4

Regulatory Requirements for Offsite Hydrolysate Shipment and Treatment

The primary mission of the Pueblo Chemical Agent Destruction Pilot Plant (PCAPP) is to safely destroy the Pueblo Chemical Depot chemical stockpile. Should it become necessary for PCAPP to send hydrolysate offsite in order to continue destruction of the chemical stockpile, all regulatory requirements must be identified and prebriefed with the Colorado Department of Public Health and Environment (CDPHE) and any other relevant regulatory bodies and must be coordinated with the Citizens’ Advisory Commission (CAC), Assembled Chemical Weapons Alternatives (ACWA), and other stakeholders so that the destruction mission is not unduly delayed.

Regulatory Background

The Resource Conservation and Recovery Act (RCRA) sets up a program for cradle-to-grave hazardous waste management.1 Treatment, storage, and disposal facilities (TSDFs) are required to obtain permits that establish specific operating conditions as well as the requirements for facility closure.

While RCRA is a federal program administered by the U.S. Environmental Protection Agency (EPA), states may seek authorization from EPA to operate their own programs, and most states have this authorization. The Colorado Department of Public Health and Environment (CDPHE) is authorized to administer the RCRA program within the state of Colorado. CDPHE’s RCRA program is defined in the Code of Colorado Regulations (CCR) at 6 CCR 1007-3.

Hazardous Waste Listings and Characteristics

Having received authorization from EPA to administer its own RCRA program, a state can make its regulatory schemes more stringent or broader in scope than the federal program. Colorado, like many of the states with past or present chemical demilitarization facilities, has chosen to make its program broader in scope than the federal RCRA program by listing specific chemical agent wastes as hazardous. Colorado-specific hazardous wastes listings include chemical munitions containing the following agents: Levinstein mustard agent (H), distilled mustard agent (HD), mustard gas, distilled mustard mixed with bis(2-chloroethylthioethyl) ether (HT), and sarin (GB) (waste codes P909, P910, and P911) and waste chemical weapons (waste codes K901, K902, and K903).2

In 2012, Colorado added hydrolysate from the treatment of 105- and 155-mm howitzer munitions and 4.2-in. mortar munitions as a waste chemical weapons listed waste and assigned to it waste code K903. The Colorado regulations define K903 hydrolysate as waste generated from the chemical neutralization of mustard agent by the addition of water and subsequent manipulation to a sustained and stable pH > 10 to ensure destruction of sulfonium ions and thiodiglycol (TDG)-mustard aggregates. K903 is not an acute listed waste but only a toxic listed waste exhibiting the RCRA toxicity characteristic. The other waste chemical weapons are listed as acute hazard waste, not only for exhibiting the toxicity characteristic but also for their reactivity and corrosivity.3

The RCRA program also establishes RCRA characteristics, which include ignitability, corrosivity, reactivity, and toxicity. The characteristics entail specific tests or definitions

________________

1 42 U.S. Code §6901 et seq.; Code of Federal Regulations (CFR) at 40 CFR §§260 to 272.

2 See 6 CCR 1007-3, Part 261.

3 Solid and Hazardous Waste Commission/Hazardous Materials and Waste Management Division, 6 CCR 1007-3, Hazardous Waste, Addition of K903 (Hydrolysate) Listing, adopted by the commission on November 20, 2012.

that, if met, would identify the waste as a “characteristic hazardous waste.” Hence, to be hazardous, wastes can either be a listed hazardous waste or a characteristic hazardous waste, or both (i.e., a listed waste that also meets one or more characteristics).

The means by which a waste is defined as hazardous is important because if a waste is a listed waste, any residue resulting from treatment of the waste is also defined as that listed waste (the derived-from rule), even if it no longer contains those attributes that made it a listed hazardous waste in the first place. For PCAPP, this means that the hydrolysate and all downstream secondary wastes retain the K903 listing designation, including the filter cake resulting from the biotreatment process. RCRA provides a delisting process that is available for waste that the waste-generating entity believes no longer meets the listing description. Delisting, however, can be a long and arduous process.

In contrast, if a waste is hazardous only because it demonstrates one or more of the RCRA characteristics, once that waste is treated or otherwise managed so that it no longer demonstrates the characteristic, it becomes a nonhazardous waste, subject to the state program for solid (nonhazardous) waste management.

