Engine Systems, Aftertreatment, Fuels, Lubricants, and Materials

Heavy-duty truck engines, emissions control technology, and fuels are central to all aspects of the 21st Century Truck Partnership’s (21CTP’s) vision of improved thermal efficiency, reduced oil dependency, low-exhaust emissions, lower cost, and improved safety. Although diesel engines used in new trucks are among the most efficient and clean on-road transportation power plants available today, in the opinion of the committee there are still opportunities for making them better. In some heavy-duty applications, gasoline spark-ignition engines are also used. Despite the fact that they are not as efficient as diesel engines, the lower cost of the engine system (which includes emissions control) and the lower cost of the fuel results in lower ownership and operating expenses relative to diesel power plants for their specific applications. However, spark-ignition engines being developed today are incorporating technologies that make them look more diesel-like (e.g., turbocharged direct-injection engines). Consequently many of the fundamental issues that need to be addressed to facilitate reduced fuel consumption in diesels are also of value for spark-ignition engines, and vice versa (e.g., spray characterization, vaporization and mixing phenomena, autoignition, combustion and emission kinetics, and cost-effective lean-emissions control systems).

This chapter covers the 21CTP programs in diesel engines, fuels and lubricants, aftertreatment systems, high-temperature materials, and health concerns raised by diesel engine emissions. In the mobility domain being addressed within 21CTP, the internal combustion engine and its associated emissions control systems and their fuels represent continuously improving, state-of-the-art transportation technologies, offering the lowest life-cycle costs for near-term propulsion technologies (21CTP, 2013, p. 33).

Commensurate with the evolution of heavy-duty (HD) engine and emissions control technologies during the first 15 years of the 21st century, vehicle fuel and lubricant technology is also changing. Petroleum-based diesel fuel regulations have been updated (e.g., lower sulfur limits) to allow for advanced emissions control components, a variety of biofuels have been developed for the purpose of extending transportation fuel supplies from renewable sources, and synthetic hydrocarbons have been produced from natural gas, recycled plastics, and organic refuse. In addition, new lubricant formulations have provided increased fuel efficiency for light-duty vehicles. Research on development of new fuel-efficient lubricant formulations for heavy-duty vehicles is in progress. It is also important to note that the supply of petroleum-based fuels from within the United States has increased significantly owing to the development of new hydraulic fracturing (“fracking”) and directional drilling techniques.

Nonpetroleum diesel fuels can be produced from renewable resources such as seed oils and animal fat, as well as synthesized from natural gas, biomass, oil sands, coal, and other resources. Cellulosic ethanol production facilities are being brought online using technology developed in part by Department of Energy (DOE) laboratories, although the volumes produced will be small. Facilities for the production of renewable diesel fuel from biomass resources continue to be developed, and the production and sale of biodiesel is growing in the United States at a modest rate.1 The use of syncrudes from tar sands in Canada has also grown. Fischer-Tropsch (F-T) diesel fuel, synthesized from natural gas, has been studied in conventional diesel engine tests in many laboratories to quantify its beneficial impact on emissions. Natural gas has also been described as a potential replacement for liquid petroleum fuels. This application is discussed in detail in a recent National Research Council (NRC, 2014) report. Future expanded use in medium- and heavy-duty vehicles will depend on lowering the cost of on-board fuel storage, as well as the cost of dispensing facilities. Lubricant properties and composition can have a beneficial effect on

________________

1 See Biodiesel Production Statistics at http://www.biodiesel.org/production/production-statistics.

vehicle fuel efficiency by reducing engine and driveline friction. Conversely, some engine oil components can adversely affect vehicle emissions by reducing the durability of exhaust emissions control devices. The sulfur, phosphorus, and ash content of lubricants needs to be minimized to prevent degradation of all types of catalytic devices.

Integral to the industries’ efforts to increase efficiency is the push to operate the engine at higher peak cylinder pressures. As oxides of nitrogen (NOx) aftertreatment systems continue to improve, there is a tendency for the industry to also push the in-cylinder temperatures higher because the improved aftertreatment can reduce the increased NOx. Consequently, propulsion materials are required that can withstand higher pressures and temperatures. These advanced materials are an enabler for cost-effective fuel savings. Given the long timeline for the identification, development, and implementation of new materials, it is essential that R&D continues without interruption.

ENGINE SYSTEMS PROGRAM: STATE OF TECHNOLOGY AND GOALS

As with any power generation device using chemical reactions to provide energy, both diesel and gasoline engines have thermodynamic constraints associated with the combustion process. These engines have additional practical constraints as well:

- Impracticality of extremely large expansion ratios,

- Inability to capture all of the useable energy in the heat rejection and exhaust flow,

- Inability to totally eliminate pumping work,

- The presence of friction due to rubbing contacts, and

- The work consumed in driving auxiliaries and accessories.

All of these constraints add up to limit the efficiency that can be obtained from practical, economical engines. Figure 3-1-1 in Box 3-1 delineates the partitioning of energy within the engine between that for the engine and that for the vehicle. The fundamental causes of these limitations are known, and the 21CTP works to coordinate and advise the federally-funded programs focused on minimizing these limitations with technologies that would be viable in the market. The specific goals of the Partnership within the Engine Systems and Fuels area are the following (21CTP, 2013, p. 33):

- Develop and demonstrate an emissions compliant engine system for Class 7-8 highway trucks that achieves 50 percent brake thermal efficiency (BTE) in an over-the-road cruise condition, improving the engine system fuel efficiency by about 20 percent (from approximately 42 percent thermal efficiency today) (by 2015).

- Research and develop technologies which achieve a stretch thermal efficiency goal of 55 percent in prototype engine systems in the laboratory. (This efficiency gain would be equivalent to an additional 10 percent gain in over-the-road fuel economy when prototype concepts are fully developed for the market.) (by 2015).

- Through experiments and models with FACE (Fuels for Advanced Combustion Engines) fuels and other projects, determine the most essential fuel properties, including renewables, to help achieve 55 percent engine brake efficiency (by 2014).

Implicit in all of the above goals is meeting emission regulations. In the NRC Phase 2 review this was a significant focus because new emissions regulations had just come into effect (NRC, 2012). These standards were met through the development and integration of new emissions control technologies into the engine system. This exemplified a transition to a new combustion system development paradigm—synergistic integration of engine and fuel combustion development to most effectively utilize aftertreatment system capabilities.

Exhaust Emissions

The considerable effort and research funding focused on improving emissions control systems is complementary to the development of engine combustion processes. To meet US2007 HD regulations, exhaust gas recirculation (EGR) combustion strategies were the primary NOx reduction technology, while diesel oxidation catalysts (DOCs) and diesel particulate filters (DPFs) were the primary hydrocarbon (HC), carbon monoxide (CO), and particulate matter (PM) reduction technology (EPA, 2000). A transition occurred to meet the US2010 HD regulations since EGR was not sufficient to efficiently meet the required 0.2 grams per brake horsepower-hour (g/bhp-hr) NOx tailpipe emissions levels. Selective catalytic reduction (SCR) was added to medium- and heavy-duty vehicles (MHDVs) to meet this new NOx requirement, while some engines were sold without SCR because some manufacturers used credits to meet an average NOx standard. Because the SCR can effectively remove NOx, the US2010 engines could then operate at higher engine-out NOx levels and run more efficiently. For Class 8 truck engines, this resulted in about a 5 percent reduction in fuel consumption for US2010 engines compared to US2007 engines. However, the trade-off required about 2 to 3 percent urea (contained in the diesel exhaust fluid [DEF]) relative to fuel (Charlton, 2010).

The requirements were adjusted again in 2013-2014, when onboard diagnostics (OBD) (2013) and the first phase of HD greenhouse gas (GHG) regulations (2014) were introduced. In conjunction with this, engine and emissions control systems were further optimized for better performance and/or reduced cost.

Now, emissions control technology needs further understanding to optimize performance, to reduce cost and fuel consumption, and to meet any future regulatory tightening.

BOX 3-1

Typical Energy Flows in an Engine

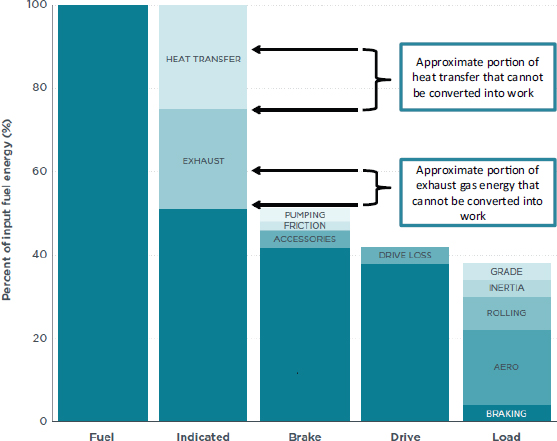

Figure 3-1-1 (Figure 2 from Delgado and Lutsey, 2014) shows a typical partitioning of the energy flows within the engine as a result of the different phenomena associated with burning the fuel to producing work. Such displays of the energy flow are very useful when interpreted from the thermodynamic perspective that different forms of energy have different potentials to produce work. Practically speaking, all of the energy in a typical hydrocarbon fuel is useful, so the fuel energy input on the left-hand side of the figure could, theoretically, be converted into useful work. Thus it is a good reference against which to evaluate engine performance.

