Mechanical Metamaterials: Design, Fabrication, and Performance

CHRISTOPHER SPADACCINI

Lawrence Livermore National Laboratory

Material properties are governed by the chemical composition and spatial arrangement of the constituent elements at multiple length scales. This characteristic fundamentally limits the properties with respect to each other and requires tradeoffs when selecting materials for specific applications. For example, strength and density are inherently linked so that, in general, the more dense the material, the stronger it is.

In my laboratory we are combining advanced microstructural design, using flexure and screw theory as well as topology optimization, with advanced additive micro- and nanomanufacturing techniques to create new material systems with previously unachievable property combinations. The performance of these mechanical metamaterials is controlled by geometry at multiple length scales rather than by chemical composition alone.

We have demonstrated designer properties of these mechanical metamaterials in polymers, metals, ceramics, and combinations thereof, yielding properties such as ultrastiff lightweight materials, negative stiffness, and negative thermal expansion. Our manufacturing techniques include projection microstereolithography (PmSL), direct ink writing (DIW), and electrophoretic deposition (EPD). With these methods, we can generate three-dimensional micro- and nanoscale architectures with multiple constituent materials in the same structure.

INTRODUCTION

Material properties can be controlled via intricate assemblies and structural organization at multiple length scales, as evidenced by naturally occurring cellular materials such as honeycombs (Ando and Onda 1999), trabecular bone (Ryan

and Shaw 2013), plant parenchyma (Van Liedekerke et al. 2010), and sponges (Shen et al. 2013). It is the architecture of the material’s structure at the micro- and nanoscale, as much as the chemical composition, that yields its mechanical properties. By designing highly ordered architectures in cellular solids, it is possible to engineer the mechanical response of these materials to create mechanical metamaterials (Deshpande et al. 2001; Gibson and Ashby 2001).

The ability to decouple properties via micro- and nanoarchitectural control can allow for unique material performance such as ultralightweight, high-stiffness, and high-strength materials (Bauer et al. 2014; Schaedler et al. 2011), negative Poisson’s ratio (Lakes 1987), negative stiffness (Lakes et al. 2001), and negative thermal expansion coefficient (Sigmund and Torquato 1997). Paramount to achieving these often unnatural properties is an ability to design, fabricate, and characterize structures for the properties of interest. In fact, this method of choosing a unique property and engineering a material’s performance through its architecture could be described as an inverse design problem. Normally, material properties are taken to be absolute and functional structures are then created from these materials. Mechanical metamaterials result from exactly the opposite approach.

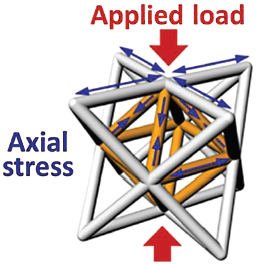

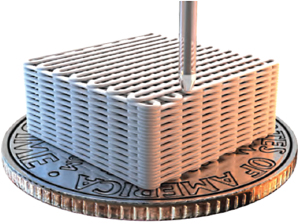

A classic example of architectural control and the resulting unique material performance is the octet truss stretch-dominated lattice (Deshpande et al. 2001) shown in Figure 1. This structure, which contains b struts and j frictionless joints, satisfies Maxwell’s criterion, where b – 3j + 6 > 0, which defines a stretch-dominated structure. Because the struts in the unit cell are designed to be

FIGURE 1 Octet truss stretch-dominated unit cell that can be tessellated in space to form a lattice. SOURCE: Zheng et al. (2014).

in either tension or compression under applied load, as opposed to bending, the lattice is mechanically efficient with a high stiffness-to-weight ratio (E/ρ). In fact, it is designed to have a linear scaling relationship between stiffness and density, E/Es ∝ (ρ/ρs), where the subscript s denotes bulk properties.

Most naturally occurring materials with stochastic porosity have a quadratic or even cubic relationship: for every order of magnitude decrease in density there is a corresponding 2 to 3 order of magnitude decrease in stiffness. The architected design fundamentally changes the scaling relationship of the lattice material through geometry rather than composition. This concept can be further advanced by taking advantage of nanoscale size effects. Strength to density relationships can be effectively manipulated with control at size-scales below the critical flaw and crack dimensions (Jang et al. 2013).