RCRA Land Disposal Restrictions

The RCRA Land Disposal Restrictions (LDRs) establish treatment standards that hazardous wastes must meet before they can be land-disposed. The LDRs apply to both listed and characteristic wastes and entail specified treatment technologies or constituent concentrations that must be met. The federal program does not identify chemical weapon or agent wastes as listed hazardous wastes, so the federal LDRs do not apply to PCAPP hydrolysate (Colorado K903 waste) unless it exhibits one or more of the RCRA characteristics. However, Colorado recently established state-specific LDR treatment standards for K901, K902, and K903.4 These LDR treatment standards would only apply to treatment of hydrolysate at a TSDF permitted in Colorado to accept such waste; currently no such permitted facilities are known to be located in Colorado.

The Colorado K903 waste LDR treatment standards apply the federal RCRA characteristics for corrosivity and toxicity, since hydrolysate may exhibit these characteristics. To be defined as K903 the hydrolysate must have a sustained and stable pH > 10. In the Colorado final rule documentation, K901 was amended to include the following language:

Up to the point in the PCAPP process where the acidic hydrolysate is manipulated to a sustained and stable pH > 10 to ensure destruction of sulfonium ions and TDG-mustard aggregates, prior to transfer from reactor.5

The current PCAPP RCRA Research and Development and Demonstration (RD&D) Permit Waste Analysis Plan, 2008, Table C-9, indicates that the hydrolysate in the hydrolysate tanks would have a pH between 10 and 12. Therefore, K903 hydrolysate from the reactor that meets the RCRA corrosivity characteristic of pH > 12.5 would have to be treated to meet Colorado LDR treatment standards, including no longer demonstrating the corrosivity characteristic or containing any regulated hazardous constituents above the limits listed in the rule.

However, if the hydrolysate is shipped to an out-of-state TSDF, the waste hydrolysate would have to be treated to meet the LDRs for characteristic wastes as adopted by the state in which the TSDF is located—for example, it no longer exhibits a RCRA characteristic (e.g., corrosivity) and meets any additional treatment requirements for known underlying hazardous constituents (e.g., solvents)—prior to final disposal.

Finding 4-1. To meet the definition of a K903 hydrolysate, a nonacute toxic listed waste, the hydrolysate must have a sustained and stable pH > 10 prior to transfer from the reactor for offsite shipment (6 CCR 1007-3, Section 268.40). Otherwise, if the pH < 10, the waste would be defined as K901, an acutely toxic waste, which would impose additional management requirements within Colorado.

Recommendation 4-1. To minimize management requirements while the waste is located within Colorado, PCAPP should ensure the hydrolysate meets the definition of K903.

Structure of RCRA Permit at PCAPP

PCAPP is currently operating under a RCRA RD&D permit because the technologies used in the hydrolysis treatment, coupled with biotreatment of the resulting hydrolysate, are a first-of-a-kind application. An RD&D permit has terms and conditions that will assure protection of human health and the environment, and it limits the treatment to those types and quantities of hazardous waste that the CDPHE deems necessary for purposes of determining the efficacy and performance capabilities of the technology or process and the effects of such technology or process on human health and the environment. RD&D permits can provide for construction of such facilities as necessary and for operation of the facility for not longer than 1 year. The permit can be renewed three times, but each renewal period cannot be for more than 1 year.6

Once the performance of PCAPP has been demonstrated to the satisfaction of ACWA, PCAPP operators, and CDPHE, PCAPP must file for a full operating RCRA permit, commonly referred to as a RCRA Part B permit. PCAPP intends to submit the Part B permit application in February 2015.7

________________

4 Ibid.

5 6 CCR 1007-3, Section 268.40.

6 See 6 CCR 1007-3, §100.25.

7 Ron Entz, environmental permitting engineer, PCAPP, presentation to the committee on July 30, 2014.

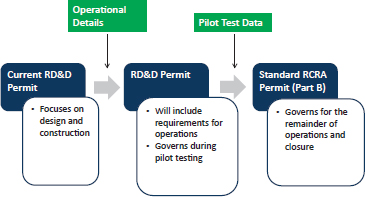

Figure 4-1 shows the additional documentation that is required as PCAPP transitions from the RD&D permit to the full RCRA permit.8

Offsite transport and treatment of the hydrolysate by an out-of-state TSDF, although allowed by RCRA regulations as administered by CDPHE, is not described or contemplated in the current RD&D permit nor is it addressed in the current full RCRA Part B permit application documentation.9

As noted by the National Research Council (NRC, 2008), PCAPP has acknowledged that a modification to eliminate the use of the biotreatment unit and to add a loading facility for offsite hydrolysate shipments would probably be a Class 2 or Class 3 modification. That report contained the following finding and recommendation:

Finding 4-7. The applications for modifications of the research, development, and demonstration permits for both BGCAPP and PCAPP proposed that a number of specific secondary wastes be shipped offsite for treatment or ultimate disposal.

