6

Hydrolysate Treatment Criteria for Success and Decision Framework

As described in Chapter 2, the Blue Grass Chemical Agent Destruction Pilot Plant (BGCAPP) will use a number of processing steps to destroy the nerve agent-containing chemical weapons stored at the Blue Grass Army Depot, including (1) separating energetics and chemical agents from the munitions; (2) neutralizing the agents and energetics with sodium hydroxide, producing agent hydrolysates and energetics hydrolysates; (3) treating the blended agent and energetics hydrolysates in supercritical water oxidation (SCWO) reactors; and (4) treating the SCWO effluent using a reverse osmosis (RO)based water recovery system (WRS). The ultimate end products of these processes are

- Water from the WRS of adequate quality to be recycled for reuse as quench water in the SCWO units,

- Filter cake from aluminum filtration that meets regulatory requirements for land disposal,

- WRS brines that are planned to be sent offsite for disposal, and

- Decontaminated scrap metals that can be recycled.

The focus of this chapter is on the processing steps that follow the production of hydrolysates and removal of aluminum from the energetics hydrolysate stream—namely, the SCWO system and the WRS. Because the technologies used by these processes have never before been used to process energetics and agent hydrolysates, there are uncertainties about how well the end-to-end process will perform. In particular, although SCWO technology has been used previously to mineralize organic compounds, it has not been used on the same physical and time scales as will be the case at BGCAPP—that is, 1,000 lb/hr per reactor, 24 hours per day, 7 days per week, for up to 3 years. While one of the three SCWO reactors to be used at BGCAPP has been tested extensively for periods of up to several hundred hours, the other two have not. During testing, the reactor that was tested processed hydrolysate simulants rather than the actual blends of energetics and agent hydrolysates that will be produced at BGCAPP. Consequently, the performance of the SCWO and WRS systems at BGCAPP will not be known with certainty until these systems are placed in operation with actual hydrolysate feed.

CRITERIA FOR SUCCESSFUL HYDROLYSATE TREATMENT

Two types of criteria can be used to assess the successful treatment of hydrolysate: performance requirements and performance goals. Requirements are conditions that must be met under regulatory permits and under Chemical Weapons Convention treaty obligations. Goals are primarily oriented toward process performance and schedule and are conditions that should be met to enable satisfactory system performance.

BGCAPP staff and system contractors have described their efforts to ensure that BGCAPP complies with performance requirements and satisfies its performance goals as a full-scale pilot plant using first-of-a-kind technologies such as SCWO.1 If the criteria established for the SCWO system and the WRS cannot be met, and if this results in an increase to the munition processing time in BGCAPP, it will not be possible to achieve the risk reduction associated with destruction of the munitions stockpile in a timely manner.

Finding 6-1. The primary criteria for successful treatment of hydrolysate involve meeting regulatory and Chemical Weapons Convention requirements and meeting process performance and schedule goals for hydrolysate treatment.

The performance requirements and goals for the SCWO and WRS are based on the results of past testing, modeling, and analysis by BGCAPP and its contractors. The perfor-

______________

1 J. McArthur, environmental manager, BGCAPP, “Regulatory Requirements and Notifications for Offsite Shipment of Hydrolysate,” presentation to the committee on January 27, 2015.

mance requirements are summarized in Box 6-1 and major performance goals established by BGCAPP are listed in Box 6-2. The operational requirements outlined in Box 6-1 generally refer to requirements articulated in the Resource Conservation and Recovery Act (RCRA) Research, Development, and Demonstration (RD&D) permit documentation and, eventually, in the RCRA Part B permit. These requirements may become more specific and/or quantitative as systemization proceeds.

The established performance goals include those outlined in Box 6-2. These performance goals are examples provided by the committee and are based on documents provided to the committee by BGCAPP (BPBGT, 2014a; BPBG, 2013; NRC, 2013). Following systemization testing to reduce performance risks, these goals may be modified to more definitively quantify successful operations.

