4

Technical Obstacles to Conversion

The conversion of a research reactor’s fuel from highly enriched uranium (HEU) to low enriched uranium (LEU) follows a set of general steps that can each present technical and/or nontechnical obstacles to conversion. This chapter outlines the general steps to conversion, the principles that define the conversion for each reactor, the constraints that result from those principles, and a discussion of reactors for which the main challenge to conversion is technical. The committee presents several ideas for overcoming the technical obstacles to conversion. The nontechnical obstacles to conversion are addressed in Chapter 5.

BASIC STEPS TO CONVERSION

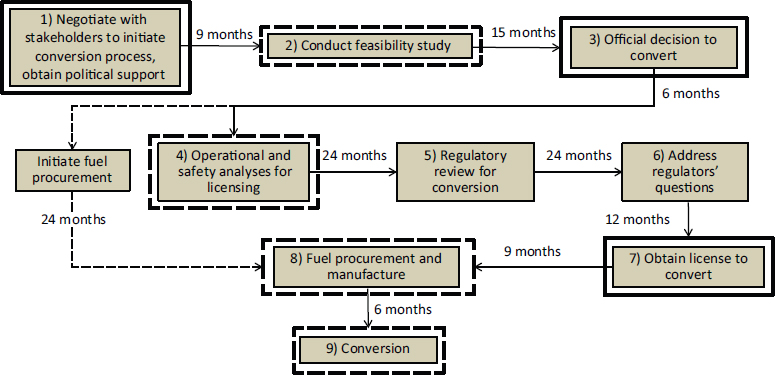

Altering the fuel of an existing operating research reactor (to LEU or other types) requires many steps and consideration of both technical and nontechnical factors (e.g., reactor performance, economics, licensing). The general steps of reactor fuel conversion, shown in Figure 4.1, are as follows:

- Negotiation by decision makers and reactor operators to initiate the conversion process followed by a political decision to consider reactor conversion.

- A feasibility study to assess whether conversion is possible.

- An official decision to convert.

- Completion of detailed operational and safety analyses for licensing.

- Regulatory review for conversion.

- Response to the regulator’s questions.

FIGURE 4.1 General steps to reactor conversion to LEU fuel. Steps dominated by nontechnical issues are surrounded by a solid line (Steps 1, 3, and 7). Technical steps are surrounded by a dotted line (Steps 2, 4, 8, and 9). Not shown: fuel development and qualification steps and time estimates. SOURCE: Office of Material Management and Minimization Office of Conversion, used with permission from the National Nuclear Security Administration (DOE).

- Granting of a license to convert.

- Fuel procurement and manufacture.

- Conversion.1

Fuel procurement proceeds along a parallel path (see Figure 4.1). Estimates of the time for each step are included in the figure. Using these estimates one could assume that, in general, conversion takes less than 9 years. Notably, the figure and this list do not include the steps and time required to develop and qualify a new LEU fuel. Fuel development and qualification, as will be shown in this chapter, are significant technical hurdles in the conversion process.

PRINCIPLES OF FUEL ACCEPTABILITY FOR CONVERSION

An assessment of the feasibility of reactor conversion involves technical steps that are guided by a set of principles intended to encourage cooperation of reactor operators and regulators and to assure the safe and acceptable operation and performance of the converted reactors. “Principles of fuel acceptability” have been used by the U.S. conversion program to assure that “a fuel assembly must be qualified, commercially available, and suitable for use in that reactor” (Stevens, 2014, p. 5).

After these principles have been met, the next step is for the reactor operator and regulator to agree to accept the fuel assembly for conversion. The italicized terms are defined as follows (Stevens, 2014, p. 5):

- Qualified fuel assembly—a fuel assembly2 that has been successfully irradiation tested and is licensable3 from the point of view of fuel irradiation behavior.

- Commercially available fuel assembly—an LEU fuel assembly that is available for purchase from a commercial manufacturer.

-

Suitable fuel assembly—a fuel assembly that satisfies criteria for LEU conversion of a specific reactor, including the following:

- — Fuel service lifetime comparable to current HEU fuel (e.g., number of fuel assemblies used per year is equal to or fewer than with HEU fuel);

_________________________

1 The Global Threat Reduction Initiative (GTRI)/Office of Material Management and Minimization (M3) conversion programs define a reactor as “converted” once the first LEU fuel assembly is inserted into the reactor core.

2 For U.S. reactors, the term fuel element refers to a collection of fuel plates that are grouped together to form a single unit. For Russian reactors, the term fuel element refers to the fuel plates, tubes, or rods. To avoid confusion, the text uses the term fuel assembly to describe a collection of fuel plates.

3 Licensing requirements may vary depending on the regulator and the country.

- — Satisfaction of safety criteria; and

- — Technical and economic performance not significantly impacted by LEU conversion so that the reactor can continue to meet its mission.

Conversion may also require addressing licensing issues or additional nontechnical issues associated with conversion (Roglans, 2014).

The original International Nuclear Fuel Cycle Evaluation (INFCE) language echoes this approach (INFCE, 1980, p. 18):

In assessing the practical feasibility of utilizing lower enriched fuel in existing research reactors, the agreed criteria are that safety margins and fuel reliability should not be lower than for the current design based on highly enriched uranium and that neither any loss in reactor performance, e.g., flux-per-unit power, nor any increase in operating costs should be more than marginal.

Reactor Performance Constraints and Associated Technical Challenges for Conversion

The three categories of performance constraints derived from the suitability of a fuel assembly for a given reactor drive many of the technical challenges for conversion.

Fuel Service Lifetime and Reactivity

The sustained fission of uranium-235 (235U) in a reactor core allows a reactor to operate. Like the fuel in an automobile’s fuel tank, which does not limit the car’s speed, but determines whether it can be started and how far it can go, there is a minimum amount of 235U needed to start the reactor (i.e., go critical) and keep it running. The reactor cycle length is the amount of time from initial criticality until a chain reaction can no longer be maintained and the reactor must be shut down for refueling. If there is insufficient 235U, then the reactor either cannot start or its cycle length will be too short, like a car with a 1-gallon fuel tank.

Typically, cycle length is an economic issue for two reasons. First, cycle length affects mission performance because frequent refueling will decrease the amount of time that the reactor will be available to produce neutrons. Second, longer cycles translate to lower fuel consumption (and therefore lower annual fuel procurement costs).

The minimum amount of LEU that must be present in a given fuel assembly to replace an existing HEU fuel assembly can be roughly estimated. The ratio of mass per element, MLEU/MHEU, has to be at least as

great as the enrichment ratio, eHEU/eLEU = 4.7 (assuming an enrichment of 93 percent and 19.75 percent for HEU and LEU, respectively) in order to preserve the amount of 235U. In fact, this ratio has to be multiplied by a factor fpenalty (which is greater than 1) to account for different penalties, such as the following:

- Uranium-238 (238U) (the dominant uranium isotope) is a neutron absorber for thermal neutrons. Additional 235U is needed in the new fuel because LEU fuel has significantly more 238U than does HEU fuel for the same volume.

- The minor elements in the fuel compound can bring some additional penalties because of their nuclear cross section. For example, in the thermal domain, Mo captures 10 times more neutrons than Al.

- The power of the reactor often must be increased to retain local performance specifications after conversion, and consequently, the mass of 235U has to be increased to keep the same cycle length (more gas in the tank for a higher operating power).4

This factor, fpenalty, can vary from 1.2 to 2.0, depending on the specific reactor.

Thus, to replace 1.0 kg of HEU in a fuel assembly, 5.6 to 9.4 kg of LEU is needed in the example above, but the actual values will depend on the details of the LEU and the core configuration of each reactor.5

Safety Constraints

Given an amount of 235U that will satisfy the reactivity and service lifetime constraints, safety margins for LEU fuel must also be satisfied. Some safety analyses are based primarily on neutronics calculations to confirm that the reactivity coefficients, the control element worth, and the reactivity insertions associated with experimental facilities are within the required margins. Safety analyses include thermal hydraulic calculations to show that the coolant flowing through and between the channels within the fuel assembly can remove the heat being generated by the fuel plates. HEU fuel assembly designs for high performance research reactors (HPRRs) rely on high coolant velocities through narrow channels to remove the heat generated by the high-power core. Current thermal hydraulic analysis techniques

_________________________

4 The option to increase operating power to compensate for reduced performance post-conversion was not considered for early conversions in the U.S. and Russian conversion programs, but has since been used. For example, the University of Missouri Research Reactor (MURR) and the High Flux Isotope Reactor (HFIR) plan to increase operating power post-conversion to compensate for reduced LEU performance.

5 This simple calculation neglects plutonium fission contributions and assumes the fuel geometries between HEU and LEU fuel remain the same.

are validated by long operational experience with the specific fuel assembly geometries of each reactor.

To simplify the thermal hydraulic and, consequently, the safety margin analysis between HEU and LEU fuels, the LEU fuel design usually retains both the contact area of the fuel element–coolant interface and the widths of the coolant channels. Thus, safety constraints for conversion are met by retaining the basic geometry of the fuel assemblies and cooling channels, thereby preserving the validity of existing safety analyses.6

Technical and Economic Performance

Since the start of the Reduced Enrichment for Research and Test Reactors (RERTR) Program, maintaining reactor performance after conversion has been a high priority. This is necessary to obtain the support of reactor operators and users. The HPRR cores produce high power densities to achieve the large neutron fluxes (approximately 1015 n/cm2-s) that enable the applications discussed in Chapter 3. In the case of in-core irradiation applications, the flux levels of thermal and fast neutrons may be important, and in some applications the distribution of neutron energies (i.e., the spectrum) at a particular irradiation position is also essential.