Recommendation 4-2. The Program Manager for Assembled Chemical Weapons Alternatives should continue to pursue the acceptance of the planned offsite shipment and disposal of secondary waste through permit modifications and stakeholder involvement.

During committee discussions at the July 2014 meeting in Pueblo, the CDPHE indicated that if offsite transport of hydrolysate to a TSDF for treatment is necessary, either under the RD&D permit or under the full RCRA operating permit, the process would require a RCRA Class 2 permit modification.10,11

For a Class 2 permit modification,12 the RCRA procedures for public participation require the permittee to send a notice of the modification request to all persons on the facility mailing list maintained by the director and to the appropriate units of federal, state, and local government as specified in the regulations and to publish this notice in a major local newspaper with general circulation. The notice must include the announcement of a 60-day comment period; the date, time, and place of a public meeting to be held in accordance with the regulations; the location where copies of the modification request and any supporting documents can be viewed and copied; and facility contact information.13 The typical time required for a Class 2 permit modification would be 3 to 6 months, whereas the typical time for a Class 3 modification would be 6 months to a year or more.

FIGURE 4-1 Transitioning of RCRA permit. SOURCE: Ron Entz, environmental permitting engineer, PCAPP, “RCRA Permit Structure and Potential Modifications for Offsite Shipment of Hydrolysate,” presentation to the committee on July 30, 2014.

The time required to implement a Class 2 modification to a RCRA permit may vary depending on regulator and public acceptance. More time would likely be needed for Class 2 or 3 if there is any controversy associated with the modification being proposed.14

CDPHE may also issue a Temporary Authorization15 having a term of up to 180 days. In most cases, Temporary Authorizations, if issued by the regulator, allow site preparation, construction, and potentially similar activities as a permit modification is being considered. Temporary Authorizations to begin construction may be especially important if offsite treatment of hydrolysate becomes necessary at PCAPP, because offsite treatment would likely require construction of a truck loading station and piping and other modifications.16

It is most likely that any issues with the on-site treatment of the hydrolysate would arise during systemization or while the facility is still operating under the RD&D permit. The RD&D permit affords the facility more flexibility within the regulatory process than would the full RCRA permit

________________

8 Ibid.

9 Ibid.

10 Doug Knappe, CDPHE PCAPP, permitting unit leader, presentation to the committee on July 30, 2014.

11 CDHPE, in the supporting documentation for adopting the addition of the K903 hydrolysate listing, specifically acknowledged that “in the event the mustard agent hydrolysate cannot be successfully treated at PCAPP, the waste may be shipped offsite to another permitted hazardous waste treatment, storage or disposal facility that may also manage the waste in accordance with the new hydrolysate listing.” (Solid and Hazardous Waste Commission/Hazardous Materials and Waste Management Division, 6 CCR 1007-3, Hazardous Waste, Addition of K903 (Hydrolysate) Listing, Adopted by the Solid and Hazardous Waste Commission on November 20, 2012.)

12 6 CCR 1007-3, §100.63(e).

13 See 6 CCR 1007-3, §100.63.

14 While the permittee identifies the modification class in the modification application, the CDPHE makes the final decision on the appropriate class of the modification. The regulations for a Class 2 modification provide for a 60-day comment period and the CDPHE has no more than 90 days after the receipt of the modification request to approve or deny the modification, with or without changes. CDPHE could also determine that the modification must following procedures for a Class 3 modification, instead of a Class 2. In addition, the CDPHE can notify the applicant of a 30-day extension for a decision; up to 120 days.