The committee anticipates that performance goals in particular may be modified as preoperational testing of the

BOX 6-1

Requirements for the SCWO and the WRS

- Meet conditions of the RCRA RD&D Permit for GB and the RCRA Part B Permit for VX for SCWO treatment of blended hydrolysates and for downstream treatment of SCWO effluent in the WRS;

- Satisfy Chemical Weapons Convention treaty requirements for agent and munition destruction; and

- Meet or exceed requirements set by the Program Executive Officer for Assembled Chemical Weapons Alternatives regarding efficiency, cost, and schedule.

BOX 6-2

Performance Goals for the SCWO and the WRS

Effectiveness Goals

- Reliably feed agent hydrolysate, energetics hydrolysate, and blended hydrolysate to the SCWO reactors.

- Processing rates for SCWO and WRS should be compatible with agent and energetics neutralization processing rates.

- Hydrolysates should have residence time of ≥10 sec in reactors at 1,150-1,200°F and 3,400 psig to ensure acceptable destruction of all organic species.

- Each SCWO reactor should have a nominal processing rate of 1,000 lb/hr and a target availability of at least 76 percent.

- To avoid filling the hydrolysate storage tanks, SCWO availability should be no lower than 55 percent.

- There should be no more than 200 ppm aluminum in blended hydrolysate feed.

- A eutectic mixture of salts and salt additives should be monitored to ensure that salts remain molten in the SCWO reactor. Current plans are to monitor salt composition before and after additive addition to confirm addition.

- SCWO effluent should meet release specifications for total organic carbon, pH, and conductivity.

- Desired time between liner replacement should be at least 300 hr for blended GB hydrolysate and at least 400 hr for blended VX hydrolysate.

- Desired time between thermowell replacement should be at least 75 hr for all blended hydrolysates.

- RO permeate for reuse as quench water for SCWO should meet the design objective of ≤500 mg/L total dissolved solids.

- RO reject should contain about 4 wt% salts.

- Sufficient recyclable RO water should be generated to meet SCWO quench water needs.

Schedule Goals

- SCWO ramp-up should begin no later than 2 months following start of BGCAPP operations and take no longer than 2 months to achieve full processing rate.

- SCWO should destroy 921,000 gal of GB hydrolysate, 166,000 gal VX hydrolysate, and 1,380,000 gal energetics hydrolysate in an operating period of 3 years.

Cost Goals

- All operating costs, including those for preventive and corrective maintenance, infrastructure, and materials, should be within available funding.

SCWO and WRS is carried out during systemization. Also, the performance goals may be evaluated under the RCRA RD&D permit, eventually becoming permit requirements once BGCAPP transitions to a RCRA Part B permit. A failure to meet the goals listed in Box 6-2 during systemization, while potentially serious in terms of impacts on process performance, schedule, and costs, would not necessarily mean that offsite transport of hydrolysate and SCWO effluent must be carried out. However, if any failure to meet these goals becomes apparent during operations, then modifications to the equipment and procedures used could be considered. If these modifications did not improve performance, then BGCAPP might need to consider offsite transport as an alternative to onsite treatment.

Finding 6-2. BGCAPP has established a set of initial performance goals for SCWO and the WRS. These are based on past testing with simulants, simulation modeling, and analyses and, based on experience to date with the SCWO and the WRS, appear to be a realistic starting point.

Recommendation 6-1. The ability to meet the initial performance goals established by BGCAPP for SCWO and the WRS should be verified as a result of testing during systemization.

Having multiple criteria to evaluate performance allows decision makers to document the extent of any underperformance. In other words, while a total failure of either the SCWO or the WRS is one possibility (although very unlikely), partial or temporary failures or periods of underperformance are more likely possibilities and their impacts on operations may be more difficult to define, predict, and address. For example, suppose that some of the initial performance goals are not met due to repeated equipment underperformance (e.g., a high failure rate of a high pressure pump or a higher than expected replacement rate for the SCWO liner), resulting in reduced SCWO availability and a longer operating schedule. Although these problems could most likely be addressed by equipment or operating procedure changes, they may incur increased operating costs. By having multiple performance goals, managers can take into consideration all of the impacts of actions taken to address problems and the trade-offs between meeting various criteria. Once multiple technical factors and contingency options have been evaluated using the performance criteria, the risk of system failure can be addressed. A graded evaluation of system failure risk would be useful to allow stakeholders to qualitatively rate the potential for overall program success at any point in the project. This type of graded evaluation would facilitate communication between stakeholders and allow them to track and document BGCAPP operations in a transparent and consistent way throughout the course of the project. Table 6-1, adapted from Review Criteria for Successful Treatment of Hydrolysate at the Pueblo Chemical Agent Destruction Pilot Plant (NRC, 2015) exemplifies a graded scale for success that could be used for evaluating SCWO and the WRS.