The size and geometry of the core must also be preserved because of the location of current in- and near-core experiments, reflectors, and beamlines within or near the existing reactor cores. Assuring that the performance requirements are met necessitates detailed neutronic analyses of proposed LEU core designs that meet the geometric and thermal and fast flux constraints.

Finally, the operational costs of using LEU fuel should not be substantially greater than those for HEU fuel. Operational considerations include cost of fuel and duty cycle of fuel assemblies.

In summary, the list of mission/performance constraints imposed on the conversion are as follows:

- Design the same amount, or more, of 235U into the LEU fuel assembly to maintain cycle length.

- Retain the basic geometry of the fuel assemblies and cooling channels to maintain safety margins.

- Retain the core geometry and size so that existing experiments and beamlines are not affected.

- The expected costs of operations after conversion should marginally compare to costs before conversion.

_________________________

6 Although this is true for many HPRRs, MITR-II operators have changed the standard design of its fuel element—by removing the fins. This is one example in which LEU fuel geometry differs from that of HEU.

Implications for Fuel Design

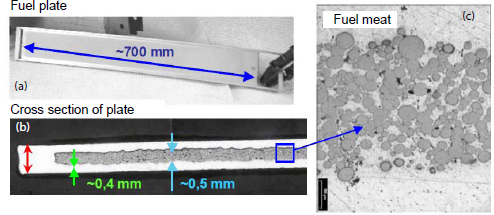

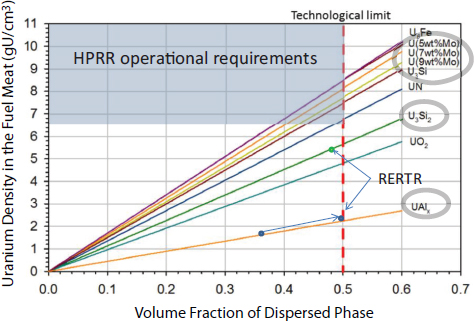

The above constraints have consequences for the LEU fuel that must be developed. The need to increase the total uranium content in the fuel meat (see Box 4.1 and Figure 4.2) by a factor of 5 to 10 while retaining fuel assembly size and geometry is one of the most critical requirements. This could be accomplished by several approaches: increasing the uranium content of the fuel particles within the fuel meat by increasing the density of the U-containing compound; increasing the volume fraction of the particles in the meat (but 50 to 55 percent is a technological limit for the manufacture of dispersion fuel by rolling7); changing the fuel type (e.g., by developing a fuel that is “monolithic” and does not need to be dispersed in a matrix); and/or increasing the thickness of the fuel meat (see Figures B4.1 and 4.2).

Many medium-power research reactors have successfully converted using high-density LEU fuel such as silicides (U3Si2 and U3Si). However, the performance requirements of the remaining unconverted HPRRs require still higher uranium densities than were needed for these previous conversions.

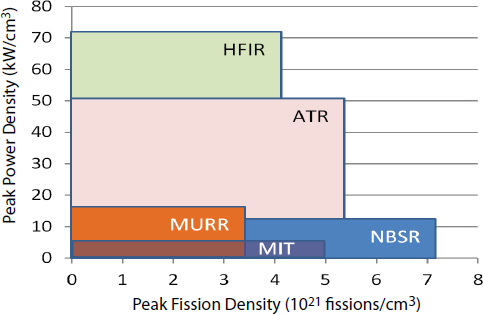

For the new LEU fuel to be qualified for use, its behavior over the operating conditions of the reactor must be understood. Both the mechanical and geometric integrity of the fuel must be maintained throughout its expected operational life. The cladding must continue to provide a barrier for fission product transport, and the coolant flow paths must not be affected by changes in the geometry of the fuel assembly. The two characteristics of the reactor environment that most impact these requirements are the local power density and the local fission density (or burnup). The local power density, a parameter related to the irradiation performance requirements, provides the instantaneous driving force for possible failure mechanisms of the fuel system due to instantaneous damage rates and thermal gradients. The local fission density,8 which is proportional to burnup, provides a measure of the accumulated fission products and fission gases and radiation damage that can lead to failure of the fuel. For each reactor, it is possible to determine the performance envelope (e.g., the highest local power density and the highest local fission density) through detailed neutronics models

_________________________

7 The limit value or technological limit of 50 to 55 percent has been determined and is used by manufacturers of material test reactor (MTR) plate-type fuel (Compagnie pour l’Etude et al Réalilsation de Combustibles Atomiques [CERCA], Babcock and Wilcox Technologies [BWXT]). Values higher than those commonly used by the manufacturers have been found to increase the complexity of the manufacturing process and reduce its yield. Additionally, values significantly greater than 55 percent could increase the risk of in-pile failures because the matrix no longer governs the mechanical and thermal properties of the fuel plate.

8 The reactor’s local fission density (fissions per cubic centimeter [fissions/cm3]) and burnup (a way to measure the amount of fuel consumed in the reactor, usually expressed in percentage of 235U consumed) are parameters that measure the extent to which the 235U is being consumed throughout the core.

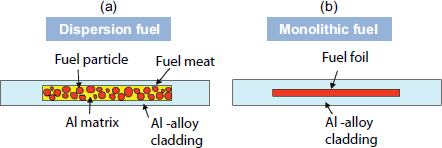

BOX 4.1

Description and Definitions of Terms Related to Fuel Composition

The figure below provides schematics of the two types of research reactor fuel discussed throughout this chapter: dispersion and monolithic fuel. Both schematics are cross sections of plate-type fuel. The dispersion fuel consists of fuel meat encased by a cladding to form the plate (Figure B4.1(a)). The fuel meat consists of particles of a uranium-containing compound or alloy (fuel particles), which are dispersed throughout a matrix. A photo of a dispersion fuel plate in cross section is provided in Figure 4.2. The uranium density of dispersion fuel can be increased by increasing the volume fraction of uranium-containing particles within the fuel meat. Because of processing issues, the maximum volume fraction of these particles is 50 to 55 percent. Uranium density can also be increased by selecting particles with higher uranium density (such as the silicide, U3Si2, fuel discussed in the text).

Monolithic fuel is composed of a uranium-containing alloy foil (fuel foil) surrounded by a cladding (Figure B4.1(b)). The text refers to a U-10Mo alloy, which is uranium mixed with 10 percent by weight molybdenum. The density of a fuel foil of a particular alloy is fixed by the alloy composition. Therefore, to increase the mass of uranium in a monolithic fuel plate, the thickness of the fuel foil must be increased.

FIGURE B4.1 Schematic cross sections of (a) plate-type dispersion fuel and (b) plate-type monolithic fuel. SOURCE: Office of Material Management and Minimization Office of Conversion, used with permission from the National Nuclear Security Administration (DOE).

and calculations. Figures 4.3 and 4.4 define the performance envelopes for the U.S. and European HPRRs. Although the location of the highest power density may not coincide with the location of the highest fission density and burnup, they can be considered to be conservative bounds on the fuel performance envelope for each reactor.9 The first step in qualifying a new fuel form is to demonstrate experimentally that the fuel system will main-

_________________________

9 Generally, the locations of highest power shift within the core as the control rods are drawn out and burnup is achieved.

FIGURE 4.2 The photos and micrographs show (a) a fuel plate, (b) the fuel plate cross section showing the fuel meat and cladding, and (c) a closeup of the fuel meat with embedded uranium compound or particles. SOURCE: Modified from Van den Berghe at al. (2015).

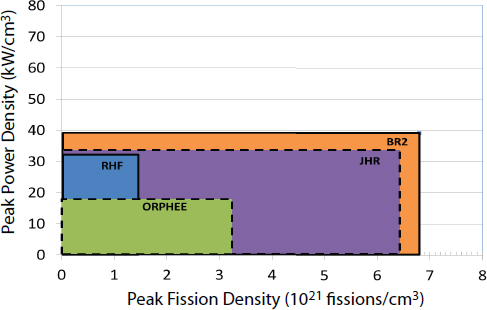

FIGURE 4.3 Fuel operating performance envelopes for the U.S. High Performance Research Reactors. In the figure, the MIT reactor is referred to as simply “MIT,” whereas throughout the report it is referred to as “MITR-II.” SOURCE: Courtesy of Argonne National Laboratory (Yacout, 2015).

FIGURE 4.4 Fuel operating performance envelopes for four European HPRRs. BR2, JHR, and RHF are expected to convert to high-density LEU fuel after it is qualified. The Orphée reactor is now expected to shut down prior to conversion. SOURCE: Courtesy of Argonne National Laboratory (Yacout, 2015).

tain its integrity under irradiation conditions throughout these envelopes (which include safety margins).

Finally, the cost of the new fuel must be considered. The cost to manufacture the new high-density UMo fuels is not well known. In addition, there is a limited supply of HEU for downblending for civilian applications (20 metric tons), and the United States does not currently have another capability to produce 19.75 percent uranium. Considering the time lines for fuel development, qualification, and conversion, there is some concern that the 20-metric-ton supply will eventually run out.10

_________________________

10 Parrish Staples, written communication, September 11, 2015: “Currently other U.S. domestic reactors as well as U.S. Government enriched uranium supply agreements and commitments of 19.75 percent supply for foreign research reactors or medical isotope production predominately pull material from the 1994 surplus HEU declaration, and those supplies are expected to be practically exhausted by around 2025. As reactors convert to LEU fuel, it is expected that the usage rate of surplus enriched uranium used to make LEU will increase and additional supplies will be needed. Should the Department [of Energy] decide to use a portion of the [2005 surplus HEU declaration] that had been reserved for [civilian] HEU supply, to make LEU for converted reactors, total supplies could be extended to around 2033.”

