2

Global Technology Awareness

The first speaker for the session on global technology awareness was Nabil Nasr of the Rochester Institute of Technology. His presentation was titled “Global Perspectives on Materials and Manufacturing.” He spoke about the United Nations Environment Programme’s (UNEP’s) International Resource Panel (IRP). Nasr explained that in UNEP there is a realization that industrialization is taking place across the globe. UNEP is concerned with issues related to where natural resources are located and who the users of these natural resources are. “It is very important to have some disciplined system in order for industrialized countries to be able to maintain and continue the work that they are doing to be able to supply the demand for product,” Nasr explained.

Nasr said that he was going to talk about material scarcity and policy interaction related to natural resources and net resource consumption. The IRP was launched in 2007 based on the realization that there would be global industrialization on a massive scale. Nasr said that everyone present was familiar with rare earth elements in China and the challenges related to the rules implemented by the Chinese government. These are the kinds of issues that IRP is interested in, he explained.

The two sister panels that also run under UNEP are the Intergovernmental Panel on Climate Change and the Intergovernmental Platform on Biodiversity and Ecosystem Services. The Basel Convention was also hosted by UNEP. Nasr serves on the resource panel, which is focused on resource efficiency. The panel is structured by having two sides: (1) a steering committee of government officials and policy makers who represent the member countries and (2) a committee of international experts. The technical members do not represent countries but rather science and

technology (S&T) in an unbiased way. The panel meets twice per year, once in a developed country and once in a developing country. This year one meeting will be in Hanoi and the other in Switzerland. The experts are vetted for connections that would make it difficult for them to be unbiased. The vetting process is extensive, so the wait time for admission is lengthy.

For half of a week, the experts meet to discuss issues; then, they spend the rest of the week meeting with the steering committee. Projects are determined by the entire group based on the priorities of UNEP related to the challenges and to natural resources and resource efficiency.

Many issues are emerging from industrialization, with a large portion stemming from metals and minerals. Nasr said that water has become a major issue as well, with predictions of global water shortages in the next 20 years or so. “A lot of what we learned in this panel is looking at areas separately was not necessarily the best way to go. There is a lot of drive right now to look at things in a holistic way,” he said. The next project will look holistically at the pressing issues: “You can’t look at water alone. You have to look at water in light of the food system and in light of industrial development and a lot of other issues.”

The panel has produced many publications over the past several years. Nasr said that it is important to give policy makers good, unbiased research. “When we deal with extraction and industrial development, many of the challenges come from developing countries where they have many resources. Having representation for these countries in a non-threatening environment helps a lot in terms of guiding them on the potential impact of policy related to what they do,” Nasr explained.

The panel has produced assessment reports on issues ranging from biofuels, to materials, to decoupling of natural resources, to economic growth. Metals have been a major issue for the panel for many years, especially with relation to metal recycling, added Nasr. “A lot of it is related to material flow and material availability,” he said. “Our goal is really resource efficiency. The goal here is to ensure that we are using resources wisely to ensure that we continue to have the resources to sustain industrial enterprises in many economies.”

Nasr said that the group has concluded that 60 to 80 percent improvement in energy and water efficiency is technically possible and commercially viable in sectors such as construction, agriculture, hospitality, industry, and transport. There has already been significant progress toward that goal and a substantial amount of data collected. The question here is not in the hand of a specific company or organization. “It is really a system issue. Many times, it is a policy-related issue. The government has a role in making sure they provide the right incentive to make things possible.”

The European Union is very active with UNEP, but the U.S. government is less active. Nasr said that he was meeting with the U.S. Department of State and the Environmental Protection Agency in order to increase their involvement.

The impact of the group’s reports and its studies is highly validated. The group will soon release several reports related to energy and water efficiency, which will rate material in terms of risk and criticality. “Materials substitution is a huge issue for our panel,” he added. Nasr stated that the panel is highly influential with policy makers from government organizations that participate, as well as with the many outside organizations that closely follow the panel’s activities.

Nasr said that one problem is that developing countries are suspicious of the data that developed countries are putting in front of them. The IRP tries to make its work science-based, which he thinks has been effective.

Nasr explained that the panel recently held a meeting in Germany that was related to the expansion of the Basel Convention in terms of classification of manufactured material. He believed that the panel was very effective in making the case that such classifications would be counterproductive to the remanufacturing of sector goals.

Some other major issues that IRP groups are addressing include global material flow and other aspects of power generation and power sources. The panel looks at these issues from a variety of perspectives. It held a meeting in Chile in 2014 to define some new priorities and identified three top issues: the circular economy and innovation, the resource nexus, and the governance of resources.

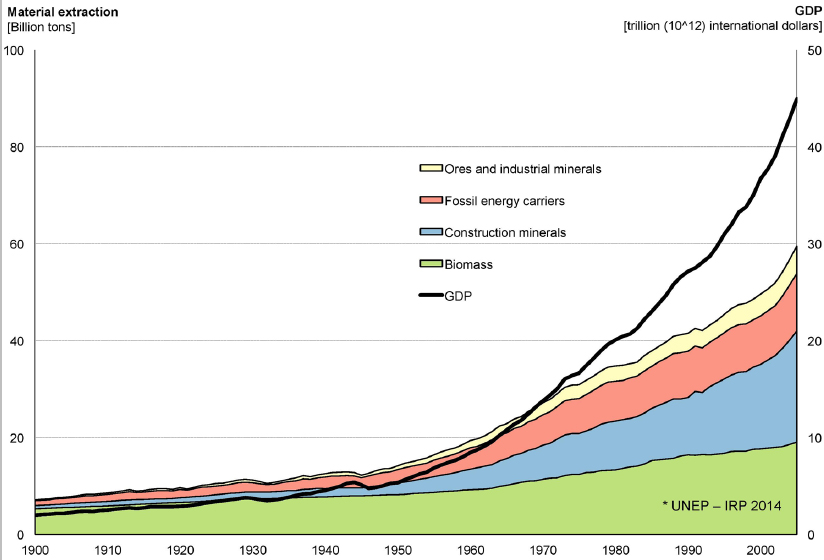

Nasr said that there is great disparity between countries with many industrial enterprises and countries with a high quantity of material and extraction of natural resources. The panel is also looking at some marine resources and issues related to sustainable development goals (see Figure 2.1).

One panel member is doing a project focused primarily on material criticality. He is investigating a variety of factors, including supply risk, environmental implication, and vulnerability to supply restrictions. He is dealing with many issues related to where material is located and what could happen. Nasr explained that this is an area of interest to many large manufacturers because of the criticality and vulnerability of material and their ability to satisfy demand. One challenge the panel identified in this area was material substitution. “If you are talking about metal to metal, the picture is not really that great,” Nasr said. “There is not enough substitution that would work well with what we have today. If you look at the periodic table and look at all of the metals there, you would see with substitution, we have significant challenges in getting to the point that we have good material substitution.”

Each project the panel undertakes involves several experts who are typically of different nationalities. Each project has a significant work scope. The panel is trying to address these issues with a more holistic and scientific approach. Its goal is to guide policy, with a focus on understanding the risks, challenges, and gaps.

The panel is attempting to develop scenarios given every consideration in light of a breakthrough technology, wars, or disruption of supplies of certain material.

Nasr noted that there has been a global increase in consumption, with the rate of resources being used per capita doubling since the 1900s. In that century, the consumption rate doubled to 8 tons per capita. The Organisation for Economic Co-operation and Development countries have the highest rate of consumption compared to all countries, from low to high income. The challenges are more complicated because lower income countries actually arise in the chart, and then the consumption rate is likely to increase at a much faster rate. The panel is working on a study addressing and developing different scenarios of how that could evolve in the next 50 years.

