The Greening of Industrial Ecosystems. 1994.

Pp. 178-190. Washington, DC:

National Academy Press.

The Utilization-Focused Service Economy: Resource Efficiency and Product-Life Extension

WALTER R. STAHEL

A key difference between the industrial economy and the service economy is that the first gives value to products that exist materially and are exchanged, whereas value in the service economy is more closely attributed to the performance and real use of products integrated into a system. In our classical, industrial economy, the value of products is essentially identified with the costs of producing them, whereas the notion of value in the service economy is shifted toward the evaluation of costs incurred to provide results in use.

The first approach considers the value of a personal computer with a printer. The second, on the other hand, evaluates the actual performance of the, system, taking into consideration not only its cost of production but also all sorts of costs associated with successful use (such as the cost of learning to use it and the cost of repair and maintenance) as well as the quality of the result. In the service economy, what is purchased is the functioning of a tool; people buy "system functioning," or performance, not products.

CHANGES AND OPPORTUNITIES AHEAD

Reuse and recycling are among the strategies for waste minimization that should lead us (i.e., the industrial countries that represent 20 percent of the world population but consume 80 percent of all resources) to a more sustainable and resource-saving economy. But how?

Waste-reduction and resource-saving strategies can be applied to the following activities:

-

Production (clean technologies through closed loops—a goal of zero waste, primary materials recycling).

-

Use (long-life goods, product-life extension, and more intensive use of goods and systems).

-

Postuse (secondary recycling of "clean," or sorted, materials, and refurbished components and parts).

Closed loops are one common denominator of waste reduction in these three radically different areas. The other common denominator is the need for management decisions to implement waste prevention. Waste prevention does not happen by accident!

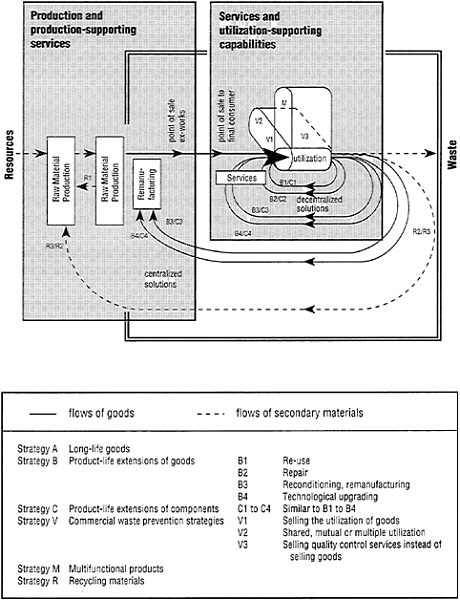

There are two kinds of loops that differ fundamentally with regard to their feasibility: (1) reuse of goods, and (2) recycling of materials (see Figure 1 and Table 1).

The reuse of goods means an extension of the utilization period of goods, through the design of long-life goods; the introduction of service loops to extend an existing product's life, including reuse of the product itself, repair, reconditioning, and technical upgrading; and a combination of these (Figure 2). The result of the reuse of goods is a slowdown of the flow of materials from production to recycling (or disposal). Product-life extension means waste prevention not only through increased use but also in production, distribution (including packaging), and recycling/disposal, as well as a reduction of the environmental impairment caused by the transport necessary for these activities. Reusing goods and product-life extension imply a different relationship with time.

The recycling of materials means simply closing the loop between postuse waste (supply) and production (resource demand). Recycling does not influence the speed of the flow of materials or goods through the economy.

It can be shown that there are fundamental differences in the economic feasi-

FIGURE 1

The reuse loop and the recycle loop. Loop 1: Waste prevention, long-life products, and product-life extension. Loop 2: Waste reduction and recycling of materials.

SOURCE: Stahel and Reday (1976/1980).

