Control of auto-ignition phasing in homogeneous charge compression ignition (HCCI) combustion has been achieved with a variety of methods that affect the thermodynamic state and the chemical composition of the charge. These methods include intake air temperature modulation (Thring 1989; J. Yang et al. 2002), variable valve timing (Kaahaaina et al. 2001), exhaust throttling (Souder et al. 2004), water injection (Stanglmaier and Roberts 1999), mass flow ratio of two fuel types (Olsson et al. 2001, 2002), and variable compression ratio (Christensen et al. 1999; Drangel et al. 2002).

Investigations of the combination of ignition, multiple-injections, positive valve overlap (PVO), and boosting or supercharging are underway for extending HCCI operation (Yun et al. 2010, 2011; Kulzer et al. 2011; Mamalis et al. 2012). Specifically at high load, boosting could provide the necessary air-dilution for moderating the rate of heat release, but it also increases the pumping losses. Flexible turbocharging (variable geometry turbine and/or dual stage) or custom made supercharging will help the efficiency but add complexity and cost. Similarly, variable valve timing that can sweep the entire negative valve overlap (NVO) to positive valve overlap (PVO) space will be expensive but instrumental for low pumping losses and fast response.

Several of these projects that are currently investigating HCCI-SI mode switching and extending the gasoline HCCI load range are discussed below.

ADVANCED COMBUSTION CONTROLS - ENABLING SYSTEMS AND SOLUTIONS (ACCESS)

(AVL, Bosch, Emitech, Stanford, University of Michigan)

The Advanced Combustion Controls - Enabling Systems and Solutions (ACCESS) project, partially funded by a DOE grant, is focused on coordinating multi-mode combustion events over the engine drive cycle operating conditions. The project goal is to improve fuel economy by 25 percent with engine downsizing from a naturally aspirated 3.6L V6 engine to a turbocharged 2.0L I4 engine with part-load HCCI operation while meeting SULEV emission standards.

Figure M.1 shows the BSFC map for a multi-mode combustion 2.0L engine capable of SI (spark ignition), SACI (spark assisted-homogeneous charge compression ignition) and HCCI operation (Nüesch et al. 2014a; Yilmaz et al. 2013). The engine relies on NVO and direct injection during NVO, variable valve lift, and external EGR to cover all of the modes. On a simulated FTP75 cycle, only 44 percent of the fuel is consumed in the advanced combustion modes (20 percent of the fuel spent in the HCCI mode and 22 percent of the fuel spent in the SACI mode) which leaves a large portion (58 percent) of the fuel spent in the SI mode (low and high load and the cold part of the FTP-75 cycle).

The ACCESS project uses the combustion concept, spark assisted HCCI (SACI), to reduce the ringing intensity (RI which is related to ringing noise level) and the rate of pressure rise and to extend the HCCI high load limit as shown in Figure M.1. The RI is moderated by dividing the energy

FIGURE M.1 BSFC map for a multi-mode combustion 2.0L engine showing operating regimes for lean HCCI (red solid), SACI (orange dotted), and the optimum boundary between modes (purple dotted).

SOURCE: Nüesch et al. (2014a).

release of the fuel into an SI-like heat release (slow flame propagation initiated by spark) followed by an auto-ignition, induced by the additional compression from the flame front. As a result, the pressure rise rate following the auto-ignition of the remaining compressed homogeneous fuel/air mixture is reduced. The ratio of the two combustion modes can be manipulated by the fraction of cold (external) and hot (internal) EGR trapped in the cylinder (Wagner et al. 2000), although accurate control of cooled EGR is difficult to achieve due to the transport delays in the flow paths.

Special attention to minimize the fuel penalty during mode transitions is being directed at the investigation of various mode switching strategies (Yilmaz et al. 2013; Zhu 2013). Table M.1 shows the fuel savings projected for an experimental vehicle with a 2.0L four-cylinder engine with multi-mode combustion, including SI, SACI, and HCCI modes, without fuel economy penalties for NOx control. Fuel economy improvements approach 6 percent for the SI/SACI/HCCI combustion modes without penalties for NOx control (Nüesch et al. 2014a).

