6

Hydrolysate Treatment Performance Goals

All stakeholders in the Pueblo Chemical Agent Destruction Pilot Plant (PCAPP) project, including Pueblo community members, the Colorado Citizens’ Advisory Commission (CAC), PCAPP government and contractor employees, Assembled Chemical Weapons Alternatives (ACWA) management, the Colorado Department of Public Health and Environment (CDPHE), and the U.S. Departments of Defense and State, share a common goal: to safely and efficiently destroy the munitions stored at the Pueblo Chemical Depot (PCD). Chemical weapons have been stored at the PCD for over 60 years. Based on discussions with PCAPP officials and CAC members, community perceptions of the risks posed by the PCD appear to be relatively stable.1 As weapons are destroyed at PCAPP and the project approaches completion, this risk profile will diminish over time toward zero. Delays in the destruction process would halt risk reduction and could protract the community’s risk profile. It can even be argued that delays would increase the risk posed by the stockpile, owing, for example, to aging munitions or loss of trained personnel.

The long-standing presence of the stockpile may lead community members to perceive the existing risk as a baseline for decision making. If this is the case, new risks that may arise from PCAPP operations—for example, shipments of hazardous materials on- and offsite, odors, and emissions—could be perceived as increasing the risk to the community. Risk-based decision making should balance the new risks against the larger, existing risk posed by the longtime existence of the stockpile. This section discusses criteria for success in treating hydrolysate with this broader risk picture in mind.

DECISION FRAMEWORK FOR DETERMINING SUCCESSFUL PLANT OPERATION

PCAPP project stages include (1) design, (2) construction, (3) systemization, (4) pilot testing, (5) operation, and (6) closure.2 The overall systemization plan prepares PCAPP for success in three areas: paper, plant, and people. The committee addresses primarily the risk reduction and mitigation portion of the “plant” subset of the overall systemization plan (PCAPP, 2014).

PCAPP is piloting a number of treatment steps that will be applied to the unique waste streams stemming from the production of hydrolysate. As a result, there are uncertainties in how well the end-to-end process will perform. In particular, the biotreatment and brine reduction systems have never been utilized for a substrate like the hydrolysate feed. Based on previous biodegradation testing, system modeling, and analysis, there is a high probability that the required level of thiodiglycol (TDG) biodegradation can be achieved. However, the efficiency and effectiveness of the PCAPP system will remain unknown until the system is placed in operation with actual hydrolysate feed.

To minimize risks associated with new applications of these treatment processes, risk reduction and mitigation activities are identified and addressed through a series of planned preoperational testing activities (PCAPP, 2014). Data from these preoperational tests will help to determine the likelihood that the system will meet performance criteria and will identify and test process alternatives in the case of process underperformance or failure.

The primary criteria for successful treatment of hydrolysate are (1) meeting Resource Conservation and Recovery Act (RCRA) permit requirements and (2) meeting ACWA requirements for treatment of the hydrolysate. This includes the production of process water from the brine reduction

________________

1 Conference call on September 5, 2014, with Judith Bradbury and Hank Jenkins-Smith, members, Hydrolysate Committee; Irene Kornelly, chair, Colorado CAC; Jeannine Natterman, CDPHE; John Norton, member, Colorado CAC; Sandy Romero, PCAPP communications manager; Nancy Schulte, study director, Hydrolysate Committee; and Thomas Schultz, public affairs specialist, PCAPP.

2 See the website for the Program Executive Office, Assembled Chemical Weapons Alternatives, at http://www.peoacwa.army.mil, accessed January 29, 2015.

system (BRS) that is of good enough quality that it can be recycled to the plant and production of a suitable filter cake that meets regulatory requirements for offsite disposal. In addition, it will be desirable to meet ACWA’s schedule for destruction of the munitions at PCAPP. In this manner, overall risk to the community in and around PCD and PCAPP will be gradually reduced. In other words, issues with operation of the biotreatment area (BTA) may be overcome while still complying with RCRA and ACWA requirements; however, they should not delay the overall schedule for destruction of the munitions.

If the plant is unable to satisfy these criteria and if the time it takes to destroy the actual munitions by PCAPP increases as a result of degraded performance of the BTA, the risk reduction goals associated with destruction of the stockpile will not be achieved in a timely manner. If the schedule for overall destruction of the munitions is delayed due to irreparable issues with the BTA, the best option for continued risk reduction to the community will be to ship the hydrolysate offsite for treatment and disposal.

Finding 6-1. The primary criteria for successful treatment of hydrolysate are (1) meeting RCRA permit requirements and (2) meeting ACWA requirements for treatment of the hydrolysate. This includes production of process water from the BTA that is of high enough quality that it can be recycled to the plant and production of a filter cake that meets regulatory requirements for offsite disposal. In addition, it will be desirable to meet ACWA’s schedule for destruction of the munitions at PCAPP.

