2

Plant Process Changes as a Result of Washout Deletion

ROCKET AND PROJECTILE DRAIN OPERATIONS

Without a water washout, agent drain from munitions will be by gravity alone. The presence of gel and solids in the agent will limit the efficacy of the drainage process, so that the quantities of agent remaining in the munitions may not meet the design specification of 98 percent agent removal from the cavity of a given projectile or rocket warhead. The amount of agent remaining adhered to interior surfaces of rocket warheads and projectile bodies at the end of each drain cycle will depend directly on the agent’s physical characteristics, which will in turn depend on the degree of agent degradation—gelling and crystallization—that has taken place within each munition. Gelation and crystal formation also affect the time required to drain a rocket or projectile of that portion of the agent that will flow by gravity.

Large numbers of munitions containing the nerve agents GB and VX have already been processed at the baseline sites; however, there are no data available on the rate or efficiency of unassisted drainage. The Blue Grass Chemical Agent Destruction Pilot Plant (BGCAPP) has information on the condition of GB and VX agent within a limited number of munitions from specific lots based on past sampling. The quantity of gel and crystals present in the GB munitions is highly variable among agent lots. Current estimates of the solid content are 5-10 percent for GB-filled munitions and 4 percent for VX-filled munitions.

Although data on agent in munitions are limited, a laboratory study of gel formation by the reaction of GB with metal halide salts found that gel and crystals form at lower temperatures and in higher quantities in munitions-grade GB than in Chemical Agent Standard Analytical Reference Material-grade GB (Yang, 2003). The extent of gel formation, and the nature of the gel product, also varied considerably depending on the metal salt examined, suggesting that varying contaminants within different batches of munitions could well explain the variable state of the agent. Yang (2003) found similar contaminants in some GB-filled munitions but does not report on the quantities or frequencies of occurrence of such contaminants. That study shows that even high-purity GB will form solids and viscous, oily products under conditions that could exist in storage. Therefore, these contaminants can be expected to be present in the less-pure munitions stored at the Blue Grass Army Depot, and there is the potential for degraded agent to be present in the munitions being processed.

Finding 2-1. Uncertainty in the number of munitions containing degraded agent and the degree of agent degradation is compounded by a lack of knowledge of the physico-chemical characteristics of degraded agent as they relate to drain times and amounts of residual agent retained in munitions at the end of the drain process. Better data are needed to properly estimate the time that will be required to process the nerve agent munitions through BGCAPP.

Recommendation 2-1. BGCAPP should gather data, such as mass drained, drain time, and any available information on physical state, for each individual munition during operations ramp up to assess the state of the agent fills and thus expected variability in drain times for each agent lot and type of munition. The acquisition of these data should continue throughout operations to continuously improve the quality of estimates as an aid toward planning of plant operations and to estimate completion times.

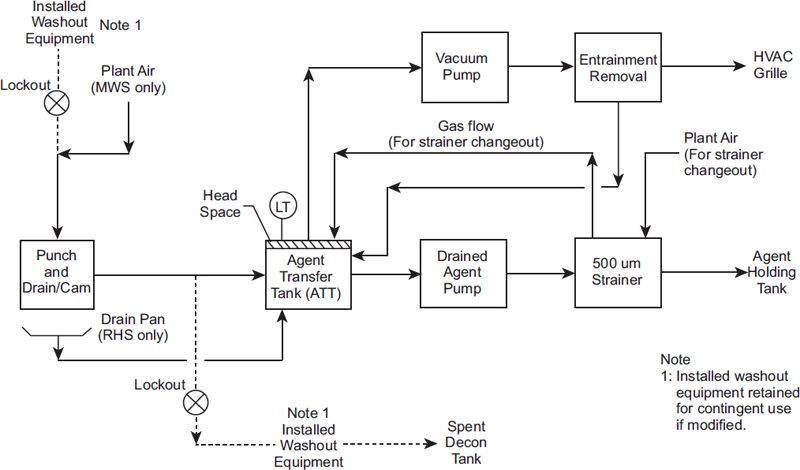

In addition to the possibility of problems being encountered in draining, the reconfigured agent transfer system has several additional components that may pose a risk of hazardous events during operations (Figure 2-1).1 The agent is