15 6 CCR 1007-3 §100.63(e)

16 Ron Entz, environmental permitting engineer, PCAPP, “RCRA Permit Structure and Potential Modifications for Off-site Shipment of Hydrolysate,” presentation to the committee on July 30, 2014.

to try to overcome internal technical obstacles in order to continue the onsite treatment of the hydrolysate, including operational and infrastructure changes to mitigate poor or nonperformance. However, if it appears that these obstacles might not be overcome for a significant time or at all and if it appears that offsite transport of the hydrolysate may be necessary while the plant is under the RD&D permit, PCAPP still would need to wait up to 6 months or more for approval of a Class 2 permit modification to allow offsite transport of hydrolysate. Munitions processing will be delayed during this period. While a temporary authorization may be issued by CDPHE for such a modification, normally this would only allow limited activities to prepare for offsite shipments until the final permit modification is approved (e.g., planning or preconstruction of truck loading facilities).

Finding 4-2. If it appears that obstacles for onsite treatment cannot be overcome and if it appears that offsite transport of the hydrolysate will be necessary, munitions processing would be delayed for 6 months or more based on the regulatory approval process for a Class 2 permit modification.

Recommendation 4-2. PCAPP should process a permit modification for the RCRA Research and Development and Demonstration (RD&D) permit that would allow for the offsite transport of hydrolysate as a backup plan. The modification application should contemplate a temporary authorization for site preparation, preconstruction, and similar activities while PCAPP is operating under the RD&D permit.

Recommendation 4-3. PCAPP should include provisions for the capability for offsite transport of hydrolysate in the PCAPP Part B permit application that PCAPP is preparing.

Any changes to the PCAPP facility, particularly those that require infrastructure changes, would require a RCRA permit modification. For instance, based on findings in Chapter 7, installation of additional onsite hydrolysate storage capacity may be considered to allow more time for remedying poor or nonperformance of components of the biotreatment area. In this example, with additional hydrolysate storage capacity, munitions destruction and agent hydrolysis could continue. However, with specific exceptions, the waste cannot be stored for longer than 1 year under the LDR regulations.

The committee notes, however, that while adding storage capacity would buy more time, if fixes to downstream processes are unsuccessful, the time and resources spent approving and installing additional storage capacity, to include permitting and other documentation, would be wasted. In this instance, PCAPP would still need to consider implementing the offsite option to ensure continued destruction of the stockpile.

Recommendation 4-4. PCAPP should prepare and process any modifications to the RD&D permit or the Part B permit application that would be needed to allow implementation of additional contingency options that may be determined to be prudent solutions to poor or nonperformance of BTA components, including additional hydrolysate storage.

The NRC (2008) report already noted that

On the basis of discussions with state regulators, Mitretek concluded that if offsite shipment of hydrolysate is adopted, neither BGCAPP nor PCAPP would be allowed to begin operations until an appropriate TSDF had been selected and a contract for receipt of the waste was in place (Bizzigotti et al., 2006).

At this time, even if the permit modification is approved for offsite shipment of hydrolysate, PCAPP has not identified an offsite TSDF that would be available to accept shipments of PCAPP hydrolysate. Identifying and contracting with an appropriate TSDF will take time. The TSDF must have characterization data on the waste to demonstrate that it can accept the waste for treatment under its current RCRA permit. If the PCAPP hydrolysate falls outside the TSDF’s normal waste acceptance criteria, that TSDF may itself have to process a RCRA permit modification. In addition, it may take weeks or even months for PCAPP to establish a contracting arrangement with the offsite TSDF, as federal contracting system requirements must be satisfied.

Finding 4-3. Identifying and contracting with an appropriate offsite TSDF that can accept the hydrolysate under its RCRA permit will require time, perhaps weeks or even months, which would prevent the expeditious implementation of offsite shipments and delay the destruction mission.

Recommendation 4-5. PCAPP should proceed as soon as possible to identify at least one acceptable offsite TSDF that is capable of accepting PCAPP hydrolysate and should establish mechanisms for contracting with appropriate TSDFs.

Another potential regulatory issue deals with the reuse of the water recovered after the dewatering of the biotreatment sludge in the brine reduction system (BRS). The RD&D permit currently requires that the BRS be operated so as to ensure that the effluent is of sufficient quality to allow it to be recycled to other portions of the PCAPP and be used as a substitute for well water.

The permit requires that samples be analyzed for either (1) the constituents listed in Appendix VIII of 6 CCR 1007-3, Part 261 or (2) an alternative list of constituents approved by CDPHE. The results should be compared with the limits for constituents found in both the Colorado Primary Drinking Water Maximum Contaminant Levels (MCLs) and the Maximum Concentrations of Contaminants for Toxicity Characteristics.17

________________

17 6 CCR 1007-3, §261.24.