The overarching question posed to the committee is this: What are PCAPP’s options to accomplish its mission of munitions demilitarization if the biotreatment and/or brine reduction systems underperform? The committee considered underperformance of the overall system as failure to meet permit requirements and failure to adequately remove specific components from the hydrolysate feed, such that the liquid effluent no longer meets requirements for reuse within the plant.

While the critical decision from the perspective of most stakeholders is if/when offsite shipment of hydrolysate becomes a necessity, a broader evaluation of PCAPP’s operational options must first be performed. Performance goals for each unit process will have to be evaluated, and a decision will need to be made regarding alternative options. If alternative options still fail to treat the hydrolysate to an adequate level, the decision to consider offsite shipment of the hydrolysate would become more likely.

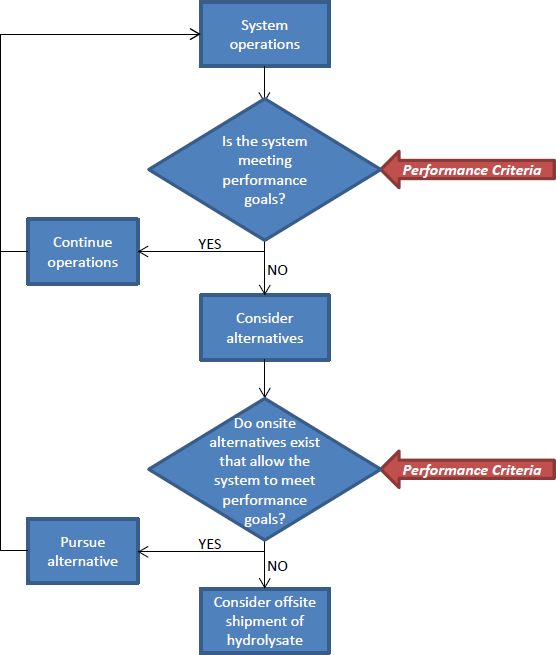

The decision framework illustrated in Figure 6-1 captures, at a high level, the considerations and decisions that drive major changes to operations. More specifically, this decision framework allows decision makers to evaluate all available options before resorting to offsite shipment of hydrolysate.

The PCAPP BTA treatment process involves three main unit processes—immobilized cell bioreactors (ICBs), the water recovery system (WRS), and the BRS—that must meet defined process performance goals in order to ensure overall system performance. The individual performance goals for these processes are evaluated in Chapter 7 using the decision framework illustrated in Figure 6-1. This simple decision framework for evaluating system performance based on performance criteria will aid in reducing risk of underperformance by helping to define reasonable alternative operational decisions. The decision framework shown here will also help build consensus among stakeholders and decision makers on important decisions about major changes to PCAPP operations; this framework is applied to individual unit processes in Chapter 7.

As described at the outset of this chapter, there are multiple stakeholders invested in the success of the PCAPP project. However, it is important to note that not all stakeholders are decision makers when it comes to making changes in operations. The PCAPP operations staff is responsible for the operations of the plant. As a result, they are the initial set of decision makers on routine, day-to-day adjustments to operations. For example, if problems are encountered in maintaining the pH or nutrient levels in the ICBs, potentially causing the system to underperform, PCAPP staff would take corrective actions to return these levels to an acceptable operational range. If an issue like this persists, the decision to pursue further alternatives might be elevated to PCAPP management or to the ACWA level and might include decisions on changes to infrastructure, especially those that might incur costs or delays—for example, installing extra holding tanks to store hydrolysate feed—or necessitate permit modifications. Additional stakeholders may therefore need to be consulted in these decisions depending on their nature or the magnitude of their impact.

PERFORMANCE CRITERIA FOR HYDROLYSATE

The decision framework is supported by a set of performance criteria (indicated by red arrows in Figure 6-1). These criteria, which include effectiveness, efficiency, cost, regulatory/permitting requirements, and stakeholder agreement, are used at two points in the framework. This enables decision makers to compare the performance of the existing system operations with the objectives or perhaps with alternative system operations. A set of performance criteria would include those outlined in Box 6-1. A goal or threshold for each criterion would need to be established by decision makers to define “successful” operations. The use of multiple criteria for performance evaluation allows decision makers to document the extent of underperformance. In other words, while a total failure of the system (although very unlikely) may be easily identified, a partial failure or a temporary failure and the resulting impacts may be more difficult to define, to predict, and to address. Multiple per-

FIGURE 6-1 Decision framework.

formance criteria add clarity to these more likely cases of underperformance.

