Proceedings of a Workshop

| IN BRIEF | |

|

September 2017 |

Sustainable Materials and Manufacturing for Renewable Energy Technology Development to 2030

Proceedings of a Workshop—in Brief

The world’s population is expected to reach 9.4-10.2 billion by 2050 based on recent growth trends, an increase of ~25 percent above current values.1 This increase is already challenging production and consumption patterns worldwide as industrialized and developing countries pursue economic growth under increasingly global and connected stresses, such as climate change, environmental degradation, poverty, limited strategic metal availability, and volatile oil prices.2 Transitions toward a more sustainable future are possible with clear, effective, and targeted goals that move investments and political will towards science, knowledge, social capacity, and technological capabilities for sustainable development. Manufacturing processes and metals industries, including renewable energy technologies, play key roles in these transitions.3

Solar photovoltaics, wind power, and energy storage systems offer viable alternatives to fossil fuels—but they also have environmental, economic, and social impacts. To explore these impacts, the National Academies of Sciences, Engineering, and Medicine’s Roundtable on Science and Technology for Sustainability held a workshop on June 12, 2017. The goals, said Roundtable co-chair Lynn Scarlett, The Nature Conservancy, were examining the sustainability implications of material demands and manufacturing processes associated with renewable energy technologies; mobilizing, encouraging, and catalyzing the use of scientific knowledge; and stimulating additional research.

This topic emerged as a priority through the Roundtable’s 2016-2017 strategic planning process, explained workshop chair and Roundtable co-chair David Dzombak, Carnegie Mellon University. The Roundtable plans for future workshops on sustainability issues related to consumer products and infrastructure.

Workshop planning committee members Michael Kavanaugh, Geosyntic Consultants, and Suzette Kimball, U.S. Geological Survey (USGS), highlighted the key topics for the day:

- Current state of innovations in materials, processes, and technologies for solar photovoltaic energy and concentrated solar power, wind energy, and energy storage systems;

- Current and potential practices and processes for acquisition and processing of materials for use in these technologies, and their implications for addressing social, environmental, and other impacts;

- Social dimensions of material acquisition and processing to support renewable energy technology development; and

- Possible approaches to the materials and manufacturing systems of the future, including knowledge gaps, critical research needs, and mechanisms for encouraging partnerships.

___________________

1 United Nations. 2017. World Population Prospects: The 2017 Revision. Online. Available at https://esa.un.org/unpd/wpp. Accessed August 14, 2017.

2 Royal Society. 2012. People and the Planet. London, UK: The Royal Society.

3 National Research Council. 1999. Our Common Journey: A Transition toward Sustainability. Washington, DC: The National Academies Press.

![]()

