1

Globalization Effects on the Research and Development Landscape

In her presentation “Globalization of Science and Technology: Opportunities and Challenges for the Department of Defense,” Ruth David, of Analytic Services (ANSER), discussed the National Research Council study on strategic engagement in global science and technology (S&T) and opportunities for defense engagement.1 She explained that the committee undertook a study of global S&T at the behest of three organizations within the Department of Defense (DoD): the Air Force Office of Scientific Research, the Office of Naval Research (ONR), and the Office of the Deputy Assistant Secretary of the Army for Research and Technology. The study was co-chaired by Arden Bement and David (see Figure 1.1).

David said that the most important point she would make is that trends matter more than an absolute value at any point in time. The rate of change in global S&T, in terms of what is happening and where it is happening, is rather dramatic. Significant shifts in top-notch research expertise are occurring in relatively short timelines. She said, “We don’t have the right measures to help us rapidly analyze and understand what is happening. . . . Those of you who have looked, for example, at the National Science Foundation science and engineering indicators know that by the time they are published, they are somewhere between 2 and 6 years old.” The same is true with other measures, although she noted that the World Bank has more timely data. David continued, “That is one of the challenges: how do you stay on top of what is happening, absent effective measures for doing so?”

___________________

1 National Research Council, “Strategic Engagement in Global S&T: Opportunities for Defense Research,” 2014.

David noted that committee member Patricia Gruber left midway through the study to take over ONR Global in London. Although it lost a contributor, the committee was reassured knowing that someone would use the results of the report, she said.2

The committee conducted a number of overseas visits, with 2-3 committee members conducting rapid tours of a handful of countries. During those visits, they met with U.S. government representatives who were forward-deployed to engage in global S&T. They also met with host nation government officials in research and development (R&D) where they could. They met with the president-level of the top research universities in several countries. They also tried to meet with an industry representative in those countries. They were trying to look very broadly for how others thought about global engagement and situational awareness in particular. “This was,” David said, “our search for the silver bullet. Who does it well, and how can we simply learn from them, adapt, and adopt best practices?”3

___________________

2 ONR Global representatives also participated in the workshop, and their remarks are included later in this proceedings.

3 Small delegations went to countries in Asia and Europe to learn about global S&T engagement practices used by universities, industries, and government agencies. The visits included Tokyo, Japan

“We didn’t find the silver bullet. We did find some things that we thought could be emulated. But in reality, this is a really hard problem, staying on top of what is happening across the global S&T enterprise,” she noted.

According to David, the committee tried to gather more information on some of the multi-national collaborations—for example, the European Union, the Framework Seven investment programs, and ANSER, in terms of the S&T investment strategy. Those groups tend to unite around specific problems shared across the member nations. They have a different view of global cooperation.

The committee’s final report had a few high-level findings, with more detail in the main body of the report. The first finding was to selectively maintain technological superiority, which implies choices and focus in research investments: “It says we cannot be the best across the board in everything.” David added that most of the people in the room would probably consider that obvious. “On the other hand, we sometimes don’t invest with that in mind” (see Figure 1.2).

But, David added, the committee’s finding also has a flip side: “If we say we must selectively maintain technological superiority, that must be based on something more than assertion and input measures. Having an established, focused investment program is important. But scrutinizing the results of that program against others in the world is equally important. That is an area where admittedly it is difficult. I think that is a really important part of maintaining technological superiority.”

David said that there is another issue, which is leveraging what others are doing: “Is this an area where we are trying to maintain the lead, in which case, we want to know what they are doing, but not tell them what we are doing? Or is it an area where we want to collaborate and leverage what they are doing? Those can be competing objectives, if not managed pretty carefully.”

The committee’s second finding was about people. “We cannot hope to be aware of what is happening across the world if our own S&T workforce is not sufficiently engaged,” David summarized. It is about researchers in the know understanding what their colleagues and peers are doing across the enterprise.

David noted that as the study continued there was a significantly constrained travel environment for DoD, compounded by essentially a prohibition against attending conferences: “We were talking with U.S. researchers who were basically saying ‘I can’t travel.’ It was actually a little bit ironic: we had people who were forward-deployed in Japan and tasked to maintain awareness of what was happening in Asia without leaving Japan.”

___________________

(April 29-May 1, 2013); Taipei, Taiwan (May 2-3, 2013); Bangkok, Thailand (July 31-August 2, 2013); Canberra, Australia (August 5-7, 2013); London, England (October 7-8, 2013); Brussels, Belgium (October 9, 2013); and Stockholm, Sweden (October 10-11, 2013).

“Our point in this effort,” David explained, “was to say, ‘if you expect them to be engaged, we have to set the conditions that enable that engagement. We have to make sure that the proceeds of that engagement are fed back to the enterprise in meaningful ways.’” But that raised another issue: How does the enterprise know what these investigators or individual researchers learn? “That was another piece of it that was very unclear,” David commented.

“It seemed to us that in certain areas, those strategies of the forward-deployed contingents were not as well integrated with the U.S.-based research staff, who were also going into those areas perhaps by virtue of individual collaborators or conferences. It just felt like things were not as well-knitted together as you might like,” David said.

The committee’s third finding was an observation: DoD and its services have a tremendous number of mechanisms in place, but the individual mechanisms are not integrated, so there is no sharing between them.

The committee’s final finding was about outcomes orientation. David said, “For every visit that we made, we asked people how they determined success. How could they tell that they were actually doing what they set out to do? In some places, there was a reasonably clear articulation of what their goals were. In some, there was not. The goals were pretty squishy. It is hard to tell if you are successful if you don’t have a pretty clear outcome in mind.” The committee thought that this was an area where some additional work was needed.

“We went in search of the silver bullet but didn’t find it. We do believe that lots of mechanisms are needed,” David described. How does the defense research enterprise, from the individual principal investigator level to the portfolio managers, know what is in people’s heads? What are the outcomes of these engagements? How is that knowledge synthesized and shared? The committee concluded that that was probably one of the more critical areas of need for the enterprise.

Although in many cases the committee did not find a clear articulation of objectives, it highlighted some important drivers of S&T engagement from a defense perspective. One driver is obviously very focused on U.S. interests, avoiding duplication and sharing costs. There are areas in which collaboration occurs across national borders. There are other areas where there has been a shared investment in large research facilities that then is used by many nations.

According to David, the committee was interested in this subject because one of the things it heard in a couple of places was that the United States is not always perceived as a good partner, primarily owing to U.S. funding mechanisms and volatility, including 1-year funding for some of these endeavors. There were also other issues surrounding governance of these major facilities that had differing levels of success.

David said that one of the things the committee heard was that industry was very clear “when they entered a collaborative endeavor with other corporations;

they hammered out governance, rights, and everything else up front.” However, it heard that “when governments went into these, there was not as much clarity around those issues about who does what, who has what rights from a decision-making perspective, shared costs, and so forth. That was an area where [the committee] thought governments in particular could learn a bit from industry.”

Another area that the committee found very interesting was the notion of helping to mature ethical norms and practices as well as standards. It visited a company in Sweden that is participating in consortia with competitor companies as a way to develop standards that are of benefit to all. David said that Sweden has a group of companies that are trying to band together to mature standards in particular areas to influence the larger standards process: “Understanding those kinds of motivations, I think, is a real driver to looking at with whom you collaborate and cooperate in these areas.”

David said that a lot of the governmental, multi-national collaborations were focused on global imperatives such as clean energy, sustainable practices, climate change, and so on. “You saw a lot of cross-border collaboration and cooperation in those areas. Everyone realizes they can’t solve the problem alone. That was another very strong motivator [for collaboration],” she said.

She explained that the study’s final point was about the notion of building collaborative and cooperative relationships with countries, not because they are at the cutting edge of S&T, but because they are potentially important strategic partners from a security perspective: “It is a very different kind of relationship, but it is one in which the United States may seed technology investments on their behalf to move them up the curve, not because we will reap an output benefit from that, but because it builds a relationship and trust in exchange that may be of importance in a different arena. When you think about collaborative relationships, that is a little bit different outcome than you might otherwise consider for global S&T engagement.”