TABLE 1 Fundamental Differences Between Reusing Goods and Recycling Materials

|

Reusing goods through product-life extension activities such as reconditioning |

Reusing raw materials through resource recycling |

|

Potential sales price depends on |

Potential sales price depends on: |

|

• Prices of comparable new goods (e.g., bottles, tires, cars) on the local markets |

• Commodity prices on the world market (e.g., scrap steel, sand for glass, rubber) |

|

• Utilization value |

• State of the world economy and of economic cycles |

|

• Rarity and collection values |

|

|

Characteristics of potential buyers are: |

Characteristics of potential buyers are: |

|

• Large number (everybody) |

• Small number (monopolistic markets) |

|

• Small volumes needed |

• Substantial volumes demanded |

|

• Short transport distances to buyer |

• Long transport distances to buyer |

|

Intensity of activity |

Intensity of activity |

|

• Mainly skilled labor |

•Mainly energy |

|

The following examples will explain these differences in concrete terms, comparing the reutilization of tires with the reutilization of the raw materials inherent in tires: |

|

|

• Retreading using a special "cold" process that enables a multiple repetition of the process |

• Recycling using a special process that consists of freezing the tires with liquid nitrogen and subsequent shredding. Irreversible |

|

• The process is environment friendly, uses medium temperatures (90°C) and produces no waste |

• The process is environment friendly and produces no waste |

|

SOURCE: Stahel (1986). |

|

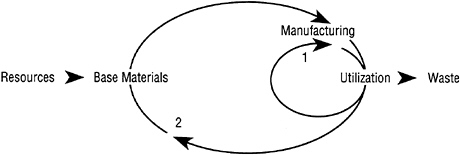

FIGURE 2

The self-replenishing system of product reuse and recycling services. Loop 1: Reuse of goods. Loop 2: Repairs of goods. Loop 3: Reconditioning or rebuilding of goods. Loop 4: Recycling of raw materials.

SOURCE: Stahel and Reday (1976/1980).

bility of these two loops. One important difference is that the smaller the loop, the more profitable it is (Table 1). It could therefore be expected that in a free market economy, manufacturers, guided by the "invisible hand," would jump to develop opportunities for reusing goods, without even looking at recycling. We all know that, in reality, the exact opposite is happening. There are gains to selling the use of goods instead of the goods themselves. When we have to sell the use of goods, we will have at least the same turnover and profit as before, when we sold products, once we made the adjustment. Again, what about the invisible hand that seems to have gone astray?

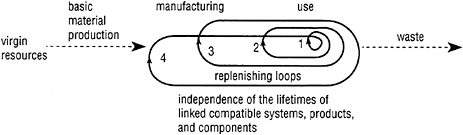

You might object that this is due to the fear that, if we considerably extend the useful life of goods in our consumer society, the economy will break down. The contrary, however, is true. Product-life extension is in many cases a substitution of labor for energy (Figure 3 and Table 2). The missing link in our analyses is liability:

FIGURE 3

The trade-offs among energy, labor, and materials for each step in product-life extension (PLE).

SOURCE: Stahel and Reday (1976/1980).

TABLE 2 Comparison of Labor and Energy Input for Production and Maintenance of a 10- and 20-Year Lifetime Car (excluding operation)

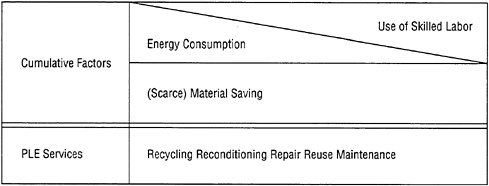

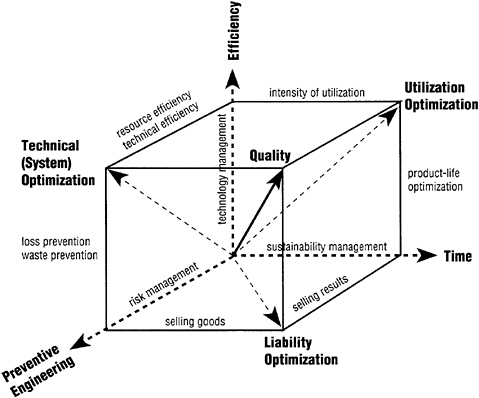

FIGURE 4

Quality defined as optimization of system functioning over long periods of time.