TECHNICAL CHALLENGES TO CONVERSION: VERY HIGH-DENSITY FUEL DEVELOPMENT

There are seven U.S.-based HPRRs (USHPRRs) that cannot be converted with existing qualified, commercially available LEU fuels (Stevens, 2014).11 This is also true for the HPRRs in Europe and Russia including the following:

- five European high-flux reactors (BR2, RHF, Orphée, FRM-II, and JHR);

- four Russian-supplied reactors of the IRT-type (IRT-Mephi, IRT-T, IR-8, and IRT-DPRK);

- two reactors that could use the same high-density fuel as the IRTs, but in circular geometry (MIR.M1 and MIR.M1 CA);

- two reactors that were identified requiring high density (probably UMo), but in pin- rather than tube-type form (IVV-2M and WWR-M); and

- six Russian high-temperature reactors that require a unique high-density fuel development/qualification effort (SM-3, SM-3 CA, RBT-6, RBT-10, PIK, and PIK PM).12

Consequently, several countries have launched efforts to develop and qualify higher-density LEU fuel that can meet the performance, safety, and operational constraints of these reactors.

Early Fuel Development Efforts

Three main fuels based on HEU were in use when the RERTR Program began in 1978:

- UAlx powder dispersed in an aluminum matrix (UAlx-Al dispersion fuel) with uranium compound densities up to 1.7 gU/cm3,

- U3O8-Al dispersion fuel with uranium compound densities up to 1.3 gU/cm3, and

- UZrHx alloy fuel with 0.5 gU/cm3.

UAlx-Al (or aluminide) fuel was developed at the Idaho National Engineering Laboratory in the 1960s for use in the 250-MW ATR (Advanced Test Reactor). U3O8-Al (or oxide) fuel was developed at the Oak Ridge National Laboratory in the 1960s for use in the 100-MW HFIR (High

_________________________

11 The reactors are ATR, ATR-C, HFIR, MITR-II, MURR, NBSR, and TREAT; the current fuel development effort is focused on the first six.

12 Roglans, written communication, September 2015.

Flux Isotope Reactor). UZrHx (or TRIGA) fuel was developed by General Atomics and used in TRIGA reactors with power levels up to 14 MW. The uranium densities of these fuels, as originally developed, are too low for converting HPRRs while satisfying performance requirements.

The objectives of the original fuel development effort in the RERTR Program were to increase the uranium densities for these existing fuels to their practical limits using LEU (less than 20 percent enriched in 235U), and develop new LEU fuel with even higher uranium densities.13

For existing fuels, LEU uranium densities were qualified up to 2.3 gU/cm3 for UAlx-Al fuel, up to 3.2 gU/cm3 for U3O8-Al fuel, and up to 3.7 gU/cm3 for UZrHx fuel (Travelli, 1989). Each fuel was tested extensively up to, and in some cases, beyond these densities.

The RERTR Program also developed silicide (U3Si2-Al) dispersion fuel, which was qualified with uranium densities up to 4.8 gU/cm3. The U.S. Nuclear Regulatory Commission (USNRC) issued formal approval for use of this fuel in domestic research and test reactors (see Figure 4.5). Many irradiation tests using this fuel have been successfully completed in research reactors around the world, and the fuel has been extensively used for the conversion of medium-power reactors in different countries, including OSIRIS in France in 1997,14 Japan Materials Testing Reactor (JMTR) in Japan in 1994, High Flux Reactor (HFR) in the Netherlands in 2006, South African Fundamental Atomic Research Installation (SAFARI) in South Africa in 2009, and more recently, MARIA in Poland in 2012.

Selection of UMo Compounds and International Decisions on Fuel Type

By the end of the 1990s, after the first conversions using LEU silicide (U3Si2), attention turned to the remaining HPRRs that were unable to use U3Si2 without severe performance losses. It was estimated15 that most of these reactors could be converted with a fuel density of 6.5 to 8.5 gU/cm3. Some reactors (such as the FRM-II reactor in Germany16) required even higher densities, available only in alternative fuel designs. The United States, the main driving force behind the conversion requirements and an

_________________________

13 RERTR’s original mission was limited to reducing HEU exports by converting U.S.supplied research reactors to LEU fuel. See Chapter 2.

14 OSIRIS was first converted in 1980 by using “Caramel” fuel (UO2, 9 gU/cm3, 7 percent 235U-enriched). The dates that appear in this list are the dates of the introduction of the first LEU silicide fuel in the reactor core.

15 Since these first evaluations, neutronic reevaluations were made, specifically for the USHPRRs, and for most of them the minimum required density is now estimated to be 9 gU/cm3.

16 The HEU-fueled FRM-II uses high-density silicide fuel originally developed as part of the RERTR Program to enable reactor conversions to LEU.

FIGURE 4.5 Uranium density in dispersion reactor fuel as a function of volume fraction (fraction of uranium that is mixed into the dispersed phase). This chart shows RERTR’s qualified LEU fuels: the increase in UAlx density from 1.8 to 2.3 gU/cm3 is shown by the two blue dots on that curve, and the new silicide (U3Si2) fuel at 4.8 gU/cm3 is shown by a single green dot. For the HPRRs to maintain operational performance, fuel densities of 6.5 gU/cm3 and higher are required, as shown by the box at the top of the figure. For U3Si2, the value 6.5 gU/cm3 is associated with a volume fraction of particles of 60 percent, which exceeds the technological limit commonly adopted. UMo dispersion fuels are currently being tested for use in the European HPRRs at 5, 7, and 9 weight percent Mo (U-5Mo, U-7Mo, and U-9Mo). The graph includes several common reactor fuels not mentioned in the text, including UN and UO2. The “technological limit” of 50 percent volume fraction for solid dispersions is shown. SOURCE: Modified from Van den Berghe at al. (2015).

important supplier of HEU,17 led the efforts with a number of scoping studies to identify appropriate fuel candidates.

Commissariat à l’Energie Atomique et aux Energies Alternatives (CEA) and CERCA were first to join U.S. efforts to study high-density dispersion fuels; this collaboration was later extended to other European countries. From 1998 to 2005, it was the “French UMo Group” or “Groupe

_________________________

17 The “Schumer Amendment” (Section 903 of the Energy Policy Act of 1992, H.R. 776) limits the U.S. exports of HEU, requiring a commitment to civilian research reactor conversion from the recipient country.

Pentapartite,” a French consortium between CEA, CERCA, and three other AREVA subsidiaries. From 2005 to 2008, the agreement was reduced to CEA and CERCA. In 2009, the European consortium was expanded to include Studiecentrum voor Kernenergie·Centre d’Etudes Nucléaire (SCK·CEN) in Belgium, and CEA, CERCA, and Institut Laue-Langevin (ILL) in France; this new consortium was named “LEONIDAS” for “Low Enriched Option Network Initiative for the Development of a European Appropriate Solution.” In 2013, the LEONIDAS consortium was further expanded to include a German partner, Technische Universität München (TUM), and formed the HERACLES (Highly enriched European Reactors Action for their Conversion in a Low Enriched Solution) Group.

A number of high-density uranium compounds were subjected to irradiation testing from which the U-xMo alloys were investigated (where x indicates the percent by weight of Mo). The UMo alloys are more malleable at high temperature than silicide fuels and are being investigated as both a dispersion and monolithic fuel (see Box 4.1). The alloys U-7Mo and U-9Mo were chosen as the best candidates for dispersion fuels (see Figure 4.5), while U-10Mo was selected for monolithic fuel.18 This selection marked the start of a number of validation irradiations to expand the fundamental understanding of the fuels required for qualification.

A UMo dispersion fuel is formed by dispersing small particles of the U-xMo alloy in a base aluminum matrix to form the fuel meat that is then clad with an aluminum alloy. As discussed below, it may be necessary to prevent, or at least reduce, the formation of an unwanted amorphous inter-layer between the particles and the Al matrix. This can be done by adding silicon, for example, to the matrix or by coating the particles to ensure the integrity of the fuel.

An important feature of dispersion fuels is the ability to vary the amount of uranium in the fuel (called the “uranium loading” and sometimes referred to as “uranium density”) by changing the volume fraction of the UMo powder in the Al matrix. This allows fuel designers to tailor individual fuel plates to their operating environment. Additionally, UMo dispersion fuel is structurally similar to existing fuels, giving it the advantage of a well-understood fuel fabrication process.

A UMo monolithic fuel is formed by sandwiching a foil of UMo alloy, usually with 10 percent by weight Mo, within an aluminum alloy cladding.

_________________________

18 The gamma phase of uranium is the only phase stable under irradiation. In the UMo alloy, molybdenum is added to uranium to stabilize this gamma phase. The choice of Mo percentage is a compromise between high values (to stabilize the gamma phase) and low values (to minimize the neutronic penalty of the alloy because Mo has a higher cross section than Al). In addition, as the percentage of Mo increases, the foil malleability decreases for the monolithic form. For dispersion fuel, 7 or 9 weight percentage of Mo is usually chosen, and for the monolithic form, 10 percent is preferred because of the higher temperatures of its manufacturing.