David said that it is important to understand the reasons for one’s actions. It is also important to understand the opportunities for tipping and queuing.4 This involves using very passive data analytics, such as analyzing journal articles, for example, and understanding publication citations and patents. “But that can’t be all of the answer. You need to take that then and say, okay, let’s peel back the reality beneath what the analytics points you to. It is a good pointer, but it is probably not the end of the answer. There are lots of other answers,” David explained.

Some of these mechanisms are more appropriate when trying to leverage what others are doing, David added. Some are more important when trying to under-

___________________

4 Tipping and queuing refers to the notion that a collection of information can be improved by coordinating activities between multiple sources. If done correctly, tipping and queuing makes the collection more refined and provides a smaller set of highly relevant data with which to work.

stand where the state of the art is in an effort to stay ahead, David explained. The particular outcome objective of an organization will drive its use of these various mechanisms. “But we believe all are important to some degree. You simply have to pick and choose according to the outcome you are trying to achieve,” David said. “Then, be sure that the set that you have chosen is knitted together in a way that allows you to leverage the benefit.”

David said that the committee characterized the landscape with three broad characteristics: distributed, interconnected, and dynamic. Distributed is geographic, interconnected is networked, and dynamic is changing. The committee concluded that all three of those dimensions are important.

David showed a chart that ranked the top 100 universities, first in overall terms and then within fields such as physical sciences, life sciences, and engineering and technology. She noted that North America still has a major part of the top 100 universities across the board. But when parsing out the data, “you find that North America has nominally 50 percent overall great universities, but 40 percent in engineering and technology.” She said that it is also important to look at measures like this over time. Over the past decade, the picture has changed significantly. For example, Asia has improved dramatically in science and engineering higher education. “The best universities for engineering and technology are distributed more broadly, I would argue, than the best universities overall. That is really the message. I think that is important,” she said.

David then referred to data about authorship of S&T articles, presenting a very interconnected picture. The data showed that virtually all of the top universities collaborate to differing degrees. Smaller countries tend to collaborate generally to a higher degree.

David noted that whereas manufacturing was sent offshore starting decades ago by industry, more recently research facilities have followed in huge numbers. There is a lot of data that shows that U.S.-based companies are preferentially building research facilities in other parts of the world. David said that there are many reasons for that: “One is access to markets. One is access to talent. Another is where the incentive structure guides them, both on the receiving end and on the sending end. There are issues that are driving those behaviors.”

Each of the companies that has done this uses a slightly different mechanism. For example, Boeing places a strong emphasis on research consortia. Almost all of them have some fairly strong emphasis on building partnerships with local universities, however, because that is a source of talent.

Some of the overseas operations are more autonomous than others. Some are highly networked, performing global information sharing, whereas others are more local. There is a slight divide depending on whether the product is physical or information-based. “There is some sense of when the bits move, but the atoms don’t have to move,” she noted, which drives how the consortia evolve.

David said that it used to be that U.S. success was attracting the best students to come to the United States to study, but that has now changed: “Part of it is the dynamic as other countries around the world build their own higher education institutions with significant stature.” Faculty have also become more mobile across national borders. But having opportunities for U.S. engineering students, not just business students, to study abroad is really important, David added (see Figure 1.3).

As industry has led the way in globalization, David said that universities have rapidly followed suit: “Virtually all of our top universities, I would say, have a lot

of global international perspective at the university level.” She said that the committee found that the countries that it visited all articulated their S&T investment strategies in the context of economic value.

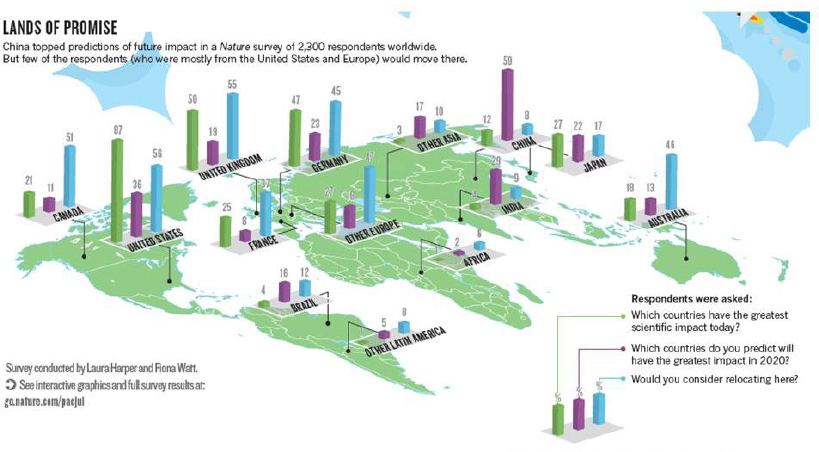

David had a final chart depicting a survey done by Nature. It had 23 respondents worldwide. Most of the respondents were from the United States and Europe. The survey asked three questions: Which countries have the greatest scientific impact today? What countries do you project will have the greatest impact in 2020? And would you consider relocating there? (See Figure 1.4.)

The survey noted a major drop for the United States, though there are still many people who want to come to the United States. There was also a precipitous rise in China, though people are less willing to relocate there. David said that a broad generalization is that the traditional western-oriented countries are declining in terms of technological impact, while Asia and the eastern countries are rising. “This is really one of the reasons I think the topic that you are talking about, even though it is more discreetly applied, is so very important to us, to our allies, and to our partners. I hope you find the silver bullet,” David said.

A workshop participant asked how the committee selected the countries to visit. Canada, Mexico, or Brazil would seem to have been strong candidates, with Mexico having made substantial investments in its facilities and equipment, so the participant wondered why the committee did not go to those countries.

David replied that the committee had a very long list of countries that it would have liked to have visited. It tried to balance the countries with whom the United States has strong traditional partnerships, such as Australia and the United Kingdom, with countries that are emerging and changing in the S&T areas in particular. David said that there were also some countries the committee wanted to visit but was unable to get through the bureaucracy to do so. The primary problem was obtaining visas because the committee was working under the auspices of DoD. David agreed that a lot is happening in Canada, but Canada is well known and has very long-term stable relationships with the United States. She added that the committee was guided in some measure by the areas in which DoD and the military services have presence. It took those as a starting point for the trip and then branched out in that local region in general. The committee talked a lot about trying to get to Brazil or Chile or somewhere in South America, but because of budget and time constraints it could not visit those countries.

A workshop participant asked about company-to-company international collaboration. David replied that, in particular, the Boeing examples were strong international collaborations built around a group of companies. But the committee was also somewhat limited by the data that it could get. Sometimes getting the details was impossible because they are not public. The committee benefited from having an individual from Boeing on the study team who was able to share his motivations about why they collaborated. The company that the committee visited in Sweden was another issue. The company was collaborating to drive standards, so it was a different reason for collaboration than normal. A great deal is happening in the private sector. Gaining access to new markets as well as talent bases motivates those collaborations. A big issue is intellectual property (IP): “That is why they have teams of lawyers that work that out right up front.”

Another workshop participant said that David had provided an excellent bird’s eye view of globalization. But the participant offered to share the “worm’s view of trying to make an individual thing work.” The participant said that the federal government put every obstacle possible in his team’s way because the project involved China. “For 15 years we have had a joint program with China. And every time I return, the Federal Bureau of Investigation is in my office.” The participant stressed that it does not matter whether one has a signed agreement between China and the United States, because that will not help the people working at the bottom who are encountering many roadblocks. David acknowledged that the committee heard this story before: “Many people have observed that practices put in place in a different world are getting in the way of what needs to happen today. These are really difficult policy issues that need a lot of focus.”