OVERVIEW OF RENEWABLE ENERGY TECHNOLOGIES

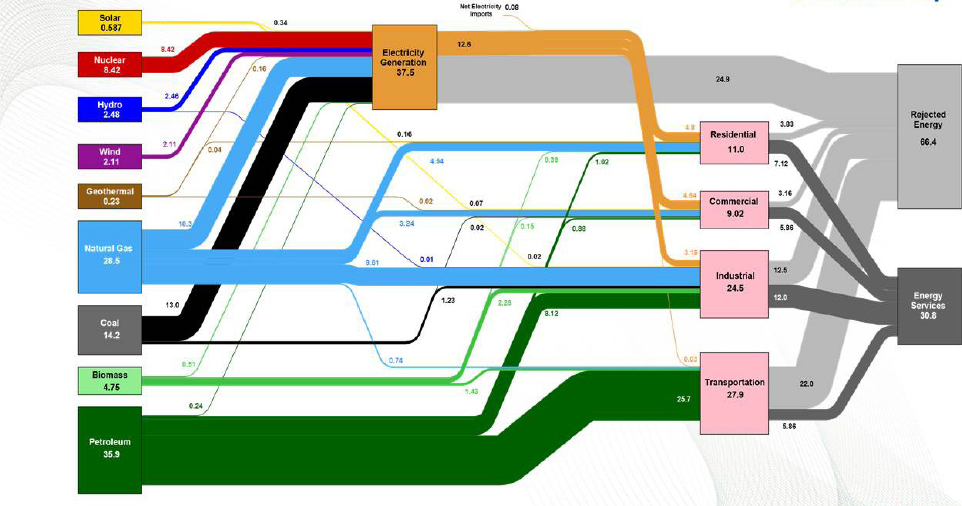

Keynote speaker Claus Daniel, director of Oak Ridge National Laboratory’s Sustainable Transportation Program, began by emphasizing that cars, trucks, and related technologies help societies build wealth and are key to upward mobility. Worldwide, higher car ownership correlates with higher gross domestic product (GDP), because people can travel further distances to access educational and employment opportunities, ship goods, and the like. As people age and stop driving, they tend to lose social interactions and their health degrades, further demonstrating the positive impact of mobility. As energy production rises for transportation and other needs, we have to find ways to sustainably work such a system, Daniel said. Oil, gas, and coal are the main sources used in world primary energy production. The United States reflects global usage, with petroleum, natural gas, and coal representing more than 78 percent of the total (see Figure 1).

Daniel stated that China leads the world in total annual renewable electrical energy production, primarily from hydroelectric and wind power, at 378 gigawatts (GW); the United States generates about 172 GW, ranking second; Germany ranks third at 84 GW; and India, Spain, and Italy respectively rank fourth, fifth, and sixth (2013 figures).4 Percentage-wise, renewables represent about 12.6 percent of total electrical energy consumption in Germany (2016 figures), compared to about 8 percent of U.S. energy production (2009 figures). Within the U.S. renewable sector, hydropower has the largest share, followed in descending order by wood, biofuels, wind, biomass waste, geothermal, and solar.

Renewables are increasingly cost-competitive compared to fossil fuels, Daniel noted, ranging from about $.05 per kilowatt hour (kWh) for large-scale hydro power to about $.30 per kWh for small-scale solar photovoltaics in 2013. (Later discussion underscored that the total amount of renewable energy in the United States has increased and costs have decreased in the past few years—smaller-scale solar PV is now about $.13 per kWh.)

Renewables offer high quality employment opportunities. Almost every U.S. state has some type of renewable energy manufacturing. Worldwide, the sector employed about 7.7 million jobs in 2014, increasing to 9.8 million in 2016, according to the International Renewable Energy Agency.

Discussion centered on lowering costs, the increasing speed of change, grid optimization related to time value and location of electricity, and need for modern data. Material supply and manufacturing directly impact the cost of renewable energy technologies, but Daniel noted the potential savings from materials depends on the technology. For small-scale solar power, installation represents a large portion of the cost, rather than materials and processing. For hydro

Source: Claus Daniel, presentation, June 12, 2017, Washington, DC. Data based on U.S. Energy Information Administration’s Monthly Energy Review, 2016. Credit given to the Lawrence Livermore National Laboratory and U.S. Department of Energy.

___________________

4 Daniel’s presentation is available at: http://sites.nationalacademies.org/pga/sustainability/pga_179288.

power, maintenance is a big issue. For wind, reliability of the gearbox and blade size limitations due to resonance frequency concerns potentially limit the amount of energy generated per turbine. Another interesting point, Daniel added, is that increasing renewable energy production frees up fossil fuels for potentially more beneficial materials applications (pharmaceuticals, plastics, etc.) compared to burning them up in engines.

One participant urged a broader view of the costs of these various technologies, including the implications for the environment and communities. Others noted the issue of site location costs, for example, offshore wind may be out of sight but requires added transmission and installation costs, and the larger wind turbine blades are getting so large that transporting them is expensive, suggesting the need to build them locally.