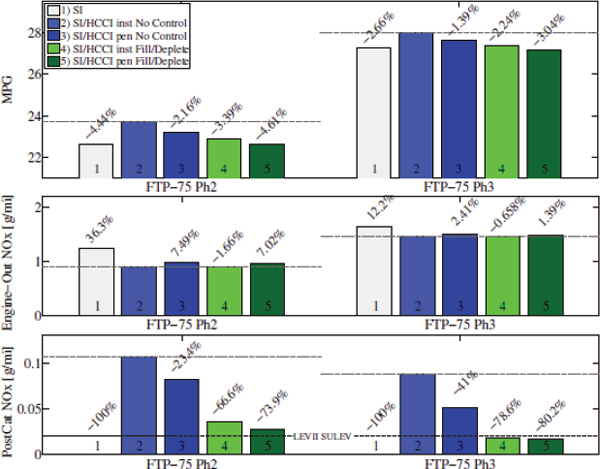

Controlling NOx emissions with a three-way catalyst (TWC) in multi-mode combustion incurs fuel economy penalties. These penalties were analyzed using a calibrated model for the case of SI/HCCI modes of combustion (Nüesch et al. 2014b). The results from this analysis are shown in Figure M.2 for fuel economy, engine out NOx, and tailpipe NOx emissions over portions of the FTP-75 cycle for several combustion modes and control cases. Case 1 is for the baseline SI mode assuming stoichiometry throughout the drive cycle to achieve maximum NOx reduction with the TWC. Cases 2 through 5 show the results from several different SI/HCCI mode switching control strategies. Case 2 does not have any oxygen storage control and leads to the highest NOx emissions while providing the largest improvement in fuel economy. Cases 3 through 5 apply various oxygen storage capacity (OSC) control strategies to reduce the NOx emissions. In Case 5, rich switches are initiated if the OSC is full and the HCCI mode is vacated, and this rich depletion mode is retained until the OSC is empty. Case 5 approaches the SULEV NOx emission requirement but negates the fuel economy benefits gained during HCCI operation (Nüesch et al. 2014a). A similar result for a drive cycle simulation was reported at the 2014 DOE Annual Merit Review (Yilmaz et al. 2014).

Based on the results shown in Figure M.2, the ACCESS project is investigating a transient lean NOx aftertreatment system that may be required for lean HCCI operation in the multi-mode combustion concept in addition to the TWC aftertreatment. A passive SCR system is being investigated which is expected to result in an increase in cost over the initial assumption of having only a TWC aftertreatment system. A passive SCR system would likely have a lower incremental cost than the active SCR systems discussed for diesel engines in Chapter 3.

| FTP-75 | HWFET | ||||

| Combustion Mode | Mode Switches | mpg | % lncrease | mpg | % Increase |

| SI | None | 22.8 | Baseline | 36.1 | Baseline |

| SI/SACI | w/o Penaltiesa | 23.5 | 3.2 | 38.0 | 3.5 |

| SI/HCCI | w/o Penaltiesa | 23.8 | 4.3 | 36.9 | 2.2 |

| SI/SACI/HCCI | w/o Penaltiesa | 24.1 | 5.9 | 38.3 | 6.1 |

| Combustion Modes | |||||

|

SI: stoichiometric AFR, internal EGR, direct injection, TWC. HCCI: Homogeneous highly dilute charge auto-ignites through compression; lean AFT, limited to low and intermediate speeds and loads due to high cyclic variability and very high pressure rise rates (ringing); very low NOx and reduced pumping losses. SACI: Spark initiates a pre-flame consuming a portion of the charge, which makes the remainder of charge auto-ignite; stoichiometric AFT; internal and cooled external EGR; TWC. |

|||||

| Examples of Mode Switches | |||||

|

SI to HCCI: Cams phased from PVO (positive value overlap) to NVO (negative value overlap); cams switched to low lift; lean AFR. SI to SACI: Cams phased from PVO (positive value overlap) to NVO (negative value overlap), cams switched to low lift; change spark timing; add external EGR; stoichiometric AFR. |

|||||

a NOx increases relative to SI mode.

