1

Introduction

The United States manufactured significant quantities of chemical weapons during the Cold War and years prior. Because the chemical weapons are aging, storage constitutes an ongoing risk to the facility workforces and to the communities nearby. In addition, the Chemical Weapons Convention (CWC) treaty, which the United States has ratified, stipulates that the chemical weapons be destroyed. The United States has destroyed approximately 90 percent of the chemical weapons stockpile located at seven sites.1 However, there are remaining stockpiles at the Blue Grass Army Depot (BGAD) in Richmond, Kentucky, and the Pueblo Chemical Depot in Pueblo, Colorado.

At BGAD, the chemical weapons filled with the nerve agents GB and VX pose particularly complicated destruction challenges that stem from a relatively diverse collection of weapons. The nerve agent-filled weapons at BGAD include about 52,000 115-mm rockets and 4,000 8-inch projectiles that are GB filled, and just under 18,000 115-mm rockets and 13,000 155-mm projectiles that are VX filled (NRC, 2005). Each rocket contains about 10.7 or 10.1 pounds of GB or VX, respectively. The 8-inch projectiles contain 14.4 pounds of GB, while the 155-mm projectiles contain 6 pounds of VX. The projectiles do not have energetics. The rockets, however, contain (in addition to agent) about 19 pounds of M28 propellant (nitroglycerine, nitrocellulose, and other additives) and about 3.2 pounds of Composition B explosive (59.5 percent RDX and 39.4 percent TNT) in bursters. There are also more than 15,000 155-mm projectiles filled with mustard agent, but the destruction of these items will utilize a static detonation chamber, and thus they are not a consideration of this study.

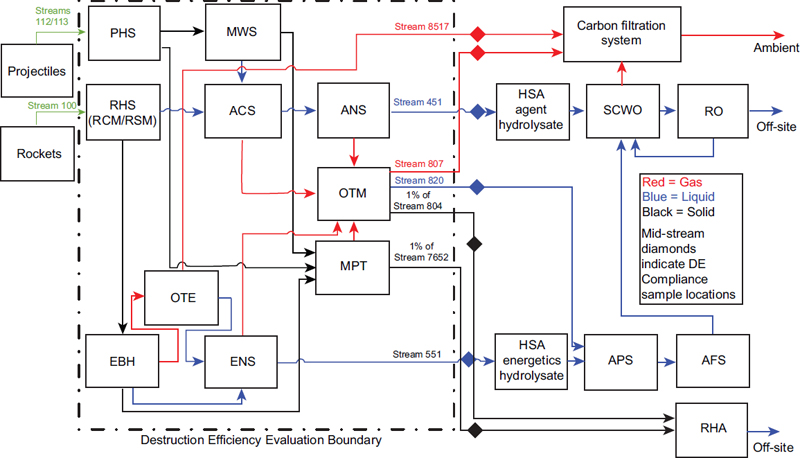

In response to a congressional mandate that destruction technologies other than incineration be identified and implemented at BGAD,2 a process based on caustic hydrolysis of the agents has been adopted. The Blue Grass Chemical Agent Destruction Pilot Plant (BGCAPP) has been built at BGAD to destroy the BGAD stockpile using these technologies. The initial process used at BGCAPP to extract agent from the munitions varies depending on whether a rocket or a projectile is being destroyed. Figure 1-1 shows the processing flow of munitions through BGCAPP.

The following sections describe munitions processing at a high level. As will be discussed below, an agent washout step has been deleted from the munitions processing processes. The process flows are largely unchanged by the deletion of the washout step. Thus, the process descriptions below describe what will happen, with the divergences resulting from washout deletion called out where they occur.

PROCESSING OF ROCKET WARHEADS

Rockets will be processed in the rocket handling system (RHS), where the rocket cutting machine first separates the rocket motors from the agent-containing warheads. Uncontaminated motors will be sent off-site for destruction, and contaminated motors will eventually be sent to the energetics batch hydrolyzers (EBHs).3 The rocket shear machine in the RHS punches and drains the warheads, generating two process streams, one liquid and one solid. The liquid stream consists of drained agents, while the solid stream consists of the drained warheads. Upon draining, the liquid agents will be directed through a three-way valve to a strainer, where solids that might clog the agent pump will be removed by filtration. The liquid will then be sent through a second discharge

___________________

1 These sites were located in or near Anniston, Alabama; Pine Bluff, Arkansas; Newport, Indiana; Aberdeen Proving Ground, Maryland; Tooele, Utah; Umatilla, Washington; and Johnston Atoll in the Pacific Ocean.