DESIGN

Numerous methods can be used to solve the inverse design problem for mechanical metamaterials. In our laboratory and with key collaborators, we have primarily been developing and using two techniques, one analytical and the other computational. The analytical method is known as freedom, actuation, and constraint topologies (FACT) and it relies on design of flexure and screw elements to create unit cells and lattices with prescribed properties (Hopkins and Culpepper 2010a,b). The computational method we have been using is topology optimization (TO), which involves optimizing a unit cell’s layout subject to an objective function and boundary conditions.

The FACT Method

The FACT method relies on use of a previously developed, comprehensive library of geometric shapes that define fundamental flexure and screw motion. These shapes enable the designer of a unit cell to visualize all the regions wherein various microstructural elements may be placed to achieve desired bulk material properties.

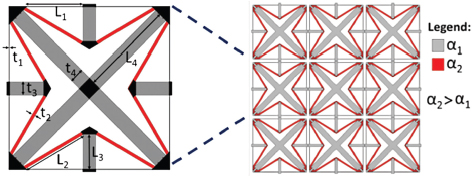

As an example, consider a two-dimensional (2D) unit cell design with negative thermal expansion that was derived using FACT and is shown in Figure 2 (Hopkins et al. 2013). In this unit cell, two materials (shown in red and grey) plus void space are required to achieve the negative property. As the unit cell heats up, the red material, which has a larger thermal expansion than the grey material, volumetrically expands more relative to its grey counterpart. Consequently, the red angled component pulls inward the center of the flexure element, which makes up the sidewall of the unit cell, while simultaneously pushing the corners of the unit cell outward. When arranged in a lattice connected at the midpoint of each sidewall, the corners grow into the void space while the sidewalls are pulled inward, resulting in an overall contraction of the lattice and hence negative thermal expansion.

FIGURE 2 Unit cell and lattice with negative thermal expansion designed using freedom, actuation, and constraint topologies (FACT). α = coefficient of thermal expansion; L = length; t = thickness. Adapted from Hopkins et al. (2013).

The FACT technique can be used to design other mechanical metamaterials with properties such as negative Poisson’s ratio and nonlinear responses.

Topology Optimization

Topology optimization is a computationally driven inverse design method. In our implementation, we utilize a finite element solver as the core physics engine and an optimization algorithm subject to an objective function and constraints to evolve the design.

A negative thermal expansion metamaterial again serves as an example. In a typical implementation, we begin with a unit cell with three phases randomly distributed throughout the space: a high thermal expansion constituent material, a relatively lower thermal expansion constituent material, and void space. An objective function such as a specific target thermal expansion for the unit cell is defined along with quantitative constraints such as stiffness and volume fraction bounds.

Initially, the finite element solver calculates the material properties for the random distribution of phases. These properties will likely be far from the target and may also violate the constraints. At this point, the optimization algorithm, which in this case is a gradient-based method, will redistribute the three phases by some small amount and the finite element solver again calculates properties. The new properties are then evaluated against the target and the previously calculated values and the optimization algorithm again redistributes material based on this information in an attempt to approach the target.

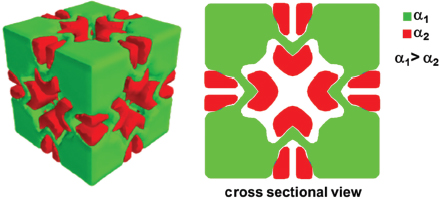

This iterative process is repeated until it converges to a design that minimizes the objective function and satisfies all constraints. An example of a topology-optimized negative thermal expansion unit cell design is shown in

FIGURE 3 Negative thermal expansion metamaterial unit cell designed using topology optimization. The red and green represent two different materials with different thermal expansion coefficients (α). Figure in color at http://www.nap.edu/catalog/21825.

Figure 3. In some cases convergence may not be achieved because the problem is overconstrained and/or has poor initial conditions.

There are significant limitations to TO methods, including a lack of knowledge about practical manufacturing constraints in the algorithm, a propensity to converge to a local minimum solution rather than a global one, and, for more sophisticated design problems, the need for expensive high-performance computing resources.