___________________

1 Neil Frenzl, resident engineering manager, Bechtel Parsons Blue Grass (BPBG), John Barton, chief scientist, BPBG, John McArthur, environmental manager, BPBG, “Changes to Munitions Drain Systems Update,” presentation on May 5, 2015, to the Committee on Chemical Demilitarization of the National Academies of Sciences, Engineering, and Medicine, Washington, D.C.

initially to be transferred into the agent transfer tank (ATT), which utilizes a vacuum pump to evacuate the ATT headspace and a drained agent pump to move the liquid agent to the strainers. BGCAPP technical staff members have rigorously specified requirements for the pumps; however, there will be the possibility of pump failures due to higher solids content in the liquid agent than originally planned. Excessive pressure in the drum demister (entrainment removal module), which is downstream of the ATT vacuum pump, is also a possibility. These failure possibilities will increase if high quantities of solids or gels drain from the munitions into the ATT. Any increase in failure events caused by these pump failures increases the probability of extending the agent processing campaign.

STRAINER SOCK LOADING

Processing munitions that have high gel or solids content is unavoidable. With the elimination of the washout step, the volume of solids being captured by the strainer system will increase. It may be that processing multiple high-gel or high-solids munitions will quickly overwhelm the strainer sock capacity, which would result in a higher frequency of change-out entries and a slowed processing rate. To accommodate this change in solids capture while minimizing the change-out frequency, the strainer unit size and the number of strainer baskets has been increased to reduce the number of worker entries required to change strainer socks. Even with increased filter capacity, the filter sock change-out frequency is estimated to be once every 3 days.2 Moreover, it remains uncertain whether the knowledge of the solids load in agent fills is adequate to develop a design that will allow the planned change-out frequency to be achieved. The compatibility of this unit with the type of solids that could be encountered in the agent is not known. Because this unit is significantly larger than the original design, it can be anticipated that the volume of material to be removed during each individual change out will increase. The impact on the time needed for an individual change out due the larger unit volume needs to be determined. Data obtained during testing and continuing during plant operation can facilitate strategic planning to minimize the impact of high-solids munitions on processing rate. If filter socks have to be changed out much more frequently and/or take longer to change out than anticipated, this could have negative schedule consequences

___________________

2 NRC Washout Deletion Committee Questions and Responses 151027 Set1, received via e-mail on November 6, 2015.

for BGCAPP operations, with implications for budget, treaty compliance, and reducing storage risk by the timely destruction of the stockpile.

Finding 2-2. Even with the change in filter sock capacity, the change-out frequency could become the rate-determining step in the processing of rockets and projectiles.

MPT AND PLANT OFF-GAS TREATMENT SYSTEM (OTM)

The agent destruction process is complicated by deletion of the washout step because agent treatment will now extend over several flow paths after drain operations. Residual agent remaining in rockets is to be sent to the energetics batch hydrolyzers (EBHs), while that remaining in projectiles is to be sent to the metal parts treater (MPT).

The MPT will be unaffected by the modified processing of the rocket components, which are transferred to the MPT only after immersion in hot caustic in the EBHs. No residual GB is expected to survive, and while VX droplets may survive the immersion step, the majority of these should be suspended in the hot caustic and not adhere to the undissolved rocket parts that are transferred to the MPT. Thus, the rocket components from the EBH are expected to be largely free of agent.

The projectiles entering the MPT will have more residual agent than the rocket warhead pieces entering the MPT because the projectile bodies are not processed through a hydrolysis step. Residual agent in the drained projectiles will vaporize and undergo pyrolysis in the MPT. The filter socks containing solids from drained projectiles will also eventually be sent to one of two MPTs for thermal decontamination and agent destruction.

The MPT is designed to process trays holding up to 40 of the 155-mm projectiles drained of VX, or up to 18 of the 8-inch projectiles drained of GB. BGCAPP has conducted numerical modeling of agent vaporization rates in the MPT under a simplifying set of assumptions. The simulation results suggest that, under scenarios involving fully loaded trays of projectiles containing 5 percent residual VX or 10 percent residual GB, the time to vaporize all agent from the projectiles only slightly exceeded the currently planned hold time in zone 1 of the two-zone MPT. Computational fluid dynamics modeling conducted by BGCAPP was used to estimate overall MPT processing times. It estimated that increasing the processing time from 60 minutes to 80 minutes for GB, or 90 minutes for VX, would ensure agent destruction. BGCAPP concluded that this increase would have minimal impacts on the schedule and duration of destruction campaigns. Computational fluid dynamics modeling also predicted that MPT processing could alternatively be conducted on partially filled trays of projectiles in order to reduce the quantity of agent processed in each batch. Either of these proposed strategies would ensure complete removal of residual agent from the metal parts.