RENEWABLE ENERGY TECHNOLOGIES – MATERIAL AND MANUFACTURING IMPLICATIONS

Solar Energy Technology Advancement

Charles Gay, director of Solar Energy Technologies for the Office of Energy Efficiency and Renewable Energy (EERE) at the U.S. Department of Energy (DOE), explained DOE’s solar portfolio falls into three broad categories: photovoltaics (PV), concentrating solar power (CSP), and systems integration.

Gay stated that manufacturing follows a learning curve—the more you do, the faster, the cheaper, and the better you are at getting costs out. Today’s costs for an installed solar power plant system are about $1 per watt—about 30 percent for the photovoltaic module and the remaining 70 percent for balancing systems. High-purity, low-cost silicon has decreased cost-per-watt. New advances, such as thin graphene layers on the surface of silicon, have the potential to lower the cost-per-watt further. The largest cost contributor in solar PVs is the packaging. More durable packaging would lengthen the life of panels.

The U.S. solar industry is growing, reflecting worldwide employment trends. Gay noted that about 1,000 new jobs, which are high-paying, $26-per-hour-average jobs, are added every week in the United States, mostly on the installation and project development side.

CSP involves a field of heliostats, or mirrors, that focus sunlight to heat molten salt to temperatures of 710ºC and drive turbines to create electricity. Turbine-scale solar energy lowers costs in the long run, but the cost of capital is a major driver. Early on, capital is necessary to build facilities to get free power from sunlight over time. Additive manufacturing also offers cost-lowering opportunities, including the high-purity, low-cost silicon described above. He pointed to 3D printing of high-nickel content materials as a promising innovation, as well as the use of supercritical CO2 which allows reduced scale modular operations and additive manufacturing.

Systems integration, DOE’s third area, focuses on grids. Combining machine learning with satellite data and weather forecasting can create estimates of the amount of power needed from distributed generation sources on the grid, and where it will best be used at a given point in time. Well-run microgrids can defer substation upgrades. Gay noted that optimizing distributed generation/consumption balances and wiring in buildings can also increase efficiencies.

Acceleration in these three areas relies on people, Gay said. New jobs are created every week, but he asked, where is the talent pipeline to fill them? The challenge is to draw on the talent and technology roadmaps in the DOE National Labs and elsewhere to speed up the cycles of learning. A DOE program, called the Catalyst Energy Innovative Prize, is aiming to boost innovation.5 Through social media, more than 5,000 entrepreneurs described solutions to energy issues. About 100 received seed money and access to labs and to energy incubators to test their ideas and qualify for additional funding. From ideation to selection spanned 90 days compared to the conventional year-long contracts. Speeding up and trying new models for innovation and bringing innovation to commercialization are two of the most critical things to consider as part of our overarching look at how to develop sustainable models, Gay concluded. He also urged tapping into new capital, including philanthropic capital.

Wind Energy Technology Advancement

Yongxin Huang, lead structure engineer for Siemens Gamesa, defined sustainable wind energy not only in terms of materials, but also in keeping factories open and people employed. That means driving down costs. The reality, he said, is people express support for the concept of wind energy; however, they are unwilling to pay higher utility costs or live near wind turbines. There is a need to deliver a smart solution to solve those problems, he commented. He urged assembling grids with other renewable energy technologies, rather than competing against each other.

___________________

5 See https://energy.gov/eere/sunshot/sunshot-catalyst-energy-innovation-prize for additional information.

Siemens Gamesa (the companies’ 2017 merger reflects other mergers in the sector, Huang noted) has 75 GW of capacity installed worldwide and employs 27,000 people. He stated that offshore wind power is “the frontline of technology advancement.” Two trends are emerging to produce more wind energy at lower costs: (1) larger turbines and (2) smarter turbines that use sensors to respond to conditions and communicate with each other.