SOURCE: Derived from Nüesch et al. (2014a), Tables I and IV.

FIGURE M.2 Drive cycle simulations (FTP-75 Phase 2 and Phase 3) for fuel economy (mpg), engine out NOx, and tailpipe NOx with the SULEV limit of 20 mg/mi for a TWC equipped 2.0L multi-mode combustion engine.

SOURCE: Nüesch (2014b).

HOMOGENEOUS CHARGE COMPRESSION IGNITION (HCCI)

(ORNL and Delphi HCCI)

Oak Ridge National Laboratory (ORNL) and Delphi are investigating ways to expand the load where gasoline HCCI can be achieved (Szybist et al. 2013; Weall et al. 2012) on a single cylinder version of a 2.0L four-cylinder engine with the compression ratio increased to 11.85:1. Recent results have shown that the load for successful HCCI operation in a naturally aspirated engine is 3.5 bar (350 kPa) IMEP, but that this can be increased to 6.5 bar (650 kPa) IMEP with high levels of boost pressure up to 1.9 bar to provide additional air dilution as well as with the use of external EGR. Both of these methods reduce the reactivity of the systems so that more advanced fuel injection timing into the NVO is required. Under boosted conditions, NOx emissions remained low (< 0.01 g/kWh). A peak indicated thermal efficiency of 41.5 percent (ISFC = 199 g/kWh) was achieved at a load of 6.0 bar (600 kPa) IMEP. ORNL and Delphi caution that the indicated thermal efficiency on a multi-cylinder engine may be lower due to increased pumping work when using an actual turbocharge instead of air provided by the test facility.

ORNL and Delphi have defined numerous concerns with controlling the HCCI engine. The most significant concern is with transient operation (1) within the HCCI mode and (2) during transition from the HCCI mode to the SI mode. Within the HCCI mode, boost pressures have relatively long response times due to turbocharger lag lasting at least several engine cycles. HCCI operation has been found to be extremely sensitive to NVO duration, and this sensitivity increases as engine load increases. External EGR also has a relatively long response time. During mode switching from HCCI to SI combustion, the manifold pressure for HCCI is too high for SI combustion without a large spike in torque. This issue is more severe with boosting where SI combustion requires throttled manifold pressure.

As part of their research on HCCI combustion, ORNL and Delphi have provided the following assessment of HCCI and its outlook:

- “HCCI has yet to achieve its promise of high efficiency and low NOx emissions in a production engine despite the first published research papers appearing over 3 decades ago.”

- “The load limitation is becoming even more critical for the relevance of HCCI combustion given the trends of engine downsizing…. The duty cycle of the engine is changed under normal driving conditions, resulting in a reduced amount of time spent at the conditions applicable to HCCI combustion.”

GASOLINE DIRECT INJECTION COMPRESSION IGNITION (GDICI)

(University of Wisconsin and General Motors)

The University of Wisconsin and General Motors have investigated the use of 87 AKI regular grade gasoline in a high speed, direct injection, light-duty compression ignition engine to extend the low temperature combustion (LTC) regime to high loads (Ra et al. 2011). This system is termed GDICI for Gasoline Direct Injection Compression Ignition. The investigation found that GDICI operation of a light-duty engine was feasible under full load conditions of 16 bar IMEP, thereby significantly extending the low-emission combustion concept (Ra et al. 2012). The engine had a compression ratio of approximately 16.5:1 and was capable of multiple injections, specifically double and triple pulse injections. Both PM and NOx emissions were reduced to levels of about 0.1 g/kg-f while achieving an ISFC as low as 173 g/kW-hr with a triple pulse fuel injection strategy (Ra et al. 2012). The engine was found to be very sensitive to EGR ratio, initial gas temperature, and injection pressure. The results obtained rely on high EGR rates, produced with an inlet pressure of 2.8 bar and an exhaust pressure of 3.01 bar, which might not be realizable with currently available turbocharging systems. The multiple-injection methodologies are also very difficult to control due to their sensitivity in highly varying spatial and temporal patterns of charge mixing.