To apply the decision framework, technical factors that could cause the system to underperform are identified. For example, if there is insufficient oxygen to meet the demand of the biomass, then the extent of TDG biodegradation is decreased. The impact of this technical factor is then evaluated to determine if operational changes should be considered. In the same example, limited oxygen supply might impact multiple criteria, including targets for biodegradation, recycle water quality, and permitting requirements. If the system is underperforming based on an assessment of these criteria, alternative onsite options (i.e., contingency strategies) are then considered. In this case, modifying the influent piping to distribute the feed across multiple chambers may improve the distribution of oxygen to meet biomass needs. As before, the impacts of implementing this alternative can be evaluated using the same performance criteria. This alternative, although it would improve the effectiveness criteria, would incur infrastructure costs and might impact the project schedule. A similar process can be used to evaluate other contingency strategies in order to determine how to proceed. At each decision point, the relevant benefits and liabilities of each option would be carefully considered.

Once multiple technical factors and contingency options have been evaluated using the performance criteria, the overall system risk can be assessed holistically. A graded evaluation of system risk would allow stakeholders to qualitatively rate the potential for overall program success at any point in the project. This type of graded evaluation will

BOX 6-1

Performance Criteria for Hydrolysate

Effectiveness Criteria

- Level of TDG biodegradation

—Design treatment goal of ≥95 percent at design flow rate, or ≥98 percent at 50-90 percent flow, TDG destruction in the ICBs.

—Minimum treatment goal of <0.1 wt% TDG when the ICB unit is being air scoured or in recovery. This would result in a treatment of >86 percent.a

—PCAPP RCRA RD&D permit performance goal of >95 percent and a target of at least 99 percent removal of the TDG and at least an average of 90 percent removal of TOC.b

- Filter cake must meet offsite TSDF acceptance criteria.

- Recycle water must meet treatment requirements so as to allow reuse within the plant.

- Odor and emissions:

—Odor levels should not exceed a dilution-to-threshold ratio (D/T) of 7/1.c

—Emissions should comply with the release requirements specified in the RCRA permit.

Efficiency/Schedule Criteria

- The BTA process rate should meet or exceed the agent neutralization process rate. Throughput buffer capacity = 30 days for ICB feedstock, plus storage capacity of WRS.

- Project schedule and projected completion date:

—Munitions destruction projected to be completed according to the ACWA schedule.

—Extended delays (e.g., beyond 30 days) may result in loss of trained workforce.

—The length of “acceptable” delay may vary across stakeholders.

Cost Criteria

- All operating costs (including unanticipated maintenance, infrastructure, and other costs) are within available funding.

Regulatory/Permitting Requirements

- CDPHE RCRA permit.

- Pueblo County certificate of designation.

- National Environmental Policy Act.

- Organisation for the Prohibition of Chemical Weapons.

_____________

a Paul J. Usinowicz, Bechtel technical advisor, “Biotreatment Area Cradle to Grave,” presentation to the committee, July 30, 2014.

b PCAPP RCRA RD&D Stage III, Class 3, Permit Modification Request, Revision 0, November 2006, Appendix D, Waste Analysis Plan, C-2a(3)(d), p. C-11.

c The dilution-to-threshold (D/T) ratio is a measure of the number of dilutions needed to make the odorous ambient air nondetectable. It is calculated as (Volume of carbon-filtered air)/(Volume of malodorous air). See RCRA permit modification #31, BTA and BRS Odor Control and Colorado Regulation No. 2, 5 CCR 1001-4. Note that the limit shown in the White Paper Bio-Treatment Area Risk Reduction and Mitigation (PCAPP, 2014), p. vii, is an odor-to-threshold ratio of 1.0 or greater.

facilitate communication between stakeholders and allow stakeholders to track and document PCAPP progress in a transparent and consistent way throughout the course of the project. Table 6-1 exemplifies a graded scale for success that could be used for the PCAPP project.

Finding 6-2. The PCAPP systemization plan (including the risk reduction and mitigation plan) lacks a decision-making process to guide major changes in operations.

Recommendation 6-1. PCAPP should implement a clear decision-making process to guide major changes in operations.