It may be necessary to add an interface layer between the fuel meat and the cladding to maintain the integrity of the fuel plate. Because it is not possible to alter the density (or uranium loading) of the uranium in the fuel meat once the UMo alloy composition has been chosen, fuel designers must rely on changing the UMo foil thickness to achieve the same flexibility in uranium content as with dispersion fuels. A rule of thumb developed by fuel manufacturers allows for a maximum of 50 to 55 percent volume fraction for UMo dispersion fuel; thus, the UMo foil thickness in monolithic fuel needs to be only about one-half as thick as the fuel meat in UMo dispersion fuel to achieve the same uranium content. Because the outer dimensions of the fuel plate are fixed by other constraints, these considerations lead to the need for different cladding thicknesses.

Current estimates of the maximum uranium density achievable in the UMo dispersion fuel are between 8 and 8.5 gU/cm3 (see Figure 4.5); UMo monolithic fuel can reach uranium densities of up to 15.9 gU/cm3, dependent on the amount of Mo in the alloy. The dispersion fuel density is sufficient to support the LEU conversion of European HPRRs (with the exception of FRM-II), but is not sufficient for the conversion of all USHPRRs. The M3 Office of Conversion made a decision to pursue a single fuel for all USHPRRs in an effort to reduce the total development costs and distribute the fixed costs of a fuel production line over all the USHPRRs; this decision is known as the “one-for-all” approach (Robinson et al., 2009; Senor and Burkes, 2014). Therefore, the U.S. conversion program is now focused on the development of the monolithic fuel form, while the HERACLES consortium is focused on the qualification of the UMo dispersion fuel. The European and U.S. LEU fuel development and manufacturing programs have similarities and differences, which are highlighted in Table 4.1.

Apart from the United States and Europe, several other countries are involved in UMo fuel development. South Korea has a complete UMo dispersion fuel program—from manufacturing to irradiation qualification—designed to support its new 15-MW Kijang Research Reactor (KJRR).19 KJRR is under construction, and it is likely to be the first reactor in the world to use UMo dispersion fuel. Its first criticality is planned for 2018 (Park, 2014, 2015).

Russia also has a large UMo dispersion fuel development program, including manufacturing and in-reactor testing of fuel elements (mini- and full-sized rods) and full-sized assemblies. The most recent experiments were performed in the MIR.M1 reactor on full-sized tube-type elements. The final irradiation tests of two experimental tube-type assemblies are

_________________________

19 For this reactor, designers chose a plate-type U-7Mo/Al-5Si dispersion fuel assembly with a density of 8 gU/cm3 for 19 inner plates, and 6.5 gU/cm3 for two outer plates of the fuel assembly.

TABLE 4.1 Comparison Between European and U.S. Fuel Development and Manufacturing Programs

| Europe | United States | |

| Management | HERACLES consortium across European Union countries (Belgium, France, Germany) | DOE/NNSA, M3 Office of Conversion |

| Organization | Strategic committee (heads of each laboratory) and technical committee | NNSA program management makes decisions based on input from four pillars led by teams of NNSA and DOE lab technical expert leads; four pillars are fuel development, fuel fabrication, conversion, and integration. |

| Funding | Primary: European Union | U.S. Congress to DOE/NNSA |

| Secondary: DOE/NNSA through M3 (this funding is not managed by HERACLES; a large fraction is spent at U.S. labs in support of HERACLES) | ||

| Review groups |

The technical committee has two standing review groups:

|

Independent review teams:

|

| Fuel type |

Primary: UMo dispersion fuel Secondary: UMo monolithic (for FRM-II) and high-density U3Si2 as a backup |

UMo monolithic fuel only |

| Fuel fabricators | CERCA, a subsidiary of AREVAa | BWXT, private company funded by DOE to make research reactor fuel (a small percentage of overall BWXT uranium fuel business), sole supplier to U.S. Navy for submarine nuclear reactor fuel |

a AREVA is a French company. Recently, CERCA has come under pressure to remain profitable while addressing a need to update facilities and develop capabilities to produce the new, high-

currently in progress and expected to end in 2016. The results, including post-irradiation examinations, of these experiments are anticipated in 2018. Once qualified, Russia plans to sell this fuel commercially to its nondomestic customers (see Chapter 5).

Argentina and Canada also have high-density LEU fuel development efforts. Argentina has been involved in the RERTR Program to develop dispersion or monolithic fuel since 1997. The Argentine National Commission of Atomic Energy (the Argentinian acronym is “CNEA”) studied the interaction between UMo and Al-Si alloy by using atomistic simulations and by experimental methods. CNEA focused its research and development program for UMo monolithic fuel on the fabrication technologies of UMo with Zircaloy-4 cladding. Canada was also involved early in the RERTR Program to develop UMo dispersion fuel in Al matrix. Now, Canadian Nuclear Laboratories (CNL) is developing an alternative concept in which the Al matrix is replaced by a magnesium matrix (Wang et al., 2015).

Fuel Testing Overview

Each test of a new fuel can take several years. Time lines for testing depend on details of each test, including the design of the experiment, maturity of the fuel system under test, and availability of space within the irradiating research reactor. Test durations and post-irradiation examinations (PIEs) time lines are defined by physical processes such as the required irradiation values and required cooling times after irradiation, which cannot be accelerated. General steps in the process are as follows:

- Definition of the experiment

- The objectives and parameters of the experiment are defined and translated into operational requirements for the test (maximum fission density and burnup, and type and number of samples).

- Rough estimate of the time needed: between 3 and 6 months, but potentially much longer (1 to 2 years) if no specific frame-

density LEU research reactor fuels. CERCA sells research reactor fuels to many of the HPRRs in Europe, and, as with operators worldwide, there is concern over the uncertainty in the pricing for the high-density LEU fuels. See Appendix E for a short discussion on the economics of LEU fuel from U.S. and French perspectives; the French consider high-density LEU fuel as a commercial venture, while the United States considers its LEU fuel development and fabrication as a government program “for the public good.”

SOURCE: Data collected by the committee during site visits to Europe and U.S. domestic reactor sites; see Appendix C.

-

work or preexisting budget is available and if several partners are involved.

- Preparation: design analysis of the experiment and production of the samples

- Analysis such as neutron or thermodynamic analyses of the proposed testing configuration and experimental conditions have to be performed and submitted to the authority in charge of the safety of the reactor.

- In parallel, samples (mini-plates or full-sized plates20) have to be produced and characterized.

- Rough estimate: between 3 and 6 months for the design and the calculation of the experiment, and between 6 and 12 months for the production or manufacturing of samples, depending on the number and type of the samples (mini-plates, full-sized plates, full-sized assembly).

- Irradiation of the samples

- The amount of time needed for this step depends on the objective of the experiment (low or high power density, maximum burnup), the enrichment used (LEU or HEU for very high-power density experiment), and the availability of the reactor. Notably, many of the irradiation tests performed on the new fuel are performed in the research reactors slated for conversion after the fuel has been qualified (e.g., Belgian Reactor 2 [BR2] or ATR).

- Rough estimate: 6 to 12 months (often more)

- Cooling

- Cooling, or the reduction in radioactivity due to natural radioactive decay, time lines of the samples depend on the type of experiment (mini-plate or full-sized assembly, for example), its activity level at the end of experiment, and the availability of a high-activity hot cell.21

- Rough estimate: between 6 and 9 months

- Post-irradiation examination

- The time line for PIE varies widely depending on the analysis required. Some examinations, such as transmission electron microscopy (TEM), are often made 2 or more years after the end of the irradiation.

_________________________

20 Irradiation testing can be performed on various-sized plates. Full-sized plates refer to plates of the same dimension as those that will be used within research reactors. Mini-plates are smaller-sized plates so that a larger number of variations of fuel composition or cladding may be investigated during the irradiation test.

21 A hot cell is a specially designed, radiation-shielded facility that allows for remote measurements and analysis of radioactively “hot” samples.

-

- Rough estimate: initial examination between 6 and 9 months with some examination taking place 1 to 2 years later.

- Analysis and synthesis of results

- Rough estimate: between 3 and 6 months

Some of the tasks listed above such as steps 1 and 2 can be performed in parallel, but others are sequential. A rough estimate for the total duration for an experiment is between 2 and 4 years. However, the details of the experiment will ultimately determine the time line (see discussion later in this chapter, e.g., Figure 4.8 for HERACLES dispersion fuel tests and Figure 4.9 for U.S. monolithic fuel test). Once testing is completed, qualification of the fuel by a specific country’s and/or research reactor’s regulatory body must be obtained adding approximately 1 to 3 years to the total time line. See Figure 4.1, steps 5 through 7, for a rough estimate for the U.S. regulatory time line.

Dispersion Fuel: Test Results and Future Testing

The first irradiation tests on UMo full-sized dispersion plates were performed by the French CEA in OSIRIS and BR2 reactors (IRIS-1, IRIS-2 tests in OSIRIS, and the FUTURE test in BR2) on U-7Mo (uranium alloy with 7 percent by weight of molybdenum), in a pure Al matrix, at densities ranging from 8.0 to 8.5 gU/cm3. These tests were conducted in parallel with the first five RERTR tests on UMo dispersion mini-plates by Argonne National Laboratory (ANL) in ATR (RERTR-1, -2, -3, -4, -5) on different U-xMo dispersion fuel (with x ranging from 6 to 10 percent) in a pure Al matrix.