GASOLINE DIRECT INJECTION COMPRESSION IGNITION (GDCI)

(Delphi, Hyundai, Wayne State University, University of Wisconsin, Wisconsin Engine Research Center)

Similar to the University of Wisconsin and General Motors GDICI engine, Delphi and Hyundai are developing, under a DOE contract, a Gasoline Direct Injection Compression Ignition (GDCI) engine with the goal of achieving full time, low temperature combustion using multiple late injections over the entire engine speed-load map from idle to full load (Sellnau 2012). Complete mixing of all the fuel in a homogeneous charge is avoided with late injections since this would lead to rapid burning of the whole mixture. Regular unleaded gasoline (90.6 RON) and unleaded gasoline with 10 percent ethanol (91.7 RON) fuels are being used in this engine. Compression ratios between 14:1 and 16.2:1 were evaluated. Low temperature combustion was demonstrated from 2 to 18 bar IMEP (Confer et al. 2012). A minimum ISFC of 181 g/kW-hr was obtained with NOx emission less than 0.2 g/kW-hr. A multi-cylinder engine with the GDCI combustion system has been built and testing was underway as of May 2013 (Confer et al. 2013). Demonstration of this engine in a vehicle, including cold starting and transient operation, is scheduled to be completed by the end of the DOE contract in 2014. In September 2014, DOE awarded a $10M cost sharing project to Delphi to accelerate the development of the GDCI low temperature combustion technology.

This project includes more than just the development of the GDCI combustion system. In the 2012 DEER Review, Delphi and Hyundai demonstrated a 13.1 percent improvement in fuel economy due to parasitic loss reduction (crankshaft and camshaft rollerization, optimized oil pump, cooled EGR for reduced pumping losses, engine downspeeding, and exhaust heat recovery). A 13.4 percent improvement in fuel economy was achieved through improvements in the engine management system (which included GDI, VVT, cooled EGR, stop/start, and control algorithms).

REFERENCES

Christensen, M., A. Hultqvist, and B. Johansson. 1999. Demonstrating the Multi Fuel Capability of a Homogeneous Charge Compression Ignition Engine with Variable Compression Ratio. SAE World Congress. SAE 1999-01-3679.

Drangel, H., E. Olofsson, and R. Reinmann. 2002. The Variable Compression (SVC) and the Combustion Control (SCC) - Two Ways to Improve Fuel Economy and Still Comply with World-Wide Emission Requirements. SAE Technical Paper 2002-01-0996. doi:10.4271/2002-01-0996.

Kaahaaina, N., A. Simon, P. Caton, and C. Edwards. 2001. Use of Dynamic Valving to Achieve Residual-Affected Combustion. SAE Technical Paper 2001-01-0549. doi:10.4271/2001-01-0549.

Kulzer, A., T. Nier, and R. Karrelmeyer. 2011. A thermodynamic study on boosted HCCI: experimental results. SAE Technical Paper 2011-01-0905. doi:10.4271/2011-01-0905.

Mamalis, S., A. Babajimopoulos, O. Guralp, and P. Najt. 2012. Optimal Use of Boosting Configurations and Valve Strategies for High Load HCCI - A Modeling Study. SAE Technical Paper 2012-01-1101. doi:10.4271/2012-01-1101.

Nüesch, S., E. Hellstrom, L. Jiang, and A. Stefanopoulou. 2014a. Mode Switches among SI, SACI, and HCCI Combustion and their Influence on Drive Cycle Fuel Economy, 20014 American Control Conference (ACC), June.

Nüesch, S.P, A. G. Stefanopoulou, L.I. Jiang, and J. Sterniak. 2014b. Methodology to Evaluate the Fuel Economy of a Multimode Combustion Engine with Three-Way Catalytic Converter. Proceedings of the ASME 2014 Dynamic Systems and Control Conference, DSC2014-6146, October 22-24.

Olsson, J., P. Tunestål, G. Haraldsson, and B. Johansson. 2001. A Turbo Charged Dual Fuel HCCI Engine. SAE Technical Paper 2001-01-1896. doi:10.4271/2001-01-1896.