Huang described his company’s efforts to develop larger wind blades at its Boulder, Colorado, Research & Engineering Center. The three blades of a turbine under development, known as the SWT 8.0-154, each have a length of 75 meters, a width of 5 meters and a rotor diameter of 154 meters. A blade weighs 25 tons (the equivalent of 16 mid-sized cars); and a rotor swept area is equivalent to 4.5 football fields. One issue is the time-consuming manual blade construction in which glass fabric is applied to a mold at a rate of 2,300 pounds of glass every hour, yielding one blade per day.

Increasing the size of a rotor is directly proportional to power generation, he explained, but the square-cube law challenges this aim: that is, for a rotor to double in power, it has to triple in volume. How can rotor size increase without becoming too heavy (e.g., a 50 ton blade is too heavy to fly)? Technology advancement attempts to defy the square-cube law through better aerodynamics (for example, curved rather than straight blades), higher-quality manufacturing processes, and stronger glass-carbon hybrid materials. Blades are in development with stiffer and lighter fibers, fatigue-resistant and low-viscosity resins, lighter core materials, and thicker laminates.

Huang pointed to the issue of recycling as wind turbines move out of service over time. What to do with these materials relates not only to wind, but also to other alternative energy technologies. In the case of wind, from 2010 to 2014, the equivalent of 212 GW of wind energy was installed, or about 450,000 blades using 2 million tons of composite materials. What will we do with the materials once they are done providing sustainable energy? Innovative alternative uses to these massive blade are needed, Huang concluded.

Energy Mass Storage Technology Advancement

According to Jay Whitacre, professor of materials science and engineering and engineering and public policy at Carnegie Mellon University, energy storage technology is not as fleshed out as solar and wind, although it has existed in some form for more than 100 years. Lithium-ion batteries, the current dominant form, have been used for about 30 years.

Whitacre focused on the creation of electrochemical energy storage (other types include pumped hydro, thermal, and ice storage), which must have two separate, coexisting systems. This is a very materials-intensive technology. Unlike wind and solar, which have a few dominant technologies, many energy storage technologies continue to vie for market share. It is not clear which type will dominate economically, making decisions difficult.

Whitacre’s lab and others attempt to decrease the cost per kWh for lithium-ion batteries, but the capital cost per kWh is not a useful metric without much more information on use-case and degradation. A variety of needs are required: to understand how long a battery will last, how many duty cycles it can accommodate, and the value placed in any given application. The lack of a good baseline confounds the industry because there is no good way to evaluate options.

Two main types of lithium-ion batteries are now produced, with cylindrical and prismatic cell formats. Both require a spectrum of major industrial chemicals, precious metals, and rare earth elements, and there is no dominant single material with the aim of cost optimization. Whitacre added that cobalt has had a dramatic increase in price and decrease in availability in the past year while the most scaled energy storage materials systems are not materials optimized. The complexity of the manufacturing process, which consists of 16 separate steps, also makes it hard to find ways to use less energy or materials.

A 2013 study by a group from Stanford University compared ratios of total electrical energy stored over the life of a storage technology, Whitacre said.6 Compressed-air and pumped-hydro batteries had the highest efficiency. Lithium-ion batteries were far less energy-efficient; lead-acid batteries, the most commonly used energy storage system today, fared even worse. Yet more robust batteries typically cost more, and some end uses do not call for the more expensive options, even if they are more efficient.

Recycling energy storage batteries is difficult because the different materials are closely wound together, making separation complicated. Whereas some valuable minerals could be recovered (such as cobalt and nickel), there are not enough units to justify the disassembly and re-segregation needed. To illustrate the complexity, Carnegie Mellon launched a company called Aquion Energy in 2009 to create a sustainable product. In the process of being purchased after suffering downsizing at the time of the workshop, the company’s recent setback illustrates the commercial challenges in creating cradle-to-cradle energy storage. Whitacre concluded his presentation by stating that more sustainable energy storage systems would require less processing of materials before insertion, aqueous-based electrolytes, high tolerance to lower purities, and very long lifetime/cycles.

___________________

6 Barnhart, C. J., and S. M. Benson. 2013. On the importance of reducing the energetic and material demands of electrical energy storge. Energy & Environmental Science 6:1083-1092.