One of the challenges the panel faces is that it looks at things from a global scale. Until 2015, the population growth in developed countries was stabilizing at approximately 2 percent, but population growth in all countries is at approximately 98 percent. This is going to significantly drive the resource consumption and industrialization that will occur in those countries.

The Ellen MacArthur Foundation in the United Kingdom is extremely interested in the circular economy. Material circularity refers to figuring out a way to bring material back to the use-phase. “By doing that, we can significantly improve

material availability and maybe impact scarcity issues related to material,” Nasr explained.

UNEP concluded that in the past 60 years, 40 percent of all internal conflicts have been linked to the exploitation of natural resources. There are significant issues about the supply of material and significant challenges in the security of some of this material.

Nasr said that three organizations have dealt with many of the issues he discussed. These are Advanced Industrial Science and Technology, the Korea Institute of Industrial Technology, and the Singapore Institute of Manufacturing Technology. Those institutions have globalization embedded in everything they do from their advisory boards down to the lab floor. An organization called the Agency for Science, Technology, and Research in Singapore spends a lot of money in benchmarking, sending its people overseas to attend international events. The organization tries not to start new projects if Germany or the United States are already involved. The organization has a lot of visiting scientists and hires people from overseas. “Globalization is in their DNA,” Nasr said.

One participant said that he noticed that the verb “decoupling” appears multiple times in the reports of IRP studies, specifically as it relates to economic growth and pollution. Nasr replied that the studies showed that unless something happens to change industrial development in the West today, and if developing countries follow the same path, there will be a serious disaster in terms of emissions, pollution, and use of natural resources. He said decoupling was one of the things that the panel adopted early: “How do we come up with innovative technology to decouple economic growth from environmental degradation because of the potential risk from countries that are trying to increase their standard of living?”

Another participant asked how the panel sees remanufacturing and innovation coming together. Nasr replied that the intensity of remanufacturing in the United States is pretty low, even in areas where the United States is very active, such as remanufacturing products. Innovation is increasing that enthusiasm. The remanufacturing industry is not currently subsidized by the government. In the meantime, it is providing a significant way of bringing the product back and closing the material loop, ensuring that material flow is recycling to good use. It is necessary to generate enthusiasm and passion for remanufacturing and to create the infrastructure for collection and remanufacturing, all of which are not presently happening.

A participant noted that the Department of Defense (DoD) does a lot of remanufacturing subsidized by the government. Nasr agreed that DoD’s use of remanufacturing saves the government a lot of money: “If you weren’t doing that, you would end up buying new systems.”

A participant asked how the panel looks at cost and trade-offs for the developed nations: How do lesser-developed nations embrace more advanced environmental standards? Nasr said that, for China, the panel argued extensively about this, but

now it supports tightening the rules, owing to the level of pollution that resulted in many large metropolises. He said that the panel believes that it is a fairness issue between industrialized countries: “‘You guys didn’t have any rules like this when you were building your industrial enterprise. We should be allowed to do this.’” But if you educate them on the price they pay and show them that this is not necessarily the right thing to do from an economical and standard of living point of view, then this can have a bigger impact. “I think a lot of it is that the studies are very telling in terms of looking at the health issues related to smog and the impact on the economy,” he continued.

Nasr said that this is where scientific studies can be very helpful. When one deals with government officials, there are a lot of political issues. Sometimes there are people who are not going to listen no matter what. “I think the structure for the panel helps to make it easier to argue some of these points,” he said.

Another participant said that he enthusiastically supported the thesis that resource scarcity can lead to conflict. This is a real issue for DoD, and the challenge is that DoD does not really get involved until there is a shooting war. Prior to that, it was more in the purview of the Department of State, or the U.S. Agency for International Development (USAID), for example. Could DoD be more engaged on this subject?

Nasr said that these are critical issues for any industrial enterprise. If it is DoD or a large corporation, for example, there is a lot at risk for waiting too long “and then you have an issue with supply of certain material that would impact your ability to sustain your operation. Unfortunately in the United States, we don’t really have active participation in a lot of these forums. The European Union has been very active and has put a lot of money in programs that are a result of the studies that were done by this panel at a very high rate, which kind of surprised me. We are trying to get the United States to be more engaged in this area.”

Some large corporations are establishing committees and high-level panels that look at material scarcity and the associated risk. This has led to material substitution becoming a big part of the panel’s strategic studies. Nasr noted that DoD or any other large entity should also be looking at this issue, even if only from a practical aspect in terms of the risks of certain materials.

The Intergovernmental Panel on Climate Change gets a lot of publicity. However, the studies of this panel, which are very scientific and conducted over a number of years with international experts, receive little attention, Nasr said.

AUSTRALIA’S APPROACH TO DEFENSE RESEARCH AND DEVELOPMENT: THE COMMONWEALTH SCIENTIFIC AND INDUSTRIAL RESEARCH ORGANISATION

Cathy Foley, science director and deputy director of manufacturing at the Commonwealth Scientific and Industrial Research Organisation (CSIRO) of Australia, spoke about processing technology. Foley is also president of the Federation of Australian Scientific and Technological Societies.

Foley started by putting Australia in context. She said that it is a big country with a small economy. There are only about 2,500 working physicists in Australia. It has a much smaller economy than the United States and only produces about 3 percent of the world’s research. Because of this, Australia needs to connect with the rest of the world.

Australia is resource rich and has been shipping a lot of raw materials to China during that nation’s incredible growth. Because of that, Australia went through the financial crisis without any considerable impact and was able to maintain a budget surplus until 2010. Since then it has maintained positive growth in its economy.

In terms of landmass, the country is almost the same size as the United States but with a far lower population distributed across a few major urban areas on the coast and almost no one in the middle of the country. Australia has to deal with distance and lack of critical mass. There is not much of a domestic market, so the country relies heavily upon exports.

In terms of manufacturing, Australia is trying to address big trends, such as recognizing the fact that there is a lot of mobility in the world, with growth in China and India. As a result, “the need for collaboration is growing greater and greater,” Foley stated, “especially as the number of research dollars that governments are able to give their researchers seems to be shrinking quite significantly pretty much all around the world.”

Foley explained that CSIRO is a government research organization, but it only gets about 50 percent of its funding directly from the government. It has to earn funding either through engaging directly with industry or by getting government grants through working for the different government departments, whether it is agriculture, environment, or defense.

CSIRO has about 6,000 people spread across 55 sites in Australia, which is a substantial geographic distribution. Its budget is slightly over A$1 billion. “We have to earn about a quarter of that from industry directly,” Foley added. “Much of our staff has Ph.D.’s and graduate degrees, but we also have a lot of students because we engage closely with the universities even though we don’t directly have the ability to give out university degrees.”

Foley explained that quality research is essential to CSIRO: “We believe that in order to make an impact with industry and for the end-user, we actually have to

be good at what we are doing.” The costs of doing business with CSIRO are high, so it has to be worth it to potential partners.

CSIRO has developed a number of technologies, such as Wi-Fi. “As a consequence of that, we actually learned a lot about intellectual property [IP] and how to manage it. In order to get return on that, we had to go through a process of litigating against major IT companies who didn’t buy licenses from us. Unfortunately, CSIRO didn’t get to keep that money. We had to give it back to the government,” she said. Other examples of technologies developed by CSIRO include an influenza drug and continuous wear contact lenses.