2 The National Defense Authorization Act for Fiscal Year 1993 (Public Law 102-484). See also, the Omnibus Consolidated Appropriations Act, 1997 (Public Law 104-208) and the Strom Thurmond National Defense Authorization Act for Fiscal Year 1999 (Public Law 105-261).

3 The separated rocket motors will be accumulated in a box. They will then be monitored using headspace monitoring for agent contamination before leaving the agent controlled area.

strainer that removes solids, which are primarily gelled or otherwise solidified agent that might interfere with subsequent hydrolysis reactions downstream. The filtered agents will then be transferred to the agent collection system (ACS).

In the original BGCAPP design, the rocket warhead bodies were to be washed out in the RHS with high-pressure, hot water that would have mechanically removed most of the residual agent on the interior walls of the munitions casing and broken up gelled and solidified materials that might have been present in the agents. This latter function, loosening and breaking up gels and solids, was deemed important because it had been estimated that solids and gels accounted for up to 20 percent of the GB in the munitions or up to 4 percent of the VX. The rinsate from the washout process was then to be directed through one of two strainer-pump-strainer trains via the three-way valve, in this case depositing the rinsate liquid into a tank that holds spent decontamination solution (SDS) (i.e., the SDS holding tank). The rinsate was then recombined with the drained agent before being sent to the agent neutralization system (ANS). The water washout ensured that nearly all agent would be processed through the ANS. This allowed measurement of any untreated agent at a single exit point from the Munitions Demilitarization Building (MDB), in order to meet the destruction efficiency (DE) requirements stipulated in the Research, Development, and Demonstration permit issued by the Kentucky Department for Environmental Protection to BGAD and BGCAPP on September 30, 2005, and in the Kentucky Administrative Regulations and the Kentucky Revised Statutes.

Before leaving the discussion of the generation of the liquid product in the RHS, it should be noted that, periodically, the filter media used in the strainers (referred to as filter socks) are expected to become clogged and require change-out. This process requires an operator equipped with appropriate personal protective equipment to enter the agent processing room to manually install new filter socks and place the clogged socks in a tray for eventual transfer to the EBHs for thermal destruction, as described later in this chapter. Manual entry is a time-consuming process with the potential to affect the overall safety and destruction schedule of BGCAPP.

The agent and wash water generated by the RHS would then be combined in the ANS to be hydrolyzed in a concentrated sodium hydroxide solution. The committee noted that when the process modified by elimination of the washout is used, only drained agent will be sent to the ANS. This hydro-

lysis occurring in the ANS eliminates the acute toxicity of the agent and generates a product that is referred to as hydrolysate, which is analyzed for residual agent. If the concentration of agent in the hydrolysate meets the specified release criteria (which are still to be determined), it is then transferred out of the MDB to the agent hydrolysate storage tank (located in the hydrolysate storage area [HSA]).4 The hydrolysate is then destroyed in the supercritical water oxidation system. Destruction of the hydrolysate is important, because it eliminates the possibility of intentionally recovering the primary hydrolysis products, which could be reacted to regenerate the original agents. As such, hydrolysate destruction is a requirement of the CWC. Hydrolysate treatment is not part of the statement of task for this report. Assuming that the clearance criteria for effluents from the MDB remain the same, washout deletion should not impact hydrolysate treatment. Therefore, hydrolysate treatment is not discussed in this report. The headspace gases from the ACS and the agent neutralization reactor (ANR) have the potential to contain agent, and are, therefore, further processed through the off-gas treatment system (OTM).

The solid process stream from the RHS consists of the warhead cavities along with their energetics-filled bursters, which, under the original BGCAPP design, were to be washed out at the RHS to remove residual agent.5 These solid components are then to be sheared into segments and transferred to the EBHs, where they are subjected to a hot (241°F at 1 atm), concentrated sodium hydroxide solution that destroys the energetics in the rocket warhead and dissolves a significant fraction of the aluminum.6 There are to be three process streams from the EBHs: liquids, solids, and headspace gases.