Of particular interest regarding the deletion of the washout process is the added agent load to the OTM system where the residual agent that is vaporized and pyrolyzed in the MPT is sent prior to being forwarded to the Munitions Demilitarization Building (MDB) heating, ventilation, and air conditioning (HVAC) filter system. The OTM is responsible for processing gases from the agent collection system, the agent neutralization system, the energetics neutralization system, and the MPT. The deletion of the washout process may impact the OTM due to the potential presence of higher quantities of agent in the gaseous effluents from these units than originally planned for. If agent vaporization in the MPT is not complete, increasing steam injection could accelerate agent vaporization. This would result in an increased rate of agent pyrolysis products fed to the thermal oxidizer (TOX) process, but if these rates can be managed by the TOX, it would reduce the required residence time within the MPT. Additional steam may also suppress particle formation.

In spite of increased agent loading delivered to the TOX, BGCAPP estimates that the residence time in the TOX will be sufficient for complete destruction of any GB or VX that goes to the OTM from treatment systems.

In any case, with the elimination of the washout step, the volume of agent processed through the MPT and OTM will constitute a larger component of overall agent destruction efficiency as compared to the original configuration. With the increased number of agent processing paths, the methodology for determining the destruction efficiency will need to be adjusted. This is topic is discussed in Chapter 3.

Finding 2-3. Agent processed through the MPT and the off-gas treatment system will constitute a significant fraction of the agent destroyed at BGCAPP. This is a departure from the original design where almost the entire agent volume was being treated by hydrolysis.

Finding 2-4. Multiple mechanisms exist for controlling the MPT throughput rate to reduce instantaneous agent loading in the MPT and the off-gas treatment system. These include, but are not limited to, approaches such as increasing the residence time in zone 1 of the MPT, reducing the number of projectiles on each tray being processed and increasing the steam addition rate to the MPT.

Recommendation 2-2. BGCAPP should evaluate whether higher agent vaporization rates in the metal parts treater (MPT) can be accommodated by optimizing the operating parameters of the MPT, the off-gas treatment system, and associated systems.

EBH AND OFF-GAS TREATMENT SYSTEM FOR THE ENERGETICS NEUTRALIZATION SYSTEM (OTE)

As previously noted, the agent destruction process is complicated by the washout step deletion because the new

processing conditions extend agent treatment over several flow process paths following drain operations. The impact of the change could impact the EBH and its off-gas treatment system (OTE).

Once the agent drain for rockets is completed, the rocket warhead is sheared; the metal parts are then sent to the EBHs where caustic is added. The mixture reaches a temperature of 241°F at a pressure of 1 atm to dissolve the energetics material in the rocket pieces. The resulting materials are sent in three directions. The caustic solution is sent to the energetic neutralization reactors (the main component of the energetics neutralization system) for final treatment of the energetics, the undissolved rocket parts are sent to the MPT, and the off-gases are sent to the OTE. In contrast to the OTM, the OTE does not contain a TOX. The OTE has a Venturi scrubber, which is meant to remove ammonia and energetics degradation products that may be present in the off-gas, and a particulate filter. While the OTE will also capture at least some agent, the effectiveness of the OTE for removing residual agent is not known and may not be adequate for agent destruction. Without the washout system in place, additional agent will remain bound to the rocket parts that are forwarded to the EBHs. Neither the volume of agent sent to the EBHs, nor that which is eventually forwarded through the EBH vapor space to the OTE, is known. Agent could find its way to the EBH vapor space by being volatilized in the EBHs rather than being hydrolyzed. In principle, the quantity of agent vapor should be modest because the boiling point of GB is 297°F (NIOSH, 2015a); however, it does have a significant vapor pressure. It is, therefore, conceivable that GB volatilization could be competitive with hydrolysis in the EBH. This is probably not an issue for VX, which has a much higher boiling point (568°F) and a much lower vapor pressure than GB (NIOSH, 2015b; Reutter, 1999). Fugitive agent making it through the OTE would then be vented to the MDB HVAC carbon filtration system.