In Chapter 7, potential technical factors in the ICBs, WRS, and BRS that may lead to insufficient treatment of hydrolysate are identified. For each potential factor, the impact on system performance is described and alternative operational strategies are identified. Finally, the technical factors, along with their corresponding alternatives, are assessed using the graded scale described in Table 6-1. The committee judges

| Grade | Definition |

| 0 | Success is practically certain (very low possibility of project failure): Operations are proceeding as expected. No PCAPP actions needed. |

| 1 | High likelihood of success (low possibility of project failure): Actions should be taken by PCAPP to prepare ahead of time for implementation of contingencies in the event of failures. For example, PCAPP might begin to prepare permit modifications and planning documents, including building plans for piping and shipping. |

| 2 | Success is uncertain (moderate possibility of project failure): Actions should be taken to prepare for implementation of contingency operations. For example, PCAPP might begin processing environmental documentation and finalizing contingency plans, purchasing needed materials, and implementing changes to the infrastructure. |

| 3 | Success is unlikely with current operations (high possibility of failure of the project): Actions are taken to accelerate the implementation of contingency operations. For example, construction of needed facilities is completed as quickly as possible, and environmental approvals are expedited if they have not already been obtained. |

NOTE: WRS, water recovery system; BRS, brine reduction system.

that PCAPP is currently operating within Grade 1. Although there is a high likelihood of success, actions should be taken by PCAPP to prepare ahead of time for implementation of contingencies in the event of failures.

Finding 6-3. The committee judges that PCAPP is currently operating within Grade 1. There is a high likelihood that PCAPP will be successful in meeting performance criteria. Conversely, there is a low possibility of failure.

Recommendation 6-2. Actions should be taken by PCAPP to prepare ahead of time for implementation of contingencies in the event of failures.

A number of the technical factors identified in Chapter 7 are being evaluated during the systemization, risk reduction, and surrogate testing processes. In this way, alternative operational strategies may be implemented before agent operations begin.

PREOPERATIONAL TESTING DATA THAT FACTOR INTO THE DECISION PROCESS

Systemization will provide PCAPP the opportunity to identify potential failure points, test alternative operational and treatment strategies, and provide valuable plant operating experience. Systemization planning should reduce negative impacts on the overall schedule due to unanticipated operational problems and reduce overall operating costs. In addition, the “Risk Reduction and Mitigation Plan” specifies additional testing beyond the previously anticipated systemization testing (Guzzetti, 2014). The systemization plan consists of approximately 6 months of operations, with the first 2 to 3 months dedicated to start-up/acclimation needs and development of steady-state operational conditions. The remaining 3 to 4 months will allow the system to operate under steady-state conditions to assure system stability and allow for data to be collected and used to assess performance and evaluate alternatives (PCAPP, 2014). Careful data collection, performance evaluation, and corrective mitigation activities taken during the start-up and steady-state phase of systemization should decrease the likelihood of delays or system failure during actual system operation.

PCAPP has outlined a risk reduction and mitigation plan that will evaluate many of the technical factors identified in the next chapter that could lead to underperformance of the BTA. Table 6-2 briefly summarizes the data that will be collected during the risk reduction and mitigation effort that will be performed concurrently with systemization. These data are being used to inform operational changes and adjustments that may need to be made before agent treatment begins in September 2015. Once treatment of actual munitions begins, operational data will be collected to monitor performance of the overall system. Operational data can be used to assess performance against the established criteria for success and will therefore be critical to the decision-making process. In the event that the BTA still fails to meet performance goals despite the use of alternative operational strategies, the downstream impacts of offsite shipment will need to be considered. These issues are addressed in Chapter 7.

Finding 6-4. In its recent white paper on risk reduction and mitigation, PCAPP has done a thorough job of identifying potential failure risks and providing targeted strategies to mitigate these risks in the BTA (PCAPP, 2014). Employing the decision-making framework outlined previously, the overall systemization plan, and the BTA risk reduction and mitigation plan provides targeted strategies for PCAPP to mitigate any operational problems that become apparent during surrogate testing and systemization.

| Systemization Phase | Type of Data Generated | Implication/Use | Contingency Option |

| Enhanced water testing in the BRS |

|

Assess the ability of the vendor’s equipment to operate as planned. | Replace equipment that does not meet specifications. |

| Respirometry studies |

|

Determine expected operational conditions, preferred biomass source to seed the ICBs, and TDG concentration for initial start-up phase. | Utilize alternative biomass seed source and modify TDG concentration for start-up phase. |

| Surrogate testing (ICBs) |

|

Control of operational parameters within the ICBs is critical to degradation of TDG. |

|

| Surrogate testing (WRS) |

|

Ensure that aeration and mixing are adequate. |

|

| Surrogate testing (BRS) |

|

Effluent from BRS must meet permitting requirement for both liquid (recycle) and solid (shipment offsite) components. |

|

SOURCE: Guzzetti, 2014.

Guzzetti, D., start-up field supervisor, PCAPP, and D. deLesdernier, Battelle, support. 2014. “Biotreatment Area Risk Reduction and Mitigation,” presentation to the committee on July 29, 2014.

PCAPP. 2014. White Paper Bio-Treatment Area Risk Reduction and Mitigation. 24852-30H-BTA-V0001. Pueblo, Colo.: Pueblo Chemical Agent Destruction Pilot Plant.