ACQUISITION, USE, RECOVERY, AND REUSE OF METALS IN RENEWABLE ENERGY TECHNOLOGIES

The above presentations on trends in solar, wind, and energy storage technologies set the stage for consideration of supply-side needs related to their material components, and the human dimensions associated with the supply chain. According to USGS figures, the United States relies on imported materials for more than 70 percent of these components.7 Over a dozen commodities or elements are entirely imported. Global events affect the supply chain—as one example, the Ebola crisis in West Africa impacted the mining of key elements. Policy implications thus go beyond research and development (R&D) of the materials themselves and also include future needs.

Supply and Demand of Minor Metals for U.S. Solar Photovoltaics and Wind Power: Scenarios and Perspectives

Nedal Nassar, chief of the Materials Flow Section at the USGS National Minerals Information Center, described the minor metals required to increase production of wind and solar power, including silver, cadmium, tellurium, indium, gallium, selenium, and germanium. Many are produced as by-products of other commodities and needed only in small quantities but are nevertheless essential.

On the solar side, different technologies require different minor metals. Globally, crystalline silicon has been the predominant solar PV technology. Until recently, cadmium telluride was gaining market share in the United States. Nassar noted that it is uncertain which technology will dominate in the future, and it will have implications for which by-product metals will be needed. Likewise, different wind turbines, and whether the turbines are on- or off-shore, also will result in different minor metal requirements.

Minor metal requirements depend on three key uncertainties that will produce a range of possible futures:

- Amount: How much new capacity will be required?

- Market share: Which renewable energy technology will dominate?

- Material intensity: How will the amount of kilograms of material per kilowatt of capacity change over time and under different scenarios?

Nassar and colleagues developed 42 scenarios based on various estimates of these three uncertainties. Highlighting results for tellurium, indium, silver, gallium, and germanium, considerations included potential future demand, competing demands for other uses, and whether the mineral has single or multiple sources. In most cases, production of the host metal and by-product (for example, selenium as a by-product of copper) are in parallel, but he pointed to two by-products that are outstripping their host metals in terms of production: gallium (from aluminium oxide and zinc) and indium (also from zinc). Nassar asked: How long is this sustainable? Can we continue to increase indium production exponentially while its host metal only increases linearly?

Preliminary study of tellurium shows less than 2 percent is recovered from its host metal of copper. Thus, one technical solution is to recover more of the by-products from the hosts. Nassar stated that geological scarcity is not likely to be the limiting factor in rare earth element availability. He emphasized it is more of an economic problem: “Are they going to be economically feasible to recover?” Nevertheless, clean power plants require approximately 15 to 43 percent more minor metals than conventional fossil fuel power systems.

In the discussion period, technological process scarcity was suggested by several participants as an additional consideration to geologic and economic scarcities. A participant noted that more than half of the known rare earth resources are in deposits for which there are no known or proven extraction techniques, and much metallurgical research is needed before commercial production is possible.