CSIRO works from discovery all the way through to commercialization in a global context. It recently restructured, splitting the organization into flagships covering different areas such as energy, land, and water. The manufacturing flagship has about 460 paid staff and approximately 200 staff who are students, visitors, and honorary fellows, located on five sites.

Foley said that CSIRO shops for the best team, wherever it is within the organization. CSIRO might have people in the minerals area working with people in the manufacturing area and also collaborating with whoever is needed, both nationally and internationally, from universities and industry. CSIRO has also worked with many companies, and the organization will not get paid if its work is irrelevant for industry.

Foley said that CSIRO has a very broad definition of materials and engineering: “We have antibiotics through aircraft bodies. We do work on proteins and plasmotics and stem cells and superconductivity.” The organization brings materials engineering, bio-engineering, devices, and sensors together with chemistry, physics, and biology in order to create processes and products that are useful for solving industry’s problems.

CSIRO is currently engaging Australian manufacturers to rebuild manufacturing in Australia. In the past decade or so, Australian manufacturing has dropped from 13 percent of the economy to about 9 percent and is still in a downward slide. At the same time, minerals, mining, and exploration are also now in decline because they were dependent upon China’s growth. “With that beginning to plateau, we have to rethink not just digging things up but being a bit smarter,” she said.

A lot of Australian manufacturing is what Foley called “traditional manufacturing,” such as automobiles, which the government used to support. “Since we seem to be very good at making cars that nobody wants to drive, they have pulled those subsidies away,” she said. Traditional manufacturing is winding down, as the expectations rise for small to medium enterprises to satisfy innovative niche manufacturing.

“Our role at the moment is to see if we can be the go-to place for manufacturers. We are opening up our doors so that particularly small to medium enterprises who can’t afford to do their own research and development [R&D] can come to our door

and be able to have access to innovation,” Foley said. “To have the ability to join into start-up communities and to recognize the importance of i-manufacturing, e-manufacturing, agile manufacturing, and the Internet of Things really makes a difference in the community.”

Foley also noted that CSIRO is linking hubs: “What we are trying to do is bring together a virtual connection by using IT such as video linkages, having the ability to host rooms where people tour and discuss with others on the other side of the country, engaging and building those connections and interactions that allow you to have true collaborations that lead to the outcomes that we are looking for.” They are also building on international connections: “Being connected internationally is critical to us as well.”

CSIRO is highly dependent on its linkages with universities. “Because we are very much dependent on getting and drawing through the creative and breakthrough research that universities undertake, we then work with them and pull that through so that we are able to do the development and work it up the [technology readiness level] TRL levels to help industry engage and translate these into new products and processes,” she explained.

CSIRO is also attempting to build intellectual capital in S&T, which is a major issue for the Australian government. Australia’s National Measurement Institute is collocated with CSIRO. Being able to understand the importance of standards and regulations with regard to export is absolutely critical, Foley explained.

Foley displayed a list of facilities, noting that they are not just doing small, independent measurements, creating small volumes of materials, or developing small processes that only work in a laboratory. “What is critical for us is to aid the work that is being done in universities so they can be scaled up and translated to industry. We do some discovery work within CSIRO, but that is downsizing, and we are linking more with our university colleagues,” she explained.

CSIRO is also working toward making these open-access facilities so that Australia has what is called a National Collaboration Research and Innovation System. The government is now providing subsidies to allow these facilities to carry some of the cost so that they can help cover the overhead costs that often drive the difficulty in making something cost-effective. Then industry can partner with CSIRO and access these expensive infrastructures.

For example, CSIRO is building an innovation center at Linfield with the state government in New South Wales. It is bringing the idea of the tech shop concept where people can come in and use computer-controlled machines and laser cutting to make prototypes, access nano and microfabrication, vacuum systems, or apply high coatings. There is a range of software tools people can use to create their designs, build their prototype, and scale up more rapidly.

Foley showed a photo of CSIRO’s fermentation facility, which allows one to make large quantities of biomaterials. It is an open facility that engages both na-

tionally and internationally. The facility can do lab-scale in order to develop the process and technique, then pilot-scale to show efficacy in whatever the product might be, and finally commercial-scale. The facility does this for other technologies as well, such as precision optics, where one can go from optical fabrication right to coating, metrology, and instrumentation.

Foley said that robotics is not at a level yet that is suitable to achieve the same qualities as human-induced formation of precision optics. “The big issue is that the customer wants to have the robotic cost, while we still have to factor in the human cost. That is a real struggle for this area. This is something particular as our expectations are high and not necessarily able to deliver on the robotics side of things,” Foley noted.

Foley also discussed her own area of research, superconducting electronics. She showed an illustration of a transmission electromicrograph of the layers of barium copper oxide forming a grain boundary. “With that grain boundary you create a structure that is very sensitive to magnetic fields, which in turn makes devices that are very sensitive to magnetic fields. You also have to be able to measure them and house them so that they can be used. In this case they have to be cooled with liquid nitrogen. You have to have a full system of electronics, math, and signal processing,” she explained. CSIRO has various applications, such as a rotating gradientometer for mineral exploration or looking for magnetic anomaly detection in unexplained ordinate or oil detection, as well as a range of other things from terahertz imaging to millimeter wave antennae.

CSIRO wants to increase the rate of discovery and facilitate disruptive changes with materials that have extreme properties and also disparate problems. “Can we have something that is strong and yet flexible, for example?” she asked.

One of the things CSIRO has done is introduced a high-throughput laboratory, which has increased the rate of discovery of a material or combinations of materials by having small volumes and then robotics. By using experimental design and engineering optimization, it is possible to have high-throughput measurement capability in order to identify the area of most interest for a particular design of the desired material. “With that we have been able to increase, in some instances, materials discovery by up to 400 times,” she explained.

As one example, CSIRO has linked in with the Australian Synchrotron and developed an efficient method that allows performing a Synchrotron analysis, which is 300 times faster, using only 1 percent of the normal amount of materials. The organization also increases the rate of discovery such that it is using more hypotheses and experimental design as well as molecular characteristics and structure design in theory and modeling.

CSIRO has been developing a polymer chemistry process that allows one to control the length of a polymer chain. It has been using this to obtain a range of different patents, which the organization has either bought or created itself, in

order to cover a number of applications. CSIRO has approximately 25 licenses with different companies to capitalize on this technology in a range of applications. It is the same with organic chemistry, where CSIRO is looking at application areas ranging from veterinary discovery to agriculture, which are using its compound libraries. CSIRO is also developing methods such as flow chemistry in order to allow industries to scale up and produce chemicals that are being invented and successfully tested in particular applications.

In the defense field, CSIRO performs fiber work, working on energy storage and harvesting integrated electronics. CSIRO is looking at soldier survivability, specifically injury prevention, through the development of new materials. One project involves developing a fabric that is comfortable and durable. “You want comfortable, but strong. Then you go through and work out different weavings so that you are able to prevent projectiles from penetrating through,” Foley said.

But Foley noted that CSIRO also has to be conscious of the downsides of new materials: “We have to make sure that we don’t develop a new material that is going to be the next asbestos and harm the worker, the consumer, and the environment. We have done significant work on theory and modeling to say whether a material is going to be a problem or not.”

Foley said the organization is working on a self-healing material that can fill in holes. This process needs to be scaled up so that this laboratory process can eventually be deployed for successful production.

Foley noted once again that Australia is big but small: “As a consequence, we need to be everyone’s friends. In the big picture of things, in the world, we come across as being far too big for our boots.” She repeated that CSIRO is not quite a university, nor is it a government research laboratory; it is somewhere in between.