SOURCE: Stahel (1991).

-

The logic of ''reuse loops" implies perfect quality and a broad service liability.

-

Selling only the use of goods implies an unlimited product liability by manufacturers and their agents (importers and shops), "from cradle back to cradle" including an environmental impairment liability at all levels (Figure 4 and Tables 3a and 3b); this is also inherent in the German Waste Law of 1986 and its provision (para. 14) regarding the manufacturer's obligations to take goods back and recycle them after use.

RECYCLING

The nice thing about the recycling of materials is not its economic attractiveness, but the fact that it carries a limited product and material life cycle liability. The liability "from cradle to grave" that is so fashionable today is really ''for cradle and grave;" it excludes unlimited use liability as well as the obligation to reuse

Table 3a How Selling the Utilization of Products Rather than the Products Themselves Affects Liability of Economic Actors

|

|

Alternative Utilization and Commercialization Opportunities |

Examples of Economic Actors |

Alternative Liability Carriers "product quality" and "utilization" |

||

|

Producer |

Fleet Manager |

User |

|||

|

SALE |

Owner is user Durable product is sold (cash or credit) • cars • white goods • clothes • computers |

Individuals |

Risk of warranty (6/12 months) |

— |

All risks for an unlimited time period (except warranty) |

|

RENTAL |

Owner is fleet manager Product is rented • cars System is rented • apartment • hotel room Service is rented • taxi |

Companies and individuals offering service • shops • Hertz, Avis • investors • hotels • taxi owners |

Risk of warranty |

All risks for the full utilization period (except warranty) |

none |

|

SELLING SYSTEM UTILIZATION |

Owner is fleet and maintenance manager System utilization is sold • transport • telecom • clothes |

Fleet managers • railways • airlines |

All risks for a period of time determined and negotiated between producer and fleet manager |

none |

|

|

Owner is producer, fleet and maintenance manager |

Manufacturers • Aia-Geveert AG • Xerox |

All risks for an unlimited period of time |

|

none |

|

|

System utilization (goods and services) is sold • photocopies |

|

Producer is also fleet manager |

|

|

|

|

SOURCE: Börlin and Stahel (1987) |

|||||

Table 3b How Selling the Utilization of Products Rather than the Products Themselves Affects Product Design and Waste Reduction Strategies

|

|

Alternative Utilization and Commercialization Opportunities |

Impact on Product Durability |

Liability for Waste and Costs of Waste Elimination |

Waste Reduction Strategies |

|

SALE |

Owner is user Durable product is sold (cash or credit) • cars • white goods • clothes • computers |

|

Costs of eliminating dispersed waste are paid by the community (local taxes) |

Re-use |

|

RENTAL |

Owner is fleet manager Product is rented • cars System is rented • apartment • hotel room Service is rented • taxi |

Fleet manager seeks most advantageouscost-performance ratio, which also involves speculation on tax depreciation rules. |

(household waste) |

Product-life extension of components Re-use |

|

SELLING SYSTEM UTILIZATION |

Owner is fleet and maintenance manager System utilization is sold • transport • telecom • clothes |

Maintenance manager engages in preventive maintenance engineering. Goal is to minimize operation costs, including costs of maintenance and waste elimination. |

|

Repair Reconditioning, remanufacturing Product-life extension of components Re-use |

|

|

Costs of eliminating concentrated waste are internalized by producer. |

|

||

|

Owner is producer, fleet and maintenance manager System utilization (goods and services) is sold • photocopies |

Producer engages in preventive engineering. The goal is zero maintenance. Full compatibility of products and systems using long-lived components. |