The second column from the left shows the energy flows associated with phenomena occurring in the cylinder. Within the cylinder the energy flow is partitioned between leaving the cylinder at the piston face as indicated work, the desired outcome, and leaving the cylinder via heat transfer or within the exhaust gas. It is also known that any energy transformation process, like combustion, that is used to release the energy bound within the fuel will have losses, or irreversibilities, associated with it. For the case of chemical reactions this irreversibility is a degradation of useable fuel energy into energy that can no longer be converted into work. This nonusable energy becomes part of the heat transfer and exhaust flow leaving the cylinder. (Approximate proportions of this nonuseful energy within the heat transfer and exhaust have been marked on the figure.a) Thus, even though there is significant energy flow leaving the cylinder as heat transfer and exhaust flow, it is not possible to convert all of that energy into work using additional energy conversion devices such as waste heat recovery, which use the heat transfer and/or exhaust flow as the energy input.

This is well understood by the researchers and engineers in the technical community and is instrumental in determining the cost-effectiveness and technical viability of incorporating work- producing devices onto the engine that use the heat transfer or exhaust flow as energy inputs.

The final three columns in the figure show what happens to the Indicated work that leaves the piston. Some of the work transferred from the cylinder into the piston must be used to affect the gas exchange within the engine (pumping), some must be used to drive auxiliaries and accessories, and some is dissipated as friction. Even though these are relatively small, any reduction in the amount of work expended on these processes represents work that stays on the shaft and makes it to the drivetrain. The work that is ultimately delivered to the flywheel is called brake work. An analogous statement can be made for the energy transfer through the drivetrain to the wheels, the fourth column. Consequently the work that makes it through the drivetrain to the wheels is called drive work.

Finally, the last column shows how the drive work is used to move the vehicle once it makes it to the wheels. The extent to which the categories in this column can be reduced directly impacts the amount of work necessary to move the vehicle.

This figure helps to put in perspective the research activities associated with the 21CTP. In regard to the Engine, Aftertreatment, Fuels and Lubricants, and Materials subprograms in 21CTP, the Indicated and Brake columns are the relevant energy partitions. In general, one would like to maximize the work that is obtained by the expansion process, and minimize the uncontrolled transfer of energy from the cylinder via heat transfer and exhaust flow. Within the engine itself, minimizing the necessary expenditure of work for pumping and driving auxiliaries and accessories is important and yields immediate benefit in terms of brake work, as does any reduction in the friction.

________________

a Approximations determined from exergy balances on the energy transformation processes within an internal combustion engine (see Caton, 2000).

Engine Systems Program

The industry has demonstrated great technical competence in reducing fuel consumption and meeting the 2010 emission standards while making a product that meets customers’ reliability and cost of operation goals and also the Environmental Protection Agency’s (EPA’s) 2014 GHG standards. What facilitates the industry’s achievements is the continued progress in understanding the technical subtleties of the thermodynamic, chemical, and physical processes involved in the conversion of the fuel energy into power. As the demands for higher efficiency and low emissions grow, so too does the need for an increasingly deeper understanding of the fundamentals. This is the principal deficit that the Engine Systems program of the 21CTP is facing as it works to achieve its efficiency goals (21CTP, 2013, pp. 40-41). The challenges specifically relating to engine system fundamentals are these:

- Inadequate understanding of the thermodynamic, chemical, and physical fundamentals of combustion and the consequent inability to incorporate them into robust simulation capabilities, especially across the full range of combustion approaches, from conventional diesel combustion to new low-temperature combustion (LTC) regimes.

- Inability to optimize in-cylinder combustion processes for efficiency via synergistic coupling of enhanced aftertreatment system performance.

- Lack of exploration and development of innovative engine processes and architectures.

FIGURE 3-1-1 Hypothetical energy audit for Class 8 truck. SOURCE: Delgado and Lutsey (2014). Attribution-ShareAlike 3.0 Unported.

The above challenges motivate the fundamental research and development projects in the 21CTP.

Although SuperTruck is discussed at greater length in Chapter 8, its engine development activities in SuperTruck are discussed here separately, before the individual DOE and Department of Defense (DOD) engine programs. SuperTruck’s engine programs interface closely with the 21CTP fundamental engine projects and are synergistic with them in achieving two of the Engine Systems’ program goals: the 50 percent BTE demonstration and the technical roadmap to 55 percent BTE. The discussion as a whole is separated into activities directed toward demonstrating 50 percent BTE on the road in a truck (Goal 1), which is a SuperTruck engine accomplishment, and then covers the activities showing a technical pathway to 55 percent BTE (Goal 2). The discussion of the SuperTruck engine teams’ work toward achieving Goal 2 segues into the discussion of the individual DOE and DOD programs nicely because of the extent to which the SuperTruck programs will be relying on the advancements made within the individual DOE and DOD projects to achieve the 55 percent goal. This is the sequence in which the research activities are discussed.

Research Budgets for the SuperTruck Program

Funding for the SuperTruck engine and vehicle program comes from two sources: the American Reinvestment and Recovery Act (ARRA) and the DOE Vehicle Technologies Office (VTO). The Cummins-Peterbilt and Daimler programs are funded through the ARRA, while the Volvo and Navistar programs are funded through the DOE VTO. There is no specific budget line item for engine development

TABLE 3-1 Estimated Federal Budgets for SuperTruck Engine Research (millions of dollars)

| SuperTruck Team | Engine Research Budget | Total Federal Budget for SuperTruck |

| Cummins-Peterbilt | 15.5 (estimate by 21CTP) | 38.8 |

| Daimler | 15.8 (estimate by 21CTP) | 39.5 |

| Navistar | 12.7 | 37.3 |

| Volvo | 7.6 | 17.7 |

within the ARRA-funded programs, Cummins-Peterbilt and Daimler. However the Partnership did provide estimates to the committee. These estimates and the engine research budgets for Volvo and Navistar, along with the total budgets of federal dollars, are given in Table 3-1.

Progress Toward Meeting Engine Goals 1 and 2

The demonstration of 50 percent BTE in a truck on the road involved integrating laboratory-proven technologies into a vehicle powertrain system, with an eye toward assessing the viability of those technologies for commercial introduction. The SuperTruck program was developed around this goal. Accomplishments in this effort are highlighted here via a table of technologies used, which has been extracted from the more comprehensive Table 8-1 given in Chapter 8. The extension of this effort to reach 55 percent BTE entails a fundamental research program to explore and quantify the potential of using advanced combustion/fuel and engine technologies that are currently being explored within research laboratories, with an eye on showing technical potential. The activities of the SuperTruck teams are closely aligned with, and will depend on the results of, the individual research programs within 21CTP. The approaches each team is taking toward this goal are summarized in the paragraphs below.

Goal 1: Develop and demonstrate an emissions-compliant engine system for Class 7-8 highway trucks that achieves 50 percent brake thermal efficiency in an over-the-road cruise condition.

Status: The Partnership has successfully achieved this goal. As shown in Table 3-2, two of the four SuperTruck teams have successfully demonstrated brake thermal efficiencies greater than 50 percent in on-road tests using commercial, ultra-low-sulfur diesel fuel.

Both Cummins-Peterbilt and Daimler are in the final stage of their SuperTruck program. Their programs end in 2015, whereas Volvo and Navistar are in earlier phases of their programs. Both the Volvo and Navistar projects have completion dates in 2016. Their not having achieved Goal 1 is attributed to not being as far along in their programs as the other two teams. It is expected that they will meet their goal of 50 percent by the time they will have completed their work.

TABLE 3-2 Achievement of Goal 1, 50 Percent Engine BTE at Cruise, by the Four SuperTruck Teams

| SuperTruck Team | Status | Complete? |

| Cummins-Peterbilt | 51% engine + WHR BTE demonstrated | Yes |

| Daimler | 50.2% engine + WHR BTE demonstrated | Yes |

| Volvo | 48% engine + WHR BTE demonstrated | TBD |

| Navistar | 47.4% BTE engine only, WHR being considered | TBD |

NOTE: WHR, waste heat recovery.

Table 3-3, which is extracted from Table 8-1, shows the engine and combustion technology that the respective SuperTruck teams are using in the 50 percent BTE engine. Each of the technologies being used can be categorized in terms of the second and third columns of the energy partitioning Figure 3-1-1. Each technology is used either to enhance the work extraction or to reduce the work expenditure for pumping, friction, accessories, and auxiliaries.