The liquid effluent from the EBHs, which contains significant aluminum, is sent to the energetics neutralization reactors where it will be neutralized at 300°F and a pressure of 3.1 atm. This liquid product is fed to the aluminum precipitation system and then to the aluminum filtration system to remove the aluminum contained in this stream. The liquid effluent from the aluminum filtration system undergoes final treatment in the supercritical water oxidation, while the solid aluminum-bearing precipitate is transferred off-site for disposal.

The gaseous effluent from the EBHs will be sent to the energetics off-gas treatment system (OTE), which consists of a scrubber and a particle filtration system. The scrubber functions to remove ammonia and energetics degradation products that may be present in the off-gas, while the filter removes particles greater than 3 mm in diameter. The gaseous effluent was originally deemed to be largely free from the possibility of agent contamination because, due to washout, only small residual amounts of agent were to be sent to the EBH in the first place. This is now not the case. Gaseous effluent from the OTE flows into the MDB heating, ventilation, and air conditioning (HVAC) system.

The solid process stream from the EBHs consists of undissolved metal parts that are periodically removed and sent to the metal parts treater (MPT) for final treatment. The MPT heats these metal components to 1,000°F and operates under a superheated steam atmosphere (125 lbs/h) to ensure pyrolytic degradation of agent. These conditions have been deemed sufficient to destroy any residual agent.

The MPT has two product streams: scrap metal, which exits the MDB for off-site disposal, and off-gas, which is sent to the OTM. The OTM is distinct from the OTE in terms of gaseous input and unit operations, as described below.

The OTM receives gaseous waste streams from the MPT, SDS, ACS, and ANS, and also from the energetics neutralization system. The OTM consists of a thermal oxidizer (TOX), followed by a Venturi scrubber and a cyclone. The TOX functions to thermally oxidize any residual organics and to remove any particulate solids that might originate from the MPT. The OTM was not specifically designed to destroy agent but would likely do that effectively.7 The TOX consists of two sections, an oxidizing section and a quench section. Sufficient air is added to the oxidizing section to ensure that the residual oxygen level in the TOX is at least 5 percent. Natural gas and a fine mist of water are added to maintain the operating temperature at 2,000°F. The TOX can operate at temperatures as high as 2,200°F if the process gas feed has a higher heating value. This higher operating temperature is needed when contaminated wood pallets, or shipping and firing tubes from the rocket handling system, are processed in the MPT. The oxidizing section has a minimum gas residence time of 2 seconds at a minimum temperature of 2,000°F. This residence time is required for destruction of polychlorinated biphenyls that will be present during processing of leakers. In the quench section, a fine mist of water is supplied to bring the exit temperature to 1,200°F. The MPT-OTM combination was designed to ensure that no residual agent would survive these combined processes.

The OTM has three process streams, all of which exit the MDB. The solid process stream (#7652) will be particulate

___________________

4 Blue Grass Chemical Agent Destruction Pilot Plant (BGCAPP) Hazardous Waste Management Facility Permit, EPA ID KY8-213-820-105, issued on September 30, 2005, Appendix B, Compliance Schedule requires BGCAPP to submit to the Hazardous Waste Branch Manager, the Waste Analysis Plan, Target Release Levels.

5 Neil Frenzl, resident engineering manager, Bechtel Parsons Blue Grass (BPBG), John Barton, chief scientist, BPBG, “Rocket Handling System/ Munitions Washout System (RHS/MWS) Design Update,” presentation on February 18, 2015, to the Committee on Chemical Demilitarization of the National Academies of Sciences, Engineering, and Medicine, Washington, D.C.

6 John Barton, chief scientist, BPBG, “Update on High Temperature Destruction of Cyanide Activities,” presentation on May 5, 2015, to the Committee on Chemical Demilitarization of the National Academies of Sciences, Engineering, and Medicine, Washington, D.C.

7 Neil Frenzl, resident engineering manager, BPBG, John Barton, chief scientist, BPBG, “Rocket Handling System/Munitions Washout System (RHS/MWS) Design Update,” presentation on February 18, 2015, to the Committee on Chemical Demilitarization of the National Academies of Sciences, Engineering, and Medicine, Washington, D.C.

from the TOX, which will likely be free of agent because the TOX operates at high temperature. The liquid process stream (#820) from the OTM, consisting of water used in the Venturi scrubber, will be sent to the aluminum precipitation system. The gaseous process stream (#807) will be transferred to the MDB HVAC system.