Another participant noted that international travel restrictions are not the only problem. There are also problems with domestic travel, even attending events related to the programs one is running. He noted that Singapore uses a lot of inter-

national experts to serve on advisory boards, to guide national laboratories, and to guide S&T. The participant said, “I find that to be very effective in making sure that the programs are calibrated, they are connected, they are aware of what is going on around the globe. They also have a lot of benchmarking that they actually do with many different programs. They hire people from many of the programs they think are at the cutting edge. It might not be the traditional or conventional ways of international collaboration, but they are very effective, even more effective than the typical conventional methods of doing that.”

David agreed: “I am a great admirer of what Singapore has put in place for its size. It is just incredibly impressive.” She noted that during one of her first visits to Singapore, one of the top-level officials opened his remarks by saying that the country maintains a 100-year plan, but it increments it 1 year at a time. “I thought, holy cow. We struggle with a quadrennial review,” David exclaimed. She added that China has openly published its S&T roadmap to 2050. It is a 100-plus-page document that lays out its strategies, programs, initiatives, investments, imperatives, and so forth. “We can argue about how effectively it is being executed or will be executed. The point is they have a plan. They have laid out vectors. When you read it, it is pretty thoughtful,” David noted.

David also said that the International Traffic in Arms Regulations (ITAR) remain an issue. She recounted how when she was in Russia 5 years ago, there were full-page advertisements in the local paper about ITAR-free products. “That clearly has become a marketing advantage in some parts of the world. There is a stack of reports that would probably come close to filling this room about the need to rethink the export control regimes.” However, there has been some recent progress, she concluded.

DISRUPTIVE TECHNOLOGIES: ADVANCES THAT WILL TRANSFORM LIFE, BUSINESS, AND THE GLOBAL ECONOMY

Michael Chui of the McKinsey Global Institute discussed McKinsey’s report, Disruptive Technologies: Advances That Will Transform Life, Business, and the Global Economy.5

Chui explained that the McKinsey Global Institute is the research arm of a management consulting firm. It recently turned its focus to disruptive technologies. Chui also stated that McKinsey has another report on global flows. “Those include global flows of goods, services, financial, flows of money and capital, and flows of people,” Chui explained, “as well as flows of digital assets.” Chui said that he agreed with David’s comments that the volume of interactions has increased

___________________

5 To read the full report, see https://www.mckinsey.com/business-functions/digital-mckinsey/our-insights/disruptive-technologies, accessed February 22, 2018.

and will likely continue to increase. He added, “The diversity of flows between countries also has thickened.”

He explained that McKinsey has a number of comparisons of previous flows, 10 or 20 years ago, where there were very thick lines among a small number of countries. “What has happened in the intervening time is all the lines have thickened and more lines have thickened around the world. We are starting to see a diversity, as well as an increase in volume of all of those flows, with a possible exception of people,” Chui explained. Temporary movement has increased, but migration has not substantially increased.

Chui displayed a chart that showed global income per capita over a long period of time, in essence the past 2,000 years. The chart showed a sudden and rapid increase in income beginning around 1850. But Chui thought the long, flat part of the chart from year 0 to 1850 was important as well. “In other words, for most of human history, we actually have not improved our welfare, at least by one measure of human welfare. It was roughly flat,” he said. But there has been a rapid increase in the past few decades. “That is correlated with a set of technology innovations,” Chui explained. “The question for our research was, what are the next sets of disruptive technologies which have the potential of making sure this doesn’t turn out like an S curve and instead continues to move up and to the right?”

The McKinsey study focused on economically disruptive technologies. The study identified 12 disruptive technologies, looking at more than 100 different technology families. The study considered technologies that were either increasing quickly or were accelerating in their development. The study also looked for technologies at an extensive reach, meaning technologies that not only were focused in one industry sector or geography, but also potentially affected billions of people or impacted multiple sectors. “Of course we are looking for economically disruptive ones,” Chui added, meaning ones that had large amounts of dollars, euros, or other currencies at stake.

In addition, McKinsey was interested not only in the potential value at stake, but also in that these technologies could be transformative—greatly shifting profit pools, changing industry structures, and changing the way that many people live their lives or do their work day-to-day.

One of the technologies McKinsey identified was the human genome project. Chui noted that this is a complicated problem. “We have about 80 to 90 percent of our DNA in common with hamsters. Sequencing the first genome cost $2.7 billion and took 13 years. We budgeted for 15, and they got it done early. Wouldn’t it be great if all of our projects went like that?” Chui asked.

Chui then showed a photo of a genome sequencer, which now costs $1,000: “You can put this in your shopping cart online, and you can get a genome sequence in a week,” he noted. The technology is advancing faster than Moore’s Law.

Chui wondered whether this technology could be economically disruptive. He pointed out that roughly half of the medical therapies that are prescribed by doctors do no good or worse. “A lot of that is because of individual variation as a result of genetics,” Chui explained. “If you are an oncologist, like my brother, the first thing you do when a patient comes in the door, if you are on the cutting edge of research, is sequence the patient, maybe sequence the tumor. There are drugs now that you only prescribe to people who have a certain set of genetic markers,” Chui explained.

“When you can program life, not only can you do that, [but] you can actually create new materials. You can take carbohydrate feed stocks [and] feed it to a bunch of E. coli, where we have programmed the genes. It will produce a precursor of diesel oil,” he added. “Being able to change the basic building blocks of life is tremendously powerful. Not only that, but the globalization effects of this are tremendous,” he continued. He noted that 25 percent of the gene sequencing capacity in the world is owned by a company called BGI. Many of its sequencers are in Davis, California. Chui stated that almost all of the sequencing machines that BGI bought were purchased from U.S. companies. “If you think about what this means globally, something that is potentially a strategic capacity, and where and who has control of it, and the potential for disruptive power, [it is substantial],” Chui added. Two of the 12 disruptive technologies that McKinsey identified in its report change the basic building blocks; these include next-generation genomics and materials.

Chui then showed a photo of the Defense Advanced Research Projects Agency (DARPA) Grand Challenge of 2014. In 2004 at the challenge’s inception, DARPA offered $1 million to the first organization that would run an autonomous vehicle 200 kilometers across the California desert. Even though the competitors included Stanford University and major defense contractors, no one won because no one finished.

Chui then showed photos of autonomous vehicles like the Google self-driving car, demonstrating tremendous achievement in less than a decade. The first Grand Challenge was in the desert so that the vehicles would not hit things. “Yet, less than a decade later, these things are out there in the wild, with pedestrians, bicyclists, all kinds of stuff going on.”

Chui explained that after one group proved that an autonomous vehicle was possible, soon many others were repeating that capability and advancing it: “Once you realize this problem is solvable, everybody goes out to solve it. Now, every automotive original equipment manufacturer has a self-driving car program.” Chui showed the Mercedes S-class car that includes a self-driving capability as a production option in Europe: “That capability now is being deployed in production in actual vehicles. This is now commercially available to consumers.”

Chui said that these are examples of the increasing accessibility and distribution of advanced technologies. “There was a time when we said, that’s DARPA stuff,

wow. It is a good thing only the government has access to that,” Chui joked. “What we are finding now is that individual consumers around the world have access to extremely advanced technology.”

Another example that Chui cited is Rethink Robotics’ Baxter robot. An industrial robot used to cost $100,000, sometimes even millions of dollars, but the Baxter product costs $20,000 and can be purchased online. “You can get it on your iPad right now and just click, add to cart,” Chui explained.

Chui noted that industrial robots in factories are considered dangerous devices: “They are in cages, and they are behind those yellow lines. What happens if you step across that yellow line? You either die or the line shuts down. They are deadly. These are deadly machines.” In comparison, the Baxter robot can be programmed by people on the factory floor who might not have a high school education.

“What does that mean? Not only is it a capability that is an increase in flexibility, an increase in training in terms of traditional robotics, but now we can start to think about automating things that we previously couldn’t think of automating. Think of service tasks, for instance, [and] food production,” Chui said. Across all those dimensions, functionality is increased. The flexibility is increased. The ability to train goes up and the prices come down, so the safety is increased. All of these technologies spend decades in development. “But that is a characteristic of an exponential curve. They feel boring for the longest time, and then, suddenly, the impact seems to accelerate faster than you would have thought,” Chui noted.