FABRICATION

Physical realization of mechanical metamaterials requires a suite of fabrication processes with unique capabilities. Additive manufacturing (AM) methods are particularly well suited to the geometric complexity of these structures and lattices. But some features and geometries in these structures are not attainable with commercially available AM tools, and so we have developed our own custom processes and materials, described and illustrated in the following sections.

Projection Microstereolithography

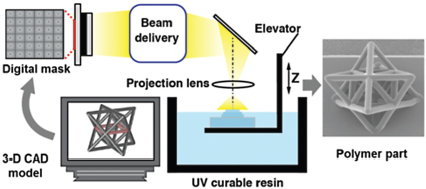

Projection microstereolithography (PmSL) uses a spatial light modulator—a liquid crystal on silicon (LCoS) or digital micromirror device (DMD)—as a dynamically reconfigurable digital photomask to fabricate three-dimensional materials in a layer-by-layer fashion.

A 3D computer-aided design (CAD) model is first sliced into a series of closely spaced horizontal planes. These 2D image slices are sequentially trans-

mitted to the reflective LCoS chip, which is illuminated with ultraviolet (UV) light from a light-emitting diode (LED) array. Each image is projected through a reduction lens onto the surface of a photosensitive resin. The exposed liquid cures, forming a layer in the shape of the 2D image, and the substrate on which it rests is lowered, reflowing a thin film of liquid over the cured layer. The image projection is then repeated with the next image slice until the desired number of layers has been fabricated to complete the 3D structure. A schematic of the basic system is shown in Figure 4 along with a photo of an example structure (Zheng et al. 2014).

We have also recently developed a scanning version of this concept, enabling us to rapidly fabricate structures approaching 10 cm in size while maintaining features as small as 10 microns.

Direct Ink Writing

Another method that we have been utilizing to fabricate these metamaterials is direct ink writing. DIW is a layer-by-layer printing approach in which concentrated inks are deposited in planar and 3D layouts with lateral dimensions (minimum ~400 nm) that are at least an order of magnitude lower than those achieved by conventional extrusion-based printing methods. Paramount to this approach is the creation of concentrated inks that can be extruded through fine deposition nozzles as filaments and then undergo rapid solidification to maintain their shape, as shown in Figure 5 (Lewis 2002; Smay et al. 2002). In many cases they can even span significant gaps across unsupported regions (Ahn et al. 2009).

Techniques such as DIW offer an attractive alternative to conventional manufacturing technologies because of the low cost of the printing equipment, ease of manufacture, and flexibility of material systems and dimensions.

FIGURE 4 Schematic (left) of projection microstereolithography (PμSL) and photo (right) of a fabricated component. CAD = computer-aided design; UV = ultraviolet. SOURCE: Zheng et al. (2014).

FIGURE 5 Direct ink writing is an extrusion-based process.

Electrophoretic Deposition

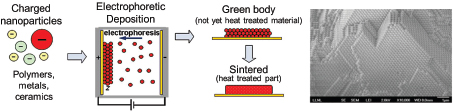

A third fabrication method that allows for the deposition of a range of materials is electrophoretic deposition (EPD), a bottom-up fabrication process that utilizes electric fields to deposit charged nanoparticles from a solution onto a substrate (Besra and Liu 2007; Pascall et al. 2014).

EPD can be used with a wide range of nanoparticles, including oxides, metals, polymers, and semiconductors. Once the particles are deposited the green body can be dried and/or sintered to adhere the particles together into a fixed structure. A schematic and fabricated nanostructure are shown in Figure 6.

EPD has traditionally been used for coating applications, such as depositing ceramic materials onto metal tooling. We have expanded the technology to enable patterning of mesoscale multimaterial structures with micron-scale tailoring. Our modifications include automated sample injection during deposition to tailor the material composition, the use of dynamic electrodes to controllably vary the electric field profile on the deposition plane and precisely pattern geometries, and in-depth process modeling to predict the deposition parameters required to achieve a specific packing structure.

Postprocessing Techniques

Postprocessing techniques can help expand the palette of usable materials and/or improve final component properties. Thermal treatments such as sintering and hot isostatic pressing are frequently used. The use of polymer structures as templates for other materials is another common method for achieving an expanded material set.