Achieving 50 percent BTE in a truck on the road, Goal 1 represents the successful integration of laboratory-proven technologies into a complex vehicle powertrain system, and the committee congratulates the Partnership and SuperTruck teams for this accomplishment.

Goal 2: Research and develop technologies that achieve a stretch thermal efficiency goal of 55 percent in prototype engine systems in the lab (by 2015).

Status: To date this goal has not been achieved, but progress has been good. It is anticipated that by the end of each of the respective SuperTruck programs, the teams will have developed a technology pathway for achieving 55 percent BTE. It is expected that the pathway will be combinations of individual technologies that are either demonstrated in the laboratory or simulated via advanced computational fluid dynamic (CFD) models.

Approaches to Meeting Goal 2

During the review, the committee heard presentations from the SuperTruck teams at its meetings, and made site visits to Cummins (August 28, 2014), Daimler (November 24, 2014), and Volvo (December 5, 2014). Achieving 55 percent BTE with a Class 7 or a Class 8 HD truck engine will be extremely challenging. The aggressiveness of the SuperTruck research programs is consistent with the high risk approach that needs to be pursued if this goal is to be

| Technology | Cummins- Peterbilt | Daimler | Volvo | Navistar |

| Base engine | 15 L inline 6, no downsizing | 10.7 L inline 6, downsized from 15 L baseline | 11 L inline 6, downsized from 13 L baseline | 12.6 L, I-6 baseline and SuperTruck |

| rpm @ 65 mph | ~1,180 | ~1,300 | Data not provided | ~1,050 or 1,125 |

| Engine efficiency features | High-efficiency turbo, low friction seals, lower power oil pump, low viscosity. Oil, cylinder kit friction reduction, higher PCP, cal. optimization, overall 30% FMEP reduction | Turbo match, optimized liner cooling, variable speed water pump, low viscosity. Oil, piston friction reduction, 15% higher PCP, cal. optimization | High-efficiency turbo, variable coolant and oil pumps, reduced friction pistons, rings, and liners, low viscosity oil, improved thermal management | High-efficiency turbo, elevated coolant temperature, low friction power cylinder, thermal insulation, reduced air flow restrictions |

| Fuel system | HPCR with reduced parasitic fuel pump | Amplified HPCR | HPCR (converted from unit injector baseline) | Amplified HPCR |

| Combustion refinement | Very high CR, piston bowl, injector match, 4.3 g/hp-hr engine-out NOx, conventional diffusion burn | High CR, piston bowl, low EGR, injector match, conventional diffusion burn, higher engine-out NOx, model- based controls | Increased CR, advanced piston bowl design, conventional diffusion burn, same engine-out NOx as US2010 | Looking at 6 g engine-out NOx, higher injection press, revised piston bowl and high CR, evaluating diesel and dual fuel options, low swirl |

| Electric drive components | Electric HVAC | Electric dual-zone HVAC | Electric HVAC, 48 V | |

| Waste heat recovery | Rankine cycle, R245 working fluid, mechanical drive, uses EGR and exhaust heat, turbine expander | Rankine cycle, ethanol working fluid, electric drive, uses EGR and exhaust heat, scroll expander | Turbocompound plus Rankine cycle with ethanol working fluid, mechanical drive, uses EGR and exhaust heat | Turbocompound, Rankine cycle, and e-turbo are being evaluated |

| Aftertreatment | High conversion efficiency, low back pressure | High conversion efficiency, low back pressure | High conversion efficiency, low back pressure | High conversion efficiency, low back pressure |

| Turbo technology | High efficiency VG | Asymmetric | High efficiency | Possible e-turbo |

| EGR loop | Reduced flow and restriction HPL | HPL | Reduced flow HPL | Reduced flow and restriction HPL |

| Variable valve actuation | No | No | No | Being evaluated |

| Cooling system | Conventional cooling package, engine-driven fan | Angled cooling package, hydraulic motor fan drive, active grill shutters | Variable speed engine-driven fan, variable-speed cooling pump | 3-speed engine-driven fan, electronic stat, high coolant temp., variable-speed cooling pump, variable coolant pressure |

| Accessory power demand | Clutched air compressor with active controls, clutched power steering pump with reservoir, cab insulation, solar reflective paint | Clutched air compressor with active controls, low-energy power steering, look-ahead smart alternator, LED lighting, cab insulation | Variable displacement oil pump, clutched air compressor with intelligent dryer control, accessories run on deceleration/coasting | |

NOTE: FMEP, friction mean effective pressure; PCP, peak cylinder pressure; HPCR, high-pressure common rail; CR, compression ratio; HVAC, heating, ventilation, and air conditioning; LED, light-emitting diode; EGR, exhaust gas recirculation; VG, variable geometry; HPL, high-pressure loop.

achieved. From a generic perspective, there is similarity in the overall approach being followed by the four teams. All of the programs are pursuing continued reduction in friction and pumping, more effective air boosting systems, smaller auxiliary and accessory loads, and improvements in their waste heat recovery (WHR) systems and are investigating advanced low-temperature combustion (LTC) approaches. All of the teams are also engaged with the aftertreatment technical community looking to capitalize on further improvements in exhaust gas treatment of criteria pollutants that will allow further optimization of the engine-aftertreatment combination. However, the details of how these technologies will be applied and the gains from each differ from program to program.

The basic premise of LTC processes stems from an understanding of the energy flow partitioning presented in Box 3-1 at the beginning of this chapter. If the in-cylinder temperatures can be kept low during the closed portion of the cycle, the thermal efficiency will increase. This is explained by the dependence of the closed-cycle efficiency of the engine on the ratio of the specific heats of the gases (γ = cp/cv) in the cylinder.2 Lower temperatures and leaner mixtures within the cylinder result in values of gamma (γ) that are larger than when the temperatures are higher or the mixtures are stoichiometric. A larger average gamma results in more work being extracted during the closed cylinder portion of the engine’s mechanical cycle, which subsequently decreases the amount of useful energy leaving the energy in the exhaust. Furthermore, lower in-cylinder temperatures also result in less heat transfer from the cylinder.

The challenge with trying to drive the in-cylinder temperatures down is that the burning velocity of the fuel and air mixture decreases as the temperature decreases, and in trying to push this concept to the limit, the time necessary to complete combustion gets too long and engine efficiency and emissions suffer. The overview of the individual teams’ programs shows that shortening the combustion interval is an important aspect of achieving the 55 percent target. The general approach in LTC strategies is to keep combustion durations short by minimizing the need for flame propagation through volumetric combustion via autoignition. Achieving this type of combustion is highly dependent on the chemical and physical characteristics of the fuel and requires very precise control of the thermokinetic state of the air–fuel mixture within the cylinder. Understanding the fundamentals of these phenomena is prerequisite to success and is a principal focus of the individual DOE engine combustion research projects in 21CTP.

Researchers have proposed many different approaches for achieving LTC. They will typically name their specific approach with an acronym, such as HCCI (homogeneous-charge compression ignition), PPCI (partially-premixed-charge compression ignition), RCCI (reactivity-controlled compression ignition)—often more generically referred to as dual-fuel combustion—and many more. One advantage of the dual-fuel approach is that using varying ratios of two fuels with different degrees of reactivity gives the operating system an additional and powerful combustion phasing control lever. Indeed the dual-fuel approach is being investigated by most of the SuperTruck teams, although to date they have not divulged the specific fuel combinations they are currently exploring.

If successfully achieved, LTC strategies yield higher closed-cycle efficiency that minimizes heat loss from the cylinder and exhibits low NOx and particulate emissions, but at the same time introduces concern about unburned hydrocarbon and carbon monoxide (CO) emissions. Consequently it is likely that aftertreatment will still be required, if not for PM and NOx, then for HC and CO, and the aftertreatment systems will most likely need to operate at lower temperatures than current systems today.

Cummins

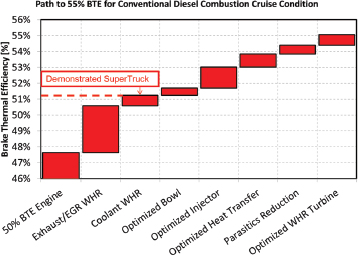

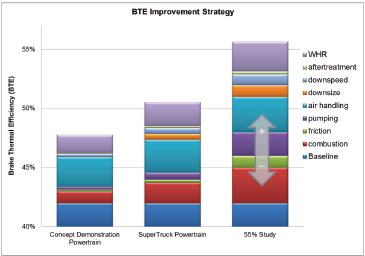

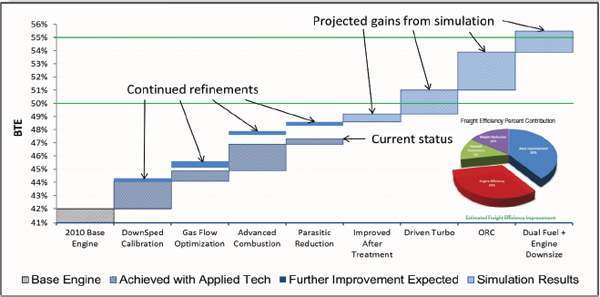

The Cummins approach to the 55 percent BTE requirement is described in its 2014 DOE Annual Merit Review (AMR) presentation (Project ACE057) (Koeberlein, 2014). Two basic combustion strategies are under evaluation. Both approaches will pursue downspeeding the engine and operating at higher loads to get the requisite power. The first approach, which uses relatively conventional diesel combustion, is summarized in Figure 3-1.