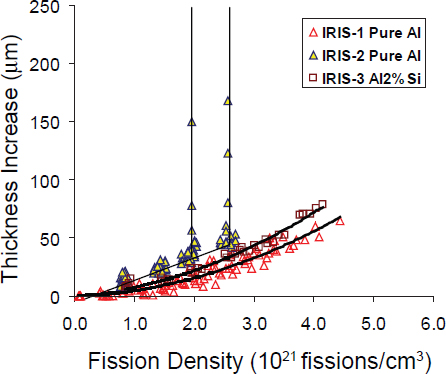

The IRIS-1 full-sized plate test performed on UMo ground particles was successful with an acceptable thickness increase (post-irradiation) of approximately 70 µm (see Figure 4.6) at low power densities (12 kW/cm3 or 140 W/cm2) and fission densities up to 4.5 × 1021 fissions/cm3 (see Figure 4.6). These test results were consistent with those of the RERTR mini-plate tests with maximum burnup values of 80 percent and fission densities of 6.0 × 1021 fissions/cm3 (Hofman et al., 2004a). The IRIS-2 and FUTURE full-sized plate tests performed on U-7Mo atomized particles at higher power densities (20 and 30 kW/cm3, respectively) resulted in plate failures at fission densities lower than 2.5 × 1021 fissions/cm3 due to excessive swelling, resulting in a sharp local increase in plate thickness (pillowing). These changes in the geometry of the plates could have impacts on the ability to adequately cool the fuel plate, potentially leading to failure of the fuel plate and contamination of the reactor.

Following IRIS-1 and RERTR tests, there was confidence in UMo qualification plans. However, the failures of the full-sized plates in the IRIS-2 and FUTURE irradiations in 2003 led to metallographic examination of

FIGURE 4.6 Results of the IRIS-1, -2, -3 tests on U-7Mo dispersion fuel. The graph shows the limited increase of the full-sized plates’ thickness up to 4.5 × 1021 fissions/cm3 in the IRIS-1 test (approximately 70 µm), the pillowing of the full-sized plates in IRIS-2, at 2.0 and 2.5 × 1021 fissions/cm3 (local sharp increase), and the stabilization in the IRIS-3 experiment by addition of 2 percent silicon in the matrix. See text for discussion on “successful” IRIS-1 irradiation versus IRIS-2 full-plate failures. SOURCE: Modified from Lemoine and Wachs (2007).

several RERTR-4 mini-plates. It was discovered that the phenomenon that led to the failure in the full-sized plates was also evident in its early stage in the higher-power irradiations of the mini-plates (Hofman et al., 2004b). It was determined that pillowing did not occur in the RERTR tests because of the limited dimensions of the mini-plates. Furthermore, the success of the IRIS-1 test, a full-sized experiment, is attributed to two factors:

- A lower-power density (lower than IRIS-2, FUTURE, and the RERTR-4 mini-plate experiments).

- Increased resistance of its fuel meat to the pillowing phenomenon due to the morphology of the ground particles (much more jagged than the spherical atomized powder).22

The failure of the FUTURE experiment was determined to have been caused by large voids resulting from excessive interaction between the UMo particles and the Al matrix (Leenaers et al., 2004), leading to plate pillowing by loss of mechanical resistance of the fuel meat. To prevent this interaction, two solutions were proposed and sequentially tested. First, the addition of Si to the Al matrix was expected to reduce the rate of interaction. Alternatively, the application of a Si or ZrN coating on the UMo powder particles was expected to avoid the interaction altogether.

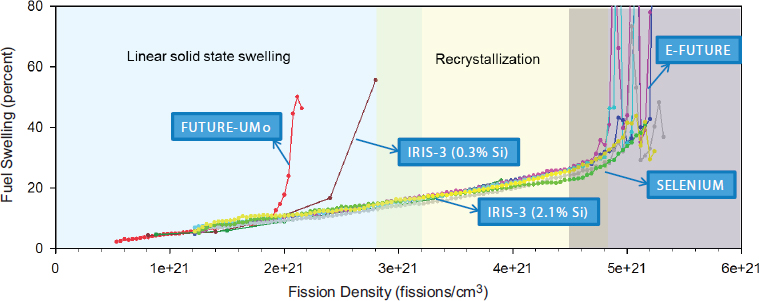

These proposed solutions clearly improved the behavior of UMo dispersion fuel, with successful irradiations up to 60 percent burnup (4.5 × 1021 fissions/cm3) as shown in Figures 4.6 and 4.7 for IRIS-3 with 2 percent Si addition in the Al matrix, E-FUTURE with 4 and 6 percent Si addition, and SELENIUM with Si or ZrN coating. The fuel plates still showed a rapid increase in swelling between 4.7 and 5.0 × 1021 fissions/cm3, which is well short of the required 6.8 × 1021 fissions/cm3 to meet operational and safety constraints of all four European HPRRs (see Figure 4.4).

The behavior at higher fission densities is not attributed to interaction-layer (IL) formation or an effect of Si added to the matrix, because the same effect is observed in the ZrN-coated U-7Mo dispersion fuel where no Si is present and only a very limited interaction layer is formed. The current working hypothesis attributes this behavior to the swelling of UMo particles due to recrystallization (Leenaers, 2014). To mitigate this effect, the HERACLES group will test the performance of UMo fuel that has been annealed to increase its grain size and homogeneity.

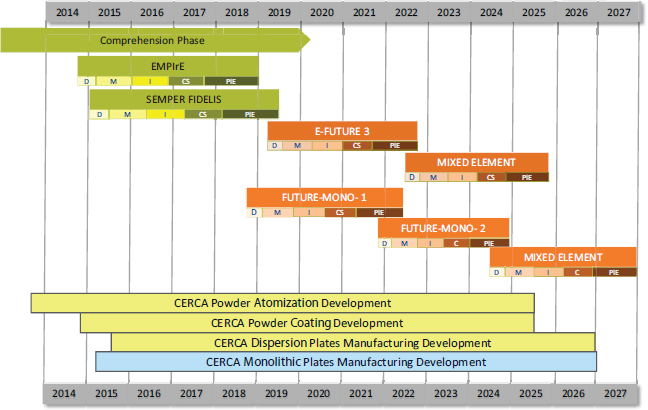

The HERACLES group currently plans six additional irradiation experiments: EMPIRE, SEMPER FIDELIS, SELENIUM 2, E-FUTURE-3, and FUTURE-MONO-I and -II (see Figure 4.8). EMPIRE and SEMPER FIDELIS are sample plate experiments. EMPIRE is a mini-plate test to be irradiated in ATR, and SEMPER FIDELIS is a subsized plate test (approximately one-third of a full-sized plate) to be irradiated in BR2. The other experiments, SELENIUM 2, E-FUTURE-3 (for dispersion fuel), and FUTURE-MONO-I and -II (for monolithic) are full-sized plate irradiation experiments. Four of these test campaigns (all but the FUTURE-MONO-I and -II monolithic fuel tests) will provide data to support the qualification of the UMo dispersion

_________________________

22 The ground particles were used for IRIS-1 because it was the only available powder when the experiment was launched. However, the grinding process currently used to make U3Si2 powder is not a viable industrial process to produce UMo powder because UMo is much more ductile than U3Si2.

FIGURE 4.7 Results of irradiation tests performed in BR2 on U-7Mo dispersion fuel: Fuel swelling from the FUTURE, E-FUTURE (plates with 4 and 6 weight by percent silicon in the matrix) and SELENIUM (silicon and ZrN coated) experiments. SOURCE: Modified from Van den Berghe et al. (2015).

fuel up to 40 kW/cm3 and 6.8 × 1021 fissions/cm3, meeting the operational and safety envelopes for Réacteur à Haut Flux (RHF), Jules Horowitz Reactor (JHR), and BR2 (see Figure 4.4). Three of these experiments will be carried out over the next 7 years (EMPIRE and SEMPER FIDELIS, from 2016 to 2019) and the E-FUTURE-3 test will be carried out thereafter (2019–2022) before irradiation of a mixed-element23 test may begin (see Figure 4.8). The dispersion fuel testing program extends to 2025.

The regulatory qualification of the UMo dispersion fuel will require irradiation of mixed-element and lead test assemblies in each candidate reactor prior to LEU conversion. In addition, the licensing process of the new fuel varies by reactor and regulatory body. Therefore, conversions of research reactors would occur several years after the conclusion of the testing program, assuming it is successful and there are no further delays.

In summary, the results of current irradiation experiments provide confidence that UMo dispersion fuels could be qualified for burnup below fission densities of 4.5 × 1021 fissions/cm3 and up to power densities on the order of 40 kW/cm3. These testing parameters meet both the operating envelope and safety margin requirements24 for one European HPRR: RHF (see Figure 4.4).

Dispersion Fuel Fabrication Status and Challenges

The HERACLES consortium is also focused on UMo dispersion fuel fabrication and qualification. Irradiation experiments for dispersion fuel are mainly being conducted on full-sized plates manufactured by CERCA using industrial processes (see the lower one-third of Figure 4.8). As such, successful irradiation experiments provide data for qualification of the fuel plate manufacturing process. In addition, there is a long history of manufacturing dispersion fuels at CERCA, much of which has been already transferred to the development of the UMo dispersion fuel manufacturing process. The most important process that still needs to be fully developed at an industrial scale is the coating of the UMo particles, which is needed to prevent interaction-layer formation.

_________________________

23 A mixed element is a standard fuel assembly in which a portion of the assembly is replaced by an experimental plate. For example, a mixed element would be formed by replacing the external ring of a driver BR2 fuel assembly (six rings of three curved HEU UAlx fuel plates) with three LEU UMo fuel plates.