Waste prevention occurs by optimizing the product-life of systems and components reconditioning, leasing, updating use, etc.). |

Long-life goods Repair Reconditioning, remanufacturing Technological upgrading Product-life extension of components Re-use |

|

|

SOURCE: Börlin and Stahel (1987) |

||||

the materials for the production of (the same) new products. Product liability "for cradle and grave" is in most cases an upgrading of the work of the grave digger— a delegation of the problem to somebody else. Said another way: The marketing expressions "Our products can be recycled 100%" and "We recycle our products 100%" are light-years apart! One rejects responsibility and liability; the other accepts it.

By putting product use into the center of economic behavior (Figure 5), we discover that besides product-life extension there are a number of other commercial and technical strategies to intensify the use of goods. According to our reasoning that "the smaller the loop, the more profitable," these commercial strategies are even more promising than product-life extension! In addition, most of these strategies increase resource efficiency; that is, they greatly reduce the amount of resources needed to produce a given result (e.g., grams of resource per wash cycle in washing machines). The reason these strategies were invisible in the first loops (Figures 1 and 2) lies in our technocratic way of analyzing environmental problems.

So, if we broaden the definition of "reuse of goods" to include optimizing the use of goods, we find a multitude of new strategies that have the following elements in common:

-

Considerable savings in resource consumption.

-

Considerable waste prevention (reduction of waste in production, distribution, recycling, and disposal).

-

A shift from a manufacturing economy to a service economy.

-

A substitution of decentralized labor-intensive service workshops for centralized (global) highly mechanized production units.

-

A substitution of labor for energy (and capital) (Figure 3) that is strongest in small loops (see Figure 2).

These strategies also imply changes in some of the basic economic concepts:

-

The inclusion of the factor "time" in economic thinking; that is, the adoption of a dynamic nonlinear approach to solutions, including the simultaneous optimization of several factors.

-

A change in the notion of economic value from "exchange value" to "utilization value."

-

A change in the notion of risk from entrepreneurial to pure risk.

-

A different attitude toward ownership where the status of utilization becomes dominant over that of property.

-

A change in the function of the point of sale from a one-time point-of-no-return in the transfer of liability and full ownership to a point of service that includes periodic renegotiation.

MORE CHANGES AND OPPORTUNITIES AHEAD

If we focus technical development on optimizing use rather than optimizing production, we realize that there are vast "white" areas on our map. To shift from a product-oriented to a utilization-oriented economy, the following competitive and technological strategies, among others, become key issues:

-

"Prevention" engineering (trying to construct systems, products, and components so that they could last indefinitely, with little or no maintenance).

-

Adaptable system design (modular design that enables later system adaptations due to changes in technologies or user requirements through the technological upgrading of existing goods rather than their substitution for new ones).

-

Risk management and consumer satisfaction on all levels, especially the system level (it is normally more economical and effective to improve system performance instead of product performance).

-

Fault-tolerant system design (in an emergency, the system should give adequate warning but enable continued use of its basic functions before it breaks down).

-

Self-protecting system design (long-life goods need to protect themselves and the environment against abuse by the user, such as rpm governors in car engine design to prevent speeding and engine damage).

-

Technical standardization of components (the marketing strategy of redesigning every product from scratch to ensure sales of spares by original-equipment manufacturers is an economic and ecological killer in any long-life approach).

-

User standardization of man-machine interfaces (for example, the standardized flight deck of modem airliners, imposed by the aircraft leasing companies, has shown the immense advantage Of this approach with regard to crew cost and maintenance reliability and cost, with savings of $250,000 to $400,000 per aircraft).

Self-curing spares (a self-explanatory concept that enables products and systems to maintain their integrity under stress, and an area where Japanese innovation appears to be far ahead of the pack).

-

In-situ monitoring of system parameters and the transmission of results to a central supervisor (as used today in aircraft engine operation, e.g., by Lufthansa, and formula-one racing cars, such systems are an important part of the "self-protection" capabilities of long-lived goods).