The process, as outlined in the permit, would allow automatic approval for recycling if the effluent meets the MCLs for those constituents that are also listed in Appendix VIII of Part 261. However, if the effluent cannot meet the MCLs, the results are to be compared with the Maximum Concentrations of Contaminants for RCRA Toxicity Characteristics. If they are below those regulatory levels, the results are to be transmitted to the CDPHE for confirmation before the effluent is considered to not be a hazardous or solid waste and to therefore be recyclable through the plant.

If the effluent does not meet the MCLs and does not meet the Maximum Concentrations of Contaminants for RCRA Toxicity Characteristics, PCAPP must stop any transfer of BRS effluent to downstream systems and must provide CDPHE with a corrective action plan before any transfer can resume. This would result in the facility needing to extract significantly more well water than planned and could delay destruction operations.

During presentations to the committee on July 29 and 30, 2014, PCAPP officials expressed some concern regarding whether the recovered water would be able to meet the primary drinking water MCLs and noted that PCAPP was considering initiating a delisting petition for the BRS effluent.18

As stated above, hydrolysate is a listed waste (K903). Therefore, under the derived-from rule, residuals generated by the hydrolysate treatment process would carry the K903 hazardous waste code and would have to be disposed of as a hazardous waste. It should be noted that materials that are reclaimed from solid wastes and that are used beneficially are not solid wastes and hence are not hazardous wastes unless the reclaimed materials are burned for energy recovery or used in a manner constituting disposal.19 In addition, the CDPHE may grant requests for a variance from classification as a solid waste for those materials that are reclaimed and then reused as feedstock within the original production process in which the materials were generated if the reclamation operation is an essential part of the production process.20 Therefore, because the water is intended for reuse within the system and never leaves the PCAPP processing areas, it could be argued that it is not a waste material. The only issue with the recovered water should be whether its quality is sufficient to support PCAPP engineering processes.

Finding 4-4. Because the water exiting the BRS is intended for reuse within the system and never leaves the PCAPP processing areas, it should not be considered a waste material. The only issue with the recovered water should be whether its quality is sufficient to support PCAPP engineering processes.

Recommendation 4-6. PCAPP should confirm with the Colorado Department of Public Health and Environment that the effluent recovered from the brine reduction system does not fall under Colorado hazardous listing for hydrolysate (K903); should process any delisting petitions, variance requests, or permit modifications necessary to accomplish this; and should turn its attention to ensuring the recovered water meets technical requirements for reuse within PCAPP.

As indicated in NRC (2008), under the National Environmental Policy Act (NEPA), PCAPP prepared and issued an environmental impact statement (EIS) covering the construction and operation of the chemical agent treatment facility. Neither that EIS nor the corresponding records of decision address offsite shipment of hydrolysate. Under NEPA regulations, if the new proposed action is not adequately covered in an existing EIS or environmental assessment, the site would have to prepare an environmental assessment, which would result in either a finding of “no significant impact” or a requirement to prepare supplemental NEPA documentation.

In The Sierra Club, et al., v Dr. Robert M. Gates, Secretary of Defense, et al., in the U.S. District Court of the Southern District of Indiana, Terre Haute Division, the plaintiffs sought to stop the government from continuing shipments of the product of the hydrolysis of the nerve agent VX from the Newport Chemical Weapons Depot to Veolia’s incineration facility in Port Arthur, Texas. In that case, the Court ruled that the government published its notice of the Record of Decision regarding the Final Programmatic Environmental Impact Statement (FEIS) for its Chemical Stockpile Disposal Program. That FEIS indicated that site-specific NEPA review, which would include the preparation of an EIS or an Environmental Assessment (EA), would be conducted for each of the chemical storage installations.

The Court found that the Army’s 1998 FEIS for the pilot test of its neutralization plan for the VX at the Newport Chemical Agent Disposal Facility (NECDF) in Indiana evaluated two alternatives: no action and the proposed process. Partly in response to certain NRC studies and partly in response to the terrorist attacks of September 11, 2001, in July 2002, the Army published Final Environmental Assessment (FEA 2002) regarding the VX destruction process at NECDF. In that FEA, the Army compared a no-action alternative with the disposal of the hydrolysate at an offsite TSDF. The FEA made no findings with respect to a specific TSDF, suggesting that such analysis would be performed later, after a TSDF had been chosen. The Army issued Final Finding of No Significant Impact (FONSI 2002) in October of that year.