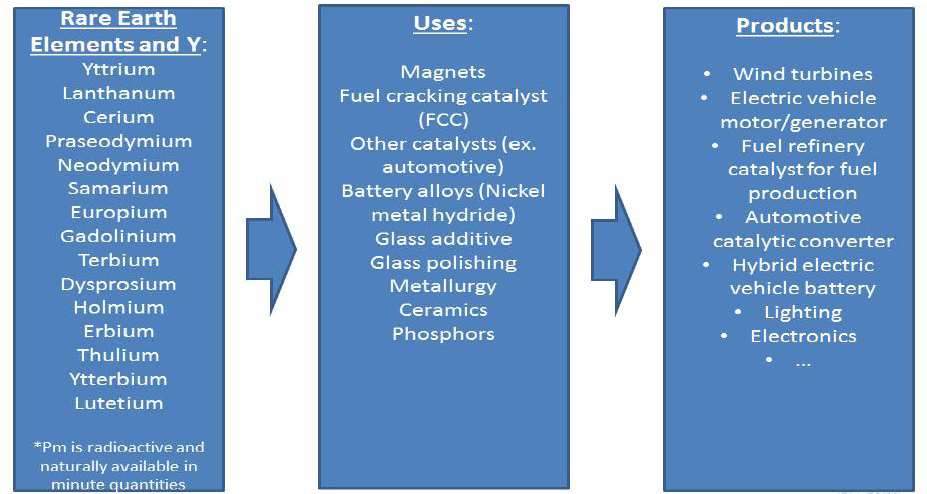

Current and Future Demand for and Reuse of Rare Earth Elements, and Related Sustainability

Elisa Alonso, a critical materials analyst for Oak Ridge National Laboratory, focused on rare earth elements, a subset of the critical materials discussed by Nassar. She positioned all critical materials on axes of importance and supply risk related to market, recycling options, and environmental concerns. Many risk factors associated with rare earth elements underscore their criticality. They have highly concentrated supply histories (in many cases, a single country dominates), are the result of by-product mining, and contain radioactive thorium. The market is small and opaque, and their dispersed end uses limit the potential for recycling. Demand risks include limited substitutability and a growing market.

___________________

7 USGS. 2016. U.S. Net Import Reliance. Available at https://www.usgs.gov/media/images/2016-us-net-import-reliance. Accessed July 3, 2017.

Source: Elisa Alonso, presentation, June 12, 2017, Washington, DC.

Alonso explained that rare earths are crucial to sustainability, part of intermediate products such as magnets for end uses that range from wind turbines to electric vehicle batteries (Figure 2). In 2010, global rare earth prices spiked as a result of export limitations from China. Although the prices have decreased, they are still higher than pre-2010 values and the spike illustrates the vulnerability of a predictable supply.

As a case study, Alonso shared her post-doctoral work with the Ford Motor Company to identify where rare earth elements are used in a typical car. The researchers identified more than 700 parts in the car that require some rare earth element, showing the extent to which all technologies rely on, and potentially compete for, these materials. To predict whether vehicles could meet 2050 fleet goals, scenario analyses used historical growth rates of material consumption; research from industry experts; and a projection of new technologies, their expected adoption, and their expected material content. Alonso presented one scenario that identified dysprosium as the most critical constraint.8 General Electric is conducting a similar analysis for lighting, and it could be applied to other industries. The goal is not to predict the future, she said, but to prioritize response alternatives using limited resources. Possible responses include material substitution, increased manufacturing efficiency, new scrap recycling, mine opening, and stockpiling. To date, three rare earths—yttrium, dysprosium, and europium—have been approved for inclusion in the National Defense Stockpile.

A question about substitutions for rare earths came up after Alonso’s presentation. A participant stated that substitutions are possible but complex, depending on the material, demand, and cost. If the elements are more expensive, then there is more of an incentive to find substitutions. When they are less expensive, the incentive to change lessens.

Meeting Demand for Critical Metals – Social Dimensions

Resources themselves are not the major challenge, said John Thompson, Wold Family Professor of Environmental Balance for Human Sustainability at Cornell University, but rather the discovery and conversion of these resources for use. He stated that the most important challenge is the jurisdictional challenge, which is highly unpredictable with no fixed timelines. There are costs involved with planning ahead and engaging with communities, but much greater costs in not taking these steps, including delays or complete upheaval in the supply chain. The supply or value chain must take account of the “people part,” or social constraints, including consumers who demand sustainably produced products, communities who live near the resource and mineral processing operations, and other stakeholders.

___________________

8 Alonso, E., A. M. Sherman, T. J. Wallington, M. P. Everson, F. R. Field, R. Roth, and R. E. Kirchain. 2012. Evaluating rare earth element availability: a case with revolutionary demand from clean technologies. Environmental Science & Technology 46(6):3406-3414.