FIGURE 6 Schematic (left) of the electrophoretic deposition process and (right) photo of a fabricated structure.

For example, a polymer structure fabricated with any one of the methods described above could be coated via electroless plating, atomic layer deposition (ALD), or chemical vapor deposition (CVD) processes. The polymer in these hybrid structures could then be thermally or chemically removed, converting the structure to pure metallic or ceramic hollow structures.

Finally, nanoparticles can be suspended in the base feedstocks such as liquid monomers, resulting in a hybrid structure with particles distributed throughout the polymer. Thermal processing can then be used to remove the polymer and densify the particles, leaving a relatively pure, nonpolymeric structure.

PERFORMANCE

Mechanical metamaterials are becoming a reality thanks to advanced fabrication and design methods. Two examples of simple lattice-based materials with unique properties are ultralight, ultrastiff microlattices and elastomeric cellular architectures with negative stiffness.

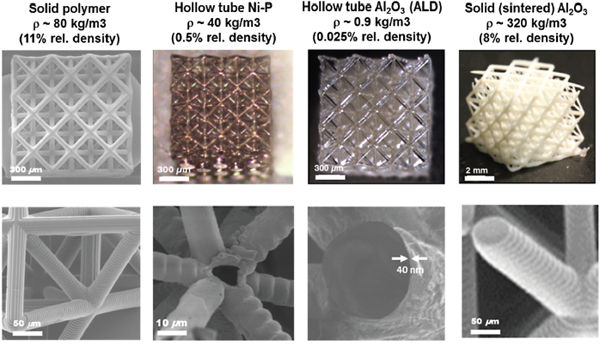

Figure 7 shows four types of octet truss stretch-dominated lattices fabricated at the microscale using PmSL. The images in the first column show a basic polymeric lattice made from hexanediol diacrylate (HDDA) with solid microscale struts and 11 percent relative density. In the next column, the same polymer structure was electrolessly plated with nickel phosphorus (Ni-P), and the polymer core was then removed via thermal processing, resulting in a lattice with 0.5 percent relative density. A hollow tube ceramic lattice, shown in the third column, was formed via ALD and similar polymer removal. This structure represents the lightest fabricated material in this test series, with a relative density of 0.025 percent and wall thickness less than 50 nm. Finally, we fabricated a lattice with alumina nanoparticles suspended in the polymer and conducted sintering procedures to remove the polymer and densify the ceramic, yielding a solid ceramic lattice with 8 percent relative density (far right column; Zheng et al. 2014).

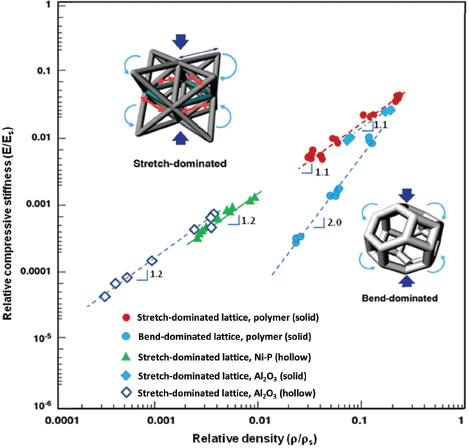

The performance of these mechanical metamaterials is illustrated in Figure 8, where nondimensional stiffness is plotted versus relative density. The fact that the

FIGURE 7 Octet truss–based mechanical metamaterials of varying materials and configurations. See text for description of techniques used to produce these structures. Al2O3 = aluminum oxide; ALD = atomic layer deposition; Ni-P = nickel phosphorus. SOURCE: Zheng et al. (2014).

FIGURE 8 Nondimensional performance of ultralight octet truss stretch-dominated lattices. AI2O3 = aluminum oxide; HDDA = hexanediol diacrylate; Ni-P = nickel phosphorus. Adapted from Zheng et al. (2014).

measured scaling relationship between these two parameters is approximately linear across all constituent material types, all relative density regimes, and regardless of hollow tube or solid strut configurations clearly demonstrates the impact of the stretch-dominated architecture. For comparison, a bend-dominated Kelvin foam architecture displayed the classic quadratic relationship when tested. Furthermore, in absolute terms, the hollow tube alumina lattices have densities approaching aerogels (known as some of the lightest materials in the world), but with 4 to 5 more orders of magnitude in stiffness due to the architected structure (Zheng et al. 2014).