Manufacturing imperatives require CSIRO to have an increased rate of discovery in translation, robotics, and modeling. IP management is also critical, an area in which CSIRO has come a long way in the past 5 years, Foley said. “We are very comfortable with IP. Our approach resides with the person who can capitalize on it the most. Our aim is to make other people successful and not ourselves. We have to pay the bills, but it is a case of mutual engagement.”

CSIRO also takes a platform technology approach where one technology can be used for a range of different applications, which is critical in making the most of the investment in R&D. CSIRO needs to work with small to medium enterprises and approach its engagement with them in a different manner compared to the way it has engaged with larger industries. It is looking at open access as well as the importance of staff transfer so it has more churn in its system. “We will be seeing more churn where people will come into the organization and leave in order to start companies or work with other companies. CSIRO is changing a bit where it is open for business at our Linfield site. It is engaging greatly with manufacturing in Australia and globally,” Foley explained.

A workshop participant noted that CSIRO’s track record for transferring technology is excellent. The participant asked Foley to share some of the strategies that have made it so effective. Foley replied that there are a couple of strategies: “The first one is being in for the long term. [In] my own area of semiconducting electronics, we have one of the few places that have actually seen a high-TC [superconducting quantum interference devices] system that has been manufactured and commercialized. There are several of these systems in existence used by mining companies and mineral explorers. It is a lifetime experience pretty much.” Not only does CSIRO provide technology to the end-user or manufacturer, but also it works with the end user or manufacturer in a partnership to help subject matter experts engage with industry.

Foley said that the other key to success is that CSIRO shares the risks of a project with the end user. She mentioned an Australian television show called Bondi Lifesaver about people being rescued from the ocean at Bondi Beach: “Inevitably when people get hurt and experience a lot of pain, they use this thing called the green whistle, which is an analgesic in a special delivery system that can be given to anyone that has low allergic reaction. It is also able to be done by paramedics. You don’t need a medical doctor to do this. For emergency medicine it has been fantastic. We developed the chemical for them, and they developed the delivery system.” The problem was that the company was too small to scale up for an international market. “We sort of did a venture capital where we put the money in and took the risk” in trying to scale up, explained Foley. “It worked. So the company took that over. Eventually we might get the royalty returned from that. They have just achieved acceptance of that technology in Europe. It is the one time I have ever had it where it looks like the return on investment will happen earlier rather than later.”

CSIRO also takes things to high TRLs, meaning it does a lot more integration beyond simply the material or a device. CSIRO also worries about what the prices are, what the housing is, or which electronics and infrastructure are needed to make a project a success. Because Australia is so isolated, Foley reminded, CSIRO has had to learn to do it all itself. “That is good and bad. One of the concerns CSIRO travels with all of the time is breadth versus depth. Is it better to be all things to all people, or is it better to do a few things and do them really well? We are struggling with that. We don’t know what the answer is. We are hoping that it will reveal itself,” Foley said.

Another participant noted that CSIRO has quite a large staff considering Australia’s population and the huge distance between the population centers. He asked about the funding model and other areas in which they work. Foley said that CSIRO has done a lot of work in the services industry in digital productivity. For example, it has helped government departments, health systems, and the banking industry to optimize their service provisions. Foley noted that the state of Tasmania is at the bottom of the country and detached from Australia. Within 5 years, it is

going to have a health bill larger than its budget for the whole state. Reeling in health costs is a huge issue. CSIRO has been working with health departments in each of the states to improve their ability to manage huge data sets.

Regarding another question about dealing with distances between centers in Australia, she explained that domestic air travel is much easier and faster than in the United States, so catching a plane is a lot like catching a bus. “We are also very good at talking on the telephone,” she added.

A participant asked about the high-throughput materials discovery and whether it is not only accelerating materials discovery, but also actually getting to innovation. He explained that his somewhat limited experience has been that often one can find many new, interesting materials, particularly in the functional material areas. They will have interesting properties, but they will be in meta-stable phases or are not amenable to scale up.

Foley replied that this is why CSIRO’s high-throughput technique is so useful, because it allows a researcher to identify the meta-stable phases and focus in on those that are stable. “You can vary a whole range of parameters like pressure and temperature and be able to go through real-time measurements as well on what materials you have got and what phases they are in. It allows you to quickly identify the ones you want,” she said.

Foley added that CSIRO has been most successful with metal organic frameworks, where it has linked metals with organic materials. The metal organic frameworks have a high volume of gas absorption, for example, so they can fractionalize it in a manner that allows them to have a particular set of properties. CSIRO is working on hydrogen storage and has been able to optimize this via the high-throughput method. It usually takes 20 years to develop a new material, but it has been 7 years to get close to commercial readiness.

THE ELECTRONICS INDUSTRY’S ROADMAPPING ACTIVITIES

Bob Pfahl, of Pfahl Consulting, LLC, discussed the electronics industry’s approach to global S&T R&D. Pfahl noted that the electronics industry is in many ways more globalized than other industries. Pfahl said that he previously worked at Motorola, where he was responsible for international manufacturing R&D and environmental technology R&D. In 1994, he set up research laboratories in China, Germany, Brazil, and Japan.

Pfahl said that he had looked at the National Research Council’s report on strategic engagement in global S&T and that the section on the electronics industry is very good. He said that for competitive reasons in the United States, Motorola started doing a roadmap comparing what it was doing with what the rest of the world was doing. “That then made us recognize that we were a global industry. We now work with the entire globe in our roadmapping,” he said.

He said that he established his environmental research group in Germany because that was where the leading research in the world was conducted at the time. “Also, I received more money as a German research firm from the German government than the entire environmental research budget that the U.S. Environmental Protection Agency disseminated to industry. There was a significant advantage to doing that. We really got top-notch research. That choice prepared us for the international market in all of the German and European requirements,” Pfahl explained. “So the choice of where you go to conduct research is very important. Because other countries can be very generous, their incentives can reduce your costs.”

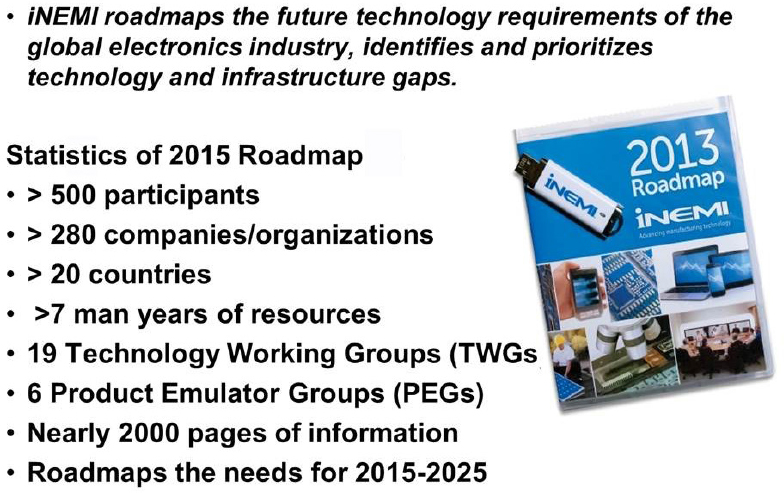

R&D consortia are critical to the electronics industry. Collaboration is essential and can include either bilateral or larger groups. Pfahl said that the International Electronics Manufacturing Initiative (INEMI) is a large R&D organization in terms of its projects: “Universities join us rather than the other way around.” Pfahl said that one of the critical issues in the electronics industry is a need to develop a shared vision of the future needs for the industry. “To develop that shared need, what is very important is to develop a roadmap, to communicate the vision that is developed by the roadmap to the entire supply chain, and to get agreement on doing that,” he explained.