| Grade | Definition | |||

| 0 | Success is practically certain (very low probability of SCWO or WRS failure): Operations are proceeding as expected. No BGCAPP actions needed. | |||

|

1 |

High likelihood of success (low probability of SCWO or WRS failure): Actions should be taken by BGCAPP to prepare ahead of time for implementation of contingencies in the event of failures. For example, BGCAPP might begin to prepare permit modifications and planning documents. |

|||

|

2 |

Success is uncertain (moderate probability of SCWO or WRS failure): Actions should be taken to prepare for implementation of contingency operations. For example, BGCAPP might begin processing environmental documentation (permit modifications) and finalizing contingency plans, and begin to initiate changes in infrastructure to permit offsite shipment. |

|||

|

3 |

Success is unlikely with current operations (high probability of failure of the SCWO or the WRS): Actions are taken to accelerate the implementation of contingency operations and stakeholders are consulted. For example, construction of needed facilities such as new piping and loading docks is completed as quickly as possible; environmental approvals are expedited, if not already obtained; and contracts for shipment offsite and disposal at a permitted treatment, storage, and disposal facility are signed. |

|||

SOURCE: Adapted from NRC (2015).

A DECISION FRAMEWORK FOR DETERMINING SUCCESSFUL SCWO AND WRS OPERATION

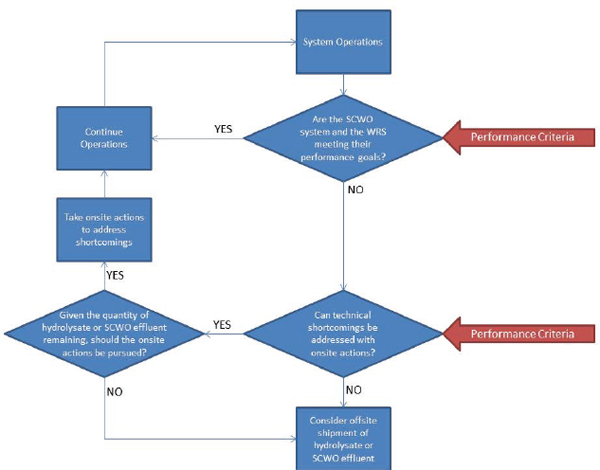

Figure 6-1 presents a possible decision framework for considering the possibility of offsite hydrolysate and/or SCWO effluent treatment. It shows the high-level considerations and decision types that drive major changes to any type of operations.

This decision framework allows decision makers to evaluate all available onsite options before considering offsite shipment of hydrolysate or SCWO effluent due to underperformance or failure of the WRS. Onsite options include the risk reduction actions (i.e., testing during systemization) that will be taken to improve SCWO and WRS performance; identification of alternative water sources for SCWO should the WRS not perform; and any onsite hydrolysate processing options other than SCWO, should they exist at BGCAPP. The SCWO and WRS processes will be continuously evaluated during plant operations, with routine corrective actions taken as needed. In all likelihood, not all of the performance goals will be met all of the time, for example, there may be

FIGURE 6-1 Decision framework for meeting performance goals.

process upsets, equipment may underperform or fail, and maintenance may take longer than expected. As a result, onsite actions may need to be taken to mitigate problems as they occur. Examples of mitigating actions include but are not limited to modifying the mix of additives to the SCWO, replacing equipment that underperforms or fails, reducing hydrolysate feed rates to the SCWO, carrying out modifications to mitigate fouling and scaling of the RO membranes in the WRS, and more frequent preventive maintenance activities. Possible mitigation actions are further discussed in Chapter 7. All of these actions would increase costs and could result in schedule delays but may be preferred to offsite shipment of hydrolysates. Other than a potential increase in risk associated with prolonged storage of munitions and hydrolysates as onsite mitigation is done, these actions should have less of an impact on BGCAPP operations, require few if any permit modifications, have little if any impact on the local stakeholders, and be consistent with the commitment to onsite treatment made by the Program Executive Office (PEO) for Assembled Chemical Weapons Alternatives (ACWA).