Thompson identified three issues in mining: people, power, and water—noting they are related to each other as well as to land issues. Even when a country’s legal framework covers mining rights, on-the-ground conflicts may occur. Other social issues include child labor and black market activity, particularly in artisanal small-scale mining, that currently involves about 100 million people. Tailings (the residue and other products left over after extracting the desired minerals) also create concerns, especially when radioactive materials are contained in waste streams.

Resource nationalism, in which countries aim to own and get full value from their natural resources, is cyclical as countries become more or less aggressive. Standards and regulations vary across countries. These jurisdictional issues can drive substitutions. Some countries have opted out of production altogether.

Regions suffer from uneven distribution of benefits from mining, Thompson explained; in many cases, individual communities benefit, but the regions where they are situated do not. In Peru’s Ancash region, companies instituted a voluntary fund to benefit the broader region from the mining activity, but this example is rare. Companies must pay more attention to the community scale, he said. They used to take a paternalist approach—build a school, build a road, and they have done their job. By contrast, engagement now is very much part of routine work. Mining companies employ social scientists and others with knowledge and experience with community engagement.

Working with indigenous peoples requires new levels of understanding. He suggested looking for opportunities to share benefits with indigenous peoples, such as the Red Dog Mine 50-50 Teck Cominco venture with the native NANA Corporation in Alaska.

Thompson called himself an optimist, seeing progress related to partnerships, approaches, technologies, regulation and certification, and public pressure. Technical and nontechnical innovation will be required to meet people’s increasing societal expectations.

In answer to a question about best practices to engage with communities, Thompson replied that the simplest, and hardest task, is to listen. In addition to listening, several participants stressed the need for co-development, co-design, mutual learning, and joint fact-finding by developing the knowledge base with the affected communities. Thompson also acknowledged the difficulty in evaluating and quantifying costs of nontechnical factors. Developing a risk-reward scenario might lead to a decision to forego an opportunity.

To reduce the environmental impacts of mining, we have to start extracting more metal from less rock instead of doing the reverse, which is what we have been doing for the past 100 years. Somehow, we have to change that equation, Thompson said. Many people support renewable energy but remain skeptical about the extractive industries needed to produce them. He noted that improvements in more efficient use of water and biodiversity are needed, but mining’s overall footprint increases as demand increases. Environmental and sustainability considerations are becoming more embedded in company operations. He pointed to safety as an example of change in the industry; regulations beginning in the late 1960s have moved safety concerns into the culture of most companies. This change demonstrates what the industry is capable of, if they employ combinations of regulation, technology, and cultural education and training to do the right thing.

RESEARCH NEEDS FOR SUSTAINABLE MATERIALS AND MANUFACTURING FOR RENEWABLE TECHNOLOGIES

In the concluding session, Cyrus Wadia, vice president of sustainable business & innovation at Nike, Inc.; Alexander King, director of the DOE Critical Materials Institute (CMI); and Roderick Eggert, professor of the Colorado School of Mines and CMI deputy director, offered syntheses of the earlier presentations from industry, federal, and academic perspectives, followed by discussion.

Wadia focused on the role of science and technology in contributing to a more sustainable landscape through the lens of public-private partnership. To him, three workshop themes emerged: innovation, talent, and incentives.

Investment in innovation is needed. The Materials Genome Initiative has served as an example of an underlying platform to inform technology development,9 but he urged greater attention to environmental performance and new packaging paradigms, not just cost. He also urged that it is critical to consider more materials innovation related to recovery to reduce waste as well as the development of new end-of-life materials tools.

To foster talent to move forward, it is necessary to embrace unconventional areas of expertise, he said, pointing to DOE’s Catalyst as an example.10 Paradoxically, many entrepreneurs focus on software and related technology development, but hard material challenges need attention.