The Semiconductor Industry Association started the International Technology Roadmap for Semiconductors, which began by roadmapping semiconductor devices. Pfahl said that Lance Glaser, who was doing the electronics work in the Defense Advanced Research Projects Agency (DARPA), recognized that DARPA was going to be using commercial, off-the-shelf technology. “The only way to do that was to have a roadmap that stated where the electronics industry was going,” Pfahl said. He said that, at that time, the leadership at Motorola was very concerned about the technology challenge from Japan, and it needed a roadmap. The two organizations formed the National Electronics Manufacturing Initiative (now INEMI) and laid out the first roadmap in 1994. That activity continues today.

Pfahl noted that until 2014, the electronics industry was very technology-driven by Moore’s Law: “Now we are in the era of ‘more than Moore.’ The system level needs are really dictating what we do. By system level, I mean that now market needs are dictating what the needs are. The INEMI side, or systems side, is becoming much more important in determining the needs than the semiconductor side in trying to achieve functionality, pick up additional functionality, and add more functionality as compared to adding more transistors.”

Pfahl explained that there are three steps in the roadmapping process. In the first step, which is developing the roadmaps, one obtains information and needs from all stakeholders throughout the industry. One looks at two periods of time, which may differ for various industries. For the electronics industry, it is 5 years for tactical needs and 5 to 10 years for strategic needs.

In the second phase, one prioritizes the areas that need more R&D. In the U.S. free enterprise system, the marketplace meets many of the needs: One supports faster production of either the materials or the components and the manufacturing simply by defining a common need. The supply chain recognizes that there is a real market, and it develops the equipment accordingly.

The third phase contains the roadblocks, what the semiconductor industry refers to as “red brick walls.” Those are ones that require further research and support through consortia or individual researchers.

Pfahl explained that if one completes the roadmapping process correctly—defining what the enabling technology needs are and quantifying those needs as opposed to defining products or technical solutions—there is no concern about IP.

In the middle phase, Pfahl said that his experience has shown that nondisclosure agreements can be used where necessary. IP is necessary in the last stage. “However, we have found that in 20 years it has never been an issue. People simply know how to work together and what to avoid. It has not been an issue, but that does not mean that you should not have IP agreements in place,” he added.

Pfahl said that from a government point of view, roadmaps are very important in stimulating economic growth on the industry side by increasing profitability. At times and in certain industries, influencing government policy and procuring R&D funding is extremely important. Today in the electronics industry, identifying and addressing industry weaknesses are also important elements of the process.

Pfahl added that finding industrial partners in the supply chain to work together, solve problems, and determine what the customers in the supply chain need is crucial. An industry-led roadmap facilitated by the government helps to meet industry’s needs.

Pfahl said that, in his experience, getting a number of the leading original equipment manufacturers, the big customers, engaged is essential. “The roadmaps should define the core infrastructure requirements. By that, I mean the manufacturing equipment, the materials, all the needs to make a product,” he said. The manufacturing process enabling technology is important to identify in a roadmap, but the product design is not, especially in the commercial marketplace.

Pfahl explained that the 2015 roadmap is about to be published. Five hundred participants from 280 companies in 20 countries have contributed to roadmapping 19 different technology areas for 6 different market segments in more than 2,000 pages. The roadmapping is not done by INEMI, which has only 7 people on staff, with one each in China, Japan, and Europe. “These contributors are all volunteers who dedicate their time to work on the roadmap because industry believes there is a great deal of value in the outcome,” he said (see Figure 2.2).

Pfahl said that some parts of the industry are not coordinated. For instance, there are Taiwanese-, U.S.-, and European-printed circuit board roadmaps. Their capabilities in technologies address the respective local needs. The various market

segments need to do separate roadmaps to cover all of these needs. He said that, originally, the structure of the roadmaps came from the capabilities of Moore’s Law. Now the driving forces have changed as various market segments produce their own roadmaps, and portable consumer use should start to dominate. At the high end, cloud computing and data communications have become a dominant growth market.

Pfahl also stated that there is something important but difficult to explain to many people: INEMI use a “product emulator” to define a market and give the characteristics that each market will need in the future without disclosing the product. “You can have very similar products that have similar characteristics, so firms that don’t even compete can be served by one type of product emulator. The key specifications that define these needs are cost, performance, size, and weight. Cost is discussed as very important. One needs to know the cost objectives that will cause the market to grow and the cost at which the product can be used. It can’t be a purely academic analysis. Emulators are used to define the cost objectives for the different places in the marketplace,” he explained.

“To execute this type of process, trust among the organizations is needed,” Pfahl explained. “That takes a long time to develop.” He added that he is currently involved with the Photonic Systems Manufacturing Coalition (PSMC) in develop-

ing a roadmap that is being conducted by INEMI and the Massachusetts Institute of Technology: “It has been interesting to watch because it is difficult to develop trust amongst these new participants. We have found that we finally agreed on two different emulators. That has gone a long way to try to initiate dialogue within the industry.”

Pfahl said that huge data centers are both a major issue and a major growth area. As an example, Facebook has just issued a challenge stating the cost objectives for its servers. “I think most people would shudder at those low costs, but it appears doable once you set a goal like that. I think you will see their needs met. Somebody has to throw a challenge into the entire supply chain to make change happen,” he said.

Pfahl noted that needs are changing rapidly, with an important issue being the need for scalable systems and packaging technology so that manufacturing lines will not require continuous change. Manufacturers prefer making evolutionary changes with a technology base. Pfahl also said that it is necessary to know when industry will make changes so that suppliers will know. “A good example is the move to environmentally preferred materials. It required a lot of coordination with the supply chain to verify that the capacity and the capabilities were there and that they knew when the major suppliers were going to make the conversion,” he said. “That type of dialogue is integral to what we do.”

Pfahl said that all firms and governments need to be involved in their own survival and looking at what is going on in the rest of the world. “What you do and how much you do is dependent on both the industry and the business model,” he added. “Because of our very disruptive technology and disruptive markets, we have to approach and address those issues. The way we do that is by developing a shared vision that will reduce the risk of the global burden of the electronics industry by having the technology in place and enabling technology that will keep the industry moving forward.” In contrast, for the pharmaceutical world, firms want to restrict competition and therefore invest their money in speculative R&D. Consequently, there is little incentive for consortia activity in that industry. But in the electronics industry, the growth is predicated on high volume, low cost, and a common technology base. This encourages a global open technology roadmapping process.

U.S. firms are very reluctant to invest large capital in an unproven, enabling technology, Pfahl said. On the military side, the world has changed from when military electronics dominated consumer electronics. The advances made in semiconductor technology through advanced military technology development now come in at a cost point that just does not meet the needs in the commercial electronics area, meaning leveraging off of military work is no longer the norm. Pfahl says he would welcome greater participation by military contractors in the roadmapping process. The military does not currently participate because it is not feasible to get clearance to provide the information to the roadmap. This is not an issue on the commercial side, Pfahl said.

Even for commercial firms there is sometimes no reward system. To make roadmapping and cooperation like this happen, this type of behavior has to be rewarded. A participant said that, in his observation, competitors will come together in a roadmapping activity when they are striving for something that none of them individually could achieve themselves. Pfahl replied that when firms think they have the greatest solution in the world, especially if they are start-ups, they want to keep it private, and they do not want to talk to their competitors. He said that they are seeing this in the photonics area right now. But the industry needs to grow larger and have common solutions.