PROCESSING OF PROJECTILES

Because the projectiles do not contain energetics, their processing does not require the EBHs and associated downstream systems. Instead, the projectiles will be sent to the munitions washout system (MWS) via the projectile handling system. With the deletion of agent washout, the only part of the MWS still used is the cavity access machine. The cavity access machine hydraulically forces a ram into the projectile, collapsing the burster well into the agent cavity, allowing the agent to drain. The burster deformation is also a CWC requirement. The agent then drains by gravity and is fed via a three-way valve and strainers to the agent storage tank in the ACS. A washout nozzle array (nozzles providing high-pressure water jets) is integrated into the shaft of the burster well ram to provide a high-pressure water spray to clean and flush the cavity. This would have washed the projectiles out with high-pressure, hot water. The washout water would have been directed into the SDS tank. As in the case of the RHS, the agent and rinsate would then have been combined in the ANS, where they would have been neutralized. Now, with washout deletion, the washout nozzle is still present in the burster well ram, but it will not be used.

Without the water washout step, the projectile bodies will be sent to the MPT after the agent is drained. Originally, the projectiles would have contained only a small quantity of residual agent adhering to their surfaces due to agent washout. With the deletion of agent washout, more residual agent will be sent to the MPT. The residual agent in the projectiles will be destroyed by pyrolysis at high temperature (1,000°F) for 15 minutes. This produces decontaminated metal scrap and off-gas as byproducts. The MPT is designed for pyrolyzing the agent in projectile bodies and functions with trays that can accommodate up to 40 of the 155-mm projectiles drained of VX, or up to 18 of the 8-inch projectiles drained of GB. After thermal treatment, the projectile bodies are deemed free of chemical agent due to process knowledge and are released for disposal off-site. The MPT will also be used to treat the filter socks that capture solids during projectile agent drain operations. Gaseous effluent from the MPT flows to the OTM, where it undergoes treatment as described above for the rocket warheads.

CONCERNS RELATED TO THE OPERATION OF THE PLANT AS ORIGINALLY DESIGNED

The BGCAPP team identified a number of concerns regarding aspects of operation according to the original design,8,9 which are summarized in the following six bulleted points:

- The mixing of VX and water may result in an exothermic, autocatalytic reaction. At the baseline plant at Tooele, Utah, a mixture of 3,000 pounds of VX and 1,200 pounds of water resulted in an exothermic reaction that elevated the temperature in the tank, causing emission of vapor and liquid carryover into a surge tank.10 The observations were consistent with laboratory-scale studies conducted by Yang and co-workers, who concluded that attack by ethyl methylphosphonate on VX was an exothermic, autocatalytic process that would lead to elevated temperatures in large-scale systems (Yang et al., 1996). Frenzl and Barton suggested that the carbodiimide stabilizers may actually facilitate this reaction by deprotonating the ethyl methylphosphonic acid,11 which is a chemical intermediate in the autocatalytic reaction pathway. Significant uncertainty remains in the understanding of the conditions that lead to the exothermic reaction. For example, it was noted that a water washout had been used to remove VX from ton containers at the Newport, Indiana, facility; yet this process did not result in a thermal runaway in the stored VX. But the wash water was not recombined with agent in that process. Weighing the totality of past experience, BGCAPP determined that the potential risk of a thermal runaway might be significantly reduced if the VX were not mixed with water.12

- Water mixing with VX will result in agent gelling. This is presumably due to aluminum salt formation with the hydrolysis product ethyl methylphosphonic acid. The aluminum originates from M55 rocket warheads.

- The original strainers may have been undersized. If this is true, then more demands would be placed on the strainer filtration function, a situation that could be exacerbated by the fact that the filterability of the gel is unknown.13 It was estimated that if the GB muni-

___________________

8 Ibid.

9 Neil Frenzl, resident engineering manager, BPBG, John Barton, chief scientist, BPBG, John McArthur, environmental manager, BPBG “Changes to Munitions Drain Systems Update,” presentation on May 5, 2015, to the Committee on Chemical Demilitarization of the National Academies of Sciences, Engineering, and Medicine, Washington, D.C.

10 Neil Frenzl, resident engineering manager, BPBG, John Barton, chief scientist, BPBG, “Rocket Handling System/Munitions Washout System (RHS/MWS) Design Update,” presentation on February 18, 2015, to the Committee on Chemical Demilitarization of the National Academies of Sciences, Engineering, and Medicine, Washington, D.C.