The approach embodied in the technologies listed in Figure 3-1 represents a continued effort at improving conventional diesel combustion. The optimized bowl, injector, and heat-transfer efforts represent combustion improvement. The team is performing simulation and experiments with the objective of shortening the combustion interval as much as possible to maximize the work from expansion and minimize heat loss. As shown in Figure 3-1, the objective is to gain approximately three percentage points improvement in engine BTE through this combustion improvement.

In addition to trying to further improve conventional diesel combustion, the Cummins-Peterbilt team is also pursuing a dual-fuel LTC strategy it calls alternate fuel compression ignition (AFCI). Simulation and laboratory results indicate that there is sufficient potential for improvement from this combustion strategy to merit further investigation. The

FIGURE 3-1 Cummins-Peterbilt SuperTruck team’s projected incremental gains to get from its current 50 percent BTE engine to 55 percent BTE. SOURCE: L. Kocher, “SuperTruck 55% BTE Update Technology and System Level Demonstration of Highly Efficient and Clean, Diesel Powered Class 8 Trucks,” presentation to the committee, Columbus, Indiana, August 28, 2014, slide 20. SuperTruck Annual Merit Review Presentations, Cummins, Inc.

________________

2 Cp, specific heat at constant pressure; Cv, specific heat at constant volume.

FIGURE 3-2 Cummins-Peterbilt SuperTruck team’s analysis and results using AFCI at 1,000 rpm and 10 bar. SOURCE: L. Kocher, “SuperTruck 55% BTE Update Technology and System Level Demonstration of Highly Efficient and Clean, Diesel Powered Class 8 Trucks,” presentation to the committee, Columbus, Indiana, August 28, 2014, slide 24. SuperTruck Annual Merit Review Presentations, Cummins, Inc.

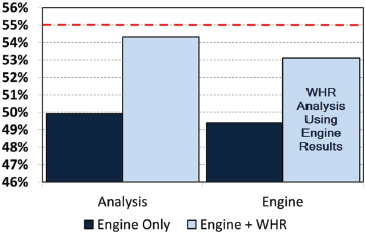

team’s current results comparing both the predictions and actual engine results are shown in Figure 3-2.

The simulation does a reasonably good job of predicting the engine-only performance. However, because the exhaust energy was lower with AFCI, the work output from the WHR system in the exhaust was lower than that from conventional diesel combustion. The Cummins AFCI approach shares challenges with other LTC strategies, including the difficulty of running the engine above 10 bar brake mean effective pressure (BMEP). Cummins plans additional work to find ways of increasing the BMEP limit. It expects the efficiency of the engine to improve as it achieves higher loads with AFCI.

Daimler–Detroit Diesel3

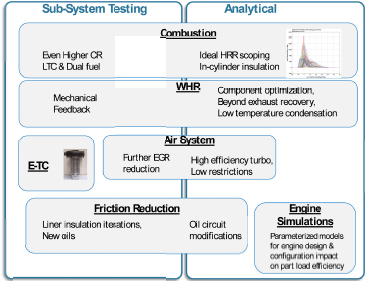

The Daimler approach to the 55 percent BTE requirement is described in the team’s most recent AMR presentation (Project ACE058) (Singh, 2014). The approach plans to use both downspeeding and downsizing of the engine. An overview of its 55 percent BTE scoping activities is presented in Figure 3-3.

Additional work on liner cooling optimization is ongoing with the Massachusetts Institute of Technology (MIT), as well as the development of new lubricants and optimization of the oil pump and lube circuits to reduce lube system power demand and further upgrades to the WHR system. Daimler-Detroit Diesel believes it may be possible to improve the WHR system contribution from 2.4 points of engine BTE (achieved in the final SuperTruck demonstration engine) to 3.6 points of BTE but acknowledges that this level of performance may prove impractical with currently available technology. As with other teams it is exploring the potential of LTC for shorter combustion intervals and lower heat loss. The team is working with the Oak Ridge National Laboratory (ORNL) on a dual-fuel engine approach, using natural gas as one of the fuels.

FIGURE 3-3 Overview of Daimler SuperTruck team’s approach to achieving 55 percent BTE. SOURCE: Singh (2014). NOTE: E-TC, electronic turbocharger; CR, combustion ratio; LTC, low-temperature combustion; HRR, heat release rate; WHR, waste heat recovery; EGR, exhaust gas recirculation.

Volvo

To achieve the target of 55 percent BTE, Volvo is pursuing different engine architectures, alternative combustion cycles, and fueling optimization (Project VSS081) (Amar, 2014). These approaches will be pursued in a downsized and downspeeded engine.

New combustion concepts like PPCI and RCCI have demonstrated very high indicated efficiencies as well as low engine-out emissions. However, these kinds of combustion are significantly more difficult to simulate than normal diesel diffusion combustion. So, enhancements to the simulation capabilities are under way. A transported probability distribution function (PDF) combustion model has been developed to address this challenge, which is backed up by extensive testing. A cetane ignition device equipped with optical access is used for testing of fuels and validation of spray and chemical kinetics submodels. Figure 3-4 shows a stack chart of where Volvo believes the improvements in engine processes can be made to achieve 55 percent BTE.

The Volvo SuperTruck program is leveraging Sandia National Laboratory’s Engine Combustion Network to validate the CFD subprograms it is developing. The team stated

________________

3 Detroit Diesel Corporation is a subsidiary of Daimler Trucks North America.

FIGURE 3-4 Volvo SuperTruck team’s stack chart of the incremental improvements in engine technology to reach 55 percent BTE from a concept demonstration powertrain. SOURCE: A. Greszler, “SuperTruck Development and Demonstration of a Fuel-Efficient Class 8 Highway Vehicle,” presentation to the committee, May 14, 2014, slide 14. Volvo Group Truck Technology.

that it is exploring a different engine architecture and running its heavy-duty engine on gasoline-like fuels, simulated as an 87 octane primary reference fuel blend.

Navistar

Navistar is also pursuing an aggressive research path in the technologies it has identified to achieve 55 percent BTE. Its approach includes downspeeding. Navistar’s simulation predicts that through continued improvements of the aftertreatment system, which will allow more efficient combustion phasing, advanced turbomachinery, thermal barrier coating, dual-fuel combustion with variable valve actuation, continued reduction in friction and parasitic losses, and incorporating an advanced organic Rankine cycle (ORC) as a WHR system, it will be able to achieve the 55 percent BTE target. An overview of the incremental gains it expects from these technologies is shown in Figure 3-5.

Progress and Fundamental Programs Toward Overcoming Technical Barriers to Achieving 55 Percent BTE (Goal 2)

As seen in the descriptions of the SuperTruck team’s activities, advanced combustion strategies and sophisticated CFD modeling are essential parts of their technical roadmaps to achieving 55 percent BTE. The requisite understanding of the fundaments of advanced combustion strategies, like LTC, and incorporation of that understanding into usable CFD codes is the focus of the individual research programs within 21CTP. Success in achieving Goal 2 will depend on the advancements being made within the individual 21CTP research programs.

The Partnership has increased its emphasis on incorporating their research results into simulations or conceptual models that can be used by stakeholders for either predictive simulation or for comparative analysis with laboratory results to gain an understanding of the data that is not achievable through routine analysis. Additionally, the development of phenomenological models, which conceptually model the different processes occurring within the engine, helps others in the field to understand the differences between processes that appear to be similar globally but are fundamentally different, e.g., different LTC approaches relative to conventional diesel or direct ignition combustion.

The 21CTP has been successful in its engine research efforts to increase BTE. Advanced CFD is being used extensively by all of the SuperTruck engine teams. Optimization of the combinations and interactions of the myriad of parameters that affect the efficiency and emissions of the complex engine systems could not have been done without advanced CFD. Details of the fuel spray breakup, how it depends on what is occurring inside the nozzle, and how the fuel then mixes with the combustion chamber gases and is impacted by the fluid motion within the chamber, along with the influence of the composition of the chamber gases on the nature of the energy conversion process, all impact the efficiency and emissions of the engine. As the industry tries to push the limits of efficient engines by lowering the engine-out emissions, an understanding of these details, as well as other phenomena like the localized boundary layer heat transfer, the state of thermal gradients within the chamber, and the evolution of the fuels’ reactivity, becomes critical. CFD simulations with accurate submodels of the thermodynamic, chemical, and physical processes occurring in the engine and the aftertreatment systems enable these activities, and will need to be advanced further to facilitate achieving Goal 2, 55 percent BTE.