-

Training operation and maintenance engineers to the highest degree and giving them the tools to gain access to the total system knowledge through expert systems. This should, in fact, be the first priority on this list. It also implies another decisive shift in the value system of society in general and engineering in particular. Are we ready for this?

If we put all this in a cube and shake it well, we get a new definition of technical quality as system functioning over long periods of time (Figure 4). It will be

hard to find a better product in the marketplace, even in 100 years' time, once a manufacturer has established itself as the "leader of quality" according to this new definition. A successful system is much harder to compete against than a successful product.

Examples of this new quality are as follows:

-

Lighthouses and guidance systems that greatly increase the safety of shipping, without having to do with the design of ships themselves.

-

Laundromats that allow a high-intensity use of leased long-life washing machines, resulting in a resource saving by a factor of 40 per wash cycle over typical home systems.

-

Lightweight aircraft tractors that lift the front wheel of an aircraft and pull it to the beginning of the runway, resulting in a saving of 10 percent for aircraft fuel.

-

Diamond—high occupancy vehicle—lanes that favor car and van pooling.

-

Computers that can be upgraded by changing a component or module instead of trading in the whole computer.

-

Multifunctional products, such as a laser scanner-fax-printer-copier, that result in resource savings per page, as well as in savings in (standby) energy, of approximately 75 percent.

Governments concerned for the future of the planet can take action in many ways that do not increase the budget deficit:

-

Government should spend R&D money not exclusively on technical innovations, but increasingly on commercial and marketing innovations. Most of the V-strategies (commercial innovations) shown in Figure 5 could be applied today instantly without any new technology!

-

Government as one of the biggest national waste producers (everything that is bought goes finally to waste) should build up a "de-curement" office at least as large as its procurement office. In the case of product reuse, one person's waste is often another person's dream! However, this other person may be at the other side of the globe and not even know the product exists, let alone that it is thrown away in working order and in large quantities.

TO SUMMARIZE

The reuse of goods, through long-life product design, product-life extension services, and strategies intensifying product use, is economically and ecologically superior to the recycling of materials. Long-life goods, product-life extension, and a more intensive use of products are part of a technoeconomic strategy within a utilization-focused service economy, which

-

Is sustainable and environment-friendly.

-

Maintains existing wealth and welfare.

-

Is modem and economically feasible.

-

Promotes technical progress and self-responsibility by economic actors.

-

Reduces the speed of the flow of resources through the economy.

-

Incorporates the idea of a higher resource efficiency.

The last two of these items are missing in most current "green" discussion, which focuses primarily on recycling.

The introduction of these strategies into the economy demands a change in the mind-set of corporations and government. However, these strategies are themselves long-term and are here to stay, once established. For strategic reasons, dynamic companies should therefore try to be the first in their field of activity to change.

REFERENCES

Börlin, Max, and Walter R. Stahel. 1987. La stratégic économique de la durabilité: Die wirtschaftliche Strategic der Dauerhaftigkeit. Société de Banque Suisse/ Swiss Bank Corporation, Basel. Cahier/Heft SBS no. 32, Nov. 87.

Stahel, Walter R. 1984. The product-life factor. In An Inquiry into the Nature of Sustainable Societies: The Role of the Private Sector, Susan Grinton Orr, ed. The Woodlands, Tex.: Houston Advanced Research Center.

Stahel, Walter R. 1986. Product-life as a variable: The notion of utilization. Science and Public Policy 13(4)(August): 196-203.

Stahel, Walter R. 1991. Langlebigkeit und Materialrecycling - Strategien zur Vermeidung yon Abellen im Bereich de Produke. Essen: Vulkan Verlag.

Stahel, Walter, and Geneviéve Reday. 1976/1980. Jobs for Tomorrow: The Potential for Substituting Manpower for Energy. Report to the Commission of the EC. New York: Vantage Press.