McKinsey also identified a set of energy-related disruptive technologies including batteries, advanced exploration fracking, and renewables. Most of those other technologies could not exist without the underpinning enabling layers of information technology. Chui noted that 2 billion people have access to the internet, but that is not even half of the world’s population. “If you think about all of the disruption, all the things that having devices like these have caused, and you think that we haven’t even reached halfway, never mind that these things will continue to evolve into glasses and all kinds of wearables and ingestibles, you can see that there are huge amounts of head room left,” Chui said.

There is also the automation of knowledge work. It is easy to comprehend automation of physical labor or even basic management of supply chains and things like that. But automation is now moving into other areas. As an example, Chui cited customer service inquiries that are conducted through text messaging. There is no way to know if one is conversing with a human or a computer program. Another example is corporate litigation and the discovery process, which used to be labor-intensive (i.e., requiring several trained lawyers) but now is automated with software. “These are people with 4 years of undergraduate training, plus 3 years of graduate training. That task is gone,” Chui said. There are now programs that can write financial reports or sports reports based upon the game score. “If this curve moves as quickly and as surprisingly as it has in other areas, you might start

to see things like engineering, maybe science, becoming increasingly automated as well,” Chui continued. Other examples include cloud computing and the Internet of Things.

McKinsey tried to size the potential economic impact of these technologies. It picked 2025 as the target date because 50–100 years was so far out that it was essentially meaningless. For the report, McKinsey chose to look for trillions of dollars of annual impact. There were some small bars on the graphs, but the small bars still represent hundreds of billions of dollars of impact. This is not only gross domestic product impact, but also value that the customer, the consumer, or the health care patient gets by living longer and having higher quality of life or lower CO2 emissions.

McKinsey also tried to size the relative hype associated with technologies, including the number of mentions in the English language press. Some things are talked about a lot and have huge amounts of value and so are appropriately valued by hype. Other things are important but are not getting much press attention. These include things like the automation of knowledge, the Internet of Things, robotics, and cloud computing. There is not always a perfect correlation between hype and value, Chui said.

Chui finished with a few observations. One is that although McKinsey sized the impact of these technologies individually, they actually have multiplicative impact: “When you combine 3D printing with robotics, et cetera, you can have even more impact on manufacturing, for instance, than you thought you had.” Chui explained that consumers are going to benefit the most from these technologies because many of the economic benefits eventually are competed away among the companies and the approximately two-thirds of the new value then shifts to the consumers.

The nature of work itself will change. A lot of this has to do with the fact that a lot of it is being automated, whether it is physical work or intellectual work. This also means that for an individual to remain employed, he/she will have to maintain what Chui calls “metaskills,” which include flexibility and adaptability.

Chui also said that many of these technologies are becoming increasingly accessible: “My dad’s high school friend in Hong Kong is teaching high school students how to do advanced genomics.” The cloud allows a company to be very small, to grow very rapidly, and to be “micro multinational,” as it is commonly phrased on the web. “You don’t actually have to grow to 1,000 people in the United States before you set up a subsidiary somewhere else. You can found a company right now where executive management is in California, and sales and marketing is based in London, and development is in China, India, and the Philippines,” Chui explained.

Finally, Chui noted that the impact is not necessarily evenly distributed: “You can look at that a number of different ways, whether it is inequality of impact, with regard to wealth and income, or if you look around the world in different geographies, clusters of places where people go will accrue more value.”

One participant asked Chui about how government agencies can try to do the same kind of disruption in technologies that companies do. “There are great examples of government agencies doing it,” Chui replied. “I think DARPA is a terrific example of the ability to create an institutional environment, hire the talent, and give a mission that allows you to look at the disruptive stuff. If you think about the elements of the DARPA model, which lots of people have written about and thought about, that actually seems like a terrific, positive case of where government can do that.”

In response to a question about the proper percentage of R&D funding in order to develop new technologies, Chui added that companies fail on disruptive innovation when times get tough and they eliminate R&D: “You fire everybody. Then you come back when things are good.” That is a flawed approach, and Chui suggested that a better approach is to say, “We are going to continue to do this over time. We are going to develop a capability. We are going to be committed to it. People will rotate through it, but we are going to make sure we have the right types of people. I think it has more to do with the constancy rather than the percentage.”

One observation from the commercial world is that even if a single company fails at something, its intellectual assets, the people, can go somewhere else. “That is the nice thing about having a dynamic economic system that works that way. You would have said during the early 2000s we wasted all that money on fiber in the ground. It eventually got used, right? But those companies didn’t survive,” Chui noted.

Another participant noted that in manufacturing policy discussions there is often an observation that innovations and disruptive technologies originate in the United States but end up getting produced elsewhere in the world. The participant wondered who would be the leading supplier to the world for that technology and how that would impact the economy.

Chui said that the United States is the acknowledged innovation hub, but where the technologies get deployed is going to vary on many factors, including energy prices, corporate structures, and many other things. Broadly speaking, a number of these technologies, particularly the automation ones, reduce the advantages of labor cost arbitrage, which is already evaporating as the world globalizes. Proximity to customer becomes easier and easier, and many of these technologies enable more physical proximity.

Another participant asked how confident McKinsey is of the 2025 timeline that it is predicting. “We are absolutely certain that our numbers are wrong,” Chui replied. But he thinks that McKinsey’s projections are pretty reasonable. Part of it has to do with what McKinsey described about many of the technologies on exponential curves: “You see them. You see them coming for a long way off. They just haven’t reached their full level of impact. It is a characteristic of exponential curves, depending on what the exponent is. They stay below the linear, and argu-

ably we think more linearly. But when the lines cross, again it tends to have more impact than you expected, or it feels that way.”

“Many of these technologies feel like, ‘oh, we have been talking about this forever. I think we are done.’ Then the next thing you know, it actually accelerates substantially. We feel pretty good about these being ones that have the potential of real disruptive economic impact. Again, we don’t think these are the only ones, but we have pretty high confidence in these,” Chui concluded.

THE ROLLS-ROYCE MODEL TO GLOBAL ENGAGEMENT

Mary Lee Gambone, of Rolls-Royce North America, talked about Rolls-Royce and globalization. She noted that her company is a power systems company, developing power systems for air, land, and sea. The company stopped making cars more than 40 years ago, and now BMW makes Rolls-Royce automobiles.

About 70 percent of Rolls-Royce’s business is aerospace, in the form of power systems for aircraft. About 25 percent of that business is defense, with the majority of that defense business being for the United States. The company also has substantial European activity. One of Rolls-Royce’s largest defense programs is the LiftSystem, which powers the F-35B Lightning II short takeoff and landing aircraft. It was designed concurrently between Bristol in the United Kingdom and Indianapolis and now is wholly manufactured in Indianapolis.