In 2003, the Army issued a transportation analysis that analyzed the environmental impacts for two routes from Newport, Indiana, to Deepwater, New Jersey, to reach the DuPont environmental treatment facility. In 2005, the Army issued a record of environmental consideration (REC),

________________

18 Presentation by Paul Usinowicz, Bechtel technical advisor, and Yakup Nurdogan, senior wastewater treatment specialist, July 29-30, 2014, and presentation by Don Guzetti, start-up field supervisor, PCAPP, and Dave deLesdernier, Battelle, July 29-30, 2014.

19 6 CCR 1007-3, §261.3(c)(2)(i).

20 6 CCR 1007-3, §260.32.

announcing that it would start neutralization of the VX at NECDF and that the hydrolysate generated from the process would be stored onsite until a suitable arrangement could be made for its treatment at a TSDF; the REC indicated its decision was covered by FEA 2002 and FONSI 2002.

In 2006, after extensive analysis and discussions with the receiving TSDF, the EPA approved the offsite treatment option. In April 2007, the Army issued another REC for the proposed action to ship caustic wastewater derived from the destruction of VX at NECDF to a permitted commercial TSDF and found that the proposed action qualified for a categorical exclusion for routine management of hazardous materials/hazardous waste operations.21 The Army relied on previous NEPA documentation to support the April 2007 REC, including previous FEIS and FEA documents. In June 2007, the Army issued another REC in response to a letter from plaintiffs concerning the safety and environmental impacts of the proposed action and used the same rationale for not performing an EIS or EA—that the hydrolysate is classified as hazardous waste and comes under the Army’s categorical exclusion for regular treatment and handling of hazardous waste from its facilities.

The Court ruled that it must defer to an agency’s factual findings when deciding whether the environmental impacts of its actions are significant and may not substitute its own judgment for that of the agency. Under such a review, the Court agreed with the government that it did not need to supplement its FEIS 1998 or the FEA 2002 or provide an additional comment period when the alternative option was proposed. The Court found that the administrative record reflected that the original NEPA documents considered onsite treatment of the hydrolysate versus shipment of the hydrolysate offsite to a permitted TSDF. The Court also found that the secondary decision to switch to another permitted TSDF22 does not need a supplemental EIS or EA because the government had taken the necessary “hard look”23 at the nature of the hydrolysate and correctly determined that it was hazardous waste.

Any permit modification to conduct the offsite shipment of hydrolysate at PCAPP would require consideration under NEPA. Unlike NECDF, the NEPA documentation provided by PCAPP did not include an alternative action for offsite shipment of hydrolysate. PCAPP may find that it needs to take a hard look at the nature of the hydrolysate and the action of shipping it to an offsite TSDF. Then it should determine if such an action would be covered by its current NEPA documentation or if it should come under the categorical exclusion or if supplemental NEPA documentation would be necessary.

Finding 4-5. If it is determined that the BTA cannot treat the hydrolysate onsite and it becomes necessary to consider shipping hydrolysate offsite, a corresponding NEPA action may be necessary, potentially delaying shipment of hydrolysate and, once storage capacity is reached, the destruction operations at PCAPP would need to halt.

Recommendation 4-7. PCAPP should immediately initiate a study to determine whether it will need to amend its current National Environmental Policy Act (NEPA) documentation or if a new action is warranted, including issuing a Final Environmental Assessment, a Final Programmatic Environmental Impact Statement, or establishing the basis for a categorical exclusion. Such a study should be completed while PCAPP is operating under its RCRA RD&D permit. PCAPP should determine the time frame the selected NEPA action would require and mitigate any delay by prefiling if it is determined that a new proposed action under NEPA is required.

PUEBLO COUNTY CERTIFICATE OF DESIGNATION

PCAPP was required to obtain a certificate of designation from the Pueblo County Board of County Commissioners before beginning operations. The county grants such a certificate only after the CDPHE has reviewed and recommended approval of the facility.24 The county also reviews written statements and supporting documentation on whether the proposed facility poses a risk to the health and/or the safety of the public and/or the environment; the density of the population neighboring the facility and the routes to and from the facility; the risk of accidents; and compliance with zoning requirements and the impact on neighboring activities—for example, agricultural activities, infrastructure, and community support services. It also considers the facility owner’s financial responsibility and prior performance records.