11 Ibid.

12 While the exothermic reaction is a concern in the storage tanks, they are not a concern in the neutralization reactors. The storage tanks are not designed to contain the reaction, in contrast to the neutralization reactors, which are designed to operate at high temperature.

13 Ibid.

-

tions contain 20 percent solids, the originally forecast processing rates would likely not be achieved. This outcome would be a consequence of the requirement to change out filter socks when 50 percent full, which entails operators making a suited entry into the room to remove and replace the sock.

- The RHS entrained air into the agent and washout water during agent washout. First-of-a-kind testing showed that excessive air flow was required to control the water spray during washout and that the diaphragm drain pumps used to move the liquid into the ACS would not handle the air/agent or air/water feed.

- Hydrogen is formed in the GB-filled rocket cavities. Hydrogen gas that is entrained in the agent mixtures would be sent to the ACS along with air or nitrogen, which are used as purge gases to ensure that the hydrogen concentration would not exceed 25 percent of the lower flammability limit, thus limiting the potential for the hydrogen to accumulate in the ACS tank headspace. At the baseline incineration sites, the room air diluted the gas, which was then thermally processed with the agent; thus, there was no flammability danger. This dilution may not occur at BGCAPP, where the agent will be pumped into the ACS for a period of time until a sufficient quantity of agent has been accumulated for processing in the ANS.

- Low points in the shared piping lengths would result in agent mixing with water, which would create the potential for accelerated corrosion. In particular, hydrogen fluoride (HF or hydrofluoric acid) is formed during the GB campaigns, which can attack the carbon steel in these sections, but the rate of HF attack was initially anticipated to be slow. However, industry experience suggests that the rate of corrosion could be fast, and the presence of low points could create situations where the HF concentration is 1 percent or higher. Studies conducted by Army personnel show that corrosion approaches 500 mils per year (mil/year) when carbon steel was immersed in 1 percent HF.14 It is worthwhile noting that at the baseline chemical demilitarization sites, carbon steel piping did not experience significant corrosion; however, a water washout was not used in these systems, an observation that provides further motivation for eliminating washout. If the GB mixing with water can be minimized or eliminated, the potential for high corrosion rates might be greatly reduced.

These concerns prompted a rigorous review that was conducted by a convened Technical Tiger Team. Their findings and recommendations, while not completely coincident with the concerns of the BGCAPP technical staff, were in agreement on multiple points. The Tiger Team generated several important recommendations that influenced the ultimate redesign:

- Revise solids design criteria.15 Originally, it was assumed that there would be up to 20 percent solids in all GB munitions, and up to 4 percent solids in the VX munitions. These estimates were felt to be conservatively high based on historical sampling evaluations. Accordingly, the criteria were adjusted.

For the GB-filled projectiles, a total of 5-10 percent of the GB fill is now projected to be un-drainable from 100 percent of the GB projectiles. There will be crystals in many if not most of the projectiles, but the GB-filled projectiles are expected to drain easily within the time allocated for projectile draining when crystals comprise less than 2 percent of the agent fill.

For the GB-filled rockets, it is estimated that 90-95 percent of the agent fill can be drained from 90 percent of the rockets within the time allocated. It is estimated that the remaining rockets will retain 30 percent of the GB-fill.

For the VX-filled rockets and projectiles, new criteria include the assumption that greater than 95 percent of the VX agent will drain from the agent cavity within the allotted drain time.

Generally, for projectiles containing crystals, only 2-3 percent of the drained agent is filterable at >500 mm. For projectiles that do not contain crystals and for all rockets, filterable content drops to 1-2 percent. This is significant because crystals >500 mm are capable of sequestering intact agent, resulting in incomplete treatment at that point in the process.

- Eliminate issues with air entrainment and hydrogen by deleting the water washout and adding a knockout pot with a dedicated vacuum pump.

- Eliminate issues with corrosion of the carbon steel in the RHS in the GB campaigns by eliminating the water washout.

- Eliminate heat buildup from the exothermic VX/water reaction by eliminating the water washout.

- Reduce the strainer change-out frequency by increasing the size of the strainer equipment.

- Eliminate RHS low points to improve draining efficiency and mitigate corrosion.