It should be noted that even if the SCWO or WRS underperform, substantial onsite capacity exists to store hydrolysate, allowing time for actions to be taken to improve SCWO or WRS performance while agent destruction continues. The two energetics hydrolysate tanks have a capacity of 550,000 gallons, or 40 percent of the total energetics hydrolysate production; the two GB storage tanks have a capacity of 600,000 gallons, or 65 percent of production; and the VX tank has a capacity of 80,000 gallons, or 48 percent of production.2 Even if SCWO were to not operate at all from the beginning, it would take 36 weeks of BGCAPP hydrolysis operation before the first tanks (the energetics hydrolysate tanks) are full.3 Also, SCWO availability, while expected to be about 76 percent, could be as low as 55 percent throughout the entire agent operations period before there would be an impact on BGCAPP agent hydrolysis operations.4 This is predicated on the availability of quench water of suitable quality, as discussed in Chapters 2 and 7.

______________

2 J. Barton, BGCAPP chief scientist, Battelle, “BGCAPP Agent and Energetics Treatment Processes,” presentation to the committee on January 27, 2015.

3 BGCAPP response via e-mail to “Eight NRC Questions for BGCAPP, Rev. 2,” received on February 27, 2015.

4 Ibid.

Factors Affecting a Decision to Move to Offsite Treatment

If the schedule for overall destruction of the munitions is delayed due to the inability of SCWO to destroy all of the hydrolysate, then following consultation with stakeholders, a decision may be made to ship excess hydrolysate offsite. A decision to terminate SCWO processing and to ship hydrolysate offsite will depend on the severity of problems with SCWO, on the time during BGCAPP operations when these problems occur, and also on the degree of confidence that BGCAPP staff have in the ability of SCWO to continue to perform adequately for the remainder of its operating life, following any onsite modifications to equipment and operating procedures to mitigate problems. If the performance problems are chronic and, in the judgment of the PEO ACWA and BGCAPP staff, are not amenable to correction, confidence in SCWO may be low enough that a decision to discontinue SCWO processing might be justified. If, however, the problems are deemed to be correctable with resulting longer term improvements in performance, a decision to incur the effort of making changes may be justified. These decisions will be made during SCWO and WRS systemization and operations and, to a great extent, will be based on the judgment of the PEO ACWA and BGCAPP staff and on their continued confidence in the performance of the SCWO and WRS technologies.

Even if onsite actions are taken that will allow continued operation of the SCWO reactors and of the WRS, decisions to take these actions will be made in the context of the schedule of overall BGCAPP operations, as indicated by the lower left decision diamond in Figure 6-1. A decision to replace or repair nonperforming equipment in order to comply with hydrolysate processing goals may be economically justified early in SCWO processing, when 2-3 years of such processing remains; a similar decision may not be justifiable a month or two before the end of SCWO processing.

Any decision to consider shipping hydrolysate offsite will need to take into account potential impacts on overall BGCAPP performance and compliance with permits and treaty obligations, as well as the stakeholder perspectives described in Chapter 3. Within BGCAPP, examples of the potential impacts of shipping hydrolysate offsite include worker risks associated with hydrolysate handling, the elimination of some solid waste streams (e.g., filter cake), and making provisions for the safe and effective transfer of large quantities of hydrolysate from the storage tanks to truck loading docks, including adding new piping, road infrastructure, signage, and room for loading.5 These impacts are discussed in greater detail in Chapter 7, in the Offsite Shipment as a Contingency Option section. The impacts will likely affect costs and the BGCAPP schedule and will need to be compared to similar impacts of making onsite changes to improve SCWO or WRS performance, if possible.