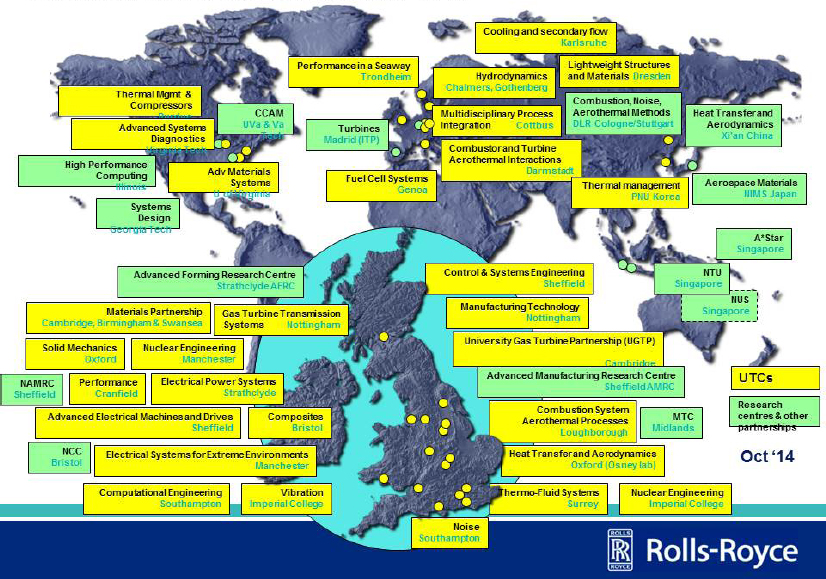

Rolls-Royce also makes engines for the V-22 Osprey and the C-130 cargo plane. All the engines on the C-130 are variants of engines that the company manufactures in Indianapolis. The A2100 engine is on the C-130J. The company has also manufactured the T56, which powers the earlier versions of the C-130. Rolls-Royce has a long history of supplying defense systems and working with DoD, the Air Force, and the Navy, as well as with the Army, developing power systems. Rolls-Royce also manufactures nuclear power systems for the Royal Navy’s nuclear submarines (see Figure 1.5).

This diversity requires a tremendous amount of innovation because there are many technologies involved. Of the 45,000 people who work for Rolls-Royce, more than 15,000 of them are engineers. “We are very much an engineering company,” Gambone said, “and innovation is very much a part of what we have to do to survive, to be able to continue to be successful.”

The company spends about $1.7 billion a year of its own investment in R&D. In Indianapolis, the company spends a significant fraction of that budget on research and lower technology readiness level (TRL) technologies, Gambone said.

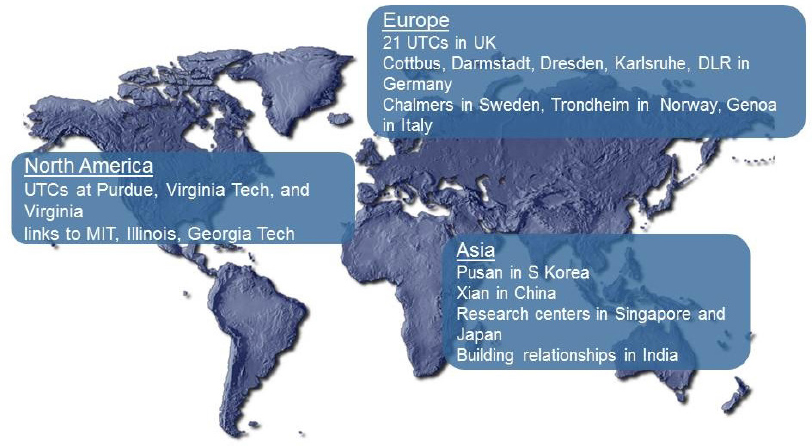

Rolls-Royce spends its R&D money globally, although there is a center of gravity in the United Kingdom where the company was started. Rolls-Royce just celebrated its centennial as a company in the United Kingdom in 2004 (and in the United States in 2015). “Obviously, they have a large footprint there. But they have

branched out globally in the way the British do so well, across North America [and] South America and [with] a growing presence in Asia,” she added (see Figure 1.6).

Rolls-Royce spends the great majority of its research dollars on technologies that are systems-ready: “What we do is we strive to have, say, technologies at a TRL 6 ready to go into preliminary design for the next system. That means we have to be thinking about technologies and how we are going to get them to a specific point, so that they are ready to go into preliminary design,” Gambone noted.

Projects that do not meet those requirements have a difficult time getting additional funding. “That is a balance we are always trying to seek. We would like to be able to say that we are going to develop technologies out for a 15-year timeframe,” Gambone said. “But the reality of it is, our seniors at the company are always looking at us saying, ‘okay, what are you going to have to put into this next engine program? What are you going to have to put into the engine program in 2 years?’” Those windows are narrow, and it creates big challenges. “That, of course, makes it even more challenging when you go to doing things globally, where people work in different time scales, as well,” she continued.

Gambone explained that Rolls-Royce puts its emphasis on university systems for TRLs 1–4: “There are probably 20 universities within the United Kingdom, but

there are many growing university technology centers” across the world, including three in the United States now. Gambone said that more will probably be added in the coming years. There are several in Central and Mainland Europe. Gambone noted that a lot of U.S. companies have difficulties working with universities because the time frame for a university and the drivers for a lot of professors are a little more long term than most industries can accept. But she thinks that Rolls-Royce has struck a good balance in large part because the relationship between industry and universities in the United Kingdom is different from that in the United States. It offers universities stable funding, usually to several professors. Rolls-Royce selects professors and research leaders in areas where it has need. It also provides stable and substantial funding over 5 years, lists its technology goals, and asks the professors if they are willing to sign up. This is very attractive to the academic community because it seems like professors spend most of their time trying to get funding. “So having a company come in and say, you don’t have to worry for about 5 years” is attractive, said Gambone. “We are going to be checking up on you obviously and working with you, but you have that guarantee. You have a fairly stable basis

of technical problems. Most of them are fairly interesting to potential graduate students” (see Figure 1.7).

Rolls-Royce also does not prohibit its university technology centers from getting leveraged funding. Most of them obtain that funding, but it helps to have an industry partner already. “It is a very synergistic relationship,” she added.

In addition, Gambone noted that Rolls-Royce also gets recruits for its workforce: “We recruit probably one-third of the graduate students. It is a fairly substantial number we bring into the company. It fuels our innovative workforce, having these graduates there.”

The company also gains access to emerging technologies, which might be difficult to fund if it were simply doing applied research in-house. “We get some thinking that is kind of outside the scope of what narrowly we can look at, just from a business perspective,” Gambone explained. “Many of the researchers we have worked with at the universities, they aren’t locked into aerospace. They are not locked into materials or manufacturing processes for aerospace. That gives us a lot of flexibility that we wouldn’t have otherwise.”

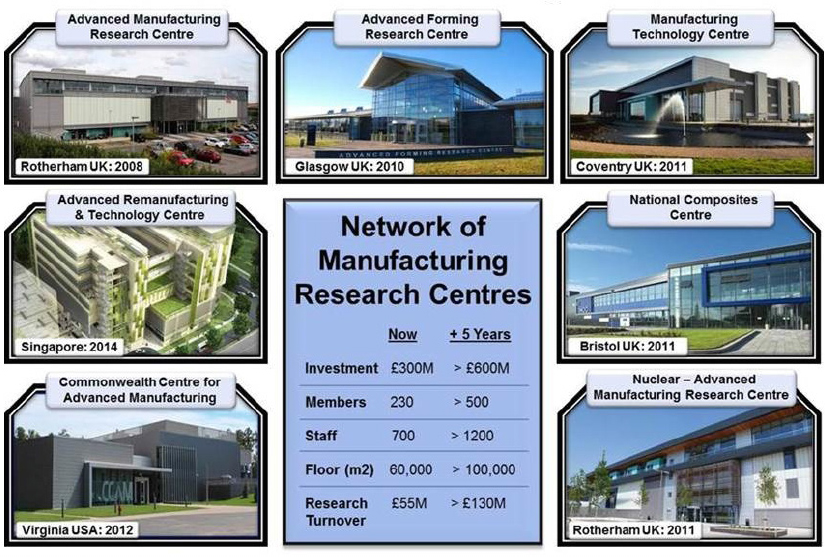

Gambone referred to the technology “valley of death”—mid-level technologies that are relatively inexpensive to develop but are much more difficult to develop to the point where they can be included in manufactured systems. The company has sought to solve this by developing advanced technology research centers for manufacturing, which are an outgrowth of its university relationships. It provides

a platform for Rolls-Royce to mature technologies that come out of universities. Sometimes the technologies actually come out of the company’s in-house applied research, in a collaborative environment with the university. Usually, Rolls-Royce employees are also working in the technology centers (see Figure 1.8).