___________________

14 Ibid.

15 Neil Frenzl, resident engineering manager, BPBG, John Barton, chief scientist, BPBG, John McArthur, environmental manager, BPBG “Changes to Munitions Drain Systems Update,” presentation on May 5, 2015, to the Committee on Chemical Demilitarization of the National Academies of Sciences, Engineering, and Medicine, Washington, D.C.

WASHOUT DELETION MODIFICATIONS

The process at the BGCAPP was subsequently modified to eliminate the munitions water washout process, both from the MWS and the RHS. This change, which is included as part of a larger set of design changes that is designated Engineering Change Proposal-87 (ECP-87), brings planned BGCAPP operations into accord with the Tiger Team recommendations that advised elimination of the water washout process.16,17 It is worthwhile noting that most of the operations remain the same. However, the process of extracting the agent from the munitions is being changed significantly, which will impact several downstream processes.

As a consequence of ECP-87, the agent drain systems were redesigned, with the objective of achieving several improved operational attributes. The specific changes are as follows:

- Accommodate two-phase flow from the RHS and MWS systems, making the system compatible with hydrogen from the RHS and adding the ability to remove gases from the liquid system;

- Modify the drain line and three-way valve to eliminate agent and water mixing;

- Meet design criteria for solids loading;

- Mitigate HF formation resulting from GB washout;

- Mitigate the heat generating, autocatalytic reaction of VX with water; and

- Control agent vapor generated by two-phase flow.

STATEMENT OF TASK

There may be unintended implementation impacts resulting from the deletion of the agent washout step in the MWS and the RHS units. These possibilities motivated Program Executive Office, Assembled Chemical Weapons Alternatives (PEO ACWA) to request that the National Academies of Science, Engineering, and Medicine convene an ad hoc study committee to examine the impacts of this design change on operations at BGCAPP. The committee was tasked with addressing the following issues:

- Assess the impact of the design change on plant operations and the impacts to plant throughput, taking into account revised rocket and projectile drain times, strainer change-out frequency, and metal parts treater throughput;

- Review and assess the calculations associated with the ability of the metal parts treater and thermal oxidizer to effectively process additional residual agent GB and VX contained in the drained rocket and projectile munition bodies;

- Review and assess the contractor’s approach to the destruction efficiency (DE) calculations and provide any suggestions that support the DE confirmation process; and

- Assess the validity of process modeling conducted to date and recommend where additional modeling may be of benefit for understanding likely plant operation performance.

APPROACH TO THE STATEMENT OF TASK AND ORGANIZATION OF THE REPORT

Chapter 2 provides a more detailed evaluation of the effects of washout deletion on the individual unit operations, which can be compared to operations as they were initially conceived and designed. Chapter 3 addresses the impact of washout deletion on regulatory compliance and permitting—specifically, the ability of BGCAPP to demonstrate compliance with the 99.9999 percent (“six-nines”) DE set forth in the Kentucky Revised Statutes. Chapter 4 discusses process modeling to date and what additional modeling may be useful.

REFERENCES

NRC (National Research Council). 2005. Interim Design Assessment for the Blue Grass Chemical Agent Destruction Pilot Plant. Washington, D.C.: The National Academies Press.

Yang, Y.C., L.L. Szafraniec, W.T. Beaudry, D.K. Rohrbaugh, L.R. Procell, and J.B. Samuel. 1996. Autocatalytic hydrolysis of V-type nerve agents. The Journal of Organic Chemistry 61(24):8407-8413.

___________________

16 Neil Frenzl, resident engineering manager, BPBG, John Barton, chief scientist, BPBG, “Rocket Handling System/Munitions Washout System (RHS/MWS) Design Update,” presentation on February 18, 2015, to the Committee on Chemical Demilitarization of the National Academies of Sciences, Engineering, and Medicine, Washington, D.C.

17 There are other approaches to removing agent from munition cavities that do not involve water, and some of these were considered by the sponsor. However, these alternatives are not explored in this report because the washout deletion approach had already been selected and implemented by the time the committee was asked to conduct this study. Implementation has included both hardware and process changes, BGCAPP construction is now complete, and the plant is entering systemization. It would be impractical to make major changes to the plant at this late stage without a major driving impetus to do so. Consequently, the committee was tasked solely with investigating the impacts of washout deletion and providing recommendations to the sponsor on how to address these impacts.