Olsson, J., P. Tunestål, B. Johansson, S. Fiveland, R. Agama, M. Willi, and D. Assanis. 2002.Compression ratio influence on maximum load of a natural gas fueled HCCI engine. SAE 2002-01-0111.

Ra, Y., P. Loeper, M. Andrie, R. Krieger, D. Foster, R. Reitz. and R. Durrett. 2012. Gasoline DICI Engine Operation in the LTC Regime Using Triple Pulse Injection. SAE Technical Paper 2012-01-1131, April.

Ra, Y., P. Loeper, R. Reitz, M. Andrie, R. Krieger, D. Foster, R. Durrett, V. Gopalakrishnan, A. Plazas, R. Peterson, and P. Szymkowicz. 2011. Study of high speed Gasoline Direct Injection Compression Ignition (GDICI) engine operation in the LTC regime. SAE Technical Paper 2011-01-1182, April.

Sellnau, M., J. Sinnamon, K. Hoyer, and H. Husted. 2012. Full Time Gasoline Direct-Injection Compression Ignition (GDCI) for High Efficiency and Low NOx and PM. SAE Paper 2012-01-0384, April.

Souder, J., P. Mehresh, J.K. Hedrick, and R.W. Dibble. 2004. A Multi-Cylinder HCCI Engine Model for Control. ASME 2004 Int. Mech. Engineering Congress and Exposition. Anaheim, California, November 13-19.

Stanglmaier, R., and C. Roberts. 1999. Homogeneous Charge Compression Ignition (HCCI): Benefits, Compromises, and Future Engine Applications. SAE Technical Paper 1999-01-3682. doi:10.4271/1999-01-3682.

Szybist, J., K. Edwards, M. Foster, K. Confer, and W. Moore. 2013. Characterization of Engine Control Authority on HCCI Combustion as the High Load Limit Is Approached. SAE Paper No. 2013-01-1665, April.

Wagner, R., J. Green Jr., J. Storey, and C. Daw. 2000. Extending Exhaust Gas Recirculation Limits in Diesel Engines. Oak Ridge National Laboratory, Internal Paper. http://web.ornl.gov/~webworks/cpr/pres/106938_.pdf.

Weall, A., J. Szybist, K. Edwards, M. Foster et al. 2012. HCCI load expansion opportunities using a fully variable HVA research engine to guide development of a production intent cam-based VVA engine: The low load limit. SAE Int. J. Engines 5(3):1149-1162. doi:10.4271/2012-01-1134.

Wheeler, J., D. Polovina, V. Frasinel, O. Miersch-Wiemers et al. 2013. Design of a 4-cylinder GTDI engine with part-load HCCI capability. SAE Int. J. Engines 6(1): 184-196. doi:10.4271/2013-01-0287.

Yang, J., T. Culp, and T. Kenney. 2002. Development of a Gasoline Engine System Using HCCI Technology - The Concept and the Test Results. SAE Technical Paper 2002-01-2832. doi:10.4271/2002-01-2832.

Yilmaz, H., O. Miersch-Wiemers, and L. Jiang. 2013. Advanced Combustion Concepts – Enabling Systems and Solutions (ACCESS) for High Efficiency Light Duty Vehicles. 2013 DOE Annual Merit Review, Arlington, Virginia, May 17. http://energy.gov/sites/prod/files/2014/03/f13/ace066_yilmaz_2013_o.pdf.

Yun, H., N. Wermuth, and P. Najt. 2010. Extending the high load operating limit of a naturally-aspirated gasoline HCCI combustion engine. SAE Int. J. Engines 3(1):681-699. doi:10.4271/2010-01-0847.

Yun, H., N. Wermuth, and P. Najt. 2011. High load HCCI operation using different valving strategies in a naturally-aspirated gasoline HCCI engine. SAE Int. J. Engines 4(1):1190-1201. doi:10.4271/2011-01-0899.

Zhu, G. 2013. Flex Fuel Optimized SI and HCCI. DOE Annual Merit Review.