24 The maximum operating envelope requirement for RHF is 2.0 × 1021 fissions/cm3 but reach testing values of 4.5 × 1021 fissions/cm3 to provide a safety margin.

FIGURE 4.8 The HERACLES time line for UMo dispersion fuel testing (status as of Quarter 4 of 2014). Each test campaign lasts approximately 3 years and includes design (D), sample manufacture (M), irradiation (I), cooling (CS), and post-irradiation examination (PIE). The SEMPER FIDELIS and EMPIRE tests are planned to begin in 2016–2017, and the E-FUTURE-3 tests are planned to begin in 2019–2022. Not shown is the SELENIUM-2 test, which is scheduled to begin in 2019–2022. SOURCE: Breitkreutz (2015).

Russia is pursuing LEU fuel development and qualification primarily for export25 based on a U-9Mo-Al matrix clad in Al that is extruded using traditional technology (Izhutov et al., 2013). Russia is developing dispersion LEU (UMo) fuel but is not currently developing monolithic fuel. The medium-density (approximately 5.4 gU/cm3) LEU fuel under development is tubular (square-shaped in cross section). It is being designed for medium-flux reactors (such as MIR.M1 and Russian-supplied reactors such as the MARIA reactor in Poland). Novosibirsk Chemical Concentrates Plant (NCCP) is fabricating this new fuel. Testing of the new dispersion fuel is expected to be completed in June 2016. A conversion analysis, including a comparative safety analysis, has been completed for MIR.M1 (Izhutov et al., 2014; Mainskov, 2015). Previous studies have shown that conversion of the MIR.M1 reactor with medium-density LEU fuels (U-9Mo dispersion, 5 gU/cm3) is feasible without loss of performance or impact to safety (Izhutov et al., 2012). However, there are no current plans to convert MIR. M1 (see Chapter 5).

A large fraction of UMo particles used in the development of the European and U.S. dispersion fuel programs were produced by South Korea (the Korea Atomic Energy Research Institute [KAERI]) using the atomization process developed for the production of the U3Si particles of the HANARO reactor driver fuel.26 KAERI has conducted five experiments (KOMO-1 to -5) in the High-Flux Advanced Neutron Application Reactor (HANARO) on partial- and/or full-sized UMo dispersion fuel rods with densities as high as 5 gU/cm3 and at power densities ranging from 9 to 12 kW/cm3. KAERI investigated many fuel parameters,27 which confirmed the results of other international tests on the clear effect of Si on the interaction layer (Park, 2015).

In order to qualify the fuel for the new KJRR reactor, KAERI has set up an experimental program in the HANARO reactor on reduced-sized plates (Program HAMP-1, -2, -3, in progress) and two full-sized fuel assemblies planned for ATR in 2016. The first results of the HAMP-1 irradiation are consistent with IRIS-3 results (expansion of 70–80 microns at burnups to 60–65 percent). KAERI and the M3 Office of Conversion made significant

_________________________

25 Information gathered during discussions held July 16–17, 2015, during committee site visits to RIAR in Dimitrovgrad. Costs of the fuel played a large part in Russia’s fuel selection, such as the choice to produce a medium-density LEU fuel without a coating (to keep the fabrication costs as low as possible).

26 The HANARO fuel is based on a rod-type fuel element produced by extrusion, in which the maximum volume fraction of particles is approximately 30 percent, limiting the U-loading of the U3Si/Al dispersion fuel at the value 3.15 gU/cm3.

27 Parameters studied in the KOMO tests include the fuel composition of the particles (UMo binary alloys or ternary alloys as UMo-1Ti or 1Zr), the size of the particles, and the matrix composition (pure Al or Al-Si with Si addition ranges from 0.4 to 8.0 percent).

investments to successfully qualify the industrial processes to manufacture UMo dispersion fuel and qualify the UMo fuel plates for the KJRR reactor to densities of 8 gU/cm3.

Monolithic Fuel: Test History and Status

The United States has selected monolithic UMo fuel, first proposed in the early 2000s, over UMo dispersion fuels because of its much higher uranium density (15.9 gU/cm3 versus 8.5 gU/cm3), which is required to meet the peak power density requirements of some of the USHPRRs (see Figure 4.3). As previously noted, monolithic fuel is fabricated by cladding a thin UMo foil with Al. The first irradiation experiments performed on mini-plates fabricated with these processes resulted in high failure rates, primarily because of the delamination of the Al cladding from the UMo foil. This behavior led to the introduction of a diffusion barrier between the foil and the cladding. A Zr barrier has proven to be successful at preventing failures at very high burnups. Experimental evidence provides confidence that UMo monolithic fuel with a Zr diffusion barrier will be qualifiable for burnups up to 8 × 1021 fissions/cm3 and power density levels up to 40 kW/cm3 (Meyer et al., 2014).28

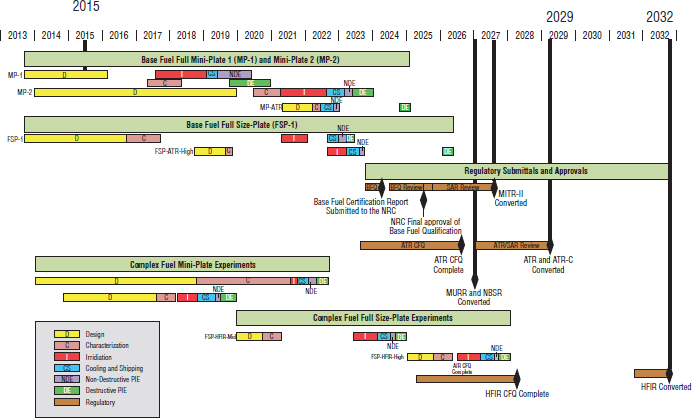

The U.S. program has divided its fuel development and qualification effort into “base fuel” and “complex fuel” programs, both of which will use the same basic UMo monolithic fuel. The base fuel program, which would meet the needs of five of the USHPRRs—Massachusetts Institute of Technology Reactor (MITR-II), University of Missouri Research Reactor (MURR), Neutron Beam Split-core Reactor (NBSR), and ATR including ATR-Critical Facility (ATR-C)—has two upcoming mini-plate irradiation campaigns, MP-1 and -2, planned to start in 2018 and end in 2022 (see Figure 4.9). The first irradiation of full-sized plates for the base fuel, FP-1, will begin in 2021 and end in late 2022. Demonstration fuel assemblies specific to each reactor will be tested from 2022 through 2024.

The complex fuel program, which is focused on HFIR fuel only, faces significant additional fabrication challenges and is therefore proceeding on a different schedule. Mini-plate experiments for the complex fuel are scheduled to be conducted in 2018 and 2022, with the first full-sized plate experiments scheduled for 2023. Additional full-plate irradiation experiments will be conducted in 2026 prior to a demonstration assembly for the complex fuel in 2028. The majority of these tests will be conducted at ATR, with some fuel assembly testing occurring in BR2.

_________________________

28 These values include a safety factor because 8 × 1021 fissions/cm3 is an approximate value for the maximum possible burnup (100 percent) of LEU fuel.

FIGURE 4.9 The roadmap for U.S. UMo monolithic fuel development, qualification, and USHPRR conversion, last updated in June 2015. Test campaigns are split into base fuel and complex fuel testing. Steps in the process are design (D), fabrication (F), characterization (C), irradiation (I), cooling and shipping (CS), nondestructive PIE (NDE), and destructive PIE (DE). SOURCE: Modified from “USHPRR Road Map_07292015.pdf” (Landers, 2015), used with permission from the National Nuclear Security Administration (DOE).

Monolithic Fuel Fabrication Status and Challenges

The fabrication process for monolithic UMo fuel presents many technical challenges. The manufacturing process has both more and different processing steps than are needed for existing dispersion fuels. These factors may well affect the relative cost of the two fuel types. The monolithic fuel manufacturing process has not yet been demonstrated as economically viable at an industrial scale.

The base fuel is a U-10Mo monolithic fuel with a Zr diffusion barrier clad in Al alloy formed via co-rolling and hot isostatic pressing processes. The current fabrication method begins by covering a cast and machined ingot of U-10Mo alloy on both sides with Zr. This is placed into a steel frame, covered on top and bottom by steel sheets, and welded closed to make what is referred to as a “can” (to prevent oxidation during the following steps). This can is hot-rolled to bond the Zr to the UMo and to reduce its thickness to the approximate required dimensions.

The foil is removed from the can, cold-rolled to the desired thickness, and cut to desired lateral dimensions. This dimensioned foil is placed into a box of Al alloy and covered by a plate of Al alloy to encase the fuel foil and diffusion barrier. Several of these assemblies are stacked with separating layers and sealed into a stainless steel can for hot isostatic pressing to bond the layers of the fuel plate. Afterwards, the plates are removed from the stainless steel can and finally cut or machined to final size.

Operators of three USHPRRs made significant changes to their fuel designs in order to simplify LEU monolithic fuel manufacturing: MITR-II, ATR, and ATR-C. MITR-II operators have agreed to remove cooling “fins” from the fuel elements after modeling and neutronic analysis showed little impact to the safety of operations. The fuel design for ATR and ATR-C originally included a burnable absorber integrated within the fuel plates, but analysis of a new LEU fuel design showed that it is feasible to move it from within the fuel plate. These are good examples of flexibility of operators with assistance from the M3 Office of Conversion to find solutions for conversion.