These timing considerations need to be part of the decision framework, as indicated in Figure 6-1. In the event that onsite changes cannot be made and offsite hydrolysate transport must be given serious consideration, it is prudent for longer-lead-time activities such as permit modification paperwork, preparations for making engineering and operational changes, and making contractual arrangements for offsite shipment to be carried out in advance, even if these activities will never be needed. Otherwise, the length of time needed to transition to offsite shipment, should it become necessary, could be significant.

While all stakeholders are interested in seeing BGCAPP operate successfully, not all, or even most, of these stakeholders are decision makers. The BGCAPP operations staff will be the decision makers for routine, day-to-day operations and any changes that may need to be made to these. For example, the BGCAPP operations staff would be the ones to address any problems that might be encountered in managing the composition of additives to the SCWO feed streams that are intended to control salt transport in the SCWO reactor. If an issue were to persist, the decision to pursue further alternatives might be elevated to BGCAPP management or to the PEO ACWA level and might include decisions such as more frequent replacement of the SCWO reactor liner, resulting in possible increased costs and schedule delays. Decisions having a greater impact, for example to discontinue using the SCWO reactors, would require stakeholder consultation to discuss alternatives.

PREOPERATIONAL TESTING FACTORING INTO THE DECISION PROCESS

To minimize the performance risks associated with the use of SCWO and the WRS at BGCAPP, a series of planned preoperational testing activities will be carried out during systemization. Systemization is defined as “the testing of all process components, subsystems, and systems, and the demonstration that the plant, procedures, and personnel are ready for toxic operations” (BPBGT, 2012). Systemization is divided into seven subphases (NRC, 2013):

- Presystemization

- Construction support

- Precommissioning

- Commissioning

- System startup

- System demonstration

- Optimization

The systemization process provides an opportunity to identify potential failure modes, test alternative operational and treatment strategies, and accumulate valuable SCWO and WRS operating experience prior to commencing hydro-

______________

5 J. Barton, BGCAPP chief scientist, Battelle, “Downstream Impacts to Plant Operations If Offsite Shipment Is Required,” presentation to the committee on January 28, 2015.

lysate processing. It is expected that this testing, with its careful data collection, evaluations of system performance, and any resultant mitigation actions will reduce negative impacts to the overall operations schedule and thus also reduce overall operating costs. It will also go a long way toward avoiding a complete failure of the SCWO and WRS.

To maximize the chances of successful systemization testing, a SCWO Working Group has been established at BGCAPP to identify gaps in SCWO knowledge and experience, provide recommendations for closing the knowledge gaps, and prepare a schedule of testing and related activities intended to ensure successful SCWO start-up and operation.6,7 These preoperational activities are intended “to address all SCWO system deficiencies identified by the [SCWO Working Group]” and will take place during the 6-month time period preceding the start of BGCAPP operations that has been allocated for the optimization subphase of systemization (BPBGT, 2014c). The activities will help to determine the likelihood that the SCWO system will meet its performance goals. They will also be used to identify and test modifications to the SCWO in case it underperforms during systemization.

The preoperational tests and related activities will address many of the technical factors that could lead to underperformance of the SCWO (BPBGT, 2014b). These activities will be carried out to address equipment issues that were identified in first-of-a-kind testing and to reduce both SCWO system risks (i.e., equipment and operational) and SCWO chemistry risks (e.g., hydrolysate feed, feed additives, aluminum removal, hydrolysate blending, and sulfur transport). Examples of the activities to be carried out include

- Evaluation of the effectiveness of sulfur blending and heating,

- Incorporate design changes from SCWO first-of-a-kind testing,

- Modification of facility control system software to reduce the incidence of unneeded shutdowns,

- Actions to improve the reliability of high-pressure air compressors,

- Testing of the integrated operation and maintenance of all three SCWO trains, and

- Review of aluminum levels in munitions and testing of reduced quench flow in the GB campaign based on aluminum levels in the hydrolysate.