A participant commented that there is nothing like a stalled marketplace to threaten growth. Collaboration then becomes the preferred path. He added that companies were more inclined in the late 1990s to collaborate than today but was not sure why. Pfahl replied that the reason is because the time to market is shorter: “Creative people in the firms are not available to participate in the roadmapping process. It is typically consultants and advisors.” Firms are also downsizing for cost reasons.

A workshop participant said that it was impressive to see the length of time INEMI has been roadmapping. It was also intriguing to see companies such as Apple and Samsung suing each other but still collaborating on new chip development. He asked what people in other sectors where roadmapping and collaboration do not exist could learn from the experience in this sector.

“The threat helps, but you see there is a reason that would make them want to collaborate on enabling technology. Once competitors see that collaboration works then they move forward and become more engaged,” Pfahl said. He added that Motorola had developed what it called the solution for lead-free solder. The company gave that to the industry and worked with the industry to develop it. Motorola had invested a lot of money but recognized the need for a common solution throughout the entire industry. “Once you start working with people, you sometimes give away technology to make sure that it becomes the industry standard,” he continued.

A participant remarked that Pfahl had mentioned that DARPA was involved in getting the first roadmap launched and then it took off on its own. The National Institute of Standards and Technology (NIST) now has a series of roadmapping efforts through the Advanced Manufacturing Technology program (AMTech). He asked about the potential for those to continue beyond the NIST involvement.

Pfahl said that he is a principal investigator (PI) on the NIST AMTech Photonics Roadmap. PSMC has offered its services to the three groups competing for creating the future center. He has also been talking to NIST personnel because they are looking for metrics on roadmapping. What matters is the success of the products and technology that arise. Pfahl said, “I think as they [saw] how effective those efforts have been, they started to participate. We will have to take a look at the next

phase. We should push to make sure that next phase succeeds.” The NIST efforts are global for the first phase but will be restrictive to whatever is put in the funding regulations for the manufacturing institute.

Another participant asked about the national photonics initiative. Pfahl replied that INEMI is putting many of the pieces together to help it succeed and that PSMC is pushing hard for everybody to understand that the activities PSMC will focus on should look at the type of driving force that has been found necessary for success, namely high volume and low cost. PSMC is putting heavy pressure on setting those goals and getting the R&D activities directed to first identify where it can greatly reduce cost and improve performance. Having done that, PSMC should get the users to agree on using said technology and what the technology should be. “Our problem right now is that there are too many streams of technology, and we need to achieve some consolidation,” Pfahl said.

PANEL DISCUSSION: GLOBAL TECHNOLOGY AWARENESS AND ENGAGEMENT OPPORTUNITIES AND CHALLENGES

Panelists: Mark Maurice, Air Force Office of Scientific Research

Shawn Thorne, Office of Naval Research, London

Ty Pollak, Universal Technology Corporation

Brian Holloway, Office of Naval Research

Lead: Bob Schafrik, GE Aircraft Engines (retired)

The first day of the workshop finished with a panel discussion on the topics presented by the earlier speakers. The panelists included Mark Maurice, who is the chief of the international office at the Air Force Office of Scientific Research (AFOSR) where he works with the detachments in London, Tokyo, and Santiago, Chile, to discover world-class basic research that would be of interest to the Air Force. Maurice has a long history of working in the Air Force Research Laboratory (AFRL).

Another panelist was Shawn Thorne, the associate director for functional materials at the Office of Naval Research (ONR) in London. Thorne previously worked for ONR Global in the Tokyo and London Offices for 6 years.

The third panelist was Ty Pollak, a senior program manager for materials and manufacturing at Universal Technology Corporation in Dayton. Pollak was an officer in the Air Force for 20 years, where he managed materials and a nanotechnology program for the AFOSR in London. While there, he initiated more than 50 projects across Europe and Israel.

The final panelist was Brian Holloway, who joined the ONR Global as an associate director in September 2013. Holloway focuses on creating new capabilities

for the war fighter. Prior to his current assignment, he was a program manager at DARPA.

Maurice started by explaining that he is an aerospace engineer with AFOSR, and he outlined the structure of AFOSR’s overseas offices. Maurice explained that the AFRL does all of the S&T for the Air Force.

When Maurice started in the Air Force there were about 23 laboratories, which consolidated to 4 laboratories in 1990 and then to 1 laboratory in 1997, headquartered at Wright Patterson Air Force Base. Four of the nine directorates are also at Wright Patterson. There are a few at Kirtland, one at Eglin, and one in Rome, New York. The other directorates conduct basic, applied, and advanced research, and they manage applied and advanced research. AFOSR does not do research itself, but rather it manages all of the basic research for the Air Force. About 30 percent of its $500 million budget goes back to the other directorates to do the work, while the other 70 percent goes to universities.

The overseas international offices that belong to AFRL are part of AFOSR. The international offices are focused on basic research—the research that is in the public domain and does not require government-to-government agreements to operate.

AFOSR has three overseas offices: London, Tokyo, and the newest one in Santiago. The London office has existed since 1952, and for many years it covered only Western Europe. Now it covers all of Europe, all of the former Soviet Union, all of the Middle East, and all of Africa.

The Tokyo office started in 1992, but, according to Maurice, in the Far East, unlike working in Western Europe, it takes a longer time to build relationships and trust. However, he said that the Tokyo office now does as much work as the London office. There are about 10 scientists in each of the London and Tokyo offices. The office in Santiago has just a few staff and relies on the program managers in Arlington. The Navy has offices that are collocated in each of the three locations. AFOSR has a few additional offices in other places, but these are the three primary offices for all of the services.

The strategy is to create awareness, provide engagement, and most importantly build relationships. “If you can build the relationships then everything else that is up there will just follow,” Maurice explained, “strengthening the partnerships [and] the interoperability, staying on the cutting edge, avoiding technological surprise, and accelerating S&T achievements.”

The offices operate with three primary programs that are also used by the Navy and by the Army. Although they might have slightly different names, they are essentially the same.

The Window on Science Program is a program that makes it simple for anyone in the laboratory to request that a scientist from abroad visit the laboratory to share work and to try to help start building relationships. The Window on Science Program supports conferences overseas. Although the program used to support

approximately 120 conferences per year, it was only able to support 26 in 2014, owing to the conference problems that affected the entire government.

The Window on Science Program can put research grants into place overseas. The research grants are typically about $50,000 and amount to only about 5 percent of the basic research budget. They highly leverage the work that they find already being done overseas.

Thorne agreed with Maurice that the services have slightly different models but all generally use the same principles. ONR Global utilized forward presence. Thorne said that ONR Global has offices in Singapore, Prague, Santiago, and São Paulo, Brazil, which opened in 2014.

The smaller offices are at embassies in order to leverage the efforts of the entire country’s team so that everyone, both the services and the U.S. Department of State, is on the same team and knows what each group is doing in each of those countries.

Thorne also referred to the Asia office and noted that it is actually a Pacific Office because it includes engagement with Australia. He agreed with a comment earlier in the day by Ruth David that there is no silver bullet. “That is because every country and every technology is different in the way that you have to engage it,” Thorne said. “I think if you try to pick one ubiquitous strategy that just means that you will fail in most of the countries that you engage with.”

In Asia, for example, face-to-face engagement is very important. “A lot of the countries we have been engaging might not be historical friends. They are not necessarily people that we have been working with for a very long time,” he said, referring to some of the Southeast Asian countries. It is important to engage when their economies are not already riding high, Thorne explained. “It means a lot more than coming in after they have been economically successful and saying now we want to be partners with them.”