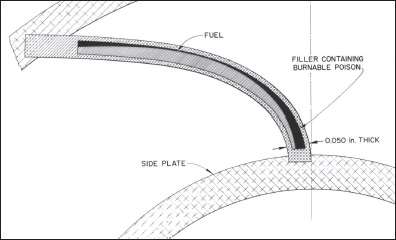

The base fuel fabrication process cannot be used for the manufacture of the HFIR fuel assembly because the fuel plate is curved in a noncylindrical shape,29 the fuel meat within the plate has variable thickness, and burnable poisons are included (see Figure 4.10). New fabrication concepts are being considered that include shaped rolls to taper the sides of the plate and extrusion of the fuel through a die of the proper cross section. Some initial studies are under way, but few results are available (Itamura, 2015; Landers, 2015; Chandler et al., 2013).

_________________________

29 The fabrication of each plate to its final shape requires skilled hand-craftsmanship.

FIGURE 4.10 HFIR fuel plate: a cross-sectional drawing of the current design of an HFIR inner fuel plate. Note the nonrectangular shape of the fuel meat and the burnable poison. SOURCE: Courtesy of Oak Ridge National Laboratory.

The USHPRR fuel development roadmap in Figure 4.9 indicates that complex fuel fabrication begins in early 2017. If successful, then this will be the first monolithic fuel qualified for use in research reactors worldwide. It is clear, however, that manufacturing this fuel will be considerably more complicated, and presumably more expensive, than the base monolithic fuel.

Economics of Monolithic Fuel Fabrication

The program to develop, fabricate, and manufacture LEU monolithic fuel plates and elements has progressed much more slowly than envisioned at the outset of the GTRI effort in 2004 (Staples, 2005; Travelli, 2004). Furthermore, the manufacturing process will require additional and qualitatively different steps than dispersion fuel fabrication and is not yet optimized.

Babcock and Wilcox Technologies (BWXT) is the U.S. manufacturer of research reactor fuel. It has compared estimates of the costs for element fabrication with monolithic fuels to the costs for fabrication of the current HEU elements. These estimates assume that the yield of fuel foils is 88 percent and the yield of plates is 90 percent, the same yields currently achieved for HEU fuel (Argon, 2015). These yields have not yet been demonstrated for monolithic fuel.

A cost model was developed in 2012 to estimate the relative percentage increase in cost of fabrication of LEU fuel plates compared to the currently fabricated HEU plates. Notably, the model does not include the following:

- The cost of the cast U-10Mo received for processing (and therefore also excludes the cost of scrap associated with making the U-10M ingot).

- The cost of incorporation of any burnable absorbers (as will be needed, potentially, for HFIR fuel).

- Shipping costs.

- Waste costs.

- Any costs related to the transition from HEU plate production to LEU plate production.

The model was refined in 2014, taking into account the extended schedule for manufacturing the elements and new estimates of labor hours associated with the fabrication of plates from different coupon sizes. The resulting estimated changes in fuel fabrication costs are shown in Table 4.2. When viewing this table it is important to bear in mind that steps in the manufacturing process have not yet been finalized, leading to additional uncertainty in the overall relative costs of LEU fuel assemblies. Finally, questions remain about the fabrication of complex fuel for HFIR, arising particularly from the need to taper the foils and to incorporate burnable poisons into the fuel assemblies.

Two USHPRRs account for over 80 percent of BWXT’s research reactor fuel commercial volume. Orders for ATR and HFIR fuel assemblies are responsible for approximately one-half and one-third, respectively, of the current fuel fabrication activities for the USHPRRs (Meyer, 2006).30 The high volume of fuel utilization allows the fixed costs of USHPRR fuel manufacture to be spread over a larger number of total fuel plates than would be possible in the absence of these two reactors.31 In short, the future demand for LEU fuel assemblies for HFIR and ATR are expected to drive the economics of LEU fuel assemblies for the remaining USHPRRs. Without a qualified fuel for HFIR and ATR, the cost per fuel plate for the remaining three USHPRRs would be expected to increase dramatically. By contrast, if one or two of the other three USHPRRs were to employ a different fuel type, then it would not have a substantial cost impact on the other reactors (assuming they would be relying on monolithic fuel).

_________________________

30 The HPRRs use (or plan to use) HEU fuel. The average annual amount of HEU feedstock at 93 percent 235U assay supplied to domestic, non-DOE reactors (MITR-II, MURR, and NBSR) over the past 10 years is approximately 20 kgU per year; this amount increases to approximately 210 kgU with the inclusion of DOE reactors (ATR, ATR-C, and HFIR). For foreign research reactors and isotope production customers (e.g., AECL-Canada, BR2 and IRE in Belgium, NRG in the Netherlands, RHF-ILL in France), the average annual amount, over the same 10-year period, is approximately 52 kgU at 93 percent 235U assay.

31 Written correspondence, Gunes Argon, August 5, 2015.

TABLE 4.2 BWXT Fabrication Cost Estimates for U-10Mo Monolithic Fuel Assemblies for the USHPRRs

| Reactor | 2012 Estimate of Cost Increase over HEU (%) | 2014 Estimate of Cost Decrease over 2012 Estimate (%) | Calculated 2014 Estimate of Increase over HEU (%) |

| ATR | 17 | 15 | –1 |

| HFIR | 115a | 16 | 81 |

| MITR-II | 13 | 16 | –5b |

| MURR | 49 | 14 | 28 |

| NBSR | 60 | 25 | 20 |

a Because of the complex geometry of the HFIR fuel and the lack of manufacturing development to date, it is roughly estimated that HFIR foil manufacturing will take twice as long as the current manufacturing process.

b The decreased projected cost for MITR-II fuel assemblies may be due to simplification in its fuel assembly design. There are large uncertainties in the values of these numbers (see text for more details).

SOURCE: Data from Argon (2015).

The decision to develop monolithic UMo fuel has introduced a number of manufacturing challenges, particularly the following:

- Whereas dispersion fuels makes it possible to achieve different uranium densities by incorporating different volumetric fractions of fuel powder in the matrix (up to a practical limit), monolithic foils have a fixed uranium density. Similar design goals can be achieved by varying the thickness of the UMo foils in the monolithic plates.

- The manufacturing of monolithic fuel plates, including thin foils, barrier layers, and cladding, poses novel challenges compared to existing reactor fuels for even the basic fuel configuration and more extreme challenges for the complex fuel required by HFIR.

- Given the increased complexity in the manufacturing processes required for monolithic fuel, the yield assumptions being used in estimating fuel costs, at least initially, are likely to be overly optimistic.

ASSESSMENT OF PROGRESS TO DEVELOP LEU FUEL

The previous sections have discussed worldwide fuel development programs, including UMo dispersion and monolithic LEU fuels. Table 4.3 summarizes the committee’s conclusions regarding the progress toward delivery of a variety of high-density LEU fuels, including the key steps of

TABLE 4.3 Assessment of Availability of Committee-Selected LEU Fuels

| U3Si2 4.8 gU/cm3 | U3Si2 5.8 gU/cm3 | UMo (Dispersion) Low Power Density (<17 kW/cm3) | UMo (Dispersion) High Power Density (>17 kW/cm3) | UMo (Monolithic) | |

| Fuel qualification: Has the LEU fuel been qualified under irradiation? Y = yes, N = no | Y | N | a | N | N |

| Manufacturing qualification: Has the manufacturing process for the LEU fuel been qualified? Y = yes, N = no | Y | b | N | N | N |

| Commercial availability: Is the LEU fuel commercially available? Y = yes, N = no | Y | N | N | N | N |

| Fuel Availability: How many years to deliver LEU fuel? Rough estimate of number of years provided | < 5 | 5–10 | 5–10 | 15–20 | 15–20 |

| Uncertainty: What is the uncertainty in the estimate of years? | Low | Medium | Medium | Medium-High | High |

a To be confirmed by the irradiation of South Korean fuel elements in ATR.

b Would have to be confirmed by additional R&D program.

NOTES: Colors highlight technical risk and uncertainty associated with each fuel with red = highest risk and green = lowest risk. The uranium silicide fuel with uranium density 4.8 gU/cm3 assumes approximately 42 percent volume of dispersant in the matrix; a uranium density 5.8 gU/cm3 assumes approximately 50 percent volume of dispersant in the matrix.

SOURCE: Developed by the committee from multiple sources.

fuel qualification, manufacturing qualification, commercial availability, and the expected schedule for fuel availability. The values in the table indicate that silicide fuel (U3Si2) is the most promising fuel that could potentially be qualified in less than 5 years. Because the South Korean program is focused on the qualification of UMo dispersion fuel at low power density (below 185 W/cm2 or 17 kW/cm3), the committee has separated this fuel from the “high” power density UMo dispersion fuel, which satisfies the usual HPRR power density-burnup envelope.

This assessment leads to the following findings:

Finding 6: Most of the technical challenges to converting the remaining research reactors to low enriched uranium (LEU) concern a few high performance research reactors (HPRRs) that require a new high-density LEU fuel to be developed and qualified.

- The timescale for designing, fabricating, qualifying, and converting to UMo LEU monolithic (U.S. program) or dispersion (European program) fuel for all HPRRs is now estimated to be around 15–20 years, resulting in nearly two decades of continued reliance on weapon-grade highly enriched uranium (HEU).

- The monolithic fuel faces more manufacturing challenges for qualification and therefore higher uncertainty and risk in the estimate of the time line.