DOE programs have made significant contributions to the capabilities of the CFD programs. The continued development of more accurate, high-fidelity, kinetic routines for different fuel mixtures has been an important contribution. An industrial collaborator, Convergent Science, has licensed a kinetic solver developed through DOE research programs and is now using its code to do simulations with these advanced kinetic routines and fluid mechanic models for many in the engine industry. Argonne National Laboratory (ANL) is preparing to launch a program called the Virtual Engine Research Institute and Fuels Initiative (VERIFI),4 an organization that will be available to industry and that integrates high-performance computing, fuel chemistry, and combustion science and engine performance with some of the world’s fastest supercomputers. This organization will facilitate simulations that industry does not have the capital resources to do but that are important to achieving the goals

________________

4 For more on the VERIFI program at ANL, see http://verifi.anl.gov/.

FIGURE 3-5 Navistar SuperTruck team’s projected improvements in the engine technologies that will enable them to achieve 55 percent BTE. SOURCE: R. Nine and R. Zukouski, “SuperTruck–Development and Demonstration of a Fuel-Efficient Class 8 Tractor & Trailer Vehicle System,” presentation to the committee, November 18, 2014, slide 12.

set for engine systems relating to reduced fuel consumption and lower emissions.

Because of the importance of CFD as a development tool, along with the rapid pace at which computing technology is changing, DOE held a high-performance computing workshop on August 19-21, 2014. The purpose of the workshop was to get feedback from users and stakeholders on the best way to integrate new research results into simulations. Discussion was on topics such as these: Is there a preferred platform by which newly developed subprograms can be publically demonstrated and critiqued? What is the appropriate role of the government in this arena? The outcomes of that workshop were not available at the writing of this report, so they could not be included in this report.

Finally, an anecdote about the success of the 21CTP: During a site visit to the Tank Automotive Research, Development and Engineering Center (TARDEC) on November 24, 2014, a subgroup of the committee was told that results from the 21CTP have been influential in production decisions on light- and medium-armored vehicles and on decisions about power plants and powertrains.

Individual DOE and DOD Engine Systems Projects and Funding Levels

As part of the review process, the Partnership supplied to the committee a listing of the projects in its research portfolio. The projects from that list that the committee has interpreted as falling within the advanced engines arena are listed in Table 3-4. They include the TARDEC Automotive Research Center, run by the University of Michigan, and the DOE programs that are focused on advancing the fundamental understanding of engine processes. As mentioned above, a committee subgroup visited TARDEC as part of the fact-finding effort. During that visit, the subgroup was told about an advanced engine program in which innovative combustion processes and an alternative engine architecture are being assessed as a high-power-density engine with improved efficiency. The presentation on this work indicated that the opposed-piston two-stroke diesel engine met or exceeded program requirements for improved BTE, heat rejection to coolant, power density, and a 50-hr durability test. In the request for proposals for the next phase of this development program, DOD specifically required the opposed-piston architecture. The results of the proposal evaluations have now been made public. TARDEC awarded two contracts, one to the Achates-Cummins team and the other to the AVL group, to design, build, test, and evaluate advanced single-cylinder (SC) opposed-piston engine technology for potential future combat vehicle applications. Both teams were given the same combat engine performance parameter targets that are representative of multicylinder engine performance expectations. The performance parameters include these:

- Specific heat rejection of 0.45 Kw/kw, which includes charge air cooling, water jacket cooling, and engine oil cooling,

- A best brake specific fuel consumption point of 0.32 lb/bhp-hr,

- A rated speed air:fuel ratio not to exceed 30:1,

- A targeted rated speed of 2,600 rpm,

TABLE 3-4 Research Projects Identified by 21CTP as Part of the Engine Systems Program (dollars)

| Public Review Project No./Title | Recipient | Funding 2012 | Funding 2013 | Funding 2014 |

| DOD017 Automotive Research Center | University of Michigan | ← | Funding not provided | → |

| ACE001 Heavy-Duty Low-Temperature and Diesel Combustion and Heavy-Duty Combustion Modeling | Sandia National Laboratories (SNL) | 815,000 | 805,000 | 825,000 |

| ACE004 Low-Temperature Gasoline Combustion (LTGC) Research | SNL | 760,000 | 740,000 | 720,000 |

| ACE005 Spray Combustion Cross-Cut Engine Research | SNL | 730,000 | 740,000 | 950,000 |

| ACE007 Large Eddy Simulation (LES) Applied to Low-Temperature and Diesel Engine Combustion Research | SNL | 500,000 | 450,000 | 200,000 |

| ACE010 Fuel Injection and Spray Research Using X-Ray Diagnostics | Argonne National Laboratory (ANL) | 1,100,000 | 1,000,000 | 850,000 |

| ACE012 Model Development and Analysis of Clean and Efficient Engine Combustion | Lawrence Livermore National Laboratory (LLNL) | 520,000 | 740,000 | 475,000 |

| ACE013 Chemical Kinetic Models for Advanced Engine Combustion | LLNL | 620,000 | 600,000 | 550,000 |

| ACE014 2014 KIVA Development | Los Alamos National Laboratory (LANL) | 720,000 | 763,000 | 695,000 |

| ACE015 Stretch Efficiency for Combustion Engines: Exploiting New Combustion Regimes | Oak Ridge National Laboratory (ORNL) | 350,000 | 350,000 | 300,000 |

| ACE052 Neutron Imaging of Advanced Transportation Technologies | ORNL | 200,000 | 200,000 | 200,000 |

| ACE054 Collaborative Combustion Research with Basic Energy Sciences | ANL | 400,000 | 320,000 | 325,000 |

| ACE075 Advancement in Fuel Spray and Combustion Modeling for Compression Ignition Engine Applications | ANL | 350,000 | 500,000 | 350,000 |

| ACE076 Improved Solvers for Advanced Engine Combustion Simulation | LLNL | 340,000 | 340,000 | 475,000 |

| ACE077 Cummins ORNL\FEERC Combustion CRADA: Characterization and Reduction of Combustion Variations | ORNL | 300,000 | 300,000 | 300,000 |

| Total federal dollars | 7,705,000 | 7,848,000 | 6,520,000 | |

NOTE: Information provided includes project number, title, lead organization, and federal dollars supporting the program.

- A rated speed power of 250 bhp and a minimum peak torque of 500 ft-lb,

- Military fuel use compatibility encompassing jet and diesel fuels, and

- Steady-state and transient smoke targets not to exceed visible limits. Both efforts also include a conceptual multicylinder engine study that targets representative combat vehicle claim space.

Although not officially categorized as part of the 21CTP program, this opposed-piston engine technology is worthy of mention because exploration of nonconventional engine architectures is an area of interest for the 21CTP.

The total 2014 federal budget for all of the DOE Engine Systems projects listed in Table 3-4 is $6.52 million. The committee was not given the federal dollar budget for the DOD-funded Automotive Research Center at the University of Michigan, so a sum total of all the engine research activities aside from the SuperTruck engine program is not known. Investigators for each of the engine systems projects with DOE funding are required to submit quarterly progress reports, participate in semiannual research progress meetings, and give a presentation at the DOE AMR. Each AMR presentation states the project’s relevance, the budget, milestones for the project, the technical approach, accomplishments, lists of collaborators, and future work. The presentations and the reviewers’ comments are available to the public.5

Brief Summary of DOE Individual Programs

The Engine Systems research programs listed in Table 3-4 span a range from fundamental experimental work, to kinetic mechanism development, to mechanism evaluation and simplification, to development of advanced numerical methods, and further development of the computational codes. The program is well managed and there is good collaboration and synergy between the individual DOE 21CTP engine projects. Brief summaries highlighting the accomplishments for each of the DOE projects shown in Table 3-4, along with links to the 2014 Annual Merit Review presentations, are given below.

Project ACE001. Using in-cylinder optical imaging, Musculus has developed a conceptual model of direct injected LTC, and the bridging between conventional combustion and LTC (2014). The model along with the in-cylinder imaging shows the spatial and temporal evolution of soot precursors. These soot evolution histories compared favorably with simulations that were performed as part of a collaboration with the University of Wisconsin. Musculus’s research has also shown how injection rate shapes affect postinjections and how piston bowl geometry affects multiple injections.