Rolls-Royce also partners with other industrial organizations at the centers. Most of these centers are operated by the university rather than owned by Rolls-Royce. The company has a number of industrial partners who are interested in the same manufacturing technologies. Because of this, there is both leveraged funding and leveraged ideas. Rolls-Royce can take the technologies that come out of the universities or out of individual companies and develop them, sometimes for marketing in the public sector. The company builds supply chains using these advanced technology research centers that then serve as the supply chain for advanced manufacturing capabilities.

Rolls-Royce started and is currently a member of the Commonwealth Center for Advanced Manufacturing, south of Richmond, Virginia, at a facility called Crosspointe. That facility is affiliated both with the University of Virginia and Virginia Tech. Many of the facilities are in the United Kingdom. Rolls-Royce is also a member of a center in Singapore called Advanced Remanufacturing and Technology, which is focused on developing repair technologies and nondestructive evaluation (see Figure 1.9).

According to Gambone, one of the things this model has allowed Rolls-Royce to do is to bring manufacturing technologies forward in a way that it has not really

been able to do in other models. What the advanced manufacturing facilities help do is move the technology into manufacturing because the equipment has already been proven. “You just put the machine on the floor, and this is how this is going to work. This is what it is going to tell you. This is how it is going to speed up. We can actually bring the day-to-day manufacturing folks into the research centers and say, ‘see, this is how it will work.’ They can watch it make a part or do a process, or they can watch it make a forging or put a coating down, so a very powerful tool,” Gambone described. Ten percent of the company’s patents come through university technology centers.

The company does face problems with this approach, including export control. Gambone noted that the Export Administration Regulations and ITAR rules changed recently, requiring the company to reclassify all of its parts: “That makes things more complicated when you are trying to figure out what you can talk to your co-workers in the United Kingdom or in Germany or in Singapore about.”

Rolls-Royce is compliant with all countries’ export restrictions; now that it is working much more collaboratively, the company is wrestling with the variation in export control restrictions for other countries with which it works. The United Kingdom sees export control in terms of IP control, which is very different from

the United States. Thus, the United Kingdom approaches it in a much different manner. Gambone mentioned that Germany has a different viewpoint as well: “It requires a lot of getting inside the heads of the people in those different countries and understanding where they are coming from to be able to negotiate agreements well.”

When an individual starts a technology development program at Rolls-Royce, that person maps out how to export, what the barriers are, where the barriers come from, and where to put the research based on said barriers. The person evaluates that export roadmap while simultaneously evaluating the stages of the technology research.

As an example, Gambone cited ceramic matrix composite, a material in which the company is very heavily invested. “We have looked at the coating. We have looked at the constituent materials. We have looked at the composite as a whole, as a material. We have looked at manufacturing that composite, putting the coating on, machining the composite. Each area of that activity has different export restrictions,” she explained.

Ceramic matrix composite is a dual-use material, so it is mostly under the jurisdiction of the U.S. Department of Commerce. “But if you are over a certain temperature, you are in the ITAR territory,” Gambone commented. The company has to identify where the line is and plan around it, while at the same time figure out what tests and trials to undergo. It cannot afford to get to a decision point and not be able to transfer the technology where it needs to be. “It takes work. But we found [that] by doing forward planning, we are much better able to conduct constructive research and not get to these barriers,” Gambone remarked.

An area closely related to export control is leverage funding. This is a real challenge in materials and manufacturing. Just as DoD has restrictions on how its research dollars can be used in other countries, other countries have similar restrictions. In some ways, other countries are much more restrictive. They get much more leveraged funding, especially in Europe and in Asia. Rolls-Royce finds that everywhere outside the United States, the available funding is often quite generous. In Germany, the LuFo funding, a German government funding program for industry development, is often upwards of 70 percent from the government and 30 percent from industry, which is quite attractive for a global company.

In the United Kingdom, the advanced research dollars are often at least 50/50. They all come with very heavy strictures: no sharing of technology is allowed outside of that country for 5 years after the program ends. “It becomes difficult to take that technology and apply it to defense systems in the United States because we would have to wait until the technology wasn’t as interesting anymore to get it. That has required a lot of complex decisions about where you put research,” Gambone said. “The question we get every time we want to do anything in the United States is, well, ‘what is your leverage funding? Where are you going to get funding?’” If it

decides to develop a new system in the United Kingdom, Rolls-Royce goes to the Ministry of Defence or to the Technology Strategy Board—because Rolls-Royce is essentially the only major aerospace company in the country, it has a lot of leverage with the government.

IP is another challenge, but Gambone thinks that if Rolls-Royce solves the other issues, IP will be easier to address: “We look at every individual country and what sorts of patents and patent protections exist. We have a strategy on where we are going to patent what technology and how rapidly we need to work to protect IP as the technology progresses. That is something that we do and we manage alongside our export strategy and our technology strategy.”

As Gambone explained, in order to manage applied research and to work effectively at Rolls-Royce, it is important to understand these other factors: “It is not like they can just go into the lab and do interesting things. They have to understand the international business around this technology, how the intellectual properties protect it, what the export rules are, things that they find much less fun, but go a long way towards protecting the company.” Rolls-Royce tries to make better tools for individual researchers so that they can understand where they are and what they need to be doing at any given time.

Gambone explained that some other issues are unique to materials and manufacturing. One large issue is environmental legislation. The company has been working on that a lot in light of the European Union’s regulation on the Registration, Evaluation, Authorization, and Restriction of Chemicals. “That has been pretty daunting. It seems like every day we hear more chemicals are going on the banned list, and trying to roll that down the supply chain is challenging,” Gambone noted.

Rolls-Royce has a fairly large infrastructure; it can handle looking at manufacturing systems and identifying where chemicals are being used, as well as looking at how those changes would affect the company. This has become difficult as the company grows its supply chain, because small manufacturers cannot deal with this sort of legislation.

Gambone added that another issue is legislation in China. Even modifications of environmental legislation occurring in the United States have caused DoD to make its own rules with which Rolls-Royce must comply. “That can be challenging when you are trying to develop technology at the same time,” Gambone explained. “If the Ministry of Defence is our customer, their focus is, of course, on U.K. resources, U.K. infrastructure. They are not really interested in growing U.S. defense capability, even if it helps them in the long run. It is always a balance of meeting all of your customer expectations and managing your global supply chain.”

Part of the challenge is dealing with expectations and biases within the company. Managing a global supply chain is quite a challenge; but in contrast to that, Gambone noted that Europeans tend to be much more broadly focused. For civil products manufactured in the United Kingdom, it is not an issue that titanium is

purchased from VSMPO-AVISMA in Russia. But the defense division must keep everything separate and monitor those supply chains.

As another example, Gambone explained that Rolls-Royce is still doing single crystal alloy development, which was centered in the United Kingdom. The company signed an agreement with an organization in Japan, but this particular organization prohibited the use of this research in defense activities.

Gambone finished by stating that there is no way to do the kind of global business that Rolls-Royce does without doing R&D globally. There is just not enough capability in any one country, in any one place in the world, to maintain competitiveness.

Rolls-Royce found a lot of different ways to leverage capability and resources using its universities and research centers. “I think the only way we have managed to do R&D globally is by very careful planning, by thinking about the barriers ahead of time and trying to adjust to them as quickly as possible,” Gambone explained.

One participant noted that in the United States, the biggest obstacle to industry–university collaboration is IP, at least from the industrial perspective. Industry expects to own the IP, but the universities take the position that they have been doing the research for many years and they own it, while industry only gets “the tip of the iceberg.”

Gambone explained that industry has to negotiate different terms. “When we set up a university technology center, there are usually some benefits to Rolls-Royce for that constant funding and that significant level of funding in terms of patents. We don’t claim all of the patents. We usually share patent rights. We either get free use of the patented material, or we will share patent rights with the university.” She added that the difference in how universities view IP is one of the reasons why Rolls-Royce only has three centers in the United States. “We found other places in the world to be much more flexible that way,” Gambone remarked.