Finding 7: The economic viability of high-density low enriched uranium fuel is highly uncertain and is a source of significant concern to the operators of high performance research reactors worldwide.

Summary of the Current Status of Conversion

The “principles of conversion” defined and supported by U.S. conversion programs since 1978 lead to constraints on the design of the LEU fuel as described previously: for example, the amount of 235U that LEU fuel assemblies must contain, their geometry and size, and the operational envelopes over which they must perform safely. One of the critical parameters for an LEU replacement fuel is uranium density. Many reactors have converted without significantly affecting their performance using LEU fuels with densities up to 4.8 gU/cm3. However, the highest-performing research reactors throughout the world cannot convert using these fuels while maintaining their performance. New very high-density LEU fuels have been developed for these reactors, but they are not yet qualified. The fuels (UMo dispersion and monolithic) did not pass initial irradiation tests over their full operating envelopes, failing at fission densities of 2.0 to 2.5 × 1021 fissions/cm3

(see FUTURE-UMo results in Figure 4.7). Investigation and determination of the root causes of the failures and identification of solutions have taken more than a decade of research and additional testing. The current estimates to qualify the UMo monolithic base and complex fuels are 12 and 13 years, respectively. Conversion of USHPRRs occurs several years later (after regulatory approval) and is estimated to occur in 2029 (for completion of the USHPRRS using base fuel) and 2032 (for HFIR).32 In other words, shipments of 93 percent HEU fuel will be required for the next approximately 15–20 years to supply the USHPRRs. Furthermore, although the new fuels are expected to, at least initially, be more expensive than existing fuels, no comprehensive cost analysis has been performed because of large uncertainties in important parameters, including specification of the manufacturing process.

ACCELERATING THE MINIMIZATION OF WEAPON-USABLE NUCLEAR MATERIAL

With the performance constraints defined above and the schedules for conversion now stretching nearly two decades into the future, the committee felt compelled to investigate the opportunities to meet M3’s primary objective of “achieving permanent threat reduction by minimizing and, when possible, eliminating weapons-usable nuclear material around the world.”33 These opportunities arise from relaxing the constraint on LEU enrichment.34Box 4.2 provides background on the proliferation and security risks associated with enrichments higher than 20 percent but well below weapon grade.

Several sources were used to provide rough estimates of the minimum enrichment required to allow conversion of each HPRR using different fuel systems. The quality of the estimates varies across the suite of HPRRs because of differing types of information collected by the committee. The results of the analysis are shown in Table 4.4.

Qualified silicide (U3Si2) fuel, as-yet-unqualified higher-density U3Si2 fuel, and UMo dispersion fuel were considered for each USHPRR, either as a path to conversion earlier than currently scheduled or as a backup option to mitigate the risks in monolithic fuel development and fabrication.

_________________________

32 USHPRR Roadmap, provided to the committee by DOE/NNSA in January 2015 and (updated) August 2015 (Landers, 2015).

33 See http://nnsa.energy.gov/aboutus/ourprograms/dnn/m3.

34 The relaxation of performance constraints has been considered by the M3 Office of Conversion and operators to some extent. Examples of successful implementation of adjustments to performance constraints are increased operational power post-conversion to compensate for LEU performance impacts (HFIR), increased experimental capabilities (NBSR), or changes to fuel element design to ease manufacturing (MITR-II).

BOX 4.2

Uranium Enrichment Level, Weapon Usability, and Proliferation-Risk Attributes

Critical mass is a good, first-order indicator for the attractiveness of enriched uranium for use in a nuclear weapon or explosive device. As shown in Figure 2.1, the critical mass drops sharply as the enrichment (i.e., the concentration of 235U in the material) increases and fewer neutrons interact with nonfissile 238U. The critical mass of 45 percent enriched uranium is 3–4 times higher and the critical mass of 20 percent enriched uranium is 12–15 times higher than 90 percent enriched uranium (weapon grade).

In addition to the amount of material needed to reach criticality, and as a compounding effect, the critical mass value can also serve as a simple indicator of the difficulty of rapidly assembling the device (which has to happen on the order of milliseconds for a uranium-based gun-type device). In general, acceleration scales inversely with mass (Glaser, 2006). Therefore, the increase in mass as enrichment decreases both weakens the chain-reacting properties of the material when it is in its final (supercritical) configuration and increases the level of difficulty of achieving this configuration. Combined, this explains why uranium enriched to less than 20 percent is considered non-weapon-usable.

To obtain a slightly more robust assessment of the weapon usability of enriched uranium, one can refer to the original memorandum prepared by the U.S. Atomic Energy Commission to establish the 20 percent limit for uranium that would be exported to foreign countries for use as research reactor fuel (Hafstad, 1954). The report uses a simple expression to estimate the amount of enriched uranium (M) needed to achieve the same reference yield (of 1 kiloton) in a nuclear explosive device as a function of the 235U concentration (ε) in the material:a

![]()

This expression can be used to estimate the relative increase of the amount of less-enriched uranium needed when compared to weapon-grade highly enriched uranium (W-HEU):

![]()

In other words, a device based on 45 percent enriched uranium requires approximately 3.4 times more material, and a device based on 20 percent enriched uranium requires approximately 13.6 times more material when compared to a device using W-HEU. This is almost perfectly consistent with the simple comparison of critical masses above.

For a more realistic assessment of the proliferation and security risks associated with research reactor fuel, these ratios ought to be weighted, however, by the amount of uranium needed to fuel a given reactor over the same period of time. A research reactor using less-enriched uranium requires more fuel and, to a first approximation, the 235U consumption remains about the same for equal power levels; for example, the fuel throughput at least doubles if the enrichment is halved.

TABLE B4.2 Quantifying Proliferation Risks of Research Reactor Fuels with Reduced Enrichment

| Enrichment (%) | Mass Ratio A (for Explosive Device) | Mass Ratio B (Fuel Throughput) | “Risk Metric” (B/A) |

| 93 | 1 | 1 | 1 |

| 45 | ~3.4 | ~2.0 | ~0.59 |

| 27 | ~8.2 | ~3.3 | ~0.40 |

| 20 | ~13.6 | ~4.4 | ~0.32 |

SOURCE: Data from Glaser (2006, pp. 1–24).

For an assessment of the net gain in proliferation resistance for every enrichment level considered, one can use the relative increase in fuel demand divided by the mass ratio for an explosive device. Table B4.2 summarizes the basic results. Very roughly, a reduction of the fuel enrichment from 93 percent to 45 percent cuts the attractiveness by about 40 percent, and a reduction from 93 percent to 20 percent cuts the attractiveness by almost 70 percent, compared to W-HEU. Put differently, and perhaps not too surprisingly, use of 45 percent enriched fuel is roughly equivalent to getting “half way” compared to a full conversion to 20 percent enriched material.

As the enrichment level is reduced, the amount of material needed for one nuclear explosive device increases significantly (Mass ratio A). At the same time, however, more fuel is needed to operate the same reactor (Mass ratio B). The ratio of both numbers provides a simple metric (a “risk metric”) to compare proliferation-risk attributes of different fuel enrichment levels: 45 percent enriched fuel offers a 40 percent reduction, and 20 percent enriched fuel offers a 70 percent reduction, compared to weapon-grade fuel (93 percent U235). Recall that the DOE material attractiveness analysis (from the perspective of an adversary) assigns a lower value of attractiveness for 50 percent or lower enrichment. This simple analysis does not account for the difficulty of using less-enriched fuel in a nuclear explosive device. Below an enrichment level of 20 percent, the use of uranium for weapon purposes is considered impractical.

_________________________

a The memorandum does not explicitly distinguish implosion-type from gun-type devices, but the absolute numbers given are apparently for an implosion-type design. Here, we assume the mass-enrichment dependency for constant explosive yield remains approximately valid for both designs.

TABLE 4.4 Approximate Enrichments Necessary to Allow Conversion from W-HEU to Lower Enrichments

| HPRR | U3Si2 4.8 gU/cm3 (%) | U3Si2 5.8gU/cm3,a (%) | UMo (Dispersion)b (%) | UMo (Monolithic)b | Years to Conversion Using UMo (Monolithic) Fuelc |

| ATR | 35–40d | ~30 | 25–30 | LEU | 14 years |

| HFIR | 35–40d | ~30 | 25–30 | LEU | 17 years |

| NBSR | ~25d | LEU | LEU | LEU | 12 years |

| MURR | ~45d | ~40 | ~35 | LEU | 12 years |

| MITR-II | ~35d | ~30 | 20–25 | LEU | 12 years |

| FRM-II | 50–60e | 35f | 30 | LEU | N/A |

| BR2 | ~27e | ~22 | LEU | LEU | N/A |

| JHR | 27e | 22 | LEU | LEU | N/A |

| RHF | ~27e | ~22 | LEU | LEU | N/A |

a Enrichment for 5.8 gU/cm3 fuel was estimated by the following ratio: [(4.8/5.8) × (enrichment)] to preserve 235U density.

b A factor of 0.85 applied to account for reactivity loss of UMo versus U3Si2 fuel.

c Chris Landers, USHPRR Road Map—June 2015.

e The 60 percent estimate is based on the required 235U inventory in the core. FRM-II operators have recently begun exploring options to increase the available fuel volume, which might enable enrichment levels closer to 50 percent. The entries for BR2, JHR, and ILL are estimated on the basis of comparisons with FRM-II.

f This value assumes U3Si2 fuel at 6 gU/cm3 with extended fuel volume (Pichlmaier et al., 2015).