Project ACE004. Dec and collaborators General Motors, Cummins, LLNL, University of California-Berkeley, University of Melbourne, and Chevron have demonstrated a peak indicated thermal efficiency of 49.8 percent and were able to explore the maximum load that could be achieved using homogeneous charge and direct injection partially stratified charge compression ignition of gasoline-like fuels (Dec, 2014). Maximum loads in excess of 16 bar BMEP were achieved, and it was concluded that significant noise reduction could be achieved with a minimal loss of thermal efficiency.

Project ACE005. Through the research efforts of Pickett and his research team, the Spray Combustion Cross-Cut Engine Research Network continues to grow (Pickett and Skeen, 2014). This network represents a collaboration among approximately 20 international laboratories, industries, and universities dedicated to a coordinated experimental and computational evaluation of engine-relevant spray conditions for the purpose of developing predictive computational tools that can be used by industry. The dissemination and collaboration is done through Sandia’s Engine Combustion Network.6

Project ACE007. In conjunction with the modeling efforts taking place as part of the Engine Combustion Network, Oefelein and his research team are continuing the development of large eddy simulation (LES) to facilitate more accurate spray and fluid mixing simulations (Oefelein et al., 2014). Trying to understand the underlying causes of cycle-to-cycle variation, correctly simulating the differences between gasoline and diesel sprays, and predicting the effects of internal nozzle geometry on the spray processes in the cylinder is currently outside the precision and fidelity of the models. Such work provides a link between the DOE Office of Science and the VTO.

Project ACE010. Dr. Powell and his research team at ANL are using the laboratory’s unique Advanced Photon Source (APS) to perform x-ray measurements of near-nozzle and intra-nozzle phenomena on production-type fuel injectors (Powell, 2014). They have been able to make detailed measurements of the internal nozzle needle wobble that occurs during injection and have measured the cavitation of the fuel inside the nozzle and the effects these phenomena have on injection and on injection variation. These results have been incorporated into the work of the Engine Combustion Network. Collaborators in this work include Delphi, Caterpillar, the University of Massachusetts-Amherst, and computational colleagues at ANL.

Project ACE012. The simulation of advanced compression ignition combustion processes, often generically referred to as LTC, requires detailed high-fidelity kinetic

________________

5 See Vehicle Technologies Office: Annual Merit Review and Peer Evaluation at http://energy.gov/eere/vehicles/vehicle-technologies-office-annualmerit-review-and-peer-evaluation.

6 See the Engine Combustion Network at http://www.sandia.gov/ecn/.

representation of the fuel and the in-cylinder fluid mechanics. Whitesides and his research team at LLNL are working on developing faster and more accurate combustion solvers to facilitate these calculations and evaluate the results using these solvers (Whitesides et al., 2014). The emphasis of this project is to use the advanced solver as a means of validating detailed engine and combustion modeling tools through simulation of LTC results from a variety of collaborators.

Project ACE013. In conjunction with the more efficient solvers, it is important to also have comprehensive, high-fidelity kinetic routines to simulate the in-cylinder combustion process. This is the focus of Dr. Pitz and his research team’s efforts (Pitz et al., 2014). They are developing predictive chemical kinetic models for gasoline, diesel, and next-generation fuels by creating surrogate fuels, which are fuel blends in which the number of components in the fuel is computationally manageable. They are developing models for FACE, which include blends that have been specified for researchers to represent a matrix of fuels in which the properties vary over a range that might be expected in the future as feedstocks change. The diesel surrogate fuel under investigation currently has nine components, a mixture of selected n-alkanes, isoalkane, cycloalkane, one- and two-ring aromatics, and a napthoaromatic. Their current gasoline surrogate has 10 components. Their work involves collaboration with many who are performing experiments and simulations to assess the representativeness of the surrogate fuels to actual fuels, and to assess the accuracy of their kinetic routines.

Project ACE014. At LANL, DOE is supporting Dr. Carrington to write the next version of KIVA, the open source software program that has been used extensively as the framework for past engine CFD simulations (Carrington, 2014). Dr. Carrington is collaborating with the University of New Mexico, Purdue University, Calumet Specialty Products Partners, L.P., the University of Nevada-Las Vegas, and many KIVA users. The new version, KIVA 4, uses a high-performance finite element method in a modular object-oriented parallel processing code. This is being coupled to faster grid generation capabilities. The general topic of advanced CFD program development, which includes the KIVA 4 program, was the focus of DOE’s High Performance Computing Workshop.

Project ACE015. At ORNL, DOE is supporting analysis of fundamental thermodynamic strategies and implementation methods that could provide an increase in efficiency that would be revolutionary rather than evolutionary. Daw and his colleagues are analyzing the potential of reformate assisted dilute combustion through thermochemical recuperation (Daw et al., 2014). They are looking at steam reforming the fuel—octane, ethanol, or methanol, for example—to maximize the fuel’s exergy while facilitating highly dilute combustion, which would reduce heat transfer and improve the working properties of the gas. Catalyst performance experiments have been performed and an engine test is under development. The research team is collaborating with SNL, the Gas Technology Institute, Cummins, the University of Michigan, and Pennsylvania State University.

Project ACE052. Toops and his research team are exploring the use of nondestructive neutron imaging to visualize the internal flow dynamics in fuel injectors and the buildup of soot and ash in diesel and gasoline particulate filters (Toops et al., 2014a). Images can be obtained at a single cross section or a complete reconstruction can be constructed to provide a cross section of the entire sample at a resolution on the order of 10-20 microns. Voids in the nozzle’s fuel reservoir can be detected. This work is in collaboration with the DOE Office of Basic Energy Sciences, the University of Tennessee, MIT, the University of California, GM, and NGK Spark Plugs.

Project ACE054. Goldsborough and colleagues at ANL are using their rapid compression machine to acquire fundamental data that will be used to develop and evaluate kinetic routines for transportation-relevant fuels at conditions representative of advanced combustion regimes (Goldsborough et al., 2014). This work is being done in collaboration with DOE Basic Energy Sciences, LLNL, King Abdullah University of Science and Technology (KAUST) and Chevron, the University of Wisconsin, and the DOE working groups on HCCI and diesel engines. The behavior of FACE and the comparison to the predictions of that behavior using kinetic mechanisms from the surrogate models is one of their projects. They are also evaluating the impact of fuel additives such as ethylhexyl nitrate (EHN).

Project ACE075. Som and his colleagues, also of ANL, are pursuing advances in fuel spray and combustion modeling for compression ignition engine applications (Som et al., 2014). This is a comprehensive program with collaborations among other groups at ANL, Convergent Science, Caterpillar, Cummins, LLNL, the Sandia Engine Combustion Network, the Advanced Engine Combustion Working Group, the University of Connecticut, and the Politecnico di Milano and University of Perugia. Simulations are being done for flow inside the nozzle tip, with 50 million computational cells, using the data from the images of the internal nozzle and needle tip motion obtained in the advanced photon source research. The simulations show the complexity of the flow inside the nozzle, how it is impacted by needle wobble, and how it impacts the spray behavior when the flow enters the cylinder. These are the capabilities that will be made available to participants in the VERIFI program, mentioned above.

Project ACE076. McNenly is the principal investigator of the program at LLNL, which is focused on the development of improved solvers for advanced engine combustion simulation (McNenly et al., 2014). Colleagues of this research team are also evaluating the effectiveness of the developed solvers to validate detailed engine and combustion models for a variety of LTC engine results, see discussion above. In the development of the solver, better algorithms and applied mathematics are being coupled with new Graphical Proces-

sor Unit (GPU) computing architecture to facilitate inclusion of improved physical submodels for better accuracy and smaller error. This is especially important as the number of species in the simulation grows. Currently, the team has demonstrated a 4.8-fold speedup over a conventional modern code for a simulation containing 2,000 species. Collaborators in this work include Cummins, Ford, Volvo, Bosch, GE Research, Convergent Science, Nvidia, ANL, National Renewable Energy Laboratory (NREL), SNL, FACE, the Advanced Engine Combustion working group, and multiple universities.

Project ACE077. Finally, in a cooperative research and development agreement (CRADA) between ORNL and Cummins, Partridge and colleagues are developing and applying an advanced EGR probe to help characterize and reduce combustion variations (Partridge et al., 2014). The probe is a laser-based multiplex EGR probe that measures CO2. Measurements are being made in the intake manifold to assess charge components and fluctuations by measurement of the residual gas backflow and external EGR. When combined with models, the nature of the residual gas in the cylinder can be predicted. This in turn will facilitate control of advanced combustion strategies. The team is also developing a multicolor, multispecies EGR probe that measures CO2, water, and the temperature of the cylinder charge components. Other collaborators include the Cummins SuperTruck engine team and the University of Central Florida. This project was given a 2013 R&D 100 Award.

As seen in the brief summaries given above, the Engine Systems research programs range from fundamental experimental work, to kinetic mechanism development, evaluation, and reduction, to advanced numerical methods, and to further development of the computational codes. The committee believes that the program is well managed and there is much collaboration and synergy between the individual projects of the DOE 21CTP engine projects. And, the program is addressing some of the important technical barriers standing in the way of achieving 55 percent BTE, Goal 2.