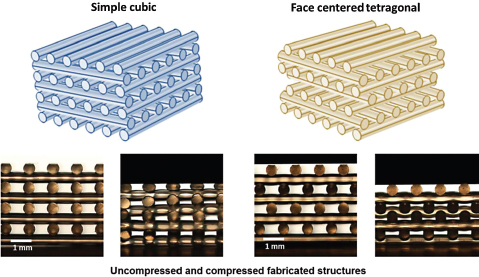

Another interesting mechanical metamaterial is shown in Figure 9. These “woodpile” structures were fabricated out of silicone with the DIW process. Varying the architecture between a simple cubic (SC) type structure and a face-centered tetragonal (FCT) configuration results in different bulk-scale mechani-

FIGURE 9 Schematics (top) and images (bottom) of silicone structures fabricated using direct ink writing. Adapted from Duoss et al. (2014).

cal properties. The cross-sections in the bottom row of the figure clearly show that the two structures will have different compressive behavior: the SC layout will be stiffer than the FCT-structured material because of the aligned versus staggered arrangement of the nodes (Duoss et al. 2014).

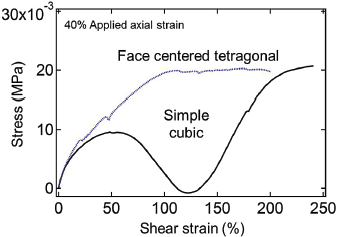

However, what is not as obvious is the difference in shear response of the two materials. Figure 10 elucidates this difference, which manifests as “negative stiffness” and can be seen in the negative slope of the stress-strain response in the SC material. The negative stiffness is a unique “snap-through” property that can be engineered into the material. It is now possible not only to control the compressive response but also to independently design and control the shear response, perhaps even with negative stiffness (Duoss et al. 2014).

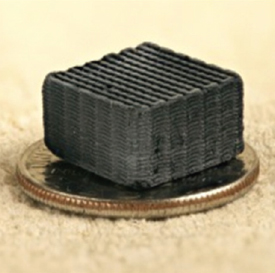

We have also begun to explore multifunctional metamaterials, combining normally disparate physics into lattice-type architectures. Figure 11 shows an early example, a printed graphene aerogel structure (Zhu et al. 2015). This simple woodpile lattice has enhanced mechanical properties and, because of the nature of graphene, significant electrical and/or chemical functionality as well. Supercapacitors with high compressibility and durability, for example, may become possible.

FUTURE DIRECTIONS

By combining mechanical metamaterials with inverse design methods and custom micro- and nanoadditive manufacturing techniques, we have been able

FIGURE 10 Shear response of elastomeric cellular architectures showing negative stiffness. MPa = megapascals. Based on Duoss et al. (2014).

FIGURE 11 Image of printed graphene aerogel, positioned atop a quarter to show size. SOURCE: Zhu et al. (2015).

to develop unique properties not previously attainable in known materials. This is just the beginning of a powerful new methodology for approaching material design and realization.

There are many potential future directions for advancing the state of the art, including through continued exploration of size-scale effects and efforts that push the boundaries of multimaterial design and fabrication. This could lead to unique new materials with groundbreaking mechanical properties and electrical or photonic functionality all in one.

ACKNOWLEDGMENT

This work was performed under the auspices of the US Department of Energy by Lawrence Livermore National Laboratory under contract DE-AC5207NA27344 (LLNL-CONF-677195).

REFERENCES

Ahn BY, Duoss EB, Motala MJ, Guo X, Park S, Xiong Y, Yoon J, Nuzzo RG, Rogers JA, Lewis JA. 2009. Omnidirectional printing of flexible, stretchable, and spanning silver microelectrodes. Science 323(5921):1590 –1593.

Ando K, Onda H. 1999. Mechanism for deformation of wood as a honeycomb structure I: Effect of anatomy on the initial deformation process during radial compression. Journal of Wood Science 45:120.

Bauer J, Hengsbach S, Tesari I, Schwiger R, Kraft O. 2014. High-strength cellular ceramic composites with 3D microarchitecture. Proceedings of the National Academy of Sciences 111(7):2453 –2458.

