for automotive applications have to pass extensive validation procedures to demonstrate durability, but there remain uncertainties—causes for anxiety—about battery life and safety. New testing tools are available to improve the prediction and identification of electrochemical failure mechanisms. Further research can enhance the utility and

FIGURE 3 United Nations Economic Commission for Europe (UNECE) R100 Fire Exposure Test. Reprinted with permission from UNECE (2013).

TABLE 5 Electrical Safety Test Matrix

| Test type | Industry standard | Government regulation | ||||||||

| Freedom Car | SAE J2929 | SAE J2464 | ISO 12405-1 | ISO 12405-3 | UN 38.3 | ECE R100 | Q/C-T 743 | KMVSS 1.48 | ||

| Overcharge | • | • | • | • | • | • | • | • | • | |

| Short circuit | • | • | • | • | • | • | • | • | • | |

| Over discharge | • | • | • | • | • | • | • | • | • | |

| High voltage exposure | • | |||||||||

| Partial short circuit | • | |||||||||

| Separator shutdown | • | |||||||||

Note: ECE=Economic Commission for Europe, ISO=International Organization for Standardization, KMVSS=Korea Motor Vehicle Safety Standards, Q/C-T=China Industry Standard, SAE=Society of Automotive Engineers, UN=United Nations.

international consistency of these testing procedures to align developments and progress.

ACKNOWLEDGMENTS

This work was supported by the US Department of Transportation’s National Highway Traffic Safety Administration (NHTSA) [DTNH22-11-C-00214] and the US Department of Energy’s Advanced Research Projects Agency–Energy (ARPA-E) [DE-AR000267].

REFERENCES

Dahn JR, Trussler S, Dugas S, Coyle DJ, Dahn JJ, Burns JC. 2013. Accurate and precise temperature-controlled boxes for the safe testing of advanced automotive li-ion cells with high precision. Journal of the Electrochemical Society 160(2):A251–A258.

DOT [US Department of Transportation]. 2008. Laboratory Test Procedure for FMVSS 305, Electric Powered Vehicles: Electrolyte Spillage and Electrical Shock Protection, TP-305-01. Washington.

Doughty DH, Crafts CC. 2005. FreedomCAR Electrical Energy Storage System Abuse Test Manual for Electric and Hybrid Vehicle Applications, SAND2005-3123. Albuquerque: Sandia National Laboratories.

Ford H. 1988. Today and Tomorrow: Commemorative Edition of Ford’s 1926 Classic. Cambridge: Productivity Press.

INEEL [Idaho National Engineering and Environmental Laboratory]. 2003. FreedomCAR Battery Test Manual for Power Assist Hybrid Electric Vehicles, DOE/ID-11069. Idaho Falls: US Department of Energy.

Sahraei E, Meier J, Wierzbicki T. 2014. Characterizing and modeling mechanical properties and onset of short circuit for three types of lithium-ion pouch cells. Journal of Power Sources 247:503–516.

Smith AJ, Burns JC, Trussler S, Dahn JR. 2010. Precision measurements of the coulombic efficiency of lithium-ion batteries and of electrode materials for lithium-ion batteries. Journal of the Electrochemical Society 157(2):A196–A202.

UNECE [United Nations Economic Commission for Europe]. 2013. Electric Power Trained Vehicles. Regulation No. 100 – Rev. 2. Geneva.