Another participant commented that General Electric tried to emulate the Rolls-Royce model but has not been as successful. The participant noted that one of the challenges at universities is determining how mature the technology is so that it can be taken to the next step. The participant asked Gambone how Rolls-Royce makes that determination. Gambone explained that Rolls-Royce tends to be very interactive with its universities: “We have one or more of our research fellows that work for Rolls-Royce.” In some cases, in its larger centers, research fellows work side-by-side with the professors on-site.

Groups of professors and Rolls-Royce researchers meet three or four times per year to review the status of a project on an every half-year basis for that project in question. They look at it from a business perspective and from a technology perspective.

Gambone also said that Rolls-Royce has to be more heavy-handed with controlling what research continues: “We have ended forays into areas that weren’t

applicable to the Rolls-Royce business direction at the time or in the foreseeable future. It seems to work pretty well especially in the United Kingdom because there are very close ties.” She also believes it works well at Purdue University and in Virginia (University of Virginia and Virginia Tech) because Rolls-Royce has a facility in close proximity. Rolls-Royce has many personnel who can interact with the universities on a regular basis: “You can’t just give them funding and direction, walk away, and come back a couple of years later. It has to be an ongoing conversation.”

Another participant said that companies want to do research to get a competitive advantage. But beyond competitors in the defense industry, there are adversaries who do not respect IP. The participant asked how Rolls-Royce navigates those kinds of issues. Gambone admitted that it is a challenge: “One of our challenges of doing U.S. defense-related research in the United Kingdom is that they view citizenship and nationalism very differently than we do, which is something I didn’t appreciate until I worked for Rolls-Royce. To them, asking somebody their national affiliation is kind of an insult. It is like asking somebody here in the United States what they make for a living. You just don’t do that.”

“When we told them that you can’t have people from certain countries working on our research projects, they found that very intrusive and were embarrassed by the fact that we insisted,” said Gambone. “It is a challenge that we have been working on for a while. I don’t know that we have any tried and true means. When we negotiate our university technology center agreements, we put a lot of strictures in place.” Rolls-Royce will tell its U.S. technology center that any student who is a foreign national working on this research project has to be vetted by Rolls-Royce. “In some cases, for some research endeavors, we have required that they had to be all U.S. citizens,” Gambone continued. One of the ways that the company is more flexible is in its restriction of research to TRL 1–3. A lot of times, the technology at that level is nascent enough so that the competitive advantage has not fully matured.

When pulling research into the advanced technology research centers for manufacturing technology, protecting ideas can be achieved more thoroughly because of this different arrangement. That is where a lot of the competitive advantage and the more value-added work is done.

Another participant asked whether there are policies for dealing with competitive advantage. Gambone replied that typically when Rolls-Royce initiates an advanced technology research center, it puts membership strictures in place to protect competitive advantage. The Commonwealth Center for Advanced Manufacturing in Virginia is completely open except to other companies that manufacture gas turbine engines. That works to Rolls-Royce’s benefit because industries that are somewhat tangential are brought in, with interesting and different ways of viewing things.

One participant added that universities do have a mechanism to have competitors sitting around the same table by having not only specific research done but

also an affiliate-research program. The participating industry funds non-specific research, where universities conduct the research for the benefit of all the affiliates. The difference in this case is that the members of these affiliate programs cannot direct the research. Members pay a membership fee, and the universities will make the best investment of that research. Mike McGrath, McGrath Analytics, LLC, observed that this can only work at the TRL 1–3 level: “I imagine as you go beyond that, you start to get closer to competitive interests.”

THE FRAUNHOFER INSTITUTE’S GLOBAL APPROACH

Andre Sharon, of the Fraunhofer USA Center for Manufacturing, started by explaining that Fraunhofer is Europe’s largest R&D organization. He spoke about how a presence in the United States has changed the Fraunhofer organization. Approximately 20 years ago, in response to globalization, Fraunhofer’s leadership decided that the research enterprise should be global as well. Sharon’s focus is on manufacturing, and the organization’s primary target is efficiency: “We believe that manufacturing in the future is going to be much more competitive. Manufacturers are going to have to be highly efficient in order to survive.”

Sharon explained that the reason for this drive is the steady leveling of the global playing field. Cost of capital will eventually equalize, including more uniform tax and industrial policies. At the same time, manufacturing is becoming more competitive as every western country is trying to reclaim or pursue manufacturing. The United States recently funded the Network of Manufacturing Institutes as a means of revitalizing U.S. manufacturing. Sharon said that England is no longer satisfied as being just a financial capital and is also funding a network of manufacturing research centers. France, Italy, and Spain are scrambling to increase manufacturing, while Germany continues to be a manufacturing powerhouse. At the same time, Asia is moving up the value chain. “As a consequence, manufacturing is going to become much more competitive. Those manufacturers that continue to rely on cheap labor costs and unsustainable regional policies are not going to survive,” he said.

Efficiency applies to the entire enterprise, from organization to labor, process, energy, and use of capital. Sharon’s center focuses on labor, process, and capital efficiency, while other Fraunhofer Institutes concentrate on organizational efficiency, energy efficiency, and other issues.

The technologies that Fraunhofer employs may not be disruptive individually, but in combination they can make manufacturers much more efficient. Sharon’s center is particularly interested in integrated additive/subtractive manufacturing, which he believes will have a wider application than additive manufacturing. The organization is also working heavily in laser processing, and it has already developed many examples and systems in which process efficiency has skyrocketed.

“Industry 4.0,” as it is known in Europe, or digital manufacturing or smart manufacturing, as it is known in the United States, will connect all of these processes together. In the United States, when one talks about the Internet of Things or smart digital manufacturing, there is a much greater emphasis placed on smart connected products. Sharon noted that in Germany, the emphasis is rather placed on smart connected processes. There is a lot of synergy and room for collaboration, he said.

In addition to technological efficiency, Fraunhofer also wants to improve efficiency in industry–university collaborations. Sharon said that in the United States, this collaboration is lacking. “There is so much good work that can be much better utilized by industry from universities, as well as more efficient international collaboration,” he said. There are challenges such as the infrastructure, IP, and culture, which draws the least attention. “If you have tried to negotiate, collaborate, or work with other countries, you can certainly see cultural differences that come into play,” he continued.

Fraunhofer is Europe’s largest R&D organization with about 20,000 employees and approximately 60 institutes around the world, 6 of which are in the United States. Fraunhofer has approximately €2 billion in annual funding. Fraunhofer receives one-third of its funding from industrial contracts and one-third from government contracts. These come from the European Union framework program and the equivalents of the National Institutes of Health, the National Science Foundation, and so on. The remaining third of the base funding comes from the German government. Sharon noted that because R&D, especially research, is a money-losing business, it needs to be subsidized. In industry R&D is supported by products, while in universities it is subsidized mostly by tuition and other sources. “You need to have sustainable, non-sun-setting base funding in order to be able conduct R&D. It cannot be seed funding,” Sharon explained.

Sharon said that Fraunhofer succeeded in Germany and then moved on to the United States and other countries to close the gap between academic research and industrial needs: “It is not just a valley of death, as people call it, a funding gap. There is also a skill set gap.”

For a typical R&D process—from idea to manufacturing and industry refinement—the early parts of the process are well defined. “There are many people that are good at doing this early basic research part. But there aren’t that many that are good at actually scaling up technologies,” Sharon said. This is the part on which Fraunhofer concentrates, so as to move ideas from the laboratory to the marketplace much more quickly. “Venture capitalists don’t invest in research. They don’t like technological risk. They want to see the technology working. Then they are taking only the market risk. ‘Will it make money for me?’ The business risk, not whether it is going to work or not.” In order to lower the risk, Sharon explained, it is necessary to concentrate on this gap.