As for the CDPHE permitting processes, the certificate holder must notify the county of any modification or changes in operations, ownership, or design for a hazardous waste processor that involve matters that are the subject of or contained in the Certificate of Designation. Within 10 days of the receipt of a modification notice, the county must notify the certificate holder of the classification of the modification: Class A, which requires no additional information or input from the certificate holder; Class B, which needs additional information or input and may require either an informal modification that needs only additional informa-

________________

21A categorical exclusion is defined as actions that normally do not require an EA or EIS, and the Army has determined that they do not individually or cumulatively have a substantial effect on the human environment. From Appendix B of 32 CFR Part 651 (AR 100-2), Environmental Analysis of Army Actions.

22 The Army switched from shipping to the DuPont treatment facility in Deepwater, New Jersey, to shipping to the Veolia incinerator facility in Port Arthur, Texas.

23 Courts consistently have held that, at a minimum, NEPA imposes a duty on federal agencies to take a “hard look at environmental consequences” (Natural Resources Defense Council v Morton, 458 F.2d 827, 838 D.C. Cir., 1972).

24 See CRS 30-20-100 and Pueblo County Code Section 17.176.090.

tion, explanation, or discussions or a formal modification, which requires a more detailed review process resulting in an amendment to the Certificate of Designation, including a 20-day public notice and comment period and public review and, possibly, a hearing following the public comment period and/or amendment to the Certificate of Designation; or Class C modification, which is for a modification of ownership, design, or operations so substantial that an amendment process is warranted. There is no provision for a Temporary Authorization, as is allowed under RCRA permitting, under the Pueblo County Code.

Finding 4-6. If a modification to the current RCRA RD&D permit becomes necessary in order to ship the hydrolysate offsite, a corresponding application for modification to the Certificate of Designation would have to be made to the Pueblo County Board of Commissioners.

Recommendation 4-8. PCAPP should initiate an action with the Pueblo County Board of Commissioners to prepare such a modification application while it is operating under its RCRA RD&D permit.

ORGANISATION FOR THE PROHIBITION OF CHEMICAL WEAPONS

The United States is a signatory to the Chemical Weapons Convention (CWC), which is overseen by the Organisation for the Prohibition of Chemical Weapons (OPCW). The treaty is administered through the U.S. Department of State. As a U.S. stockpile destruction site, PCAPP is subject to onsite monitoring of the destruction process by OPCW representatives. Not only is the mustard itself subject to the CWC, but also subject to it are what are known as Schedule 2 compounds, which include chemicals that may be used to manufacture chemical agents, or chemical agent precursors. Many of these Schedule 2 chemicals are also used in industrial processes to produce other products. TDG, which can be used in the manufacturing process for mustard, is also a common hydrolysis product contained in mustard hydrolysates and, therefore, is a Schedule 2 chemical under the CWC.

The primary purpose of the biotreatment system at PCAPP, to which mustard hydrolysate is fed, is to mineralize the organic compounds present in the hydrolysate, including TDG. TDG resulting from the hydrolysis process at PCAPP is expected to be present in mustard hydrolysate at a concentration of around 56,000 mg/L, or parts per million (ppm). The hydrolysate fed into the immobilized cell bioreactors is to be diluted for an effective concentration of approximately 7,000 ppm TDG. The current PCAPP RD&D RCRA permit requires the treated hydrolysate to be sampled in the immobilized cell bioreactor (ICB) effluent tanks and then analyzed for TDG and total organic carbon (TOC) to determine the effectiveness of the biodegradation process. The performance goals for the biodegradation process are established in the RCRA permit as achieving a performance goal of greater than 95 percent and a target of at least 99 percent removal of the agent hydrolysate product, TDG, and an average of at least 90 percent removal of TOC.25 In addition, according to PCAPP presentations, the goal of the treatment process is to achieve <0.1 wt% TDG. At present, however, it is unclear whether the OPCW agrees with any of the above stated treatment goals for TDG treatment.26

During the pilot test of the first-of-a-kind application of these biotreatment technologies beginning in September 2014 through July 2015 (see Chapter 6), PCAPP intends to feed a hydrolysate surrogate into the biotreatment area processes at PCAPP (PCAPP, 2014). PCAPP will procure TDG from a manufacturer in Germany to conduct these tests.