Finding 2-5. With the deletion of munitions washout, some of the chemical agent from the rocket warheads will be sent to the EBHs. Some fraction of the agent introduced into the EBHs will be volatilized and then flow into the EBH OTE. The OTE does not have a TOX, so some of the agent transported from the EBH to the OTE may penetrate to the MDB HVAC.

Recommendation 2-3. BGCAPP should conduct modeling and experimental studies to bound the quantity of agent present in the OTE vent stream (stream #8517).

IMPACTS ON THE OVERALL MDB HVAC SYSTEM

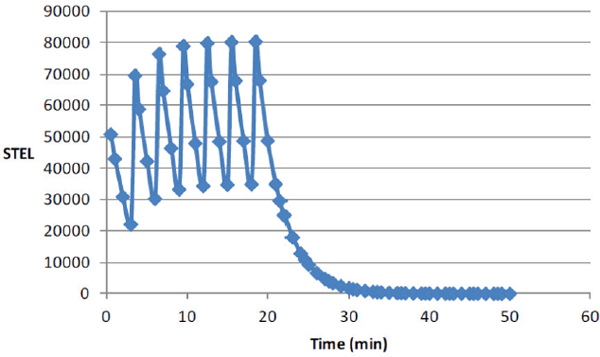

The final area of potential impact from the elimination of the washout process is the overall MDB HVAC system. Key to this system is the activated carbon bed vapor scrubbing system, which is the last piece of process equipment through which the air passes after it exits the processing building and before it is sent into the atmosphere. The elimination of the washout step increases the quantity of agent contained in the projectiles and rocket warheads that can be partitioned into other parts of the building system. Some of this material may end up in the air within the room and may, therefore, be forwarded to the carbon beds for capture. In the case of VX, the assessment of the Tiger Team is that the effect will be negligible because the vapor pressure of VX is low.3 This is not true for GB, on the other hand, and it may be that the change will increase agent load to the carbon filter banks. Therefore, there is the possibility for an increase in the carbon filter change-out frequency, along with an increase in the length of operations and disposal costs. The initial assessment of the Tiger Team was that at most only one additional change out of a carbon filter bank would be required; however, it is likely that there is uncertainty in this assessment. Figure 2-2 presents the results of modeling efforts of the expected GB venting load to the room air that provided the basis of these conclusions. One carbon filter change out is already planned.

The Tiger Team suggested that venting near the MDB HVAC would lower agent vapor levels, and, in fact, without implementing this approach, it estimated that 30-35 minutes would be required for GB concentrations to decrease to less than the short-term exposure limit (Figure 2-2).

Finding 2-6. During punch and drain operations, vapors are released directly to the room air and are exhausted through the MDB HVAC system. The primary mode of capture of these vapors is the carbon filter bank. This function is part of the original plant process; however, the washout deletion may affect agent concentrations in the gas phase that will be transferred to the MDB HVAC system.

Recommendation 2-4. BGCAPP should complete modeling to estimate the agent load to the carbon beds in the absence of a munition washout step to ensure that the lifetime of these beds is known.

REFERENCES

NIOSH (National Institute for Occupational Safety and Health). 2015a. Sarin (GB): Nerve Agent. Atlanta, Ga. http://www.cdc.gov/niosh/ershdb/emergencyresponsecard_29750001.html.

NIOSH. 2015b. VX: Nerve Agent. Atlanta, Ga. http://www.cdc.gov/niosh/ershdb/emergencyresponsecard_29750005.html.

Reutter, S. 1999. Hazards of chemical weapons release during war: New perspectives. Environmental Health Perspectives 107(12):985-989.

Yang, Y.-C. 2003. Synthesis and Characterization of GB Gels. Report 0151-090403.

___________________

3 Neil Frenzl, resident engineering manager, BPBG, John Barton, chief scientist, BPBG, “Rocket Handling System/Munitions Washout System (RHS/MWS) Design Update,” presentation on February 18, 2015, to the Committee on Chemical Demilitarization of the National Academies of Sciences, Engineering, and Medicine, Washington, D.C.