According to Thorne, in many cases this requires a simultaneous bottom-up and top-down approach, the balance of which depends on the country. High-level meetings can be valuable, and Thorne said he did this with Vietnam at its Academy of Science and Technology.

“If you are not actually getting researchers together from both sides, you are really not going to accomplish a whole lot other than lots and lots of banquet dinners and coffee breaks. If the researchers aren’t part of the process, you are really not going to get any good science done. I think that is something that is sometimes forgotten when meetings are put together. One of the things I have found is generally when you attend a meeting in Asia, they will have a lot of their scientists there. If we don’t have our scientists there as well what is going to come out of it is not what we would hope,” Thorne added.

Thorne said that the rules are changing. About 6 years earlier when he was working in Tokyo and doing some programs with Singapore, there was a great

bonus for Singaporean professors who were able to get U.S. government funding on a project. If they were able to secure some funding from ONR, the Singapore government would often give them an order of magnitude more money. This was a great opportunity for the United States to leverage its money. However, Thorne said that the prestige of U.S. funding is fading. “As Asian science continues to advance and the United States becomes less the number one in everything, that 10 times multiplier is going to disappear,” he said.

When he was in Australia, ONR created a program with the University of Monash, which works closely with Australia’s defense agency, the Defence Science and Technology Organisation, to look at corrosion studies and friction stir welding of aluminum alloys. The research was addressing marine alloys and ships because corrosion is a common problem in both countries. “There is a lot of know-how in Australia about dealing with these problems,” Thorne said. “That represented an excellent way that we could have university professors working together. There are professors on the U.S. side as well. Also, both of them were very much plugged into their own defense research agencies.”

Thorne considered that to be a bottom-up approach. He also said that the Air Force ran a very successful nanoscience program both with Korea and Taiwan. The way that it worked was that AFRL gave money to U.S. professors, while Taiwan and Korea gave money to their own professors. With a staged process, they were encouraged to develop collaborative research proposals. Thorne believes that the fact that it was nanoscience was important because it was an area where both countries were putting a heavy emphasis. “It also represents a discipline where we don’t really know what is going to come out of it,” he said. “It had the potential to access disruptive technologies, but we didn’t know which disruptive technologies there were yet.”

Thorne noted that both sides were energizing their own research professors: “That is where you get good collaborations. It was balanced with good institutions from Korea and Taiwan and good institutions from the United States.”

The real benefit to AFRL was that U.S. professors were well tied in to AFOSR programs. There was a route for transitioning that technology back to something that defense could use. There was also top cover because their countries’ Academies of Science were encouraging their own professors to participate.

Thorne explained that during the past few years, there have been active piezoelectronic ceramic programs with Japan and Korea. Although these materials are crucial to U.S. naval programs, the United States has problems manufacturing them.

Pollak explained that he spent almost 4.5 years in the London office for AFOSR. He discussed the three main steps to build an international portfolio. He said that first one has to have a good idea of what S&T hurdles the specific service is trying to address. The second piece is to gain an understanding of one’s area of responsibility and where the excellence resides. The third piece is, given what the need is

and what is available, to identify where one can actually make a difference. Pollak also said this last step was the most challenging and most overlooked.

The Air Force, the Navy, and the Army have a wide diversity of S&T needs. Europe has an established S&T base comparable to North America, with excellent universities and research institutes at the applied research level.

In the United Kingdom the advanced manufacturing initiatives in many advanced institutes are attempting to bridge the valley of death. So one question is, where can one go to make a difference? Pollak said, “You have to have an understanding of where you have already engaged. If you have already built connections, then those can be somewhat self-sustaining. Are there folks there working with domestic PIs where you can build a collaboration and support? That will have a longer-term presence,” he said.

For instance, Pollak cited projects that he has funded in Liverpool over 3 years with a co-PI who was at the University of Illinois, Urbana-Champaign, and funded by AFOSR. They submitted a joint proposal, and they each funded their own sides. Then they have a self-sustaining international engagement at the university level. Pollak said that they had a very healthy relationship in the United Kingdom with the Defence Science and Technology Laboratory. They would participate in their program reviews and would even pitch to them because they had the United Kingdom’s materials community as part of these reviews.

One thing that Pollak said that he focused on was surveying enabling technologies, in particular materials modeling, new characterization activity, new nano-material synthesis and characterization, and new manufacturing technologies. This was mostly due to the wide variety of materials and nanotechnology needs.

Pollak stressed that longevity was important: “You are looking at enabling activity. You are trying to build a relationship that is going to last longer than your own tour.” Pollak added that there is so much attention on Asia that he felt that the London office was ignored.

“There is so much good work going on in Western Europe,” Pollak noted. “While Asia is rising, Europe is already there in a lot of these areas. How do we tap into that?” There was little management interest in putting large initiatives in Europe, he said. It was a fiscal year 2012 program that funded nine projects at $1.6 million. Each of these had to have someone who was in the laboratory or in AFOSR who was a contributing program officer. Several of those projects were able to fund up-front for 4 years, which is something that is no longer possible, Pollak said.

In the past couple of years, there have been policy changes that have made some of these engagements arduous. Pollak said that Universal Technology Corporation had a program review shortly before he left the London Office. He returned to Dayton and had seven of the PIs give talks, as well as a couple of other invited speakers from Europe who were not funded. They had some of the Multi-University Research Initiative leads present who were in the United States, an AFRL-funded

Center of Excellence PI from a Johns Hopkins material modeling program, and researchers from all three of the service laboratories—NRL, AFRL, and ARL. Pollak said that that was the kind of lasting impact possible with global engagement.

Pollak added that the use of analytics is becoming steadily more important. Universal Technology Corporation identified some holes, particularly in its Nordic engagement, while he was there: “We tried to plug those with some targeted site visits in Finland and the materials and nanotechnology activity there.”

Teaming was very important, Pollak stressed. “We had all of our offices being forward-deployed and collocated.” But it is impossible to cover everything, he added. “I was one person to cover materials and nanotechnology in a third of the world,” he said. “It is very difficult to do. You have to partner with the other services and glean as much information from them as possible. It also really helped when you went into a new institution strategic site visit and you had representatives from all three services; they saw that there was some real DoD interest in engaging.”

Holloway remarked that it was a rewarding job: “It is a great job because you get to talk to people that are passionate about what they do and like what they do and want to do it even faster, better, and more efficiently.” There was a real value to “leveraging funds that already exist whether they be from the Singapore government, or from the EU Framework 7, or Horizon 20/20,” Holloway noted. “There is an opportunity for U.S. R&D, especially U.S. DoD R&D, to leverage millions and millions of dollars with small dollar investments.”

Holloway said that this helps in terms of basic science as well as applied S&T development. It can accelerate the timeline to get to efficient technology: “In the end, I think what we all want from the DoD R&D enterprise point of view is to create technology that is of use to the war fighter and to the Pentagon. It is not to do R&D for R&D’s sake. It is to develop new things that are of use to our customers.” Every government is now on a tighter budget, so leveraging is valuable to everyone.

“One of the things that I wanted to point out about potential opportunity and benefit for international engagement is the value of that intellectual engagement. It is not just about the money. There is significant validation to researchers outside of the United States to have engagement with and explicit collaboration with the United States, specifically the U.S. DoD R&D infrastructure.” The reputation of the military laboratories, the military funding agencies, and the U.S. military as an R&D enterprise is still very good and maintains a lot of value overseas in the science community, Holloway continued. “That engagement is often something that will drive people to work within our system to try and encourage collaboration and utilize the opportunities that we present, even when it may not make the most financial sense to them.”