These and other activities to reduce performance risk are discussed in greater detail in Chapter 7, where technical factors that could lead to SCWO and WRS underperformance are identified. For each factor, the potential impact on system performance is described, a performance grade based on experience to date is assigned, and alternative onsite contingency options are identified. Since preoperational testing to reduce performance risks will begin during the latter phases of systemization, it is premature to assign overall grades to the SCWO and the WRS.

The benefits expected from this testing include improvements in operator capabilities, safer operations, improved equipment reliability and availability, optimization of the mix of feed additives and salt transport, and reduction in materials costs (e.g., maximizing liner and thermowell life).

Finding 6-3. A preoperational SCWO testing program will be conducted during systemization. This program, developed by the BGCAPP SCWO Working Group, is intended to identify gaps in knowledge, experience, training, and equipment performance and to result in improved SCWO operations.

The committee notes that there is no WRS working group similar to the SCWO Working Group. The systemization plan for the WRS is at present very basic, with little of the detail shown in the SCWO Systemization Planning Report (BPBGT, 2014c). Examples of potential WRS issues, discussed in Chapter 7, include the likelihood of high solids loading to the multimedia filters, no apparent provision for clean backwash water, and unknown removal efficiency for the titanium dioxide particles. These types of issues will need to be examined as part of preoperational testing of the WRS units. Preoperational testing of WRS is critical to ensure that the system provides an adequate amount of quench water to the SCWO units.

Finding 6-4. No preoperational WRS testing program similar to the SCWO testing program presently exists—for example, one that describes potential performance gaps, recommendations for correcting these gaps, and a plan for implementing these recommendations.

Recommendation 6-2. BGCAPP should establish a WRS Working Group to develop a comprehensive preoperational testing program for the WRS that will identify gaps in knowledge, experience, training, and equipment performance and result in efficient WRS operations.

The preoperational test results will inform any operational changes and adjustments needed prior to hydrolysate treatment. Once actual hydrolysate processing begins, operational data will be collected to monitor performance of the SCWO and WRS against established performance criteria and to make further changes to operating procedures, process chemistry, and equipment where it is necessary and feasible to do so. If the SCWO and the WRS fail to satisfy their regulatory requirements and their performance goals despite the implementation of changes that are made following the risk

______________

6 G. Lucier, deputy chief scientist, BGCAPP, “Supercritical Water Oxidation Risk Mitigation Activities,” presentation to committee on January 28, 2015.

7 The composition of the SCWO Working Group is discussed in the SCWO Systemization and Likelihood of Insufficient Treatment section in Chapter 7.

reduction tests and despite the onsite contingency options discussed in Chapter 7, offsite hydrolysate shipment as a contingency option would need to be considered. This is also addressed in Chapter 7.

BPBG (Bechtel Parsons Blue Grass). 2013. Test Report for Supercritical Water Oxidation (SCWO) First-of-a-Kind (FOAK) Test (Preliminary Draft). SDN-24915-00-GQY-GGEN-00094. Richmond, Ky.

BPBGT (Bechtel Parsons Blue Grass Team). 2012. Systemization Implementation Plan (SIP), Rev. 0, August 30. Richmond, Ky.: Blue Grass Chemical Agent Destruction Pilot Plant Program Office.

BPBGT. 2014a. Characterization of Supercritical Water Oxidation (SCWO) Operating Requirements. 24915-00-30R-SCWO-00001. Richmond, Ky.

BPBGT. 2014b. Recommendations for Correcting Potential Gaps in Supercritical Water Oxidation (SCWO) Knowledge, Experience, and Performance. 24915-00-30R-SCWO-00003. Richmond, Ky.

BPBGT. 2014c. Supercritical Water Oxidation (SCWO) Working Group (SWG) Systemization Planning Report. 24915-00-30R-SCWO-00004. Richmond, Ky.

NRC (National Research Council). 2013. Assessment of Supercritical Water Oxidation System Testing for the Blue Grass Chemical Agent Destruction Pilot Plant. Washington, D.C.: The National Academies Press.

NRC. 2015. Review Criteria for Successful Treatment of Hydrolysate at the Pueblo Chemical Agent Destruction Pilot Plant. Washington, D.C.: The National Academies Press.