___________________

9 For more information about this multiagency effort, see https://www.mgi.gov.

10 For more information, see https://energy.gov/eere/sunshot/sunshot-catalyst-energy-innovation-prize.

Related to incentives, Wadia asked how the Roundtable could provide leverage so companies consider sustainability in tandem with business solutions, not as an afterthought. “Zero compromise” should mean making products that benefit the consumer and the planet. He asked: how do we show the world, and multinationals in particular, that the zero compromise is possible?

King noted that the system of 17 National Laboratories, begun in the 1940s, remain at the forefront to solve technical challenges. Four years ago, they were asked to assure continued sources of critical materials, particularly rare earth elements. Generally, it takes about 15 years to develop a mineral deposit that has been identified; 18-20 years to invent a newly identified deposit. Yet the labs, with their repository of expertise, instruments, and computational platforms, found solutions in a fraction of that time. King stated that the National Labs strive to break speed records for developing new technologies as solutions to materials shortages. The CMI works with universities with access to expertise and skills, and shows the potential of collaboration. He acknowledged barriers in labs working together, including collaboration that can evolve into a highly competitive environment, and emphasized the need to listen carefully to industry as they have many insights into successful collaboration approaches.

Eggert began with the observation that renewable energy requires nonrenewable minerals. The challenge is to overcome this seeming tension. Recycling has a role to play, but is limited by economic incentives, the composition of the products themselves, and product lifetimes. The world is not running out of primary raw materials, although technical, social, and environmental limitations, rather than geologic availability, determine supply. To ensure the availability of nonrenewable resources for renewable energy requires new technological options to meet future needs. Eggert stated that social science plays a role. For example, material flow analysis can track where the materials are and their paths throughout their supply chains, including environmental and economic analysis.

During the final discussion session, many participants noted the importance of attracting young people to careers in metallurgy and related industries. It is a volatile sector, and some of the jobs may lie in other fields that draw upon a metallurgy knowledge base. The interdisciplinary field of Industrial Ecology, for example, is growing. Young people need to be engaged in seeing these fields as ways to solve the world’s problems. Another discussion point was how to implement a cradle-to-cradle approach in the materials manufacturing sector. Wadia responded that leadership is key, with sustainability issues embedded throughout a company. A participant asked if there should be investment in R&D for sea bed mining of some elements. Eggert suggested a small fraction of R&D funding go to explore this objective, but it is a very long-term possibility. He also said mining from seawater has other environmental concerns.

DISCLAIMER: The Proceedings of a Workshop—in Brief was prepared by Paula Whitacre as a factual proceedings of what occurred at the meeting. The statements made are those of the author or individual meeting participants and do not necessarily represent the views of all meeting participants, the planning committee, or the National Academies of Sciences, Engineering, and Medicine.

REVIEWERS: To ensure that it meets institutional standards for quality and objectivity, this Proceedings of a Workshop—in Brief was reviewed by Steve Bergman, Shell International Exploration & Production Company (ret.) Thomas Graedel (NAE), Yale University. The review comments and draft manuscript remain confidential to protect the integrity of the process.

PLANNING COMMITTEE: David Dzombak (NAE), Carnegie Mellon University (Chair); Michael Kavanaugh (NAE), Geosyntec Consultants; and Suzette Kimball, U.S. Geological Survey. Staff: Vaughan Turekian, senior director, Science and Technology for Sustainability (STS) Program; Michael Dorsey, senior program officer, STS Program; Emi Kameyama, associate program officer, STS Program; and Nicole Lehmer, senior program assistant, STS Program.

SPONSORS: This workshop was supported by the National Academies’ George and Cynthia Mitchell Endowment for Sustainability Science.

For additional information regarding the meeting, visit: www.nas.edu/sustainability.

Suggested citation: National Academies of Sciences, Engineering, and Medicine. 2017. Sustainable Materials and Manufacturing for Renewable Energy Technology Development to 2030: Proceedings of a Workshop-in Brief. Washington, DC: The National Academies Press. doi: https://doi.org/10.17226/24876.

Science and Technology for Sustainability

Policy and Global Affairs

Copyright 2017 by the National Academy of Sciences. All rights reserved.