Besra L, Liu M. 2007. A review on fundamentals and applications of electrophoretic deposition (EPD). Progress in Materials Science 52(1):1– 61.

Deshpande VS, Fleck NA, Ashby MF. 2001. Effective properties of the octet-truss lattice material. Journal of the Mechanics and Physics of Solids 49(8):1747–1769.

Duoss EB, Weisgraber TH, Hearon MK, Zhu C, Small W IV, Metz TR, Vericella JJ, Barth HD, Kuntz JD, Maxwell RS, Spadaccini CM, Wilson TS. 2014. Three-dimensional printing of elastomeric, cellular architectures with negative stiffness. Advanced Functional Materials 24(31):4905– 4913.

Gibson JL, Ashby FM. 2001. Cellular Solids: Structure and Properties. Cambridge, UK: Cambridge University Press.

Hopkins JB, Culpepper ML. 2010a. Synthesis of multi-degree of freedom, parallel flexure system concepts via freedom and constraint topology (FACT) —Part I: Principles. Precision Engineering 34(2):259–270.

Hopkins JB, Culpepper ML. 2010b. Synthesis of multi-degree of freedom, parallel flexure system concepts via freedom and constraint topology (FACT)—Part II: Practice. Precision Engineering 34(2):271–278.

Hopkins JB, Lange KJ, Spadaccini CM. 2013. Designing the microstructure of thermally actuated materials using freedom, actuation, and constraint topologies. Journal of Mechanical Design 135(6):061004.

Jang D, Meza LR, Greer F, Greer JR. 2013. Fabrication and deformation of three-dimensional hollow ceramic nanostructures. Nature Materials 12:893–898.

Lakes R. 1987. Foam structures with a negative Poisson’s ratio. Science 235(4792):1038–1040.

Lakes R, Lee T, Bersie A, Wang YC. 2001. Extreme damping in composite materials with negative-stiffness inclusions. Nature 410:565 –567.

Lewis JA. 2002. Direct-write assembly of ceramics from colloidal inks. Current Opinion in Solid State and Materials Science 6(3):245–250.

Pascall AJ, Qian F, Wang G, Worsley MA, Li Y, Kuntz JD. 2014. Light-directed electrophoretic deposition: A new additive manufacturing technique for arbitrarily patterned 3D composites. Advanced Materials 26:2252–2256.

Ryan TM, Shaw CN. 2013. Trabecular bone microstructure scales allometrically in the primate humerus and femur. Proceedings of the Royal Society B: Biological Sciences 280:20130172.

Schaedler TA, Jacobsen AJ, Torrents A, Sorensen AE, Lian J, Greer JR, Valdevit L, Carter WB. 2011. Ultralight metallic microlattices. Science 334(6058):962–965.

Shen JH, Xie YM, Huang XD, Zhou SW, Ruan D. 2013. Compressive behavior of luffa sponge material at high strain rate. Advances in Engineering Plasticity XI 535-536:465– 468.

Sigmund O, Torquato S. 1997. Design of materials with extreme thermal expansion using a three-phase topology optimization method. Journal of the Mechanics and Physics of Solids 45(60):1037–1067.

Smay JE, Cesarano J, Lewis JA. 2002. Colloidal inks for directed assembly of 3-D periodic structures. Langmuir 18(14):5429 –5437.

Van Liedekerke P, Ghysels P, Tijskens E, Samaey G, Smeedts B, Roose D, Ramon H. 2010. A particle-based model to simulate the micromechanics of single-plant parenchyma cells and aggregates. Physical Biology 7(2):026006.

Zheng X, Lee H, Weisgraber TH, Shusteff M, DeOtte J, Duoss E, Kuntz J, Biener MM, Ge Q, Jackson J, Kucheyev SO, Fang NX, Spadaccini CM. 2014. Ultralight, ultrastiff mechanical metamaterials. Science 344(6190):1373–1377.

Zhu C, Han TY, Duoss EB, Golobic AM, Kuntz JD, Spadaccini CM, Worsley MA. 2015. Highly compressible 3D periodic graphene aerogel microlattices. Nature Communications 6:6962.