Approaches to Goal 3

Goal 3: Through experiments and models with FACE and other projects, determine the most essential fuel properties, including renewables, to help achieve 55 percent engine brake efficiency (by 2014).

(When asked for clarification of the intent of Goal 3, Kevin Stork, DOE, responded that the fuels research in the 21CTP was to “support experimental and modeling work to determine the impacts of fuel properties on enhancing (or hindering) attainment of advanced combustion modes, such as LTC, over a greater portion of an engine map.”)

Status: A more detailed discussion of the fuels and lubricant research within the 21CTP is given in a separate section later in the chapter, so only general comments will be made here. The committee feels that fuel research is much more important than what is stated or implied in Goal 3. As mentioned in the preceding summary of DOE engine research, FACE provides researchers with the ability to perform experiments with fuels of known characteristics, having property ranges that are within the range of variations that might be seen in future fuels. This is superior to running specific blends of research grade fuels that are not representative of what an engine will experience in the field. Using FACE also helps with the kinetic model development being pursued in the surrogate fuel simulation program. Researchers can now test their advanced kinetic models against realistic, but known, fuels in real engines, an important step in developing simulation capabilities for predictive behavior. The committee believes a more detailed understanding of the impact of fuel characteristics on engine operation and potential facilitation of advanced combustion will also enable the high-level objective of maximizing the utility of our fossil fuels, thus reducing their use.

Partnership Responses to NRC Phase 2 Recommendations: Engine Systems

NRC Phase 2 Recommendation 3-1. The 21CTP fundamental research program should continue to provide important enablers for the 55 percent BTE goal, and DOE should continue to look for leverage opportunities with other government- and industry-funded projects.

21CTP Response: The Partnership agrees with the need to continue research toward the 55 percent thermal efficiency goal, and has included this as a research goal for the SuperTruck partners (with technology scoping toward this goal being the major activity).

The Partnership will continue to look for new opportunities to work together: one possible new collaborative arena is the recently announced partnership between DOE and the U.S. Army (the Advanced Vehicle Power and Technology Alliance). DOE is working with the U.S. Army to identify areas of common interest that could result in collaborative research efforts.

NRC Phase 2 Recommendation 3-2. The DOE should ensure that the engine R&D for the goal of 50 percent BTE at over-the-road cruise conditions and the stretch goal of 55 percent BTE in an engine in a laboratory that will now be carried out under the SuperTruck program receive the appropriate share of the SuperTruck funding and benefit extensively from the DOE-funded research programs in advanced engine combustion.

21CTP Response: Participating SuperTruck companies are also involved in the rest of the VTP R&D program (the advanced combustion MOU, the advanced engine crosscut team, and the Annual Merit Review), and are thus made

aware of the DOE-funded advanced engine combustion programs. DOE’s Annual Merit Review included the SuperTruck team members as active participants, and presented the entire research portfolio to them. This ensures that SuperTruck teams are aware of the portfolio and can harvest breakthrough results for their use

NRC Phase 2 Recommendation 3-3. The DOD and the DOE should increase their awareness of one another’s programs and look for opportunities to share technologies on areas of joint interest, such as thermal efficiency. One way to encourage interaction is for the DOE to invite DOD program participants to present their findings at the DEER (Diesel Engine-Efficiency and Emissions Research) Conference.

21CTP Response: In 2011, DOE and the U.S. Army announced the formation of a research collaboration, the Advanced Vehicle Power and Technology Alliance. DOE is working with the U.S. Army to identify areas of common interest that could result in collaborative research efforts. This partnership should enhance the interaction between these federal departments: some areas of collaboration have already been identified. The U.S. Army also participates in meetings of the Diesel Crosscut Team and the light-duty USCAR partnership with DOE and industry partners. Incorporation of DOD presentations at the yearly DEER meeting will also be considered: DOD has presented papers at DEER in the past, and DOE’s role as the chair for the meeting will ensure that DOD can have access to presenter slots as needed.

Committee Comment on 21CTP Responses

The committee is pleased with the responses by 21CTP to the NRC Phase 2 recommendations. Unfortunately there has not been a DEER Conference since the Phase 2 review, so DOD participation has not been possible. The committee commends DOE and DOD for the formation of the Advanced Vehicle Power and Technology Alliance.

Findings and Recommendations: Engine Systems

Finding 3-1. The 21CTP has successfully met Goal 1, to develop and demonstrate an emissions-compliant diesel engine system for Classes 7 and 8 highway trucks that achieves 50 percent brake thermal efficiency in an over-the-road cruise condition. The engine uses a waste heat recovery system.

Finding 3-2. The projects in the engine systems portion of 21CTP represent a closely coordinated set of research activities that are pursuing a better fundamental understanding of processes critical to efficient engine operation. Fundamentals associated with fuel injection, sprays, gas exchange, in-cylinder flows, advanced combustion processes, plus comprehensive yet robust kinetic routines for realistic fuels are being investigated. The learning from these activities is being incorporated into models, both detailed and phenomenological, which serve as tools for advanced engine development. Integral to this effort is the continued advancement of the base computer program itself and the solvers that facilitate rapid computational turnaround time. The program is well managed and interfaces well with industry stakeholders.

Finding 3-3. The 21CTP has realized the importance of transferring the new knowledge generated in its research programs into the stakeholder community and is active in disseminating this learning via appropriate forms and forums, such as the development of computer submodels that can be used by other researchers in the field, and through user groups such as the Engine Combustion Network, to maximize leverage and learning obtained from the research by encouraging broad base participation within the scientific community.

Finding 3-4. Increased emphasis has been placed on issues such as numerical algorithm development, advanced computer architectures, and CFD code development. The Partnership’s awareness of the importance of these activities was evinced by the high-performance computing workshop DOE sponsored in August 2014.

Recommendation 3-1. With the increased importance of advanced CFD for developing the engines and operating scenarios necessary for minimum fuel consumption and in light of DOE’s role in the generation of new knowledge that gets incorporated into these CFD codes as submodels, a critical review of the Partnership’s program to develop the next-generation code (KIVA 4) should be performed. Feedback from the participants of the high-performance computing workshop should be matched against the current code development activities, and the adequacy of the current program should be assessed. If necessary, the next-generation code development should be adjusted.

Finding 3-5. Achieving Goal 2, 55 percent BTE in a laboratory engine, will be very challenging. This is a high-risk, high-reward fundamental research program. It is an important stretch goal because it will facilitate identifying the potential of different advanced engine, fuel, and combustion concepts for increased engine efficiency, even though these concepts may not be commercially viable in the near future.

Recommendation 3-2. The fundamental diesel engine research program pursuing advanced technologies and combustion processes and engine architectures to achieve 55 percent BTE should continue to be a focus of the 21CTP engine activities. However, the experiments and modeling should maintain a focus on dynamometer R&D, as opposed to attempting to build a demonstration vehicle. The achievement of this goal should be extended from 2015 to 2020, in order to have sufficient time to carry out R&D on this stretch goal. Also, this activity should not be at the expense of efforts

to reduce load-specific fuel consumption via system integration and road load reductions.

Introduction

HD diesel aftertreatment systems have evolved worldwide as separate systems. Europe was developing and optimizing the SCR systems to meet Euro IV and V regulations (2005, 2008 respectively), while Japan and the United States were developing diesel particulate filter (DPF) technology. Both technologies came together to meet the US2010 and Euro VI (2013) HD regulations. New U.S. regulatory requirements went into effect in 2013 and 2014, when OBD (2013) and the first phase of the medium- and heavy-duty vehicle fuel efficiency and GHG regulations (2014) were introduced.

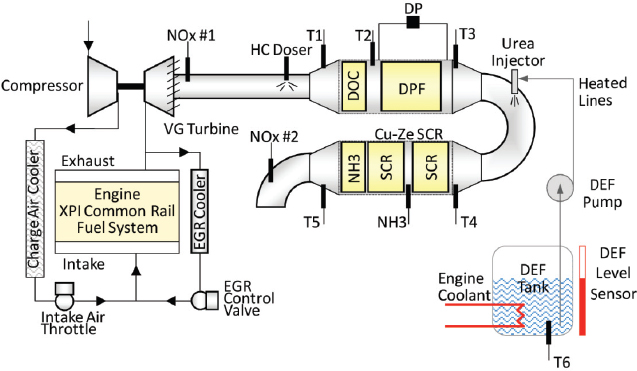

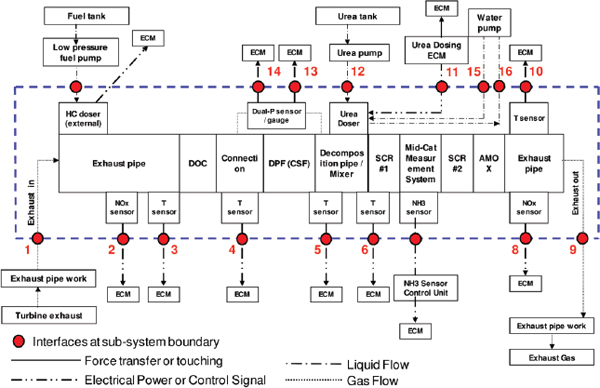

More-efficient SCR systems allow higher engine-out NOx, resulting in further reduction in fuel consumption and low engine-out PM levels. The NO2 levels coming out of the diesel oxidation catalyst (DOC) are sufficient in many 2013 engines to oxidize the PM retained on the filter without the need for high-temperature active regeneration. This resulted in filters with less PM mass and lower back pressure. An example of a modern emission control system architecture is shown in Figure 3-6.