Fraunhofer uses a very simple model. “In universities, you have faculty. They work together with students, and they come up with great ideas, great research. It usually stops at the laboratory bench top level because universities don’t have the incentives, nor the resources to take that research beyond the lab bench. If you then throw full-time engineering staff into the mix, now you have faculty, students, and engineers working together, then you can really do great things,” Sharon explained. “You can do it on an industrial timetable versus a Ph.D. student’s thesis timetable.” This model has worked extremely well over the past 60 years, which enabled Fraunhofer to grow to become Europe’s largest R&D organization.

Sharon explained that in Germany, there is a Fraunhofer Institute next to every major university that works with the university and specializes in a particular market segment or industry sector. There are approximately 50 such Fraunhofer Institutes in Germany, each concentrating on different markets such as lasers, information technology, biotech, semiconductors, and energy. Sharon provided one example, noting that Fraunhofer invented MP3 compression. “This has impacted many industries and has created tens of thousands of jobs,” he said.

Fraunhofer connected each of its six U.S. centers to a U.S. university, instantly creating a collaborative cluster. Each one of these centers in the United States was part of a specific institute in Germany, so there was collaboration between the institutes and the university, as well as among universities. There are also centers in other parts of the world.

The Boston University Center for Manufacturing Innovation is the oldest Fraunhofer center in the United States and is part of the Fraunhofer Institute for Production Technology in Germany. The center is located on the Boston University campus and collaborates closely with a well-known engineering school at the Technical University of Aachen in Germany. The center in Boston concentrates on the development of next-generation automation systems and instruments. It primarily targets biotech biomedical markets, photonics, sustainable energy, and other advanced manufacturing processes. A lot of what the center does lies at the intersection of life sciences and engineering.

Fraunhofer has developed some sophisticated systems, not simply bench-top models, at the centers. One example is a system that reprograms tobacco plants to synthesize the proteins or antibodies that are used to make vaccines. The technology was developed jointly by one of the Fraunhofer Institutes in Germany and one of the Fraunhofer centers in the United States. To prove the concept, they grew some tobacco plants in a small greenhouse, infiltrated them with the biological vector, harvested the proteins, and demonstrated in the laboratory that they can produce a few milligrams of vaccine matter. DARPA was interested in the technology but wanted it scaled up to produce millions of doses of the vaccine cost-effectively and, more importantly, quickly in case of a national pandemic.

This is an alternative model to the traditional way of making vaccines using eggs. Fraunhofer developed a fully automated factory that makes vaccines from tobacco plants. It turned a farming process into an industrial process in which the plants are grown hydroponically on trays. They are automatically seeded and grown in special controlled environments, then automatically infiltrated with biological vectors to produce the right proteins and antibodies. Using this process it is possible to go from an unknown threat to a complete vaccine much faster. In addition, the factories now can be deployed anywhere, from the middle of Manhattan in a warehouse to a third-world country. There is a factory in Delaware undergoing U.S Food and Drug Administration validation that is producing some vaccine matter for clinical trials.

Laser processing is another area in which Fraunhofer concentrates. Lasers can work on a variety of materials, from steel, to plastics, to magnesium deposits. For example, Fraunhofer has developed a laser-based process that cuts labels in a roll-to-roll process, which is vastly more efficient than the traditional approach using mechanical dies. Another system it developed follows plant-breeding strategies by using lasers to cut samples from the leaves of plants. This eliminates cross-contamination and improves efficiency.

Additive manufacturing, Sharon said, is getting a lot of enthusiasm, only some of which is warranted. It has been identified by the World Economic Forum as one of the top 10 most promising technologies. But it also has limitations, and Sharon said that it is important to keep that in perspective. “It is not the Holy Grail for manufacturing. It is not going to be the one solution that makes American manufacturing more competitive,” he said.

Fraunhofer has a system for using selective laser melting to make turbine stators. It also has an integrated additive/subtractive manufacturing system for making turbine blades. Using laser-based deposition and finish-milling, Fraunhofer can manufacture a blade in a few minutes. It deposits coarse layers of metal, which milling tools then go over and create the required surface finish. It uses laser-based metrology to determine what has been deposited. By integrating the two technologies, Fraunhofer has shortened the production process, compared to additive manufacturing alone, and produced a finer finish at the end. “One thing that Fraunhofer did learn in coming to the United States was entrepreneurial culture,” Sharon said. “That is one area that they will admit that in Germany and Europe, in general, is way behind.”

Fraunhofer had a large quantity of technology that it developed for creating fiber optic components, which is a very difficult manual process. There is no equivalent to soldering, and fiber cannot be soldered to another fiber or to a modulator. For a simple optical electronic device, one needs to attach one input fiber and one output fiber. The process was previously done manually using hundreds of workers, similar to textile factories, only instead of sewing machines the opera-

tors would have microscopes and little pliers and tweezers. Before the fibers could be connected, they had to be aligned accurately. The fibers also had to be prepped, stripping the small and delicate glass fibers. They then had to be cleaned and cleaved with a diamond cut and aligned within a few microns of the chip in order to get good light coupling. Fraunhofer developed technologies that automated this process. It spun out a company and raised $50 million in venture capital. Originally, the idea was for the company to develop and sell automation equipment, like Applied Materials. But then due to global financial changes, Fraunhofer decided that instead of selling equipment, it would use the manufacturing equipment in-house in the United States. Fraunhofer had a cost advantage in manufacturing and was more profitable selling the actual fiber optic components instead of the equipment to manufacture them.

Fraunhofer started a company called kSARIA, which is doing very well. “If you fly in airplanes that have in-seat entertainment, a lot of the systems are actually driven by kSARIA fiber optics,” Sharon said. These systems are on just about every military platform that uses fiber optics. These include the Patriot missile, fighter planes, ships, and submarines. This automation is used to make the manufacturing processes more efficient while producing in Massachusetts, which Sharon noted is not exactly the cheapest labor region in the country.

Sharon said that the best type of collaboration is always human collaboration. Fraunhofer has a very intensive internship program, accepting many interns from across the globe. It also sends U.S. students to Europe, where they learn how business is done on both sides of the Atlantic. This experience gives them extremely high value in industry.

A participant asked how Fraunhofer deals with the environment in U.S. universities where people are rewarded by publication and dissemination of work, without necessarily taking it all the way to implementation: “What kind of incentive or system do you have in place that gets people to be excited about crossing that bridge in the United States?”

Sharon replied that the faculty at the universities still work on the earlier research side, while the engineers do more of the applied part. The faculty can still publish papers, but by combining it with engineering, they can take that research all the way to deployment. Each of the systems that he showed to workshop participants involved highly advanced research—the faculty get to publish papers on basic research, while the engineers get to build the systems that they deliver to companies. Another participant noted that the National Science Foundation now has a program called I-Corps, where the point is to take research and get it market ready.

A participant had a question on catalyzing cooperation and coordination across the institutes: “How do you do it? You pointed out that there is a pairing of the U.S. institute with a German institute. What are the best mechanisms to get the collaboration going across the institutes?”

Sharon replied that when he first joined Fraunhofer some 16 years earlier, he asked one of the Fraunhofer Institutes who its biggest competitor was. What they told him was, “‘oh, it is another one of the Fraunhofer Institutes in Germany.’” There is overlap and competition, just like in a university. It makes for a healthy environment. “Some institutes compete for the same contracts from industry, government, et cetera,” he continued. Money is the vehicle that promotes collaboration among universities. The same applies within Fraunhofer because it is so big. If it does not have the expertise in-house in a certain aspect of that project, then the organization subcontracts another Fraunhofer Institute in Germany or the university. It is through subcontracts where money changes hands. Also, several Fraunhofer Institutes and universities can team up and go after a large government grant. In the end, everyone has incentives to bring in revenue. The model where Fraunhofer gets one-third from government, one-third from industry, and one-third base funding provides sustainable non-sun-setting funding, but it is still only one-third of the revenue. Sharon noted that there is always an incentive to do well “because if you don’t, you are going to get less base funding because it is one-third of your revenue. They are linked. You can go very quickly into a downward spiral if you don’t succeed. On the other hand, if you are growing and doing well, you get more base funding.”