“When they are running a €5 million program, you sometimes have to stop and wonder why they would even bother to talk to me about a $50,000 ONR Global

grant,” Holloway said. “It is that validation. It is that inclusion that they seem to really value,” he added.

“But there are some barriers,” Holloway said, and “there have been more and more that have popped up over the last few years. First of all, I think we all acknowledge the political optics as well as the logistics of sending large amounts of money overseas for collaborative efforts is not feasible. We are not going to match dollar-for-dollar a €5 million effort in the United Kingdom.” Holloway said that this means that the grants are much smaller, even down to $10,000. “The smallest grant I have put out is $2,300. To a Polish researcher, that actually mattered a lot,” he said.

For those small grants, there are generally two different scenarios, Holloway said. “One is to that Polish researcher or a faculty member in Saudi Arabia or in the United Arab Emirates where you are trying to build strategic relationships or facilitate strategic relationship-building. The second is where you are talking to somebody at one of those top 100 universities that were listed earlier, the best of the best. These are people that are good no matter where you are and no matter what you are doing. They are the best. You want to engage with them because as a representative of the U.S. government, DoD R&D, they can help me solve my problems more efficiently, faster, better, or even just make them feasible to solve.”

But the bureaucratic hurdles can be a problem, such as requiring people to register on three different websites with different registration systems and different timelines asking for different information. “In some cases, it is the same information in a different question or format for people whose first language is not English. It is a little problematic,” he acknowledged. “Then we need you to hurry up and do that so that you can wait weeks if not months before I can give you an answer as to whether we are going to be able to get you money. The hurry up and wait especially for people who are not used to the U.S. government way of doing business [can be aggravating]. There is not necessarily control over how fast we are able to get money in the London Office for ONR Global,” Holloway said.

In addition, the inability, in some cases, to offer multi-year commitments, to be able to provide funding for 3 or 4 years, limits the attractiveness of the program. Holloway said that in the United States, the universities and research laboratories understand that: “It is part of the game. It is part of the process. When you are talking to people that are not used to that kind of process there is a huge amount of reluctance that has caused significant problems, including universities not allowing faculty to hire graduate students on our money because the graduate student is not guaranteed stipend support for the duration of their Ph.D.”

“In both cases, when you are talking about the best of the best, these people have a desire to collaborate. We offer access to infrastructure, to U.S. experts, to U.S. data sets. The military has been very good about collecting data over a wide variety of problems over a large number of years,” Holloway said. But the aggravations and the inability to commit money for more than a year can drive people away. “At some

point they do make the decision that it is just not worth it. We lose an opportunity in the short term, and we have damaged our long-term reputation and credibility. That is not a hypothetical,” Holloway stressed. “In the last 4 months, I have had two researchers turn me down for a request for white papers and proposals. They said they have dealt with us before. They have dealt with ONR Global before, and it is just not worth it.”

Holloway said that the last point that he wanted to mention in terms of barriers was not one that he thought could be well-addressed at the policy level but rather at the engagement level. “This is part of the reason why you need people that are forward-based that are out there doing the face-to-face contact. In a lot of cases there is an explicit reluctance to deal with the U.S. military. In Japan it is actually codified in some of the legislation and policies and procedures of the Japanese government,” he said. But it is also true in other places such as Germany. “I have run into it several times with German universities that there is a reluctance to even accept money from the U.S. military.”

Holloway said that this is where the face-to-face engagement and the ability to explain in detail and in person what they do can be valuable. They can explain the difference among basic, applied, and applicable research, and what restrictions do and, more importantly, do not come with much of the international funding. “That is very important. You have to try and overcome those cultural and preconceived notions of what we are trying to accomplish,” Holloway said.

Schafrik asked why none of the panelists mentioned India: “Is it because you don’t think there is interesting work going on? Are they too difficult to deal with?” Holloway said that it is the opposite: “At ONR Global, we actually have one associate director who resides in Singapore for logistics reasons, but his entire focus is India. He is a country-specific associate director. That is all that he does. For us, it is a strategically important area of the world. I think it falls into both categories. There is some very good work going on there and the quality of the work is rapidly accelerating. It is an area that we have been told our management would like to encourage positive relationships.” Maurice added that AFRL has a delegation going to India. But he reminded everyone that sanctions were imposed on India because of its nuclear testing in the late 1990s, although those sanctions were later lifted. “They do a lot of good work at the universities. They are catching up a little bit as they come along in the government laboratories,” he added.

In response to a question about small dollar grants, Pollak said that they are actually rather flexible to work with. “I will give you a great example of somebody that we worked with at under $100,000 a year: Andre Geim, at University of Manchester, [is] the father of graphene as it were. The exfoliator of graphene is probably more accurate. [He has] a 2010 Nobel Prize in Physics, and he has been funded by the Navy since 2007 [and] by the Air Force since 2008,” Pollak said. “He is extremely happy working with us because we make it easy. We actually provide a

small amount of dollars to do fun stuff. In Europe, one of the challenges is they are trying to push a lot of the science to application and started doing some of the more exploratory work that might not get funded in England or the European Union. They were able to do some fun stuff and set the stage for larger programs,” he said.

Thorne added that when Geim was interviewed about his interactions with U.S. DoD funding sources, he said that it has been the easiest process in order to get a grant approved that he has ever gone through. Thorne added that DoD still has a competitive advantage to maintain. It also has to be vigilant about making the process easy and allowing professors to do something that they cannot otherwise do.

That comes in two forms, Thorne explained. “First of all, it is really hard to get formalized collaboration programs across borders. There are not a whole lot of formal funding agencies that do that type of work. EU funds EU professors. National Science Foundation [NSF] funds U.S. professors. Money doesn’t like to go across borders in general. Offering this exception allows professors who would like to collaborate and informally do things like swap graduate students over the summer and cross-train post-docs. That is where you get a lot of value. That is why we can get away with smaller amounts of money.”

The value and the attraction is challenging professors to do the type of high-risk/high-reward research that typically would not be funded by some place like NSF, which uses a peer review cycle. “The DoD funds crazy ideas every once in a while because every once in a while they work,” Thorne said. “That type of proposal doesn’t generally get through peer-review. Sometimes it does and sometimes it doesn’t.” In countries that do not have that portfolio of funding sources, it is really important, Thorne said. “It is a huge advantage that we have.”

Thorne also stressed that something that makes this attractive is that ONR does most of its funding in basic research. “These professors really want to publish. We encourage them to publish. That is a win for us. They are not holding back their results, because they want their name in Science. It is free for everyone to use.”

A participant disagreed with the characterization of NSF. “NSF loves high-risk, high-payoff research,” he said. But he wanted to know more about export controls. Holloway responded that ONR Global, AFOSR, and the Army only provide 6.1 and 6.2 funding, so it is basic and at best applicable research funding. ONR Global did fund a project dealing with software that raised some export control issues, but it was a U.K. start-up company that it funded, and it would like to return to the United States and demonstrate the technology. ONR Global facilitated a conversation with the U.K. government for its approval by first contacting the Defence Science Technology Laboratory in the U.K. Ministry of Defence.

Another audience participant commended the panelists for understanding that science goes from the bottom up, not the top down, and for not creating international institutes in the centers. He noted that China had been sending students to the United States in the 1980s, and now those former students are running many

of the institutes in China: “They want to interact with us. The little amount of money that you are talking about could have tremendous leverage if you do it from the bottom.”