The required OBD system adds significant complexity, with upwards of 18 control points, as illustrated in Figure 3-7 (Stanton, 2013). The OBD system is needed to diagnose deficiencies in the emissions control system and allow the defective parts to be identified to facilitate remediation. Major industry efforts are being expended on OBD, and emissions control system choices are always made in the context of OBD requirements.

The results of these efforts to date are quite impressive. In many cases the tailpipe concentration of fine particles is less than that of ambient air. NOx reductions are approaching 98 percent from engine-out levels. In Europe, trucks have lower NOx emissions per kilometer than modern diesel cars (Bergmann, 2013).

California is now independently considering another 90 percent reduction of the HD NOx tail pipe standard for around 2020 (CARB, 2015). EPA may consider following with similar tightening depending on the level of the new National Ambient Air Quality Standard (NAAQS) ozone standard, proposed in December 2014 to be in the range of 65 to 70 ppb. To have minimal impact on fuel consumption, these new tail pipe NOx levels (~0.02 g/bhp-hr) will require nominally 99.5 percent NOx reductions on the hot federal test procedure (FTP) cycle and 96 percent reductions on the cold FTP cycle, both of which depend on additional innovations in emissions control technology. The California initiative will stimulate new approaches to HD NOx aftertreatment, particularly related to cold start emissions. Some technologies being considered are SCR filters (SCR catalyst coated on DPF) to

FIGURE 3-6 Layout of a modern HD diesel emission control system. SOURCE: D. Stanton, “Systematic Development of Highly Efficient and Clean Engines to Meet Future Commercial Vehicle GHG Regulations,” SAE Int. J. Engines 6(3): 1395-1480. Reprinted with permission from SAE paper 2013-01-2421Copyright © 2013 SAE International.

FIGURE 3-7 Example of OBD layout for a 2013 HD aftertreatment system. SOURCE: D. Stanton, “Systematic Development of Highly Efficient and Clean Engines to Meet Future Commercial Vehicle GHG Regulations,” SAE Int. J. Engines 6(3): 1395-1480. Reprinted with permission from SAE paper 2013-01-2421 Copyright © 2013 SAE International.

add SCR catalyst closer to the engine, and low-temperature NOx adsorbers that release the NOx at higher temperatures when the SCR is functional. Further, at such high deNOx efficiencies, proper management of the diesel emission fluid (ammonia) will be critical to prevent the formation of N2O, a powerful greenhouse gas. Expected OBD requirements at these very low tail pipe NOx levels are not achievable with today’s sensor and modeling technology.

Although 21CTP has no specific aftertreatment goals, in the February 2013 Roadmap (21CTP, 2013, p. 45), 21CTP listed several aftertreatment elements to the overall technical strategy:

- High-efficiency SCR.

- Resolve remaining issues on DPF regeneration, ash loading and removal, and aging.

- Mitigate sulfur effects.

- Improve the catalyst materials and systems for lean NOx catalysis with urea and other reductants for performance over a wider temperature range while minimizing reductant slip.

- Develop monitors and thresholds for sensors in controls and diagnostics in conjunction with OBD. Develop and use fundamental knowledge of catalysts and sensors for OBD methods.

- Materials for catalysts and filters that have high efficiency, low back pressure, and minimal space requirements for at least 1 million miles of durability.

- Robust sensors with direct sensing of emissions constituents (e.g., PM, N2O).

Aftertreatment Projects

The NRC Phase 2 report (2012) put the total spending during the previous 7 years of 21CTP heavy-duty truck aftertreatment work (through FY 2010) at about $37 million. Spending FY 2011 through FY 2014 was about $13 million, for a total of about $50 million of aftertreatment-related funding over 11 years ($4.5 million per year average). Table 3-5 describes the expenditures on active aftertreatment projects reported to the committee by 21CTP since the NRC Phase 2 review.

The aftertreatment research and development community is quite active, with upwards of 400 technical papers and presentations annually presented worldwide on industry- and government-funded work. In the opinion of the committee, the body of work sponsored by 21CTP ought to complement, not duplicate, the industrial programs. Following is a summary of the 21CTP project progress with comments on corollary work from outside the DOE projects.

TABLE 3-5 Expenditures on 21CTP Aftertreatment Projects (dollars)

| Public Review Project No./Title | Recipient | 2012 Funding | 2013 Funding | 2014 Funding | Note |

| ACE022 Joint development and coordination of emissions control data and models (CLEERS analysis and coordination) | ORNL | 350,000 | 712,000 (700,000)* | 558,000 (650,000)* | *According to 2014 AMR |

| ACE023 CLEERS aftertreatment modeling and analysis | Pacific Northwest National Laboratory (PNNL) | 750,000 | 750,000 | 750,000 | |

| ACE026 Enhanced high- and low-temperature performance of NOx reduction materials | PNNL | 300,000 | 300,000 | 300,000 | Funding matched by Cummins in CRADA |

| ACE028 Experimental studies for CPF and SCR model, control system, and OBD development for engines using diesel and biodiesel fuels | Michigan Technological University | 607,000 | Project completed in FY 2012; 323,000 matched funding | ||

| ACE032 Cummins/ORNL-FEERC CRADA: NOx control and measurement technology for heavy-duty diesel engines, self-diagnosing smart catalyst systems | ORNL | 450,000 | 595,000 (400,000)* | 232,000 (350,000)* | *According to 2014 AMR; funding matched by Cummins in CRADA |

| ACE089 Development of radio frequency diesel particulate filter sensor and controls for advanced low-pressure drop systems to reduce engine fuel consumption | Filter sensing technologies | 487,000 | 386,000* | 836,000* | *From 2014 AMR; total private share adds 565,000 |

| Totals | 2,944,000 | 2,743,000 | 2,676,000 | ||

Crosscut Lean Exhaust Emission Reduction Simulation (CLEERS) Program

The Joint Development and Coordination of Emissions Control Data and Models (ACE022 and ACE023) is a project managed by ORNL with subprojects managed by the Pacific Northwest National Laboratory (PNNL). The core activities are to support and coordinate emissions control research, which evolves with DOE priorities and industry needs. Efforts are communicated to the 22 industrial partners, 11 universities (including three in Europe), and two national laboratories through monthly teleconferences and an annual workshop that is open to the public. The 2014 workshop had more than 100 attendees, 39 technical papers, and 12 posters. Topics most pertinent to the 21CTP included diesel particulate characterization and filtration; SCR catalysts, reaction mechanisms, and modeling of urea spray; oxidation and reforming catalysts; passive adsorbers and traps; multifunctional catalysts and aftertreatment devices; emissions controls and engine integration; low-temperature catalysis; interpretation of experimental aftertreatment measurements; development of microkinetic and global reaction mechanisms; drive-cycle simulations of conventional and hybrid vehicles; and engine exhaust speciation. Examples of recent accomplishments of CLEERS are the provision of basic data in support of vehicle systems aftertreatment modeling; the establishment of a new online database for references relevant to modeling of emissions control devices; the analysis and reporting of results from a 2013 industry priority survey; the measurement of NH3 storage isotherms on a commercial small pore Cu zeolite; the development and application of analytical techniques for extracting adsorption enthalpies from isotherm data; and the development of reaction mechanisms for NO SCR reactions that are consistent with reaction rate measurements and diffuse reflectance infrared spectroscopy (DRIFTS) observations. Future work will continue mechanistic investigations into small pore Cu zeolite and candidate NOx adsorber materials, with emphasis on low-temperature operating conditions and will initiate the characterization of passive adsorber materials and protocols for their development.

Emissions Projects

Project ACE026. The CRADA project “Enhanced High and Low Temperature Performance of NOx Reduction Materials” focuses on determining factors that limit low- and high-temperature NOx performance, including mechanisms for deactivation for candidate materials due to hydrothermal aging and poisoning mechanisms. NOx adsorber work that ended in 2014 shows enhanced potassia-titania high-temperature NOx storage catalysts deactivated through irreversible