The industrial grade TDG to be used for Biotreatment Area Risk Reduction and Mitigation, as a Schedule 2 chemical, is subject to the requirements of the CWC. Under the CWC Industry Inspection Preparation Handbook, any facility that produces, processes, or consumes in excess of 10 metric tons of any Schedule 2 chemical is subject to inspection. Accordingly, it will be subject to oversight by the OPCW.27 Under OPCW export requirements for TDG, a mixture containing 20 percent of TDG does not require a license for export to a state party to the CWC but is prohibited from being exported to a state not party to the CWC. A mixture containing 35 percent requires a license for export to certain state parties. A mixture containing less than 7 percent does not require a license for export to any destination, including a state not party to the CWC.28

The PCAPP plan is to treat the hydrolysate surrogate in the biotreatment process as if it was actual mustard hydrolysate. Following a number of pretests and demonstrations, actual testing with surrogate will begin in March 2015. PCAPP will then transition from treatment of hydrolysate surrogate to actual mustard hydrolysis beginning in mid-September 2015.29

Finding 4-7. The RCRA permit performance goal for the biotreatment process is >95 percent and a target of at least 99 percent of removal of agent hydrolysate product, TDG as

________________

25 PCAPP RCRA RD&D Stage III, Class 3, Permit Modification Request, Revision 0, November 2006, Appendix D, Waste Analysis Plan, C-2a(3) (d), p. C-11.

26 Paul Usinowicz, Bechtel technical advisor, and Yakup Nurdogan, senior wastewater treatment specialist, presentation to the committee on July 30, 2014.

27 Under the CWC Industry Inspection Preparation Handbook, any facility that produces, processes, or consumes in excess of 10 metric tons of any Schedule 2 chemical is subject to inspection.

28 Department of Commerce, Bureau of Industry and Security, Chemical Weapon Convention: Import and Export Requirements, http://www.cwc.gov/outreach_industry_publications_cwc007.html#F_6_.

29 Don Guzzetti, start-up field supervisor, PCAPP, and Dave deLesdernier, Battelle, presentation to the committee on July 30, 2014.

measured in the ICB effluent tanks.30 The PCAPP Pilot Test Demonstration Plan proposes a goal of ≤0.1 wt% for TDG in the effluent.31 The PCAPP presentation indicated criteria of >95 percent TDG removal efficiency at design flow rate and ≥98 percent TDG removal efficiency at 50-90 percent design capacity and ≤0.1 wt% TDG when the ICB unit is being air scoured or in recovery.32

Finding 4-8. At present, it is unclear whether the OPCW agrees with any of the above treatment goals for the TDG present in the hydrolysate.

Finding 4-9. The testing process with hydrolysate surrogate will result in waste streams similar to those that will be produced during the actual mustard treatment campaigns at PCAPP and that will feed into the ICBs, the BRS, and the water recovery system, ultimately producing filter cake.

Recommendation 4-9. ACWA should work with the CDPHE and, if necessary, OPCW to demonstrate the efficacy of the treatment goals for thiodiglycol during the hydrolysate surrogate testing portion of the overall biotreatment area risk reduction and mitigation process. PCAPP should also work with regulators to establish a final treatment standard or goal in the RD&D permit and the final Part B permit.

Bizzigotti et al. 2006. Analysis of Offsite Treatment of Hydrolysates from Chemical Agent Destruction Pilot Plants. Mitretek report MTR 2006-22, October. Falls Church, Va.: Mitretek Systems.

NRC (National Research Council). 2008. Review of Secondary Waste Disposal Planning for the Blue Grass and Pueblo Chemical Agent Destruction Plants. Washington, D.C.: The National Academies Press.

PCAPP (Pueblo Chemical Agent Destruction Pilot Plant). 2014. White Paper Bio-Treatment Area Risk Reduction and Mitigation. 24852-30H-BTA-V0001. Rev. 000. April.

________________

30 PCAPP RCRA RD&D Stage III, Class 3, Permit Modification Request, Revision 0, November 2006, Appendix D, Waste Analysis Plan, C-2a(3) (d), p. C-11.

31 PCAPP Pilot Test Demonstration Plan, CDRL H002, 24852-GPP-GYPM-00006, Revision 000, August 2013, Table 2-1, p. 2-5.

32 Presentation by Paul Usinowicz, Bechtel technical advisor, and Yakup Nurdogan, senior wastewater treatment specialist, July 29-30, 2014, and presentation by Don Guzzetti, start-up field supervisor, PCAPP, and Dave deLesdernier, Battelle, July 29-30, 2014.